Showing 115 items matching "hand crank"

-

Mont De Lancey

Mont De LanceyCake Mixer, Landers, Frary & Clark, Circa 1905

... , operated by hand-cranked handle with a wooden knob. Mixer attaches... cake mixer with 2 beaters and 1 whisk, operated by hand-cranked ...Tinplate round cake mixer with 2 beaters and 1 whisk, operated by hand-cranked handle with a wooden knob. Mixer attaches to a table with a screw on clamp.whisks, food processing equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Cherry and Sons, 1890-1920

... to an exterior metal hand crank with turned wood handle, through a hole.... Beneath the hand crank is a hole from the interior lined ...The subject item is a good example of a large, hand-operated Bentwood box butter churn used to make up to 14 pounds of butter. It was made in Gisborne, Victoria, by the famous manufacturer, E. Cherry, and is known as an Improved Patent No.2 model probably dating from the late 1800s. The Cherry works specialised in making all types of butter churns and equipment for both domestic use on farms and small butter factories during the late nineteenth and early to mid. twentieth centuries. Milk was "separated" to retrieve the cream which was then beaten to make butter. E Cherry began making various models of Cherry butter churns in 1858, Edward Cherry migrated from Herefordshire England to Australia in 1855 with his wife Ann Appleby, nee Davis, and established a joinery workshop at Gisborne, Victoria. He began by making butter churns in his spare time and his product soon became popular allowing him to establish a viable business. A factory was established in 1875 and he started to make churns of all sizes including up to industrial scale. He exported his products to many countries around the world, Edward Cherry died in 1909 and the business was then run by his son George until he died in 1917. E Cherry's other son Thomas (1861-1945) was also involved in the firm maintaining an interest for several years. He had been born in Gisborne and became a senior house medical surgeon at the Melbourne Hospital in 1890. He continued his studies at Kings College London, eventually becoming a renowned bacteriologist and agricultural scientist. A significant giving an snapshot into how early industrial manufacturing became established in Australia.Rectangular manual butter churn, footed wooden box containing an X-shaped wooden interior rack, which is joined to an exterior metal hand crank with turned wood handle, through a hole in the box. Beneath the hand crank is a hole from the interior lined with metal. The lid has a carry handle affixed to the lid on two cross pieces attached to the lid by brass screws.Label in block transfer Manufactured by Cherry & Sons Pty Ltd Gisborne, Victoria Size "00"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, butter churn, cherry and sons, wooden butter churn -

Puffing Billy Railway

Puffing Billy RailwayLister Auto Truck

... petrol motor which is Hand Cranked to start.... cylinder petrol motor which is Hand Cranked to start. Lister Auto ...The Lister Auto-Truck was a small monowheel tractor built for moving light loads around factories, railway yards and similar sites. They were built by R A Lister and Company of Dursley, Gloucestershire, well known for their range of small stationary engines The Auto-Truck was one of several monowheel tractors to appear in the 1920s and '30s, with the availability of small, reliable petrol engines, as developed for motorcycles and the stationary engines for which Lister were already known. These were tricycle vehicles, with the single leading wheel used for both drive and steering. Their simple construction carried most of the mechanism on this wheel as a single unit, the chassis with the trailing wheels being little more than a trailer for balance. Simplicity was a key feature. The engines were single-cylinder and air-cooled. Ignition was by magneto, rather than requiring a battery and electrical system. One of these designs was produced in the 1920s by George Grist of the Auto Mower Co., Norton St Philip, Somerset. The engine was a JAP 600 cc four-stroke air-cooled sidevalve, a typical small engine of the time. The Auto Mower Co. were Lister agents and when Lister heard of this 'Auto-Truck' they bought one for use in their own factory. It was used to carry heavy engine castings from the foundry to the machine shop. Lister customers saw them and there was such interest in wanting to buy them that Lister negotiated with Auto Mower to build them under licence. Although Lister were already well known for their small petrol stationary engines, these were heavy cast-iron engines with water hopper cooling and unsuitable for vehicle use. Lister remained with the JAP engine for the Auto-Truck. The Auto-Truck was designed for use in factories or other places with smooth surfaces of concrete or tarmac. This allowed the use of small solid-tyred wheels with only simple suspension, making the vehicle simple, cheap and lightweight. They had little ability on soft surfaces though and could even topple over if driven carelessly across slopes. Their design was a compromise between the top-heavy nature of the tall engine grouping above its wheel and a well thought-out chassis for stability. The bearing between them was a large diameter ring roller bearing, mounted at the lowest part of the chassis. This gave rigidity and stability, even after long wear. A ring of rolled channel girder was attached to the engine group and rollers on the chassis carried the load upon this. On early Auto-Trucks this bearing is set very low, in line with the chassis members, and is covered by thin steel plates. The front panel of the engine cover is distinctive with large ventilation holes and a Lister signature cut through it. Strangely this panel is made of thick cast iron, providing substantial weight high on the engine and only adding to its top heaviness. To improve visibility of moving vehicles in noisy factories, this panel was often painted white, the rest of the vehicle being Lister's usual brunswick green. The driver was seated on a Brooks bicycle saddle, which in recognition of the lack of vehicle suspension, was carried on the end of a cantilevered bar that acted as a leaf spring. A wide handlebar on the engine group was used for steering. A squeeze bar the width of this handlebar engaged the clutch. Controls included a hand throttle, a gear lever with two forward and one reverse gears, and a large handbrake lever. The engine unit rotated freely for a full 360° rotation. When used in reverse, the Auto-Truck could either be driven from the saddle, looking backwards over the driver's shoulder; or they could dismount, swivel the engine unit around and control it as a pedestrian-controlled truck from behind. Under the engine cover were two equal diameter tanks, a fuel tank for petrol and a shorter oil tank. Engine and chain-drive lubrication used a total-loss oil system, controlled by a small pump and needle valve. Info Ref: Lister Auto-Truck - Wikipedia https://en.wikipedia.org/wiki/Lister_Auto-TruckHistoric - Industrial monowheel tractor for moving light loads around factories, railway yards and similar sites.The Lister Auto-Truck - small monowheel tractor Made of steel with three wheels. Powered by a J.A.P single cylinder petrol motor which is Hand Cranked to start.Lister puffing billy, lister, lister auto truck, monowheel tractor -

Kew Historical Society Inc

Kew Historical Society IncFunctional object - Laundry Equipment, American Wringer, Household Clothes Mangle, Twentieth Century

... Large mechanical hand cranked household laundry mangle... Rolls Large mechanical hand cranked household laundry mangle ...A large device for drying laundry consisting of two rollers between which the wet laundry is squeezed (or wrung); a mangle. American English uses the term 'Wringer' whereas UK English uses the term 'mangle'. Later devices were typically electrified.Large mechanical hand cranked household laundry mangle with hardwood rolls and metal fittings. Information about the equipment is stamped/incised on both the metal and wooden frame.Household Clothes Mangle /American Wringer No 120 / Inc Metal Bearings / / Hardwood Rollslaundry equipment, household mangle, wringer -

Mont De Lancey

Mont De LanceyKnife Cleaner, Circa 1929

... Cast iron and wood encased, hand-cranked, static type knife...-and-dandenong-ranges knife cleaners Cast iron and wood encased, hand ...Cast iron and wood encased, hand-cranked, static type knife cleaner. Wooden box shape with cast iron and wood handle and 'buffer' enclosed within.knife cleaners -

Mont De Lancey

Mont De LanceyKnife Cleaner, Circa 1910

... 14" diameter hand-cranked Fly wheel turning through gears... hand-cranked Fly wheel turning through gears, with twin 4 ...14" diameter hand-cranked Fly wheel turning through gears, with twin 4" diameter rollers, knife cleaner. Painted green on a red painted base."Original Model Patent"knife cleaners -

Mont De Lancey

Mont De LanceySharpener

... Cast iron mower blade sharpener, hand-cranked fly wheel... mower blade sharpener, hand-cranked fly wheel with a wooden ...Cast iron mower blade sharpener, hand-cranked fly wheel with a wooden handle. Two (2) smaller wheels for turning 'cleaner'. Attached to a wooden base.International Chicago U.S.A.sharpeners -

Mont De Lancey

Mont De LanceyKnife Cleaner, Circa 1890

... screws. Hand cranked, twin rubber roller...., within 2 sides held together by metal screws. Hand cranked, twin ...Cast iron knife cleaner, with iron and wood handle for turning 2 rubber rollers, within 2 sides held together by metal screws. Hand cranked, twin rubber roller."Spong & Co" "UneeK"knife cleaners -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press

... A hand cranked pedestal drill press, embossed "Union...-Museum Shipwreck-coast Flagstaff-Hill-Maritime-Village A hand ...A hand cranked pedestal drill press, embossed "Union" and "IH276", wooden handle on the fly wheel, handle has copper wire wrapped around it, 845 mm high, 475 mm wideflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Diving compressor and helmet, 1944

... pipe stored separately). Compressor is hand cranked. US Navy... equipment diving equipment communication under water hand cranked ...Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water pumps, refrigeration equipment, and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards, and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering, and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air, and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A.Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman's fortunes began to decline as an aging Sir Robert Davis failed to invest, or change the company's business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire-fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998). (For information regards the diving helmet & Frank King see Notes Section at the end of this document)The items are very significant as a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. The company that made the equipment was a leading inventor,developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job. Frank Kings' diving helmet and compressor (communication pipe stored separately). Compressor is hand cranked. US Navy diving helmet, Mark V. Two maker's plates attached. Made in 1944.On rear "WATER SUPPLY" On front 'PATENT" " Logo: Images (Lion, Crown, Horse, Shield within an oval) "SIEBE, GORMAN & Co. Ltd. SUBMARINE ENGINEERS, LONDON.flagstaff hill, warrnambool, maritime museum, great ocean road, us navy diving helmet, commonwealth government salvage, diving helmet, marine salvage, frank king, diver, siebe. gorman & co ltd, submarine equipment, diving equipment, communication under water, hand cranked, diving compressor -

Mont De Lancey

Mont De LanceyIce Cream Maker, Shepard's Lightning, Circa 1880

... , with a cast iron hand-cranked handle and a wooden knob. Mechanism... the cream, with a cast iron hand-cranked handle and a wooden knob ...Cream is put in the metal drum, and in the surrounding space within the wooden bucket. A mixture of ice and salt is packed, turning the crank wheel rotated and paddle in the drum and mixed the cream as it froze within the encircling ice.Wooden assay barrel with two galvanised metal bands around it. Sealed inside is a cast iron drum for freezing the cream, with a cast iron hand-cranked handle and a wooden knob. Mechanism is attached to barrel with bolts and screws. Shepard's Lightning made in USA 6 oz. (On the churning mechanism) Pat. Sept 25 88, March 17 91, Feb 23 92 (On the Drum) 713 (On the Crank handle) -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMilk and Cream Fat Tester Centrifuge

... Early hand crank centrifuge for measuring the butterfat... Early hand crank centrifuge for measuring the butterfat content ...In 1890 D. Babcock invented a test for measuring the amount of butter fat in milk, either on the farm or in the dairy or creamery. Samples of milk were put in the glass vial and then spun (by cranking the handle) causing the cream to separate from the non-fat milk thus determining the percentage of cream in the milk. The product was then priced accordingly.Dairy farming in the Kiewa Valley was the main industry with farmers keen to test the quality of their milk before selling it. This centrifuge enabled them to test the amount of milk and cream being produced by their herd. This '1903 Butter Fat Tester' made 100 turns per minute. Early hand crank centrifuge for measuring the butterfat content of milk in the farm dairy or creamery. It has 4 brass / copper removable canisters with glass vials and tubes that fit inside. The glass vials bulge at the bottom and are marked with measurements 1, 2 etc.Numbers on the glass vialsmilk and cream tester, dairy farming, centrifuge -

Anglesea and District Historical Society

Anglesea and District Historical SocietyButter Churn, E. Cherry & Sons, Pre 1900-1930

... is joined to an exterior metal hand crank through a hole in the box...., wooden, hand operated with wood and metal turning handle. It has ...Butter churn, wooden, hand operated with wood and metal turning handle. It has a detatchable wooden lid. Called the bentwood box churn. Outside is an x shaped wooden rack which is joined to an exterior metal hand crank through a hole in the box.Side: E. Cherry & Sons, Gisbornebubb family, evans family, butter churn, bentwood box churn -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSeparator

... Separator machine. Hand-crank operated milk separator..." stamped on 2x separator chutes. Separator machine. Hand-crank ...Separator machine. Hand-crank operated milk separator, Crown Separator Co Pty Ltd. Multi-part separator stand with bowls (2) and attachments including a spanner small cone shaped objects on homemade stand. ."42D022" stamped on 2x separator chutes.Manufacture's plate "MADE IN SWEDEN" , "CROWN SEPARATOR / HEAD OFFICE 547 FLINDERS ST MELBOURNE". ."42D022" stamped on 2x separator chutes. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, milk separator, farm machinery, dairy machinery, dairy industry, crown spearator co, cream -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyGrinder/Mincer - Meat

... out of a circular grinder. The hand crank is curved... to spill out of a circular grinder. The hand crank is curved ...Old farm kitchen tool used for mincing meat manually.Used at Tawonga, in the Kiewa Valley, by resident Des WartonCast iron with dull smooth surface consisting of a tap to screw it onto a table, a barrel enclosing the auger that turns when the handle is wound around and forces the meat to spill out of a circular grinder. The hand crank is curved with a wooden knob . The outlet is oval shaped.Embossed on barrel: "Universal" Embossed on outlet "2" Embossed on handle "L.F. & c - New Britain Conn U.S.A."household tool, kitchen, meat mincer, grinder, universal no. 2 -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkClothes wringer, Acme Wringers Ltd, mid 19th century

... on hand crank, two fold-up grey and white guides on either side.... rubber rollers with screw adjustment, wooden handle on hand crank ...Hand operated clothes wringer, white enameled steel with red and chrome detailing. Two screw attachments for mounting on a trough, white rubber rollers with screw adjustment, wooden handle on hand crank, two fold-up grey and white guides on either side. -

Mont De Lancey

Mont De LanceyIce Cream Maker

... it. Bottom band forms base with a cast iron three feet stand and hand... base with a cast iron three feet stand and hand-cranked wheel ...Wooden ice cream maker with three green metal bands around it. Bottom band forms base with a cast iron three feet stand and hand-cranked wheel. Cast iron locking mechanism on top. Wire and wooden handle to carry. Within a metal drum for freezing cream.Original Model 2ice-cream churns -

Nillumbik Historical Society Incorporated

Nillumbik Historical Society IncorporatedTool - Portable Sleeper Drill, Early 20th century

... to 45 degrees using double hand cranks and gears. A rack can... to 45 degrees using double hand cranks and gears. A rack can ...This drill was used in the construction of the Eltham-Hurstbridge Railway extension in 1911. The device was placed over the wooden sleeper to drill holes for the iron spikes which held the rail down. Example of tools needed to build railway in early 20th Century in the Diamond Valley.Drill mechanism mounted on wooden frame. Mechanism tilts to enable holes to be drilled vertically (normal) or at angles up to 45 degrees using double hand cranks and gears. A rack can be engaged to raise and lower the mechanism and drill bit. Mechanism appears original. Base frame replaced recently. #drill, #railwayconstruction, #sleepers, #tilting, #handoperated -

Orbost & District Historical Society

Orbost & District Historical Societysewing machine, late 1860's - 1870's

... A small black hand-cranked lockstitch sewing machine... indecipherable marks. A small black hand-cranked lockstitch sewing ...The early settlers of Orbost had to be self sufficient making their own clothes, tableware, bed coverings, furnishings and equipment. Many women were skilled dressmakers and craft workers. This item reflects that time.A small black hand-cranked lockstitch sewing machine. It has a backwards C-shaped body. The wheel and base are decorated with a gold pattern. On the end above the needle assembly is a brass plate The balance wheel has a handle. The pattern on the wheel is a gold border with two gold, red and green stars formed by interwoven triangles. On the cloth plate is stamped "Patent March 1867 Heron Gresham" with some indecipherable marks.sewing-machine needlework -

Orbost & District Historical Society

Orbost & District Historical Societymangle, Ewbank Emerald and Keighley Ironworks, 1910-1918

... aid. This one is powered by a hand crank and used to wring... aid. This one is powered by a hand crank and used to wring ...Before the invention of spin driers around the 1950's most households had a mangle. A mangle or wringer is a mechanical laundry aid. This one is powered by a hand crank and used to wring water from wet laundry and seems to be a commercial one. This mangle is from the Orbost Club Hotel. It was used in the Club Hotel and later by Bronwen Di Bari in her art workshop.This item was used by the Orbost Club Hotel, the first hotel in the Orbost district.It was built in 1884 by Mr J.A. Petterson with the licence in the name of Mr Thomas Maguire, Mr Petterson's step-son (more information in Deborak Hall's In Times Gone By).A large commercial wooden and cast iron laundry mangle. It has two wooden trays and two wooden rollers. It was originally painted green. There are four metal casters on the bottom. It has a metal spring to adjust the tension with two tap handles.On side - EWBANK On turning wheel - 511 On wood at top - 24 X 5 1/4 (size of rollers) EMERALD laundry mangle wringer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Diving Compressor, Siebe Gorman & Co. Ltd, 1880-1890

... , London, eccentric hand cranked in brass mounted mahogany case..., eccentric hand cranked in brass mounted mahogany case ...This compressor was part of the E.G. Ward Collection. It is connected to the diving suit and boots also in our collection. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water-pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr. E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The compressor is a very significant item as it gives a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. Siebe & Gorman the company that made the equipment was a leading inventor, developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job during the early days of marine exploration.A single cylinder divers' pump by Siebe Gorman & Co Ltd, London, eccentric hand cranked in brass mounted mahogany case with instructions to the underside of the lid, brass covered pressure gauge and air outlet, brass makers plaque to the front, water inlet and outlet to the rear, green painted lifting rings. Machinery has some blue painted areas on the metal.Plate on the back 'WATER SUPPLY" "WATER OVERFLOW" "WATER DRAIN-IN" Pressure gauge dial "BOURDON'S PRESSURE GAUGE" STEBE GORMAN & CO. LONDON", "LBS PRESSURE" "FEET OF SALT WATER" Plate on the front " PATENT, Siebe Gorman & Co Ltd Submarine Engineers" below emblem (Lion, Crown, Horse)flagstaff hill, warrnambool, flagstaff-hill, maritime-museum, diving compressor, london, siebe gorman & co ltd, marine technology, life saving, deep sea diving, maritime museum, maritime village, manine history -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Wertheim Sewing Machine, c1880

... A Wertheim hand–crank sewing machine c1880. The hand... body of machine A Wertheim hand–crank sewing machine c1880 ...Hugo Wertheim (1854–1919) arrived in Melbourne in 1875. He became a successful agent for sewing machines manufactured by his father’s cousin Joseph Wertheim in Frankfurt, Germany. Hugo married Joseph’s daughter Sophie Emilie and they settled in Melbourne. Hugo made many trips back to the main factory in Germany and, with extensive advertising, established a thriving business for sewing machines, bicycles, pianos under various ‘brand names’ - Wertheim, Electra, Planet, Griffin, Hapsburg. It has been said that Dame Nellie Melba preferred a Wertheim piano for her performances. In 1908 Hugo opened a large piano factory in Bendigo St Richmond, Victoria. His son Herbert maintained the business until the factory closed in 1935.The pioneer settlers and market gardeners of Moorabbin Shire had to be self reliant and made their own clothing and utensils. This sewing machine was one of many items they used to exhibit the skill and craftsmanship of the women in these families. A sewing machine was a necessary part of each home.A Wertheim hand–crank sewing machine c1880. The hand machine was operated by turning the handle. The hand machine could also be fitted to a stand with table and draws, the machine could then be used by hand or foot. This type of sewing machine was widely used in many homes, in an era when hand-made clothes were the “norm”, and clothes were mended, or ‘re-made’ into another garment 'WERTHEIM' across body of machinemelbourne, clothing, brighton, moorabbin, germany, piano, pioneers, richmond, bentleigh, dressmaking, market gardeners, early settlers, craftwork, sewing machines, wertheim hugo, wertheim joseph -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - PICTURE THEATRE EQUIPMENT

... 1894, hand cranked Pathe projector (Paris).... 16 inch record. UK. Thomas Edison's Kinetoscope 1894, hand ...Photocopy images of foreign picture theatre equipment 16 inch transcription disc on a turntable fixed to a projector, open air cinema screen middle of picture behind Art gallery & Capital theatre, Golden Drive in carbon arc lamp, carbon arc lamp, sound on disc 16 inch record. UK. Thomas Edison's Kinetoscope 1894, hand cranked Pathe projector (Paris).audio-visual technology, audio-visual appliances, picture theatre -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumInstrument - Becquerel Phosphoroscope (incomplete), c1860-1880

... by the hand crank linked to a gear mechanism. The sample is placed... and are turned by the hand crank linked to a gear mechanism. The sample ...The phosphoroscope was invented by Alexander Edmund Becquerel and used to measure the amount of time that a phosphorescent substance will glow after being irradiated by a brilliant source of light.The phosphoroscope consists of a round metal chamber with a pair of rotating discs inside, arranged so that no light can pass directly through the chamber. The discs have cut-out windows spaced equally at regular angular distances and are turned by the hand crank linked to a gear mechanism. The sample is placed in a specially designed holder into the small opening near the gearing, and it is exposed to the light source through the large rear condensing lens.Engraved on chamber: 'Phosphoroscope de E. Becquerel / J. Duboscq a Parisbecquerel phosphoroscope, phosphoroscope, optical instruments, phosphorescent, alexander edmund becquerel, jules duboscq, france -

The Beechworth Burke Museum

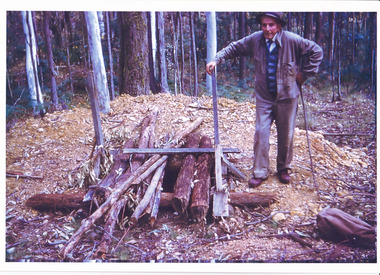

The Beechworth Burke MuseumPhotograph

... . The windless was a structure mounted over the shaft, fitted with a hand.... The windless was a structure mounted over the shaft, fitted with a hand ...The date this photograph was taken is unknown. Estimated date 1960-70s. The gentleman in the photograph and location the photograph was taken are also unknown. Perhaps in the Beechworth or Stanley area. The photo is associated to another record, 6856 as it has the same elderly gentlemen in the image. He is able to be identified through wearing the same clothes and distinctive hat in both photographs. The photograph is associated to mining as the gentleman is standing next to a small mine site where perhaps a windless or whip was mounted over the entrance of the shaft. The windless was a structure mounted over the shaft, fitted with a hand-cranked winch, which was usually constructed from wood that would have been found in the surrounding area. Colour rectangular photograph printed on glossy photographic paper.Obverse: Reverse: 6856/ mining, windlass, whip, empty record -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Hand operated seed broadcaster

... plants that do not need to be in neat rows. The hand-crank... plants that do not need to be in neat rows. The hand-crank ...Seed broadcaster were used to distribute seed across a small area or to fill in patches where seeding has been missed. This method does not ensure a uniform distribution of seeds unless the person using the machine walks at a very measured pace. It also requires a lot of time and manual labour if used in larger areas. It was most used for planting cover crops, grains, grasses and similar plants that do not need to be in neat rows. The hand-crank broadcast seed spreader was invented in 1868 by Samuel S. Speicher (aka. Spyker) in Indiana, USA. By 1955 new developments included the invention of a seed broadcaster on wheels and these smaller spreaders started to disappear.This item is representative of agricultural machinery used on a local, national and international level in the late 19th and early 20th century.A metal hand seed broadcaster. A hopper at the top was the receptacle for seed. The wheel with a handle on the side when turned drives the cogs attached to an axle. This action rotates the attached spindle with blades to propel seed out the front of the broadcaster. The broadcaster would have had a shoulder strap and a bag of seed would have been added to the hopper and secured with twine through the holes around the top.agricultural tools, farm machinery -

Anglesea and District Historical Society

Anglesea and District Historical SocietyPocket Phonograph, Palliard Cie (St Croix), Circa 1926

... to the unit by a small hand crank, and sound was amplified by a small... was supplied to the unit by a small hand crank, and sound was amplified ...This mikiphone has an approximate manufacture date of circa 1926. It is stamped in the interior with the maker’s mark of Palliard Cie (St Croix), who partnered with the patent owners, Nicolas and Etienne Vadasz for the large scale production of the mikiphones. A Mikiphone – or Pocket Phonograph is one of the earliest versions of a portable music player. The Mikiphone was small enough to fit into a pocket for portability, and once unpacked had the ability to play 10” records. Power was supplied to the unit by a small hand crank, and sound was amplified by a small resonator. It is estimated that 100,000 to 180,000 of the units were made between 1924 and 1927. Luxury editions were also available with either a gold or silver casing. Le Corbusier is quoted as saying he could ‘see in the Mikiphone the essence of Esprit Nouveau’. The pocket gramophone is significant for historical and social reasons. It is primarily an enabler of leisure activities due to its portability and size. The design of the object is also significant as it showcases design advancements in the early part of the 20th century. The Swiss made "Mikiphone", the smallest talking machine ever placed on the market folded up to the size of a large pocket watch or small cheese case. Production stopped in 1927. A total of 180,000 were made. A few were made in a luxury version with gold or silver case for a "Pretentious clientele".Inside on dial: Mikiphone / Pocket Phonograph / Swiss made / System Vadasz. Outside: Pocket Phonograph / Mikiphone / System Vadosz / Patented in all countries.pocket phonograph, mikiphone, gramophone, pocket, music player, swiss made, switzerland -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Mincer, late 19th or early 20th Century

... was hand cranked which forced meat through a metal plate... was hand cranked which forced meat through a metal plate ...A meat grinder, commonly known as the meat mincer, is used for chopping meat into fine pieces. Alternatively, it can be used for the mixing of raw or cooked meat, fish and vegetables. It is the best way to process meat, and is a widely used piece of equipment by butchers and in the home.. Butchers have been known to use either mincing knives or meat cleavers in the kitchen for years to produce a quantity of minced meat. This was a slow and laborious process. The advent of the meat mincer has not only made the mincing process easier but also faster. The meat mincer has slowly evolved over the years into what it is today. The first meat mixer or meat mincer was invented in the 19th century by a German inventor named Baron Karl Drais. Although some versions of the device date back to much earlier. The oldest form of meat mincer was hand cranked which forced meat through a metal plate with several small holes in it, which resulted in long and thin strands of the meat. The meat was fed into the funnel that was placed at the top of the mixer. This meat would pass through a hand cranked screw conveyor that would squash and mix the meat before passing it through the metal plate. Needless to say, this was again a slow and laborious procedure to follow to produce large quantity of meat. With passage of time, this hand cracked machine became powered by electricity. The meat mincer has a great adaptability and efficiency now. The huge variety in mincer plates allows a butcher to produce different types of minced meat in any shape desired. However, traditional manual meat mincers have not really changed a lot. They are manually operated and made of cast iron, as earlier. They are similar to the original mincer designs, dating back to the early 1900s. Some butchers still prefer using a variety of mincer knives. Adapted from: https://brennan-group.com/blogs/news/history-of-the-meat-mincerThe development of the meat mincer enabled both butchers and home cooks to process and grind meat effectively.Clamp on meat mincer with handle for rotating the mincing apparatus inside.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, meat mincer -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryEquipment - Magneto Electric Machine

... and the patient's hands before cranking the machine to produce a small... the sponges and the patient's hands before cranking the machine ...Experimentation with electricity for medical purposes has its origins in the late 18th Century. Throughout the 19th Century it became more common, including as a proposed treatment for 'nervous' disorders. This device is a small, portable, 'at-home' device.Device for administering electric stimulation to patients. Consists of a wooden box containing a hand driven generator, with terminals for the attachment of electrodes that may be held by the patient or placed against the patient's skin. The directions for use include information about wetting the sponges and the patient's hands before cranking the machine to produce a small electric shock. electricity, medicine -

The Beechworth Burke Museum

The Beechworth Burke MuseumPostcard, George Symons, c.1990

... structure mounted over the mining shaft and fitted with a hand... structure mounted over the mining shaft and fitted with a hand ...The photograph printed on this postcard comes from the collection of the Mitchell Library in Sydney. It is sepia in tone and depicts seven men standing and sitting around a mine shaft in the Beechworth region. The photograph has been dated to approximately 1872. This period in history post-dates the Victorian gold rushes which occurred 1852-1853 in Ballarat, Bendigo and Beechworth. During this period, in the 1870s, the surface alluvial gold had been discovered and removed from location. Therefore, in order to reach the deeper and less accessible alluvial gold, diggers began to dig shafts into the earth. These shafts sunk below the ground level by 20 to 30 feet and required timber structures around the entrance and winches to bring the paydirt to the top. The top of this wooden structure is visible behind the man standing in the upper right of the image. This type of mining was highly dangerous as mines often caved in which injured the minors and often resulted in death. Thus, following this period, in the early 1900s, miners opted instead for hydrolic slucing which cut away the earth without the devastating consequences of a mine cave in. This particular group of miners appear to have been unable to afford a horse (then worth around 50 pounds) which were generally used at mines like this to help pull buckets attached to ropes up and down the mine. Instead, this group brought the buckets up and down by windlass. The windlass was a wooden structure mounted over the mining shaft and fitted with a hand-cranked winch which enabled the bucket attached to the rope to be brought up and down.Gold was first discovered in Beechworth in Spring and Reid's Creek in the summer of 1852-1853. At its popularity, this region had approximately 8000 people on the gold fields searching for gold on the banks of these creeks. These periods did not require the use of heavy machinery or the digging of deep mining shafts like the one depicted in this image. Therefore, this image has important connotations for the technologies associated with mining during the approximated 1870s when gold was harder to access. This is a later period in gold history which does not fit into the "gold rush" period. Instead, it occurred after the surface gold had disappeared and therefore, is essential for researchers who are investigating the mining techniques and structures used to reach the alluvial gold which was located deeper under ground in the 1870s. This period predates the use of big heavy machinery used to mine in the 1900s which include dredges. Images such as this one can also impart essential information as to the wardrobe and fashion of men during this period. It also imparts knowledge about the landscape of Beechworth which is useful for people researching the environment and impact of gold mining in the north-east region of Victoria. In addition, since this image is a postcard reproduction of an early Australian image which may date to approximately 1990 it can impart knowledge as to the interests of people during this time period when there may have been an increase into Australian history.A sepia tone facsimile of an early Australian photograph (circa 1872) printed as a postcard.Obverse: BEECHWORTH / Victoria, Australia / Reverse: GM 2 3275 / CORRESPONDENCE / AUSTRALIAN / YESTERYEAR / CARDS / ADDRESS / Published by George Symons (057) 65 3240 / THE MINEHEAD C. 1872 / The easily gleaned gold of the early fields did / not last very long. In order to reach less / accessible alluvial gold diggers began sinking shafts as much as twenty to thirty feet down / and the mines required timbering and winches / to bring the paydirt to the top. / This syndicate has been unable to afford the / luxury of a horse (about 50 pounds) and so everything / must go up and down by windlass and rawhide / bucket. / Photo: Mitchell Library, Sydney / A sepia tone facsimile of / an early Australian photographmining album, gold mine, beechworth, burke museum, mine shaft, postcard, australian yesteryear cards, george symons, the minehead, gold fields, alluvial gold, early australia, c.1872, 1872, gold diggers, north east victoria