Showing 5630 items matching "snapshot"

-

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncNegative - Haeusler Glass Negatives Collection - Jack Parker and the pony he taught to do tricks

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s. This digital image was produced from one of the glass negatives that form part of the collection, probably taken by Louis Haeusler (b.1887) with the photographic equipment in the Wodonga Historical Society Haeusler Collection. Parker Family - Samuel Skelton Parker, Jack Parker’s father, migrated to Australia from Ballymena, Country Antrim, Ireland in 1884. He married Bridget Cusack from County Clare in 1883. They had children William, James, Jack, Samuel and Rachel. After working on a station in northern NSW, they moved to Barnawartha and set up a butchery and later a bakery. In 1890 the family moved to Wodonga, buying a property in West Wodonga, which he called “Park Hall” after his home in Ireland. The property is now the location of the Wodonga Golf Club in Parkers Road, West Wodonga.This item is unique and has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It contributes to our understanding of domestic and family life in early twentieth century Wodonga, as well as providing interpretative capacity for themes including local history and social history.Digital image created from the Haeusler Glass negative collection. Jack Parker and his pony in the centre front of the image. Jack taught this pony to perform several tricks. The Parker family home and some outbuildings are visible in the background. This is a substantial brick house with corrugated iron roof.wodonga pioneers, haeusler family, glass negatives, dry plate photography, parker family wodonga -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncNegative - Haeusler Glass Negatives Collection - Jack Parker with the pony he taught to do tricks

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s. This digital image was produced from one of the glass negatives that form part of the collection, probably taken by Louis Haeusler (b.1887) with the photographic equipment in the Wodonga Historical Society Haeusler Collection. Parker Family - Samuel Skelton Parker, Jack Parker’s father, migrated to Australia from Ballymena, Country Antrim, Ireland in 1884. He married Bridget Cusack from County Clare in 1883. They had children William, James, Jack, Samuel and Rachel. After working on a station in northern NSW, they moved to Barnawartha and set up a butchery and later a bakery. In 1890 the family moved to Wodonga, buying a property in West Wodonga, which he called “Park Hall” after his home in Ireland. The property is now the location of the Wodonga Golf Club in Parkers Road, West Wodonga.This item is unique and has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It contributes to our understanding of domestic and family life in early twentieth century Wodonga, as well as providing interpretative capacity for themes including local history and social history.Digital image created from the Haeusler Glass negative collection. Jack Parker sitting on his pony which is lying down on the ground. Jack taught this pony to perform several tricks. The Parker family home and some outbuildings are visible in the background. This is a substantial brick house with corrugated iron roof.wodonga pioneers, haeusler family, glass negatives, dry plate photography, parker family wodonga, horsemanship -

Wodonga & District Historical Society Inc

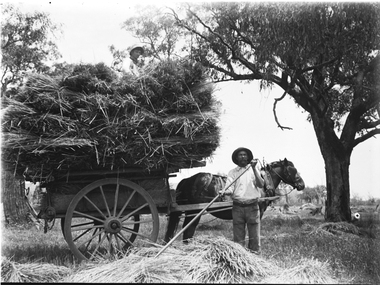

Wodonga & District Historical Society IncNegative - Haeusler Glass Negatives Collection - Sam Parker's Farm c1910

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s. This digital image was produced from one of the glass negatives that form part of the collection, probably taken by Louis Haeusler (b.1887) with the photographic equipment in the Wodonga Historical Society Haeusler Collection. Parker Family - Samuel Skelton Parker, Jack Parker’s father, migrated to Australia from Ballymena, Country Antrim, Ireland in 1884. He married Bridget Cusack from County Clare in 1883. They had children William, James, Jack, Samuel and Rachel. After working on a station in northern NSW, they moved to Barnawartha and set up a butchery and later a bakery. In 1890 the family moved to Wodonga, buying a property in West Wodonga, which he called “Park Hall” after his home in Ireland. The property is now the location of the Wodonga Golf Club in Parkers Road, West Wodonga.This item is unique and has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It contributes to our understanding of domestic and family life in early twentieth century Wodonga, as well as providing interpretative capacity for themes including local history and social history.Digital image created from the Haeusler Glass negative collection. A man spreading hay with a rake in the foreground. A horse and cart loaded with hay is behind him.wodonga pioneers, haeusler family, glass negatives, dry plate photography, wodonga families, early farming -

Melbourne Legacy

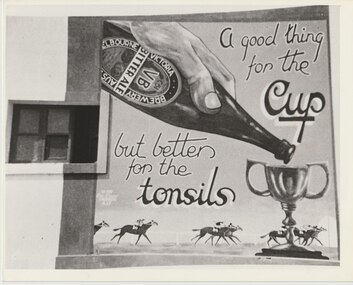

Melbourne LegacyPhotograph, A Mural West of Tobruk, 1941

A photo of a mural in Libya painted by a South Australian Sapper of a bottle of Victorian Bitter Ale being poured into the Melbourne Cup trophy and horses racing. The photo, and two others, were sent to Melbourne Legacy in 1979 by Legatee Syd Wilson of Yamba NSW. He thought Melbourne Legacy might be able to use them to generate money by selling them for advertising or publicity. He said they were enlargements of snapshots he had found in his old army trunk. The text says 'A good thing for the Cup but better for the tonsils'. Legatee Wilson's letter says the murals were: 'painted on three walls of a white concrete Italian block house (Police Check post I think), some 18/20 miles west of Tobruk, between Tobruk and Derna, and near a captured Italian airfield, somewhere about February 1941. Obviously they were painted by a Victorian Sapper. They were very well done, by a competent Sign-writer/artist, in correct and excellent colours (captured Itie paint no doubt - there was plenty in their Naval Stores at Tobruk).' (NB Itie was slang for Italian). 'The photos were there when we were coming back from Western Libya sometime in March 1941, prior to the 6th Division going to Greece.' From the AWM website the signs were painted by South Australian painter, SZ538 Sapper Leslie John “Doc” Dawes, 2/3rd Field Company, Royal Australian Engineers. There are several photos on the AWM site including the building the three murals were on.Photos taken by a Legatee when on active service in Libya in World War 2. They were donated to Legacy when it was thought they could be used for fundraising, which shows that Legatees were conscious of the way Legacy needs to generate funds to continue its work.Black and white enlargement of a photo taken in Libya of Victorian Bitter Ale for the Melbourne Cup mural.tobruk, beer, victorian bitter ale, ale, horse racing, murals, world war 2 -

Melbourne Legacy

Melbourne LegacyDocument - Eulogy, James George Gillespie MBE, Hon. FIS Aus, FRICS, 1987

A copy of two addresses made at the funeral service for Legatee James George Gillespie, a long serving Legatee. The funeral was held on 25th May 1987 at St Stephen's Church, Caulfield. The addresses were by Rev. Vere Heazlewood (Parish Minister) and Wing-Commander Ron Austin. The article is very similar to the VALE notice published in the Bulletin and includes a snapshot of his life and career as a surveyor and long history of service in many fields. He was a member of the RMIT Council, and on the board of the Royal Women's Hospital - both of whom named building after him. He served on the Hospitals and Charities Commission, and the Nurses Memorial Centre and Greenvale Geriatric Centre. Plus many more. He enlisted in the AIF 18 months after his older brother had been killed on the first day of the landing at Gallipoli. He was in the 46th Battery, 12th Artillery Brigade as a gunner. He served in France and Belgium and was in Paris on the day the Armistice was signed. In World War 2 he was called up and was appointed Assistant-Director of Survey, with a rank of Lieut-Colonel. Jim Gillespie joined Legacy in June 1928, being nominated by Frank Doolan and seconded by Harold Peters. He filled many posts, including vice-president in 1937 and President in 1938 The article was part of an folder about of past presidents that served on the LCC in preparation for the photo board that was produced. The folder included biographical details and obituaries, eulogies and death notices of some Legatees. The items have been catalogued separately.A record of the life and service of Legatee Jim Gillespie. The information was published in the Bulletin and collected to record the lives of prominent legatees in a folder.Photocopy x 5 pages of the addresses made at the funeral of Legatee James Gillespie.eulogy, past presidents, jim-gillespie -

Wodonga & District Historical Society Inc

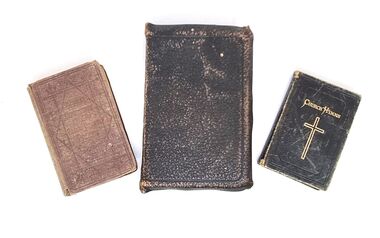

Wodonga & District Historical Society IncBook - Haeusler Collection - Bible and Hymn books, c1890s

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s. This Bible belonged to Louis Alfred Haeusler, son of Johann Heinrich Ferdinand Haeusler and Ernestine Wilhelmine nee Rogasch. Louis was born in Wodonga, Victoria on 23 December 1898 and died on 2 February 1960. The other 2 volumes belonged to Louis' sister Eleonora Lydia Haeusler (Nellie), born 14 October 1883 and died 25 November 1979. Louis was the father of John Alfred Lyell (Alf) Haeusler who bequeathed this collection to the Wodonga Historical Society. The Bible was published by Collins' Clear Type Press, a Scottish publishing company founded in 1892.The volume "Church Hymns" was published by the Society for Promoting Christian Knowledge, the oldest Anglican missionary organisation which was originally founded in 1698. This copy was published in London C1885. The Hymnal Companion to the Book of Common Prayer (2nd Edition) was published by Sampson Low, Marston and Company of London C1893.This item is unique and has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It is representative of the religious traditions adopted by this family in Wodonga. A collection of 3 religious books including a Bible, Hymn book and Hymn Book companion. They have different coloured leather covers. Handwritten inside front cover of Bible: L.A. Haeusler/ Wodonga, Vic. Handwritten inside front cover of Hymnal Companion: Eleonora L. Haeusler / St. Lukes, Wodonga Handwritten inside Church Hymns: To Nellie with love from Sister Tilly 20.8.02haeusler family, religious publications, society for promoting christian knowledge, sampson low, marston and company -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncNegative - Haeusler Glass Negatives Collection - Ted McKoy and his horse

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. Edgar Francis ‘Ted’ McKoy. Born on 21 January 1881 at Wodonga to parents Alexander Joseph McKoy and Emma House. He was the 11th child born to Joseph and Emma. During 1858, Joseph and Emma travelled from Parks Camp in New South Wales to Wodonga. Joseph’s brother James was already living on the border. They settled at Wodonga and raised a very large family. Ted grew up on the horse stud of his parents – the land is where the Wodonga Caravan Park and Wodonga TAFE are now located. Several streets in the area are named after Joseph’s horses. Ted developed his considerable skills with horses with the help of his father who was a renowned breeder. Ted married Laura Annie McVean at 'The Vicarage' Wodonga on 1 Mar 1905. They had four children - Harold Glenn, Vera, Beatrice Mabel and Gladys. They settled at Ted’s stud Moorefield Park. Ted was a well-known horse breeder in his own right and won many prizes at agricultural shows. He had trotting horses, show hacks and Clydesdales. He worked for many years as the Wodonga Pound Keeper and was well-known throughout the district. Ted died on 7 Jul 1947 at Albury District Hospital and was buried at the Wodonga Cemetery.This item is unique and has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It contributes to our understanding of domestic and family life in early twentieth century Wodonga, as well as providing interpretative capacity for themes including local history and social history.Digital image created from the Haeusler Glass negative collection. Mr. Ted McKoy showing one of his horses. The McKoy family ran a horse stud for many years in Wodonga West, Victoria.wodonga pioneers, haeusler family, glass negatives, dry plate photography, mckoy family wodonga -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncNegative - Haeusler Glass Negatives Collection - Ted McKoy and his horse

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. Edgar Francis ‘Ted’ McKoy. Born on 21 January 1881 at Wodonga to parents Alexander Joseph McKoy and Emma House. He was the 11th child born to Joseph and Emma. During 1858, Joseph and Emma travelled from Parks Camp in New South Wales to Wodonga. Joseph’s brother James was already living on the border. They settled at Wodonga and raised a very large family. Ted grew up on the horse stud of his parents – the land is where the Wodonga Caravan Park and Wodonga TAFE are now located. Several streets in the area are named after Joseph’s horses. Ted developed his considerable skills with horses with the help of his father who was a renowned breeder. Ted married Laura Annie McVean at 'The Vicarage' Wodonga on 1 Mar 1905. They had four children - Harold Glenn, Vera, Beatrice Mabel and Gladys. They settled at Ted’s stud Moorefield Park. Ted was a well-known horse breeder in his own right and won many prizes at agricultural shows. He had trotting horses, show hacks and Clydesdales. He worked for many years as the Wodonga Pound Keeper and was well-known throughout the district. Ted died on 7 Jul 1947 at Albury District Hospital and was buried at the Wodonga Cemetery.This item is unique and has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It contributes to our understanding of domestic and family life in early twentieth century Wodonga, as well as providing interpretative capacity for themes including local history and social history.Digital image created from the Haeusler Glass negative collection. Mr. Ted McKoy showing one of his horses. The McKoy family ran a horse stud for many years in Wodonga West, Victoria.wodonga pioneers, haeusler family, glass negatives, dry plate photography, mckoy family wodonga -

Camberwell Girls Grammar School

Camberwell Girls Grammar SchoolPhotograph Album, Kodak Australia

The album contains early images of the School at the new site in Torrington Street, Canterbury. The photographs have extensive captions that date and document key events in the School's development. Grey cardboard album made up of twenty-four pages held together by blue cords and a dark blue ribbon. Pages are loosley in date order [note incomplete years] document a range of school activities, at Camberwell Girls Grammar School orginally known as St Mark's School, Camberwell from 1927- 1959. Locations include the now School site with the original house "Torrington" with early images of classes amd students in 1927; 1931-1932 Scenes in the School grounds including Kindergarten classes; forms and sporting teams. Pageants held in 1932 include the Shakespearean Pageant held 23rd April and the Pageant of all Nations. Formal team and class photographs taken by the photogrpaher Stuart Tompkins, Camberwell are included in 1933 and 1935. 1932 snapshots taken in 1932 Kindergarten with English children sent to Australian for safety with teacher Miss Nancy White. Sports Day and Combined Sports Day from the 1950s and a School holiday tour of Heron Island and a Coronation pageant both in 1953. Dedication of the Secondary block 10th March 1956; Kindergarten at St Hilary's with Mrs Kilgour in 1957. The last page shows an image of Principal Mrs AR Mace [former name Miss Louisa Stafford Taylor] with her husband Canon Mace at a School Sports Day 1959. -

Mt Dandenong & District Historical Society Inc.

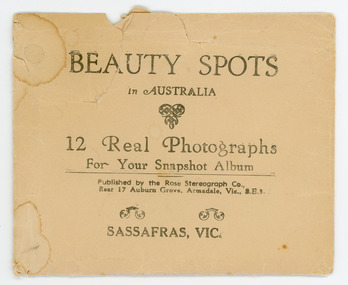

Mt Dandenong & District Historical Society Inc.Photograph, Beauty Spots in Australia. Sassafras, c1913

This set of small photographs was produced by the Rose Stenograph Co. c1913 to be included in photograph albums. The area known as South Sassafras, was opened up for settlement in 1893 and the name was changed to Kallista in 1925.A small, paper envelope containing 12 photographs of Sassafras that are reproductions of Rose Series postcards. There are 10 different photographs, 32a and 32c have doubles.Envelope : BEAUTY SPOTS in AUSTRALIA 12 Real Photographs For Your Snapshot Album Published by the Rose Stenograph Co. Rear 17 Auburn Grove, Armadale, Vic 3.E.3 SASSAFRAS, VICTORIA Photograph 32a - THE ROSE SERIES P. 905 CLEMATIS AVENUE, SHERBROOKE, VIC. Photograph 32b - THE ROSE SERIES P. 1603 THE CASCADES, SASSAFRAS, VIC. Photograph 32c - THE ROSE SERIES P. 204 PANORAMA AT SASSAFRAS, VIC. Photograph 32d - THE ROSE SERIES P. 4046 MAIN ROAD, SASSAFRAS, VIC. Photograph 32e - THE ROSE SERIES P. 1502 SASSAFRAS CREEK, SASSAFRAS, VIC. Photograph 32f - THE ROSE SERIES P. 1501 TOURIST TRACK, SASSAFRAS, VIC. Photograph 32g - THE ROSE SERIES P. 4244 TOURIST TRACK, SOUTH SASSAFRAS, VIC. Photograph 32h - THE ROSE SERIES P. 2725 CLEMATIS AVENUE, SHERBROOKE, VIC. Photograph 32i - MAIN ROAD, SASSAFRAS, VIC. Photograph 32j - THE OLINDA - SASSAFRAS ROAD, VIC. rose series, rose series, sassafras, sherbrooke, sassafras creek -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaPhotograph - Photograph, Sepia, Anne Treverton Goldsmith (nee Lobb), Picnic at Glenfern, King's Birthday 1906, 9 November 1906

Gathering of seafarers and MTS clergy and LHLG members, at Glenfern 1906. Mrs Mary Danne daughter of Reverend Kerr Johnston was a widow at the time and was renting Glenfern, the property once owned by the Boyd family, and started a private primary school she called Newington College. A member of the Mission's committee from 1905 to 1926 when she passed away, a bras plaque was made in her memory and placed in the chapel of the Flinders Street Mission. (see item 0690) In the Standard published on Saturday 17 November 1906, page 4 we could read: "In connection with the Victoria Missions to Seamen a successful and pleasant outing, was given to the sailors in port on King's Birth day. Mrs. Danne, of "Glenfern," St. Kilda, threw her house and grounds open tor sports and tea. Cricket, football and sports were enthusiastically pursued, and ample justice was done to the substantial tea provided by Mrs. Danne and her friends. The Misses Danne, Miss Godfrey and other ladies were untiring in their attentions. Mr. Axell, first officer of brig Fairy Rock, in a few appropriate words thanked Mrs. Danne and the ladies, on behalf of the sailors, for their kind hospitality. Snapshots of the party were taken by Mrs. Goldsmith. Mr. C A. Holmes and Mr. Cedric Campbell acted as stewards and starters for the races. On the invitation of the chaplain (Rev. A G. Goldsmith*) ringing cheers were given for Mrs. Danne and the ladies. Before the party broke up Mrs Danne addressed a few kind words to the men and gave them all a shake of the band at the gate. The rest of the evening was spent at the Institute, Beach street, where games and competitions were carried on to the accompaniment of vocal and instrumental music. The prizes won at the sports etc., were distributed, and after singing the National Anthem the party broke up."Thanks to the article in the Standard, Saturday 17 November 1906, page 4, we learn that some of the early sepia photographs were taken by Mrs Gurney Goldsmith herself.Small monochrome photograph depicting a group of seamen and ladies with the Mission's Flagstaff.1906, glenfern, st kilda east, picnic, lhlg, king's birthday, edward vii, mary alice isabelle danne nee johnston, 1851-1926, reverend kerr johnston, 1812-1887, boyd family, sailors, seamen, seafarers, bowler hat, cap, boater hat, snapshots, camera, photographer, sports, cricket, football, ethel augusta godfrey 1861-1935, mr axell, fairy rock, charles arthur holmes (-1947), mrs gurney goldsmith, anne treverton goldsmith (nee lobb), cedric campbell -

Wodonga & District Historical Society Inc

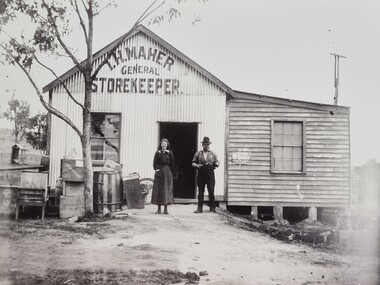

Wodonga & District Historical Society IncNegative - Haeusler Glass Negatives Collection - T. H. Maher general storekeeper at Ebden, Victoria

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. This digital image was produced from one of the glass negatives that form part of the collection, probably taken by Louis Haeusler (b.1887) with the photographic equipment in the Wodonga Historical Society Haeusler Collection. Thomas Hugh Maher, born 1881, was the youngest of 11 children of Owen Maher and Sarah nee Finn. After migrating from Ireland and marrying in Sydney in 1853, Owen and Sarah eventually made their home at “Fairview”, Bonegilla, Victoria in 1870. Owen later became a member of the first shire council formed in Wodonga. Thomas attended school at Bonegilla, then as a boarder at St. Joseph’s College in Sydney for his final two years. He returned to work on the farm until his father settled him on a small farm at Ebden. He married Jane Rowley from Bethanga. For some years Thomas and Jane conducted the general store and post office at Ebden which was next to their home ‘Marara”. When Jane died in 1916, Thomas leased “Marara” and moved to Melbourne. After marrying a second time, Thomas returned to Wodonga where he set up a real estate business. In about 1924, Thomas received compensation for his Ebden property when it was resumed for the development of the Hume Weir. He returned to Melbourne where he saw out the rest of his days until his death in 1952 aged 71 years old.This item is unique and has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It contributes to our understanding of domestic and family life in early twentieth century Wodonga, as well as providing interpretative capacity for themes including local history and social history.Digital image created from the Haeusler Glass negative collection. Thomas Maher and his wife Jane operated a general store at Ebden in Victoria.haeusler family, glass negatives, dry plate photography, thomas maher ebden, ebden general store -

Bendigo Military Museum

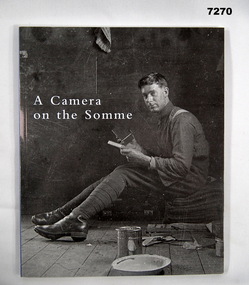

Bendigo Military MuseumBook - BOOK, A CAMERA ON THE SOMME, BPA Print Group, C.2009

The origin of the book goes back to 2007 when a tin of nitrate negatives (Cat No 1248.2) came to the Bendigo RSL Museum via Aylene Kirkwood (Eaglehawk Heritage Society) and her friend Jean Grinton, Jack Grintons Daughter. The tin of negatives had been sitting in a shed at Jeans place for many years. The RSL Museum sorted some to see what they were about and were mostly WW1 era overseas. The Museum had some reproduced by Wayne Eels a Dark Room Technician and the quality was amazing. A small number were shown at an exhibition in a talk by Museum Curator Peter Ball in March 2008. The exhibition was called “Snapshots and Stories” by Corrine Perkin from the Bendigo Art Gallery and included a number of Bendigo Historical groups. The RSL Museum by then had put together 44 images in 11 frames to make a story (cat No's 5880P to 5890P) and shown at the Bendigo District RSL Sub Branch Inc in April 2008. The exhibition included memorabilia from Jean Grinton. Corrine Perkin who was at the opening spoke to the Curator Peter Ball with the view that a travelling exhibition could be made from this. After discussions then began 12 months research between Corinne and Peter identifying people in the photos, places, deciphering Jack's Diary, researching the 38th Bn to gain an overall picture of Jack and Bert Grinton, producing photos for quality. Eventually an exhibition of photos (Cat No's 7100P to 7179P), story boards with photos (Cat No's 7180 to 7187) came into being. The opening was at the Bendigo Art Gallery on the evening of June 13th 2009 with Les Carlyon as guest speaker and went through until August 2nd. The exhibition was accompanied by memorabilia of Jacks Daughter Jean and Bert's Daughter Dorothy. The exhibition then went onto 4 more locations including the Melbourne Shrine of Remembrance. Jacks service details are in Cat No 1280, Berts are in Cat No 1320P.Book, cardboard cover, 64 gloss pages. Front cover shows Jack Grinton in Barracks hut 19 England in 1916. The book relates to the photo collection of Jack Grinton and his brother Albert (Bert) both in the 38th BN AIF. The publication is in 6 sections. 1. Preface - Karen Quinlan, Director Art Gallery. 2. Two brothers, a Camera and a War to end all Wars - Corrine Perkin, Exhibition Curator Bendigo Art Gallery. 3. The Great War - Les Carlyon, Journalist and Author. 4. Photographing War - Colin Harding, Curator photographic technology, national media museum UK 5. The Grinton Collection in 6 Sub Sections; Living behind the lines. The burden of war. Trip of a lifetime. Portraiture and remembrance. Quota 45: The journey home. Life after 1919.book, camera on the somme, grinton, 38th -

Federation University Historical Collection

Federation University Historical CollectionBooklet, Churchill & District Community Association, Churchill's 40th Anniversary, 2005

Green and brown soft covered book of 16 pages.non-fictionchurchill, monash university, hazelwood, yallourn, eel hole, eel hole school, cigar, hare's house, binishell, gippsland, gippsland campus, gippsland campus collection -

Wodonga & District Historical Society Inc

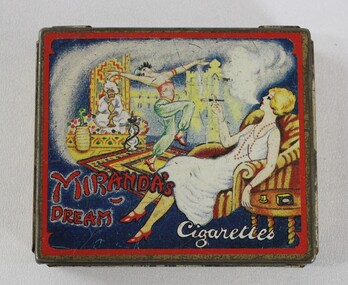

Wodonga & District Historical Society IncFunctional object - Haeusler Collection Mid-Century 'Miranda's Dream Cigarettes' Tobacco Tin, Dodo Designs

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s. This tobacco tin is one of the many objects in the Haeusler Collection that provides insight into life in early to mid-twentieth century Wodonga, and Australia more broadly. Smoking in the first half of the twentieth century was incredibly common in Australia and other western countries. In 1945, more than three out of every four men and one in every four women were regular smokers. While rates of smoking decreased over the next two decades due to observations and research regarding the links between smoking and illness, an increase in tobacco use was documented after the advent of television as people were bombarded with advertisements for cigarettes. These advertisements, much like the image on the Haeusler Collection 'Miranda's Dream Cigarettes' Tobacco Tin, depicted smoking as sophisticated and glamorous, distracting consumers from the serious health risks associated with smoking. Orientalist depictions of Middle East were common in tobacco advertising in the West in the first half of the twentieth century, an attempt to associate cigarettes with the supposed sensuality and mystery of the Orient. There have been significant changes in both legislation and popular perceptions of smoking in Australian society since the manufacture and consumption of 'Miranda's Dream Cigarettes'. In 1992 the Tobacco Advertising Prohibition Act was introduced, making it illegal in Australia to publish or broadcast messages that encourage people to start or continue smoking. In 2011 the Australian government also introduced plain packaging laws to reduce the appeal and promotion of tobacco products, and make health warnings more effective. This item has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It contributes to our understanding of domestic and family life in early twentieth century Wodonga, as well as providing interpretative capacity for themes including local history and social history. A tobacco tin with a coloured illustration of a woman in stylish 1920s-1930s dress sitting in an armchair smoking a cigarette, while watching an Orientalist scene featuring a belly dancer and a snake charmer wearing a turban. Branding on the lid of tin: "Miranda's Dream Cigarettes"cigarettes, tobacco, smoking, cigarette tin, haeusler, haeusler collection, wodonga -

Wodonga & District Historical Society Inc

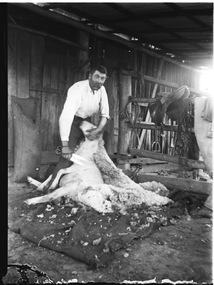

Wodonga & District Historical Society IncNegative - Haeusler Glass Negatives Collection - Harry Schuster blade shearing

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s. The Schuster family were also of German migrant background. Johannes Edward Schuster was born in Hoyles Plains, South Australia and with his wife Johanna and young family moved to Victoria circa 1882. He took up farming land in Wodonga West. The St John’s Lutheran Church Sunday school hall was erected from part of the proceeds of the sale of some 41 acres of land at Wodonga West, which had been bequeathed to the Wodonga congregation by the late Johannes Edward Schuster. This land was the original home site of the Schuster family on arrival from South Australia. Shearing - Although the first mechanised sheep shearing machine was created by James Higham, from Melbourne in 1868, the use of blade shears were more common well into the early 20th century. Pastoralists on smaller holdings continued to either shear their own sheep or employ blade shearers rather than outlay the cost of machines. In large sheds, professional shearers worked as they travelled the country. They would earn around 17 to 20 shillings per day in the early days of the wool industry. However mechanisation continued and by 1915 most sheep shearing sheds in Australia contained sheep shearing machines. The original machines were powered by steam and later combustion engines were used. This digital image was produced from one of the glass negatives that form part of the collection, probably taken by Louis Haeusler (b.1887) with the photographic equipment in the Wodonga Historical Society Haeusler Collection.This item is unique and has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It contributes to our understanding of domestic and family life in early twentieth century Wodonga, as well as providing interpretative capacity for themes including local history and social history.Digital image created from the Haeusler Glass negative collection. Harry Schuster shearing sheep using blade shears. wodonga pioneers, haeusler family, glass negatives, dry plate photography, blade shearing, schuster family -

Eltham District Historical Society Inc

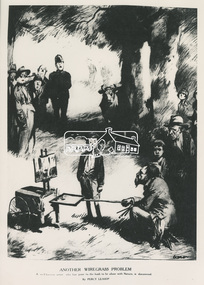

Eltham District Historical Society IncFolder, Percy Leason, 1930s

Folder of information on Percy Leason, Artist, Cartoonist, Historian, Anthropologist, Eltham, 1930s. 1. Photo: ANOTHER WIREGRASS PROBLEM: A well known artist who has gone to the bush to be alone with Nature, is discovered, By Percy Leason 2. Photo: SCENE DURING THE EIGHT HOURSS' DAY SPORTS AT WIREGRASS, By Percy Leason 3. Photo: "FIRE!": "An unfortunate occurrence. When the members of the Wiregrass Fire Brigade assembled at the Fire Station last evening for their weekly practice, they were horrified to discover that the building was on fire." - WIREGRASS WEEKLY CLARION, By Percy Leason 4. Photocopy: "Goliath and the Prodigal David" by Percy Leason 1931 5. Photocopy: "Yes you are improving the place. I'll have to increase your rent." by Percy Leason 1933 6. Photocopy: Cartoon by Percy Leason 1931 7. Photocopy: Cartoon by Percy Leason 8. LEASON, Percy Alexander, Painter and Illustrator; Who's Who in Australia, XIVth Edition 1950 9. LEASON, Percy Alexander, Painter and Illustrator; Who's Who in Australia, date unknown 10. Percy Leason 1889-1959 11. LEASON, Percy Alexander, 1889-1959, Painter and Illustrator 12. Percy Leason: Artist, cartoonist and Historian, by L.J. Blake, B.A., B.Ed., M.A.C.E. (President of the R.H.S.V.); An Address to the Society on Tuesday evening 27 August 1968; The Victorian Historical Magazine, pp 158-180 13. Catalogue: The Percy Leason Collection on view in The la Trobe Library 20 September - 29 October 1971 14. Invitation: Christmas Exhibition, The Wiregrass Gallery, 4 December 1977 15. Newspaper clipping: Artist's retreat, 1980 16. Newspaper clipping: Sharper than snapshots by Giles Auty; Arts, Review, The Weekend Australian, November 13-14, 1999 17. Works by Percy leason held by Castlemaine Art Museum, October 2018alan whitmore estate agents, biography, eltham*, exhibition catalogue, la trobe library, landscape, percy leason, rhsv, shire of eltham pioneers photograph collection, wiregrass gallery -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Haeusler Collection Lactogen baby formula measuring spoon c.1920s

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s. This item is a Nestlé Lactogen baby formula measuring scoop used in the preparation of formula for bottle feeding. It was used by Ilma Margaret Ernestine Haeusler (née Tasker, b.1900 in Tallangatta) to feed her son Alfred who was born in 1922. Ilma died in childbirth in 1928. This measuring spoon is one of several objects in the Haeusler Collection concerning early childhood that provide insight into family and home life in early twentieth century Wodonga. The first fully artificial infant milk formula, Farine Lactee, was developed in the 1860s. Companies continued to attempt to develop synthetic formulas which nutritionally replicated human breast milk in the decades that followed. Nestlé began producing Lactogen in 1921. It was marketed to women as a nutritionally superior substitute for breast milk, and as a nutritional supplement for breast feeding mothers. From the 1920s, when the Haeusler Collection measure was produced and used, Nestlé employed nurses in major Australian cities to promote Lactogen and its supposed health benefits to new mothers. They also used print advertisements to offer free product samples and instruction booklets advising on pregnancy and infant care for the same purpose. Nestlé was formed in 1905 by the merger of the Anglo-Swiss Milk Company, established in 1866 by brothers George and Charles Page, and Farine Lactée Henri Nestlé, founded in 1866 by Henri Nestlé. The company grew significantly during the First World War and again following the Second World War, expanding its offerings beyond its early condensed milk and infant formula products. In the twenty-first century, Nestlé has faced criticism and boycotts over its decision to market baby formula as an alternative to breastfeeding in developing countries. The adoption of bottle feeding in countries without access to clean water and sanitation infrastructure has contributed to high infant mortality rates. This item has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It contributes to our understanding of domestic and family life in early twentieth century Wodonga, as well as providing interpretative capacity for themes including local history, social history, and women’s history.Silver toned alloy measuring spoon for Lactogen infant formula, produced by food and drink manufacturing company Nestlé. Embossed with the Lactogen brand name, and teaspoon and tablespoon measurements. "LACTOGEN MEASURE" on central handle/"TABLESPOON" on large inner scoop/"TEASPOON" on small inner scoopchildren, babies, household, domestic, motherhood, family, kitchen -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionWork on paper - Vertical file, Dairies

1. Laurie & Alice Izod, interviewed June 2001 for the Burwood Bulletin; followed up by Jocelyn Hall; her typed notes (1 page). 2. ’70 years of togetherness’, Burwood Bulletin article about Laurie & Alice Izod (undated but from June 2001) (1 page). 3. Copy of certificate given to Vera Breedon, 1.1.1901 – a memento of inauguration of Commonwealth of Australia (1 page). 4. Death: C.H. Breedon, Argus, 15.1.1921 – sourced from Trove (1 page). 5. History of Breedon family and other notes about Surrey Hills from Horace Breedon, 1979, (2 pages). 6. Dairies by Horrie Breedon, 1980 (2 pages). 7. Towt’s dairy : 2 interviews with Jean Rae (nee Towt), one undated, other dated 1991 (2 pages). 8. Notes on the Kilpatrick family from a friend, undated (1 page). 9. Notes on the Kilpatrick family, dairy and house, 1988 (2 pages). 10. Notes on Cash family, undated (1 page). 11. Notes re Kenneally family, undated (1 page). 12. Notes on dairy in Robinson Street, undated (1 page). 13. And 2 generations back . . . . , undated (1 page). 14. Notes from Marie George, undated (1 page). 15. Snapshot of a local business, undated (1 page). 16. Costello family notes, undated (1 page). 17. Costello’s dairy, undated (1 page). 18. Herman Webb – conversation with Alan Holt c. 1986-7 (1 page). 19. Webb’s dairies – handwritten notes, undated (3 pages). 20. Webb’s dairy - typed copy of above notes, 1987 (1 page), and 3 pages of miscellaneous notes. 21. Details re Bignell Lone Pine Dairy photos; summary of interview by Sue Barnett with B., J. & D. Bignell 1997; and additional details 1996; and notes re contemporary photos of Lone Pine 1996-7 (3 pages). 22. 2 shop dockets – Lone Pine Dairy 1997 & 1999. 23. Photo of A.C. Bignell. 24. Bovill’s dairy: from Alan Holt’s records, undated (1 page). 25. Bowen family information used during a historic walk by N. Hiscox and D. Wisewould, 1988 (1 page). 26. Bovill family, undated (1 page). 27. Bowyer and Bovill family notes, May 1991 (3 pages). 28. Dairymen and dairies in Surrey Hills, by Alan Holt, undated (8 pages).Government Gazette specified dairies, 9.1.1948 (1 page). 29. Government Gazette specified dairies, 7.10.1963 (2 pages). -

Eltham District Historical Society Inc

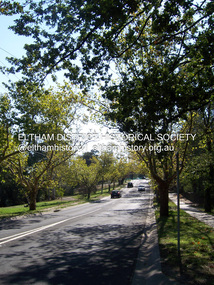

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, Avenue of Honour, Main Road, Eltham, 20 April 2008

The suggestion of an Avenue of Honour may have been originally put forward by Lady Irvine who was a member of the Welcome Home Committee. The Avenue of Honour was established to memorialise all those from Eltham who enlisted (some of whom were still fighting overseas at the time), similarly as the Shire of Eltham (Soldiers) Memorial Park was in tribute to all from the Shire who enlisted. The twenty-seven names of those killed from Eltham were engraved on the Eltham War Memorial Obelisk unveiled in 1919 at the corner of Main Road and Bridge Street. From an article in the Heidelberg News and Greensborough, Eltham and Diamond Creek Chronicle, September 22, 1917, p. 2, it was reported: Some few weeks ago a public meeting was held in the Eltham Rechabite Hall for the purpose of forming a committee to make necessary arrangements for the return of our brave lads from the front, with the result that the following officers were elected, viz., Sir William Irvine. president; Cr. R. D. Taylor, vice-president; Rev. T. W. Sapsford, secretary; Mr R. E. Gilsenan, treasurer; with a very strong committee of local residents. Lady Irvine then suggested that it would be nice to plant an Avenue of Honor, which was carried out in a very cheerful and spirited manner on Saturday afternoon. Cr Taylor and Mr R. E. Gilsenan occupied themselves during the fore-forenoon in getting the lining-out and other preliminaries ready, but shortly after one o'clock the willing workers could be seen wending their way towards the township, with picks, shovels. &c., on their shoulders, and in a very short time the gang at work was in appearance a very lively and pretty sight, the only thing that was missing was the camera, to have had a few snapshots taken. A little after 3 o'clock Sir William and Lady Irvine, and Mr W. Gray and family, arrived by motor. Cr Taylor then explained that their object in gathering together so hurriedly to plant the avenue was on account of the lateness of the season, and being offered 100 trees, free of charge, by Cr. Wm. G. Gray; of Allwood Nursery, Hurst's Bridge (for which the committee are deeply grateful to him and the public highly appreciate his generous offer). Sir Wm. Irvine then spoke at some length on the ravages of this cruel war, and the good that must result therefrom in bringing all closer together; he also referred to our brave lads who were fighting for us, and thought it was for those at home to show their appreciation by planting the Avenue of Honor. Lady Irvine thou proceeded to plant the first tree, which was an English oak: Sir William following by planting a Spanish chestnut; and Mrs W. G. Gray a sycamore. After that the gathering refired to the entrance of Mr R. E. Gilsenan's green paddock to partake of refreshments, which the ladies had kindly provided for the willing band of workers. Work was again taken to in earnest, and the planting finished, all being satisfied that they had done good work. At the Eltham Shire Council’s monthly meeting held May 6, 1918, Cr. Gray promised to give Council £20 to £25 worth of trees if the Council would plant and guard them. His desire was that a tree be planted in the name of every soldier lad who has gone to the front. Each tree was later adorned with a brass plaque with the name of a soldier and a wooden tree guard placed around them. Over the years many trees died, and following roadworks were replanted on a new alignment. Nillumbik Shire Council is continuing this process of replanting trees in a new alignment to move them away from overhead power lines and to clear the VicRoads reserve. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p119This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, avenue of honour, main road, eltham -

Orbost & District Historical Society

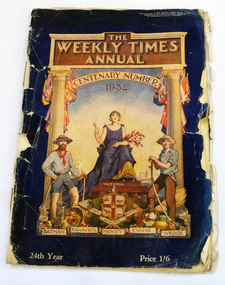

Orbost & District Historical Societymagazine, Edgar H. Baillie, The Weekly Times Annual, October 1934

The first Weekly Times Annual was published on November 4, 1911 and was produced until the Depression forced its demise in 1934. It was reintroduced in 2009.This magazine was the final edition published before a long gap of more than 70 years. The publication was an annual snapshot of Victoria - both rural and metropolitan.A magazine with full page colouedr photographs - Weekly Times Annual 24th Year.magazine weekly-times-annual media news -

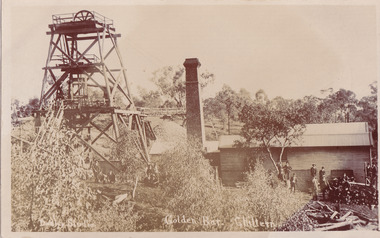

The Beechworth Burke Museum

The Beechworth Burke MuseumPostcard, c1900-1912

This object is a photographic postcard showing some of the above-ground structures of the Golden Bar mine in Chiltern, including a building with a smokestack and the poppet head which is used to haul equipment, materials, and men above or below ground. The Golden Bar site, mined by the Golden Bar Mining Company which was formed in 1901, managed to yield approximately 12,453 oz of gold before work stopped in 1912 - it was one of the principal mines in the area, as well as the deepest and one of the richest. The text on the postcard was handwritten by H.Gordon (?) to Issy (?), to show the mine where he presumably worked as he promises to take them 'above and below'. The postcard can be approximately dated to between 1901-1912. It is stated that after 1902 Kodak added the line on the postcard backs to divide into correspondence and address sections as seen on the reverse of this object. In addition, there is also a similar Kodak photographic postcard in the Burke Museum collection that is dated to 1908 and has the same specific font type and manufacturer markings (see references for link). Lastly, the Golden Bar mine ceased operations in 1912 so the photograph was likely taken prior to this. This photographic postcard is a rare and fair conditioned representation of one of the most significant gold mines in the Chiltern area, showing the above ground structures at the time it was being actively mined. This postcard also holds social significance as a snapshot of working life in the gold mining rush of Victoria, and a personal record of one of its miners. A sepia rectangular postcard printed on card.Obverse: Dudley Studio / Golden Bar. Chiltern Reverse: BMM 8034 / Post Card. / Correspondence. / Address Only. / Kodak. Austral. 110 / My Dear Issy (?), / A card only, to show (?) the mine / and when you come down I will / take you above and below, / All (...) love, me to. Has the baby / gone home yet Heini (?) wants to know / give my love to Syd when next you write / Your loving (...), H. Gordon (?)photographic postcard, postcard, chiltern, golden bar mine, golden bar mining company, dudley studio, kodak -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to late 19th Century

A jack plane (or fore plane) is a general-purpose woodworking bench plane, used for dressing timber down to the correct size in preparation for truing and/or edge jointing. It is usually the first plane used on rough stock, but in exceptional cases can be preceded by the scrub plane. Jack planes are 300–460 mm long and 64–76 mm wide, with wooden-stocked planes sometimes being slightly wider. The blade is 44–57 mm wide that is often slightly convex (or ground with rounded corners) to prevent digging in to or marking the work. The cut is generally set deeper than on most other planes as the plane's purpose is to remove stock rather than to gain a good finish (smoothing planes are used for that). In preparing stock, the jack plane is used after the scrub plane and before the joiner plane and smoothing plane. The carpenters' name for the plane is related to the saying "jack of all trades" as jack planes can be made to perform some of the work of both smoothing and joiner planes, especially on smaller pieces of work. Its other name of the fore plane is more generally used by joiners and may come from the fact that it "is used before you come to work either with the Smooth Plane or with the Joiner". Early planes were all wood, except for the cutter, or combined a wood base with a metal blade holder and adjustment system on top. Although there were earlier all-metal planes, Leonard Bailey patented many all-metal planes and improvements in the late 19th century. A jack plane came to be referred to as a "No. 5" plane or a "Bailey pattern No. 5" at the end of the 19th century. A vintage tool made by an unknown company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could remove large amounts of timber. These jack or dressing planes came in various shapes and sizes to achieve a flat and even finish to timber surfaces before the use of smoothing planes and came in many sizes. A significant tool from the mid to late 19th century that is still in use today with early models sought after by collectors. It gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting edged hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items. Jack Plane handle is attached by large screw there is a round piece of wood tacked to front. noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jack plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Groove Plane, Prior to 1950

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. The subject planes blade is designed to cut a groove and it's blade maker (M Gilmour) is not listed by collectors of vintage planes as a known plane makers of the 19th or 20th century.A vintage tool made by an unknown maker, this item was made commercially for firms and individuals who worked in wood and needed a tool that could produce an ornamental finish to timber. These profiled planes came in various shapes and sizes to achieve the required decorative finish. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Grooving PlaneM Gilmour stamped on bladewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, moulding plane, groove plane, joiners tools, hand plane, carpenters tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Jug, Between 1910 -1936

The beginning of standardised weights and measures began In Victoria when the Melbourne Observatory received sets of standard weights and measures, which had been tested in Britain against the then British Imperial standards. These included the primary standard yard and pound for the Colony of Victoria. Other standards of weights and measure held by shires and the administrative body's within the colony could then be compared to these primary standards. A Weights and Measures Act was passed in Victoria in 1862, establishing local inspectors throughout the colony. By the 1870s each local council and shire in Victoria held a set of standards that were used to test scales, weights and dry measures used by wholesalers, factories and shops. Every ten years the councils’ standards would themselves need to be rechecked against the Victorian Standards. The checking was done by the Victorian Customs Department in the 19th century, but with the transfer of responsibility for customs to the Federal Government in 1901, weights and measures function was retained by the Victorian Government and was shifted to the Melbourne Observatory. In 1904, a new building was erected at the south end of the Great Melbourne Telescope House, where the standard weights and measures and testing equipment was installed. This room had a large whirling apparatus for testing air meters and became known as the Whirling Room. When the Melbourne Observatory closed in 1944, the Weights and Measures Branch was formed to continue and this branch remained at the Observatory site unit until 1995.An example of a brass measuring jug made specifically to maintain government standard liquid measurements that were sold to the public. The probability is that this artefact was made sometime between George V reign (1910-1936) and gives us today a snapshot of how imperial weights and measures were checked by Government departments prior to decimalisation and how a standard for the various types of measurement was developed in Australian based on the Imperial British measurement system. The container has social significance as an item used in Victoria as a legal standard measure to ensure that goods sold in Victoria were correct. Jug brass haystack form with a deep lip and pouring spout, small neck and broad base. It displays a curved pistol handle. Inscription at base of handle top of jug stamped 61 GVR SM. These marks signify that the measure complied with the Victorian Government capacity liquid standard measurement. Item made during the reign of George V (1910-1936 (GVR).Other marks indicate model number (61) & SM possible could be either small measure, the maker, or Standards Melbourne.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Galvanised Jug, 1930s

The beginning of standardised weights and measures began In Victoria when the Melbourne Observatory received sets of standard weights and measures, which had been tested in Britain against the then British Imperial standards. These included the primary standard yard and pound for the Colony of Victoria. Other standards of weights and measure held by shires and the administrative body's within the colony could then be compared to these primary standards. A Weights and Measures Act was passed in Victoria in 1862, establishing local inspectors throughout the colony. By the 1870s each local council and shire in Victoria held a set of standards that were used to test scales, weights and dry measures used by wholesalers, factories and shops. Every ten years the councils’ standards would themselves need to be rechecked against the Victorian Standards. The checking was done by the Victorian Customs Department in the 19th century, but with the transfer of responsibility for customs to the Federal Government in 1901, weights and measures function was retained by the Victorian Government and was shifted to the Melbourne Observatory. In 1904, a new building was erected at the south end of the Great Melbourne Telescope House, where the standard weights and measures and testing equipment was installed. This room had a large whirling apparatus for testing air meters and became known as the Whirling Room. When the Melbourne Observatory closed in 1944, the Weights and Measures Branch was formed to continue and this branch remained at the Observatory site unit until 1995.An example of a galvanised measuring jug made specifically to maintain government standard liquid measurements that were sold to the public. The probability is that this artifact was made around the first quarter of the 20th century and gives us today a snapshot of how imperial weights and measures were used before decimalisation and how a standard of measurement for merchants was developed in Australian based on the Imperial British measurement system. The container has social significance as an item used in Victoria as a legal standard measure to ensure that goods sold in Victoria were correct given the item is galvanised it was probability used for kerosene or petrol etc not for liquids used for human consumption. Jug conical shaped with rounded top coming to a very slight point wide handle at back. VIB.L.66 1/2 Gall capacity unsure of the markings 66 could mean the model number capacity is 1/2 an imperial gallon VIB.L markings not known possibly a company or Victorian Department that the jug was made for and no longer active.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGalvanised Jug

The beginning of standardised weights and measures began In Victoria when the Melbourne Observatory received sets of standard weights and measures, which had been tested in Britain against the then British Imperial standards. These included the primary standard yard and pound for the Colony of Victoria. Other standards of weights and measure held by shires and the administrative body's within the colony could then be compared to these primary standards. A Weights and Measures Act was passed in Victoria in 1862, establishing local inspectors throughout the colony. By the 1870s each local council and shire in Victoria held a set of standards that were used to test scales, weights and dry measures used by wholesalers, factories and shops. Every ten years the councils’ standards would themselves need to be rechecked against the Victorian Standards. The checking was done by the Victorian Customs Department in the 19th century, but with the transfer of responsibility for customs to the Federal Government in 1901, weights and measures function was retained by the Victorian Government and was shifted to the Melbourne Observatory. In 1904, a new building was erected at the south end of the Great Melbourne Telescope House, where the standard weights and measures and testing equipment was installed. This room had a large whirling apparatus for testing air meters and became known as the Whirling Room. When the Melbourne Observatory closed in 1944, the Weights and Measures Branch was formed to continue and this branch remained at the Observatory site unit until 1995. An example of a galvanised measuring jug made specifically to maintain government standard liquid measurements that were sold to the public. The probability is that this artifact was made around the first quarter of the 20th century and gives us today a snapshot of how imperial weights and measures were used before decimalisation and how a standard of measurement for merchants was developed in Australian based on the Imperial British measurement system. The container has social significance as an item used in Victoria as a legal standard measure to ensure that goods sold in Victoria were correct given the item is galvanised it was probability used for kerosene or petrol etc not for liquids used for human consumption. Galvanised Iron jug with rounded top, Inscription on handle at back. 2 gallon GV.35flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Galvanised Jug

The beginning of standardised weights and measures began In Victoria when the Melbourne Observatory received sets of standard weights and measures, which had been tested in Britain against the then British Imperial standards. These included the primary standard yard and pound for the Colony of Victoria. Other standards of weights and measure held by shires and the administrative body's within the colony could then be compared to these primary standards. A Weights and Measures Act was passed in Victoria in 1862, establishing local inspectors throughout the colony. By the 1870s each local council and shire in Victoria held a set of standards that were used to test scales, weights and dry measures used by wholesalers, factories and shops. Every ten years the councils’ standards would themselves need to be rechecked against the Victorian Standards. The checking was done by the Victorian Customs Department in the 19th century, but with the transfer of responsibility for customs to the Federal Government in 1901, weights and measures function was retained by the Victorian Government and was shifted to the Melbourne Observatory. In 1904, a new building was erected at the south end of the Great Melbourne Telescope House, where the standard weights and measures and testing equipment was installed. This room had a large whirling apparatus for testing air meters and became known as the Whirling Room. When the Melbourne Observatory closed in 1944, the Weights and Measures Branch was formed to continue and this branch remained at the Observatory site unit until 1995.An example of a galvanised measuring jug made specifically to maintain government standard liquid measurements that were sold to the public. The probability is that this artifact was made around the first quarter of the 20th century and gives us today a snapshot of how imperial weights and measures were used before decimalisation and how a standard of measurement for merchants was developed in Australian based on the Imperial British measurement system. The container has social significance as an item used in Victoria as a legal standard measure to ensure that goods sold in Victoria were correct given the item is galvanised it was probability used for kerosene or petrol etc not for liquids used for human consumption. Jug galvanised conical shaped with rounded top, handle at back. 3 gallon GV.27flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Hair Tongs, Marcel Grateau, 1900 +

Marcelling is a hair styling technique in which hot curling tongs are used to induce a curl into the hair. Its appearance was similar to that of a finger wave but it is created using a different method. Marcelled hair was a popular style for women's hair in the 1920s and 30s often in conjunction with a bob cut. For those women who had long hair, it was common to tie the hair at the nape of the neck and pin it above the ear with a stylish hairpin or flower. Accounts vary about the invention of the style, but Marcel Grateau (1852–1936) is widely credited with inventing the hair styling technique in the 1870s. He started with a small salon in Montmartre, Paris where his clients were the poorer classes. As he developed the waving method that would later become the Marcel wave, using heated curling irons, The inventor and stylist emigrated to the United States and changed his name to François Marcel Woelfflé, sometimes reported as François Marcel. He was granted U.S. patents for implements for performing the technique; the first, U.S. patent 806386, entitled "Curling-Iron", was published in 1905, and the second, entitled "Hair-Waving Iron", for an electric version, under the name François Marcel, was published in 1918. His obituary appeared under the name Francois Marcel Grateau in 1936. Originally the irons had to be heated in the fire, but hair easily got burnt until 1924 when electric irons were invented and the temperature could be regulated. A significant item that gives us a snapshot not only into women's hairstyles of the 1920s and 1930s but a look into the social norms of that era. Therefore the item is of social interest in regards to the story it tells and the development of women's fashion in hair styling.Marcel Tongs, metal, used to impart a hair wave by heating and crimping the hairNoneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, tongs, curling tongs, hairdressing -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Diving Compressor, Siebe Gorman & Co. Ltd, 1880-1890

This compressor was part of the E.G. Ward Collection. It is connected to the diving suit and boots also in our collection. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water-pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr. E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The compressor is a very significant item as it gives a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. Siebe & Gorman the company that made the equipment was a leading inventor, developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job during the early days of marine exploration.A single cylinder divers' pump by Siebe Gorman & Co Ltd, London, eccentric hand cranked in brass mounted mahogany case with instructions to the underside of the lid, brass covered pressure gauge and air outlet, brass makers plaque to the front, water inlet and outlet to the rear, green painted lifting rings. Machinery has some blue painted areas on the metal.Plate on the back 'WATER SUPPLY" "WATER OVERFLOW" "WATER DRAIN-IN" Pressure gauge dial "BOURDON'S PRESSURE GAUGE" STEBE GORMAN & CO. LONDON", "LBS PRESSURE" "FEET OF SALT WATER" Plate on the front " PATENT, Siebe Gorman & Co Ltd Submarine Engineers" below emblem (Lion, Crown, Horse)flagstaff hill, warrnambool, flagstaff-hill, maritime-museum, diving compressor, london, siebe gorman & co ltd, marine technology, life saving, deep sea diving, maritime museum, maritime village, manine history