Showing 90 items

matching substance use

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking iron, Mid-to-late 20th century

Caulking is the use of cork or other substances to seal the seams and joints of the vessel to make them watertight. Caulking lasts for quite some time but eventually dries out and needs to be replaced. A hammer is often used with a caulking iron to drive it along the seams. The caulking iron’s blade is tapered to be narrower at the tip to make it easier to remove it from the joint. The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings. You can see Laurie’s inscription on the tool called a ‘bevel’. Laurie worked for Ports and Harbours, Melbourne, for over 50 years, beginning in the early 1960s. He and a fellow shipwright inscribed their names on a wheelhouse they built in 1965; the inscription was discovered many decades later during a repair of the plumbing. Many decades later Laurie worked on the Yarra moving barges up and down the river and was fondly given the title ‘Riverboat Man’ His interest in maritime history led him to volunteer with the Maritime Trust of Australia’s project to restore and preserve the historic WWII 1942 Corvette, the minesweeper HMAS Castlemaine, which is a sister ship to the HMAS Warrnambool J202. Laurie Dilks donated two handmade displays of some of his tools in the late 1970s to early-1980s. The varnished timber boards displayed the tools below together with brass plaques. During the upgrade of the Great Circle Gallery Laurie’s tools were transferred to the new display you see there today. He also donated tools to Queenscliffe Maritime Museum and Clunes Museum.The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright at Ports and Harbours in Melbourne in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings.Caulking iron, or broad chisel, wooden handle with reinforcing on the ends, metal shaft that tapers down from the handle to the end of the blade. It has an inscription. It once belonged to shipwright Laurie Dinks.Stamped into metal " - - WARD /(image of crossed swords) WEFT / WARRANTED"flagstaff hill, warrnambool, great ocean road, shipwreck coast, maritime museum, maritime village, shipwright, carpenter, shipbuilding, ship repairs, hand tool, equipment, ship maintenance, cooper, tool, marine technology, caulking iron, jerry iron, broad chisel, caulking, sealing, laurie dilks, l dilks, port and harbours melbourne -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking mallet, mid-to-late 20th century

Caulking is the use of cork or other substances to seal the seams and joints of the vessel to make them watertight. Caulking lasts for quite some time but eventually dries out and needs to be replaced. A mallet or hammer is often used with a caulking iron to drive it along the seams. The caulking iron’s blade is tapered to be narrower at the tip to make it easier to remove it from the joint. The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings. You can see Laurie’s inscription on the tool called a ‘bevel’. Laurie worked for Ports and Harbours, Melbourne, for over 50 years, beginning in the early 1960s. He and a fellow shipwright inscribed their names on a wheelhouse they built in 1965; the inscription was discovered many decades later during a repair of the plumbing. Many decades later Laurie worked on the Yarra moving barges up and down the river and was fondly given the title ‘Riverboat Man’ His interest in maritime history led him to volunteer with the Maritime Trust of Australia’s project to restore and preserve the historic WWII 1942 Corvette, the minesweeper HMAS Castlemaine, which is a sister ship to the HMAS Warrnambool J202. Laurie Dilks donated two handmade displays of some of his tools in the late 1970s to early-1980s. The varnished timber boards displayed the tools below together with brass plaques. During the upgrade of the Great Circle Gallery Laurie’s tools were transferred to the new display you see there today. He also donated tools to Queenscliffe Maritime Museum and Clunes Museum.The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright at Ports and Harbours in Melbourne in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings.Caulking mallet; a thick wooden handle with a round ‘T’ cross-bar near the end. Metal reinforcing is added around the ends of the head. Both sides of the wooden head are flared outwards towards the end. The head is reinforced where it intersects with the handle and around the ends of the head just above the tips. It once belonged to shipwright Laurie Dinks.flagstaff hill, maritime museum, maritime village, warrnambool, shipwreck coast, great ocean road, shipwright, carpenter, shipbuilding, ship repairs, hand tool, equipment, caulking, ship maintenance, cooper, shipwright’s tools, shipwrights’ tools, tools, maritime trade, caulking mallet, caulking iron, laurie dilks, l dilks, port and harbours melbourne -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking iron, mid-to-late 20th century

Caulking is the use of cork or other substances to seal the seams and joints of the vessel to make them watertight. Caulking lasts for quite some time but eventually dries out and needs to be replaced. A mallet or hammer is often used with a caulking iron to drive it along the seams. The caulking iron’s blade is tapered to be narrower at the tip to make it easier to remove it from the joint. The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings. You can see Laurie’s inscription on the tool called a ‘bevel’. Laurie worked for Ports and Harbours, Melbourne, for over 50 years, beginning in the early 1960s. He and a fellow shipwright inscribed their names on a wheelhouse they built in 1965; the inscription was discovered many decades later during a repair of the plumbing. Many decades later Laurie worked on the Yarra moving barges up and down the river and was fondly given the title ‘Riverboat Man’ His interest in maritime history led him to volunteer with the Maritime Trust of Australia’s project to restore and preserve the historic WWII 1942 Corvette, the minesweeper HMAS Castlemaine, which is a sister ship to the HMAS Warrnambool J202. Laurie Dilks donated two handmade displays of some of his tools in the late 1970s to early-1980s. The varnished timber boards displayed the tools below together with brass plaques. During the upgrade of the Great Circle Gallery Laurie’s tools were transferred to the new display you see there today. He also donated tools to Queenscliffe Maritime Museum and Clunes Museum.The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright at Ports and Harbours in Melbourne in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings.Calking iron, a metal tool with a round flat top and head that flares outwards to a wide wedge shape. It once belonged to shipwright Laurie Dinks.flagstaff hill, maritime museum, maritime village, warrnambool, shipwreck coast, great ocean road, shipwright, carpenter, shipbuilding, ship repairs, hand tool, equipment, caulking, ship maintenance, cooper, shipwright’s tools, shipwrights’ tools, tools, maritime trade, caulking iron, laurie dilks, l dilks, port and harbours melbourne -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking iron, mid-to-late 20th century

Caulking is the use of cork or other substances to seal the seams and joints of the vessel to make them watertight. Caulking lasts for quite some time but eventually dries out and needs to be replaced. A mallet or hammer is often used with a caulking iron to drive it along the seams. The caulking iron’s blade is tapered to be narrower at the tip to make it easier to remove it from the joint. The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings. You can see Laurie’s inscription on the tool called a ‘bevel’. Laurie worked for Ports and Harbours, Melbourne, for over 50 years, beginning in the early 1960s. He and a fellow shipwright inscribed their names on a wheelhouse they built in 1965; the inscription was discovered many decades later during a repair of the plumbing. Many decades later Laurie worked on the Yarra moving barges up and down the river and was fondly given the title ‘Riverboat Man’ His interest in maritime history led him to volunteer with the Maritime Trust of Australia’s project to restore and preserve the historic WWII 1942 Corvette, the minesweeper HMAS Castlemaine, which is a sister ship to the HMAS Warrnambool J202. Laurie Dilks donated two handmade displays of some of his tools in the late 1970s to early-1980s. The varnished timber boards displayed the tools below together with brass plaques. During the upgrade of the Great Circle Gallery Laurie’s tools were transferred to the new display you see there today. He also donated tools to Queenscliffe Maritime Museum and Clunes Museum.The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright at Ports and Harbours in Melbourne in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings.Caulking iron; an iron tool with round flat surface on top, above a narrow, long round handle that flares outwards to form a thick, narrow wedge shape. It once belonged to shipwright Laurie Dinks.flagstaff hill, maritime museum, maritime village, warrnambool, shipwreck coast, great ocean road, shipwright, carpenter, shipbuilding, ship repairs, hand tool, equipment, caulking, ship maintenance, cooper, shipwright’s tools, shipwrights’ tools, tools, maritime trade, caulking iron, laurie dilks, l dilks, port and harbours melbourne -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)'Atomist' atomiser associated with Dr Frank Forster

The all purpose 'Atomist' atomiser was used from the 1930s to the late 1960s. The atomiser had a detachable nasal mount, and a rubber bulb which was attached to a length of tubing. It also had an adjustable spray tip. It could be used as an anaesthetic cocaine or other spray. In the 1950s it was in extensive use as a laryngeal, nasal and throat spray. The spray nozzle could be turned upwards or downwards and was similar in appearance to the De Villiers Canadian spray. The atomiser could also be used as a vaginal douche with lotion for the treatment of vaginal infections. An atomizer spray consisting of a glass container with a hollow metal tube at front and long black rubber tubing attached to a rubber bulb at the rear. Glass container has residue of white liquid in it. WARNIING: dried white powdery substance may be arsenic. Contained in sealed bag. Handle wearing nitrile gloves and ensure examination is in open area, not enclosed space. -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumMeldometer, Joly

Joly Meldometer The Joly meldometer was created to determine the melting point of minerals. W.E. Wilson, an astronomer and author, stated in 1900 that the Joly meldometer consisted of a ‘a strip of platinum on which minute fragments of any mineral can be placed, while any alteration in its length can be determined by means of a micrometer screw which touches a lever connected with one end of the strip. The strip can be heated by an electric current, and is calibrated by observing the micrometer readings corresponding to the temperatures at which some substances of known melting-points melt’i . One reason why the Joly meldometer was seen as a successful addition to science was the small amount of any substance that it required for testing. Only a minute sample was needed for the instrument to work and so a tiny part could be taken from a delicate item without destroying itii . The instrument was originally manufactured by the Irish company Yeates & Son of Dublin. The Yeates family business was established in the early 1790’s and is thought to have operated until approximately 1922iii . Their business slogan was recorded as ‘Instrument makers to the University’, a slogan which proudly exhibited their relationship with Trinity College, Dublin. The company was located directly opposite Trinity College, the place where the Joly meldometer was created. Working in such close proximity must have assisted this business relationship. The inventor of this meldometer was Irishman John Joly. Joly was born in 1857 at the Church of Ireland Rectory, Hollywood House. His education led him to Trinity College Dublin where, by 1891, he had obtained a Bachelor of Engineering degree as well as a Doctorate of Science. The entirety of his working life appears to have taken place at Trinity College although he is known to have travelled in order to consult with other scientists such as the world renowned Sir Ernest Rutherford. The Joly meldometer was used for a variety of different purposes, with scientists often adapting the instrument to suit their own needs. For instance, the previously mentioned astronomer W.E. Wilson adapted the meldometer to assist him in measuring the radiation of the suniv . Joly used his device in an attempt to ascertain the age of the earth. In 1913, along with Sir Rutherford, Joly came to the conclusion that the earth was approximately 400 million years old. They did this by analysing the decay of radioactivity in minerals. According to our present knowledge of the earth this was a much more accurate date than the dates Joly had previously derived. He had first thought that the earth was 97 million years old due to the volume of sodium in the oceans. Joly’s second analysis of the topic had resulted in the age of 80 million years. This figure was based on the accumulation of sediment. Apart from designing his meldometer, Joly is also remembered for his work with colour photography. In 1894 Joly discovered a method for creating colour photographs from a single platev . He also studied the use of radiation as a treatment for cancer and persuaded the Royal Dublin Society to establish the Radium Institute to assist hospitals. In 1933 Joly passed away at the age of seventy-six. Jacqueline Eager Student Projects Placement, Cultural Collections 2005 iMollan, Charles, Irish National Inventory of Scientific Instruments, Samton Limited, 1995, p. 302. iiJoly, John, 'On the determination of the melting points of minerals, Part 1. Uses of the meldometer', Proceedings of the Royal Irish Academy, Vol. 2., 1891. iiiInstitute for Learning Technologies, "Stephan Mitchell Yeates' http://www.ilt.columbia.edu/projects/bluetelephone/html/yeates.html, accessed on 04.10.2005 ivMollan, Charles, Irish National Inventory of Historic Scientific Instruments, op cit. vMollan, Charles, The Mind and the Hand: Instruments of Science 1685-1932, Samton Limited, Dublin, 1995, p. 34.The following from #2975 in UDE UNIVERSITY COLLEGE DUBLIN ENGINEERING list in the “Irish National Inventory of Historical Scientific Instruments” by Charles Mellon (P/C in file for Cat no 272. “....meldometer as an instrument ‘for the purpose of finding the melting-points of minerals, hence its name. As used by him (Joly), it consists of a strip of platinum,on which minute fragments of any mineral can be placed, while any alteration in its length can be determined by means of a micrometer screw which touches a lever connected with one end of the strip. The strip can be heated by an electric current, and is calibrated by observing the micrometer readings corresponding to the temperatures at which some substances of known melting-points melt’.” Ref. : J. Joly, Proc. Roy. Irish Acad. 3rd series vol 2 (1891),38-64. -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryBottle, Chloroform

Chloroform began to be used as an anaesthetic agent in 1847. It was administered by dropping the substance on to a handkerchief held over the patient's nose and mouth.Clear glass bottle with frosted neck and fluted lip with a glass lid that has a frosted stopper and heart shaped handle piece for lifting the lid out of the bottle. The bottle is housed in a black circular cardboard case with red inner lining. Cotton padding has been stuffed in the top of the lid to protect the bottle stopper.Printed in gold leaf on top of case lid: CHLOROFORMchloroform, anaesthesia, surgery, administration -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Book, Sayer-Jones, Moya, Beyond The Call: Stories From Veterans And Their Families (Copy 2)

... with mental illness and some with substance use. Beyond The Call ...The stories celebrate the way in which partners and famiies have supported veteran family members, many of whom are challenged with mental illness and some with substance use.The stories celebrate the way in which partners and famiies have supported veteran family members, many of whom are challenged with mental illness and some with substance use.post-traumatic stress disorder, families of military personnel - australia, vietnam -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumBox - plastic, 1940

Used by Internee Camp 3 Victoria.Square red plastic box/container with lid, containing solid whitish substance, possibly tooth paste powder.Rosodowt.Maker details underneath in Germantatura, ww2, container, commercial -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPhotograph - Black and white prints and negatives, Students in Class, c. 1950

Enlargement. of black and white photograph B91.172 Chemistry class. R.D.M. Soil Indicator colour chart on table and substances in test tubes. Front row: Margot George, Peter Smith. A further enlargement (B92.564) was used in the Centennial Display. Same students in B91.174.Inscribed, Students in Class Room Burnley Gardens B19-1238. Similar Negs B19-1237. Dup B87, B19-1239. Dup B88, B19-1240. Dup B89."r.d.m. soil indicator, colour chart, test tubes, margot george, peter smith, students in class, chemistry class -

Clunes Museum

Clunes MuseumEquipment - DYE SCALES IN CABINET

... SET OF METAL SCALES AND WEIGHTS USED TO WEIGH DYE... SCALES USED IN DYE ROOM AT CLUNES KNITTING MILL KNOWN AS CLUNES ...METALIC SCALES USED IN DYE ROOM AT CLUNES KNITTING MILL KNOWN AS CLUNES INTERKNIT HOSIERY CO. FROM COMPLETE SET OF SEVEN WEIGHTS FROM .100 TO 1 GRAMSSET OF METAL SCALES AND WEIGHTS USED TO WEIGH DYE SUBSTANCES AT CLUNES KNITTING MILL. ENCASED IN A GLASS AND TIMBER CABINETlocal history, textile, knitting mill interknit hosiery co. -

Whitehorse Historical Society Inc.

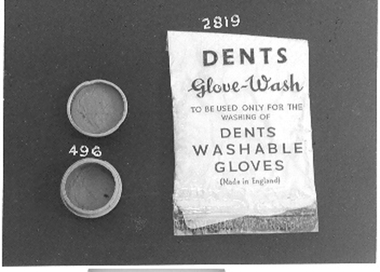

Whitehorse Historical Society Inc.Functional object - Glove Wash

Small plastic bag containing cream coloured substance with washing instruction.Dents, Glovewash. To be used for the washing of Dents washable gloves.domestic items, cleaning -

Parks Victoria - Days Mill and Farm

Parks Victoria - Days Mill and FarmFunctional object - Funnels

Used for pouring liquids and other substances.Funnels x 7, handmade. 6 conical shaped, 2 of these have angled spouts, vertical spouts on other 4. 1 x squarish shaped funnel, spout, vertical. 6 funnels have a ring for hanging purposes. Some have mesh where the spout joins body of funnel.[square funnel]: shell motif/ "BIO.." -

Kew Historical Society Inc

Kew Historical Society IncFunctional object - Desk calendar and hand blotter

Desk calendar with adjustable day, dates and months also used as an ink hand blotter. The calendar is made out of a chrome-like substance while the blotter is padded fabric.Nilhand blotters, desk calendars -

City of Greater Bendigo - Civic Collection

City of Greater Bendigo - Civic CollectionEquipment - Crucible, Bendigo Pottery

Assay is a process of metallurgy and chemical analysis used to determine proportions of precious metals in ores and other metallurgy substances such as silver or gold. The process helps identify pollutants present within a sample and can indicate a high level of pollution in a mining site. Stoneware crucibles are used in the fire assay process due to their ability to withstand high temperatures. Fire assay is a three step process where by samples from the mine are ground in a find powder and then mixed with dry powder chemicals. This mixture is heated in a crucible to extreme temperatures (crucible fusion) until all of the powers fuse into a glass like slag. Once this reaction is complete, the contents are poured into a mold and cooled. In step three (known as cupellation) the mixture is separated in a fire assay cupel and once this is complete the cupel with reveal a small bead of precious metals. Established by George Guthrie in 1857 (about 5km north of its current site) and then again seven years later in 1864 after it initially closed, Bendigo Pottery remains one of the most influential and longest running potteries in Australia. Over the years the Pottery has contributed to the growth and development of the district through both its products including building products, table ware and decorative and commemorative war as well as artistically, being responsible for training and supporting many potters locally. It has partnered with the City on various tourism promotions and the Civic Collection holds a number of important items within its collection.Two stoneware vessels of differing dimensions (0287.1 & .2). Unglazed and porous, showing extensive signs of use. Stamped and marked on the outside. 0287.2 has a shaped pouring lip. Six smaller items, coins, buttons (0287.3,.4,.5,.6,.7,.8) were found with the crucibles but their relationship to the assay items is unknown.0287.1; Large crucible; Bendigo Pottery / E. 0287.2; Small crucible: Pottery / C Icity of greater bendigo commerce, city of greater bendigo mining, making a nation exhibition -

Parks Victoria - Maldon State Battery

Parks Victoria - Maldon State BatteryPot, Melting

... Possibly used to melt substance over the stove in the assay... Historic Area Maldon goldfields Possibly used to melt substance ...Possibly used to melt substance over the stove in the assay room. Forged iron oval bowl shaped pot with long hollow cylindrical handles on either side (threaded on one end) and slightly bent. -

Mont De Lancey

Mont De LanceyDetonator box

Small, orange and white tin box with hinged lid for one hundred detonators.On lid: "Nobel No. 6. 100 detonators for rich explosives. Alfred Nobel. Thistle Brand. Manufactured in Gt. Britain. Glasgow" "6 6" on front and back panels, "For use wherever safety fuse is allowed" on left side panel and "Must be handled with great care and kept dry. The composition must not be scratched or pricked with a pin, nail, knife blade or other hard substance, as any act of this kind may cause explosion" on the right side panel.explosives equipment -

Harcourt Valley Heritage & Tourist Centre

Harcourt Valley Heritage & Tourist CentreCricket Bat, Pre 1915

Presented by W Hampson, Used & loved by Rowland Hill and skillfully weilded by him in many matches played for Harcourt cricket club. Harcourt was admitted to the Bendigo District Cricket association in 1924. Formed from a small community it was said “ everyone played cricket in Harcourt” Most of the players lived on fruit orchards, owned the status symbol of the time – a motor car- and were widely regarded as people of substance. Clearly they possessed the necessary pre-requisites for acceptance into the wider cricket community. Dates from the era when ‘gentlemen’ played cricket. Also notable for its connection with Colonel Robert Gartside, who was Killed in Action at Gallipoli on 8/05/1915Timber cricket bat with partially bound handle, split corner, many indentations and gilt letteringHarcourt CC Capt R Gartside Mr W Hampson, Best Bowling Average -

Wodonga & District Historical Society Inc

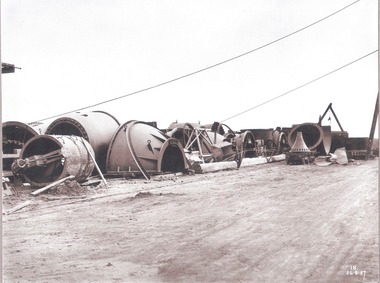

Wodonga & District Historical Society IncAlbum - Hume Reservoir Australia Album - Needle valves, August 1927

This set of photos is from a leather bound album bearing the inscription "HUME RESERVOIR AUSTRALIA" plus 'The Rt. Hon. L. C. M. S. Amery, P. C., M .P.' all inscribed in gold. It was presented to The Rt. Hon. L. C. M. S. Amery, P. C., M. P, Secretary of State for Dominion Affairs on the occasion of his visit to the Hume Reservoir on 2nd November 1927. This album is of local and national significance as it documents the planning and development of the Hume Reservoir up to 1927. It was the largest water reservoir in the British Empire. The album records the pioneering engineering work that went into its construction.DEPARTMENT OF PUBLIC WORKS, N.S.W. RIVER MURRAY WATERS SCHEME. HUME RESERVOIR. 34. Needle Valves. Some of the needle valves in parts stacked ready for removal by the cableway to their positions on the outlets. There are seven of these, 7 feet 6 inches in diameter. The heaviest single part weighs about 10 tons. New South Wales. August 1927. A needle valve is a type of valve which can be used to regulate flow of a substance, usually either gas or water, through an appliance or system. The unique feature of the value is the inclusion of a small plunger, with a shape akin to a needle.hume reservoir australia, river murray waters scheme, hume reservoir construction -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumInstrument - Becquerel Phosphoroscope (incomplete), c1860-1880

The phosphoroscope was invented by Alexander Edmund Becquerel and used to measure the amount of time that a phosphorescent substance will glow after being irradiated by a brilliant source of light.The phosphoroscope consists of a round metal chamber with a pair of rotating discs inside, arranged so that no light can pass directly through the chamber. The discs have cut-out windows spaced equally at regular angular distances and are turned by the hand crank linked to a gear mechanism. The sample is placed in a specially designed holder into the small opening near the gearing, and it is exposed to the light source through the large rear condensing lens.Engraved on chamber: 'Phosphoroscope de E. Becquerel / J. Duboscq a Parisbecquerel phosphoroscope, phosphoroscope, optical instruments, phosphorescent, alexander edmund becquerel, jules duboscq, france -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Rib Bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale rib bone with advanced stage of calcification as indicated by brittleness. None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Mangan Hedenbergite

This specimen was recovered from Broken Hill, NSW. It was given the name Mangan Hedenbergite in 1819 by Jöns Jakob Berzelius in honor of Mr. Anders Ludvig of Hedenberg who was the first to define hedenbergite as a mineral. Hedenbergite, belongs in the pyroxene group having a monoclinic crystal system. The mineral is extremely rarely found as a pure substance. Mangan Hedenbergite is a manganese bearing variety of Hedenbergite. Manganese is the world’s fourth most used mineral after iron, aluminium, and copper primarily because it has no satisfactory substitute in its major applications. Globally, the steel industry is the primary user of manganese metal, utilizing it as an alloy to enhance the strength and workability of steel and in the manufacture of tin cans. Manganese is a key component of certain widely used aluminium alloys and, in oxide form, dry cell batteries used in electric vehicles. These batteries are in high demand. Another potential use for manganese may as an additive to help coat and protect a car’s engine. Manganese is also used for non-metallurgical purposes such as plant fertilizers, animal feed, and colorants for bricks. This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.A hand-sized mineral specimen in shades of silver and blackmanganese, open cut mine, manganese ore processing, bell bay, tasmania, northern territory, steel industry, zinc-carbon batteries, alkaline batteries, tin cans -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Kangaroo Flat Gold Mine Collection: core samples

Core samples are cylindrical sections of a naturally-occurring substance, such as sediment or rock, that are obtained by drilling with a special drill and brought to the surface for examination. Core samples are used in underground or undersea exploration and prospecting. . The hole made for the core sample is called the "core hole"1. Colour photocopy of original photo. Four separate images of core samples. Core samples are placed side by side, lengthwise. western mining corporation, goldmining, kangaroo flat gold mine, rock samples, core samples, exploration -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips, whalebone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Vertebrae, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Whalebone The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The bone of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as whalebone. Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale bone Vertebrae with advanced stage of calcification as indicated by deep pitting. Off white to grey.None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Jaw Bone, Undetermined