Showing 172 items matching "gold processing"

-

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Ore crusher, Golden King mine, Yarrambat, 22 January 2008

Prior to 1929 Yarrambat was known as Tanck's Corner or Reynold's Corner after Frederick Tanck who owned land north of Ironbark Road at the corner of Yan Yean Road, and Thomas Ryenolds who owned the property opposite. Tanck's Corner was at the centre of gold bearing country. Gold was mined here until 1984 when the last operating mine, the Golden King mine in North Oatlands Road closed. It was owned by the Clayton family and in the 1960s was the only private family gold mine in Victoria. Larger mines had their own batteries and stampers to process the ore. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p23This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, battery, clayton family, gold mining, golden king mine, ore crusher, tancks corner. reynolds corner, yarrambat -

Eltham District Historical Society Inc

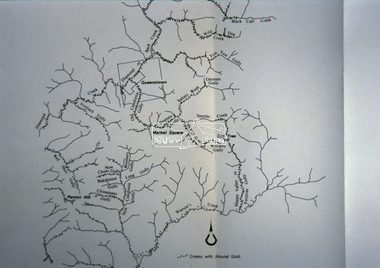

Eltham District Historical Society IncSlide - Photograph, Creeks with Alluvial gold, St Andrews, c.Sep. 1989

... views. Map Creeks Alluvial gold St Andrews Process Date Sep 1989 ...Part of a slide show presentation "Bridges & Waterways of the Shire" by Russell Yeoman to the 13 September 1989 Society meeting. The presentation included slides of historic photos from the Shire of Eltham Pioneers collections as well as several recent views.35mm colour positive transparency (1 of 33) Mount - Agfa CS System grey 8 dotsProcess Date Sep 1989map, creeks, alluvial gold, st andrews -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Tess Justine (Nillumbik Shire Council), Murray's Bridge over the Diamond Creek, Eltham North, 19 Feb 2022

Murray's Bridge over the Diamond Creek on the Diamond Creek Trail just prior to demolition and replacement with a new steel bridge. Heritage advice obtained by Nillumbik Shire Council, following a suggestion by the Eltham District Historical Society (EDHS), is that the original bridge appears to have been a simplified version of the Country Roads Board’s (CRB) standard timber bridge design of the early-to-mid 1920s. In c1990 Murray’s bridge was renovated with three recycled steel girders as part of a bike/pedestrian path in the reserve. During these alterations many parts of the bridge were removed, and some were replaced. Heritage advice indicates the condition of Murray’s bridge is poor. The remaining original parts are all in poor condition, with severe weathering, splitting and rot, especially to the stringers retained on the bridge. Heritage advice is that Murray’s Bridge does not have sufficient significance in the cultural history of the Nillumbik area to warrant inclusion in the Nillumbik Shire Heritage Overlay and also does not have sufficient significance as a rare survivor to warrant inclusion in the Nillumbik Shire Heritage Overlay. There are no indications in the historical record that this site was individually important to the cultural history of this area. EDHS is comfortable with the heritage advice provided to Council and has worked closely on this project with Council. EDHS has suggested some of the removed timbers be used in the vicinity of the bridge for landscaping and possibly seating, so as to retain these remnants close to the site of the original bridge, which is the last old timber bridge along the lower reaches of the Diamond Creek. Mary (Sweeney) Murray and John Wright Murray selected 80 acres, Lot C Section 16 and Lot 5 Section 17 Parish of Nillumbik, under an occupation license in 1866. John died in 1867 and freehold was granted to his son John in 1873. The farm was known as ‘Laurel Hill’. John Junior was an Eltham Shire councillor and sometime president from 1887 up until 1897. He added Lot A Section 16 to the farm in ca1888. John and his younger brother James arranged to rent/purchase Lot B Section 17, across Diamond Creek to the west, in ca1900. It appears that John and James farmed separately for a few years, with a new homestead built for James ad family on the high point of Lot B Section 17 in ca1910. John sold off Lot 5 Section 17 in 1912. When John died in 1912 James took over the land on both sides of the Diamond Creek. The old homestead on the west side of the Creek disappeared. A farm bridge over Diamond Creek from this period may have been located close to the northern boundary of the farm. John Langlands, owner of the farm known as ‘Ihurst’ on the west side of Diamond Creek to the south of the Murray’s land, died in 1907. In 1909 his land was then subdivided into 100 lots to become the ‘Glen Park Estate’. Other similar subdivisions of nineteenth century farms around Eltham in this period included the ‘Franktonia (or Beard’s) Estate’ to the northeast and ‘Bonsack’s Estate’ between Eltham and Greensborough. Soon after the opening of the railway extension line from Eltham to Hurstbridge in 1912, Glen Park and nearby residents including James Murray agitated for a railway station or siding to be located half-way between Eltham and Hurstbridge, so that the Glen Park residents who used the railway daily did not have to walk into the Eltham or Hurstbridge stations. Some believed Coleman’s Corner (opposite Edendale Farm) was an appropriate spot for the platform. James Murray was among those who thought the railway should be located on his land, closer to half-way between Eltham and Hurstbridge stations. The Railways Commissioners warned that the locals would have to fund these works themselves. The Glen Park Estate residents initially had difficulty accessing Eltham by road, with only an old low-level bridge over Diamond Creek at the south end of their estate. A new timber trestle bridge across the creek, now on Wattletree Road, was opened in 1915. Road access to the north was gained in 1927 when the new Murray’s Road, which crossed the Murray’s land, was built. Residents continued to agitate for a Glen Park station. By 1926 the Railways Commissioners’ preferred site was on the Murray’s land. They arranged an estimate of cost of a full-length platform. The estimate was too much for the locals, who in 1928 argued unsuccessfully for a shorter and hence cheaper platform. By 1929 Murray had agreed to donate the land, but the locals would still have to fund the works. Murray decided, unilaterally it would appear, to commence work on a timber trestle road bridge over Diamond Creek to link the new Murray Road to the proposed station. Late in 1929 he stopped work on the bridge, for reasons unknown, but started work again and completed the bridge in 1931. There is no further newspaper evidence of the campaign for the Glen Park station until 1939, when Murray and another local, Mr Maxwell, met the Railways Commissioner. The Glen Park locale now included 45 homes on the west side of the creek and 20 on the Eltham side. Most of the residents used the train every day. The Commissioner remained adamant that only a full-length platform could be built for safety reasons. It appears the campaign dissolved at this point. The increasing move to cars may have had an impact. There is no evidence of Murray’s bridge ever being connected to Murray’s Road, or of it having wide use for any purpose by locals. James Murray died in 1947 and the farm was taken over by his son James (Jim). Jim started to sell off parts of the farm in the 1980s, retaining a few acres around the ca1910 homestead and building a new house there. Recreation reserves were established along the creek. In ca1990 Murray’s bridge was renovated with steel girders as part of a bike/pedestrian path in the reserve. The old farmhouse was demolished in ca2014. * * * A theory posted on local community Facebook groups was that the bridge was built in the 1860s and was built to be more robust than was necessary for the movement of cows from one side of the creek to the other. It was suggested the robustness was necessary to support the weight of gold ore being transferred from a mine on Murray’s land to a railway siding near Murrays Bridge (presumably for transfer and processing at Diamond Creek). Perhaps this may have been one of the motivators for Murray, who really knows? Knowing when mining operations ceased on his land and how that fits the overall timeline would be useful but at the time the bridge was built, local gold production was minimal at best. The known facts are: • The railway line came to Eltham in 1902. • The extension of the railway from Eltham to Hurstbridge was constructed in 1912 so no railway line even existed through Murray's property until 1912 and the Victorian Railways maps at the time show no such siding on Murray’s property. • In 1923 a new company was formed in anticipation of the old Diamond Creek Gold Mine being re-opened. The mine had been previously closed and flooded. It was noted in the press at the time that the mine was within a mile of the railway. Nothing really came of this. • Construction of Murrays Bridge was commenced by James Murray in early 1929 in anticipation of a proposed flag station being nominated on his land, but work ceased shortly afterwards. The proposed flag station was commonly referred to as Glen Park as the residents of the Glen Park Estate wanted Option 1, located near them with the platform adjacent to Colemans corner. This was probably never going to fly as it was virtually in eyesight of Eltham station. Allandale Road was the third option, but the Commissioners' preferred option was No. 2 - on Murray's property. • The Railway Commissioners were not going to finance any such station and the works had to be funded by private landowners and residents, hence Murray investing in this himself. • Murray recommenced work two years later and finished his bridge in 1931 but unfortunately for him, the proposed flag station never eventuated. The bluestone siding you reference may well have been built by Murray as part of the proposed station platform. • Up until then, apart from the Main Road bridge, which was washed away in 1924, virtually all local crossings over the Diamond Creek were low lying bridges – Kaylocks Bridge at Brougham Street, Diamond Street bridge, Glen Park Road bridge. It is expected that Murray also had a low-lying bridge to connect his land either side of the creek. These were all washed away or severely damaged multiple times in the 1920s. Lessons were learnt, and Murrays Bridge appears to have been built in accordance with Country Road Board standards of the time. Flood damage was ongoing, and even more recently constructed raised bridges kept getting washed away, e.g., the new Wattle Tree Road bridge in 1958 just months after completion. Murray’s bridge was reinforced with steel some 30 years ago presumably to provide additional floodwater resistance, given the history of bridges disappearing in floodwaters. • In March 1932 it was reported in the Advertiser that there were still some prospectors operating around Eltham North who apart from further scarring the face of the earth over the previous two years had gained significant experience but little gold - hardly a driving factor for constructing a dedicated railway siding and bridge to transfer gold ore. It is far more probable that James Murray was hoping to have the railway station located on his property and invested his money by building the bridge to lead to it as well as a station platform. Had the station eventuated, it may well have driven up the value of his land for subdivision and new housing estates like the Glen Park Estate. That did not eventuate. Whilst the bridge was indeed old (90 years), the core structure being completed in 1931, it had been modified substantially from original and hence had no significant historic value – i.e., it was not a representative example of its type, construction, and age. Given that the bridge was not worthy of saving, the Eltham District Historical Society with Council’s support, and the Eltham Woodworkers group endeavoured to see what suitable sized timbers were salvageable to fabricate a commemorative seat. Unfortunately, the experts at the Woodworkers group were unable to salvage any suitable length/width timbers to fabricate the seat due to the presence of rot. Last remaining wooden trestle bridge on the Diamond Creek Trail just prior to demolition and replacementBorn digital image (27)diamond creek (creek), diamond creek trail, murrays bridge, ‘laurel hill’, john wright murray, mary (sweeney) murra, john murray jnr, james murray, john langlands, ‘ihurst’, ‘glen park estate’, beard's estate, franktonia, bonsack's estate, glen park estate, glen park railway station -

Federation University Historical Collection

Federation University Historical CollectionBook - Book - Scrapbook, Ballarat School of MInes: Scrapbook of Newspaper Cuttings, Book 68, March 1995 to May 1995

Collection of newspaper articles related to Ballarat School Of Mines.They cover activities and advertisements for staff. The papers concerned are The Courier, Ballarat, The Australian, The Age ad other region papers over the period of 11 March 1995 to 11 May 1995.Book with yellow cover, front, spiral bound. teaching positions advertised, pre-employment courses, courses available, enrolment for smb courses, ballarat region's workskill, workskill olympics in hairdressing in ballarat, return of paddle steamer, ararat secondary college adopts charter, smb training restaurant, smb horticulture complex, certificate in food processing introduced, plan to relocate senior campus, luke loader pastoral apprentice of the year, students protest workcover policy, closer links with uni needed, geoffrey blainey re writing, program to help child care students, permaculture, early ties with geology, dan daly gold medallist, play therapy in hospital, smb campus link-up, fire threat at smb, james hare apprentice chef, ballarat uni grows, smb maintains record, proposed tafe campus for stawell, education in the 90's, push for rail centre, volunteers vital to community, mining to much more, doug cowles obituary, smb and grampians national park -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Ballarat School of Mines Corbould Building

Corbould Hall was named after Ballarat School of Mines alumni WIlliam Corbould. William Corbould was the son of a Ballarat tailor. He attended Ballarat College, and obtained certificates in assaying and metallurgy at the Ballarat School of Mines (SMB) in 1883, studying under the revered Professor Mica Smith. Corbould was not a born student and remembered his first experience at SMB: 'From the Registrar's Office I was led to be introduced to the Professor of Chemistry, one Mica Smith. The initial encounter gave me little encouragement - his large laboratory was filled with hundreds of bottles bearing strange labels with queer symbols on them. My heart sank. At the first opportunity I grabbed my hat and made for the door, but the good professor called me back. I pointed out that I was never any good at school ... so it was no use pretending to be clever enough to understand all those weird symbols! The Professor told me not to worry about that and took me to one of the benches where he found a blowpipe and a charcoal block. Mixing together two powders from bottles on the shelf he transferred a sample to the charcoal and directed the bunsen flame onto it. Soon it began to melt and a white bead appeared in front of my eyes. He then took a test tube and added a little colourless liquid from each of two bottles. A beautiful dark blue colour appeared. My interest was won.' During Corbould's mining career he travelled to Europe twice, and visited most of Australia's main mining fields. Corbould started his career as an assayer at Pinnacle Silver Mine, Silverton, and was then a self-employed assayer at Broken Hill. Corbould became an assayer for the infant BHP mine, and later worked in Kalgoorlie and Coolgardie, including managing Hannan's Reward, the oldest gold mine on the Kalgoorlie gold field. He spent 13 years at the Mount Elliott copper fields as general manager. In 1923, at the age of 57, Corbould went to Mount Isa and reported on options, experimented with new metallurgical processes and floated a company. John Carden of CRA said: 'Corbould was the man who brought Urquhart to Mount Isa. He was the man who made it all possible. He is tremendously important in the Mount Isa story, because he was the first technical man, the first professional man on the scene. He was responsible as I said, for bringing finance to the place, but I think even more importantly he was the first man to recognise the need to put all the little claims in the Mount Isa discovery together. I think perhaps his major contribution to Mount Isa was this amalgamation on the various claims. He recognised that the ore bodies at Mount Isa were not as rich as Broken Hill and they would never have survived had it been fragmented, so he was terribly important.' After completing major financial negotiations for Mt Isa Mine from London in 1927 Corbould remained in Europe where he remained until his death. Corbould was awarded the Legion of Honour of the American Institute of Mining and Metallurigical Engineers for fifty years service. Corbould died at Monaco in 1949 at the age of 82. He bequested 6000 pounds to the Ballarat School of Mines, his will stating 'for the purpose of founding a scholarship to commemorate the memory of the late Alfred Mica Smith'. The accumulated income from this sum provides the Mica Smith travelling scholarship, enabling successful students in mining, metallurgy or chemistry to undertake a year's travelling abroad. The first award was made in 1957. In the same year a general purpose hall at SMB was named the Corbould Hall as a tribute to a distinguished former student and generous benefactor.ballarat school of mines corbould building, corbould hall, corbould building -

Federation University Historical Collection

Federation University Historical CollectionPamphlet - Promotional brochure, Bachelor of Visual Arts, Graphic Design/Multimedia, c1999

Promoting the Graphic Design/Multimedia program being offered by the University of Ballarat at the Mt Helen Campus. Promoted course as "one of the smallest and arguably the best three year programs of its kind in Australia and the South Pacific region." The brochure lists student awards received including Platinum and Gold in the AGFA International Young Designer Contest, 1999; two meritorious awards in The Art Directors Club Student Awards, New York, USA 1999; Graphis New Talent 1999; two Gold in Souther Cross Packaging Awards, 1998. At time of publication, the School of Arts, Visual Arts reportedly had 210 students with majors in Graphic Design/Multimedia, Ceramics/3D, Painting, Drawing, and Multidiscipline. Minors studies included Printmaking, Photography, 3D, 2D, and Graphic Communication. ___ Course aimed to train "independent, flexible thinkers". The course promised to "Promote creativity, originality and imaginative thinking; Develop self-directed learners, displaying initiative in the formation of ideas and the confidence to construct personal responses; Develop appropriate conceptual, technical and professional skills; Develop the student's critical process: ability to undertake research, and to make informed decisions; Clarify thinking, concepts and understanding and deep knowledge, attitudes and skills enabling the designer to respond to community needs." Studio and working environment described as "one open space with working facilities for approximately 75 students across 3 year levels. The area is divided up into work stations where 1st, 2nd and 3rd year students intermix, allowing a natural interaction. These workstations are configurations of six, consisting of two students from each year level. This reinforces the area's ongoing development with an open ethos and cross-level delivery and learning. This maximises the use of information in order for it to be applied throughout all levels of the learning process, whilst allowing a natural mentor arrangment to be developed for all first year students, " "The open ethos approach also encourages students and staff to freely express their opinions in relation to design via cross-level critiques, whilst allowing for a liberal arts approach and structure to the development of the creative process." "Emphasis is placed on experimentation, innovation, expression and the development of the individual's design philosophies, concepts and style." Also notes the 24 hour access Macintosh laboratory, with 34 Power Macintosh computers, ratio of one for every 2.5 students. Each with a Fujitsu Dyna Magneto Optical drive for file storage and transport. Two Sharp scanners, Phaser Dye-Sublimation Extra Tabloid colour printer and Ricoh A3 colour printer. Two large format printers. Digital and video cameras. Software: Adobe Photoshop, Illustrator, Acrobat; QuarkXpress; Macromedia Freehand; Pagemaker; Premier; Director; 3D Extreme; Sound Eidt, Shockwave, Infinite 3D and After Effects. Approx 4.5 staff, "all of whom are practicing designers. They have a full understanding of industry requirements and trends which assists in the development of industrial contacts when specialists are required." Prospective students interviewed in late Nov/ early Dec, face to face. Present a "comprehensive folio of work", academic records, references. "Selection is determined by the perceived potential of the student, their motivation and reason for study within the field as well as their previous experience in the Visual Arts. Folio work should be representative of the individual's ideas and abilities. Qualities of importance are: originality, innovation, imagination, experimentation and a competent display of the basic skills associated with visual arts [evidence of drawing skills should be included]." Demonstration of GD/MM computer skills an advantage. Students also asked to bring sketch books. Promotional brochure for prospective students. 8pp Double fold brochureuniversity of ballarat, federation university, graphic design, multimedia, bachelor, degree -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

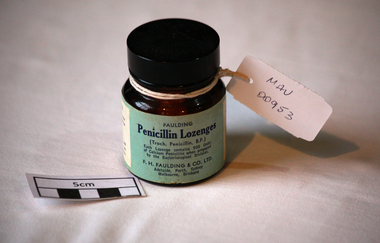

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Glass, brown bottle 'Penicillin Lozenges', 20thC

F. H. Faulding & Co was a pharmaceutical company founded in Adelaide, South Australia in 1845 by Francis Hardey Faulding 1816 – 1868, a native of Swinfleet, Yorkshire, He arrived in Sydney on the Nabob in February 1842,and travelled on the brig Dorset to Adelaide in May, where he opened a pharmacy at 5 Rundle Street in 1845.The pharmacy flourished, so he purchased a warehouse in Clarence Place in the city and transferred the manufacturing and wholesale arms of the business there. In 1861 he entered into partnership with Luther Scammell (1826–1910).a Yorkshireman, who had received medical training at Guy's Hospital, and arrived in Adelaide in 1849. Faulding died in 1868 and Scammell took over the business, however he was forced to retire in 1889 when the Bank of Adelaide threatened foreclosure after a series of failed mining and pastoral speculations. Two of his sons, Luther Robert Scammell FCS LSA ( 1858 – 1940) and William J. Scammell ( 1856 – 1928) acquired the manufacturing and wholesaling operations, and the business name, in 1888; the retail shops were sold to reduce the debt to the bank.The company expanded under the two brothers and later two sons of each became directors of the company. In June 1921 Faulding & Co. became a private company, with L.R. Scammell as chairman and managing director. He continued to run the firm's affairs until 1935.Two of the Faulding company's major innovations were the development of a process for distillation of eucalyptus oil, and the development of the test for determining the eucalyptol content of the oil. Faulding's success was founded on eucalyptus oil, which formed the basis of an antiseptic marketed as "Solyptol" (for soluble eucalyptus oil). The test became the industry standard, and the British Pharmacopoeia standard method in 1898. Other well-known products were Milk Emulsion (a pleasant alternative to cod-liver oil), Solyptol Soap, (which won a gold medal at the Franco-British Exhibition in London in 1908), Solyptol disinfectant, junket tablets, cordials, essential oils for perfumery and reagents such as Epsom salts, most produced in its factory in Thebarton The Faulding Co. built success around optimising the delivery of oral dosage form drugs. A brown glass bottle with a plastic screw top that contained 'Penicillin Lozenges' made by F.H. Faulding Co. Ltd . AustraliaFAULDING / Penicillin Lozenges / ( Troch. Penicillin B.P.) /......... / F.H.Faulding & Co. Ltd. / Adelaide, Perth, Sydney, / Melbourne, Brisbane on back DIRECTIONS......pharmacy, medicines, f.h. faulding co. ltd, penicillin lozenges, antibiotics, dentists, glassware, bottles, moorabbin, bentleigh, cheltenham -

Eltham District Historical Society Inc

Eltham District Historical Society IncNegative - Photograph, Members of the Hill family, early Eltham settlers, c.1860

Mrs Georgina Hill (wife of Henry), nee Reynolds (of Research, Vic.) in cap [possibly misidentified by donor - see note below] with Mrs Isaac Hill and her children (left to right) Amelia Hill, (born 1853) Mrs Isaac Hill with baby Isaac (born 1860, Eltham) on her lap. Mary Jane Hill (born 1857, Eltham) seated on Mrs Henry Hill's lap and Bob Hill. The Hill family were early settlers of the Eltham area. Daguerreotype photo enclosed in a leather bound clam shell box with felt lining and gold trim. Donated by Mrs Ivy Edna Hill, 4/1 Bridge Street, Eltham, 4 June 1966 and includes copy of her note identifying the people. Daguerreotypes were one of the first forms of early photographs. They initially appeared in Europe in 1839 and were produced in large numbers to the early 1850s but were superseded by more modern and flexible forms of technology by 1860. The photo was usually formed on a thin copper plate with light sensitve silver iodide. They have a mirror-like appearance and the image itself was mirrored. They were usually inserted into a case or frame made of wood bound in leather or velvet and cost about one guinea in Australia, the equivalent of a week's wages. With the advent of the gold-rush and growing population came an increase in numbers of photographers both studio and travelling. The daguerreotype process was protected by patents and could only result in a single image from which no copies could be made. With new technology involving wet colloidion glass plate negatives and albumen paper prints of which multiple copies could be produced at significantly reduced cost, the dauguerreotype quickly fell out of favour. An accompanying note with the photo written by Edna Hill of 4/1 Bridge Street Eltham dated 4 June 1966 states: "Dear Mr Watson, I think the enclosed old time photograph will be of interest to you. It would have been taken about 1860. The two ladies are the wives of the original pioneers of the Hill family. The one in the cap was the wife of Henry Hill, the other of Isaac Hill. The children are those of Mrs Isaac Hill, and grandchildren to Henry Hill. The little girl on the left is Amelia, the baby Isaac, the second girl is Mary Jane, and the boy on the right is Bob Hill. They grew up tobe Uncles and Aunts of my late husband. I greatly appreciated a letter received a few months ago per Cr Pelling, from the Shillinglaw Cottage Committee. Yours sincerely, Edna Hill" Victorian birth registrations show Mary Jane Hill was born 1857 in Eltham (9879 / 1857) and Isaac Hill at Eltham in 1860 (1972/1860) NOTE: Mrs Isaac Hill was Ellen Fitzsimons (1834-1863), mother to Henry Hill. Mrs Georgina Hill, wife of Henry cannot be the lady in the cap as she was not born till 1864. Georgina Reynolds (1864-1927) married Henry Hill (1862-1948) in 1884. This lady has significant wrinkling of the face, especially around her mouth. It is possible that she is the mother of Mrs Isaac Hill (Ellen Fitzsimons) who was Isabella Fitzsimons (nee Ferguson).This photo forms part of a collection of photographs gathered by the Shire of Eltham for their centenary project book,"Pioneers and Painters: 100 years of the Shire of Eltham" by Alan Marshall (1971). The collection of over 500 images is held in partnership between Eltham District Historical Society and Yarra Plenty Regional Library (Eltham Library) and is now formally known as 'The Shire of Eltham Pioneers Photograph Collection.' It is significant in being the first community sourced collection representing the places and people of the Shire's first one hundred years.Digital image 4 x 5 inch B&W Negsepp, shire of eltham pioneers photograph collection, eltham, hill family, research (vic.), women, amelia hill, bob hill, daguerreotype, early settlers, georgina hill (nee reynolds), isaac hill, mary jane hill, mrs henry hill, mrs isaac hill, ellen hill (nee fitzsimons), isabella fitzsimons (nee ferguson) -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTin Bushells, after 1937

Bushells tea and coffee producers started in Brisbane(1883) and expanded to Sydney, Melbourne(1899), Fremantle and finally to Auckland(1937). Like other Pacific Island sourced condiments Tea and coffee were a lot easier to import than British or European goods. Local Australian industries were starting to develop and grow to overcome the long transportation times and the high costs of goods from traditional suppliers. Bushells Pty Ltd is a prime example.This "Bushells" Coffee tin is a good example of Australian "grown" condiment suppliers serving the "whole" of the Australian marketplace. Rural areas were not neglected and the purchase price for goods were a reasonable levels. Kiewa Valley experienced a population growth from the late 1940's and due to the migrant works in the Kiewa Hydro Scheme the greater use of coffee was initiated. Rural areas, on the whole, where the population was more connected to some degree with a British heritage lineage were predominately tea drinkers. The American film productions, however, screened in Australia post 1950's showing a greater degree of coffee drinking "stars" had a long term effect upon the drinking habits of the rural populous. This round tin of coffee with lid is made from pressed steel lid framed top and bottom. Sturdy cylindrical body is made of cardboard. Paper information label is pasted onto the container with promotional and logo information.In large print and on opposite sides are two manufacturers labels.The topprint and on a diagonal slant in gold letters on a dark blue background is "BUSHELLS" underneath this "PURE" and below this on a red background "COFFEE". On one side in smaller print "EASY TO MAKE" and below this "Use one dessert-spoonful for each cup of coffee desired. Place in the pot and pour over it fresh water briskly boiling. Let stand for five minutes, then strain". Below this "1 IB. net" and underneath is a signature "BUSHELLS" below this in small print "Pty. Ltd." Below this, in a vertical row are"SYDNEY MELBOURNE fREMANTLE AUCKLAND"coffee and tea processors and distributors, hot drink suppliers -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyFrame - Photograph

This photograph frame with its decorative floral and Greek patterned boarder was typical of the early 1900's when photography was in the hands of the professional artist. It was in a period before the "instant" photo and required a dark room and processing liquids for development. It was therefor in a time when photographs were "shot" only at important events be they family or public occasions.This photograph frame holds and protects, part of a very significant occasion, the 90th birthday photograph of the matriarch of one of the founding families within the Kiewa Valley. The frame therefore has historical significance.This gold painted aluminium photograph frame has a glass (broken) pane within a formed inlay and two swivel clip toggles. These are installed to allow the photograph to be securely positioned within the correct alignment of the the frame.The metal front plate has seven rivets holding the cloth covered cardboard back frame to the metal front cover. The front part of the frame has sculptured wild flowers and is boarded with a Greek "key" pattern. Half way on the back panel is a rectangular swiveled stabiliser flap. See also KVHS 0093.photograph frame early 1900's, the roper family -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Daguerreotype Photo Case, Members of the Hill family, early Eltham settlers, c.1860

Mrs Georgina Hill (wife of Henry), nee Reynolds (of Research, Vic.) in cap [possibly misidentified by donor - see note below] with Mrs Isaac Hill and her children (left to right) Amelia Hill, (born 1853) Mrs Isaac Hill with baby Isaac (born 1860, Eltham) on her lap. Mary Jane Hill (born 1857, Eltham) seated on Mrs Henry Hill's lap and Bob Hill. The Hill family were early settlers of the Eltham area. Daguerreotype photo enclosed in a leather bound clam shell box with felt lining and gold trim. Donated by Mrs Ivy Edna Hill, 4/1 Bridge Street, Eltham, 4 June 1966 and includes copy of her note identifying the people. Daguerreotypes were one of the first forms of early photographs. They initially appeared in Europe in 1839 and were produced in large numbers to the early 1850s but were superseded by more modern and flexible forms of technology by 1860. The photo was usually formed on a thin copper plate with light sensitve silver iodide. They have a mirror-like appearance and the image itself was mirrored. They were usually inserted into a case or frame made of wood bound in leather or velvet and cost about one guinea in Australia, the equivalent of a week's wages. With the advent of the gold-rush and growing population came an increase in numbers of photographers both studio and travelling. The daguerreotype process was protected by patents and could only result in a single image from which no copies could be made. With new technology involving wet colloidion glass plate negatives and albumen paper prints of which multiple copies could be produced at significantly reduced cost, the dauguerreotype quickly fell out of favour. An accompanying note with the photo written by Edna Hill of 4/1 Bridge Street Eltham dated 4 June 1966 states: "Dear Mr Watson, I think the enclosed old time photograph will be of interest to you. It would have been taken about 1860. The two ladies are the wives of the original pioneers of the Hill family. The one in the cap was the wife of Henry Hill, the other of Isaac Hill. The children are those of Mrs Isaac Hill, and grandchildren to Henry Hill. The little girl on the left is Amelia, the baby Isaac, the second girl is Mary Jane, and the boy on the right is Bob Hill. They grew up tobe Uncles and Aunts of my late husband. I greatly appreciated a letter received a few months ago per Cr Pelling, from the Shillinglaw Cottage Committee. Yours sincerely, Edna Hill" Victorian birth registrations show Mary Jane Hill was born 1857 in Eltham (9879 / 1857) and Isaac Hill at Eltham in 1860 (1972/1860) NOTE: Mrs Isaac Hill was Ellen Fitzsimons (1834-1863), mother to Henry Hill. Mrs Georgina Hill, wife of Henry cannot be the lady in the cap as she was not born till 1864. Georgina Reynolds (1864-1927) married Henry Hill (1862-1948) in 1884. This lady has significant wrinkling of the face, especially around her mouth. It is possible that she is the mother of Mrs Isaac Hill (Ellen Fitzsimons) who was Isabella Fitzsimons (nee Ferguson).Early pioneer settlers of ElthamAntique daguerreotypes in hinged gold frame, glass encased in a small clam-shell box lined with padded red felt and with catchamelia hill, bob hill, early settlers, eltham, hill family, isaac hill, mary jane hill, mrs henry hill, mrs isaac hill, daguerreotype, georgina hill (nee reynolds), research (vic.), sepp, shire of eltham pioneers photograph collection, women, ellen hill (nee fitzsimons), isabella fitzsimons (nee ferguson) -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - Brick, 94 Merri Street Warrnambool, Circa 1850

The building at 94 Merri St is amongst the earliest buildings in Warrnambool. It was possibly constructed before 1854 and maybe as early as 1848. The original building consisted of four main rooms under a hip roof. The outer walls were masonry , apparently rubble The Heritage Council indcate that on the balance of probabilities this was the general store of Richard Osbourne and John Moffat Chisholm built in 1847-48.The building at 94 Merri Street had historical and architectural significance to the state of Victoria. It was a rare example of surviving, pre separation building with associated interest in its materials and components It is associated with Richard Osbourne who founded the Warrnambool Examiner(1851_1889) and the town’s first historian. Architecturally, the significance of the house lay in the hand -wrought timber framing. All the major timbers in this building had been hand sawn. The Gold rush of the 1850’s saw this process mechanised. A kitchen fireplace in the rear skillion included a large block of Merri Creek Mudstone, a combination of “tufa” and clay that was used in the Warrnambool District as an excellent substitute for fire bricks. The house was demolished in 2011 and items of significance were salvaged, this brick being one. While some bricks were imported, there is evidence that there were a number of brick burning businesses in operation around this time. However it is difficult to ascertain to which group this brick belongs. Red clay rectangular brick. Contains some small gravel like material, possibly ferrous buckshot, grey mortar remnants on side and diagonal crack along one side.warrnambool, 94 merri street, richard osbourne, john moffat chisholm, hand sawn timber, brick, building materials -

Cheese World Museum

Cheese World MuseumDVD, A Look at our History -Vol.2, 2005

Series of interviews with former employees of Kraft (Allansford) and directors of Warrnambool Cheese and Butter Factory discussing their time and experiences as employees and directors of the factories. Warrnambool Cheese and Butter Company Ltd was established in 1888 and in 1935 developed a relationship with Kraft Foods Australia whereby Kraft leased premises from WCB. The two companies shared the milk collected to make their core products of cheese (Kraft) and butter and milk for domestic use (WCB). This arrangement continued until 1997.Gold DVD in plastic case, B&W cover with colour WCB logo.A Look at our History: Ron Campbell, Steve Heazlewood, Jim Mahony, DJ (Barney) Loganallansford, heazlewood, steve, campbell, ron, mahony, jim, logan, dj (barney), wcb, warrnambool cheese and butter factory company ltd, kraft foods ltd, dairy industry, dairy processors, factories, local history, cairns, peter, cheese manufacture -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Teapot, First half of the 20th century

Lusterware is a type of pottery or porcelain with a metallic glaze that gives the effect of iridescence. The technique on pottery was first developed in Mesopotamia (modern Iraq) in the early 9th century. It is produced by metallic oxides in an overglaze finish, which is given a second firing at a lower temperature in a "muffle kiln", or a reduction kiln, excluding oxygen. The Lusterware effect is a final coating applied over the ceramic glaze, and fixed by a light second firing, applying small amounts of metallic compounds (generally of silver or copper) mixed with something to make it paintable (clay or ochre). This is then fired in a reducing atmosphere at a temperature high enough to "soften" the glaze from the first firing, and break down the metallic compounds, leaving a very thin ("perhaps 10 or 20 atoms thick") layer that is fused with the main glaze, but is mainly metal. Lusterware normally only uses one colour per piece, and the range is limited a "gold" derived from silver compounds was historically the most common. The process has always been expensive and rather unpredictable, always requiring two firings, and often the use of expensive materials such as silver and platinum. The very thin layer of luster is often delicate, and many types of Lusterware are easily damaged by scratching removing the metallic layer, or by contact with acids. Lusterware has therefore always been for display and occasional use, although by the 19th century it could be relatively cheap. Many pieces show the luster effect only working correctly on parts of the surface, or not at all. An item probably made in Staffordshire UK where this type of pottery was popular in the late 19th century by unknown pottery as the subject item has no marks. The teapot at this time cannot be associated with a historical event, person, or place, provenance regards manufacture is unknown, item assessed as a collection asset given it was produced before 1950.Teapot ceramic ornate copper lusterware abstract floral design handle has a protruding sculptured bird for thumb grip. Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, teapot, tea set, kitchen ware, ceramic, lusterware, pottery, staffordshire uk, pottery finishes -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Federation University Historical Collection

Federation University Historical CollectionComputer, Mutlitech Industrial Corporation, Micro-Professor MPF-IP and manuals, 1983 (estimated)

The Micro-Professor I Plus (MPF-IP) was a low cost, versatile microcomputer system featuring sophisticated software and hardware capabilities. (MPF-IP) boasted a display panel with the ability to display 20 characters using 16-segment fonts. All 64 standard ASCII characters could be displayed. The operation of the MPF-IP was controlled by an 8k monitor program which resides in the Read Only Memory (ROM). The monitor, aided by 4k Random Access Memory (RAM), enabled the user to enter a comprehensive set of single keystroke commands, making it easier for the user to use the CPU, memory and I/0 devices. This allowed the user to concentrate of microprocessor software development and application design. The system allowed printing at 48 lines per minute, and the ability to permanently record the commands, data, programs, status and other messaged. Each character printed by the printer is in a 5 by 7 dot matrix. Although the prime purpose of the programming was for machine language object code formed as hexadecimal numbers, the Micro-Professor has an embedded Tiny Basic interpreter for which formation of some of the alpha characters using a standard 7 segment display was ingenious. The program memory consisted of non volatile 2 kilobytes electrically programmable ROM whilst the Random Access Memory came with 2 kilobytes of static RAM but could be upgraded to 4 kilobytes by insertion of another chip. The entire memory space of 64 kilobytes was accessible by way of the terminals on the left hand side of the board. Engineering and Science students from the Ballarat School of Mines and the Ballarat College of Advanced Education used a class set (as they were relatively inexpensive at approx. $100 each) during the mid to late 1980s. Student were encouraged to borrow the Micro-Professors in order to assist in learning how to use them. Only one was ever not returned on time. When pressed to return the device the student confessed that his dog had chewed the plastic case. This is still in our collection complete with bite marks! The Micro-Professor used a Zilog Z80 microprocessor. This was the most powerful of the 8 bit microprocessors at the time. Zilog was derived from the Intel 8080 microprocessor. The Z80 had 158 instructions of which the Intel 78 instructions were a subset. The Intel processor continued on through development in the IBM computers as 8086, 80286, 80386, 80486 and later the pentiums. Zilog lost most of its market share when it developed the 16 bit Z8000 microprocessor. Although the microprocessor was excellent, the lack of peripherals caused users to abandon Zilog products. A brown and gold plastic box containing a microcomputer for use in classrooms. Four manuals are titled 'Micro-Professor MPF-IP user's Manual', 'MPF-I Experiment Manual (Software/Hardware)', Micro-professor MPF-IP experiment Manual (Software/Hardware)' and Micro-Professor MPF-I Monitor Program Source Listing.microcomputer, micro computer, micro professor, electronics -

Federation University Historical Collection

Federation University Historical CollectionBook, Machinery for Metalliferous Mines, 1894, 1894