Showing 172 items matching "19th century furniture"

-

Flagstaff Hill Maritime Museum and Village

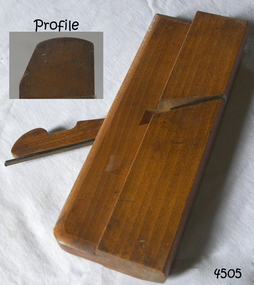

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, 1869-1920

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane Hollow type Marked Routledge No.8 Blade Stamped JAS Burden (owner). flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Between 1869 early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Plane, Moulding, Hollow Size No 18 Routledge Maker (Owner "J.A.S.Burden")flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Richard Routledge, Late 19th to early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use to produce a decorative moulding for a piece of furniture, door trims etc, or other timber items that had to be accomplished by using hand tools and in particular one of these types of planes. Profiled planes came in various shapes and sizes to achieve the required decorative finish. A significant tool from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Rebate Moulding plane Size 1/2"Maker R Routledge Birmingham also marked Owner Jas Burdenflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Richard Routledge, Late 19th to early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use to produce a decorative moulding for a piece of furniture, door trims etc. or other timber items that had to be accomplished by using hand tools and in particular one of these types of planes. Profiled planes came in various shapes and sizes to achieve the required decorative finish. A significant tool from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Plane Moulding type size 1/8" Maker stamped R Routledge & JAS Burden (owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane. Stamped JAS Burden (owner) also No 2flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Auburn Tool Company, 1870 to 1893

Moulding Plane: A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. Auburn Tool Company: The Auburn Tool Company is known to exist from 1864 to 1893. George Casey reorganized the firm of Casey, Clark and Company as a joint-stock company in 1864, under the company name of Auburn Tool Company. The 1865 New York State Census noted the firm as a manufacturer of the plane, plane irons, and skates. The production that year was listed as 30,000 pairs of skates and 35,000 planes along with 25,000 dozen plane irons. The plane irons carried the trademark "Thistle". Both skates and plane irons were made from welded wrought iron and cast steel. The Auburn Tool Company was among the five leading plane manufacturing firms existing in the mid to late 19th century USA. Others were: H. Chapin's Son; Greenfield Tool Company; and Sandusky Tool Company. Auburn Tool Company, with these others, was also a founding member of the Plane Makers Association, organized around 1858 to fix prices. Most of the companies tools were manufactured by prisoners and in 1866 the firm was outbid for prison labour by J M Easterly and Co. After losing the contract with the prison authority they constructed a new building and continued in the plane manufacturing business with private labour. The 1870 US Census reported the firm had 21 machines, driven by water power, employing 66 males, producing annual products valued at us$70, 000. After A. Howland and Company was dissolved in 1874, the Auburn Tool Company again resumed using contract labour at the State Prison until 1877. The Auburn Tool Company merged with the Ohio Tool Company of Columbus, Ohio, on Nov 14, 1893. Although plane manufacturing was continued at Auburn until after 1907, after this merger the firm went under the name of the Ohio Tool Company. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. It also gives an insight into how many manufacturing companies bid for the rights to use prison labour to make their products at this time in our history. Decorative wood Moulding, plane Round type Auburn New York. Owner A Neudt Size 14 flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood smoothing plane, 1850-1890

A smoothing plane is a wood plane used for making a smooth surface to wood surfaces traditionally, these planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape or size required. The blade, or iron was likewise formed to the intended flat or level profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding and smoothing planes for the full range of work to be performed. Large crown mouldings or smoothing plane surfaces required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. This plane is a coffin pattern smoothing plane and is unmarked so the maker is unknown however it's design and patina indicate it was probably made in the mid to late 19th century and would be regarded as a vintage or antique item sought after today by collectors of vintage tools. A vintage tool made by an unknown maker, that was made commercially for firms and individuals who worked in wood and needed a tool that could produce a flat or level finish to timber. These types of planes came in various shapes and sizes to achieve the required finish to timber surfaces used in cabinet making. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools only. Smoothing Plane Coffin type Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. A vintage tool made by an unknown maker, this item was made commercially for firms and individuals who worked in wood and needed a tool that could produce a ornamental finish to timber. These profiled planes came in various shapes and sizes to achieve a decorative finish. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Moulding Plane, concave cut.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. A vintage tool made by an unknown maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use to produce a decorative moulding for a piece of furniture, door trims etc, or other timber items that had to be accomplished by using hand tools and in particular one of these types of planes. Profiled planes came in various shapes and sizes to achieve the required decorative finish. A significant tool from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Moulding Plane W size has 4 screws holding side together (repair)J Allin GN stamped inside W size 16 one end and Inglis R F Sharp on other end.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, J Hastie, 1766-1802

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane Hollow type No15 J Hastie Stamped EG W.M flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, 1890-1920

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown moulding required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool made by an unknown company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc. or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Wood Moulding, plane Rabbet Hollow type Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, John Manners, 1792-1822

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: We know little of John Manners other than his firm was acquired by Alexander Mathieson & Sons in 1822, Mathieson were one of the leading makers of hand tools in Scotland at this time. 1792 was deemed by Mathieson & Sons to be that of its foundation and it was in all likelihood the year in which John Manners had also set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, it is presumed having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker, from 1822 we hear nothing regards what happened to John Manners.A vintage tool made by a known maker John Manners the item is a significant wood working tool from the late 18th century that today is quite rare. As this maker sold his business to Alexander Mathieson another collectable tool maker in the early 19th century. This item would be sought after by wood working tool collectors and it gives us a snapshot of how cabinet makers went about creating furniture during this time period. Wood Moulding plane Side Bead - Single Box type Stamped Manners (Maker) (also inside stamped GN, & W, M. Nicol also F W. probably owners of item over the years.)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Richard Routledge, Mid 19th to early 20th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a little known maker, this item would have been made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. At a time when to produce a decorative moulding for a piece of furniture, door trims etc. had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Moulding plane round type Marked Routledge 64 Bull Street also stamped (JAS Burden owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Complex Moulding Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool made by an unknown maker, this item was made commercially for firms and individuals who worked in wood and needed a tool that could produce a ornamental finish to timber. These profiled planes came in various shapes and sizes to achieve a decorative finish. Although the item is marked J Dixon no reference can be found at this time for a maker of complex moulding planes J Dixon of London. The plane could have been made by an unknown maker and sold through a merchandising agent of which there was one in London at the time. It is this agent J Dixon that could have stamped his mark on the item and then sold the plane on giving the impression J Dixon was the maker, this practice was quite common in the 18th & 19th centuries. This item is still regarded as a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Panel Plough Plane white wood, blade missing. Stamped "J Dixon London" also has the letter "B" stamped flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood working, cabinet making, complex moulding plane, j dixon london, mouldings -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding plane, G Davis, 1821-1876

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about George Davis is he and his successors made planes in Birmingham, England, from about 1821 to 1876. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals who worked in wood and needed a tool that could produce a ornamental finish to timber. These profiled planes came in various shapes and sizes to achieve a decorative finish. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Moulding plane centre bead, also called Single Bead Reeding Plane. Stamped maker G Davis Has GM inside W (owner) flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane, moulding, single bead reeding plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, William Bishop, 1818

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about William Bishop is that he made planes in Grey Coat St Westminster, London, around 1818. He is listed in business directories of the time but nothing before or after this date. There are many of his decorative moulding planes of all sizes and designs for sale and given that his moulding planes are vintage his wood planes are well sought after by collectors today. A vintage tool made by a little known maker, this item was made for cabinet makers and individuals who worked in wood and needed a tool that could produce a ornamental finish to timber. These profiled planes came in various shapes and sizes to achieve the required decorative finish. This item is a significant tool from the late 18th to early 19th century that today is quite rare and sought after by collectors of vintage tools. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Plane Moulding Hollow type Marked Burden (Owner) also stamped JB and Iflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Supreme Court of Victoria Library

Supreme Court of Victoria LibraryBrass Gasalier Pillar, 1888

The Government Gazette of September 28, 1888 advertises the acceptance of a contract of 276 pounds for the purchase of a "Pillar gasalier for Library, New Law Courts". The area under the dome was obviously found to be poorly illuminated and the purchase of the pillar light was approved. A table for the library had been approved in January and these two pieces of furniture were to complement each other.The gasalier pillar is of state significance as a unique survivor of gas light illumination. It is an important part of the interior decoration of the library, contributing to its intact 19th century furnishings.The gasalier has a blackwood base, with an elaborate serpentine brass fit out for the lighting with etched glass shades. The gasalier is topped by a small figure of an emu, on the lower finials are kangaroos. While originally designed for gas the gasalier was converted to electricy in the early 20th century. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Chair, 1900-1914

Bentwood furniture is a type of furniture made by bending wooden rods into the required shape after they have been heated with steam. Mundus bentwood chairs are among the most successful examples of early mass-produced furniture. The inventor of manufacturing chairs using this method was Gebrüder Thonet. The subject item was made at Josef Jaworek small factory that produced bentwood chairs and was the only Polish member associated with the Mundus furniture company of Vienna. This company was founded in 1907 and Mundus went on to merge with J & J Kohn in August of 1914. Mundus furniture was a significant manufacturing company, active in several places in the Austro Hungarian Empire, at the end of the 19th century and early 20th century. Factories seem to have existed in multiple locations including Poland. Their products carry diverse labels, such as "Budapest", "Borlova", "Czechoslovakia", etc, some of the furniture was co-signed with "Jacob and Josef Kohn". Mundus also merged with Gebrüder Thonet in 1922 the inventor of the bentwood chair.The subject item is believed to be associated with the original Warrnambool Town Hall and would have been part of the buildings furnishings. The town Hall played a significant role in both local government and social events of local and district areas. It was not only a place for Council meetings but community events and social events. The item is significant as it is an early example of mass-produced manufactured furniture from a company in Austria that pioneered this type of furniture around the turn of the late 19th and early 20th centuries. This item is now regarded as a collector's piece giving it additional significance and interest.Bentwood chair (2 of 4), painted black, inner back is curled loop. Seat has leather cover, attached with studs. Ventilation holes under seat in star pattern. Splayed legs with bracing ring. Marks: pressed into some legs, under seat, paper label on rim under seat says the chair is made in Austrla.Marks: "3" is pressed into some legs, chalk letters under seat "RS", makers label, cream with dark print; on either side are 2 coins, top left coin has bust of a man, top right has an emblem with 1885 under it. Text of label "MOBEL-FABRIKEN / von / JOSEF JAWOREK / Teschen, osterr, Schlesien"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, bentwood chair, café chair, restaurant chair, josef jaworek, austrian chairs, furniture, gebrüder thonet -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Chair, early 29th century

The Bentwood chair has been called ‘the world’s most popular chair’. The original Bentwood chair, was designed by German-Austrian cabinet maker and Master Joiner, Michael Thonet (b.1796 - d.1871) and introduced to the market in 1859. Thonet started his business in his home town of Boppard as an independent cabinet maker in 1819. In the 1830’s he began trying to make furniture from glued (laminated) and bent wooden slats. Over the next few years his attempts to patent this process failed in Germany, Great Britain, France, and Russia. He then began using lightweight, strong wood and bending it into elegant, comfortable furniture. The Bentwood technology took Thonet years to perfect. In simple terms, the wooden rods or lengths were wet by soaking or steaming, bent into shape and then held in place until they hardened into the moulded curved shape or pattern. The wood usually chosen for the bentwood chairs was maple or beech. Thonet had revolutionised an older process by industrialising the process. The dowels of wood were cut and prepared as components of furniture, treated by the ‘bentwood’ process, then ready immediately for assembling with very little extra workmanship needed. Thonet held 2 patents for this process, the second one ended on 10th July 1869 and was non-renewable. At the Trade Fair at Koblenz of 1841 Prince Klemens Wenzel von Mettemich was very impressed with Thonet’s furniture, especially the chairs. In 1842 Thonet sold his Boppard business and emigrated to Vienna, and began working, along with his sons, on the interior decoration of the Palais Leichtenstein, for the Carl Leistler establishment. In 1849 he began his own business again, the Gebruder Thonet to include his sons (translated “Brothers Thonet”). He produced the “No. 1” Bentwood chair. He received a bronze medal for his Vienna bentwood chairs at the World Fair in London in 1851, and a silver medal in Paris in 1855. In 1856 he opened a new factory in Koritchan (Moravia), where there were extensive woods of beech trees available for his enterprise. In the next years, five more Eastern European production sites were established in Bystritz (1862), Nagy-Ugrócz (1866), Wsetin (1867), Hallenkau(1867) and Nowo-Radomsk(1880). Thonet’s 1859 No. 14 “chair of chairs” (or “Konsumstuhl Nr. 14” – coffee shop chair no. 14) was the most famous of all of Thonet’s Bentwood chairs. In 1867 he received a gold medal at the Paris World Fair. This new style of furniture making became very popular. Up until 1830 50 million of these chairs had been produced. By the 1870’s Thonet owned offices in almost 20 countries, with sales locations across Europe, in Chicago and New York. In 1889 he set Thonet set up a head office in Frankenberg, Hesse. Bentwood models designed in the mid to late 19th century featured hand-caned or laminated wood seats and were usually stamped with the country of origin. The Bentwood elements were the backrest, seat rim and legs. Typically the seat was covered with ‘bucket’ leather. After the Patent ran out in 1869, companies such as Jacob & Josef Kohn began the production of bentwood furniture.The popularity of the Bentwood chair that was introduced by Michael Thonet in the 1850s is due to its versatility and timeless quality. Its style, whether varnished or painted, suits any room in the house. The lightweight chairs are also popular for café and restaurant seating, as well as for public gatherings. They can be easily moved around and grouped in a variety of ways to suit any occasion.Chair, bentwood, pair of two. Backrest has full length inverted U inside frame. Support rail and wire reinforcing between legs. 3692.01 seat has floral pattern pressed into wood 3692.02 seat is plain (replacement seat). Made by Harnison & Co.3692.01 chair's marks; Label ""HARNISON & CO./ NEUSOL / BUDAPEST" and "WIENER NOBEL" and "(symbol) N inside circle, under Crown" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, domestic furniture, dining furniture, bentwood chair, harnison & co., neusol, budapest, wiener nobel -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Document - Benjamin C Jewell Probate 1890, 1890

This 1890 document contains the will and probate papers of Benjamin Charles Jewell who died in 1889. English-born Benjamin Jewell was a Warrnambool stonemason who was the licensee of the Steam Packet Hotel (later Lady Bay Hotel) from 1883 to 1889. His executors were Christopher Beattie, a Warrnambool undertaker and James Tallent, manager of the Warrnambool Corporation Yards. Benjamin Jewell left his estate of property, household furniture and cattle to his wife, Ellen Jewell. The solicitor, Ernest Chambers, had his office in Kepler Street with Thomas Goodall, a legal clerk, managing this office. Tait collection: item 9 of 62This document is of interest because of its contents - the will and probate of Benjamin Jewell, a Warrnambool businessman of note in the 19th century - and because of its lawyer, Ernest Chambers, also well-known in Warrnambool at that time. This is a piece of parchment folded in two with a seal of the Supreme Court of the Colony of Victoria attached by a blue ribbon. The writing in handwritten in brown ink. One page is blank. There is some pencil writing at the top left hand corner. Apart from some discolouration the document is in good condition.‘13/9 E.J.W. Chambers, 7241’benjamin jewell, ernest chambers -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Book, Swintons Stock book 1869, 1860s

This ledger is a Warrnambool Swintons Store stock book and contains the sales of stock from September 1869 to an unknown date (perhaps to the end of 1870) and entries for 1871, 1872 and 1873, 1889, the 1890s and some dates early in the 20th century. William and Ann Swinton migrated to Australia in 1854 and for a decade William Swinton worked as a builder and carpenter in the Warrnambool area, erecting many buildings, including the Wangoom Presbyterian Church. In 1865 he opened a store in Timor Street, Warrnambool selling groceries, glassware and china. In 1888 the business was known as William Swinton and Sons. Branch shops were opened in Cudgee, Nullawarre, Wangoom, South Warrnambool and West Warrnambool. When William died his son Robert became the first managing director of Swintons Pty Ltd. In 1934 the business split in two with George Swinton and Sons selling furnishings, clothing and glassware and Swintons Pty Ltd selling seeds, hardware and produce. Today the Swinton family still operates a furniture and bedding store in Timor Street. This ledger is very important as an early memento of the Swinton Stores in Warrnambool. It gives details of sales in the 19th century and has material relating to the assets of the founder of the business, William Swinton at the time of his death. It is of great interest to researchers. The current family business in Timor Street Warrnambool is the oldest family business in Warrnambool and, with the Swinton name associated with businesses in Timor Street for 152 years, is among the oldest family businesses in Australia. This is a dark green hard cover ledger with light brown leather bindings on the spine and cover edges. There is gold lettering on the spine. The cover is stained and the leather is torn and partly detached in places. The insides of the cover have a blue and white mottled patterning. The pages are blue with printed red lines. The entries are handwritten in black ink. There are four loose pages and two pieces of a plant dried and preserved between two pages. ‘Day Book’ ‘Stock Book Warrnambool September 2nd 1869’ swinton family, warrnambool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Bentwood Chair, Mundas Furniture Manufactures, 1907 to 1920

Bentwood furniture is a type of furniture made by bending wooden rods into the required shape after they have been heated with steam. Mundus bentwood chairs are among the most successful examples of early mass-produced furniture. Mundus furniture was a manufacturing company, active in several places in the Austro Hungarian Empire, at the end of the 19th century and early 20th century. Factories seem to have existed in multiple locations, as the products carry diverse labels, such as "Budapest", "Borlova", "Czechoslovakia", etc. Some of the furniture was co-signed with "Jacob and Josef Kohn". In 1914 Mundus merged with J. & J. Kohn, and in 1922 with Gebrüder Thonet the inventor of the bentwood chair.The item is significant as it is an early example of mass-produced manufactured furniture from a company in Austria that pioneered this type of furniture around the turn of the 19th century. The item is now a collector's piece giving it additional significance.Bentwood ChairMundus Vienna Austriashipwreck coast, flagstaff maritime museum, flagstaff hill village, bentwood chairs, mundus furniture company, furniture, manufactured furniture, vienna austria -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Complex Moulding Plane, Joseph Gleave & Sons, Late 19th to Early 20th Century

Joseph Gleave & Sons was working as a plane maker in Manchester from 1832 and was at Oldham Street from 1854 to 1868 and (as Joseph Gleave & Son) from 1868 to 1913. The company made complex wood planes of which the subject item is an early example. The company sold tools from other makers as well and was based in Oldham Street Manchester. Since that time the company has adapted and mutated and is still buying and selling tools and industrial supplies to this day. However the company stopped making complex wood planes in 1926. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce an ornamental finish to timber. The tool was used before routers and spindle moulders came into general use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims, etc. or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish.A significant tool from the late 19th to early 20th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves handmade shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any decorative timber item.Complex Moulding Plane, Torus Bead. Stamped J. Gleave (Maker), No 7 & T. Moody (owner)flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, josphe, joseph gleave & sons, complex plane makers, carpenders tools, woodworking tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, 1819-1901

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The Holtzapffel dynasty of tool and lathe makers was founded in Long Acre, London by a Strasbourg-born turner, Jean-Jacques Holtzapffel, in 1794. The firm specialized in lathes for ornamental turning but also made a name for its high-quality edge and boring tools. Moving to London from Alsace in 1792, Jean-Jacques worked initially in the workshop of the scientific-instrument maker Jesse Ramsden, Anglicizing his name to John Jacob Holtzapffel. In 1794 he set up a tool-making partnership in Long Acre with Francis Rousset and they began trading under the name of John Holtzapffel. From 1804 he was in partnership with the Mannheim-born Johann Georg Deyerlein until the latter died in 1826, trading under the name Holtzapffel & Deyerlein. Holtzapffel sold his first lathe in June 1795, for £25-4s-10d, an enormous price at the time. All of Holtzapffel's lathes were numbered and by the time he died in 1835, about 1,600 had been sold. The business was located at 64 Charing Cross, London from 1819 until 1901 when the site was required "for building purposes". The firm then moved to 13 and 14 New Bond Street and was in premises in the Haymarket from 1907 to 1930. John's son, Charles Holtzapffel (1806–1847) joined the firm in 1827, at around which time the firm became known as Holtzapffel & Co. Charles continued to run the business after his father's death. He wrote a 2,750-page treatise entitled Turning and Mechanical Manipulation, published in 1843 which came to be regarded as the bible of ornamental turning. The final two volumes were completed and published after his death by his son, John Jacob Holtzapffel (1836–1897). When Charles Holtzapffel died in 1847 his wife Amelia ran the business until 1853. John Jacob II, the son of Charles and Amelia, was head of the firm from 1867 until 1896. A nephew of John Jacob II, George William Budd (1857–1924) became head of the firm in 1896. His son John George Holtzapffel Budd (1888–1968) later ran the business. By the early twentieth century, ornamental turning was going out of fashion, and the firm sold its last lathe in 1928. A vintage tool made by a well-known firm made for firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane Holtzaffel 64 Charing & Owner J Heath 9/16" marked opposite endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, plane, j heath -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . J Moseley. maker and R Knight & J Heath also stamped stamped (Owners)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, 1832-1864 made in London

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about J Budd is that he was a tool maker and retailer that operated a business in London between 1832 to 1864. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the early to mid 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane J Budd London & No 4 opposite end Stamped J Heath (owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, j budd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, 1832-1864 made in London

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about J Budd is that he was a tool maker and retailer that operated a business in London between 1832 to 1864. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the early to mid 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane J Budd London maker & No 6, opposite end Stamped J Heath (owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, j budd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, 1832-1864 made in London

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about J Budd is that he was a tool maker and retailer that operated a business in London between 1832 to 1864. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the early to mid 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane J Budd London & No 12 at opposite end, stamped J Heath (owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, j budd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, 1832-1864 made in London

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about J Budd is that he was a tool maker and retailer that operated a business in London between 1832 to 1864. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the early to mid 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane J Budd London & No 10 opposite end, Stamped J Heath (owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, j budd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, 1832-1864 made in London

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about J Budd is that he was a tool maker and retailer that operated a business in London between 1832 to 1864. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the early to mid 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane J Budd London & No 14 opposite end Stamped J Heath (owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, j budd