Showing 151 items matching " smelter"

-

Federation University Historical Collection

Federation University Historical CollectionBook, Cyaniding for Gold, 1939, 1939

500 of these books were printed, and many were used in the field, making good copies very rare. A simple but detailed account of the process written especially for the working miner and the small syndicate, the Quintessential Australian gold Mining book.Orange, hard, cloth covered b270 page book with brown dust jacket. Chapters include sampling sand and slime dumps; treating sand; aeration; treatment of slime; smelting; solution testing; cyanide solution; air- slaked lime; cyanding in Queensland; copper troubles; treatment of concentrates; amalgamations; assaying; floatation; chemistry; testing for minerals. Includes photographic reproductions of a cyanide plant for sand; aeration tower; mixer tank; Eleanora cyaniding plant; mining, gold, cyanide, cyaniding, leaching, smelting, slimes -

Orbost & District Historical Society

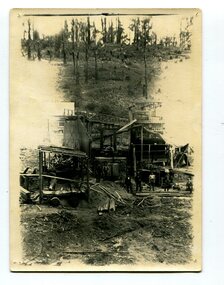

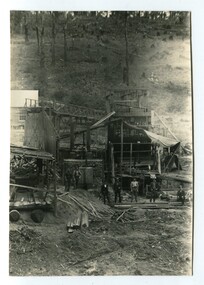

Orbost & District Historical Societyblack and white photograph, late nineteenth - early 20th century

Gold was found at Club Terrace in 1896. One of the best finds at Club Terrace was the 'Ace of Clubs' mine which was later sold to the Mallina Gold Mining Company. Syd Cadwallader was appointed manager of the company. The gold was smelted and brought to Orbost on horseback. The only protection against thieves was a revolver and riding crop, which the manager always carried. The 'Ace of Clubs' was eventually closed as the company was unable to cope with the rising water problem. (information Newsletter February 2011 - John Phillips)This is a pictorial record of mining methods in East Gippsland in the late 19th century to early 20th century.A black / white photograph of a mine. It is in a bush setting. Men are standing in front of timber mine constructions. Some wooden buildings can be seen behind the structureson back - "Cadwallader's Malina Mine"mining-gold mining-east-gippsland cadwallader-malina-mine gold-mining-battery -

Federation University Historical Collection

Federation University Historical CollectionBooklet, Ballarat School of Mines Student's Magazine, Second Term, 1904, 1904

Table of contents: Editorial, Victorian School of Mines, Extraction of copper, The Diehl process, Analysis of materials used in assaying, Definitions of electrical terms, Mine managers - Practical and Unpractical, Geology at Lake Burrumbeet, Smelting argentiferous lead, Geology notes, Nature - Aphorisms by Goethe, Our illustrations, The estimation of a girl, The abolition of thunderstorms, Send-off to Messers L. Smith and S. Austin, Students' annual reunion, Correspondence, Past students, Diplomas and Certificates, Sports, News and notes, Editorial notes.Pale gray booklet of 18 pagesballarat school of mines, students' magazine, stephen hart, l. smith, s. austin, past students, f. a. marriott, l. j. lambert, h. krause, nettle, h. irwin,, a. atkins, l. seal, t. davis, r. robin, b. roy, d. elder, w. b. blyth, a. gillespie, j. huston, k. moore, obituary, alfred g. johnstone, cecil s. wakley., r. o. inglis, g. w. cornell, s. austin, s. g. turrell, l. seward, j. burrows, w. j. lakeland, douglas runting, godfrey s. hart, latham watson, samuel j. lindsay -

Federation University Historical Collection

Federation University Historical CollectionBooklet, Ballarat School of Mines Student's Magazine, Fourth Term, 1906, 1906

Table of contents: Editorial, Visit to the Cathcart Proprietary, Electric pumps, Random memories, Mining at and about Howell, N.S.W., Correspondence, Obituary, Routine assaying on a free milling W.A. gold ore, The deep leads and the old divide in the Ballarat district, The Lake Superior copper mine, The Melbourne trip, Hints on portraiture, Presentation fund, Electric power house, The Bun Club, Notes on copper smelting, Past students, Rowing notes, News and notes, Answers to correspondents, Editorial notices.Cream coloured booklet of 30 pagesballarat school of mines, students' magazine, obituary, alex saunders, a. e. c. kerr, j. a. reid, w. s. macartney, past students, f. m. lush, c. h. beaumont, o. e. jager, w. b. blythe, a. d. turner, j. w. hawthorne, p. a. pratt, l. lambert, donald clark, n. stuckey, s. b. vial, w. b. tucker, p. s. anderson, a. b. reid, r. j. robin, f. a. marriott, w. h. macready, c. mactaggart, g. s. hepburn, c. magennis, g. d. evans, alex fraser, g. govett, w. brokenshire, reg. williamson,, h. b. cooke, a. s. coyte, f. brinsden, r. vaughan, s. radcliff, harold irwin, f. t. fleetwood, max gaunt, j. t. marsh, w. b. blythe, a. d. turner, miss kerfupps,, din jurquot -

Federation University Historical Collection

Federation University Historical CollectionMagazine - Magazine of 24 pages, Baxter & Stubbs, Print, Ballarat School of Mines, Student Magazine, Second Term, 1912, 1912

Table of Contents: Editorial, Quick combination methods in smelter assays, Twelve health precepts, News and notes, Correspondence, A neglected path of duty, Past students, A friendly castigation, Scientific brotherhood, The material constituents of a student, Henry Sutton, Old companions, Rapid methods for proximate analyses, Football, Temperance, Gas in the mine, The steam shovel at Panama, Physical properties of iron in relation to its chemical composition, The smallest engine on record, The diesel engine, Bendigo's rich goldfields, Concrete and steel, Dredging in Brazil, Editorial notes.Green booklet of 24 pageseditorial, quick combination methods in smelter assays, twelve health precepts, news and notes, correspondence, a neglected path of duty, past students, a friendly castigation, scientific brotherhood, the material constituents of a student, henry sutton, old companions, rapid methods for proximate analyses, football, temperance, gas in the mine, the steam shovel at panama, physical properties of iron in relation to its chemical composition, the smallest engine on record, the diesel engine, bendigo's rich goldfields, concrete and steel, dredging in brazil, editorial notes., alumni, f. brindsren, b .h. bennets, e. bleske, j. r. booth, a. s. coyte, h. b. cooke, t. a. couper, t. e. copeland, l. j. coulter, j. dickinson, g. h. davenport, w. e. eyres, e. fraser, a. a. gibson, g. govet, j. a. grant, e. c. hurdsfield, h. a. krause, w. kingston, h. r. kofoed, f. a. marriot, h. s. martin, d. m'dougall, c. w. nash, j. a. reid, j. sutherland, g. sides, e. trend, r. m. vaughan, s. b. vial, c. h. vale, o. c. witherden, e. m. weston, l. a. westcott, j. watson, j. worthington, j. adam, wilfred avery, h. baxter, h. caulfield, a. cropper, e. b. crossley, w. currie, dave don, hilary dowling, chas. fraser, a. d. galloway, w. geldard, hubert hall, g. s. hart, w. b. hirt, h. e. hawksworth, carl janssen, w. t. lakeland, l. j. lambert, c. lund, k. bryon moore, f. a. moss, jack orr, d. a. bunting, l. seward, h. s. sheppard, c. e. sands, n. stuckey, r. vale, r. watts, reg. williamson, wm. blythe, l. w. g. buchner, thos. davis, w. e. figgis, e. o. gregory, jack grieves, a. s. leathes, dave lilley, wm. macartney, guy ramsay, carl. moore, vic. nicholls, garnet nightingale, g. m. roberts, r. r. robin, len. seal, h. valentine, r. g. walker, n. buley, a. campbell, h. cornell, a. guy, h. hull, o. e. jaeger, m. mitchell, r. i. moore, j. r. sides, h. j. whittingham, c. s. whykes, colin c. corrie, h. miles, vic. milington, r. a. j. roberts, john r. booth, w. l. allen, f. c. hall, v. m. booth, e. s. anderson, r. blight, b. serjeant, m. williamson, fred j. martell, editorial, quick combination methods in smelter assays, twelve health precepts, news and notes, correspondence, a neglected path of duty, past students, a friendly castigation, scientific brotherhood, the material constituents of a student, henry sutton, old companions, rapid methods for proximate analyses, football, temperance, gas in the mine, the steam shovel at panama, physical properties of iron in relation to its chemical composition -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSign - Hudson's Soap Enamel Advertising Sign, Patent Enamel Co Ltd, c. late 19th century- early 20th century

Hudson's Soap Powder, was the first satisfactory and commercially successful soap powder and was made in Liverpool by Robert Spear Hudson. He was also an innovator in using advertising, commissioning striking images from professional artists and paid for publicity , something which few other businesses did, and as such Hudson's soap became a household name. Horse, steam and electric tramcars, print periodicals and chemist shops carried his advertisements. This sign was manufactured by Patent Enamel Co Ltd was a company built in 1889 at Selly Oak, Borough of Birmingham, West Midlands, England, United Kingdom. The business was the first factory specifically devoted to enameled iron sign making. It had twelve furnaces for fusing the enamel, two scaling furnaces, and a large printing room, plus a huge area for steampipe drying. The company also smelted its own enamels and colour oxides. It is believed that the factory was decommissioned and demolished in the 1960's.the first factory specifically devoted to enameled iron sign making. It had twelve furnaces for fusing the enamel, two scaling furnaces, and a large printing room, plus a huge area for steampipe drying. The company also smelted its own enamels and colour oxides.The factory was decommissioned and demolished in the 1960s.The signage demonstrates the increasing demand for domestic soap products and new forms of advertising. The soap business was apart of the flourishing export trade between Australia and Britain during the height of the British Empire.Enamel advertising sign for Hudson's soapflagstaff hill, warrnambool, maritime museum, hudson's soap, advertising signage, patent enamel co ltd, selly oak, borough of birmingham, robert spear hudson -

Orbost & District Historical Society

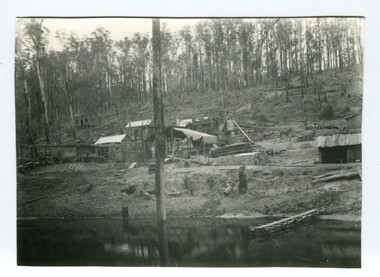

Orbost & District Historical Societyblack and white photograph, 1895 - 1905

This photograph shows the Battery Goldmine at Club Terrace from 1896 - 1905. Gold was found at Club Terrace in 1896. One of the best finds at Club Terrace was the 'Ace of Clubs' mine which was later sold to the Mallina Gold Mining Company. Syd Cadwallader was appointed manager of the company. The gold was smelted and brought to Orbost on horseback. The only protection against thieves was a revolver and riding crop, which the manager always carried. The 'Ace of Clubs' was eventually closed as the company was unable to cope with the rising water problem. (information Newsletter February 2011 - John Phillips)This is a pictorial record of gold mining in East Gippsland during the late 19th - early 20th century.A black / white photograph of a mine site with timber mine constructions spread around. There is a river in the foreground. Some wooden buildings can be seen in the background.gold-mining-battery-mine club-terrace -

Orbost & District Historical Society

Orbost & District Historical Societyblack and white photograph, 1896 - 1905

This photograph shows the Battery Goldmine at Club Terrace from 1896 - 1905. Gold was found at Club Terrace in 1896. One of the best finds at Club Terrace was the 'Ace of Clubs' mine which was later sold to the Mallina Gold Mining Company. Syd Cadwallader was appointed manager of the company. The gold was smelted and brought to Orbost on horseback. The only protection against thieves was a revolver and riding crop, which the manager always carried. The 'Ace of Clubs' was eventually closed as the company was unable to cope with the rising water problem. (information Newsletter February 2011 - John Phillips) This is a pictorial record of gold mining in East Gippsland during the late 19th - early 20th century.A black / white photograph of an operational mine with scaffolding and bridges. There are several men standing in front.mining-club-terrace mallina-mine battery-mines gold-mining-east-ippsland -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - ORIENTAL BANK: EAGLEHAWK, 1860's ?

black and white photo mounted on same size board. Group of 30 men and boys outside double storey building with verandah with iron lace. At left man mounted on horse. At rigfht, horse and 4 wheeled vehicle. At centre 2 men, 1 each side of box with '1311' 4 pieces of smooth material piled on box ( smelted gold ? ) At far left, 2 girls, 1 bending down. On left hand window of building 'old' On RH window ' …. Mercial bank'? Above doorway at far left ' private entrance'organization, business, oriental bank, eaglehawk -

Ballarat Tramway Museum

Ballarat Tramway MuseumNewspaper, "Daylesford Has a Great Asset", 13/10/1971 12:00:00 AM

Newspaper clipping from the Ballarat News?? of 13/10/1971 about the Annual General Meeting of the Daylesford Historical Society and the work it has done over the last 12 months, its collection, with a photo of SEC Ballarat tram being unloaded in Daylesford with former mining school smelting chimney in the background. Mentions Mr. Stan Hoath as President and Mr Tom Evans MLA who chaired the meeting during the election. Item on the top of the cutting has "Published every Wednesday Ballarat, Wednesday, October 13, 1971". See Reg. Item 2914 for the same photo, different caption.trams, tramways, daylesford, 11, stan hoath -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - Golden City Implements Foundry, Ironbark, Bendigo, 1960-1980s

This foundry had been a landmark in Mt Korong Road for many years. It began with an Osborne and Mitchell. After 1914 when mining declined, it became the Golden City Implement boundary and the name can still be seen painted on on the façade which faces the intersection of Marong Road (Calder highway) and Eaglehawk Road. The interior is a mass of used and un-used machinery scattered amongst modern lathes and more modern apparatus. The yard was a fascinating graveyard of past times, with old mining and agricultural scrap everywhere mixed up with coke and slag from the smelting sheds at the rear. A feature of the foundry was the manufacturer of cast iron lace. National Trust Survey Data Sheet and article from the Bendigo Advertiser November 4th 1981. Osbornes Ironbark Foundryhistory, national trust bendigo collection, bendigo, foundary, iron bark bendigo -

Federation University Historical Collection

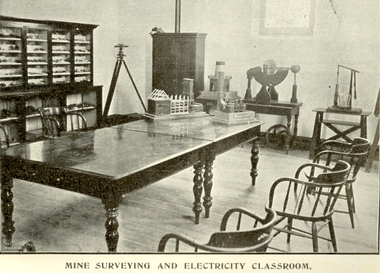

Federation University Historical CollectionBook, Moonta School of Mines Annual Report, 1903, 1905

The Moonta School of Mines was intended for students who wanted to increase their knowledge of those arts and sciences which were especially important to miners and others similarly engaged. The School had subsidiary classes at Wallaroo Mines. It was the only institution on the Yorkes Peninsula furnishing technical education The School was situated close to the Moonta Mines, at that time the most important copper mines in Australia. The the mines students were able to acquire practical knowledge of the work of a miner. The close by smelting works at Wallaroo were seen to be of great service to those wanting to become acquainted with chemistry and metallurgy. Subjects taught at the Moonta School of Mines included Chemistry, Metallurgy, Steam and the Steam Engine, Magnetism and Electricity, Mathematics, Machine Design, Mine Surveying and Leveling, Drawing, Plumbing and Sheet Metal Work.Grey soft coloured book with images of the interior of the Moonta School of Mines in South Australia, and members of Council .moonta, moonta school of mines, rogers, mueller, pomroy, martin, blatchford, richardson, brown, potter, w. peter hughes, ricky hains, henry lipson hancock, henry richard hancock, r.e. hancock, david james, edwin martin, bessie poole, kim potter, james richardson, g. warrington rogers, t. cooke and sons, g. ulrich, schools of mines, wallaroo, billy muir, south australia -

Federation University Historical Collection

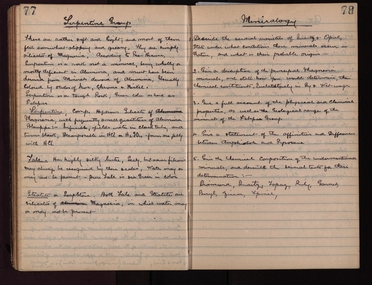

Federation University Historical CollectionBook - Diary, John Kennedy, John Kennedy's Ballarat School of Mines Lecture Notes, 1889

John Kennedy was born on 04 April 1862, the son of ship carpenter Robert Kennedy and his wife Florinda (Aitken), and the brother of Malcolm and Colin Kennedy. In 1860 the family migrated to Melbourne where Kennedy senior set up as a shipwright. In 1879 Malcolm and John, who trained as a naval architect, joined their father as Robert Kennedy & Sons, shipbuilders and shipsmiths. On 27 December 1883 at North Melbourne, Malcolm married Ann White with Presbyterian forms. Next year Robert Kennedy & Sons removed to Hobart where with John W. Syme and W. J. Duffy, partners until 1889, they took over the Derwent Ironworks & Engineering Co., a foundry formerly owned by the (Alexander) Clark family. The Kennedys also acquired the patent slipyard, formerly Ross's, at Battery Point. After the shipbuilding industry in Hobart began to flag John also turned to mining: he attended the Ballarat School of Mines, and reopened the Hobart smelters which had been an adjunct of the Derwent Ironworks in the 1870s. He made several voyages overseas on smelting business and as mining promoter, and was a member of the London Stock Exchange. In 1913-14 he was manager of Tongkah Compound (1910); Robert Kennedy & Sons was reputed to have contributed to the success of the Hobart-run Tongkah Harbour, Thailand, tin mines by developing a suitable dredge. The brothers also held shares in the Irrawaddy Burma Co. John was a member of the Australasian Institute of Mining Engineers and from 1932 an honorary life member of the American Institute of Mining & Metallurgical Engineers. John died in Hobart on 10 January 1937. (Ann G. Smith, 'Kennedy, John (1862–1937)', Australian Dictionary of Biography, National Centre of Biography, Australian National University, http://adb.anu.edu.au/biography/kennedy-john-7092/text11963, published first in hardcopy 1983, accessed online 24 April 2020.) A book covered in black leather with 'John Kennedy' embossed on the front in gold. The book contains notes from the time he studies at the Ballarat School of Mines. The beginning of the book has an alphabetical section where John Kennedy has created an index.Inside front cover 'John Kennedy Nena Wharf Hobart Tasmania.' john kennedy, australasian institute of mining engineers, ausimm, american institute of mining metallurgical engineers, ballarat school of mines, lecture notes, lecture notebook, antinomy, brick clay, carbon, coal, copper, chemistry, clay, chrome, electricity, fire clay, gas, gold, gold bullion, glass, gold test for, iron metallurgy, light, lead, metallurgy, mica, mineralogy, pyrites, sulphur in pyrites, sugar, slags, wolfram, preparation of pure gold, scorification, gold bullion assay, petrography, melting poinys of bodies, metric system, geology, mount morgan, queensland, rock salt, assay of tailings, classification of rocks, muffle furnace, ballarat school of mines wind furnace, assay of antinomy, recovery of silver from solutionsheat pyrometer, spectroscope, organic acids, metallurgy of iron, assat of copper, cornstock lode nevada, mount morgan queensland, scarification, elmwood, metallurgy of lead, specific gravity, copper assay, seperation of gold from other metals, test for gold, wet assay, mercury -

Bendigo Historical Society Inc.

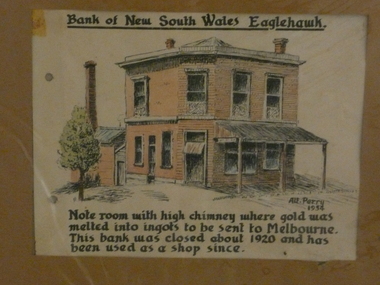

Bendigo Historical Society Inc.Painting - BANK OF NEW SOUTH WALES EAGLEHAWK

Watercolour and black pen painting of the Bank of New South Wales, Eaglehawk. Written on bottom of art:' Note room with high chimney where gold was melted into ingots to be sent to Melbourne. This bank was closed about 1920 and has been used as a shop since' Artwork signed by Alf Perry 1954. Two punch holes on LH side. Written on back in pencil : Only 3 banks in Victoria had a smelting room with tall chimney. The gold was bought and refined and melted into ingots. The three banks were at Eaglehawk, Castlemaine and Bendigo (from publicity officer Bank of NSW Melbourne). I have established that the Castlemaine Bank NSW definitely did not have a chimney stack as in this picture. My information came from an old member of Castlemaine Bank of NSW staff in 1962.'eaglehawk, commercial, bank of nsw -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - COSTERFIELD SMELTING AND REFINING CO WORKS

Three Auction catalogues with greenish covers for a sale on 3rd July, 1941 at the Costerfield Smelting and Refining Co. Works, Costerfield of Machinery, Plant & Equipment comprising - 4 Diesel Engines, Jaques Crusher, 2 Boilers, Chilian Mill, Huntington Mill, 2 Steam Engines, Blast and other Furnaces, Exhaust Fan, Lighting Plant, Cyanide Plant, Pumps, Buildings, Piping, Tools, etc. One copy has 'Marked Catalogue' written across the top of the front cover. Some of the lots have the price written beside them, some have a note and some prices are written on the right side of the page. Signed at the end - J. H. Curnow & Son 21/7/41. J. H. Curnow & Son were the auctioneers and the Cambridge Press were the printers of the catalogue.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - costerfield smelting and refining co works, j h curnow & son, j l jamieson, the cambridge press -

Bacchus Marsh & District Historical Society

Bacchus Marsh & District Historical SocietyCeramic, Tile manufactured by Darley Firebrick Company

The manufacture of firebricks is believed to have begun in Bacchus Marsh in the 1880s when William Thomas Wittick in partnership with a Mr Ackers, and later a Mr Telford, quarried a rich deposit of fire clay at Darley. In 1902 financial assistance was provided by David Mitchell a significant businessman and contractor from Melbourne and the business then expanded and became a major supplier of refractories for gas works in Melbourne, with side lines in moulded fire bricks for foundries and smelting furnaces and complete kiln lines for potteries. The business traded under the name Darley Firebrick Company and later as Darley Refractories Ptd Ltd and was in business for over 100 years. The tile (aka refractory) described in this record was possibly produced for use in very high temperatures (in excess of 1,000°F [538°C]) encountered in modern manufacturing. More heat-resistant than metals, they are used to line the hot surfaces found inside many industrial processes. The date the tile was produced is unknown.Rectangle shaped ceramic tile'Darley 26' inscribed within a circledarley firebrick company, refractory materials, wittick family bacchus marsh, william thomas wittick 1857-1939, darley refractories ptd ltd -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Galena (with quartz), unknown

Galena is the natural compound of lead and classed as a sulphide, it crystallises in a cubic pattern and its chemical formula is PbS. Galena is a primary source of both lead and silver. This specimen of Galena comes from Broken Hill. Broken Hill has one of the world’s largest and most significant deposit of ore for the production of lead. Mining of Galena at Broken Hill began with the staking of land by Charles Rasp in 1883. By the following year, in 1884, Rasp and six others had formed Broken Hill Mining Company. Broken Hill Mining Company eventually evolved into BHP group limited and is currently the largest mining company in the world and the largest company in Australia. There is archaeological evidence from artefacts discovered in Turkey that humans have been extracting lead from galena by the process of smelting since at least 6500 BCE. This specimen also has quartz on the top surface which is frequently discovered alongside Galena. This mineral specimen is of historic significance as a sample of Galena extracted from Broken Hill during the 19th century. Mining for Galena in Broken Hill begin in 1883 by Charles Rasp and evolved into the world’s largest mining company – BHP Group Limited. Broken Hill is one of the world’s most significant deposits of ore for the production of lead. This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.A flat, hand-sized, grey sulphide specimen that is the natural compound of lead with a quartz formation on the top surface. Existing Label: GALENA / (with quartz) / Locality: Broken Hill / N.S.W 120 x 70 x 29geological specimen, geology, geology collection, burke museum, beechworth, galena, galena quartz, quartz, charles rasp, broken hill mining company, bhp group limited, bhp, lead, ore, lead sulphide, sulphide, silver, broken hill -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - Mine Managers, a glimpse at a large subject. From Ballerstedt to Buerger

Mine managers had a variety of roles. They were a go-between for investors or shareholders and were responsible for the effective utilisation of human and physical resources above and underground. From the early 1870's the Bendigo school of mines held courses and exams leading to a Mine Manager's Certificate. These certificates were awarded in 3 classifications:- 1st class certificate holders could manage any mine where large and expensive machinery was used. They needed knowledge and competence in areas such as surveying, underground plan drawing, ventilation, amalgamation, retorting and smelting. They must also be literate and numerate. 2nd Class:- able to manage any mine where steam machinery was in use. 3rd Class:- for mines where there was no steam machinery . They needed to have a good knowledge of whim, whip or windlass work. Conversations continued through to the 1920's about whether the requirement for a Managers Certificate should be made compulsory under amendment to the Mines Act 1883. There were also discussions of the minimum amount of mine experience applicants should possess.A research paper detailing the history of managers and their role in the Bendigo gold fields. A short address prepared by James A. Lerk April/ May 2002. 8 pages.mine managers, ballerstedt, buerger -

Wodonga & District Historical Society Inc

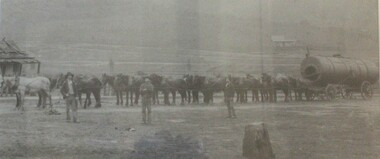

Wodonga & District Historical Society IncPhotograph - North-Eastern Gold Days, 1900

Bethanga was established as a result of the discovery of gold. Gold was first reported in the Bethanga area in 1852. Before 1876 gold mining in the Bethanga district occurred to the north of the town and was known as the 'Talgarno diggings'. Reports of alluvial gold date back to 1852. Early gold fields were worked at Ruby Creek, Gold Creek and Jarvis Creek. The opening of the Bethanga goldfields began with the discovery of a gold-bearing quartz reef on New Year’s Day 1876. The 'Gift' mine site is located southeast of Kurrajong Gap lookout to the west of Bethanga township. The Great Eastern Copper Smelting Works was opened in 1878. Due to the nature of the gold-bearing quartz reef, the gold was difficult to extract, and the discovery of copper led to a change in focus. It was not until the early 1890s that an efficient technique for extracting the gold from the ore was discovered, and once again gold became the focus, with copper as a by-product. Bethanga was removed from the official list of goldfields in 1912, however some mining activity has taken place since.This image reflects an important time in the development of Bethanga and Northeast Victoria.A large mounted and framed image of horse teams and their owners hauling a large boiler to the gold mine near Bethanga, Victoria. On label beneath image: "North-eastern "Gold Days"/ Combined teams hauling a boiler to Bethanga Mines, 1900. Teamsters - Mr. G. Pearce, W. Chapple, G, Bannon." Donated by Ron Saunders and Barbara Cadman"bethanga, gold mining northeast victoria, gold mining bethanga, bethanga history -

Federation University Historical Collection

Federation University Historical CollectionBook, Bedford McNeill, Mining and General Telegraphic Code, 1899, 1899

McNeill's Code was arranged to meet the requirements of mining, metallurgical and civil engineers, Directors of Mining, Smelting companies; bankers; stock and share brokers, solicitors, accountants, financiers and general merchants. Bedford McNeil )Assoc. M. Inst. C.E.) was an Associate of the Royal School of Mines; Member of the Institution of Mining and metallurgy and of the north of England Institute of Mining and Mechanical Engineers; and a Fellow of the Geological Society. "OBITUARY - Mr. Bedford McNeill IT is with regret that we announce the death on September 18, due to cerebral hemorrhage, of Mr. Bedford McNeill, the well-known mining engineer, at fifty-five years of age. Apart from his high reputation as a mining engineer, Mr. McNeill’s name was almost a household word in connection with the telegraphic code compiled by him, which was issued originally in 1893, and in an enlarged and revised form in 1908. This code is employed almost without exception by mining-companies and engineers, to whose use it was specially dedicated, and other business men have found it extremely practical for cable communications. [Nature 98, 94-94 (05 October 1916)] Black hard covered book of 807 pages by Bedford McNeil. Contents include: General suggestions for using code; Morse signals, alphabet and figures; Timetable west of Greenwich; Timetable east of Greenwich; map; Alphabetical Code; Survey of Mineral Properties; Numbers; English Money; American money; Lineal measurement; Weights; Letters; Cables; banks; Finance Companies; Substitutions; Extra Code. The book includes the following advertisements: Nobel's Explosives Company; Otto Aerial Ropeways; Tabloid Medicine cases & Chests; Charleton's Report Book for Mining Engineers; Bornhardt's Electrical Firing Machine; On a page towards the front "R. Brook"morse code, mcneill, bedford mcneill, mining, noble's explosives company, otto, charleton, tabloid, bornhadt, brook, r. brook, telegraphy, morse -

Federation University Historical Collection

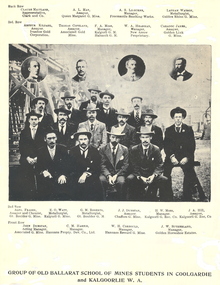

Federation University Historical CollectionPrint - Document, Group of Old Ballarat School of Mines Students in Coolgardie and Kalgoorlie, Western Australia, 1900, 1900

In 1900 a group of former Ballarat School of Mines students working in Western Australia commissioned and presented a bust of Professor Alfred Mica Smith to the School. The former students are Claude Maitland (CLark & Co.); A.L. Hay (Queen Margaret Gold Mine); A.S. Lilburne (Freemantle Smelting Works); Latham Watson (Golden Rhine Gold Mine); Arthur Kildahl (Ivanhoe Gold Corporation. Thomas Copeland (Associated Gold Mine); F.A. Moss (Kalgurli Hold Mine, Hainault Gold Mine); W.A. Hearman (New Arrow Propriety); Caradoc James (Golden Link Gold Mine); Alex Fraser (great Boulder Gold Mine); E.O. Watt (Kalgurli Gold Mine); G.M. Roberts (great Boulder Gold Mine); J.J. Dunstan (Chaffers Gold Mine); H.W. Moss, (Kalgoorli Gold Rec. Co); J.A. Hill (Kalgoorli Gold Rec. Co); John Dunstan (Associated Gold Mine); C.M. Harris (Hannans Propriety Development Co. Ltd); W.H. Cobould (Hannans Reward Gold Mine); John W. Sutherland (Golden Horsehoe Estates)The original photo was presented to Professor Alfred Mica Smith by the 'Old Boys' pictured.A printed image of former students of the Ballarat School of Mines, and donors towards commissioning a bust of their former lecturer Professor Alfred Mica Smith. ballarat school of mines, mining, western australia, coolgardie. kalgoorlie, maitland, hay, lilburne, watson, kildahl, copeland, moss, hearman, james, fraser, watt, roberts, dunstan, hill, harris, corbould, sutherland, william corbould, john sutherland, john w. sutherland -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wrench, Late 19th Century

Johann Elias Bleckmann (1784-1856) founded a steel goods shop in Ronsdorf near Dusseldorf Germany. After completing a business education in his father's business, his son Johann Heinrich August Bleckmann (1826-1891) gained further experience through travel in North and South America. When his father died, he took over the steel goods store and moved it to Solingen. He bought a hammer mill in Mürzzuschlag Styria (Austria) in 1862 and converted it into a modern crucible casting steel smelter. His "Phoenix Steel", which he produced himself, achieved worldwide renown. He then went on to establish a file and tool factory and later founded a steel and plate rolling mill. Apart from cutlery blades, the company's self-produced steel was also processed into tools, scythes, rifle parts, etc. His sons Eugen and Walter continued after his death in 1891 at the Phoenix steelworks. However, by the end of the First World War, the two brothers fell into economic difficulties as a result of eliminating a large part of their foreign trade. In 1921, the company was converted into a public limited company and merged three years later with the company Schoeller & Stahlwerke. Made by Bleckmanns a significant Austrian manufacture of cutlery and tools in a recognized area of Germany famous for the production of steel items. The item is giving a snapshot of early colonial and European trades persons tools and gives an interesting insight into the development and progression of European tool and steel development and innervation prior to the First World War.Drop hand forged steel wrench with unusual locking mechanism to size jaw opening made by J E Bleckmann, Solingen Germany.Machine stamped on handle of wrench LOTUS L R GEBRAUCHS under has MUNSTER, J E BLECKMANN, SOLINGEN Germany. [ Translated: LR Gebrauchs= use,usage, or custom application] [Lotos] Translated: Lotus ie flower] [Solingen =town in Rhine valley]manufactures, tools, engineering, blacksmith, workshop tool, dropforged, handmade, wrench, adjustable wrench, phoenix steel, j e bleckmann, solingen, murzzuschlag, steel mill, cutlery, steel foundery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing Plane, Johann Heinrich August Bleckmann, 1870 to 1920

Johann Elias Bleckmann (1784-1856) founded a steel goods shop in Ronsdorf near Düsseldorf Germany. After completing a business education in his father's business, his son Johann Heinrich August Bleckmann (1826-1891) gained further experience through travel in North and South America. When his father died, he took over the steel goods store and moved it to Solingen. He bought a hammer mill in Mürzzuschlag Styria (Austria) in 1862 and converted it into a modern crucible casting steel smelter. His "Phoenix Steel", which he produced himself, achieved worldwide renown. He then went on to establish a file and tool factory and later founded a steel and plate rolling mill. Apart from cutlery blades, the company's self-produced steel was also processed into tools, scythes, rifle parts, etc. His sons Eugen and Walter continued after his death in 1891 at the Phoenix steelworks. However, by the end of the First World War, the two brothers fell into economic difficulties as a result of eliminating a large part of their foreign trade. In 1921, the company was converted into a public limited company and merged three years later with the company Schoeller & Stahlwerke. Made by Johann Heinrich August Bleckmann a significant Austrian manufacture of cutlery and tools in a recognized area of Germany famous for the production of steel items. The item is giving a snapshot of early colonial and European trades persons tools and gives an interesting insight into the development and progression of European tool and steel development and innervation prior to and just after the First World War.Plane Smoothing type with flat base. Has wooden wedge and iron missing. Knob handle is set on top and at the front. Iron 1 3/5 inches wide. Marked "Bleckmann (symbol) Safingen" "GN".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Fluorite (purple)

Fluorite comes in a variety of natural colours and crystal formations and glows under ultraviolet light (the word 'fluorescence' comes from the same etymological source). In its pure form, calcium fluoride, it is a colourless combination of the elements calcium and fluorine, but gains its colour from trace elements that infiltrate or replace calcium within its crystal structure during its formation. Although fluorite crystals polish well and can achieve a high level of lustre, the mineral is very soft (4 on MOHS hardness scale) so it is unsuitable for use in rings and must be handled and stored carefully if used in other forms of jewellery. Most crystals of the mineral are too coarse for decorative purposes but have been mined under the name fluorspar for a variety of commercial and industrial purposes. These include the production of hydrofluoric acid, smelting metal alloys, producing glazes and ceramic finishes and use in medical and dental products. An existing label for this specimen indicates that its origin or collection-point was 'probably USA.' Fluorspar, the form of fluorite used commercially and industrially, was mined in significant quantities in the counties of Hardin and Pope in South-Eastern Illinois throughout the Nineteenth and Twentieth Centuries. Fluorite was made Illinois' state mineral in recognition of its contribution to the state's identity and economy. The specimens are significant as examples of surveying activity undertaken to assess and direct the development of the mineral resource industries, as well as the movement to expand human knowledge of earth sciences such as mineralogy and geology in the nineteenth century.The specimen is a piece of purple shaded fluorite (also known as fluorspar), the mineral form of calcium fluoride. The unpolished specimen presents a dark purple interior with a substantial dark grey crust representing the matrix from which the specimen was obtained. Existing label: Flourite / (purple) / probably / USA / BB /burke museum, beechworth, geological, geological specimen, fluorite, flourite, calcium fluoride, hydrofluoric acid, jewellery, indigo shire, north-east victoria, mining, illinois, usa, united states, fluorine, gemstones, purple stones -

Federation University Historical Collection

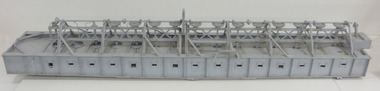

Federation University Historical CollectionUnknown - Model, Edwards' Ore Reduction Furnace Model, pre 1924

This model of a mechanical ore roasting and chloridising furnace was invented and patented by Thomas Edwards of the Edwards Pyrites Smelting and Ore Reduction Company. This new type of furnace produced a high standard of sulphur free ore known as ‘sweet roasted’. Edwards used this model for demonstrations in the USA. Of note is the central large vertical cogwheel (externally driven) which drives small vertical cogwheels via angled cogging drives. These in turn drive a horizontal wheel. Each side of the vertical wheel is set on an opposite side to the horizontal wheel of its neighbours, resulting in opposite direction rotation of neighbouring horizontal wheels. Each horizontal wheel turns a rabble (set of vertical iron paddles) within the furnace. These rabbles, each turning in opposite direction to its neighbours, move the roasting ore in a zig-zag path through the furnace. The elongated furnace with its line of rabbles produced a much ‘sweeter’ roasted ore than could be obtained from a typical tank-shaped furnace. In 1924, when the model was donated to the Ballarat School of Mines, Ballarat’s Courier newspaper reported, ‘Apart from its historical and education value, the gift should serve to stimulate the inventive faculties of the students who have to win fame for the school and for themselves in the metallurgical world.’ The furnace model was donated to Ballarat School of Mines and used as an educational prop from 1924. The model relates to the mining industry which is a significant part of Ballarat's history and heritage. Ballarat School of Mines is the oldest Technical School in Australia and is celebrating 150 years in 2020.Metal model of Edwards' Ore Reduction Furnace. The model includes cogwheels, rabbles and other details. Scale is thought to be around 1:20M259ballarat school of mines, edwards, pyrites, ore reducation, edward retallack, mining, model -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (Item) - (SP) CAC History Boomerang Description WS Robinson File No 1 7.1.1935 to 18.8.1942 Various Correspondence R3

Correspondence Notes on the "Boomerang" Interceptor 18/8/42 Correspondence re setting up aircraft industry in Australia - between W S Robinson, A G Brown (CAC), S A Middleton (Austral Development Ltd London.), Douglas Aircraft Company, F Mitchell, BHP,, Essiungton Lewis BHP, Australian William S. Robinson had been Managing Director of Broken Hill Associated Smelters, based in London. He had played a key roll in negotiating the British Zinc Corporation’s investment in mining at Broken Hill NSW and formation of the resultant Australian business The Zinc Corporation. Returning to Australia, he was appointed to high levels of Australian Government during the Second World War to formulate policy on wartime demands for Australia's industrial and metals supply. Robinson was held in high regard by successive Prime Ministers and was a close associate of Essington Lewis, head of Broken Hill Pty Ltd (BHP). W.S. Robinson was a strong believer in aviation and business and air transportation having backed the purchase of two DH.84 Dragons in 1933 by associate company Western Mining Corporation to carry out a 12-month aerial photographic survey. He promoted the formation of Commonwealth Aircraft Corporation at Fishermans Bend, Melbourne to ensure Australian production of military aircraft. -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (Item) - (SP) CAC History Aviation Syndicate Minutes and Agenda

Correspondence Notes on the "Boomerang" Interceptor 18/8/42 Correspondence re setting up aircraft industry in Australia - between W S Robinson, A G Brown (CAC), S A Middleton (Austral Development Ltd London.), Douglas Aircraft Company, F Mitchell, BHP,, Essiungton Lewis BHP, Australian William S. Robinson had been Managing Director of Broken Hill Associated Smelters, based in London. He had played a key roll in negotiating the British Zinc Corporation’s investment in mining at Broken Hill NSW and formation of the resultant Australian business The Zinc Corporation. Returning to Australia, he was appointed to high levels of Australian Government during the Second World War to formulate policy on wartime demands for Australia's industrial and metals supply. Robinson was held in high regard by successive Prime Ministers and was a close associate of Essington Lewis, head of Broken Hill Pty Ltd (BHP). W.S. Robinson was a strong believer in aviation and business and air transportation having backed the purchase of two DH.84 Dragons in 1933 by associate company Western Mining Corporation to carry out a 12-month aerial photographic survey. He promoted the formation of Commonwealth Aircraft Corporation at Fishermans Bend, Melbourne to ensure Australian production of military aircraft. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; pair of U-shaped carved blocks, unpainted. The blocks have opposing metal pins and holes to hold them together. One block has a disc shape carved into the base. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; hexagonal wooden shape painted orange. The thick carved wooden shape is in halves forming a hole when locked together with the dowel pegs and opposing drilled holes. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912