Showing 5339 items matching "manufactures"

-

Stawell Historical Society Inc

Stawell Historical Society IncArchive, North Western Woollen Mills Certificates Australian Chamber of Manufacturers 1995, 1995

CertificateSixty Years Membership stawell, manufacturing -

Stawell Historical Society Inc

Stawell Historical Society IncArchive, North Western Woollen Mills Certificates Australian Department of Defence 1993. Other Copy No Date, 1993

Department of Defencestawell, manufacturing -

Stawell Historical Society Inc

Stawell Historical Society IncArchive, North Western Woollen Mills Certificate of Appreciation. Ararat Legacy. No Date

Certificatestawell, manufacturing -

Stawell Historical Society Inc

Stawell Historical Society IncArchive, North Western Woollen Mills Certificate of Appreciation. From Stawell District Hospital 1979, 1997

Green Certificatestawell, manufacturing -

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia, 2000

North Western Woollen Mills became Norwellan Textiles then AUNDEAdvertising Poster. The Genuine Australian Bluey. Norwellan Woollen Millsstawell, manufacture -

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia, 1923

Share Certificate Stawell Woollen Mills. Issued to Edmund H Ghrimesstawell, manufacture -

Maldon Vintage Machinery Museum Inc

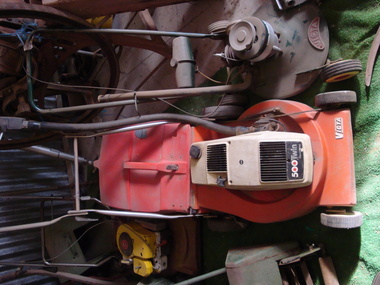

Maldon Vintage Machinery Museum IncMotor Mower

A rare object, not many were manufactured because of an inherent design fault in positioning the pistons vertically and it was found there was insufficient pressure to deliver oil to the top one.Victa twin cylinder rotary mower with grass catcher. Rubber tired wheels. Painted orange.On engine cowl "500 Twin / 170 cc 2 Stroke". On base "Victa".mower, grass cutting, domestic -

Maldon Vintage Machinery Museum Inc

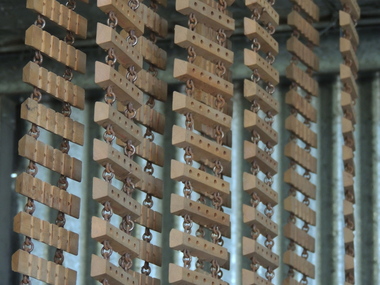

Maldon Vintage Machinery Museum IncDrive Belts, Estimated c 2000

Type used in wool weaving at Castlemaine Woolen Mill.Six new wooden drive belts used in Woolen Mills. Comprising rectangular pierced wooden blocks held together by short lengths of chain.weaving, manufacturing, wool -

National Wool Museum

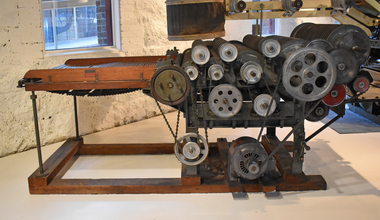

National Wool MuseumMachine - Carding Machine, CSIRO, 1960s

After scouring, the wool fibres are still tangled together. Carding untangles the fibres by brushing and straightening. The wool moves through a series of wire brush rollers that revolve at different speeds and in different directions to tease apart the wool. The fibres emerge from the machine as a continuous filmy web - called a sliver. The sliver must be thinned and divided into strands before the next process. Carding machines constantly require tuning. A highly skilled technician maintained and adjusted the speed of the rollers on the machine. This machine was developed by the CSIRO in the 1960s as a small-scale experimental machine. Industrial carding machines were four times the size of this one. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box. Also another gold plaque read: Experimental Carding Machine donated to The National Wool Museum by C.S.I.R.O Ryde has been rebuilt by Nick Sokolov of Comb Research & Development with the help of Bernard Tolan.Carder with small roller missing at coiling end. Driven by three horse power motor. Wooden slated feed table synchronised to overall gearing.carding machine, machines, wool industry, manufacturing, wool processing -

National Wool Museum

National Wool MuseumFunctional object - Yarn Spinner and Accessories, John Nesbitt, 19th Century

Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design.Custom made wooden hinged box with a hook latch. Brass yarn spinner, attached to a mahogany wood plinth base, which spins fibre into cord/yarn/thread. It has dials to set the rate that it spins. Metal plaque with black inlaid enamel lettering. Small cork inlay. Brass rod with hinge and wingnut, and ball at end. Ball at end has an adjustment mechanism. Rod also has an adjustable circular collar. Pair of curved tweezers. Circular magnifying glass on long thin handle. Glass has two concave lenses. Weaving sample in shades of blue, green and brown. Twill weave. Alternate pattern samples separated by red thread.Brass plaque on base of spinner: 42 MARKET St / John Nesbitt / REGd TRADE MARK / LIMd / MANCHESTER Underside of wooden plinth: 4976apparatus, textile, testing, spinning, nino corda, magnifyer, tools, brass, mahogany, tweezers, yarn, spinner, design, john nesbitt, manchester, england, 19th century, engineering, manufacturing -

National Wool Museum

National Wool MuseumFunctional object - Cymbal Circular Sock Knitting Machine, 1900-1940

Black knitting machine featuring crank handle and circular knitting needles, with gold lettering. CYMBAL / FOREIGNknitting, socks, machines, manufacturing, cymbal -

National Wool Museum

National Wool MuseumDocument - Wool Register Card

Card used by Collins Bros Pty Ltd, established 1874.Cream card with black printed text. Printed: Factory No. / WOOL / REGISTER / Lbs. / Rates / Invoice Value / Charges / Stock Value / Invoice Date / Sale No / Broker / Brand / Lot No / Bale No / Description / Type / Date Issuedcollins bros mill pty ltd, manufacturing, geelong, wool -

National Wool Museum

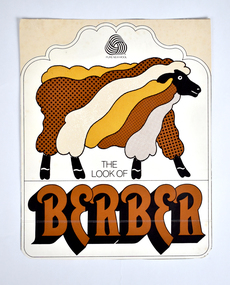

National Wool MuseumCard - Packaging – The Look of Berber, c.1980s

Modern industrialized Berber carpets are distinguished by a loop pile construction type that gives a similar appearance to the distinct knot of traditionally woven Berber carpets. The modern carpets usually contain small flecks of dark colour on lighter shades of background colours resembling a natural undyed version of the traditional carpets. Berber is known for being one of the oldest and most durable kinds of carpet. Traditionally, Berber carpets are carpets hand-woven by the Berber people in North Africa and the Sahara. The carpets come in traditional and modern designs, which are distinguished by different knotting patterns, dyes and fabric textures. The origin of carpet weaving by the Berber populations dates back several millennia. The hand-spun cloth they created was named after the individual tribe, and they used natural fibres to create cloaks, rugs and other fabrics. Card showing printed text and graphic featuring an image of a sheep in tones of orange, brown and cream. Printed: PURE NEW WOOL / THE / LOOK OF / BERBERcollins bros mill pty ltd, manufacturing, geelong, wool, berber -

National Wool Museum

National Wool MuseumTextile - Blanket, Albany Woollen Mills, Albany Woollen Mills blanket, c 1950s

Note from collector: I love the generous size and thickness of Albany blankets and know someone who collects from this Mill only. The colour shades and combinations Albany used are still so gorgeous. From Western Australia. Note from collector - "For more than 100 years blankets were made all over Australia in over 100 woollen mills. My aim, is to preserve 100 examples of these wonderful pieces of history. Ten years ago I started collecting the iconic Onkaparinga travel rugs, so that on movie nights at home there would be plenty to go around. Everyone had their favourite; even the cat had his own – a small red tartan one. Keeping an eye out for those travel rugs at op-shops and markets, collectable stores and bazaars, led to noticing vintage blankets. I'd never really thought about them before or paid much attention though of course I had grown up with them at my grandmother's. When I discovered my first Laconia cream blanket with blue stripes, my eyes just went gaga. Well that was it, I was hooked and since then over 500 blankets have passed through my hands. These common, everyday items, found in all households for so many decades, were traditional engagement gifts. Pairs were prized wedding presents turning into family heirlooms. They were fashionable dressers of beds, givers of warmth, bestowers of security and reliability. The comfort found in these objects resonates with almost all of us; we grew up with them ourselves or fondly recall them in a grandparent’s home. There is no modern replacement with the integrity of these old blankets, many of them now older than most of us. They are romantic, sensible, special, familiar, nostalgic and nothing else feels so appropriate in so many situations. No offense to the great Aussie doona, but from hippie to hipster, at a music festival, picnic, campsite or couch, a vintage blanket is something coveted by all. This industry that employed tens of thousands and must have been such a huge contributor to the economy is almost completely lost now. Blanket Fever is an ode to everything that came before: the land, the sheep, the shearers, the hands, the mills, the weavers, the designers, the distributors, the department stores. To the grandparents that gave them, the people that received them, the families that kept them; thank you. I’m passionate about my collection of Australian blankets manufactured in mostly Victoria, South Australia and Tasmania from the 1930s to the end of the 1960s. The collection has blankets from each of these four decades representing the styles and fashions of their time and includes dated advertisements which help determine the eras the blankets are from. " Checked blanket, blues and creamAlbany Woollen Mill/Blanket/All Pure Wool/Emblem: A, Albany blanket, blanket fever, wool, albany, albany woollen mills -

National Wool Museum

National Wool MuseumPhotograph - Women's Basketball Team, Albion Mill, 1941

Gwen Low, who donated this photograph, was the Captain of this 1941 Women's Basketball Team and worked at the Albion Mill.Black and white photograph showing an outdoor portrait of seven women, with four standing at the back and three kneeling in foreground. The woman in the centre front is holding a basketball. The women are wearing matching uniforms with heart motives. Trees and buildings are shown in the background.albion mill, geelong, wool, industry, sport, basketball, teams, women's sport, manufacturing -

National Wool Museum

National Wool MuseumPhotograph - Women's Basketball Team, Albion Mill, 1942

Gwen Low, who donated this photograph, was the Captain of this 1942 Women's Basketball Team and worked at the Albion Mill. The uniforms were made from fabric woven at the Albion Mill.Black and white photograph showing an outdoor portrait of seven women standing side on in a line. The woman in the front is holding a basketball. The women are wearing matching sports uniforms. albion mill, geelong, wool, industry, sport, basketball, teams, women's sport, manufacturing -

National Wool Museum

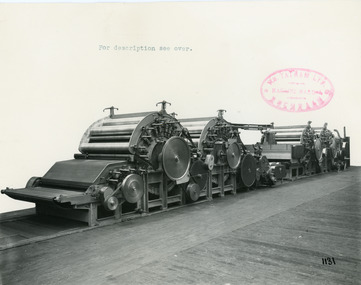

National Wool MuseumPhotograph - Product Photograph, Semi-Continental Card Set

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A carding machine disentangles and cleans wool fibres and then aligns the individual fibres so that they are parallel with each other.The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of an Semi-Continental Card Set in a landscape format. The first photo is of the whole machine, the second is a close up of the mid section of the machine.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1131 Rear - Semi-Continental Card Set arranged to receive latest pattern Automatic Feed fitted with Peralta, improved type Parallel Fiber Feed permitting of passageway between Scribbler and Carder. Four-tier Continuous Tape Condenser. 8038.2 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1132 Rear - Showing Peralta with hydraulic pressure to rollers and working with improved pattern Parallel Fibre Feed arranged with passage between the two main sections.textile machinery, tatham, carding machine, wool manufacture -

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Tape Condenser

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A Tape Condenser is a device that receives the wide fibre web from a woollen card, divides it, and rubs each section into a sliver. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of a Tape Condenser in a landscape format. The first photo is of the front of the machine, the second is of the rear.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1138 Rear - Showing new model Tape Condenser with all-Perspex Guards, new gear box type of main drive to Condenser. New mounting of all Tape Rollers, cross shaft drive to Variable Speed Gear Box for drive to rubber shaft and many other improved features. 8038.2 - Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1140 Rear - New Model Four-teir Tape Condenser showing rubbing motion side Note greatly improved guarding completely enclosing rubbing motion and gearing, also Variable Speed Drive to Rubbing Motiom via heavy ‘V’ Belt. The drive is taken by cross-shaft from the main gearing of the Condenser. Rubbing Motion has all roller bearing eccentrics throughout.textile machinery, tatham, wool manufacture, tape condenser -

National Wool Museum

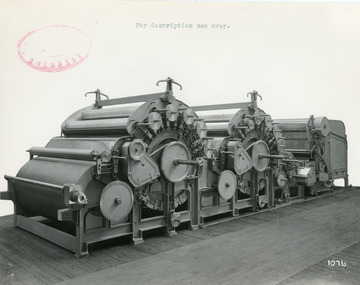

National Wool MuseumPhotograph - Product Photograph, Two-Part Scribbler

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The scribbler was the first part of a group of machines known collectively as the carding engine. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Two-Part Scribbler in a landscape format.Front - top margin: For description see over. Front bottom right corner - 1076 Rear - Two-Part Scribbler, Semi-Continental Type with Patent Automatic Feed having Extended Hopper. Cylinders in this case are 50” diam. Doffers 36” diam. Drive to strippers and other parts by ‘V’ Belts. Note improved guarding to Fancy Chain Drives, also feeder gearing.textile machinery, tatham, wool manufacture, scribbler, carding -

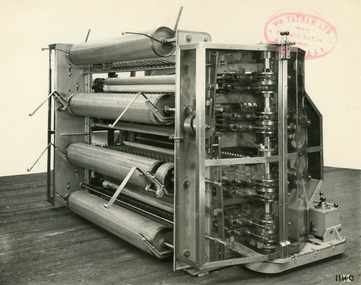

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Patent Parallel Fibre Feed

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Patent Parallel Fibre Feed machine is used for connecting Breaker and Finisher Card Sections. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Parallel Fibre Feed in a landscape format. Black wiritng on the rear, typed with a typewriter. Front - top margin: For description see over. Front mid left edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1106 On machine bottom right quadrant - TATHAMS Rear - New Patent Parallel Fibre Feed for connecting Breaker and Finisher Card Sections. This Machine incorporates a completely new type Plaiter Motion, the operation of which is quite unique.textile machinery, tatham, wool manufacture, carding, patent parallel fibre feed machine -

National Wool Museum

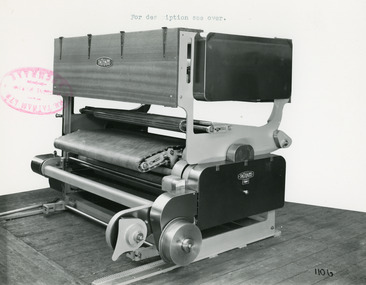

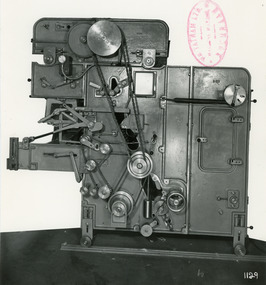

National Wool MuseumPhotograph - Product Photograph, Patent Automatic Feed Machine

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. An Automatic Feeding Machine automatically and sequentially supplies uncarded wool to carding machines, The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Automatic Feed Machine in a portrait format. Black wiritng on the rear, typed with a typewriter.Front - mid left corner - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1129 Rear - Patent Automatic Feed with Extended Hopper fitted with balanced pressure plate which operates through Variable Speed Device to regulate speed of spiked lattice in accordance with material in Hopper. Electro-Magnetic Clutch Drive to spiked lattice controlled by Mercery Switch on scale arm. Diagonal Scale Pan with improved knife edge suspension. Dual Trap Doors over Pan actuated by Solenoid. Automatic device to slow spiked lattice just prior to weigh being obtained. Ball or roller bearings to main shaft, combs and other parts. Self-aligning bearing to timing shaft etc.textile machinery, tatham, wool manufacture, carding, automatic feeding machine, wool -

National Wool Museum

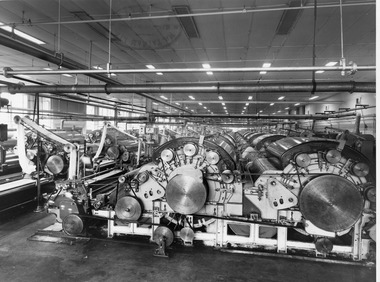

National Wool MuseumPhotograph - Carding Machines

Sales photograph for William Tatham Ltd. of Rochdale, to showcase new Carding Machines in a newly developed textile factory. The photograph was taken in Glasgow, Scotland.A black and white photo of a room filled with working Carding Machines in a portrait format. A man is working at the end of the closest machine.On rear - top margin - Showing Card Sets in new Card Room. Bottom right corner - Commercial Artists photographers and blockmakers Scottish Studios and Engravers LTD. 196 Clyde st. Glasgow. C C.P.D 6893 Dtextile machinery, wool manufacture, carding, wool, glasgow -

National Wool Museum

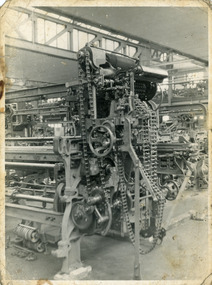

National Wool MuseumPhotograph, Loom, Unknown

Photograph of a Hutchinson, Hollingworth and Co. Limited Loom gears and mechanisms. Hutchinson, Hollingworth and Co. was an Oldham-based loom manufacturer estalished in 1860 by Messrs. John Hutchinson (c.1816-1888) of Cawthorne and James Hollingworth(c.1834-1895) of Holmfirth.Three black and white photographs in portrait format of a looms gear mechanisms.8052.1 - front on machine mid left quadrant - Hutchinson, Hollingworth and Co 8052.2 - front on machine mid left quadrant - Hutchinson, Hollingworth and Cotextile machinery, wool manufacture, wool, loom -

National Wool Museum

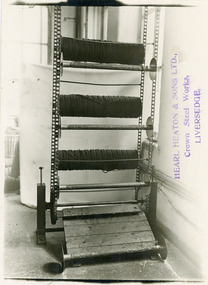

National Wool MuseumPhotograph, Yarn Spinning Machine, Unknown

Photographs most likely used for promotional purposes. The photographs are of a yarn spinning machine used to place yarn onto bobbins. The machine was made by Hearl Heaton and Sons Ltd, founded in 1809. The company played an important part in Britain’s Industrial Revolution, providing bobbins to the textile mills across the North of England.Four black and white photographs of a yarn spinning machine. The first two photos show the machine in the lower floor of the building and the last two are on the upper floor. The are connected by the two chains working the machine.8053.1 - Front right edge - Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge. 8053.2 - Rear middle - No.1 Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge. 8053.3 - Front top edge - Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge. 8053.4 - No. 2 Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge.textile machinery, wool manufacture, wool, spinning -

Beechworth RSL Sub-Branch

Beechworth RSL Sub-BranchFlying Suit, 1988

This flying suit would have been worn by a pilot of the Royal Australian Air Force. It is a drill suit and most likely was not used in active service. This flying suit dates to 1988. It is no longer manufactured and is an historically significant article of military clothing. It is also in good condition.Olive drab coloured overalls. Full length sleeves and full length legs. Two pockets on the front of each leg. One zip at the front of each leg with extra fabric in the interior for fabric width enhancement. One access zip on each hip. Two diagonal breast pockets, either side of chest. One small pocket on each arm. All pockets are fastened with metallic brass colour zips. Another pocket on the left upper arm with stitched sections for storing pens. A silver coloured metallic pen holder is clipped and stitched into this section. One epaulet on each shoulder, each fastened with a brass coloured metallic stud. Regular shirt collar. One long zip at the front from the groin to the collar. This has two zip handles, each with a thin piece of leather attached to aid zipping. A patch with inscriptions machine stitched to nape of neck interior. Three brass coloured metallic studs, with a small piece of size adjustment fabric (and the clipping stud attached to this) on each sleeve. Three brass coloured metallic studs, with a small piece of size adjustment fabric (and the clipping stud attached to this) on each side of the waist. One rectangular leather clip attached to the upper right leg pocket. Patch stitched to nape of neck interior has the following inscriptions: A.G.C.F. VIC 1988 (symbol of broad arrow) SIZE.3 8415.66.013.1557 NO NAMEflying suit, royal australian air force -

Parks Victoria - Wilsons Promontory LightstationIt has been suggested that it is possibly part of the clockwork mechanism of the third order Fresnel lens, which was a component of the Chance Brothers lens system introduced to the lighthouse when the optics were upgraded in 1913, and subsequently removed in 1975. Further research may confirm its association with the lens and increase its heritage importance. The well-made brass fitting has second level significance as a possible former component of the clockwork mechanism manufactured by Chance Brothers in c.1912.Brass, round, knurled fitting.One end of the fitting has a cylindrical knob end with a smooth surface; the other has a broader cylindrical knob with a knurled surface to allow for gripping and turning.

Parks Victoria - Wilsons Promontory LightstationIt has been suggested that it is possibly part of the clockwork mechanism of the third order Fresnel lens, which was a component of the Chance Brothers lens system introduced to the lighthouse when the optics were upgraded in 1913, and subsequently removed in 1975. Further research may confirm its association with the lens and increase its heritage importance. The well-made brass fitting has second level significance as a possible former component of the clockwork mechanism manufactured by Chance Brothers in c.1912.Brass, round, knurled fitting.One end of the fitting has a cylindrical knob end with a smooth surface; the other has a broader cylindrical knob with a knurled surface to allow for gripping and turning. -

Mont De Lancey

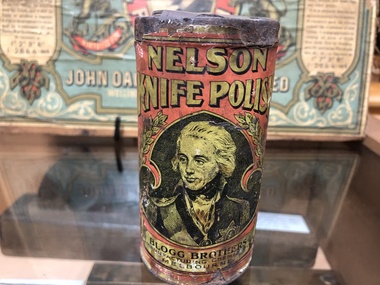

Mont De LanceyKnife Polish and Poster, Blogg Brothers Manufacturing Chemists

Tin of knife polish, with picture of Lord Nelson on front. Advertising poster for knife polish with a picture of Wellington, pasted on a wooden board."Nelson Knife Polish" on tin. "Wellington Knife Polish" on advertising poster.knife polishers, advertising posters -

Mont De Lancey

Mont De LanceyKnife Cleaner, The World's Manufacturing Company, Circa 1885

'The World's' hand-cranked rotary knife cleaner, with a wooden knob on handle."The World's Manf'g. Co. London England"knife cleaners -

Box Hill RSL Inc.

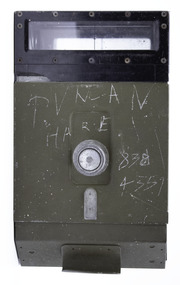

Box Hill RSL Inc.Functional object - AFV Periscope, Minneapolis-Honeywell, c. 1943

This periscope was used during WW2 extensively made for armoured vehicles.Minneapolis-Honeywell was approached by the US military for engineering and manufacturing projects. In 1941, Minneapolis-Honeywell developed this superior tank periscope and camera stabilizers, as well as the C-1 autopilot.Rectangular periscope with screw & clip device to hold in position, painted olive drab.On one label: PERISCOPE M6/ MINNEAPOLIS HONEYWELL REGULATOR COMPANY/ No 4XO/ 1943. On paper label: Periscope Adjustments Knob Settings (indecipherable). On one side handmade scribbling unable to analyse: PVNCAN/HARE/838 4551periscope, armoured vehicles, tanks, ww2, us army, chaffee, stuart, shermann, minneapolis -

Trafalgar Holden Museum

Trafalgar Holden MuseumFunctional object - Gladstone bag with shoes and slides

Used for carrying papers or alternatively clothing Ca 1900Manufactured by Holden and FrostRectangular shaped leather case, hinged in center, lockable, lock in center of case, under leather handle. Two steel brackets on top to allow locking straps to stay in place.S.B.B.leather, lockable, gladstone, bag