Showing 131 items matching "iron wheel"

-

Federation University Historical Collection

Federation University Historical CollectionBook - Book - Ledger, Ballarat School of Mines Donation Book, 1978-1896, 01/01/1878 - 01/08/1896

Leather bound ledger with hand written details on donations to the Ballarat School of Mines Museum or the Ballarat School of Mines Library. The Ledger was made by J. McHutchison, Bookbinder, paper ruler and Account Book Manufacturer. 267. 07 July 1880 - John Lynch Junior - Smythesdale - Cast of "Golden Age" nugget found at Browns by Co-operative Party - 12 men. Weight 75 oz 12 dwts 12 grs 294. 24 June 1880 - W.H. Shaw - Ballarat - 94 numbers of 'The Engineer'. 295. 28 June 1880 - Rivett Henry Bland - Clunes - Specimen of water pipe from the Port Phillip Consols Mine encrusted with Carbonates of lime and magnesia and sulphate of lime with earthy matter. 418. 17 June 1881 - F. Ratte - Sydney - Catalogue of Rocks, minerals, etc of New Caledonia. 462. 28 September 1881 - Dr Bunce - Ballarat - Concretionary Basalt with Car. Lime and Magnesia. 465. 06 September 1881 - J.J. Sleep (Chairman of the Board) per favor of E.W. Spain, Esq, Manr - Ballarat - Diamond drill core from "Carisbrook Freehold Estate" - cut at a depth of 150 feet. Dedrites from Munster Gully ... 517. 20 January 1882 - William Lester - Ballarat - The Agricultural Teacher 549. 24 March 1882 - C.E. Grainger Manager Ballarat Woollen Mills - Ballarat - Samples of dyed and raw wool and dye material. 600. 04 July 1882 - Henry Sutton - Ballarat - 13th Annual Report of the Aeronautical Society of Great Britain. 1222. 31 October 1884 - Trooper Dowling - Miner's Rest - Owl 1223. 04 November 1884 - W. McKeenan - 3, Adair St, Ballarat - Flying Squirrel. 1259. 16 January 1885 - A.A. Buley - Ballarat - Prospective of Grenville College 1885 1428. 06 October 1885 - Ballarat - Collection of mineral specimens from Silverton (Collected by Mr James Murray). 1442. 20 October 1885 - Ballarat - Specimen of fossil fruits collected by Haddon by Charles Brown. 1682. 28 February 1887 - James Lamb - Ballarat - Copy of the Ballarat Times Newspaper of 3rd December 1854, framed and protected on both sides with glass. 1730. 23 May 1887 - Bella Guerin - Ballarat - Copy of the Victorian Review No 74 December 1885 4786. 27 March 1894 - James Oddie - Ballarat - 3 mineral specimens 4835. 01 August 1896 - P.V> Barnard - Ballarat - {ortion of Mining truck wheel altered to oxide of iron found in the old workings of the Golden Gate Mine at a depth of 200 feet. (4235 is last entry)ballarat school of mines, ballarat school of mines museum, donations, henry sutton, bella guerin -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Mathieson and Son, 1860 to 1910

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces. The name spokeshave dates back to at least the 16th century, though the early history of the tool is not well documented. The name spokeshave reflects the early use of the tool by wheel wrights. The first spokeshaves were made of wood usually beech with steel blades, before being largely superseded by the development of metal-bodied spokeshaves in the latter half of the 19th century, though many woodworkers still use wooden spokeshaves. Due to their widespread use and versatility vintage wooden spokeshaves remain commonly available and relatively low in price. Spokeshaves consist of a blade or iron secured to the body or stock of the tool, which has two handles – one for each hand. The bottom surface of the tool is called the sole. The blade can be removed for sharpening, and adjusted to vary the depth of the cut. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached, as with a draw knife. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. There are a wide variety of different types of spokeshave, suited to different trades and applications. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tin men's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm.A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used to shape various items mainly in use by wheel wrights. A significant vintage item from the mid to late 19th century that today is quite sought after by collectors. It gives us a snapshot of how trade people predominately worked materials such as wood by hand and with tools that were themselves hand made shows the craftsman's art of the time. Spokeshave with blade 4 inches wide.Mathieson and Son Glasgow. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spokeshave, mathieson and son, carpentry tools, wheel wright tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ship Rope Block, Russell & Co, Circa 1886

This double-sheaved wooden ship’s block or pulley is a mechanical device used for lifting and moving heavy objects. It has two grooved wheels joined together, each with an axle between the cheeks or sides of the grooved wheel. Blocks and tackle are included in a ship’s rigging. These pulleys and ropes are used for the mechanical advantage they provide for lifting, moving and re-arranging the setting of the sails, which are very heavy work. Blocks are also used to load and unload the ship’s cargo. The FALLS of HALLADALE- The sailing ship Falls of Halladale was an iron-hulled, four-masted barque, used as a bulk carrier of general cargo. She left New York in August 1908 bound for Melbourne and Sydney. In her hold was general cargo consisting of roofing tiles, barbed wire, stoves, oil, and benzene as well as many other manufactured items. After three months at sea and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland on the 15th of November, 1908. The captain and 29 crew members survived, but her cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson's navigational error, not too technical failure of the Clyde-built ship. The Falls of Halladale was built in1886 by Russell & Co., at Greenock shipyards on the River Clyde, Scotland for Wright, Breakenridge & Co of Glasgow. The ship had a sturdy construction built to carry maximum cargo and was able to maintain full sail in heavy gales, one of the last of the 'windjammers' that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. The new, raised catwalk-type decking allowed the crew to move above the deck in stormy conditions.This artefact is important as it is an example of the materials and design of late-19th century ship’s rigging equipment. The object is also significant for its association with the historic sailing ship Falls of Halladale, wrecked in local waters in the early 20th century. The clipper ship Falls of Halladale shipwreck is of historical significance and is listed on the Victorian Heritage Register, No. S255. She was one of the last ships to sail the Trade Routes. She was one of the first vessels to have fore and aft lifting bridges. The vessel is an example of the remains of an international cargo ship and also represents aspects of Victoria’s shipping industry.Ship's block; a double-sheave wooden block with thick concretion on it. The rope block was recovered from the wreck of the sailing ship, Falls of Halladale.Noneflagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, falls of halladale, shipwreck, peterborough, 1908 shipwreck, peterborough shipwreck, russell & co., greenock, wright breakenridge & co. glasgow, clipper ship, machine, mechanical advantage, block, wooden block, pulley, tackle, sheave, ship rigging, double-sheave, twin sheave, captain david wood thomson, iron ship, four-masted ship, sailing ship, windjammer, clyde, wright, breakenridge & co of glasgow, fore and aft lifting bridges -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill -

Federation University Historical Collection

Federation University Historical CollectionBook, D.C. Davies et al, Metalliferous Minerals and Mining, 1892, 1892

Brown hard covered, illustrated book of 518 pages. It includes a bookplate of the Ballarat Ironworkers' and Polytechnical Association Library Rules. The book was bequethed to the Ironworkers' Association by the late James Oddie.mining, minerals, quartz, nova scotia, california, germany, ural mountains, gold deposits, virginia, new england, new brunswick, brazil, australia, new south wales, mount morgan, new zealand, africa, statistics, india, phillipines, aruba island, silver, russia, nevada, ruby hill, nevada, utah, emma mine, nevada, colarado, red mountain district, colorado, yankee girl mine, arizona, mexico, peru, bolivia, chili\copper, south africa, italy, austria, norway, swedan, france, cornwall, dolcoath mine, sandstone, parys mines of anglesea, carnarvonshire, cardiganshire, wicklow, ireland, mississippi valley, wisconsin, lake superior, wyoming, cuba, jamaica, venezuela, south australia, york peninsula, flinders ranges, japan, tin, banca, malaysia, bohemia, saxony, sweden, spain, cligga point, rin lodes of cornwall, andalusia, belgium, shropshire, isle of man, durham, westmoreland, limestone, flintshire, dengigshire, canada, lead, zinc, siberia, hungary, silesia, sardinia, algeria, ireland, new jersey, iron, lancashire, missouri, michigan, superstitions, equipment, cages, stopes, winzes, timbering, ventilation, fans, drilling, boring, dynamite, electricity, blasting, horse whims, water wheels, boilers, petterson's elephant ore stamp, stamper battery, jogs, linkenbach table, panning, cradle, quartz mining, hydraulic mining, alluvia; mining, altai mountains, north wales, neugluck mine, freiberg, christbescherung mine, drei prinzen lode, miask, woodville, virginia, gongo soco, brazil, sierra nevada, california, st john del rey mine, brazil, leydenberg gold field, south africa, banket reefs, transvaal, kongsberg, norway, santa rosa mine, peru, huelva, spain, dolcoath mine, cornwall, parys mine, anglesea, waterbury copper mine, lake superior, copiapo, chilli, altenberg, saxony, whea; uny, cornwall, wast wheel mine. redruth, cornwall, cligga point, cornwall, old hewas mine, cornwall, hartz, germany, snailbeach mine, shropshire, llangynog, north wales, van mine, mongomeryshire -

Federation University Historical Collection

Federation University Historical CollectionImplement, Machine Wheel with Mandrel

A mandrel (/ˈmændrɪl/; also mandril or arbor) is one of the following: * a round object against which material can be forged or shaped; or * a flanged or tapered or threaded bar that grips a workpiece to be machined in a lathe. A flanged mandrel is a parallel bar of a specific diameter with an integral flange towards one end, and threaded at the opposite end. Work is gripped between the flange and a nut on the thread. A tapered mandrel (often called a plain mandrel) has a taper of approximately 0.005 inches per foot and is designed to hold work by being driven into an accurate hole on the work, gripping the work by friction. A threaded mandrel may have a male or female thread, and work which has an identical thread is screwed onto the mandrel.Iron frame with handle. Vice section for attaching to bench. Mandrel for shapingmachine wheel, mandrel, forged, shaped, holds workpiece -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Laundry equipment, Mangle, c1900

The mangle was used in the laundry at Key's, Exchange Hotel. This large, iron framed, manual, machine with 3 cylinders for rolling and pressing washed clothes was a prominent and necessary piece of equipment used by early settler women in Moorabbin Shire 1800 to mid 1900sThis large Mangle was used at The Exchange Hotel, Nepean Highway, Cheltenham , built in 19thC , now known as The Tudor Inn.A large, iron framed, manual, machine with 3 cylinders, for rolling and pressing washed clothes, connected by cogs manually operated by turning a side wheel with a large crank handle.On an oval plate at base of iron frame 'W. Summerscales / & Sons / Keighley Englandclothing, brighton, moorabbin, linen, washing machine, bentleigh, market gardeners, laundry equipment, mangle, early setters pioneers -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Wagon Wheel Spanner c1900, c1900

Among the early settlers in Moorabbin Shire were blacksmiths who made tools for the other settlers who were establishing the homes, market gardens, farms, orchards and various businesses. Early settlers were self reliant and repaired their own equipment for kitchen,dairy, farm, horses, wagons, carts using various tools . These large spanners were used on a horse-drawn wagons, carriages, stagecoaches, and carts. A wheelwright would use this tool to make or repair the wheels. All sizes of buggy spanners, or wagon wrenches, were needed as wagon wheels were of many different sizes. This wagon wheel spanner is typical of the type used by early settlers in Moorabbin Shire c1900 Horse-drawn wagons were used to transport the produce of the market gardeners to the Melbourne markets. Buggies, Traps and Jinkers were popular with farmers, Doctors, and Councillors for trips into town before the advent of the motorized vehicles.A steel wheel wrench, spanner for wagon wheels. c1900 wagons, wheelwrights, spanners, iron rimmed wheels , early settlers, market gardeners, blacksmiths, tools, building equipment, hammers, moorabbin shire, bentleigh, mckinnon, highett, cheltenham,mcewan james pty ltd, melbourne, bunnings pty ltd, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ship Rope Block, Russell & Co, Circa 1886

This double-sheaved wooden ship’s block or pulley is a mechanical device used for lifting and moving heavy objects. It has two grooved wheels joined together, each with an axle between the cheeks or sides of the grooved wheel. Blocks and tackle are included in a ship’s rigging. These pulleys and ropes are used for the mechanical advantage they provide for lifting, moving and re-arranging the setting of the sails, which are very heavy work. Blocks are also used to load and unload the ship’s cargo. The FALLS of HALLADALE- The sailing ship Falls of Halladale was an iron-hulled, four-masted barque, used as a bulk carrier of general cargo. She left New York in August 1908 bound for Melbourne and Sydney. In her hold was general cargo consisting of roofing tiles, barbed wire, stoves, oil, and benzene as well as many other manufactured items. After three months at sea and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland on the 15th of November, 1908. The captain and 29 crew members survived, but her cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson's navigational error, not too technical failure of the Clyde-built ship. The Falls of Halladale was built in1886 by Russell & Co., at Greenock shipyards on the River Clyde, Scotland for Wright, Breakenridge & Co of Glasgow. The ship had a sturdy construction built to carry maximum cargo and was able to maintain full sail in heavy gales, one of the last of the 'windjammers' that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. The new, raised catwalk-type decking allowed the crew to move above the deck in stormy conditions.This artefact is important as it is an example of the materials and design of late-19th century ship’s rigging equipment. The object is also significant for its association with the historic sailing ship Falls of Halladale, wrecked in local waters in the early 20th century. The clipper ship Falls of Halladale shipwreck is of historical significance and is listed on the Victorian Heritage Register, No. S255. She was one of the last ships to sail the Trade Routes. She was one of the first vessels to have fore and aft lifting bridges. The vessel is an example of the remains of an international cargo ship and also represents aspects of Victoria’s shipping industry.Rope block, wooden double-sheave mechanical device with a short length of chain attached and remnants of the metal frame. It was recovered from the Falls of Halladale.Noneflagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, falls of halladale, shipwreck, peterborough, 1908 shipwreck, peterborough shipwreck, russell & co., greenock, wright breakenridge & co. glasgow, clipper ship, block and rigging, ship’s block, iron ship, four-masted ship, sailing ship, windjammer, clyde, wright, breakenridge & co of glasgow, fore and aft lifting bridges, machine, mechanical advantage, block, wooden block, pulley, tackle, sheave, ship rigging, double-sheave, twin sheave, captain david wood thomson -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVehicle - Furphy Water Cart, J. Furphy & Sons, c. 1942

This horse-drawn, two-wheeled cart with a tank, is known as a Furphy Farm Water Cart that was made in Shepparton, northern Victoria, c. 1942. John Furphy (1842-1920) was born in Moonee Ponds, in 1842 to Irish immigrant parents and subsequently raised in the Yarra Valley before the family moved to Kyneton in central Victoria, where he completed an apprenticeship with the firm Hutcheson and Walker. Murphy began operations of his own at a site on Piper Street in Kyneton in 1864. He relocated for a business opportunity and founded the first blacksmiths and wheelwrights shop in the newly surveyed town of Shepparton in 1873. Furphy invented many farming tools and machines including a patented grain-stripper, and won awards at the 1888-89 Melbourne International Exhibition. His most famous invention is the Furphy Farm Water Cart, designed in the 1880s, at a time when water for most households and farms was carted on wagons in wooden barrels. The Furphy’s water cart is a single item that combines a water metal tank and a cart. The design of the cart was simple yet effective, and became popular very quickly and established itself as a vital piece of farming equipment. The water cart has had a number of words cast into its ends over many years. References to the foundry’s location in Shepparton, as well as advertising of other products also manufactured by J. Furphy & Sons were present on the ends. However, the most significant set of words to feature on the tank, was a poem encouraging continual improvement: ‘Good Better Best, Never Let it Rest, Until your Good is Better, And your Better Best’. During The Great War (1914-1918), the water cart was used by the Australian militarily at a large AIF (Australian Imperial Force) camp in Broadmeadows (Melbourne) where thousands of men were camped for months, before being transported aboard. Furphy Water Carts provided water to the troops, and were usually placed near the camp latrines, which was one of the few places the troops could share gossip and tall tales away from the prying eyes and ears of their officers. The water cart drivers were also notorious sources of information, despite most of their news being hearsay, or totally unreliable. By the time the men of the AIF were in engaged in combat on the Gallipoli Peninsula and the Western Front, the carts used for water supply had no markings and became simply referred to as Furphys. This owed as much to the coining of the term ‘Furphy’, Australian slang for suspect information or rumour. After a number of decades as principally a soldier’s word, 'Furphy' entered the broader Australian vernacular and was used mainly by the political class until recently when the term was taken up by a Australian brewer as a beer brand. This Furphy Water Cart was purchased by Friends of Flagstaff Hill in 2014. The support of local individuals, organisations and businesses enabled its restoration and later its installation alongside the existing late-19th century water pipe stand and 1940s hand pump The Furphy Farm Water Cart is of historical significance as it represents a famous Australian time-saving and energy-saving invention of the 1880s, replacing the labour intensive activity of collecting and dispensing water from barrels and casks on the back of carts. The water cart’s connection with manufacturing companies J. Furphy & Sons and Furphy Foundry are significant for being early Australian businesses that are still in operation today. Furphy carts are of military significance for the role they played during The Great War (1914-1918) in Australian army camps, and theatres of war in Europe and the Middle East, to supply the AIF troops with fresh water. A wooden framed, two-wheeled, horse-drawn cart, fitted with a horizontally mounted, cylindrical metal tank. The tank is made of rolled, sheet steel with a riveted seam, and cast iron ends with cast iron ends. The spoked metal wheels have fitted flat iron tyres and metal hubs. A metal pipe is joined to the outlet. The tank is silver coloured, the ends, wheels and trims are crimson, and the script lettering on tank sides is black. There are inscriptions on the tank, ends, and hubs. The water tank was made in 1942 in Shepparton, Australia, by J. Furphy & Sons and has a capacity of 180 gallons (848 litres). Hub perimeter, embossed “J. FURPHY & SONS” “KEEP THE / BOLTS TIGHT” Hub centre embossed [indecipherable] Tank, each side, painted “J. FURPHY & SONS / Makers / SHEPPARTON” Tank ends, embossed – “FURPHY’S FARM WATER CART” “BORN ABOUT 1880 – STILL ‘GOING STRONG’ 1942” “j. FURPHY & SONS / MAKERS / SHEPPARTON - VIC “ “S - - - - - L MANUFACTURERS” [SPECIAL] “SPIKE ROLLERS” “SINGLE TREES” “PLOUGH WHEELS” “IRON CASTINGS” “LAND GRADERS” “STEEL DELVERS” “CAST IRON PIG” “CHAIN YOKES” “GOOD – BETTER – BEST / NEVER LET IT REST / TILL YOUR GOOD IS BETTER / AND YOUR BETTER – BEST” Image [Stork carrying a baby] above shorthand, transcribed "Produce and populate or perish" Image [Furphy Pig Feeder] beside ‘Cast Iron Pig’ Shorthand, transcribed “"Water is the gift of God but beer and whiskey are concoctions of the Devil, come and have a drink of water"warrnambool, flagstaff hill maritime museum, water cart, furphy cart, furphy tank, furphy farm water cart, furphy, john furphy, john furphy & sons, furphy foundry, kyneton, shepparton, mobile water tank, jinker, hutchinson & walker, blacksmith, farm equipment, implement maker, tool maker, horse drawn, stork and baby, good, better, best, barrel, tank, first world war, wwi, eastern front, gallipoli, j furphy & sons -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Water standpipe, Langlands Bros. & Co, 1880-1893

This water standpipe is believed to be the only one of its kind in working order. It was originally located in Warrnambool, on the hillside at the corner of Mickle Crescent and Banyan Street, providing water for the Chinese Market Gardens below, on the flats. It was removed from this location on May 2nd, 1979, with the intention to relocate it at the new Flagstaff Hill Maritime Museum & Village. The standpipe lay in storage for years until the Warrnambool Company, Chemblast, offered to restore it for use as a working display. The display was officially opened on March 31, 2014. The water from the adjacent lake is drawn out with a hand operated water pump, and goes up into the standpipe, where flows through the canvas hose and into the top of the Furphy Farm Water Cart. The display is a visual acknowledgement of the years served by Flagstaff Hill volunteer and Friends of Flagstaff Hill Chairperson, Bob Crossman. Warrnambool’s early settlers had no water supply prior to the mid-1850s. They relied on rain water tanks, domestic wells and springs. The town experienced a huge, destructive fire in William Bateman Jnr. & Co.’s large produce store in November 1856, which highlighted the need for both a fire brigade and a good supply of water. In 1863 a volunteer fire brigade was established. In August 1880 the town celebrated the installation of its first water standpipe on the corner of Liebig and Timor streets. The water was pumped from springs at Cannon Hill through the connected pipeline to the standpipe, then distributed to households via horse and cart. Each of the licenced cart drivers were compelled by Council regulations to keep their carts full from sunset to sunrise, ready to cart water to outbreaks of fire. They received a fee for this service. In 1893 the town installed a water supply, sourced from the Merri River, stored in a reservoir basin and tower in north Liebig Street, and distributed throughout the town in a system of pipes. By late 1939 a reticulated supply was installed, with the water piped in under the Otway Scheme. Standpipes are still used in modern times in rural and remote areas for homes, farms, stock, agriculture and firefighting. Many commercial or government owned standpipes are metered, charging a fee for the quantities of water supplied. This water standpipe was made by Langlands Foundry Co. Limited, Melbourne, which was establish in 1842. It was Melbourne’s first foundry and iron shipbuilder, and one of the largest employers in Victoria at the time. Langlands was known for its high quality workmanship and wide range of goods for mining, engineering, marine, railway and other industrial uses. The company made the first cast bell, the first lamp posts in the colony, and the boiler for the first Australian train. In the 1860s it produced cast iron pipes for the Board of Works, which laid the pipes for Melbourne’s first reticulated water supply. The firm was bought by Austral Otis Co. in 1897.This water standpipe is significant historically as it is believed to be the only one of its type in working condition. The standpipe is significant for being manufactured by early colonial firm Langlands Foundry of Melbourne, which was known for high quality, cast iron products. The firm made the boiler for the first Australian train, assembled the first Australian paddle steamer and made the first Australian cast bell and lamp posts. Langlands was one of the largest employers in Victoria at the time. The standpipe is significant historically as it represents the evolution of water supply services in Australia. Standpipe; vertical cast iron water pipe, painted crimson, fixed in position, tapering inward from the round base to the rectangular joint near the finial on top. A hexagonal pipe extends at right angles from the joint, with an outlet fitting and flow-controlling wheel on the end. A length of canvas hose hangs from the outlet fitting. Inscriptions are on one face of the joint. The standpipe was made by Langlands Foundry Company of Melbourne. Embossed “LANGLANDS FOUNDRY CO. / LIMITED / ENGINEERS / MELBOURNE”warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, flagstaff hill, standpipe, stand-pipe, water standpipe, fire standpipe, firefighting equipment, water supply equipment, chinese market gardens, banyan street, liebig street, water tower, bateman’s fire, working display, water supply, town water, rural water, reticulated water, cannon hill spring, merri river, otway water, water carters, horse and cart water supply, volunteer fire brigade, langlands foundry, early melbourne, iron works, bob crossman, late 19th century water supply -

Bendigo Historical Society Inc.

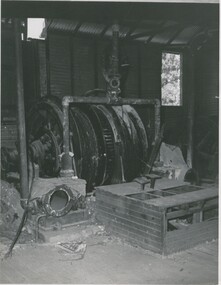

Bendigo Historical Society Inc.Photograph - DEBORAH EXTENDED MINE, 1960's ?

black and white photo : machinery in mine. Corrugated iron shed. Cable on large wheel. Winding engine. ' Horwood & Sons Winder, Deborah Extended Mine - now on display on Central Deborah ' .Alan Doney ( J. Lerk 17.3.2000 )organization, business, deborah extended mine -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - ORIENTAL BANK: EAGLEHAWK, 1860's ?

black and white photo mounted on same size board. Group of 30 men and boys outside double storey building with verandah with iron lace. At left man mounted on horse. At rigfht, horse and 4 wheeled vehicle. At centre 2 men, 1 each side of box with '1311' 4 pieces of smooth material piled on box ( smelted gold ? ) At far left, 2 girls, 1 bending down. On left hand window of building 'old' On RH window ' …. Mercial bank'? Above doorway at far left ' private entrance'organization, business, oriental bank, eaglehawk -

Bendigo Historical Society Inc.

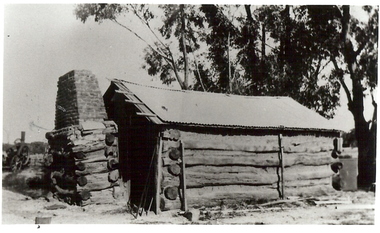

Bendigo Historical Society Inc.Photograph - BURNT GULLY PHOTOS, 1924

Burnt Gully - possibly near Woodvale. a. Black and white photo: men standing behind, alongside bagged grain. Steam farm engine on RH side. Written on rear of photo: threshing team at lunch engine Ruston Procter steam. 8 horse power, single cylinder, working pressure 75 lbs per square inch. 80 revs per minte. Fly wheel 6 feet in diameter. b. Pilcher's thresher on Robert Riley's farm, Burnt Gully. Bullock drivers Bill Pilcher, Paddy Mulcair. Bullock drawn threshing machine, large group of men standing alongside and to rear of machine. Two men standing on top of thresher. Steam traction engine on far left of photo. c. Pioneer log cabin Burnt Gully, the home of the Grafton family, demolished about 1930. Hut of slab construction, with corruated iron roof over timber slats. Chimney of logs and slabs topped with bricks on LH side of house. Steam farm machine in background on LH side.unknownagriculture, farm, grafton familyh, robert riley, bill pilcher, paddy mulcair, burnt gully. -

Bendigo Historical Society Inc.

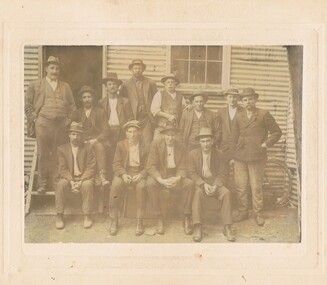

Bendigo Historical Society Inc.Photograph - GROUP OF TWELVE MEN OUTSIDE CORRUGATED IRON BUILDING

Sepia photograph, outside of twelve men outside a building of corrugated iron. Sash window in back. Men wear hats, boots and work clothes. Bicycle wheel and steps in background. Mounted on cream board. Inscriptions: Printed at BR corner on card 'WH Robinson, Photo, B (?)'W H Robinsonperson, group, males -

Bendigo Historical Society Inc.

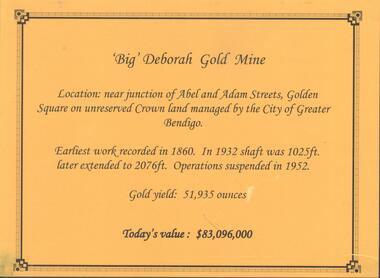

Bendigo Historical Society Inc.Photograph - DEBORAH GOLD MINE, GOLDEN SQUARE

Information display card regarding the 'Big' Deborah Gold Mine, located near the junction of Abel and Adam Street, Golden Square. Earliest work recorded 1860. Shaft 2076 feet. Operations suspended in 1952. Gold yield 51,935 ounces. Battery shed still on site containing a 5 head stamper which was originally a 20 head stamper. The battery was manufactured by Horwood's Foundry, Bendigo. Photos of mine site taken in 2012: a.Engine room concrete footings, iron work visible. Pepper corn trees in background. Pampas grass in foreground. Steel mesh fence on RH side, enclosing the poppet head site. b. Concrete footings, peppercorn tree in background. c. Corrugated iron shed constructed over the stampers. Steel mesh front. d. Steel poppet head, no winding wheel at top. Pampas grass in foreground. e.. Stamper shed and steel poppet legs in background enclosing dilapidated wooden poppet head legs. f. Close up image of weights in stamper room g.Winding wheel on stampers h.Looking upwards to top of stampersbendigo, mining, deborah gold mine -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - MERCURY BUCKET

Cast iron mercury bucket, used to hold mercury, potentially in the process of recovering minute pieces of gold mixed in soil and sediments. See research page for description of one process of using mercury to extract gold.gold mines, mining equipment, mercury bucket, miners used mercury in a number of ways to amalgamate gold, with each mill or battery operator having their preferred method depending on the nature of the ore. by the late 1850s the most common way of crushing goldbearing quartz ores or consolidated alluvial cements was in a stamp battery. the battery featured heavy iron stamp heads held in a frame, with each head often weighing up to 500 pounds (226 kg) or more (see msv 1880, page 45) (birrell 2005). stamp heads were lifted and dropped by a rotating overhead cam shaft driven by a steam engine or water wheel. ore was fed into a large cast-iron battery box, mixed with a steady stream of water, and pulverised by the stamp heads. in some batteries, mercury was placed in the base of the boxes to amalgamate with freed gold. the violent agitation of the mercury in the mortar box, however, could cause the mercury to break into myriad tiny globules that were carried away by the water with the tailings, thus losing a certain amount of gold in the process (thompson 1867; ritchie & hooker 1997). the water and sand slurry was splashed by the falling stamps from the box through fine mesh screens and onto inclined wooden tables below the mortar box (figure 2). the tables were covered with copper sheets or plates coated with mercury, which caught and amalgamated with a portion of the gold. the grey putty-like amalgam was periodically scraped off the sheets and retorted in a furnace to collect the gold and recover the mercury for reuse. mercury was inevitably lost from the plates, while poor maintenance resulted in further losses of gold and mercury in the tailings. mercury use and loss from gold mining in 19th century victoria. peter davies1, susan lawrence, and jodi turnbull, department of archaeology and history, la trobe university. -

Stratford and District Historical Society

Stratford and District Historical SocietyPoison Cart

Cart was operated by the Briagolong Rabbit Suppression League. It was purchased by the donor at the clearing sale for Jim Kelly in the late 1980s/early 1990s. Jim was the son of the main organiser of the Briagolong Rabbit Suppression League. Copies of the Minutes and accounts have been obtained, and are catalogued separately. Wood on cart was in much degraded condition, whole cart repaired by George Parker of the Stratford and District Historical Society, 2010.Rabbit poison cart by T.H. Hicks of Sydney. Consists of wooden frame and floor 80cm high, wheels with cast iron hubs. Chain-driven from one wheel, operator's seat at rear, with a lever mechanism to control the trench forming attachment. Horse shafts 2.6 metres long. Serial number is cast in one side of the bait bin, and not on the other."Ideal" / T.H. Hicks / Patentee / Nth Botany No 5102 / N.S.W.rabbits, vermin destruction -

Puffing Billy Railway

Puffing Billy RailwayWheel Spike for 1914 Foden Traction Engine, 1914

... engine spike wheel spike None Cast Iron Spike curves to 18cm ...1914 foden traction engineHistoric Farm - Logging Equipment Cast Iron Spike curves to 18cm at right angle. 12mm diameter hole for attachment to wheel. Four even recesses to improve traction.Nonepuffing billy, foden, traction engine, spike, wheel spike -

Puffing Billy Railway

Puffing Billy RailwaySide Tipping Wagon - W. G. Allen & Sons (Tipton) Ltd

Built by W. G. Allen & Sons (Tipton) Ltd., Tipton, Staffordshire, England. This vehicle was used on the construction of dams, etc., and the Jindivick tunnel at Tarago in Gippsland for the state Rivers & Water Supply Commission of Victoria. The small wheel located on the side ran up a suitably located ramp automatically tipping the hopper and emptying the contents. Historic - Industrial Narrow Gauge Railway - side tipping wagon used by the State Rivers & Water Supply Commission of Victoria - Jindivick tunnel at Tarago, Victoria, AustraliaSide Tipping Wagon made of Iron, steel and wrought ironpuffing billy railway, pbr, side tipping wagon - w. g. allen & sons (tipton) ltd, puffing billy, side tipping wagon, w. g. allen & sons (tipton) ltd, jindivick tunnel, state rivers & water supply commission of victoria -

Puffing Billy Railway

Puffing Billy RailwayV. R. Krupp 1888. IV. Rail, 1888

60lbs rail that was used throughout the Victorian rail network. In 1887 Gibbs, Bright and Co. had a contract with Victorian Railways for railway and canal construction and supply of Krupp Rails. Gibbs, Bright and Co were merchant bankers and shipping agents and merchants who where also Directors of the GWR ( Great Western Railway ) and the Ship The "Great Britain" in England Gibbs, Bright and Company had principally been involved in shipping and trading, mainly in the West Indies, but following the discovery of gold in Victoria they established an office in Melbourne and soon became one of the leading shipping agents and merchants in the Colony. They expanded into passenger shipping and soon established offices in Brisbane, Sydney, Newcastle, Adelaide and Perth as well as launching passenger services between England, Mauritius and New Zealand. Gibbs, Bright also held a number of financial agencies from British mortgage, finance and investment companies as well as representing several British insurance companies in Australia. In addition they conducted a growing import business as well as an export business that included livestock, dairy produce, wool and flour. Also the company played a substantial part in the development of Australia's mineral resources, starting with lead in 1895, and later venturing into tin, gold, copper, cement and super phosphates. In Australia, after WWI, many of the larger companies were managing their own import and export so Gibbs, Bright and Company tended to focus its Agency business on smaller companies while expanding their interest into other markets such as timber, wire netting, zinc, stevedoring, road transport, marine salvage, gold mining as well as mechanical, structural, electrical and marine engineering. The Company's shipping interests continued to grow as well and still formed a major part of its business. In 1948 the parent company in England took the major step from tradition when they changed the business from a partnership into a private limited company. The name was the same, Antony Gibbs and Sons Limited, and in practice the effect of the change was very little. Some of the firm's branches and departments had already become limited companies and the formation of a parent company simplified the structure. The Australian operation was in time changed to Gibbs Bright & Co Pty Ltd in 1963. In 1848 Alfred Krupp becomes the sole proprietor of the company which from 1850 experiences its first major growth surge. In 1849 his equally talented brother Hermann (1814 - 1879) takes over the hardware factory Metallwarenfabrik in Berndorf near Vienna, which Krupp had established together with Alexander Schöller six years earlier. The factory manufactures cutlery in a rolling process developed by the brothers. Krupp's main products are machinery and machine components made of high-quality cast steel, especially equipment for the railroads, most notably the seamless wheel tire, and from 1859 to an increased extent artillery. To secure raw materials and feedstock for his production, Krupp acquires ore deposits, coal mines and iron works. On Alfred Krupp's death in 1887 the company employs 20,200 people. His great business success is based on the quality of the products, systematic measures to secure sales, the use of new cost-effective steel-making techniques, good organization within the company, and the cultivation of a loyal and highly qualified workforce among other things through an extensive company welfare system. From 1878 August Thyssen starts to get involved in processing the products manufactured by Thyssen & Co., including the fabrication of pipes for gas lines. In 1882 he starts rolling sheet at Styrum, for which two years later he sets up a galvanizing shop. The foundation stone for Maschinenfabrik Thyssen & Co. is laid in 1883 with the purchase of a neighboring mechanical engineering company. In 1891 August Thyssen takes the first step toward creating a vertical company at the Gewerkschaft Deutscher Kaiser coal mine in [Duisburg-]Hamborn, which he expands to an integrated iron and steelmaking plant on the River Rhine. Just before the First World War he starts to expand his group internationally (Netherlands, UK, France, Russia, Mediterranean region, Argentina). info from The company thyssenkrupp - History https://www.thyssenkrupp.com/en/company/history/the-founding-families/alfred-krupp.htmlHistoric - Victorian Railways - Track Rail - made by Krupp in 1888Section of VR Krupp 1888 Rail mounted on a piece of varnished wood. Rail made of ironpuffing billy, krupp, rail, victorian railways -

Puffing Billy Railway

Puffing Billy RailwayLister Auto Truck

The Lister Auto-Truck was a small monowheel tractor built for moving light loads around factories, railway yards and similar sites. They were built by R A Lister and Company of Dursley, Gloucestershire, well known for their range of small stationary engines The Auto-Truck was one of several monowheel tractors to appear in the 1920s and '30s, with the availability of small, reliable petrol engines, as developed for motorcycles and the stationary engines for which Lister were already known. These were tricycle vehicles, with the single leading wheel used for both drive and steering. Their simple construction carried most of the mechanism on this wheel as a single unit, the chassis with the trailing wheels being little more than a trailer for balance. Simplicity was a key feature. The engines were single-cylinder and air-cooled. Ignition was by magneto, rather than requiring a battery and electrical system. One of these designs was produced in the 1920s by George Grist of the Auto Mower Co., Norton St Philip, Somerset. The engine was a JAP 600 cc four-stroke air-cooled sidevalve, a typical small engine of the time. The Auto Mower Co. were Lister agents and when Lister heard of this 'Auto-Truck' they bought one for use in their own factory. It was used to carry heavy engine castings from the foundry to the machine shop. Lister customers saw them and there was such interest in wanting to buy them that Lister negotiated with Auto Mower to build them under licence. Although Lister were already well known for their small petrol stationary engines, these were heavy cast-iron engines with water hopper cooling and unsuitable for vehicle use. Lister remained with the JAP engine for the Auto-Truck. The Auto-Truck was designed for use in factories or other places with smooth surfaces of concrete or tarmac. This allowed the use of small solid-tyred wheels with only simple suspension, making the vehicle simple, cheap and lightweight. They had little ability on soft surfaces though and could even topple over if driven carelessly across slopes. Their design was a compromise between the top-heavy nature of the tall engine grouping above its wheel and a well thought-out chassis for stability. The bearing between them was a large diameter ring roller bearing, mounted at the lowest part of the chassis. This gave rigidity and stability, even after long wear. A ring of rolled channel girder was attached to the engine group and rollers on the chassis carried the load upon this. On early Auto-Trucks this bearing is set very low, in line with the chassis members, and is covered by thin steel plates. The front panel of the engine cover is distinctive with large ventilation holes and a Lister signature cut through it. Strangely this panel is made of thick cast iron, providing substantial weight high on the engine and only adding to its top heaviness. To improve visibility of moving vehicles in noisy factories, this panel was often painted white, the rest of the vehicle being Lister's usual brunswick green. The driver was seated on a Brooks bicycle saddle, which in recognition of the lack of vehicle suspension, was carried on the end of a cantilevered bar that acted as a leaf spring. A wide handlebar on the engine group was used for steering. A squeeze bar the width of this handlebar engaged the clutch. Controls included a hand throttle, a gear lever with two forward and one reverse gears, and a large handbrake lever. The engine unit rotated freely for a full 360° rotation. When used in reverse, the Auto-Truck could either be driven from the saddle, looking backwards over the driver's shoulder; or they could dismount, swivel the engine unit around and control it as a pedestrian-controlled truck from behind. Under the engine cover were two equal diameter tanks, a fuel tank for petrol and a shorter oil tank. Engine and chain-drive lubrication used a total-loss oil system, controlled by a small pump and needle valve. Info Ref: Lister Auto-Truck - Wikipedia https://en.wikipedia.org/wiki/Lister_Auto-TruckHistoric - Industrial monowheel tractor for moving light loads around factories, railway yards and similar sites.The Lister Auto-Truck - small monowheel tractor Made of steel with three wheels. Powered by a J.A.P single cylinder petrol motor which is Hand Cranked to start.Lister puffing billy, lister, lister auto truck, monowheel tractor -

Puffing Billy Railway

Puffing Billy RailwayPhoenix Foundry Plate

Phoenix Foundry Plate - replica Made about 2010 cast off original from locomotive Y112 The Phoenix Foundry (1857-1906) fabricated iron and brass products - including engines and pumping gear for the mining industry, locomotives, steam rollers, water pipes, water gauges and diverse small items. Throughout its operation the business was located at premises on Armstrong Street, Ballarat . Background In 1852, at the age of thirty-three and after a year of operating his own engineering business at Williamstown, Lancashire-born blacksmith and engineer George Threlfall (1819-1897) arrived on the Sebastopol gold plain and immediately undertook blacksmith work repairing picks and tools for the miners. Little did he know that this fledgling business would be the genesis of the most iconic business of nineteenth-century Ballarat. At approximately thirty-nine years of age, English mechanical engineer Richard Carter (c1814-1883) came to Australia on board the Arrogant - arriving in Melbourne on 19 April 1853. He soon travelled to the Ballarat goldfields. Born in the year 1830 in Belfast (Ireland), mechanical engineer William Henry Shaw (1830-1896) arrived in Australia in October 1853. He worked briefly with George Threlfall at Sebastopol, then moved to Geelong to manage the small foundry of Frederick Moore. Twenty-four year old English-born iron moulder Robert Holden (c1831-?) left his home in Belfast (Ireland) in late 1854 and travelled from Liverpool to Melbourne on board the James Baines - arriving in February 1855. Afterwards he joined his brother-in-law William Henry Shaw in Ballarat. History Foundation to Incorporation In March 1857 George Threlfall joined in business with Richard Carter, William Henry Shaw and Robert Holden. They relocated Threlfall's successful engineering enterprise from Sebastopol to new premises in Armstrong Street, Ballarat. This business was then known variously as the Phoenix Iron Works Company, Phoenix Foundry or Messrs Carter and Co. By 15 April 1857 they were advertising that they were open for business as engineers, millwrights, boiler makers, smiths, iron founders and brass founders. In January 1858 George Threlfall left the partnership. Incorporation to 1889 1890 to Closing locomotive Y112 Builder: Phoenix Foundry, Ballarat Builder’s Number & Year: 238 of 1889 Designer: Kitson & Co Wheel Arrangement: 0-6-0 No. in class: 31 Entered Service: 24 July 1889 Taken off Register: 11 May 1961 The origins of the Victorian Railways Y-class lay with the decision by Kitson & Co, Leeds to place a 0-6-0 freight locomotive on display at the Centennial International Exhibition, Melbourne in 1888, together with a 2-4-2T suburban passenger locomotive. This marketing initiative proved successful as the Victorian Railways were clearly impressed with these machines, with both purchased after the exhibition and becoming the patterns for new standard locomotive types. Thirty examples of the 0-6-0 heavy freight design were ordered from the Phoenix Foundry, Ballarat, becoming the Y-class for main line heavy freight duties, while the 2-4-2T design became the E-class for Melbourne suburban passenger duties (represented by preserved locomotive E 236). The Y-class prove successful in service and accrued high mileages. They were inevitably superseded by more modern and powerful steam locomotives and a number cascaded into shunting and yard pilot duties, often with the addition of shunters steps along both locomotive and tender. Y 112 was one of the last in service when withdrawn in 1961. Fortunately it was saved for preservation and plinthed in central Ballarat, ostensibly in commemoration of Phoenix Foundry. I understand it is owned by the Sovereign Hill Museums Association. During the 1980’s, Y 112 was leased to Steamrail Victoria and restored to operation at an industrial site in Ballarat. Y 112 features an attractive lined apple green livery and has performed various rail tours around Victoria since restoration. It is normally based at the Steamrail depot in Ballarat East. Y 112 is the only 19th century design in operational condition in Victoria and as such is one of the oldest working steam locomotive in Victoria . Historic - Phoenix Foundry Plate - replica Made about 2010 cast off original from locomotive Y112Phoenix Foundry Plate Oval shaped plate with an image of a phoenix centered at the top with lettering surrounding it.Phoenix Foundry No 238 Ballarat Company Limited 1889.puffing billy, phoenix foundry, ballarat, locomotive y112, phoenix foundry plate - replica -

Puffing Billy Railway

Puffing Billy RailwayMalcolm Moore No. 1013 - Four Wheel Diesel Rail Tractor Gauge 2'0", circa Nov 1943

Malcolm Moore No. 1013 Four wheel Diesel Rail Tractor Gauge 2'0" Malcolm Moore rail tractor (Builder’s Number 1013) It was built for the Australian Army in 1943. It was sold to the Inkerman Sugar Mill in Queensland around 1948 for hauling cane and shunting at the works. This rail tractor was originally powered by a Ford side valve V8 petrol engine. It was purchased from the Inkerman Mill of Pioneer Sugar Mills in 1982. Historic - Industrial narrow gauge Railway - Diesel Rail Tractor - used by the Australian Army and Inkerman Sugar Mill in QueenslandDiesel Rail Tractor made of iron and wrought irondiesel rail tractor, puffing billy, inkerman mill, industrial narrow gauge railway, gauge 2’0”, inkerman sugar mill, australian army -

Puffing Billy Railway

Puffing Billy Railwaygrinding wheel, Blacksmith

... iron Blacksmith grinding wheel ...Blacksmith grinding wheel - stone is original but stand has been made by Puffing Billy Museum volunteers stand scrapped - damaged - Feb 2018Historic -Industrial Tool - Grinding wheel Blacksmith grinding wheel - stone is original but stand has been made by Puffing Billy Museum volunteers Wheel made of stone and wrought ironblacksmith grinding wheel, puffing billy -

Puffing Billy Railway

Puffing Billy RailwayMachine - Conveyor / Loader, Munro Engineers Pty Ltd, 1955

Munro Engineers Pty Ltd, Handilift Stacker & Loader' The Land on which the Menzies Creek railway station and Museum are built on was once apart of James Hermon's & his son William Hermon's property on which this Munro Handilift Stacker & Loader was used. Historic -Industrial Tool - Handilift Stacker & Loader - used on Jame's Hermon's property on which the Menzies Creek Railway is built on Munro Engineers Pty Ltd, Handilift Stacker & Loader made of steel and wood and wrought ironMunro Engineers Pty ( symbol map of Australia ) Ltd, Ballarat Vic. On side - No. 3147 On wheel - no, 2052puffing billy, munro engineers, handilift stacker & loader, hermon, menzies creek -

Puffing Billy Railway

Puffing Billy Railway19 NBH - Passenger Carriage - Excursion Car, Between 1997 and 1998

19NBH - Excursion Car Puffing Billy Service History or Notes Between 1997 and 1998 the Puffing Billy railway built six more NBHs, numbered 18-23. These had steel frames, padded seats, and a wide "window sill". At first glance they look the same as the previous NBHs. There are other minor construction differences due to the use of steel framing. 19NBH entered traffic on 5/12/1997 Currently these six steel framed NBHs (numbers 18-23) are being modified to provide double doors and space for wheel chairs at one end. The photo on the right shows the exterior of one such NBH. These have a seating capacity of 24 passengers.Historic - Puffing Billy Railway Narrow Gauge - Passenger Rolling Stock: Excursion Car19 NBH - Passenger Carriage - Excursion Car made of wrought iron and timber19NBHpuffing billy, pbr, rolling stock, 19 nbh, narrow gauge - passenger rolling stock, passenger carriage - excursion car -

Puffing Billy Railway

Puffing Billy Railway20 NBH - Passenger Carriage - Excursion Car, Between 1998 and 1989

20NBH - Excursion Car Puffing Billy Service History or Notes Between 1979 and 1988 the Puffing Billy railway built six more NBHs, numbered 18-23. These had steel frames, padded seats, and a wide "window sill". At first glance they look the same as the previous NBHs. There are other minor construction differences due to the use of steel framing. 20NBH entered traffic on 19/12/1997 Currently these six steel framed NBHs (numbers 18-23) are being modified to provide double doors and space for wheel chairs at one end. The photo on the right shows the exterior of one such NBH. These have a seating capacity of 24 passengers.Historic - Puffing Billy Railway Narrow Gauge - Passenger Rolling Stock: Excursion Car20 NBH - Passenger Carriage - Excursion Car Steel Iron and timber20NBHnbh, puffing billy, narrow gauge -

Puffing Billy Railway

Puffing Billy Railway22 NBHC - Passenger Carriage - Excursion Car for wheelchairs and Guard's Van, Between 1997 and 1998

22 NBHC - Passenger Carriage - Excursion Car - specially modified for Wheelchair access allowing it to carry for wheelchairs and Guard's Van Puffing Billy Service History or Notes Between 1979 and 1988 the Puffing Billy railway built six more NBHs, numbered 18-23. These had steel frames, padded seats, and a wide "window sill". At first glance they look the same as the previous NBHs. There are other minor construction differences due to the use of steel framing. 22NBH entered traffic in 1998. Currently these six steel framed NBHs (numbers 18-23) are being modified to provide double doors and space for wheel chairs at one end. The photo on the right shows the exterior of one such NBH. These have a seating capacity of 24 passengers. Oct 2009 - Rebuild continues. Aug 2016 - 22NBC Wheel flats removed Sept 2016 - 22NBC Wheel flats removedHistoric - Puffing Billy Railway Narrow Gauge - Passenger Rolling Stock: Excursion Car 22 NBH which has been converted by the addition of a Guard's Van compartment and modified for Wheelchairs access by Puffing Billy Railway and re classed & numbered 22NBHC22 NBHC - Passenger Carriage - Excursion Car - specially modified for Wheelchair access allowing it to carry wheelchairs and to have a Guard's Van compartment. made of wrought iron and timber22NBHCpuffing billy, pbr, rolling stock , 22 nbhc