Showing 146 items

matching engine boiler

-

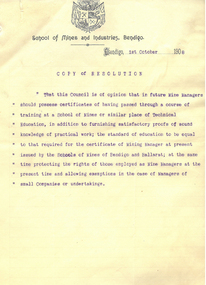

Federation University Historical Collection

Federation University Historical CollectionLetter, Ballarat School of Mines, 1908, 1908

... & Chalmers Ltd, Manufacturersw of mining machinery, steam engines... & Chalmers Ltd, Manufacturersw of mining machinery, steam engines ...October inwards correspondence for the Ballarat School of Mines. * School of Mines and Industries, Bendigo (certification of Mine Managers) * Telegram - examination papers * Commonwealth telegram - Ballarat School of Mines battery availability for crushing ten tons. * Letterhead from the Roneo Co., Melbourne * J. Donald of Wallace St, Toorak * Letterhead from York Chambers, 49 Queen Street, Melbourne - signed J. Kaufmann * Letterhead from Cochran & Co - re Cocnran boilers * Letterhead of Thames School of Mines, New Zealand * Letter re James Chambers missing school from his father James Chambers Snr of Talbot * Education Department Circular * letter signed by F.W. Calaby * F.W. Silberberg & Co re crucibles * Letterhead of New Black Horse Mining Company - signed E. Howell * Australasian Institute of Mining Engineers, 57-59 Swanston Street, Melbourne - signed D.L. Stirling * Letterhead of John F. Paterson * Letterhead of the Welcome Stranger Dredging Company, Dunolly - W.J. Parker manager * Letterhead of Nevett and Nevett Barristers and Solicitors, Lydiard Street, Ballaarat * John Barker, H. Barbour * Telegram re Brearley Lyndhurst * Letterhead of the Commonwealth Minerals Co - John F. Paterson, Legal Manager * Query re courses at the Ballarat School of Mines - A. O'Mara * Stone to be crushed, Egerton from J.H. Davidson * Letterhead from 'Terascoa' Port Kembla signed by W.S. Macartney * Letter from Thomas Williams * Letterhead from Australian Institute of Mining Engineers regarding excursion to Toongabbie and Walhalla - Signed D.L. Stirling * Assay from George Brearley of Lyndhurst via Scottsdale * Letterhead of Berry United Deep Leads Limited, Ulina * Embossed leather classes for coachwork from S. Mee of Clunes * The Lord Nelson North Gold Mning Company No Liability signed by Edward H. Shackell * Correspondence from May Consolidated Gold Mining Company, Transvaal signed by Jason Hawthorne * Letterhead of the Northern Assurance Company, 448 Collins St, Melbourne * Letter fom James Lidgett of "Braelands" Myrniong * Gordon sides asking for a reference * Letterhead of Fraser & Chalmers Ltd, Manufacturersw of mining machinery, steam engines, boilers and machinery for systematic milling, smelting and concentration of ores, signed by W.R. Caithness * Letterhead of the Board of Examiners for Engine-Drivers, signed by R. Birrell * Letter concerning outstanding amount due to theBallarat East School of Design, signed by Edward Reid, Manager * Letterhead of the Ballarat Public Library concerning an outstanding amount in the School of Design Account. * Letterhead of the A. Gallenkamp and Co. regarding their new catalogue * Letterhead from the Creswick Advertiser, Albert Street, Creswick * Handwritten letter from John Brittain inviting Ballarat School of Mines students to join him at the telescope weather permitting * Letterhead of Victorian Railways, signed by E.B. Jones * Letterhead of the Ballarat East Town Clerk's Office * Letterhead of Elliott, Maclean and Co. Handwritten letter re Dressmaking from J.H. Wrightrand, south africa, kalgoorlie, school of mines and industries, bendigo, certification of mine managers, bendigo school of mines, telegram, ballarat school of mines battery, roneo co., melbourne, j. donald, york chambers, cochran & co, thames school of mines, new zealand, james chamberseducation department circular, f.w. calaby, * f.w. silberberg & co, crucibles, new black horse mining company, e. howell, * australasian institute of mining engineers, john f. paterson, welcome stranger dredging company, dunolly, w.j. parker, nevett and nevett, john barker, h. barbour, brearley lyndhurst, commonwealth minerals co, a. o'mara, j.h. davidson, 'terascoa' port kembla, w.s. macartney, thomas williams, australasian institute of mining engineers, excursion, toongabbie, walhalla, d.l. stirling, george brearley, lyndhurst via scottsdale, berry united deep leads limited, ulina, embossed leather classes for coachwork, s. mee, clunes, the lord nelson north gold mning company no liability, edward h. shackell, may consolidated gold mining company, transvaal, jason hawthorne, northern assurance company, james lidgett, "braelands" myrniong, gordon sides, fraser & chalmers ltd, mining machinery, w.r. caithness, examiners, ballarat east school of design, edward reid, ballarat public library, school of design, a. gallenkamp and co., creswick advertiser, john brittain, telescope, victorian railways, e.b. jones, ballarat east town clerk's office, elliott, maclean and co., dressmaking, j.h. wright, ausimm, berry united, school of mines and industries bendigo, lyndhurst tasmania, may consolidated gold co germiston transvaal, transvaal, germiston, roneo, thames school of mines, schools of mines, welcome stranger dredging co, cowley copper development syndicate ltd, department of mines, maryborough school, pharmacy board of victoria, tongalla survey camp, ballarat fine art gallery association, central microscopical -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - COSTERFIELD SMELTING AND REFINING CO WORKS

... - 4 Diesel Engines, Jaques Crusher, 2 Boilers, Chilian Mill..., 2 Boilers, Chilian Mill, Huntington Mill, 2 Steam Engines ...Three Auction catalogues with greenish covers for a sale on 3rd July, 1941 at the Costerfield Smelting and Refining Co. Works, Costerfield of Machinery, Plant & Equipment comprising - 4 Diesel Engines, Jaques Crusher, 2 Boilers, Chilian Mill, Huntington Mill, 2 Steam Engines, Blast and other Furnaces, Exhaust Fan, Lighting Plant, Cyanide Plant, Pumps, Buildings, Piping, Tools, etc. One copy has 'Marked Catalogue' written across the top of the front cover. Some of the lots have the price written beside them, some have a note and some prices are written on the right side of the page. Signed at the end - J. H. Curnow & Son 21/7/41. J. H. Curnow & Son were the auctioneers and the Cambridge Press were the printers of the catalogue.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - costerfield smelting and refining co works, j h curnow & son, j l jamieson, the cambridge press -

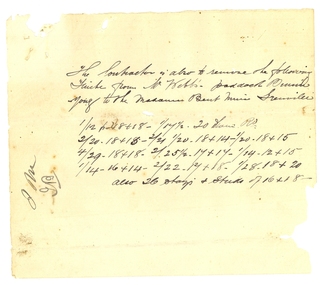

Federation University Historical Collection

Federation University Historical CollectionDocument, Contract for the Madame Bent Gold Mining Company, 1886, 1886

... 2 Engines 2 boilers pumping gear, Bob, Poppett heads... 2 Engines 2 boilers pumping gear, Bob, Poppett heads ...Handwritten on foolscap paper, with red seal on last page.1) The Subcontractor is also to remove the following [ ? ] from Mr Webb's paddock ... to the Madame Bent Mine Grenville ... .2) Specification for the taking doan, removal and reerection 2 Engines 2 boilers pumping gear, Bob, Poppett heads and Capstone etc, for teh Mdame Bent G.M.Cy Grenville. The company will provide ... .3) Morey's Coys yard, together with holding down bolts, and the following ... .4) to the extent of Bed ... Carpentry Work - To carefully take down the poppet heads and co... and erect the same on the claim complete ... .5) Engine Framing as shown for the winding engines and pumping engines. Properly fitted to get ... .6) The boilers to be fed in front. The contractor to cut and drill all necessary holes in the boilers and pipes - to fire blow ... The contractor to make good any damage or breakage or loss to machinery or any part hereof that may occur to it during the removal of the reerection of same. The loss or damage, if any, not being made good by the contractor, or in the event of the works not being proceeded with to the satisfaction of the Company;s Engineer, The company's Engineer hereby ... .7) of the whole of the works, and in default thereof the COntractor shall forfeit the sum of two pounds ... Signed James Malcolm Witness L. Menz The Common seal of the company was affixed this thirteenth day of December:/86 by its manager James Burrell in the presence of [illegible] managers Seal - Madame Bent Gold Mining Company Durham Lead Buninyongmadame bent gold mining company, richard squire, james malcolm, james burrell -

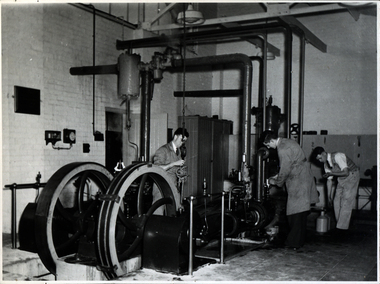

Federation University Historical Collection

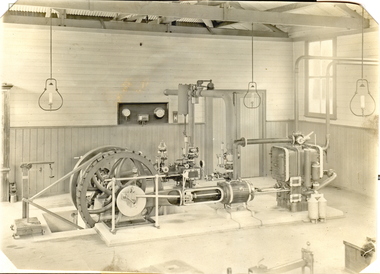

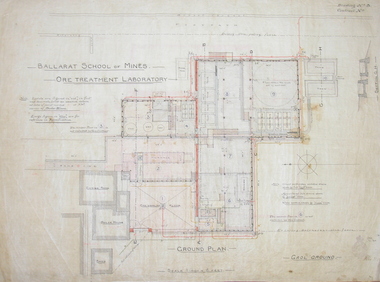

Federation University Historical CollectionPhotograph - Black and white photograph, Ballarat School of Mines Model Steam Engine

... , including the experimental steam engine and boiler. The experimental..., including the experimental steam engine and boiler. The experimental ...The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.Black and white photograph of the Davey Paxman Experimental Steam Engine. On the brake is returned serviceman Norman WIlliam Ludbrook (Diploma Electrical Engineering, 1952). Far right is Roy E. Mawby (Diploma Electrical Engineering, 1950)steam engine, model steam engine, davey paxman, electrical engineering, laboratory, scientific instrument, norman ludbrook, norman william ludbrook, roay mawby, roy e. mawby -

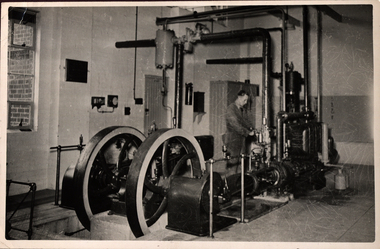

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph - Black and white, Ballarat School of Mines Model Steam Engine

... , including the experimental steam engine and boiler. The experimental..., including the experimental steam engine and boiler. The experimental ...The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.Black and white photograph of the Davey Paxman Experimental Steam Engine installed at the Ballarat School of MInes. steam engine, model steam engine, davey paxman, thomas bath, experimental steam engine -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Ballarat School of Mines Davey Paxman Experimental Steam Engine, c1902

... , including the experimental steam engine and boiler. The experimental..., including the experimental steam engine and boiler. The experimental ...The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only. Black and white photograph of an experimental steam engine which was produced for the Ballarat School of Mines. It was designed for experimental purposes, such as testing of efficiency, etc. The laboratory which housed the steam engine was lit with gas lighting. davey paxman experimental steam engine, model steam engine, davey paxman, steam, thomas bath, thermodynamics -

Federation University Historical Collection

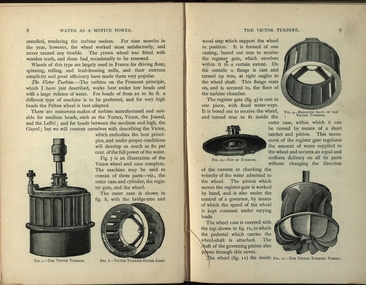

Federation University Historical CollectionBook, Machinery for Metalliferous Mines, 1894, 1894

... engines and ventilating machinery, Steam boilers/engines and oil... ventilation oil engine california america water steam boilers steam ...The 1st edition of this famous work, giving an excellent account of the machinery used in late 19th century metal mining in the UK and overseas is very rare. It covers a wide range of equipment - pumps, steam engines, drills, winding engines, stamps & concentration mills, aerial ropeways, tramways and early uses of electricity etc. Brown hard cloth covered book. xvi 564 pages with additional advertisements, with over 300 illustrations and drawings, some fold out. Chapters include Water as a motive power, Wind engines and ventilating machinery, Steam boilers/engines and oil engines, hoisting machinery, draining of Mines, pumping engines, rock drilling machinery, boring machinery, concentration machinery, sizing and classifications trommels, joggers and jigging, fine concentration, milling of gold ores, milling of silver ores, amalgamation plates and machinery, dry and roasting machinery, chlorination and cyandide processes for the extraction of gold, electricity as a motive power for mining, electric lighting and blasting, aerial wire ropeways, transport by rail and road. There a a number of lovely line illustrations in the book including: Poncelot's undershot waterwheel; Fromont furnace;Victor turbine; Pelton waterwheel; Root's positive blower;Cross section and front elevation of Lancashire boiler; Robey's Compound Mill Engine; Portable Winding Plant; Iron Pit Head Gear ; Loading Arrangement in an Incline Shaft; kibble; Worthington Pump; California Pump; Scram's Air Compressor; Rock drill Bits; Special Sharpening tools; Boring tools;Rotating Picking table; Ore Feeder; roller crusher; stamp battery; round buddle; slime table; vanner; amalgamating plant; belt elevator;roasting furnace;splicing wire rope; capel; tipping waggon;mining, cornish pump, linkenbach table, water wheel, ventilation, oil engine, california, america, water, steam boilers, steam engines, oil engines, pumpimg, rock drilling, boring, jiggers, milling, silver, gold, drying and roasting, chlorination, cyaniding, lead, zinc, copper, electricity, electric lighting, wire ropes, transport, wind engine, poppet head -

Bendigo Historical Society Inc.

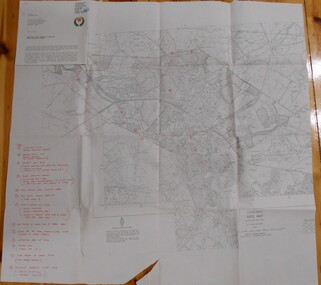

Bendigo Historical Society Inc.Map - BENDIGO HISTORICAL SOCIETY COLLECTION: EAGLEHAWK MINE MAP

... present B. Johnson's No. 2 Mine, engine mountings, old boiler..., engine mountings present B. Johnson's No. 2 Mine, engine ...Base map Australian map grid of Eaglehawk area. Map has letter attached from the Department of Conservation, Forests and Lands, 22 March, 1990, addressed to Felicity Kingerlie, BHS, requesting information regarding the historic mining sites marked on the map. Sites marked are: A. Golden Age Mine, engine mountings present B. Johnson's No. 2 Mine, engine mountings, old boiler foundations C. Johnson's No. 1 Mine, mullock retaining wall made from sandstone, engine mountings, remains of old building demolished? D. Toma's Eucalyptus Factory, old boiler still there, boiler shed, chimney (remnants of) outlet drain, distilling vats, dam, remnant of winch. E. New Argus Mine,mullock heap F. New Moon Mines Dams (1) stone walls G. North Lightning Hill Mine, engine mountings, quartz retainer wall, Pascoe and Simmons open cuts and other open cuts here too H. New Prince of Wales Mine and Poppet Head I. Quarry site for stone, excavation (for miners cottages in Clarke Street) J. Lancashire open cut mine K. Virginia Hill (cynaide vats etc) L. South Prince of Wales mine, now capped and fenced M (possibly ) Catherine United Mine, engine mountings, battery mountings?bendigo, mining, eaglehawk mines -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Barometer, 1867

... engines and boilers. The foundry prospered despite high wages... engines and boilers. The foundry prospered despite high wages ...Langlands Company History: Langlands foundry was Melbourne's first foundry and iron shipbuilder established in 1842, only 8 years after the founding of the Victorian colony by two Scottish immigrants, Robert Langlands and Thomas Fulton, who had formed a partnership before emigrating (1813–1859). The business was known as the 'Langlands Foundry Co'. Henry Langlands (1794-1863), left Scotland in 1846 with his wife Christian, née Thoms, and five surviving children to join his brother Robert. By the time he arrived in early January of 1847 the partnership of Robert Langlands and Fulton had dissolved as Fulton had gone off to establish his own works. It was at this time that the two brothers took over ownership of Langlands foundry. Several years later Robert retired and Henry became sole the proprietor. The foundry was originally located on Flinders Lane between King and Spencer streets. Their sole machine tool, when they commenced as a business, was a small slide rest lathe turned by foot. In about 1865 they moved to the south side of the Yarra River, to the Yarra bank near the Spencer Street Bridge and then in about 1886 they moved to Grant Street, South Melbourne. The works employed as many as 350 workers manufacturing a wide range of marine, mining, civil engineering, railway and general manufacturing components including engines and boilers. The foundry prospered despite high wages and the lack of raw materials. It became known for high-quality products that competed successfully with any imported articles. By the time Henry retired, the foundry was one of the largest employers in Victoria and was responsible for casting the first bell and lamp-posts in the colony. The business was carried on by his sons after Henry's death. The company was responsible for fabricating the boiler for the first railway locomotive to operate in Australia, built-in 1854 by Robertson, Martin & Smith for the Melbourne and Hobson's Bay Railway Company. Also in the 1860s, they commenced manufacture of cast iron pipes for the Board of Works, which was then laying the first reticulated water supply system in Melbourne. Langlands was well known for its gold mining equipment, being the first company in Victoria to take up the manufacture of mining machinery, and it played an important role in equipping Victoria's and Australia's first mineral boom in the 1850s and 1860s. Langlands Foundry was an incubator for several engineers including Herbert Austin (1866–1941) who worked as a fitter at Langlands and went on to work on the Wolesely Shearing machine. He also founded the Austin Motor Company in 1905. Around the 1890s Langlands Foundry Co. declined and was bought up by the Austral Otis Co. in about 1893. History for Grimoldi: John Baptist Grimoldi was born in London UK. His Father was Domeneck Grimoldi, who was born in Amsterdam with an Italian Father and Dutch mother. Domeneck was also a scientific instrument maker. John B Grimoldi had served his apprenticeship to his older brother Henry Grimoldi in Brooke Street, Holburn, London and had emigrated from England to Australia to start his own meteorological and scientific instrument makers business at 81 Queens St Melbourne. He operated his business in 1862 until 1883 when it was brought by William Samuel and Charles Frederick, also well known scientific instrument makers who had emigrated to Melbourne in 1875. John Grimoldi became successful and made a number of high quality measuring instruments for the Meteorological Observatory in Melbourne. The barometer was installed at Warrnambool's old jetty and then the Breakwater as part of the Victorian Government's insistence that barometers be placed at all major Victorian ports. This coastal barometer is representative of barometers that were installed through this government scheme that began in 1866. The collecting of meteorological data was an important aspect of the Melbourne Observatory's work from its inception. Just as astronomy had an important practical role to play in navigation, timekeeping and surveying, so the meteorological service provided up to date weather information and forecasts that were essential for shipping and agriculture. As a result, instruments made by the early instrument makers of Australia was of significant importance to the development and safe trading of companies operating during the Victorian colonies early days. The provenance of this artefact is well documented and demonstrates, in particular, the importance of the barometer to the local fishermen and mariners of Warrnambool. This barometer is historically significant for its association with Langlands’ Foundry which pioneered technology in the developing colony by establishing the first ironworks in Melbourne founded in 1842. Also, it is significant for its connection to John B Grimoldi who made the barometer and thermometer housed in the cast iron case. Grimoldi, a successful meteorological and scientific instrument maker, arrived in the colony from England and established his business in 1862 becoming an instrument maker to the Melbourne Observatory. Additional significance is its completeness and for its rarity, as it is believed to be one of only two extant barometers of this type and in 1986 it was moved to Flagstaff Hill Maritime Village as part of its museum collection. Coast Barometer No. 8 is a tall, red painted cast iron pillar containing a vertical combined barometer and thermometer. Half way down in the cast iron framed glass door is a keyhole. Inside is a wooden case containing a mercury barometer at the top with a thermometer attached underneath, each with a separate glass window and a silver coloured metal backing plate. Just below the barometer, on the right-hand side, is a brass disc with a hole for a gauge key in the centre. The barometer has a silvered tin backing plate with a scale, in inches, of "27 to 31" on the right side and includes a Vernier with finer markings, which is set by turning the gauge key. The thermometer has a silvered tin backing plate with a scale on the left side of "30 to 140". Each of the scales has markings showing the units between the numbers.Inscription at the top front of the pillar reads "COAST BAROMETER" Inscribed on the bottom of the pillar is "No 8". and "LANGLANDS BROS & CO ENGINEERS MELBOURNE " The barometer backing plate is inscribed "COAST BAROMETER NO. 8, VICTORIA" and printed on the left of the scale, has "J GRIMOLDI" on the top and left of the scale, inscribed "Maker, MELBOURNE". There is an inscription on the bottom right-hand side of the thermometer scale, just above the 30 mark "FREEZING" Etched into the timber inside the case are the Roman numerals "VIII" (the number 8)flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, warrnambool breakwater, coast barometer, coastal barometer, barometer, weather warning, ports and harbours, fishery barometer, sea coast barometer, austral otis co, coast barometer no. 8, henry grimoldi, henry langlands, john baptist grimoldi, langlands foundry co, meteorological instrument maker, robert langlands, scientific instrument maker, thermometer, thomas fulton -

Federation University Historical Collection

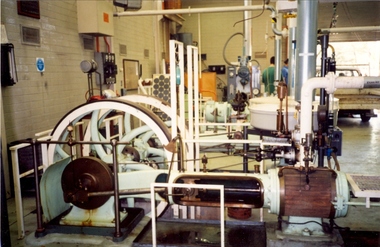

Federation University Historical CollectionPhotograph - Colour photograph, Davey Paxman Experimental Steam Engine in the Mount Helen Workshop, c1994

... , including the experimental steam engine and boiler. The experimental... the experimental steam engine and boiler. The experimental Davey-Paxman ...The Davey Paxman Experimental Steam Engine was purchased by the Ballarat School of Mines as the result of a bequest from Thomas Bath.The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.davey paxman experimental steam engine, model steam engine, steam, thermodynamics laboratory, thomas bath, bequest -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Boiler explosion at Ringwood station 20th June 1894 for engine 297R. "Heard in Box Hill"

... on the engine the boiler of which exploded on Saturday night... on the engine the boiler of which exploded on Saturday night ...Black and white photographs - 2 copiesTyped below photograph, "Boiler explosion at Ringwood station 20/6/1894. Heard in Box Hill". Article from newspapers:- Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 21 Official enquiry. The Board of Enquiry appointed by the Railway Commissioners to enquire into the causes of the boiler explosion which shattered the locomotive at Ringwood on Saturday night, assembled at the Railway department on Wednesday to commence its deliberations, The board consisted of Mr R. Fulton, engineer, C. W. McLean; engineer to the Marine Board, and Mr Mephan Ferguson, iron-founder. There is some difficulty at the outset about the constitution of the board; It was suggested that the Apt of Parliament contemplated that boards of experts, after the manner of the present one, needed, to have their appointments confirmed by the Governor-in-Council. The point, however, was not considered sufficiently important to prevent the board from proceeding with evidence. Robert Greyford, stationmaster at Ringwood, was the first witness. He said he saw the explosion on Saturday night at about twenty minutes to 8. There was a rush to the engine to see what had happened, and the driver and fireman were both found on the platform of the engine. The driver seemed badly hurt, but the fireman, to all appearances, was not so badly injured. They were both attended to and sent up to Melbourne by the last suburban train. Witness had a look at the engine and found the dome and all the plates round the boiler blown clean, away. The springs were also blown clean away. The Chairman (Mr Fulton) : Did you measure the distance ? Witness: Yes; one of the plates was 209 yards away. A piece from the top of the boiler 15 pounds in weight he found driven into the hard beaten track 410 yards away. Several pieces of boiler plate were found scattered at various distances. The buildings roundabout were injured. The Chairman; Did you notice anything peculiar about either of the driver or the fireman ? — No ; nothing wrong, with either of them. If the engine was blowing off at all, it must have been very light. In your opinion, were they perfectly sober ? — Perfectly. In approaching the station, is there a down or an up grade? — A very slight down grade. How is the road from Healesville ? — Up and down all the way. It is down, grade for about 200 yards coming into Ringwood station. They shut off ; steam about a quarter of a mile away, and come in at a good pace. They generally put on 15 pounds of steam while they are in the station. Mr Ferguson : Had the driver the usual load on ? — Yes ; about the usual load. Witness added that he had known the driver personally for about 10 years, and he had always been a careful, steady, sober man. He did not know the fireman so well. John Palmer, porter at Ringwood station, also saw the explosion. He was attending to the train on its arrival. He was knocked down by the force of the explosion. When he got up he saw the engine driver being carried into the office covered in blood. He noticed nothing peculiar about the driver and fireman, nor about the engine. Mr McLean : How far were you from the engine when you were knocked down ? — From ten to fifteen yards. William Paul, the guard of the train to which the injured locomotive Was attached, said he was looking at the engine at the very moment the explosion occurred. It seemed to come from exactly under the dome. The force of it took him off his feet. He was about 15 yards from the tender. When he rose he tried to reach the engine, but could not do so on account of the steam and coal dust. He called out to know whether any of the passengers were injured, and got no response, so that he concluded they were all right. All the lamps but about half dozen were extinguished by the force of the explosion, although the glass was not broken. He could testify most distinctly that the driver and fireman were both sober. The driver was a man who never drank. The steam started to blow off about a minute and a half before the explosion took place. The last place at which the engine took water was Healesville. The Chairman : Do yon know anything of the quality of the water there ? Is it creek water ? — Yes ; it comes from the Graceburn River. You never heard of its quality ?— No. How long have you known this engine on the road— About 13 months. Hew long have you known the driver on this line ? — About six weeks. I have known the fireman several years. The driver was a strict teetotaller, and I never saw the fireman take anything to drink in his life. Mr T. H, Woodroffe, chief mechanical engineer of the Victorian Railways, produced a report he had written to the secretary, about this explosion. The document gave facts concerning the engine and the explosion. It stated that the rapture seemed to have occurred at the rim of the plates adjoining the fire box. The engine was built at the Phoenix Foundry, Ballarat, in 1883. It was repaired at various times, the last time being in July of last year when it was sent to the Port Melbourne shops, and was then tested to a cold water pressure of 195 and found all right. It was the custom to overhaul all locomotives about every five years. The Chairman : There were no very heavy repairs in July, 1893; were there? — Not to the boilers. The shop manager's report says that the plug and safety tap holes were repaired, five new copper studs put in firebox, ash-pan door repaired, tender cleaned and overhauled, and studs re-rivetted, and boiler tested to pressure of 195, cold water. Mr Woodroffe read the report of the repairs effected to the boiler in December, 1888. That would be the time the plate was put in the boiler. On that occasion three new plates were put in the bottom and the boiler tested up to 195. The Chairman: Do you keep a record of the water used ?— Yes, the water in this case, I think, came from the Maroondah scheme. Mr Woodroffe said boilers were examined front time to time in the running sheds. In his opinion every possible care had been taken to keep the engine in proper care. There might, however, be lessons learnt from this. The Chairman: No doubt. From his examination of the plates [the] witness did not think the state of them could have been detected from the outside. There were no signs of leakage or sweating or anything of that sort. The next witness- was Walter Stinton, workshop manager at Newport and he said that the injured engine had been repeatedly repaired under his charge. He gave a technical account of the repairs effected on various occasions. The testing of locomotives was under his special notice. They had a high pressure pipe running; round the works, and a pump set at 2001b. When the boiler was pumped full of water the pressure when applied up to 1951b. The board appointed by the department to inquire into the Ringwood locomotive boiler explosion sat again at Spencer street on 25th inst. Mr R. Fulton presided and the other members of the board were. Mr Mephan Ferguson and Mr C. W. McLean. Charles Grubb, foreman of the boiler-makers at the Newport workshops, said he had inspected the pieces of plate that had been blown out of the engine, and after examining them, pointed out to the Chief Mechanical Engineer the portion where the plate had started to burst. It was under the lap, on the right hand side of the boiler. The grooving might be accounted for by bad water. During the past twenty years he had examined all the boilers that came into the Williamstown workshops, and while some were hardly marked at all, others were very badly eaten away. The practice was to cut out the defective portions. In this case the boiler was repaired in a similar manner. The Chairman : Can you suggest any other way of repairing so as to prevent accident ? — No, unless by taking out a plate on one side from the joint, and carrying it further up so as to avoid the joints meeting, or by taking out the plate altogether. What would.be the cost .of putting in a new " plate I—Perhaps about double the price; but I wouldn't recommend that course. It would be putting a new plate against plates that have been in use ten years or so and that would not be advisable. I think the present system better. I consider the present system of repairing the best. This is the first we have had so bad like that, to my knowledge. You attributed this to bad water. Is there no other probable cause ? — Well; unless the iron be bad. This was Lowmoor iron. I think this accident was caused by the eating away of plates. This one was the worst I have seen, for the short time it had been running. We use three classes of iron — Lowmoor, Monkbridge and Bowling. By Mr Woodroffe (Chief Mechanical Engineer) ; There are engines still running that were repaired at the same time as this one, in 1888, and. in the same way. These are engines 339 and 333. They have been recently examined and are in splendid order. What in your experience, is the age of a boiler on the Victorian railways? — From 17 to 20 years our earlier boilers stood. The later boilers don't stand so well. How is that? — There is difference in construction, and the material is lighter. The old boilers had thicker plates. Have you been asked in any way to curtail boiler affairs? — No, sir; nor in any way. You have never hesitated to carry out any necessary repairs? — Never. Our orders have been to exercise every care in examining, repairing and renewing boilers. Witness said that his practice was when an engine came into the workshop to find out how long she had been running. If over five years, he informed the workshop manager, and they thought it necessary the tubes were taken nut. If everything was in good order witness reported to the manager. The cost of taking out the tubes and putting them in again was about L20. Mr Woodroffe : Have you ever hesitated to repair a boiler on the score of expense ? — No, never. Mr McLean : Hew do yon ascertain whether a boiler requires repairs?— I keep a record of every boiler examined. From every boiler that comes in I have the dome covers taken off, and when it is practical I get inside. l can almost tell from the top of a boiler what the bottom is like. If there is any doubt about it I have the tubes taken out. If I have suspicion of defective plate I cause to have bored a triangle in the plate at the point where there is the most wear. There is a travelling inspector who visits all the running sheds of the colony except Port Melbourne and tests the boilers. He reports to us and we note what he points out. Alfred Thompson, locomotive inspector of the eastern section, said he knew this engine, 297R. He read a list of her repairs. He heard of the accident on Saturday night and went up to Ringwood. The Chairman : Did you ever notice anything peculiar about the engine? — No, I considered her A1 and would not have hesitated to have put on 140lb pressure owing to the repairs she had undergone. Witness considered that the explosion was caused by the expansion and contraction of the plates ; and, no doubt, the plate had been eaten away through bad water. The other side of the boiler showed: signs of corrosion: By Mr Woodroffe ; Is every care taken with the boilers ? — Yes, every possible care is taken for the safety of boilers, Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 EXPLOSION OF A LOCOMOTIVE BOILER, NARROW ESACPE FROM FATALITIES. THE DAMAGED ENGINE. [See drawing of loco – saved in “Railways” folder] The explosion of a locomotive boiler at Ringwood on Saturday evening, formed the subject of much discussion in railway circles on Monday. The Minister arrived at the office at an unusually early hour and immediately entered into a consultation with the acting chairman, Mr Kibble, and Mr Commissioner Murray. As the result of the interview it was resolved to ask three gentlemen of acknowledged engineering experience to sib as a board with the . object of inquiring into the cause of the accident and furnishing a report. Mr Richardson and the Commissioners are tally seized of the importance of having a searching investigation into the accident, and, with Mr Murray, the former went to Ringwood to inspect the scene of the disaster. They will he accompanied by Mr Woodroffe. During the morning no official report had come to hand from the driver or fireman of the engine in reference to the accident, but that is thought to be due to the circumstance that they have not sufficiently recovered to be able to give a circumstantial account of what occurred. The engine was one of the old R's, and, Mr Kibble pronounced them to be about the best class of engines used. So far nothing can be said as to the probable cause of the accident, as the broken plating of the engine has not been submitted to the inspection of experts. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 STATEMENT BY THE FIREMAN. This morning Thomas Miles, fireman on the engine the boiler of which exploded on Saturday night, is suffering from an injury to the spine, as well as a very severe shaking to the system. He states that he was fireman on the engine attached to the train which left Healesville on Saturday evening, at ten minutes to 8. Everything went all right until Ringwood was reached, when, .just as the train was about to continue its journey, a load explosion took place and Miles remembers nothing more until he was picked np on the platform ; and found himself suffering from a pain in the back, and an injury to his arm. He cannot think of any reason which could have caused the explosion, as there was plenty of water in the boiler, and everything seemed working all right. Mr R. Fulton, consulting engineer, of Queen street; Mr McLean, a member of the Marine Board ; and Mr Mephan Ferguson, engineer, have consented to act as a board to inquire into the cause of the engine boiler explosion at Ringwood on Saturday evening. The board has been appointed under section 117 of Act 1135, which provides that the Governor-in-Council may direct the taking of a such a step. Mr1 Fulton will act as chairman of the board, which met for the first time at the railway offices, Spencer street, this forenoon. Before separating the members of the Board paid a visit to the Prince's Bridge locomotive sheds in company with Mr Woodroffe, the chief mechanical engineer, for the purpose of inspecting the shattered boiler. It has been stated that the explosion is known to have been caused by a flaw in a plate which was put on the boiler about four years ago, but enquiries have tailed to elicit anything in support of that view. The engineers connected with the department are not inclined to say anything on the subject. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 14 April 1894, page 20 The Ringwood Boiler Explosion, The Minister of Railways has received the supplementary report of the board appointed by him to investigate the circumstances connected with the explosion of a locomotive boiler at Ringwood. In their first report the board did not attach blame to anyone. Mr Richardson felt satisfied that the responsibility of having the engines properly inspected and overhauled periodically could be fixed if the inquiry were extended. He therefore referred the matter again to the Board, who took further evidence. In the report now furnished, the Board hold Loco. Inspector Thompson blameable, but point out as a mitigating circumstance that he had not received "written instructions" respecting inspections and overhauls. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 7 July 1894, page 32 The Ringwood Boiler Explosion. The Minister of Railways takes exception to the tone of a paragraph appearing in a morning contemporary respecting the Ringwood boiler explosion. It makes it appear that Mr Richardson has referred the report of the board which considered the facts connected with the explosion to the Crown solicitor simply because he differed from the finding of the board. The Minister explains that when he received the report he found that the responsibility for having boilers properly inspected and overhauled had not been clearly fixed. He personally obtained farther evidence on that point, and arrived at a conclusion, from which the commissioners differed. As he did not like to take upon himself the responsibility of deciding upon the effect of the evidence, he submitted the matter to the Crown Solicitor, but that officer did not furnish him with the information sought. He has, therefore, referred the question to the Attorney-General, together with the draft of a regulation respecting boiler inspections and overhauls in the future. Mr Richardson says that his whole aim is to have the responsibility positively fixed. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 28 April 1894, page 23 The Minister of Railways has completed his consideration of the supplementary report received by him from the Ringwood Boiler Explosion Board. The report, it will be remembered, held Loco-Inspector Thompson blameable for the non-inspection of the boiler, but considered there was extenuating circumstances. There was a certain amount of doubt as to the absolute instructions given for overhauling engines periodically. Mr. Richardson is sending the report on to the Commissioners with instructions that the responsibility respecting inspection of boilers shall be made clear for the future. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - Note book, Webb Bros, Early 20th century

... , dairying utensils, steam boilers, and oil engines. They were also..., dairying utensils, steam boilers, and oil engines. They were also ...This little slate notebook was given by Webb Brothers to their customers as an advertising tool. The Webb Brothers Company a large manufacturing firm in Lava Street, Warrnambool, making windmills, dairying utensils, steam boilers, and oil engines. They were also engineers, brassfounders and wholesale tinsmiths and plumbers. Motor car work became a speciality in the 1920s. In 1921 they opened a branch of their business in Melbourne (Bayswater) and the name of the firm became Presha Engineering Company. This notebook is of some interest as it was provided by Webb Brothers, an important company in Warrnambool in the late 19th and early 20th centuries. It is also an example of the advertising techniques used by business houses at that time and an interesting example of the use of a slate pencil and slate pages as a recording mechanism.This is a brown leather notebook with three pages of slate material making eight spaces for recording notes. Notes recorded in slate can be rubbed out and the space used again. The slate pencil container is on the side of the notebook but the pencil is missing. The cover is mottled with creamy-yellow lines. The pages are edged in red and there is scribble on some pages. Front page of notebook: ‘Before purchasing talk to Webb Bros. & Co., Windmill Makers, Engineers, Ironworkers etc. Lava Street, Warrnambool ‘Phone 27, Made in Germany’ Scribble on first page ‘Wanted known’ webb brothers, warrnambool, brassfounders -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Ephemera - Tag Webb Bros

... utensils, steam boilers and oil engines and other items associated..., steam boilers and oil engines and other items associated ...Webb Brothers & Co. were a large manufacturing company in Lava Street, Warrnambool at the end of the 19th century and the beginning of the 20th century. They manufactured windmills, dairying utensils, steam boilers and oil engines and other items associated with plumbing, tinsmithing, engineering, brassfoundries, and, later in the 20th century, motor car work. In 1921 they opened a branch of their business in Melbourne. It is not clear for what reason Webb Brothers made this tag. It may have been a practice piece for their labelling of products or it may have been an advertising gimmick. The firm did not appear to manufacture any items for which a leather tag would be appropriate unless the tag was attached by a chain. This item is of minor interest in itself but it is an interesting adjunct to the items and information we hold on one of Warrnambool’s important industries – Webb Brothers & Co of Lava Street. This is a leather tag in the shape of a shield. It is smooth on one side and rough on the other and the shape has been roughly cut out. The name of the company (Webb Bros) has been embossed on the centre panel.Embossed on front: ‘Webb Bros & Co. Makers, Warrnambool’webb brothers & co., warrnambool -

Federation University Historical Collection

Federation University Historical CollectionBook - Exercise Book, Assaying Lecture Notes, c1890s

... Assaying steam engines boilers cornish boilers Exercise book ...Exercise book with marbled cover. Handwritten lecture notes inside including Setting of Boilers, Bursting Pressure of Boilers, The Babcock and Wilcock, Purchasing an Old Cornish Boiler, blow off pressureassaying, steam engines, boilers, cornish boilers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Tap, mid-late 19th century

This type of large, brass tap is typical of the plumbing fittings manufactured in the late 19th and early 20th centuries. The tap has encrustations and concretion inside, showing that it had been in the sea for quite some time. The pipe leading to the spout is squashed, nicked and appears to have been sawn or broken off. It could have once been part of the plumbing from a ship, perhaps from one of the boilers used in the kitchen, for bathing or for laundry or cleaning. The name “BEST” on the tap signifies that it could have been made by Robert Best who began his Birmingham brass foundry c. 1840, and even though The information from the donor is that tap was given to her father (1906-1982) who lived in the Warrnambool district. It was likely given by a cray fisherman or diver, who said that the tap came from the Loch Ard shipwreck, wrecked on Mutton Bird Island, east of Port Campbell, Victoria, on 1st June 1878. This could easily be the case but there is no provenance for it. ROBERT BEST, BRASS FOUNDRY Circa 1840 Robert Best founded his brass foundry business and was referred to as a Brass Chandelier of Birmingham”. In 1864 an advertisement in the Journal of Gas Lighting, Water Supply, & Sanitary Improvement announces Best and Hobson, late Robert Best, 100 Charlotte Street Birmingham, manufacturers of Chandeliers, Brass and iron fittings, Steam and Water-cocks etc. gas apparatus of every description, Plumber's brass foundry, with works at Birmingham and Great Bridge, Staffordshire. In 1867 Best & Lloyd was formed, after Best and Hobson went into liquidation, manufacturing at the Cambray Works of Wattville Road, Handsworth. It was a light industrial engineering works and one of the owners was Robert Dudley Best’s father. Robert Dudley Best (1892-1984) later took over the business of Best & Lloyd. The company is still in business at Downing Street, Smethwick, Birmingham. In 1878, brass ship furniture and bell fittings stamped “BEST” was made by William Udal & Co., who advertised as manufacturers of BEST cast and stamped brass foundry goods. This large brass tap is typical of industrial tapware of the mid-late 19th ancenturies 20th century. The location of the tap when found is associated with the Warrnambool district and could have easily been from a shipwreck due to the encrustation found inside the tap. Due to its design and manufacturer, the tap is associated with the mid-late 19th and early 20th-century manufacture of plumbing fittings. Tap, brass, heavy-duty, with butterfly handle. The design and style are typical of the plumbing of the late 1800s. Inscription pressed into the handle, within rectangular border "BEST". Encrustation and concretion are inside the tap spout. “BEST” on one side of the tap handle (Also, a label from the donor attached to the tap “from the wreckage of the LOCH ARD")flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, robert best brass foundry, best and hobson, best & llyod, birmingham brass foundry, brass tap, best brand tap, heavy duty brass tap, industrial brass tap, boiler tap, 19th century plumbing, 19th century tapware, 19th century plumbing fitting, tap with butterfly handle, tap salvaged from shipwreck, brass fittings, steam engine fittings, water-cock fitting -

Seaworks Maritime Museum

Seaworks Maritime MuseumModel ship, SS Iberia, 1873

SS Iberia (1873-1903) was built by John Elder & Co. (Govan yard no.162 Glasgow) and launched 6 December 1873 at a cost £151,600. However, due to strike delays, her maiden voyage was not until 21 October 1874. The Iberia was one of the last of the barque-rigged, clipper-bow type of steamer built for the Pacific Steam Navigation Company. At the time, she was also the second largest ship in world, after the Great Eastern. In 1877, a joint Orient Line and Pacific Steam Navigation Co. venture began a fortnightly mail service, first sailing between England and Australia on 12 May 1880, via Gibraltar, Naples, Port Said, Ismalia, Suez, Colombo, Albany, Adelaide, Melbourne, Sydney. Details: - Tonnage: 4,671 g, 2,982 n. - Dimensions: 433ft 6in (132.13m) x 45ft (13.72m) x 35ft 1in (10.69m). - Powered by a single screw, compound inverted 2 cylinder; 750 NHP; 4,000 IHP engine with steam pressure of 70 lbs, 4 cylindrical boilers, 2 to each funnel. - Speed 14 knots - 1873 Passengers: 100 1st, 150 2nd, 340 3rd Class. - 1893 Passengers: 140 first, 50 second, 800 third Some significant dates in her history include: - 1881: Replaced "Aconcagua" as standby vessel on the London - Suez- Melbourne - Sydney route - 1882: Government transport during the Egyptian Arabi Pasha Campaigns - 1883 Jan 25: Placed on regular service to Australia - 1890 Jun 11: Reverted to the Liverpool - Valparaiso route - 1893: Iberia sailed to Australia to replace a disabled ship. The journey via the Cape was non-stop at 14 knots in 32 days - 1893- Fitted with triple expansion engine; 3 cylinders, 600 NHP; 4 cylindrical boilers; 13 knots; fitted by J.Rollo & Sons, Liverpool - 1903: Broken up at Genoa. 1873 single screw, compound inverted, 2 cylinder; 750 NHP, 4000 IHP, Steam pressure 70 lbs, 4 cylindrical boilers, 2 to each funnel, 14 knots. Second largest ship in the world in 1874 (after the Great Eastern). Cost 151, 600 pounds. 1893 Triple expansion engine fitted. 3 cylinders 600 NHP, 4 cylindrical boilers, 15 knots, fitted by D Rollo and Sons, LiverpoolThe body of the model is carved and molded wood painted in black and white, the planked deck with detailed fittings and rigging, raised on a wooden base with simulated waves. At this time yards removed. "Iberia" -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaManual - Manual, Ship engineering, PLIBRICO, Plibrico Modern Boiler Settings, 1960s

... manuals manual boilers maintenance engineers engine rooms george ...Mariner Duncan had a particular regard for the Mission to Seafarers. A plate for display on a commissioned new table at the MTSV acknowledges his bequest and the material donated. Collectively the G W Duncan material includes: photographs, professional data memorabilia and written and commercially printed resources. The memorabilia relates to his career at sea and in particular the role of an engineer, including a handwritten manual of notes and references relating to the mechanical and engineering aspects and areas of responsibility for maintenance. A stapled book with black cover and the word PLIBRICO in ochre printed at top centre.mariner manuals, manual, boilers, maintenance, engineers, engine rooms, george winfield duncan (1922-2017), ship engineer, s.s. athenic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Stretcher, 1965 to 1999

A Neil Robinson stretcher is a lightweight carrying device modelled on Japanese bamboo litters, the Neil Robertson rescue stretcher was developed in the early 1900s by John Neil Robertson. Used for lifting an injured person vertically. The stretcher is made from stout canvas reinforced with bamboo slats. The stretcher is designed for removing an injured person from spaces wherein access, doors or hatches are too small to permit the use of regular stretchers. Spaces such as ship engine room spaces, cargo holds, pump rooms, boiler rooms etc. are a few examples of such compact spaces.An item designed to transport injured personnel from tight places, either at sea or on land.A rescue stretcher made from white canvas reinforced with bamboo slats and adjustable canvas straps. The canvas straps are secured with metal buckles and there is a metal ring attached to lengths of ropes at both ends. Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, stretcher, neil robertson, neil robertson rescue stretcher, rescue equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBearing cap, (estimated); Before The Newfield completion in 1889

This bearing cap is thought to be from a donkey winch engine, (or steam donkey, or donkey winch), which is a small secondary steam engine with a cylindrical shaped boiler. In 19th century merchant sailing a steam donkey was often used in marine applications such as to help raise and lower larger sails, load and unload cargo or to power pumps. The bearing cap could have been used on the donkey engine to hold the rod of the winch gear wheel in place, or bolted to another bearing cap around the neck on the top of the boiler’s cylinder, connecting it to the flue. The Newfield was a three-masted iron and steel barque, built in Dundee, Scotland, in 1889 by Alexander Stephen and Sons. It was owned by the Newfield Ship Company in 1890 and later that year It was registered in Liverpool to owners Brownells and Co. The Newfield left Sharpness, Scotland, on 28th May 1892 with a crew of 25 under the command of Captain George Scott and on 1st June left Liverpool. She was bound for Brisbane, Australia, with a cargo of 1850 tons of fine rock salt, the main export product of Sharpness. At about 9pm on 28th August 1892, in heavy weather, Captain Scott sighted, between heavy squalls, the Cape Otway light on the mainland of Victoria but, due to a navigational error (the ship’s chronometers were wrong), he assumed it to be the Cape Wickham light on King Island, some 40 miles south. He altered his course to the north, expecting to enter Bass Strait. The ship was now heading straight for the south west Victorian coast. At about 1:30am the Newfield ran aground on a reef about 100 yards from shore and one mile east of Curdie’s Inlet, Peterborough. The ship struck heavily three times before grounding on an inner shoal with 6 feet of water in the holds. Rough sea made the job of launching lifeboats very difficult. The first two lifeboats launched by the crew were smashed against the side of the ship and some men were crushed or swept away. The third lifeboat brought eight men to shore. It capsized when the crew tried to return it to the ship for further rescue The rescue was a difficult operation. The Port Campbell Rocket Crew arrived and fired four rocket lines, none of which connected with the ship. Peter Carmody, a local man, volunteered to swim about one mile off shore to the ship with a line to guide the fourth and final lifeboat safely to shore. He was assisted by James McKenzie and Gerard Irvine. Seventeen men survived the shipwreck but the captain and eight of his crew perished. The Newfield remained upright on the reef with sails set for a considerable time as the wind slowly ripped the canvas to shreds and the sea battered the hull to pieces. The Marine Board inquiry found the wreck was caused by a "one man style of navigation" and that the Captain had not heeded the advice of his crew. According to Jack Loney ‘… when the drama was over . . the Newfield was deserted except for the Captain’s dog and two pigs.’ Peter Carmody was awarded the Bramley-Moore medal by the Liverpool Shipwreck and Humane Society for Saving Life at Ssea, which he received by mail on January 21st 1893. The medal and a letter of congratulations were donated to Flagstaff Hill Maritime Museum by Peter Carmody’s grand-daughter Norma Bracken and her son Stuart Bracken on 25th May 2006. The Bearing Cap joins other items in the Newfield collection.Flagstaff Hill’s collection of artefacts from the Newfield is significant for its association with the shipwreck Newfield, which is listed on the Victorian Heritage Registry. The collection is significant because of the relationship between the objects. The Newfield collection is archaeologically significant as the remains of an international cargo ship. The Newfield collection is historically significant for representing aspects of Victoria’s shipping history and its association with the shipwreck.Brass bearing cap from the wreck of the sailing ship “Newfield” is possibly from a donkey winch engine. The half-circle shaped cuff with a rectangular brass block attached to the outside of each end of the half-circle. Both blocks have a round hole in their centre and are approximately the same depth and width as the cuff. Midway around the half-circle cuff is another brass block that is about twice the depth of the cuff. It appears to have been a circular shape that has been modified to match the width of the collar, having had the sides of the circle cut off to leave straights edge parallel to the edges of the cuff. In the centre of this block is another hole, and there appears to be the head of a bolt inside this hole. The bearing cap is lightly encrusted.1893, flagstaff hill, flagstaff hill maritime museum, maritime museum, warrnambool, newfield, 1892, 28 august 1892, port campbell, shipwreck, nineteenth century, ship, curdie s river, victorian shipwrecks, barque, ship wreck, 29 august 1892, 19th century, bearing cap, donkey engine, donkey winch, steam donkey -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSteam-engine coupling, On or before 1889

This Steam Engine Coupling was recovered from the wreck of the Newfield and is thought to be part of a Donkey Engine (or steam donkey, or donkey winch), which is a small secondary steam engine with a cylindrical shaped boiler. In 19th century merchant sailing, a steam donkey was often used in marine applications such as to help raise and lower larger sails, loading and unloading cargo or for powering pumps. The barque Newfield left Liverpool on 1st June 1892 with a cargo of 1850 tons of fine rock salt for Brisbane. About six weeks later the ship ran into very heavy weather approaching the Australian coast. On 28th August at about 9pm her master, Captain George Scott, observed between the heavy squalls the Cape Otway light on the mainland of Victoria, but due apparently to a navigational error (the chronometers were incorrect), he mistook it for Cape Wickham on King Island, some 40 miles south. He altered course to the north expecting to run through the western entrance of Bass Strait, but instead, at about 1:30am, the ship ran aground about about 100 yards from shore, one mile east of Curdies River. The vessel struck heavily three times before grounding on an inner shoal with six feet of water in the holds. The Newfield remained upright on the reef with sails set for a considerable time as the wind slowly ripped the canvas to shreds and the sea battered the hull to pieces. Seventeen men survived the shipwreck but the captain and eight of his crew perished.Flagstaff Hill’s collection of artefacts from the Newfield is significant for its association with the shipwreck Newfield, which is listed on the Victorian Heritage Registry. The collection is significant because of the relationship between the objects. The Newfield collection is archaeologically significant as the remains of an international cargo ship. The Newfield collection is historically significant for representing aspects of Victoria’s shipping history and its association with the shipwreckCoupling is believed to be part of the Donkey winch's steam-engine. Threaded brass collar (with side outlet) attached to a copper pipe via a locking nut, and a four holed flange with bolts and coupling plate the other end.warrnambool, shipwrecked coast, flagstaff hill, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, shipwrecked artefact, 1892, 1893, 28 august 1892, 29 august 1892, barque, curdie's river, donkey engine, newfield, nineteenth century, peter ronald, peterborough, port campbell, shipwrecks, steam engine coupling, steam donkey, victorian shipwrecks -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Badge, Before 1855