Showing 619 items

matching bits

-

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPhotograph - Colour and black and white photocopy and document, The Egg and Poultry Producer, The Macauley Family, 1872-2013

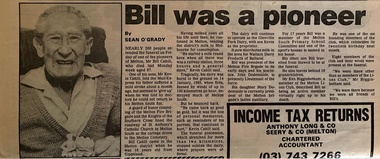

History and reminiscences with photocopied photographs and a newspaper article about the family and life at Burnley as children. John Macauley and son, Bill, lived at Burnley 1914-1972. History and reminiscences with photocopied photographs and a newspaper article about the family and life at Burnley as children. John Macauley and son, Bill, lived at Burnley 1914-1972. Egg Curators. (1) p.3(b) "Weigh-in at start of new Egg Laying Competition, c. 1940 with Bill and father John T. Macauley." (2) p.5(c) "P.R.L. 1960." Plant Research Laboratory. (3) p.5(d) "Path leading to Plant Breeding Plots. 1960." (4) p.7(a) 1959." (5) p.7(b) "Drive-Burnley Gardens 1949." (6) p.7(c) "Seed Testing Laboratory built 1966." (7) p.9 "1990's." Probably a bit earlier. (8) p.9 "2013." Actually pre 1991. (9) p.9 "Averil and Esmerelda 1959." (10) p.11(b) "1960 view showing 6 hen pens of Random Sample Laying Test. Residence (built 1960) at rear." (11) p.12(a) "1959 view of potting-shed/glasshouse on way to orchard." Note cactus collection. (12) p.12(b) "1960 view of 'Hydrangea Walk'-orchard fence on left." (13) p.12(c) "2013 view of path leading to the above pathway." (Hydrangea Walk.) (14) p.14 "Burnley Gardens Kneens house at rear 'Jack' 1960's." (16) p.14 "Horticultural College c.1967." (17) "The 'family' tree re-visited by Janice & Alison Downman Dec 1995." (18) Newspaper article, "Bill Macauley leaves the birds," from "The Egg and Poultry Producer" August 1972.family life, burnley, children, john macauley, bill macauley, egg curators, egg laying competition, plant research laboratory, janice downman (née macauley) -

Federation University Historical Collection

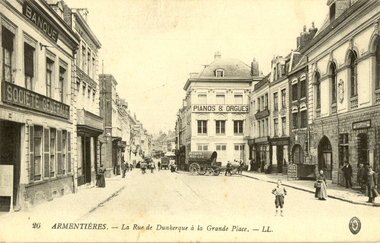

Federation University Historical CollectionPostcard - Black and White, La Rue de Dunkerque a la grand Place, Armentiers, c1916, c1917

Holmes Family WW1 memorabiliaA number of people stand in a street surrounded by double storey architecture.Verso: "Dear Willie, I promised to drop you a line, so he goes. Well at present I am in france having -a-go-at the Germans, and so far out Battery is getting on alright. But I must say the Germans greet us know and again with a few shells, and I can assure you they are no friends of mine. I have just been out watching the German anti-aircraft Guns shelling our Aeroplanes. it is a very lucky shot that brings one down. i have seen a little bit of the World since I left australia, And I must say I like france better than egypt. The country at present is looking very nice, it being Spring time, The grass is about 6 foot high, and nothing on it to eat it as most of the people have cleared out from around here. I have not seen anything of Harry over this way as yet. Perhaps he is still in Egypt. Well Willie now about taking another cow to Clunes. Ay What. The name on the front of this card should be familiar to you in the War news. Well Willie Au revoir for present. remember me to all. Your fond cousin, Ron W." chatham-holmes family collection, armentieres, world war one, postcard, clunes, france -

Federation University Art Collection

Federation University Art CollectionPainting - Artwork, Trudi Harley, 'Fallen' by Trudi Harley, 2009

Trudi HARLEY Born Korumburra, Victoria Born in country Victoria Trudi Harley graduated with a Bachelor of Education (Art and Craft) at Victoria College, Burwood. After teaching for 10 years in both Government and Independent schools in Melbourne she worked as a Sales Executive and Art Educator for Cavalier Art Supplies for 16 years. Recently Trudi Harley completed a Bachelor of Arts (Visual Arts) (Honours) with Distinction between 2008 – 2009, and a Master of Arts (Research), Visual Art between 2010 – 2012 at the University of Ballarat (now Federation University). Maintaining an artistic practice while in a business partnership Trudi Harley owns and runs Atelier Art Supplies in Williamstown, Victoria, which is a major supporter of the arts in the western suburbs of Melbourne/ This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.Artist's Statement: As an artist am continually drawn to ‘what makes us who we are’ and as a result the work, whatever it may be, is a reflection on what makes me who I am. In this I refer to perception, experience and memory as aspects that contribute to our sense of reality. By using these references I intend to engage the audience and develop a sense of connection and community through the visual image. ‘Fallen’ was not necessarily a reflection on my own life but of life in general as I recall at the time I had a family member who was struggling to cope with their own reality. I can also recall at the time reflecting on the adage ‘walk a mile in my shoes’ and the pressures we all face in life. Added to this were my own influences of upbringing, I have always been particularly drawn to fabrics and patterns as my mother was/is (getting a little old now) a seamstress and my father was a bit of a ‘perfectionist’. During my honours study I came across the term ‘Esperpento’ which included such visual elements as exaggeration and unusual viewpoints. Fallen was a comment on the psychology associated with expectations in life, or more importantly those expectations placed on offspring by their parents. This painting reflected the consequences of not living up to those expectations. It is unfortunate that in life, by the time you get to the point of realising that you have the opportunity to set your own standards, that you’ve probably embodied a great many set of values by osmosis and that you’ve now claimed them as your own. The view is from above to dramatize the subject, the figure placed compositionally in the top right hand corner to open up the picture plane and allow for the narrative to continue outside the visual area of the canvas. It was also in this painting that I rubbed back some of the darker oil paint to allow the lighter underpainting to show through.art, artwork, trudi harley, harley, carpet, portrait, self-portrait, alumni -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - POPPET LEGS AND ENGINES -WHERE SHIFTED TO

Handwritten notes where poppet legs and engines were taken. New Chum Goldfields - To Golden Fleece. To Deborah. To Central Deb. Carlisle Poppet Heads - to Guilford Plateau, then to Nell Gwynne Reefs. Williams United Engine (Sq Con Reds) - To Ulster then North Blue, then Nth Deborah. Central Blue Engine, with Corliss valves, to Deborah. Windmill Hill Legs to Sebastian, then to Deborah. Big Blue Legs - to Central Deborah. (Legs) South Moon to South Virginia. (Engine) Sth Moon to South Virginia, & driver put on side of drums. Fortuna Hustlers Engine - to ? ?, then to Bird's Reef, then to Herc No 1. Then to Nth Virginia. New Oswald (Malson) Engine left at Sth Moon, not allowed to put in, as it was a loose eccentric. Unity Legs - to Herc. No 1. Then to Ironbark. Ironbark Engine - To Wattle Gully. (Converted to electric winder). 222 - Several Compressors. The fire at the Unity mine in 1907. The fire at the Garden Gully mine in 1911. The fire at the Princess Dagmar in 1913. The light on the Ellenborough flagpole. Tambour Major. Joe Sheard in diving suit. Lansell's Little 180 - Vertical engine. Driver to right side and at floor level. Lansell's bit 180 - Vertical engine. Driver on top of engine. Floor between. Lansell's Needle. - Wooden legs with crossstays reaching from top of legs to close to bottom. Winder - Single Link engine. Hard to get drivers. Confidence Extended. Koch's Pioneer. - Shaft a big angle. Central Blue - Old Sheepshead - same. Vict Catherine - Winder - one drum in front of other, shaft at such an angle. Very hard to see which cage or tank at surface. Specimen Hill and Carlisle - Back-handed first motion engines. Central Nell - Winder from Lord Nelson mine, St Arnaud - Driver behind drums. Turned valve opp. To usual to turn steam on and off.document, gold, poppet legs and engines, shifting about - poppet legs and engines, new chum goldfields, golden fleece, deborah, central deborah, carlisle, guilford plateau, nell gwynne reefs, williams united, ulster, north blue, nth deborah, central blue, windmill hill, sebastian, big blue, south moon, south virginia, fortuna hustlers, tambour major, bird's reef, herc no 1, nth virginia, new oswald (maldon), unity, ironbark, wattle gully, 222, garden gully, princess dagmar, ellenborough, joe sheard, lansell's little 180, lansell's big 180, lansell's needle, confidence extended, koch's pioneer, central blue, old sheepshead, vict catherine, specimen hill, carlisle, central nell, lord nelson mine (st arnaud) -

Bendigo Military Museum

Bendigo Military MuseumPostcard - POSTCARD, ASH, U.K, F. Frith and Co, c. WW1

Cards collected by R.H. Baron when visiting his Uncle who lived near the village of ASH, UK. c.Nov 1918. Part of the "Robert H. Baron", No. 3596 and Cooper Collections. See Catalogue No. 1981P for details of Baron's service.1. Coloured photograph of a street featuring building including a Post Office. 2. Coloured photograph of a house fronting a gravel road. 3. Sepia toned photograph of a gravel road, vegetation and trees. 4. Sepia toned photograph of a row of houses fronting a gravel road. 5. Sepia toned photograph of a row of houses. Man standing next to a horse and cart. Large pond in foreground. 6. Sepia toned photograph of a row of houses. Man standing next to a horse and cart. Large pond in foreground. 7. Sepia toned photograph of a river with boats moored on bank. Buildings on far side of river. 8. Sepia toned photograph of a row of houses fronting a road. 9. Sepia toned photograph featuring people on a wharf. Row of houses in back ground.1. Pinewood Post Office, Ash. Handwritten in faded black ink on back: 'This is the road Uncle lives in. he live just about opposite the cross (or house in middle) I made on the card, Bob'. 2. York House, Ash. Handwritten in black ink on back: 'Just near my Uncle's place in Ash, Bob.' 3. Fox Hills, Ash. Handwritten in faded black ink on back: 'Letter from R.H. Baron to his brother Freddy - no date.' 4. Ash Common, Victoria Hall, etc. Handwritten in faded black ink on back: ' Of course you will know Ash as you have wrote it bit when writing to Uncle, Bob'. 5. Ash Village & Pond: Handwritten in faded black ink on back: 'This is Ash Village - is about 1 mile from where Uncle lives. Bob.' 6. Ash Village and Pond: Handwritten in faded black ink on back: 'Letter to Elsie from R.H. Baron - no date.' 7. Ash Vale. The Wharf. Handwritten in faded black ink on back: 'Letter to Elsie from R.H. Baron - no date.' 8. Ash Vale. The Wharf. Handwritten in faded black ink on back: 'Partial letter to R.H. Baron's brother - c.Armistice Day. 9. Ash Vale. Handwritten in faded black ink on back: 'Another view of Ash, Bob.'robert h. baron, cooper collection, postcards, ash uk, ww1 -

Eltham District Historical Society Inc

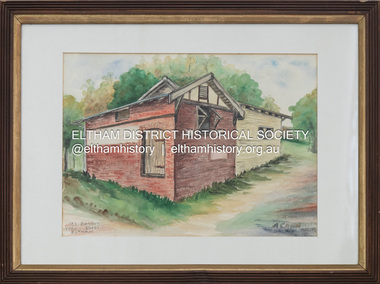

Eltham District Historical Society IncPainting, Audrey Cahn, Old Bakery, York Street, Eltham, May 1974

Painted for the Shire of Eltham Historical Society by Audrey Cahn, a member of our Society for many years and Vice President till 1978. Audrey was the sister of the late Charis Palling, founding president of our Society. She had remained a member for many years although she had moved from her family home at Warrandyte to live with her daughter in New South Wales. Audrey had been blind for some years but maintained a local interest by having our Newsletter read to her. Audrey's associations with Warrandyte started because her father Professor Osbourne had bought 60 acres in 1904. " Gold mining was beginning to die out and Warrandyte was a decaying area. Land was cheap because of the lack of transport and the soil was poor for farming” Audrey said. Audrey first attended school in the city at the Church of England Girls Grammar School and was always a bit rebellious. “If I felt some restrictions were unfair or some judgement unjust, I resented it”. Audrey got into Agricultural Science at Melbourne University and in 1928 was the second women to get such a degree. Audrey married in 1926, and later divorced Leslie Cahn an architect. They had twin daughters whom she left with her parents in Warrandyte while she studied dietetics during the depression. She found employment as a microbiologist at the Kraft/Walker Milk and Cheese Factory in Drouin - she drove home at weekends to see her daughters who were then at boarding school. During the war Audrey was in charge of catering at the Heidelberg Military Hospital – again the appointment of a women caused some unrest. She was in the army for more than 4 years and achieved the rank of General which-made her the most highly-ranked-woman at the hospital. After the war she became a senior lecturer in Dietetics at Melbourne University, again being aware of the limitations her gender brought to promotion possibilities. During her time at the university, she undertook a series of studies in nutritional biochemistry. Of especial note is the analysis of common dietary foods so that the composition and calorific value, the data that was needed for inclusion in Food tables - that professional sports people and weight-watchers so avidly follow today! She was an early proponent of the need to reduce fat intake and to substitute saturated fats with polyunsaturated fatty acids. In the 1950's Audrey and fellow workers established norms for the growth of Australian children to be compared with British and American children. Over 17 years they concluded that Australian children were overweight and inactive - what is new! She bought a cottage in Warrandyte as her home. In 1968 she retired to further develop her other interests as a potter and painter. Audrey was a foundation member of the group of potters that set up Potters Cottage. Audrey died in 2008 aged 102. (Ref:Newsletter No. 185 March 2009)art, artwork, audrey cahn, eltham, old bakery, york street -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Block, Alexander Stephen and Sons, 1869

These remains of a block, shackle and wire are from the sailing ship Newfield. This would have been one of the hundreds of blocks and shackles used in the rigging of the vessel. The Newfield was a three-masted iron and steel barque, built in Dundee, Scotland, in 1869 by Alexander Stephen and Sons. It was owned by the Newfield Ship Company in 1890 and later that year It was registered in Liverpool to owners Brownells and Co. The Newfield left Sharpness, Scotland, on 28th May 1892 with a crew of 25 under the command of Captain George Scott and on 1st June left Liverpool. She was bound for Brisbane, Australia, with a cargo of 1850 tons of fine rock salt. On the night of 28 August 1892, the Captain mistook the Cape Otway light for that of Cape Wickham (King Island) and altered tack to the north and east putting the vessel on a collision course with the Victorian coast. At around 3:40 am the Newfield struck rocks about 100 yards from shore, and 5 feet of water filled the holds immediately. The captain gave orders to lower the boats which caused a disorganised scramble for safety among the crew. The starboard lifeboat was cleared for lowering with two seamen and two apprentices in her, but almost as soon as she touched the water she was smashed to bits against the side of the vessel, and only one of the four reached safety ashore, able seaman McLeod. The rough sea made the job of launching lifeboats very difficult. The first two lifeboats launched by the crew were smashed against the side of the ship and some men were crushed or swept away. The third lifeboat brought eight men to shore. It capsized when the crew tried to return it to the ship for further rescue The rescue was a difficult operation. The Port Campbell Rocket Crew arrived and fired four rocket lines, none of which connected with the ship. Peter Carmody, a local man, volunteered to swim about one mile offshore to the ship with a line to guide the fourth and final lifeboat safely to shore. He was assisted by James McKenzie and Gerard Irvine. Seventeen men survived the shipwreck but the captain and eight of his crew perished. The Newfield remained upright on the reef with sails set for a considerable time as the wind slowly ripped the canvas to shreds and the sea battered the hull to pieces. The Marine Board inquiry found the wreck was caused by a "one-man style of navigation" and that the Captain had not heeded the advice of his crew. For his heroic efforts, Peter Carmody was awarded the Bramley-Moore medal by the Liverpool Shipwreck and Humane Society for Saving Life at sea on January 21st 1893. The medal and a letter of congratulations were donated to Flagstaff Hill Maritime Museum by Peter Carmody's granddaughter Norma Bracken and her son Stuart Bracken on 25th May 2006. Flagstaff Hill’s collection of artefacts from the Newfield is significant for its association with the shipwreck Newfield, which is listed on the Victorian Heritage Registry. The collection is additionally significant because of the medal awarded to a local man Peter Carmody. The Newfield collection historically also represents aspects of Victoria's shipping history and its association with the shipwreck.This is what remains of a block, shackle and wire from the wreck of the sailing ship “Newfield”. The object is heavily encrusted. The exterior (cheeks) of the block is missing. The disc of the block has a channel part way around its face, about 2 cm from the edge. Two long, narrow plates are joined onto the centre of the disc’s face with a bolt through the centre. The other ends of the two plates join onto the elbow of the shackle. The elbow of the shackle is also joined onto a rod. At the other end of the rod can be seen the ends of thick wire strands.block, 1893, flagstaff hill, flagstaff hill maritime museum, peter carmody, newfield, 1892, port campbell, shipwreck, ship, victorian shipwrecks, barque, ship wreck, peterborough, sailing ship, 29 august 1892, block and shackle, curdies river, bramley-moore medal -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Porthole, Alexander Stephen and Sons, 1869

This large brass porthole is from the sailing ship Newfield this would have been one of the many port holes in the vessel used for light and ventilation. The Newfield was a three-masted iron and steel barque, built in Dundee, Scotland, in 1869 by Alexander Stephen and Sons. It was owned by the Newfield Ship Company in 1890 and later that year It was registered in Liverpool to owners Brownells and Co. The Newfield left Sharpness, Scotland, on 28th May 1892 with a crew of 25 under the command of Captain George Scott and on 1st June left Liverpool. She was bound for Brisbane, Australia, with a cargo of 1850 tons of fine rock salt. On the night of 28 August 1892, the Captain mistook the Cape Otway light for that of Cape Wickham (King Island) and altered tack to the north and east putting the vessel on a collision course with the Victorian coast. At around 3:40 am the Newfield struck rocks about 100 yards from shore, and 5 feet of water filled the holds immediately. The captain gave orders to lower the boats which caused a disorganised scramble for safety among the crew. The starboard lifeboat was cleared for lowering with two seamen and two apprentices in her, but almost as soon as she touched the water she was smashed to bits against the side of the vessel, and only one of the four reached safety ashore, able seaman McLeod. The rough sea made the job of launching lifeboats very difficult. The first two lifeboats launched by the crew were smashed against the side of the ship and some men were crushed or swept away. The third lifeboat brought eight men to shore. It capsized when the crew tried to return it to the ship for further rescue The rescue was a difficult operation. The Port Campbell Rocket Crew arrived and fired four rocket lines, none of which connected with the ship. Peter Carmody, a local man, volunteered to swim about one mile offshore to the ship with a line to guide the fourth and final lifeboat safely to shore. He was assisted by James McKenzie and Gerard Irvine. Seventeen men survived the shipwreck but the captain and eight of his crew perished. The Newfield remained upright on the reef with sails set for a considerable time as the wind slowly ripped the canvas to shreds and the sea battered the hull to pieces. The Marine Board inquiry found the wreck was caused by a "one-man style of navigation" and that the Captain had not heeded the advice of his crew. For his heroic efforts, Peter Carmody was awarded the Bramley-Moore medal by the Liverpool Shipwreck and Humane Society for Saving Life at sea on January 21st 1893. The medal and a letter of congratulations were donated to Flagstaff Hill Maritime Museum by Peter Carmody's granddaughter Norma Bracken and her son Stuart Bracken on 25th May 2006. Flagstaff Hill’s collection of artefacts from the Newfield is significant for its association with the shipwreck Newfield, which is listed on the Victorian Heritage Registry. The collection is additionally significant because of the medal awarded to a local man Peter Carmody. The Newfield collection historically also represents aspects of Victoria's shipping history and its association with the shipwreck.Heavily encrusted large brass porthole, complete with glass intact object is a circular, thick glass window surrounded by a round brass frame and attached to a round brass porthole frame with 9 bolt holes. This porthole was recovered from the wreck of the NEWFIELD.Nonewarrnambool, peter carmody, newfield, port campbell, shipwreck, nineteenth century, ship, victorian shipwrecks, peterborough, peter ronald, dog screw, newfield porthole, bramley-moore medal, flagstaff hill maritime museum, shipwreck artefact, ship fitting, ship window -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Skylight frame, Alexander Stephen and Sons, 1869

This skylight frame would have been fitted on the Newfield’s poop deck (or raised deck that forms the roof of a cabin at the aft or rear of the ship). It would have covered and protected a glass pane that allowed light to enter the area below desk. The glass pane from the skylight is missing. The Newfield was a three-masted iron and steel barque, built in Dundee, Scotland, in 1869 by Alexander Stephen and Sons. It was owned by the Newfield Ship Company in 1890 and later that year It was registered in Liverpool to owners Brownells and Co. The Newfield left Sharpness, Scotland, on 28th May 1892 with a crew of 25 under the command of Captain George Scott and on 1st June left Liverpool. She was bound for Brisbane, Australia, with a cargo of 1850 tons of fine rock salt. On the night of 28 August 1892, the Captain mistook the Cape Otway light for that of Cape Wickham (King Island) and altered tack to the north and east putting the vessel on a collision course with the Victorian coast. At around 3:40 am the Newfield struck rocks about 100 yards from shore, and 5 feet of water filled the holds immediately. The captain gave orders to lower the boats which caused a disorganised scramble for safety among the crew. The starboard lifeboat was cleared for lowering with two seamen and two apprentices in her, but almost as soon as she touched the water she was smashed to bits against the side of the vessel, and only one of the four reached safety ashore, able seaman McLeod. The rough sea made the job of launching lifeboats very difficult. The first two lifeboats launched by the crew were smashed against the side of the ship and some men were crushed or swept away. The third lifeboat brought eight men to shore. It capsized when the crew tried to return it to the ship for further rescue The rescue was a difficult operation. The Port Campbell Rocket Crew arrived and fired four rocket lines, none of which connected with the ship. Peter Carmody, a local man, volunteered to swim about one mile offshore to the ship with a line to guide the fourth and final lifeboat safely to shore. He was assisted by James McKenzie and Gerard Irvine. Seventeen men survived the shipwreck but the captain and eight of his crew perished. The Newfield remained upright on the reef with sails set for a considerable time as the wind slowly ripped the canvas to shreds and the sea battered the hull to pieces. The Marine Board inquiry found the wreck was caused by a "one-man style of navigation" and that the Captain had not heeded the advice of his crew. For his heroic efforts, Peter Carmody was awarded the Bramley-Moore medal by the Liverpool Shipwreck and Humane Society for Saving Life at sea on January 21st 1893. The medal and a letter of congratulations were donated to Flagstaff Hill Maritime Museum by Peter Carmody's granddaughter Norma Bracken and her son Stuart Bracken on 25th May 2006. Flagstaff Hill’s collection of artefacts from the Newfield is significant for its association with the shipwreck Newfield, which is listed on the Victorian Heritage Registry. The collection is additionally significant because of the medal awarded to a local man Peter Carmody. The Newfield collection historically also represents aspects of Victoria's shipping history and its association with the shipwreck.Skylight, frame only. The heavily encrusted brass framework has eight bolts around the long side, and four metal bars forming two ‘v’ shapes across the centre. The frame is, slightly concave towards the inner side. The shorter ends of the frame each have a ‘U’ shaped bracket attached in the centre. The shorter ends are wider on one end and taper towards the other end to about a quarter of the thickness. The frame was recovered from the wreck of the NEWFIELD.Noneflagstaff hill maritime museum, newfield ship wreck, alexander stephen & sons, brownells & co, captain george scott, great ocean road ship wreck, peter carmody, bramley-moore medal, liverpool shipwreck and humane society, skylight cover, skylight frame, ship fitting, light cover, newfield -

Melton City Libraries

Melton City LibrariesLetter, Letters from Fred to Mattie, 1910-11, 1913-14, 1916, 1920

Letters sent to Martha (Mattie) dated from 1907 to 1920. Each letter is an edited version of the original pertaining to aspects of Fred Myers life as a shearer. Cobran Stn via Deniliquin Thursday Sept 1st 1910 …I got a reply from Eynesbury and a favourable reply, it starts on the 13th Oct so I will have plenty of time to get there, in fact far to much as we will finish here in a month full time so that will leave a fortnight to spare. We got rain here at last and it has put us back considerably as we only worked Monday. I have been idle ever since. We will probably start again Saturday. The weather has taken up nice and fine again…. I hope it will keep up to the cut out now I have 800 sheep shorn up to date and am fifth among thirty men so I’m doing well I think. Did you get the pound I sent? I’m sending two more this time, which I drew on Saturday. I don’t like sending too much as there is a chance of it going astray. Postcard Cobran Sept 18 1910 Just a note to let you know I am all right. I was disappointed not getting a letter yesterday, Saturday…I won’t get it now till next Saturday. We have three weeks here yet. I am sending 2 and tell me if you got the other 1. Cobran Stn via Deniliquin NSW Sunday 21st August (1911) ..I’m having a good time here, a good cook and the best of everything, no fires to lights or kettles to boil just get up and wire in but plenty of hard work. The sheep here a pretty rough but much better than Wandook. I am well among them here we had a little rain on Friday but not enough to stop us so we have got one full week in and the weather is now lovely I have been basking in the sunshine all morning and feel strong and fit as a fiddle. They are all a grand lot of men here I only knew one out of the lot but now them all pretty well now. We have a bit of a concert here every night almost. There are a few good singers here and we also had a phonograph up from the station with all the latest records. We have has two dances amongst ourselves, very boisterous affairs indeed they do make the dust fly. I have not ventured to take part in them yet and don’ think I will either. I get enough dancing all day long and besides I have to furnish the music. You ought to see them going when I rattle up the concertina they do make the dust fly. Sample of letters written by Fred Myers to his wife Mattie Myerslocal identities -

Mission to Seafarers Victoria

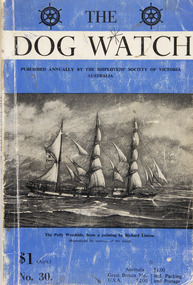

Mission to Seafarers VictoriaJournal (item) - Periodicals-Annual, Shiplovers' Society of Victoria, The Annual Dog Watch

This journal provides the reader with glimpses of the adventures and hardships of a seaman's life. Many of the stories are of sailing ships.Contributes to our knowledge of the importance of shipping and places on record those stories of the sea which would otherwise be lost.Contents Foreword - Commodore Dacre H. D. Smyth, R.A.N. - 7 Editorial - Pondering on Polly - 9 Progress Of The "Polly Woodside" - J. F. Yuncken - 13 Nearly Another "Birkenhead" - E. J. Batten - 21 Pawn Of The Storm - N. S. Smith - 27 The "Golden Plover" - I. L. Barton - 35 The "Brier Holme" - Ross Osmond - 43 The "Joseph H. Scammell" - A. D. Long - 47 A Western Port Boatman - Arthur Woodley - 51 Apology To A Freighter - C. E. Bonwick - 52 When Ships Burned Coal -- The 'Black Gang' - E. Carpenter - 53 From The Galley -- Fried Chicken - R.G.E. - 57 Just a Bit Outside The Law - Captain C. Meyer - 59 More Of Pearling Off The ARU Islands - Capt. W. J. Cowling - 63 A Medal Well Earned - L. A. Marchant - 70 The Tale Of The "Komet" - Harrow Morgan - 72 A Passage From England To Australia in the "Gauntlet" - Sven Tvermoes - 79 A Tug Of The Past - H. R. Watson - 94 Commodore Beal To The Rescue - Capt. F. K. Klebingat - 98 The Peacock From The Sea - J. M. MacKenzie - 106 The Man From Timbuctoo - L. de Neumann - 110 H.M.A.S. "Tingira" - D. C. Ricketts - 112 Inverneill At Iquiqui 1912 - Major M. H. O. Forbes - 116 The "Bear" - S. A. E. Strom - 121 Book Reviews - - 125 Glossary - - 128 More After Thoughts - W. F. Cook - 129sailing ships, steamships, shipping, seafaring life, shiplovers' society of victoria, dog watch, polly woodside -

Melbourne Tram Museum

Melbourne Tram MuseumEphemera - Timetable/s, Public Transport Victoria (PTV), Timetable Notice giving details of temporary changes to service as part of the COVID 19, 2020

Timetable Notice giving details of temporary changes to service as part of the COVID 19 response where route 12 diverted by La Trobe St, and thus provided a service along Spencer St. Route 30 was suspended. Route 11A was introduced between Docklands and St Vincent's Plaza. htd4777i1.pdf shows a timetable alteration, reduction of services after 8pm, introduction of the 8pm to 5am curfew and stage four restrictions that were to apply (hopefully) for a six week period. Set of 23 digital timetables generally applicable from 10-11-2019 and two timetables for route 11 and12 applicable from 13 July. This change was a bit confusing at the time. Image files are htd4777iRx - x being the route number. Route 1 - East Coburg - South Melbourne Beach Route 3 and 3A - Melbourne University - East Malvern - and via St Kilda Beach - two timetables for each Route 5 - Melbourne University - Malvern Route 6 - Melbourne University - Glen Iris Route 11 - West Preston - Victoria Harbour Docklands Route 12 - Victoria Gardens - St Kilda Route 16 - Melbourne University - Kew Via St Kilda Route 19 - North Coburg - Flinders St Route 30 - St Vincent's Plaza - Etihad Stadium Docklands - though the stadium was renamed Marvel after Marvel comics by Disney during May 2018. Route 35 - City Circle - NOT Published. Route 48 - North Balwyn - Victoria Harbour Docklands Route 55 - West Coburg - Domain Interchange Route 57 - West Maribyrnong - Flinders St Route 58 - Toorak to Route 59 - Airport West - Flinders St Route 64 - East Brighton - Melbourne University Route 67 - Carnegie - Melbourne University Route 70 - Wattle Park - Waterfront City Docklands Route 72 - Camberwell - Melbourne University Route 75 - Vermont South - Etihad Stadium Docklands Route 78 - North Richmond - Balaclava via Prahran Route 82 - Footscray - Moonee Ponds Route 86 - Bundoora RMIT - Waterfront City Docklands Route 96 - East Brunswick - St Kilda Beach Route 109 - Box Hill - Port Melbournetrams, tramways, timetables, yarra trams, route 1, route 3, route 5, route 6, route 8, route 11, route 11a, route 12, route 16, route 19, route 30, route 48, route 55, route 57, route 58, route 59, route 64, route 67, route 70, route 72, route 75, route 78, route 82, route 86, route 96, route 109, covid-19, st vincent's plaza, spencer st -

Halls Gap & Grampians Historical Society

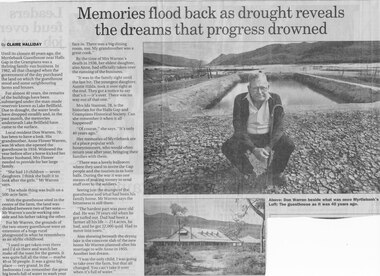

Halls Gap & Grampians Historical SocietyNewspaper - B/W

Until the closure 40 years ago, the Myrtlebank Guesthouse near Halls Gap in the Grampians was a thriving family - run business. In 1962, all that changed when the government of the day purchased the land on which the guesthouse stood and some neighbouring farms and houses. For almost 40 Years, the remains of the buildings have been submered under the man made reservoir known as Lake Bellfield. Due to drought, the eater levels have dropped steadily and, in the past month, the memories underneath Lake Bellfield have come to the surface. Local resident Don warren 70, has been to have a look. His grandmother Anne Flower Warren, was 56 when she opened the guesthouse in 1916. Widowed, the year before after a horse kicked her farmer husband, Mrs Flower needed to provide for their large family. "She had 13 children - seven daughters. I think she built it to look after the girls," Mr Warren says, "The whole think was built on a 500 acre farm." With the guesthouse sited in the centre of the farm, the land was divided between two of her sons- Mr Warren's uncle working one side and his father taking the other. For Mr Warren, the grounds of the two-storey guesthouse were an extension of a huge rural playground in what he remembers as an idyllic childhood. "I used to get taken over there and I'd sit there and watch her make all the toast for the guests. It was quite full all the time - maybe 40 or 50 people. It was a great big place - very grand. In the bedrooms I can remember the great big bowls full of water to wash your face in. There was a big dining room, too. My grandmother was a great cook." By the time of Mrs Warren's death in 1936, her eldest daughter also Anne, had officially taken over the running of the business. "It was in the family right until the last bit. The youngest daughter, Auntie Hilda, took it over right at the end. they got a notice to say that's it - it's over There was no way out of that one." Mrs Ida Stanton, 78, is the historian for the Halls Gap and Grampians Historical Society. Can she remember it when it all happened? "Of course" she says "It's only 40 years ago" Her memories of Myrtlebank are of a place popular with honeymooners, who would often return year after year, bringing their families with them. "There was a lovely ballroom where they used to invite the Gap people and the tourists in to have balls. During the war it was one means of making money to send stuff over to the soldiers." Seeing just the stumps of the guesthouse and what had been his family home, Mr Warren says the bitterness is still there. "The hardest part was poor old dad. He was 70 years old when he got turfed out. Dad had been a farmer all his life - 214 acres, he had, and he got 22,000 quid. Had to move into town" Also showing beneath the drying lake is the concrete slab of the new home Mr Warren planned after his marriage to wife Anne in 1955. Another lost dream. " I was the only child, I was going to take over the farm, but that all changed. You can't take it over when it's full of water.Newspaper clipping of history of Myrtlebank by Don Warren and photo of Don at old site of pooland guest House photo Article by Claire Halliday from newspaper 2002accommodation, guesthouses, myrtlebank -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageRangefinder, E R Watts & Sons, 1930-1945

E. R. Watts and Son, makers of theodolites and other surveying instruments, of 123 Camberwell Road, London. The company was established in 1856 by Edwin Watts at twenty-three he had saved £100 from his earnings to start the business with his staff consisting of one boy and later Alexander Clarkson as an apprentice with the workshop a small room over a Bemondsey stable. Watts' first order was from Negretti and Zambra for a mining dial Alexander Clarkson In the early days the firm worked mainly on marine compasses. Edwin Watts would go down to the Docks to adjust the compasses once they had been installed on the ships. In May 1873 the business moved to larger premises a house with a garden. The workshop was also the home of Mr and Mrs Watts and their five sons and three daughters. By now there were fifteen to twenty men employed by the firm. The company were commissioned to supply the Theodolites and Levels for the construction to the Canadian Pacific Railway in 1881. Towards the end of the century, the firm began to make heliographs continuing to produce them for the government until just before the Second World War when by agreement assigned their manufacture to another firm. 1904 The first dividing engine was completed by George William Watts. It was so remarkable an instrument at the time and for years afterwards, In 1907 Arthur Ames went to Canada and started an organisation in Winnipeg in 1909 this became a separate company called E. R. Watts and Son Ltd. of Ottawa. This firm developed considerably and was eventually with the co-operation of three other instrument companies (Cambridge Instrument Co, Ross, and Negretti and Zambra), were reconstituted as ”Instruments Ltd” of Ottawa and Toronto. During the next ten years, the firm expanded greatly to include glass grinding, leather work, dividing and engraving, testing, adjusting and packing. This expansion was continued during the First World War when workshops were completed and the machinery installed and running within eleven weeks from the start of construction. During the war, a Sergeant Coles, among the rats, lice and mud of the trenches, fitted various bits of scrap into his cocoa tin and made the first Flash Spotter for plotting the positions of enemy guns. Coles was rushed home to the firm's factory where he and George William Watts designed a spotter not made out of a cocoa tin and as a result, the Watts Vertical Force Variometer was developed during WWI. Other Watts instruments made in the First World War included the Light Mountain Theodolites which were taken on Mt Everest expeditions. In 1919 ER Watts and Sons was incorporated as a limited company and in 1939 G. A. Whipple joined the Board of Directors. Shortly afterwards, Frank Charles Watts died having been Chairman of the firm for over 37 years and seen it through the First World War with all its expansions and difficulties. He was succeeded by his brother George William Watts with the vacant post of Managing Director being filled by G. A. Whipple. During the Second World War, the company expanded further and the number of employees rose to well over 1,300. In 1946 Watts acquired 78% of Adam Hilger and the microscope maker James Swift and Son Who were Manufacturers of Theodolites, Levels, Alidades, Meteorological Instruments, Variometers, and many other types of scientific instruments Then in 1948 the company amalgamated with Adam Hilger as Hilger and Watts which was then incorporated as a public company.Naval Rangefinder with a vertical wooden handle, and an arrangement of optical lenses. Three reversible brass inserts calibrated on both sides in yards, correspond to various base heights, (20 and 25 feet, 30 and 35 feet and 40 and 50 feet). They are fitted along the axis of the instrument. When the scale for the appropriate base height is selected and inserted, the carriage can be slid for coincidence and the distance read at the index mark on the sliding carriage.inscribed "Rangefinder Cotton Type Mk II" Calibrated scale up to 5000 yds (50 ft), 5000 yds (35 ft), 4000 yds (25 ft) made by E. R. Watts & Son.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, rangefinder, cotton type, e r watts & sons, naval range finder, marine equipment -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Eltham Hardware and Timber Co, Main Road, Eltham, opposite Railway Station. c.1952, 1952c

The Eltham Hardware and Timber Company first opened on Main Road opposite the Railway Station around late 1922. An advertisement placed in the Hurstbridge Advertiser advised that the Hardware Store had just opened with a varied stock of Saws, Hammers, Nails, Shovels, Screw Drivers, and every article required in a house or on a farm. People were also encouraged to try their Jams, Pickles, Sauces, Cups and Saucers, etc. A few months later in May 1923, William Walker, a plumber, placed an advertisement wishing to to announce that he had taken over the ELTHAM HARDWARE STORE, and asked for the continued support of the district. He also noted that all kinds of Plumbing work was done. Walker remained the proprietor of the Hardware Store for many years regularly advertising its services and wares up until at least 1941. The trail goes a bit quiet then but he does appear in the 1944 Electoral Roll listed as a Plumber, of Main Street, Eltham. However he is not listed in the 1949 Electoral Roll but his son, Thomas Roy Walker, also a plumber of Main Road is listed. Thomas had been on active duty overseas during the Second World War and returned at the end of 1945. It is assumed that William died sometime between 1945 and 1949. On November 18th, 1950 the Hardware Store and residence was auctioned on site by Scarff Bros. Pty Ltd. It is presumed that this is when J.N. Burgoyne and Sons took over the business. It would have been around this time the picture of the store was taken for only three years later, in October 1953, the business and dwelling was again put up for sale, this time by Trebilcock Bros, in two separate lots. LOT 1. — ELTHAM HARDWARE AND TIMBER CO. Freehold and Property, Plant, Fittings and Business; Plus Stock at Valuation. To be Sold as a Going Concern. THE FREEHOLD PROPERTY Comprises Large Brick and Timber Shop. Well Fitted. Has Good Light. Comfortable 3-Room Dwelling and Detached Bungalow, H.W.S., Phone, Garage and Outbuildings. Situate on Large Allotment, 50 Ft. x 150 Ft. Aprox. THE BUSINESS: Flourishing Hardware and Builders’ Supplies, Crockery, Glassware and Gifts, Dry Cleaning Agency and Petrol Reseller Licence (1 Bowser Installed), Oil Storage. Annual Turnover Aprox. £12,000. Audited Figures Available, Old-established Business Comprehensive Stock is Good, Clean and Saleable (Value Approx. £4000). TERMS: £1000 Deposit, Balance 30 Days. VACANT POSSESSION. LOT 2. — Superb Shop Sites. Adjoining the Above Property. Land 58 Ft. x 150 Ft. (Approx.). Erected on Land Is Old Style 4-r Timber Dwelling, Set Well Back from Footpath. Leaving Ample Apace to erect Shops. Also Small Shop Let as Agent’s Office. To Be Sold Subject to Existing Tenancies, Gross Rentals £106 12/ Per Annum. Terms: £1000 Deposit, Balance 30 days. GENERAL: Eltham Is a Rapidly Developing Area only 12 Miles from G.P.O. Street Frontage of these Two Adjoining Properties Is 108 Feet By Depth of 150 Feet in the Heart of Expanding Shopping Centre, directly Opposite Station Entrance. Full Details and Inspection Available on Application from the Auctioneers: TREBILCOCK BROS. AUCTIONEERS and ESTATE AGENTS, Coincidentally, the Hardware Store was taken over by Richard Phillip Trebilcock, an electrical engineer from Mayona Road, MontmorencyNegative black and white film 120 6x6 formatSingle frameeltham, main road, 1951 chevrolet deluxe, ampol, eltham hardware and timber, j.n. burgoyne and sons, petrol bowser, william walker, richard phillip trebilcock -

Puffing Billy Railway

Puffing Billy RailwayEquipment - Victorian Railways Carriage Foot Warmer

During prestige, long distance train journeys some carriages had air-conditioning, and the majority of passengers had to brave unheated carriages. To offer some comfort during the winter months, the non-air-conditioned carriages were provided with footwarmers. These were metal containers roughly 100 mm thick and 300 mm wide, and about 750 mm long, which were filled with salt crystals (concentrated crystalline hydrated sodium acetate). The footwarmers were covered by sleeves of thick canvas, and two footwarmers were usually placed in each compartment of non-air-conditioned carriages. To activate the chemicals, the footwarmers were heated almost to boiling point. This was done by removing the canvas sleeves and placing the footwarmers in a large bath of very hot water. After they had been heated, they were removed from the bath and the sleeves refitted. They were then ready to be placed in the carriages. The McLaren patent foot warmer was used on railways in New South Wales, Queensland, Victoria and South Australia as well as South Africa and New Zealand. It was during the 1901 royal visit by the Duke and Duchess of Cornwall that these foot warmers were first used in New Zealand in the royal carriage. Before railway carriage heating was introduced, McLaren patent foot warmers were placed on the floor of New South Wales government railway carriages from 1891 to provide a little passenger comfort. The rectangular steel container worked a bit like a hot water bottle but instead of water contained six and a half kilograms of loosely-packed salt crystals, (concentrated crystalline hydrated sodium acetate). This was permanently sealed inside the container with a soldered cap. After the foot warmer was heated in vat of boiling water for about one and a quarter hours the crystals became a hot liquid. (The melting point for sodium acetate is 58 degrees). There was a whole infrastructure of special furnaces set up at stations for the daily heating of foot warmers. By 1914 the Victorian railways had 4,000 foot warmers in service and by 1935 there were 33 furnaces at principal stations to heat them. After about 10 hours the container was picked up by the handle and given a good vertical shake which helped the cooled liquid reform into a solid mass of hot crystals. Staff or sometimes passengers shook them en route when the foot warmers began to get cold. However, as they were heavy this was only possible by fit and agile passengers. At the end of the journey the containers were boiled again for reuse on the next trip. Sodium acetate railway foot warmers were introduced in Victoria in 1889, Adelaide to Melbourne express in 1899. "Shaking up" on this service took place at Murray Bridge and Stawell on the tip to Melbourne and at Ballarat and Serviceton on the trip to Adelaide. The use of foot warmers began to decline in New South Wales from the 1930s with the first trial of carriage air-conditioning in 1936, steam heating from 1948 ad LP gas heating from 1961. By the early 1960s the main services using foot warmers were the overnight mail trains. info from : http://www.powerhousemuseum.com/collection/database/?irn=67564#ixzz4UBNzVf6t Under Creative Commons License: Attribution Non-Commercial There was a whole infrastructure set up at stations for the daily heating of foot warmers in special furnaces. In Victoria alone in 1935 there were 33 heating works.Historic - Victorian Railways - Carriage Heater - Foot warmerA rectangular-shaped stainless steel casing with a welded seam down the back and welded ends. There is a handle at one end for carrying and shaking. Inside the foot warmer are two baffle plates and three trays to contain the sodium acetate. There was a cast-iron ball in each internal compartment. puffing billy, victorian railways, carriage haeter, foot warmer, passenger comfort, station furnace, railway ephemera, early heating methods -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - NEW CHUM LINE OF REEF - NOTES ON SHAFT DETAILS ON THE NEW CHUM LINE OF REEF

Ten pages and one smaller page of notes showing depth of shaft, sill, size of shaft, relation to line of reef, depth bottom plat, depth to bottom of well, number of compartments, reference and remarks. Mines mentioned are: Young Chum, Old Chum (Old South), Shamrock, Shenandoah, New Chum Railway, Eureka Ext'd, South Belle Vue United, Lansell's 222, Denis Shaft, New Chum United, Ellesmere (North Shaft), New Chum Consolidated, Ellesmere No 1 or (South Shaft) also known as New Chum Coy, Garibaldi, Craven's, Lansell's Bit 180, North Old Chum, New Chum & Victoria, Old Chum, Lazarus New Chum Main, Lazarus New Chum (Old), Victoria Reef Gold (Ironbark), Victoria Consols, Adventure & Advance, Gt Central Victoria, Ballerstedt, Humbold, Victoria (Reef) Quartz, Pearl (later Hercules New Chum), Hercules Extended (Pearl (South) later, North Hercules, Hercules and Energetic, Hercules (Old),South Devonshire, Duchess Tribute, New St Mungo, Duke of Edinburgh, New Victoria Catherine (later Hercules Consols), Dixon's Tribute, Great Victoria Extended, Hopewell, Saxon & Celt Extended, St Mungo, Princess Alexander,West United Devonshire, United Devonshire, Duchess of Edinburgh, Sadowa, (Old) St Mungo, Lady Barkly, Princess Alice (South St Mungo) previously Gov. Barkly, Unicorn (Trib), Phoenix, Williams (New), Acadia Catherine, William United (Old Shaft), Snob's Hill Shaft, York & Durham, Belmont & Saxby, Ellenborough, Catherine Reef Extended, New Franklin, Murchison, Catherine Reef United Main Shaft, Catherine Reef United South Shaft. Small page has notes on the York and Durham: Reference - Matthew Mann - Mine Manager's Report 3/7/1893. This paragraph: Quote - 'Also measured main shaft from surface 1,430 and found it to be 1,416 feet and from Brace - 1,428 feet. Poppet legs 12 feet. Reference - Matthew Mann - Mine Manager's Report 15/7/1893 'Received cheque from La Belle Co. for 2 pound 13 shillings - which I payed into credit of Company'. Note: Report shows this to happen on several occasions. Note initialled AR.document, gold, new chum line of reef, new chum line of reef, notes on shaft details on the new chum line of reef, young chum, old chum (old south), shamrock, shenandoah, new chum railway, eureka ext'd, south belle vue united, lansell's 222, denis shaft, new chum united, ellesmere (north shaft), new chum consolidated, ellesmere no 1 or (south shaft) also known as new chum coy, garibaldi, craven's, lansell's bit 180, north old chum, new chum & victoria, old chum, lazarus new chum main, lazarus new chum (old), victoria reef gold (ironbark), victoria consols, adventure & advance, gt central victoria, ballerstedt, humbold, victoria (reef) quartz, pearl (later hercules new chum), hercules extended (pearl (south) later, north hercules, hercules and energetic, hercules (old), south devonshire, duchess tribute, new st mungo, duke of edinburgh, new victoria catherine (later hercules consols), dixon's tribute, great victoria extended, hopewell, saxon & celt extended, st mungo, princess alexander, west united devonshire, united devonshire, duchess of edinburgh, sadowa, (old) st mungo, lady barkly, princess alice (south st mungo) previously gov. barkly, unicorn (trib), phoenix, williams (new), acadia catherine, william united (old shaft), snob's hill shaft, york & durham, belmont & saxby, ellenborough, catherine reef extended, new franklin, murchison, catherine reef united main shaft, catherine reef united south shaft -

Ballarat Tramway Museum

Ballarat Tramway MuseumEphemera - Ticket/s, State Electricity Commission of Victoria (SECV), Set of SEC predecimal tickets - Wal Jack Collection, 1960's

Yields information about the style and printing of tickets used in Ballarat tramways and how they were presented at the commencement of the SEC fare system. Generally issued c1963, some have dates on rear.Group of eight different pre-decimal values of used SEC Ballarat Tickets, ex the Wal Jack Collection. Tickets already held on the BTM system in blocks. All except .7, have a tartan or criss cross back. 1. - 5d Green (5 No. - B400836, B265927, W808385, B400835, Z742326) - note the same as Reg Items 3991 and 3994, though the printing of the section marks do vary a bit. These were not imaged. 2. - 5d Green (M714336) - imaged - has different section system on the side to the above - used 1/3/1963. 3. - 6d Teal - (34 No.) - some sequential - All A series. Note the same as Reg Item 3993. 4. - 6d Teal (L918047) - imaged 4009i4 - has different section system on the side to the above. 5. - 8d Red - (5 No. all A series, 292132 & 3, 206314, 315138 & 362937) - note the same as Reg Item 3984. 6. - 2d Red (S306797) - different section layout to Reg item 3986. 7. - 1 1/2d - (Ad705016) - black ticket, with red overprint of 1 1/2d fare and ticket prefix number - similar to Reg Item 2115, but different sectional layout. The section layout is the same as Reg Item 2116. Has Bushells Pty Ltd Tea advertisement on the rear. 8. - 3d City Section, Orange - (3No. A032622, 036606, 047637) - note the same as Reg Item 3982. All have dates on the rear - August 1963. 9. - 3d Concession - Orange, (A447731, 470928) - note the same as Reg Item 3989 and 4001. One has date of 1/3/63 on rear. 10 - 4d Brown (7 No. Y997727, 998446, Z004193, 005655, 012671, 018609 & 024899) - Some have dates of 1963 in pencil on the rear. Note the same as Reg Item 3995, though different series letter. All tickets and Reg Item 4006, 4007, 4010 to 4018 were received originally in a folded cloth wrapper - wax canvas? - with "All Since 1/3/1963 /3d Concession since 1/8/63" written in pencil on it. Stored with this item. See image btm4009i3. Tickets have not been formally numbered on the rear for this item No. All numbers recorded except for the 6d Teals. trams, tramways, secv, ticket -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century