Showing 298 items

matching hand power

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBelt Linesman Pole, circa mid to late 1900's

This linesman belt was used under the 1947 Electricity Regulations and before tighter Occupation and Health regulations (late 1990's early 2000's) were introduced that mechanical lifting platforms(wherever possible) replaced the belt up the pole method.The safety concern was that it required that tools needed by the linesman had to be placed in a large canvas bag and attached to the belt (extra weight) then the linesman had to climb the ladder. Ladders had to be at the correct angle and not able to "slip" from their initial footings. A full harness and a secondary fall belt is now mandatory for pole linesmen. The safety of fellow workers could be compromised if they were required to assist or recover the first linesman if needed. In 2006 an additional 269 registered lineworkers were employed. Please note that the terminology of linesman has become unisex. The linesman's belt enabled the linesman to place his feet against the pole adjust the belt (if needed) and lean back securely allowing both hands to be free to work with. This linesman belt is very significant to the Kiewa Valley due to the numerous poles and high voltage overhead power structures that needed maintenance for the extensive "mushroom" installation of electrical power polls(wood and metal). On high poles (steel) climbing pegs were welded on, however in the Alpine areas snow in winter caused an OH&S problem which were hard to overcome. The safety of a linesman when maintenance of electricity line on poles can be highlighted by the New Zealand linesman who survived an 11,000 volt shock when carrying out maintenance. For the record 11,000 volts is four times more powerful than execution by "the electric chair". The maintenance of the linesman's belt was his responsibility (keeping it clean and in "good" condition). Labour laws change this initial responsibility, from the linesman, to the employer. Climbing pegs were installed on higher poles that extended beyond the reach of ladders.This thick leather linesman belt is made from two lengths of heavy lengths of leather straps sewn together to make up 80% of the belt. The remaining 20% is "the belt tonge" which has eleven holes for three (solid steel tang) buckle connections.kiewa hydro electricity scheme, victorian state electricity commission, relays, generators, electrical pole maintenance -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomTraining Set, Universal, Wireless, No 1, about 1948

The kit is packed in 2 wooden transit boxes. The Training Set is a semi-portable instrument for training operators in morse reading and sending and R.T. communication. The set comprises audio oscillators for morse reading, morse interference and background noise interference, power supply for microphones, an audio amplifier, and a switch board for group working with up to six independent, contained in the instructor's set. The instructor and each operator under training has a receiver-head gear, a hand microphone and a morse key. The instructor has an additional morse key used for providing morse interference. In the case of each operator, the microphones and headphones plug into an "operator's control unit" fitted to the table in front of each operator. The units also house a morse key, and are connected to the instructor's set by four-core cable. Plug and socket connections are used. The apparatus may be used for a class of up to 36 operators. Working Instructions - filed on Object Data Record radio, wireless, training set -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPapers - Kiewa Hydro Electric Scheme

Kiewa Hydro Electric Scheme constructed by the SECV and completed in 1961The SECV constructed the KHES from the late 1940s to 1961 in north east Victoria9 black & white pages numbered 213 to 221 held together by a staple in the top left hand corner. Photocopied from 'Water Power June 1962'kiewa hydro electric scheme, water power 1962 -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyVacuum Cleaner - Electrolux

Vacuum cleaners have been part of the household for many years. Beginning as simple tools blowing the dust to the current sucking up the dust and being powered by electricity. From the shape of a barrel to those that stand upright, from being fitted onto a 'sled' to those with wheels and from heavy to light.Used by a resident in the Kiewa Valley Electrolux cannister steel vacuum with leather handle at the top, the electric socket (and cut power cord attached) at one end and the cloth covered hose at the other end. Two steel extension handles, hose and cord works. Parts with combination dusting and upholstery tool and hardwood floor dust mop and refrigerator crevice tool. The cannister sits on a 'sled' of two long rods on each side.Hand written on the cannister "1932 Model" "Electro / lux / Made in Sweden / Design Nr B156 Registered" on top On bottom "Ser 1234 No. 1456 / Volt Watt" ....(not legible)electrolux, vacuum cleaner 1932 -

Kiewa Valley Historical Society

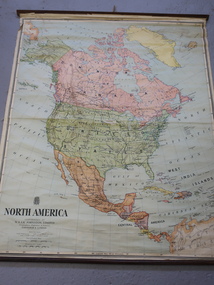

Kiewa Valley Historical SocietyMaps - Educational x 10 and Kiewa Scheme x1

Maps were used to teach children geography, the explorers, the minerals, the world etc. The school bought and stored the maps so that they were available for use. This predated electronic devices. The KHE Works map was hand drawn showing lots of detail.These maps were used by the Bogong Primary School. The Kiewa Hydro Electric Works was built by the SECV and produced hydro power. This map may have been used by pupils as well as workers on the Works. Large coloured maps on canvas, with a wooden beam along the top and bottom. Each one has a cord attached to the top so that the map may be hung up on a wall. Some are made by Chas. H. Scally & Co., Baronia Ave., Wollstonecraft, N.S.W. The Kiewa Hydro Electric Works map is pinkish and shows Rocky Valley Dam, Lake Guy and Mt Beauty pondage in dark blue.maps, educational maps, geography, primary school, kiewa hydro electric works -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySlate - School, early 1900

Historically this school writing slate pre-dates paper and electronic writing pads. This was used for non permanent written communication within or outside the classroom. It use was mainly as a quick temporary method and could be easily erased by cloth or fingers. As it could be used repeatedly without additional cost and was therefore a very cheap method of teaching and learning outdoors as well as indoors. This was especially relevant to country schools and outdoor excursions. It was fairly robust but could shatter if allowed to fall on the ground.This item evolved from a form of communication, that of primitive engravings on stone. This tablet was a refined writing/drawing pad that did not require any electronic/battery power input. This writing slate was so useful in an era where relative isolation (Kiewa Valley Schools) from electronic and cheap writing pads was the reality and the norm. This was a time when the hand writing and hand drawing was a basic form of non spoken communication. Students used this slate pad to reinforce their skills which would come in handy when they needed to produce temporary notices on slate information boards, e.g. rail/bus-time/route alterations.Writing slate used for Primary School classes. Wooden frame. Has hole in frame and string threaded through to allow it to be hung on a hook or nail.slate pads, chalk boards, school learning utensils -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPlane Wood, 1890 -1900

J.E. Bleckmann were German Blade makers, registry shows Bleckmann (1899, No. 37190):J.E.Bleckmann, Solingen, registry class 9b). As well as blades for wood working tools they were also sword makers (used in American Civil War), Bayonet makers 1871-1918 and also pocket cutlery (pocket knives) as per advertisement 1907.This wood plane holds historical importance as carpentry tools such as this would have been used in the construction of local homes, outbuildings, furniture. It represents an era before power tools. Investigation is ongoing as to ownership and specific use in the area. Hand made wooden hand plane with metal blade. Carpentry tool from 19th century1/38 / 34 mm stamped into wood on front edge of plane. Metal Blade inscribed "J.E. BLECKMANN/ WARRANTED / CAST STEEL / SOLINGEN/GERMANY"tool, blade makers, hand plane, woodworking. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph KHS Rail, Kiewa Hydroelectric Scheme Railway, Circa1940s

This photograph shows part of the railway constructed and used for the removal of soil and rocks from the tunnels bored out of the mountains for the pipeline servicing the Hydro Electricity power stations in the Kiewa Hydroelectric Scheme. This photo details an era when there were 4,000 construction workers located in two main accommodation camps, Mount Beauty (the larger one) and Bogong village. These accommodation sites were constructed and maintained as a secured or gated residential area with access only available by a special pass authorised by the Kiewa Hydroelectric Scheme. All the power used by the rail system was from electric motors connected to batteries. Overhead power poles seen on either side of the embankment details that electricity from the Scheme was in use. This use was cleaner and more environmentally friendly than the coal still used by large locomotives from city to country railways. The worker shown is not however wearing protective head and hand coverings. This is also an era where there was a lack of health and safety legislation covering workers in dangerous working conditions.Scanned photo of original black and white photo on Kodak XtraLife II paper. Picture is of a section of railway track servicing the tunnels of the Hydroelectric scheme during the 1940s - 1950sOn back of photo "Kodak XtraLife II paper"railway in kiewa electric scheme, tunneling -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph Tailrace tunnel Arch Drive, Tunnel face at Tailrace showing Arch Drive, between 1943 and 1952

... to the upper level. tailrace power station water construction Hand ...This photo was taking during construction of the tailrace tunnel between West Kiewa Power Station and Mt. Beauty. Much of the area was unstable and timber supports were erected prior to concreting. The tunnel was commenced in 1941 and completed in 1952. It brings water from the power station into the open tailrace at Mt. Beauty and then into the regulating pondage before discharge into the Kiewa River.Shows method of construction for supporting walls and ceiling of tunnel with timber, size of tunnel (note worker on upper level), and conditions in the work place during construction in the 1940's/50's - note the timber ladder to gain access to the upper level.Black and white photographHand written on back of photograph "Tunnel face at Tailrace showing Arch Drive".tailrace, power station, water, construction -

Kiewa Valley Historical Society

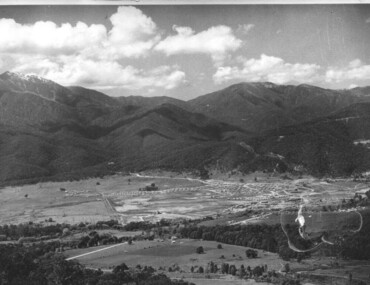

Kiewa Valley Historical SocietyPhotograph of Mt. Beauty, Mt. Beauty from transmission line, Approx 1950/51

This photo is of the very newly constructed State Electricity Commission town of Mt. Beauty. The houses up to Nelse street were erected from 1946 onward and then the township was extended beyond Nelse Street in 1950 which places this photograph about 1950/51. There is no evidence of work being commenced on the regulating pondage but the tail race canal can be seen on the centre right of photo. The workmen's camp was enlarged in 1950 to the extent of providing accommodation for a total of 1,200. There are a number of dwellings on Simmonds Creek and the road to Falls Creek can clearly be seen. Snow capped Mt. Bogong is in the upper left of the photo with Mt. Beauty behind the township rising to Big Hill beyond that.Shows the newly constructed town of Mt. Beauty surrounded by farmland and before the regulating pondage was built to discharge water from the power stations via the West Kiewa tail race tunnel into the Kiewa River. Black and white photographHand written on back of photograph "Mt. Beauty from Transmission Line"mt. beauty, construction, pondage, state electricity commission -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900s

This item wasused before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength. This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) within the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools was and still is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron, hand operated Auger has a short barrel shaped cylinder at one end (known as the "Eye") and at the other end a Helical screw blade (screws the cutting edge into wooden material, thereby creating a hole 3/4 inch diameter in the wood) . The barrel section at the top permits a metal or wooden leverage plank to be inserted. The main rod has a 180mm long cutting/screw blade running from the bottom up towards the "eye" end. From the end of the screw blade to the handle is 380mm and cylindrical, but this changes at 550mm from the "eye" end to a 14mm x 10mm rectangular shape shaft.This shaft end is welded to the "Eye".On the shaft below the "eye" is stamped " MATHESON GLASGOW" on the front side and a spade (cards) symbol on the back.auger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

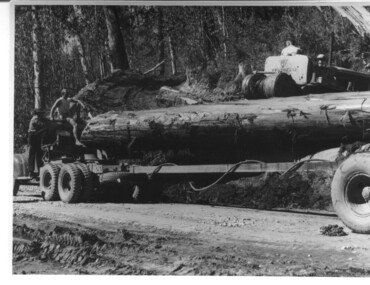

Kiewa Valley Historical SocietyPhotograph, logging at McKay Creek, Logging at McKay Creek, 1949/50

This photo was most likely taken at the site of the proposed McKay Creek Power Station. Excavation of this site was commenced in 1951 but an access road (a rough, narrow track) was put it in 1948 and widened in 1954. The State Electricity Commission would have milled logs from this area at their mill at Howman's Gap. The timber was used for building of housing and camps and provided a much needed resource as there was a general shortage of this commodity. The power station was relocated underground owing to repeated problems with landslides in the area. Restricted financial resources and the repositioning of the power station retarded construction activities and it was not completed until early 1961. An historical pictorial record of the type of machinery used in the 1950's - logging truck with bogie attached, the bull dozer and winch for hauling logs to the truck and note the lack of protective clothing!Black and white photograph showing a logging truck, bogie and bull dozer with winch for hauling the logs to the truck. Two men are on the truck, a driver on the bull dozer and a large log on the bogie. Hand written on the back of photo "Logging at McKay Creek".logging, mckay creek, timber, machinery -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0471 for another 1/8th inch hole.A number 5 stamped on the flat sideauger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0470 for another 1/8th inch hole.auger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCalendar Desk Perpetual, circa mid 1950s

This item appears to be a calendar which was in use for a multiple clientele office e.g. post office, commercial office or bank, school or educational administration area, small government office or hospital administration in the Kiewa Valley or its region. The time this item was first used, electrical or battery powered desk and office calendars did not exist for semi isolated rural regions. These type of perpetual calendars not only looked impressive but were not affected by power shortages. This was a time when not all of Victoria was adequately supplied by power. This item is quite relevant to the Kiewa Valley as it demonstrates that the time before the Hydro electricity generators where built (Mount Beauty to Falls Creek), power supplies were not keeping up to the ever increasing demand from city and rural customers. This item was in a period before mass produced automated date and time pieces were available and hand operated date and time pieces were both in a social and commercial sphere a necessity.Wooden box (varnished) with three openings (on the front) detailing ,the day(Monday to Sunday), the date (1st to 31st) and the month (January to December). On the right side of the calendar box are two winding screws (RHS 6 steel) for each opening. These permit the scrolling of the information i.e. day, number and month. This ability results in a desk calendar which is perpetual. On the back there is a steel (screwed on) hanger with a slot for wall screw.perpetual calendar, office calendars, desk calendars, desk furniture -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTelephone - Wall Mounted 184, Circa mid 1900s

This handset appeared via Australia Post Office and was to some degree manufactured in Britain just prior to 1939. During and after World War II these handsets were made in Australia. The handset belonged to the SEC Victoria and later the Kiewa Hydro Electricity Scheme. As this unit has a winder arm (to notify the switchboard) it would have resided in a workshop/machine shop and not in an office. The durability of the bakelite covering gave good protection in any environment. In years later the bakelite came in colours. This type of handset being able to endure rough handling was ideal for the surroundings of the alpine terrain. It would have been at the various outside outposts or foreman posts as swift communications was essential and communications with all sectors of work in the Hydro Electricity Scheme was mandatory, not only for safety reasons but also for efficient operational day to day progress. Also refer to article in "This Week" Newsletter 30th June 2023. Article attached to paper copy.This Australian Post Office 184 black coloured bakelite wall mounted phone was initially developed by Ericsson Telephones Ltd Britain. It was used by the SEC Office based at Mount Beauty and therefore has a winder (for power and notification to the switchboard. The hand piece (large ear and voice receptors)is placed vertically above the dial up winder.On the winder plate in hand writing is" turn handle lift handset" and below the handle "when finished replace handset turn handle"sec communications, wall telephone, internal communications kiewa hydro electricity scheme -

Orbost & District Historical Society

Orbost & District Historical Societylantern, 1939?

Blackout lantern used in WW11. This type of lantern was used during both World War. It is an artillery siege lamp and was originally used by artillery units. The lamps were powered by a single candle, the light being magnified by a lens. A shutter closes over the lens to give an illuminated vertical line. They were used originally in fortified siege artillery positions as a general purpose lamp. They were also used as aiming lamps when they were placed in front of artillery positions and used as a guide in aiming at night. These lamps were often used on the front of bicycles to guide at night. Donated by Clem Heather. Forestry Commision, carved faces on trees with axe., builder of tall. spliced single pole fire towers. This item is considered rare and important. It is historically and technically siginficant at a national level.Small black metal blackout lantern with handle. Front of lantern has round shield with small slit - small door at side for easy lighting of candle. It is hand held or placed on flat area, open base so candle can be inserted and 'screwed' in. Front is a magnifying glass and it has metal lens cover with vertical slit. lantern blackout ww11 military candle-power lamp -

Orbost & District Historical Society

Orbost & District Historical Societyhand drill, Mid 20th century

... commonly used before the widespread use of power tools. tool hand ...This item is an example of a domestic woodworking tool commonly used before the widespread use of power tools.A hand drill with three wooden handles. The main gear is painted red.On right handle - Made in China with some Chinese lettering.tool hand-drill -

Orbost & District Historical Society

Orbost & District Historical Societyrebate plane

... commonly used before the widespread use of power tools. woodworking ...This item is an example of a domestic woodworking tool commonly used before the widespread use of power tools.A wooden rebate plane with a brass adjusting knob. It has a cutting edge, such as a sharpened metal plate attached to a wooden body,woodworking-tool hand-rebate-plane -

Orbost & District Historical Society

Orbost & District Historical Societyhand shears, early 20th century

... of power tools. tool hand-shears On blade - Red Reaper Hand Shears ...These hand shears were used for sheep shearing. They appear to be dual purpose sheep or topiary shears. They would have been used on a rural property in early Orbost. This item is an example of a hand tool used commonly before the widespread use of power tools.A pair of metal hand shears with a circular loop handle. On blade - Red Reaper Hand Shears 219 Ward & Payne 303 SHEFFIELD ENGLANDtool hand-shears -

Orbost & District Historical Society

Orbost & District Historical Societymangle, Early 20th century

... home version, powered by a hand crank or electrically... and is powered by a hand crank.... home version, powered by a hand crank or electrically ...A mangle or wringer is a mechanical laundry aid consisting of two rollers in a sturdy frame, connected by cogs and, in its home version, powered by a hand crank or electrically. A household mangle/wringer could be attached to a bench for easier use. The washing process itself involved lifting the items from the cold soak and wringing or mangling each item before transferring them, with more soap flakes, into the copper for boiling. Items that remained soiled, even after an overnight soak, were rubbed on a scrubbing board before being transferred to the copper. The clothes mangle would be used to squeeze out all the excess water. Clothes would then be hung out to dry on a clothes line, or laid over a clothes-horse next to the kitchen or living room fire. This one was owned by the mother of Bob Clarke, an Orbost resident.This item is an example of the typical laundry equipment used by families in the Orbost district in the early 20th century.Clothes mangle [wringer] which has a wooden and metal turning handle. It has a ratchet and 2 tap screws for pressure. It has of two rollers in a frame, connected by cogs and is powered by a hand crank.On top - "No. Hardwood Rolls 124" Front - "Household Clothes Mangle Steel ball bearings The American Wringer Company New York USA"laundry wringer mangle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking Tool, A Mathieson and Son, Early 20th century

Caulking is the traditional technique used on wooden vessels built with butted or clinker-built planks to fill the gaps between these planks while still allowing the wood to flex and move. This involved driving the irons, hammered in with the mallet, deep into the seams to open them up. After this, spun yarn, oakum (hemp) or cotton was driven deep into the gaps. The hemp or cotton was soaked in creosote or pine tar to make the joins watertight. Caulking also played a structural role in tightening up the hull or deck by reducing the longitudinal movement of the neighbouring planks. The subject item was made by Alexander Mathieson & Sons but the company was established in 1792 when John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker”. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over by Mathieson and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street Edinburgh. In the 1851 census, Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his father's name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, but it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river bailie in 1868, a magistrate in 1870 and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. In the Company's later years both Thomas's sons, James Harper and Thomas Ogilvie were involved in the continuing life of the firm. James followed in his father's footsteps in becoming a local public figure. He was appointed Deputy Lieutenant of the County of the City of Glasgow and was made a deacon of the Incorporation of the Hammermen of Glasgow in 1919. His brother Thomas Ogilvie was recorded as a tool manufacturer and employer in the 1911 census. Thomas Ogilvie's son Thomas Alastair Sutherland Ogilvie Mathieson was born in 1908 and took a rather different approach to engineer, however, by becoming a racing driver. In 1947 he wed the French film actress Mila Parély. The firm had won many awards at world fairs for their goods. At the Great Exhibition, London, 1851. Prize medal for joiners' tools in the class of Cutlery & Edge Tools, Great London Exposition, 1862. Prize medal honoris causa. International Exhibition, Melbourne, 1880. Gold medal International Exhibition of Industry, Science and Art, Edinburgh, 1886. Prize medalThe firm Alexander Mathieson & Sons were one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages and other industries, both locally and far and wide. The subject item is of further significance as it gives a snapshot of the technological development of sailing ships and their operation before steam-powered vessels took over around the world. Tools such as the subject item demonstrate the traditional craftsmanship and skill of the shipwright and the aesthetic quality of the timber ships designs of the time. Caulking tool Off-set. Stamped on blade "Mathieson & Son Glasgow" also stamped in handle, James S Steele tool box.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, james s steele, caulking iron, caulking tool, offset caulking tool, alexander mathieson & sons, shipwrights tools, ship building, clinker hull caulking, sailing ships -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Adze, Ward & Payne Ltd, Between 1843 to Mid 20th Century

An adze is an ancient and versatile cutting tool and has been in use for thousands of years. Adze are similar to an axe but with the cutting edge perpendicular to the handle rather than parallel. They have been used since the Stone Age. Adzes are hand tools used for smoothing or carving wood. The subject item was made by Ward & Payne of the Limbrick Works at Hillsborough, Sheffield England manufacturers of hand-forged tools. Their trademark registered in 1850 was a Letter "W" & "P" stamped into the steel. The firm was established by David Ward (1767-1822) in 1803 the company became David Ward & Sons, in 1837 after Ward's son Edward joined the firm. In 1845 Henry Payne the founder's son-in-law became a partner but died in 1850 after which the company reverted to the Ward family. The business then concentrated on making carving tools, chisels and gouges. In 1882 David Ward's grandson David Ward Jr. (1835-1889) purchased land and built a factory at Sheffield North known as the "Limerick Wheel". For a time Wards operated from both 106-114 West Street Sheffield and at Limbrick Road, Hillsborough on the river Loxley. By 1911 they had expanded into making spades, forks, sheep shears and many other types of edged tools including drills and wood planes. In 1967 Wilkinson Sword purchased all the company's share capital and continued to sell Ward & Payne tools until 1970 when a fire burned the factory down and housing development was built on the site.The subject item is significant as it gives a snapshot of the technological development of sailing ships and their operation before steam-powered vessels took over around the world. Tools such as the subject item demonstrate the traditional craftsmanship and skill of the shipwright and the aesthetic quality of the timber ships designs of the time. Adze with wooden handle curved painted green with patent number and maker's name inscribed on inside curve of blade. Inscribed "Patd 561 Ward" "2w". flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, smoothing tool, hand tool, carpenders tool, adze, coopers tool, woodworking tools -

Marysville & District Historical Society

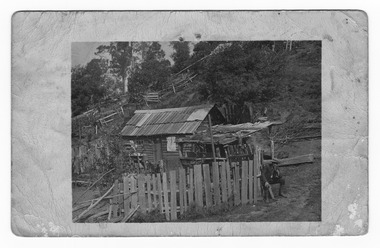

Marysville & District Historical SocietyPostcard (item) - Black and white postcard, Unknown

An early black and white photograph taken at the Golden Bower Mine Camp in the Cumberland Valley in Victoria.An early black and white photograph taken at the Golden Bower Mine Camp in the Cumberland Valley in Victoria. The Golden Bower gold mine was a quartz reef mine. William Edward Chester discovered the Golden Secret gold vein which became part of the Golden Bower Mine at Chesterville near Donovans Creek on the Cumberland goldfield which he mined with George Locke until the late 1930s. POST CARD CORRESPONDENCE. ADDRESS ONLY. KODAK/ AUSTRALIA 30/06/10 Rose Hill/ Fitzwilliam Street/ Kew Should have written/ to you months ago about the/ photos I took at Easter./ Sorry to say the one of the little/ girls was no good I expect/ you will recognise both these/ places/ K McDowell Mrs Fletcher/ Golden Bower Mine/ Via Marysville J Mahoneygolden bower gold mine, cumberland valley, victoria, quartz reef mining, water-powered battery, william edward chester, george locke, chesterville, donovan's creek, cumberland goldfield -

Flagstaff Hill Maritime Museum and Village

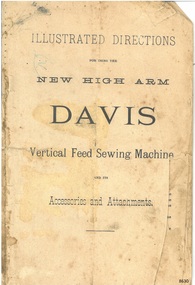

Flagstaff Hill Maritime Museum and VillageBook - Instruction Manual, Illustrated Directions for using the New High Arm Davis Vertical Feed Sewing Machine, 1883-1885

This book of Illustrated Directions was produced for use with the Davis New High Arm Vertical Feed (VF) Sewing Machine. The first model of the High Arm was produced in 1881, and the ‘New’ model, Model 2 VF, was introduced from 1883 and continued at least until 1885, when the Model 3 VF was manufactured. Job Davis, an inventor, showed his Davis Sewing Machine to two brothers in Watertown. The brothers, John and Joseph Shaldon, who founded the Davis Sewing Machine Company in February 1868 in Watertown, New York. The firm moved to Ohio in the 1890. Its early sewing machines were known as the Vertical Feed machines. These machines differed from others, in that there were two presser feet that moved and held the cloth as the needle went in and out of it. This type of action was also called ‘walking foot’ by makers of similar machines. Other machines used a feed dog below the machine’s bed to move the fabric. The Davis Company was awarded a Patents for its improvement to sewing machines. London offices were set up at 54, Queen Victoria Street, London in 1982. It was known as the Vertical Feed Sewing Machine Company. An article published in March 1885 states that the London Manager of the Vertical Feed Sewing Machine Company has 300,000 machines world-wide, including 4,000 in England alone. It claimed that the Auxiliary Forces Uniform and Equipment Company in Limerick, Ireland, was running its machines with steam power and could produce first-class work at the rate of 1,500 stitches per minute. The hand stitched binding of the manual is an example of early book binding processes. The is significant for its relationship to the Davis New High Arm Vertical Feed sewing machine, which was invented in 1866 and became popular in the domestic market. It was also used in industrial conditions as a labour-saving machine, one of the many machines that were part of the Industrial Revolution when steam power replaced manual power in many factories. Paper book with stitched binding. Printed text and illustrations contained within the 42-page booklet. The manual includes drawn diagrams and instructions for use of the Davis New High Arm Vertical Feed Sewing Machine, a foot treadle machine made in the 1880s. Front cover: "ILLUSTRATED DIRECTIIONS for the NEW HIGH ARM DAVIS Vertical Feed Sewing Machine and its Accessories and Attachments"flagstaff hill maritime museum and village, great ocean road, shipwreck coast, sewing machine manual, davis sewing machine, new high arm sewing machine, model 2 vf, vertical feed, sewing machine instructions, sewing machine directions, job davis, john sheldon, joseph sheldon, high arm sewing machine, watertown, new york, vertical feed sewing machine company, treadle, steam sewing machine, auxiliary forces uniform and equipment company, limerick, ireland -

Federation University Historical Collection

Federation University Historical CollectionEquipment - Transmitter

Small rectangle box (cigar box), with wooden roll, covered in copper wire,brass bar, with wooden peg which meets copper wire on roll, 2 metal pegs on outside of box, which could attach to power leads (could be crystal set) or something to do with early morse code transmission. There is a lever that can be disconnected from an electrical force, that could produce a morse code"EARTH" & "ARIEL" hand carved on one end "PHONES" (hard to decifier) on other endballarat, radio, inventions, inventor, ariel, crystal set, electricity, electronics -

Federation University Historical Collection

Federation University Historical CollectionObject, Synchronome Co. Ltd, Synchronome Frequency Checking Master Clock No. 2191, c1930

Information from Norman F. Dalton: Ballarat had a reticulated DC supply in the early part of last century and in 1905 had sufficient generating capacity to enable the trams to be changed from horse drawn to DC electricity. The use of electricity increased with the main power station located on Wendouree Parade, near Webster Street, under the ownership of The Electric Supply Company of Victoria. AC generating plant was installed in 1925 and conversion to AC proceeded. In 1934 the company was taken over by the State Electricity Commission Victoria (SECV) and more AC generation was installed and the changeover of customers was accelerated. This is around the time that the Synchronome Frequency Checking Mast Clock was installed at the Wendouree Parade Power Station. The SECV Annual Report of 1921 states: ::Section 11 of the act directed the COmmission to enquire into the question of securing the adoption of such standards of plant and equipment of a system, frequency and pressure for the generation and distribution of electricity as will admit of the efficient interconnection of undertakings throughout the State. In 1934 when the SECV took over the Ballarat operations the question of linking with the State grid had been a planned operation for some years but due to financial considerations had hindered it and in fact would continue to do so for a further 10 years. So while the need for close frequency control for interconnection was hardly an issue, the need to keep electric clocks correct was important, particularly as this item was a frequent sales point to cover the inconvenience and sometimes expense of converting from DC to AC. The clock is a very accurate pendulum clock with provision for varying effective length during operation for precise time regulation. There are two normal time dials and one is controlled by the pendulum and the other is operated by the system frequency. When the clock was in use it was installed by the MEter and Tests Laboratory and the time was checked daily by radio time signals. The two dials were repeated in the operators control panel in the Power Station. A maximum deviation between the two dials was set in the operating instructions (eg 5 seconds) and the operator would correct this when necessary by remote manual alteration of the turbine governor set point. The clock was used to drive and regulate a system of "slave" clocks which were used to display the time in various locations around the power station. A slave clock is a simple clock which is driven by a small electric motor, its accuracy is regulated by the master clock every 30 seconds to ensure that it and all the other slave clocks in the station are on exactly the right time; slave clocks were placed in various locations, from common rooms to workshops. A master clock could potentially run thousands of slave clocks at one plant. The clock also contains a rectifier. A rectifier is a device that is used to convert AC power to more stable DC current.Two clocks in a timber case. Both are electric, one is powered by the main pendulum mechanism, the other is a self contained electric clock. The main mechanism is of the gravity arm and roller type, which sends an impulse to the slave clocks every 30 seconds. The This Synchronome Frequency Checking Master Clock was used at the Ballarat Power Station. Below the main section of the case is a smaller cabinet containing a rectifier to provide consistent DC power for the clock. The rectifier was made by the Victorian company Hilco, which was located in Burwood. There is a high chance this is not the original rectifier from this clock as there appears to be brackets to hold a larger device in the space the rectifier occupies.Front below main clock face on front of case: "Patented Sychronome Brisbane" Lower left-hand clock face: "Frequency time" Lower right-hand clock face: "Standard Seconds" Synchronous electric clock mechanism on door (Frequency time clock): >200/250 V. 50~ >"Synchronomains" Made in England >Direction indicator for clock starting switch >"To start move lever in direction of arrow and release" >"Patent applied for" Mechanism for "standard seconds" clock: >"English Made" >"Patented" >Serial number "321" >0 above right-hand pillar on front-plate Mechanism for "standard seconds" clock: >"English Made" >"Patented" >Serial number "321" >0 above right-hand pillar on front-plate Mechanism for main clock face: >"English Made" >"Patented" >Serial number "8751" >0 above right-hand pillar on front-plate Inside case, back panel, top enamel plate: >Seconds Battery + Pos. > Battery Common or - Neg. >1/2 min dials Inside case, back panel, bottom enamel plate: external seconds dial Inside case, right hand side, electrical knobs: two switches, both "A.C. mains" Pendulum rod, below suspension spring: Serial number (?) 0000005 Rectifier in bottom cabinet: >"Hilco Rectifier" >"A.C. Volts 230/240" >"Model 1060/S" >"A.C. Amperes" >"Serial No. 1060/S >"Phases 1" >"D.C. Volts 6" >"C.P.S. 50" >"D.C. Amperes 1" >"Made in Australia by Hilco Transformers McIntyre St., Burwood, Victoria." Bakelite electrical plug: makers mark Lower cabinet, RH side panel, pressed tin plate: "AC" (upside down) Brass speed adjustment, outer right RH side: "S" and "F" Ivory and wood pendulum beat ruler: >Ruler, with 0 in centre and numbers 1-5 in ascending order from centre on left and right. > "Synchronome Patent." Steel plate, back panel, inside case, right hand side: >N R A" (descending) >"2191" serial number/part number Face of main clock: "Synchronome Electric" synchronome frequency checking master clock, electricity, state electricity commission, wendouree parade power station, secv, clock, time, pendulum, electric supply company of victoria, norman f. dalton, ballarat power station, rectifier, slave clock -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Block, Late 19th to early 20th century

A sailing block is single or multiple pulleys with one or more sheaves that are enclosed in an assembly between cheeks or chocks. In use, a block is fixed to the end of a line, to a spar, or a surface. A rope line is reeved through the sheaves, and maybe through one or more matching blocks at the far end, to make up what's known as a tackle. The purchase of a tackle refers to its mechanical advantage. In general, the more sheaves in the blocks that make up a tackle, the higher its mechanical advantage. The matter is slightly complicated by the fact that every tackle has a working end where the final run of rope leaves the last sheave. More mechanical advantage can be obtained if this end is attached to the moving load rather than the fixed end of the tackle. Various types of blocks are used in sailing. Some blocks are used to increase mechanical advantage and others are used simply to change the direction of a line. A ratchet block turns freely when a line is pulled in one direction but does not turn in the other direction, although the line may slip past the sheave. This kind of block makes a loaded line easier to hold by hand and is sometimes used on smaller boats for lines like main and jib sheets that are frequently adjusted. A single, large, sail-powered warship in the mid-19th century required more than 1,400 blocks of various kinds and sizes.A historic item from an old sailing vessel from the late 19th to early 20th century, unfortunately. It represents part of the rigging required to set the sails on a wind-powered vessel.A two sheave wood sailing block with metal hook and becket. One sheave missing. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, block, sailing block, two-sheave block, 2 sheave wood block, marine technology, sailing equipment, rigging, rigging block -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Water Pump, Goulds Manufacturing Co, 1915-1925

Gould manufacturing company was founded in 1848 at Seneca Falls, New York when Seabury S. Gould purchased an interest in Downs, Mynderse & Co. and the firm became Downs & Co. Wooden pumps were produced at the time in an old cotton factory building. In 1869, the name of the company was changed from Downs & Company to Goulds Manufacturing Company. Seabury S. Gould was regarded as a man of unusual vision, and as the founder of Goulds Manufacturing Company he was keen to start producing cast iron pumps. An iron pump, he believed, would overcome all the disadvantages of a wooden pump. It would be strong and efficient and provide fresh flowing water for the pioneers. He ran the company until after the American Civil War and because Goulds Manufacturing had a foundry, they also produced all kinds of cast iron products such as corn shellers, bells, sad irons, sinks, tools, and a line of fire engines. From 1848 to 1964 a Gould family member had always been President of the company. However, the company ownership in 1964 was transferred from family-owned stock to public offerings and employee ownership of stock. The subject item called the "N e w Deluge" was an improved bilge pump for vessels having not more than 25 feet depth of hold. It was also used by contractors for pumping out excavations and was well adapted for irrigation use. This hand pump was designed to be used where a hand pump of large capacity was desired. Goulds made many different types of pumps to suit differing pumping situations such as. Well Pumps, Hydraulic Rams, Diaphragm Pumps, Tank Pumps, Sprayers and Small Capacity Power rumps. Goulds Triplex, Centrifugal, Rotary and Deep Well Power Pumps The subject item was first introduced to the market in the Goulds catalogue of 1915 and became a very popular pump used in Australia and the USA. It is manufactured by a company still trading today with offices in Australia and many other countries.Hand Pump cast iron with long reversable pumping lever and cylindrical casing there are 4 metal holes for fastening to floor surface. Painted black. Embossed "NEW DELUGE" "- - -" and "No 16" or "No 18".warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, pump, hand pump, goulds manufacturing -

Flagstaff Hill Maritime Museum and Village

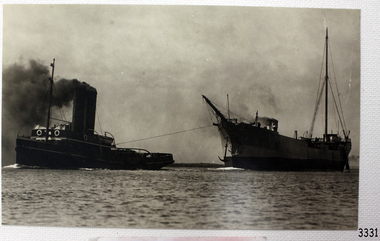

Flagstaff Hill Maritime Museum and VillagePhotograph, C. 1915 - 09/07/1917

This black and white photograph of the tugboat NYORA towing the steam ship INVERNESS-SHIRE was taken between 1915, when the INVERNESS-SHIRE was dis-masted, and 9the July 1917, when NYORA tragically sank. The sailing ship INVERNESS-SHIRE was a four masted steel barque built in 1894 by Robert Duncan & Co. Limited, Glasgow, U.K. (The supervising engineer during the building was William Cumming. He accompanied every ship he’d built on their maiden voyages from UK to Melbourne.) In 1916 she was purchased by A/S Christiansand (Sven O. Stray), Kristiansand, Norway and renamed SVARTSKOG. In October 1920 she disappeared at sea, carrying a cargo of coal, and all hands were lost. The steam powered NYORA was a powerful tugboat and a salvage vessel built by J.P. Rennoldson & Sons Ltd, South Shields, Tyne and Wear, UK. She was originally launched with the name NEPEAN in May 1909, then as NYORA in August 1909 and registered in Melbourne in November 1909 by owners Huddart Parker Pty Ltd. She was made of steel, had triple-compounded steam engines, and her dimensions were 306 ton, 135.0 x 25.1 x 13.6ft. The Melbourne tug NYORA was known as “one of the best known tugs in Victoria, and carried the latest appliances for firefighting and salvage purposes.” She serviced the Port of Melbourne for most of her career. In July 1917 NYORA was towing the American schooner ASTORIA from Port Pirie to Sydney, because ASTORIA’s engines had broken down; she had been delivering a large cargo of timber. On July 9th the vessels were two days out from Port Pirie. At 10:30am NYORA foundered after casting off at Cape Jaffa, 50 miles south of Kingston, South Australia, and sank. Only 2 of the 16 crew survived; NYORA’s Master, Captain W.M. McBain (William Murray) and helmsman, able seaman Gordon Lansley. They were rescued by the two Cape Jaffa light keepers, Jamieson & Clark, who launched the rescue from the Cape Jaffa lighthouse on Margaret Brock Reef. Both men were brought to the lighthouse keeper’s cottage where they recuperated after their long exposure to the rough. (The Queenscliff Sentinal of 14th July 1917 noted that both saved men originated from the same district; Gordon Lansley was from Queenscliff and Captain McBain formerly from Point Lonsdale.) The ASTORIA was “in a very dangerous position ten miles west of the Margaret Brock reef near the Cape Jaffa lighthouse, setting towards the land.” Captain Solly from Beachport later said “Owing to the position … the ship was very fortunate in making Guichen Bay in safety, as she did” (Guichen Bay is south of Robe). Captain Bull, manager of Huddart Packer Pty Ltd, NYORA’s owner, was unable to see any reason for the foundering, as the NYORA was well known for its seaworthiness. At a hearing later on, the Marine Board could blame on no-one either, but found that the ship had been swamped by heavy seas, and had listed to one side when a load of 40 tons of coal in sacks on her deck shifted. The tow line to the ASTORIA was cut to try and save the tug but a huge wave swamped her, crashed open the engine room door and flooded the compartment. It was impossible to launch the lifeboats due to the listing of the sea and NYORA sank within 15 minutes. There was some criticism of the length of time it took Captain Solly and the lifeboat crew to get from Beachport to Cape Jaffa to help with the rescue. However, they had great difficulty in the very strong seas, taking 9 hours just to reach Robe, which was only 32 miles away. There they filled the tanks with ample benzene for the task ahead (impossible to do at sea at the time), took in food and brought on board the Robe Harbour Master, Mr Sneath. The Harbour Master was then able to safely pilot the lifeboat to Cape Jaffa in the smoother coastal waters, saving very much time, but by the time they arrived at Cape Jaffa the 2 survivors had already been taken to the lighthouse on the mainland. There was also a question as to the chances of the ship ASTORIA lowering a lifeboat to help with the disaster. Captain Solly explained that it would have been impossible without sacrificing the lives of the lifeboat crew , due to the great height of the ship out of the water and the roughness of the sea. Captain Svenson, of the ASTORIA, said himself “We are ourselves in a helpless position” and “"Cannot see anything of lifeboats”. One of the 14 lost crew of the NYORA was Hugh Edwards, whose body was not recovered. The descendants of Captain William McBain have continued the seafaring heritage. His son was also a tugboat captain (Captain Norman Clive McBain), working mostly from Reid Street Pier, Williamstown, who would often take his own grandson out to sea to spend time with him on his tugboat. Now that grandson has built a tugboat in memory of his heritage and spends time in it with his own grandson. The Cape Jaffa original lighthouse has been dismantled and moved to Kingston and is now a Lighthouse Museum. The attached photographs of Margaret Brock Reef, and the Cape Jaffa Lighthourse keeper's cottage (now in ruins) is courtesy of Capt. William McBain's great grandson, who visited the area in 2015. There is a model of the NYORA in Museum Victoria, donated by Huddart Packer & Co Ltd. in 1937. This photograph is significant for its association with the tugboat NYORA, that is part of the seafaring history of the Port of Melbourne and associated Victorian ports. Black and White photograph of the tugboat NYORA and steam ship INVERNESS-SHIRE. C. 1915-1917.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, historic maritime photograph, lighthouses, shipwrecks, steamships, j.p. rennoldson & sons ltd, huddart parker pty ltd, nepean, nyora, inverness-shire, astoria, captain w.m. mcbain, william cummings supervising engineer, cape jaffa lighthouse, beachport lifeboat, captain solly, captain svenson, margaret brock reef