Showing 1081 items matching "metal manufacture"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Anchor, Henry P Parkes & Co, 1885 - 1904

In about 1820 Henry Pershouse Parkes, from Dudley, established the Tipton Green Chain and Anchor Works (Staffordshire). The firm’s products included cables, chains, anchors and all kinds of forgings. In 1851 some tests were carried out on the company’s chains to demonstrate the tensile strength and fibrous toughness of the iron used in their production. The iron used on this occasion was supplied by Summer Hill Iron Works. Some of the chains were exhibited at the Great Exhibition in 1851 and also at the 1855 French Exhibition in Paris, where they won a prize medal. Henry Pershouse Parkes died in 1867 and appears to have been succeeded by his son, who had the same name. In 1867 the firm produced the largest anchor in the world, at that time. It was built for Brunel’s S. S. Great Eastern to the patented design of Joseph Beterley, of Liverpool. The anchor, which weighed eight tons was twenty six and a half feet long and cast from iron supplied by Bloomfield Iron Works. It was tested at Tipton Proving House and found to be able to stand a strain of 100 tons. Henry Pershouse Parkes junior went into partnership with Alexander Stewart Ross to form Henry P. Parkes and Ross. The partnership came to an end in 1885 and the company became Henry P. Parkes & Company. In 1904 the business was sold and became H. P. Parkes and Company, under the control of N. Hingley & Sons Limited, of Netherton. In 1944 the company’s name was changed to Richard Sykes and Son Limited, then in 1947 it became H. P. Parkes & Company Limited. The business went into liquidation in 1966.The item is significant as an early example of a well known prize winning British anchor and chain maker from the mid 19th century. The company name on the anchor indicate the period of manufacture making it a significant item prized today by collectors.Anchor 5 pronged metal with loop at bottom to attach anti-snag rope. Long shank painted black. Label attached "Henry P Parker and Co"flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, five pronged anchor, henry p parkes & co, tipton green chain and anchor works -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Anchor, Early to mid 20th century

Anchors are used to stop boats from moving and today are usually made of metal, and they are made to catch the ocean floor (the seabed). There are two main types of anchors: temporary and permanent. A permanent anchor is called a mooring block and is not easily moved. A temporary anchor can be moved and is carried on the boat. When people talk about anchors, they are usually thinking about temporary anchors. An anchor works by either weight (mass) or shape. Shape is more important to temporary anchors, and design is very important. Anchors must resist wind and tide, and also the up-and-down movement of waves. The subject item is a foundry produced item made specifically for marine use, at present there is no history or manufacturing provenance currently available as the item is unmarked.The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item is believed to have been produced in the first half of the 20th century by an unknown manufacture and its design is known as the "Kedge Admirality" pattern.Kedge Admirality design anchor metal with double bent hook & Halibut. Stock, eye, loop and shackle at top of anchor. Stock held in position with pin. Anchor painted black.Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ships anchor, marine eqipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Sides & Skinner, First half of the 20th century

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces. The name spokeshave dates back to at least the 16th century, though the early history of the tool is not well documented. The name spokeshave reflects the early use of the tool by wheelwrights. The first spokeshaves were made of wood usually beech with steel blades, before being largely superseded by the development of metal-bodied spokeshaves in the latter half of the 19th century, though many woodworkers still use wooden spokeshaves. Due to their widespread use and versatility vintage wooden spokeshaves remain commonly available and relatively low in price. Spokeshaves consist of a blade or iron secured to the body or stock of the tool, which has two handles one for each hand. The bottom surface of the tool is called the sole. The blade can be removed for sharpening, and adjusted to vary the depth of the cut. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached, as with a draw knife. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. There are a wide variety of different types of spokeshave, suited to different trades and applications. A now vintage tool made by an Australian manufacture in NSW who specialised in making pruning shears, hacksaw frames and heel shaves under the Erskin brand name. This tool is now sought after by collectors even though it was probably made in the first quarter of the 20th century. It gives a snapshot of how carpenters work with wood by hand showcasing their craftsmanship. Hollow face Spokeshave, metal body with black enamel finish. Erskin stamped on frontflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spokeshave, cabinet makers tools, wood working, cutting tool, shaping tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Megaphone, Merriman Brothers, First quarter of the 20th century

A megaphone or loudhailer is usually portable or hand-held, the cone-shaped acoustic horn used to amplify a person's voice or other sounds and direct it in a given direction. Used to communicate with others over distances. In Greek mythology, "Stentor" was a Greek herald during the Trojan War. His name has given rise to the adjective "stentorian", meaning loud-voiced, for which he was famous. The large funnel-shaped device is made of recoated cardboard that is riveted together. It has a metal mouthpiece at the narrow end and a metal edge at the wide end, and a metal handle. The design indicates that it is a ‘Stentor Megaphone’ patented on 4 April 1899 by a company in Boston. Stentor brand megaphones were manufactured by Merriman Brothers, in Boston. In 1898 the brothers specialised in hardware for yachts their workshop was at 139 Border St. East Boston, Mass. They also made other equipment, which included pulley blocks, winches and fittings, and were well-known worldwide before the company closed in 1995. Merriman megaphones, including the familiar cheerleader megaphones, came in different sizes, Their patent for the device, dated April 4, 1899, specified details such as the 'rivets, metal mouthpiece, and adjacent parts, and an undated pamphlet promoting the Stentor Megaphone emphasizes its 'highly finished' appearance 'with nickel mouthpiece, rim and other fittings'. The Stentor Megaphone has significance for its provenance and historic value, and also as a relatively rare item of equipment once used worldwide in marine situations, such as light stations and many other similar applications where a person voice needed to be amplified.Megaphone conical shape cardboard with riveted seam, nickel plated reinforcing ring, mouthguard Made in the USAflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, megaphone, loud hailer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Snatch Block, First quarter of the 20th century

A snatch block is a heavy-duty pulley inside a metal casing. It is primarily designed for handling heavy goods, working as a pulley point that can redirect the course of a winch line. Snatch blocks are also used to increase the lifting or pulling capacity of wire hoists and winches. There is no history or manufacturing provenance currently available.The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item is believed to have been produced in the first quarter of the 20th century.Snatch block, metal, one sheave, with a large hook that has a hole drilled through its tip.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, snatch block, metal snatch block, lifting gear, rope pully, marine technology, ship rigging -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Anchor Lamp, Bef. 09-02-1984

The kerosene lamp was one of the most common oil lamps used and was manufactured until the 1980s. An anchor lamp like the lamps in this pair would be raised on the highest ship mast at night to signal other seafarers that the ship was at anchor or sailing at night. The metal loops on opposing sides of the lamp could hold a pair of rods or ropes. and be used to raise the lamp.The lamp is made to the design of a 19th and early 20th-century kerosene anchor lamp carried as essential marine equipment and used as a signal lamp on sailing ships. Lamps; a pair of cylindrical kerosene anchor lamps. Each has a flat back, a hinged door, a metal handle and two metal loops or guides fixed on each side. The glass window is convex and inside the lamp is a wick in an enamel wick holder.brass lamp, lamp, anchor kerosene lamp, kerosene lamp, marine equipment, marine lamp, navigation, light, ship light, ship lamp, lantern, maritime, nautical, safety lamp -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Marine Lamp, William W M Mc Geoch Ltd, 1910 to 1925

In 1832 William McGeoch & Co., Ltd was established, by William McGeoch senior at 113 Argyle St Glasgow as hardware merchants and exporters, and later were manufacturers of lamps and electrical fittings for ship, railway and domestic use. In the 1900s the company had expanded and had offices at 28 West Campbell Street Glasgow with a factory and warehouse located at the Warwick Works, 46 Coventry Rd, Birmingham. In 1922 the company had expanded and were employing 400 to 500 people. William seniors three sons had joined their father in establishing the business around 1888. The business was run by William McGeoch senior with Williams three sons Alexander, William and Andrew also taking an active part in the day to day running of the company. The company had expanded to such a degree that they were now manufacturing a variety of ships' hardware. This included metal cabin furnishings, signal lamps, ships' oil and candle lamps, motor lamps, switches, switchboards, electrical accessories and fittings. In 1982 William McGeoch & Co., Ltd was acquired by Bowthorpe Holdings Ltd.A lamp made by a significant manufacturer of marine equipment that made fittings for many famous ships including the Titanic.Marine oil Lamp with glass panels. Front panel missing. Access through glass panel door at side flat metal back. Metal fuel reservoir and no burner. Metal rounded chimney on top. Embossed McGeogh Maker Glasgowwarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, lamp, ships lamp, wm mc geoch ltd, hardware merchants, ships outfitters -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGlue Bottle, Joseph Armstrong Angus & Co, 1920s -1950

Angus & Co. was a large ink, gum, and paste manufacturing company established in Melbourne in 1896 by Joseph Armstrong Angus (1860-1936.) The company's premises included a bottle works to supply bottles for its many products. The company supplied various inks, gums, and paste too many business and domestic customers. Mucilage is a thick, gluey substance produced by nearly all plants and some microorganisms. These micro-organisms include protists who use it for their locomotion. The direction of their movement is always opposite to that of the secretion of mucilage. It is a polar glycoprotein and an exopolysaccharide. The mucilage in plants plays a role in the storage of water and food, seed germination, and thickening membranes. Cacti (and other succulents) and flax seeds are especially rich sources of mucilage. Mucilage is edible. It is used in medicine as it relieves irritation of mucous membranes by forming a protective film. It is known to act as a soluble, or viscous, dietary fiber that thickens the faecal mass, an example being the consumption of fiber supplements containing Psyllium seed husks. Traditionally, marshmallows were made from the extract of the mucilaginous root of the marshmallow plant (Althaea Officinalis). The inner bark of the slippery elm (Ulmus rubra), a North American tree species, has long been used as a demulcent and cough medicine and is still produced commercially for that purpose. Mucilage mixed with water has been used as a glue, especially for bonding paper items such as labels, postage stamps, and envelope flaps. Differing types and varying strengths of mucilage can also be used for other adhesive applications, including gluing labels to metal cans, wood to china, and leather to pasteboard. An early item from the late 1920s for office use as a glue by a well-known Melbourne manufacturer of office supplies of inks, glues, rubber stamps, and mucilage gums, etc.Bottle of Mucilage. Manufactured by Angus & Co Ltd Aust. Contents 20 Ozflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWeapon - Double Barrel Shotgun, Mid to late 19th Century

Philip Webley was born in 1813, he was the younger brother of James Webley who was born in 1807. Both were born in Birmingham. Towards the end of the 1800s, the firm claimed establishment in 1790, this must have been the date James and Philip's father or grandfather originally established a bullet or gun implement making business. It was not, as is often stated, the date William Davis established his business. Philip Webley was apprenticed in 1827 to Benjamin Watson. James Webley also seems to have been apprenticed but to who is not known. In 1834 James and Philip established their partnership as percussioners, lock filers and gun makers at 7 Weaman Street,Birmingham which was William Davis' old premises Davis, a gun implement maker, mould and toolmaker, died in 1831 and his wife Sarah inherited the business at 84 Weaman Street which she ran with her daughter, Caroline. On 5 January 1838 Philip Webley married Caroline. Philip was recorded at 84 Weaman Street from 1838 as a gun percussioner, lock filer and gun maker and this is when the partnership was last recorded, but the brothers apparently continued to co-operate until 1845 when Philip reportedly sold his interest to James and used the money to purchase Sarah Davis' business. Even then, they worked together particularly about the design and manufacture of percussion revolvers. Philip Webley was recorded in the 1851 census as a 38-year-old gun and pistol implement manufacturer living at 84 Weaman Street with his wife Caroline they had four sons and one daughter Thomas William, Emma, and Philip Jnr, and two other sons, James, and Henry and Philip's cousin, also lived with the family probably as a nurse, Sarah Haywood. On 4 February 1853 Philip Webley registered patent No. 335 for a hinged revolver and on 14 September 1853 he registered patent No. 2127 for improvement for the first muzzle-loading percussion cap and ball revolver which became known as the "Longspur". In 1859 Philips son Thomas William, aged 21, was made a partner in the firm, which then changed its name to P Webley & Son and described itself as "Gun and Pistol Makers and Patent Revolving Pistol Makers", probably exploiting Philip Webley's patent No. 305 of February 1853 for a revolver frame and lock, and its improvement under patent No. 2127 of September 1853. Thomas later went on to managed the shotgun side of the business. From about 1863 up to the First World War, the firm made rook rifles for Holland & Holland. From the 1890s they supplied magazine rifles. In 1863 and 1864 the firm's address was given as 83-84 Weaman Street, but from late 1864 to 1875 their address was 84 Weaman Street. By 1874 the firm had a showroom in London at an unknown address. In 1875 the firm expanded into 82-84 and 88-89 Weaman Street. The item is an early muzzle loading sporting shotgun not in very good condition and is unusable as a firearm and not very significant historically or valuable, although made by a well known and respected manufacturer of firearms there are many better examples of shotguns made by P Webley and Son in collections and for sale. This particular example is of a standard pattern for utilitarian use of which many were made. Shotgun, black powder, muzzle Loading, double barrel, percussion cap. P Webley & Son maker on left and right lock and P Webley & Son James St London on top of barrel. Barrel split in two. Has 14 stamped under each barrel with Birmingham proof marks for black powder shotguns. on undersides of both barrels. Proof marks used are early metal parts have decorative engravings of a gun dog flushing a birdwarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, gun, shotgun, double-barrel shotgun, firearm, muzzel loading shotgun, philip webley, black powder, percussion cap, hunting weapon, birmingham gun manufactures, w & c scott & son -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Pipe Fitting, Before 1878

This artefact is a functional, non-decorative fitting that essentially transports gas from a wall attachment to a lamp. It is a brass and copper gas lamp fitting, designed to direct and control the flow of gas from a flanged wall fitting to an exit nozzle that was lit. It was raised from the LOCH ARD shipwreck site by Flagstaff Hill divers in 1972. Related pieces can be found in the Maritime Village collection. The LOCH ARD left Gravesend (London) on 2 March 1878, bound for Melbourne, with a crew of 37, 17 passengers, and a diverse and valuable cargo of manufactured goods, luxury items, and refined metal; some of which was to be on show at Melbourne’s first International Exhibition in 1880. At 3 am, 1 June 1878, the ship was wrecked against the high limestone cliffs of Mutton Bird Island on Victoria’s southwest coast near Port Campbell. Only two people survived the disaster — Tom Pearce, a male crew member, and Eva Carmichael, a female passenger. The cargo proved too difficult to salvage in the vessel’s exposed condition and was largely written off. The manifest of goods in the LOCH ARD’s holds included “Fittings gas (4 cases)”. The gas lighting of streets, public buildings, and the dwellings of wealthier private citizens were already well-advanced in the cities and major towns of the Australian colonies. In 1841 Sydney was the first to be gas-lit with 23 street lamps, 106 hotel lamps, and 200 private residences connected to the Darlinghurst “gasometer” by an underground network of metal pipes. “The dim days of oil and tallow are gone by!” pronounced one newspaper, flushed with civic pride. The 1850s Gold Rush promoted a similar attitude of confidence and affluence in the Colony of Victoria. In 1855 Melbourne was connected to its system of subterranean gas pipes despite the same high rates of 25 shillings per 1000 cubic feet being charged, (reduced to 15 shillings in 1865 with cheaper sources of coal). By1858 Kyneton had its gasworks to light the town (fuelled by eucalyptus leaves) and Geelong followed suit in 1860. Had the LOCH ARD reached its intended destination in 1878, the four cases of brass gas light fittings on board would probably have found a ready market.The LOCH ARD shipwreck is of State significance — Victorian Heritage Register S417. Flagstaff Hill’s collection of artefacts from LOCH ARD is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. It is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417). The collection is significant because of the relationship between the objects, as together they have a high potential to interpret the story of the LOCH ARD. The LOCH ARD collection is archaeologically significant as the remains of a large international passenger and cargo ship. The LOCH ARD collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the LOCH ARD, which was one of the worst and best known shipwrecks in Victoria’s history. This pipe is a gas lamp fitting. This extensively corroded fitting is made of brass and copper alloy. It comprises a 31 cm copper pipe of 1.5cm diameter which is connected to a 6.5cm diameter wall flange (via a flow tap and an adjustable swivel valve) at one end, and to a screw-in square coupling with a nozzle or gas jet at the other end. The copper pipe is dented and corroded and has three holes. The brass attachments are a more robust cast metal but the adjustable mechanisms are concreted into immobility by ocean sediment. No discernible maker’s marks. In unrestored but fair condition. The pipe with the fitting was recovered from the wreck of the LOCH ARD.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, gas lamps, gas lighting, gas works, brass fittings, gas pipes, loch ard, 1878 shipwreck, victorian affluence, colonial gas lighting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTelephone

Telephone for wall, metal, black in colour with metal box, crank handle and plastic handpiece. Made by the "Telephone Manufacturing Co, London." Wiring cover between handpiece and phone is perishing. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, telephone, telephone manufacturing co, london, communications -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageKettle, Clark and Co

Kettle metal with spout, lid and handle. Manufactured by Clark and Co. Black in colour, rusted. Lid missingflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kettle, clark and co -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Safe, Willow Ware Pty Ltd, 1920s -1950

Willow started business in 1887 as a metal working company based in Melbourne Australia, making tinned biscuit and tea canisters. The outbreak of the First World War saw their manufacturing change to making armaments and essential packaging for the war effort. In the early 1920’s, the Willow brand was established. Making tin plated canisters and baking pans with the well-known Willow pattern, imprinted on them. Some other items in production at this time include billies, boilers, basins and Coolgardie safes. In the late 1950’s, the company ventured into plastics production. Stepping away from its very successful tin plating industry of more than 50 years. In 1965, the company name changed to Willow Ware Pty Ltd, to be more closely linked to its Willow brand. Willow Ware is still in business today. A food safe known as a “Coolgardie” meat storage made by an emerging Australian company no longer in bushiness. This item gives a snapshot into early Australian manufacturing specifically aimed at the Australian market.Safe metal kitchen food safe with 2 shelves, a hinged door and latch and a small swivel wire handle at the top. Painted light green, rusting.Willowwarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, safe, food safe, meat safe, coolgardie safe, domestic object, kitchen object, willow ware, food preservation, kitchen safe -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGeological specimen - Slate, c. 1886

This rectangular slate of 'beautiful, unusual, expensive, green' American roof tile was amongst tiles recovered from the wreck of the Falls of Halladale. Salvaging began in 1974 by volunteer divers, using local cray-fishing boats. An efficient system was devised that enabled the recovery of up to 4,000 of the still neatly packed slates a day. Many of 22,000 salvaged slates can be seen on roofs of eight buildings in the Flagstaff Hill Maritime Village. The sought-after slate doesn't need any special treatment before use. Some of the slates have slight red staining that comes from over 70 years in the wrecked vessel's rusting hull. The four-mast iron barque 'Falls of Halladale' left New York in August 1908 and, due to a navigational error, floundered off the rocks at Peterborough, Victoria, in the following November. None of the 29 lives on board were lost. Crowds gathered for months to watch the tall ship slowly break up. The green American slates were carried on board as ballast. As well as over 56,000 of the American slates, the large cargo on the Falls of Halladale included benzine, costly timber, rolls of printing paper, coils of barbed wire, thousands of metal bolts, hardware items, tableware, American walnut desks and medicine. Some of the cargo was later recovered. The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual beautiful green American slates (roof tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29 The Falls of Halladale was a four-masted sailing ship built-in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. The lines flag was of red, blue and white vertical stripes. The Falls of Halladale had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck stormy conditions. This idea is still used today on the most modern tankers and cargo vessels and has proved to be an important step forward in the safety of men at sea. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roof tiles (roof slates), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the night of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on the south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. This slate tile is significant for its connection with the wreck of the Falls of Halladale. The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Unusual beautiful green American slate, rectangular shape, recovered from the wreck of the Falls of Halladale. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, falls of halladale, green american roofing slate tile, roof tiles, slate, slate roof tiles, falls of halladale shipwreck, shipwreck cargo, russell & co. -

Federation University Historical Collection

Federation University Historical CollectionBook, American Institute of Mining Engineers, Transactions of the American Institute of Mining Engineers, Vol 1, 1871-1873

Meetings of the institute were held in Wilkes-Barre, Bethlehem, Troy, Philadelphia, New York, Pittsburgh and Boston.Red hard covered book. Contents include: * List of members * Geological Distribution of MIning Districts in the United States (R.W. Raymond) * The Relation between the Speed and Effectiveness of Stamps (R.W. Raymond) * Remarks on the Waste in Coal-Mining (R. P Rothwell) * An Eccentric Theodolite (Francis Vinton) * The Use ad Advantages of the Prop Srew-Jack (E. Gaijot) * The Manufacture of Iron and Steel Rails ( John B. Pearse) * The importance of Surveying in Geology (Benjamin Smith Lyman) * Use of Blast-Furnace Slag (T. Egleston) * The Geonostical History of Metals (T. Sterry Hunt) * The Mining and Metallurgical Laboratories of the Massachusetts Institute of Technology (Robert H. Richards) Stamped "Department of Mining University of Melbourne"american institute of mining engineers, mining engineering, prop screw jack, mining districts in the united states of america, waste inn coal mining, lehigh zinc company, lake superior copper districtblast furnace, rolling versus hammering ingots, indianablack coal, pig-iron, longwall system of mining, wickersham process, midlothian colliary, virginia, plummet lamp, diamond drills -

Red Cliffs Military Museum

Red Cliffs Military MuseumMess kit, 1939 (exact)

This is part of a collection donated by Mrs Margaret McKenzie that belonged to her husband and was issued to him during the Second World War, the mess tins were marked with names of places, ships and battle locations. Other items include a postcard sent home in August 1941 and a photo of Australian troops on parade at Wewak in August 1945Aluminium Mess tin set, 2 rectangular tins one smaller to fit into larger. Inscriptions engraved on 4 sides containing locations of training, ships and battle areas. Additional markings include year of manufacture and company along with Department of Defence broad arrow. Item is stamped metal with wire handle on the large tin. Wire carry handle missing on smaller tin. "Inscription on base of mess tin large. 'DARLEY ALBANY/ SYDNEY/ PERTH/ TRINCOMALEE:CEYLON/ PORT TUFIC/ SUEZ CANAL/ EL CANTARA/ GAZA/ JERUSALEM/ HIFA TELAVIV/ BETHALEM/ BAYROUTA/ JUDEDES FIAKE/darwin, world war two, pan set messing, mess tins, aluminium, 2nd aif, 8th battalion, vx52576, pte, mckenzie, c mckenzie, 1939, c b ltd, 1941 1945, 19th australian infantry training battalion, b company, 21st august 1941, finchaven, wandecla, cairns, brisbane -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Containers, tin 'John Bull' Tyre Repair, mid 20thC

... was formed to manufacture rubber to metal components - Metalastic... was formed to manufacture rubber to metal components - Metalastic ...John Cecil Burton and his brother Cecil Hubert formed The Leicester Rubber Company in 1906, to sell imported cycle tyres. The Company's patriotic 'John Bull' trade mark came into force a few years later in 1908. In 1915 the Rubber Company started to manufacture its own bicycle and pram tyres at its Evington Valley Road site in Leicester, and in 1928 they started to mass produce car and motorcycle tyres at the site. The name was changed to the John Bull Rubber Company in 1934, and in 1937 an associated company was formed to manufacture rubber to metal components - Metalastic. In 1955 the John Bull group companies merged, and in 1958 the company became part of the Dunlop Rubber Company.An empty blue tin with a hinged lid for 'John Bull' Tyre repair outfitLid top ; JOHN BULL Reg. T / REPAIR OUTFIT/John Bull Rubber Co. Ltd. Evington, Valley Mills, Leicester Trade Mark ;Central Photo of 'John Bull' encased in a circle around is written ' Made for the Man who will have the Best' / TRADE / MARK Lid Inside ; INSTRUCTIONS FOR REPAIRING PUNCTURES/ ................ Base ; RIDE / JOHN BULL TYRES / and you will have practically no use for this OUTFIT* tyres, rubber, bicycles, cars, prams, leicester, england, john bull rubber company, burton john c , hubert cecil, leicester rubber company, dunlop rubber pty ltd, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Education, Pen Nibs ' R. Esternbrook Co. Ltd, 20thC

Dip pens emerged in the early 19th century, when they replaced quill pens. They were generally used prior to the development of fountain pens in the later 19th century, and are now mainly used in illustration, calligraphy, and comics. A nib pen usually consists of a metal nib with capillary channels like those of fountain pen nibs, mounted on a handle or holder, often made of wood. Other materials can be used for the holder, including bone, metal and plastic. Generally speaking, dip pens have no ink reservoir; therefore the user has to recharge the ink from an ink bowl or bottle in order to continue drawing or writing. Birmingham, England was home to many of the first dip pen manufacturers. John Mitchell pioneered mass production of steel pens in 1822; prior to that the quill pen had been the most common form of writing instrument. His brother William Mitchell later set up his own pen making business in St Paul's square. The Mitchell family is credited as being the first manufacturers to use machines to cut pen nibs, which greatly sped up the process. Germany 1842 began at the factory of Heintze & Blanckertz in Berlin By 1860 there were about 100 companies making steel nibs in Birmingham, but 12 large firms dominated the trade. Dip pens are rarely used now for regular writing, most commonly having been replaced by fountain pens, rollerball pens, or ballpoint pens. However, dip pens are still appreciated by artists, as they can make great differences between thick and thin lines, and generally write more smoothly than other types of pens. Dip pens are also preferred by calligraphers for fine writing. Richard Esterbrook was a Cornish Quaker from England who saw an opportunity in the United States to manufacture Steel Pens. In 1856 R.Esterbrook traveled to the US to set up shop as 'The Steel Pen Manufacturing Company' where Richard made these steel pens by hand using special tools and machines (mostly that Richard had to invent). In 1858 he was able to establish himself as the sole pen manufacturer in the USA and he changed the company name to 'The Esterbrook Steel Pen Mfg. Co.' The company settled down in Camden, New Jersey. Quality was a key factor in his success. His steel pens were versatile, long lasting, and came in many different styles to fit the varied writing styles of the public. Sadly, Richard Esterbrook didn't see the 'empire' his company was to become as he passed away in Atlanta on October 12th 1895 . in 1896 they started an Esterbrook branch in England to join the ranks of the other main pen manufactures in Birmingham . In 1912 the company had gotten so large that they erected a 5 story building, just to continue manufacturing pens. By 1920 the fountain pen was fast becoming more popular amongst people who were tired of 'dipping.' To meet this demand the company manufactured its first fountain pen. In 1930 the company sought less expensive means of manufacturing pens because gold and 'jewel' tips were too expensive and in this same year they began selling fountain pens in England . The Esterbrook Company began using the metal Iridium which they called 'Durachrome.' To meet the fountain pen demand the company reformed as 'The Esterbrook Hazel Pens Ltd.' In 1940 war had come to strike a blow at the Esterbrook company. On November 19th 1940 their England location was hit by an incendiary bomb destroying half of the location! To make matters worse, when putting out the fire using a human water bucket chain, someone accidentally grabbed a bucket of paraffin and set the place further ablaze. Oddly enough, the company was able to rebuild the structure during the war. However, the government had placed a stipulation that 50% of its capacity was to be used for government related purposes. In 1947 the company bought out John Mitchell and the American branch had already acquired Hazel Pen Co. The company re-formed again as 'The Esterbrook Pen Company.' This is the last company name the dip pen nibs were manufactured under. A box of Steel dipping nibs for writing pensOn Box; Photo of man / R. Esternbrook Co. / PENS / PROBATEsteel nibs, writing pens, education, schools, writing, caligraphy, artists, moorabbin, bentleigh, cheltenham, dip pens, inkwells, fountain pens, mitchell john, birmingham england, esternbrook richard, maple barbara -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

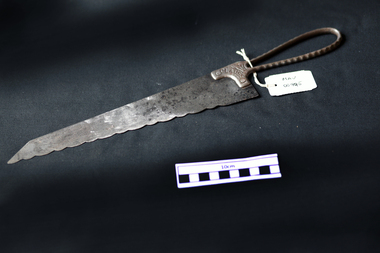

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, Bread Knife 'Clauss', c1900

Clauss Cutlery’s long and vivid history started in early 1880’s when John Clauss and his younger brother Henrie established Elyria Shear Works in Elyria, Ohio. At one time the company was the largest manufacturer of scissors and shears in the world and was acquired by Acme United Corporation in 2004. John and Henrie Clauss, of German origin, started Elyria Shear Works from a one-room building in Elyria, Ohio Together with five employees, they began manufacturing scissors, shears, straight razors and serrated kitchen knives In August 1887, the Company moved to Fremont, Ohio to be near an accessible, abundant supply of natural gas which had recently been discovered. 1889, disaster struck as the plant was completely destroyed by fire, In 4 months Clauss built a new plant and was back in full operation and changed the company’s name to Clauss Shear Company. 1919 Clauss Shear merged with Henkel Company, to become Henkel-Clauss Company. Henkel Company was founded in 1906 to manufacture manicure and pedicure files, knives, shears and razors. After World War II, Clauss was unable to compete with European firms producing household scissors and shifted its focus to industrial scissors. In 1967 Clauss was taken over by Alco Standard Corporation who integrated Clauss into its existing structure to manufacture tools for industrial niche markets. Clauss made surgical scissors for eye operations, heavy duty metal cutting shears, poultry shears for gutting chickens and specialty items such as anti-acid, anti-magnetic tweezers for the electronics industry. Clauss had approximately 100 employees and produced about $18 million in annual revenues in the late 1980s, but profits continued to decline. In 2004, Acme United Corporation acquired the Clauss inventory, trademarks and brand names from Alco Industries for approximately $500,000A large Bread Knife with scalloped / serrated edge and looped handle Front : CLAUSS Back : FREEMONT / OHIOcutlery, knives, clauss shear company, ohio, freemont, market gardeners, early settlers, moorabbin, cheltenham, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Objects, adhesive surgical tape, 20thC

... on a metal reel width 2cm Manufactured Objects, adhesive surgical ...Surgical tape or medical tape is a type of pressure-sensitive adhesive tape used in medicine and first aid to hold a bandage or other dressing onto a wound. These tapes usually have a hypoallergenic adhesive which is designed to hold firmly onto skin, dressing materials, and underlying layers of tape, but to remove easily without damaging the skin. Surgical tape is often white because it contains zinc oxide, which is added to help prevent infections. In 1845, Dr. Horace Day made the first crude surgical tape. It was created by combining India rubber, pine gum, turpentine, litharge (a yellow lead oxide), and turpentine extract of cayenne pepper and then applying that mixture to strips of fabric. It was the first “rubber-based” adhesive tape called Leukoplast for the German company Beiersdorf AG. Larger scale manufacturing of similar medical tapes began in 1874 by Robert Wood Johnson and George Seaburg in East Orange, NJ. (Johnson & Johnson Pty). 1921, Earle Dickson, who bought cotton for Johnson & Johnson, fixed a piece of gauze to some cloth backed tape and the first Band-Aid ® was invented. A roll of white adhesive surgical tape on a metal reel width 2cmaround wheel: ADHESIVE TAPE MANUFACTURED / MINDS MAKES REPAIRS Symbol of a butterfly in centre medical dressings, early settlers, moorabbin, cheltenham. bentleigh, johnson & johnson pty ltd, adhesive surgical tape, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

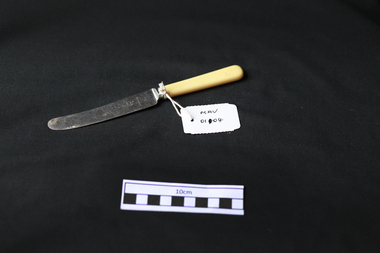

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, cutlery butter knife, c1930

Rodd's was established by George & Ernest Rodd in Melbourne in 1919.They were manufacturers and wholesalers of precious metal jewellery. Later they began to manufacture high quality silver plated cutlery under the brand name “Rodd”. They then expanded into holloware when they took over Platers Pty. Ltd. who produced a very high quality range of silver plated Sheffield Reproduction Silverware, under the brand name “Hecworth”. Rodd’s established a large factory at 150 Barkly St., St. Kilda, Melbourne. During WW2 with a staff some 200, the factory produced ordnance components to help with the war effort. Rodd’s established sales offices in the main city centres of all States. The company prospered. In December, 1960, Rodd [Australia] Ltd. was merged with Mytton’s Ltd., Melbourne, and became part of the newly formed company Mytton Rodd [Australia] Ltd. Mytton’s were also producers of silver plated cutlery under the brand name “Grosvenor” and were strong competitors to the Rodd brand of cutlery Australia wide. It was a friendly take over and the Directors of Rodd [Aust.] Ltd. were appointed to the board of Mytton Rodd [Aust.] Ltd., and some to the Holding Company Mytton’s Ltd. Mytton’s were heavy manufacturing engineers producing a large range of stainless steel products including: kitchen sinks of various design, beer barrels [9 and 18 gallon kegs] for the breweries, milk vats for cooling and storing milk on dairy farms, a large range of dairy and industrial vessels, road transport tanks, LPG tanks, low pressure pre-mix vessels for the soft drink industry. They also produced a range of domestic bathes, steel railway sleepers, using their 3000 ton hydraulic presses. Mytton’s also had their own non ferrous foundry and rolling mill which produced nickel silver sheet used in the manufacturer of their silver plated cutlery. They also produced copper sheet for their own and industrial use. Mytton’s had factories in York St., South Melbourne and Port Melbourne. Rodd [Aust.] Ltd. set up a manufacturing, distribution plant in Auckland, New Zealand, circa 1960. This company began producing precious metal jewellery in a rented space in the premises of Matthey Garret Ltd., Bullion Merchants, in Drake St., Auckland. Later they moved into their own building in Sale St., Auckland. The company prospered and purchased land and built a factory at 121 Apirana Ave. Glen Innes, Auckland, circa 1964. ( B. McCulloch Rodd Pty Ltd)A butter knife with stainless steel blade and bone handle c1930on blade; RODD / STAINLESScutlery, stainless steel, cheltenham, moorabbin, bentleigh, early settlers, rodd aust ltd, mytton rodd pty ltd, aukland, port melbourne -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

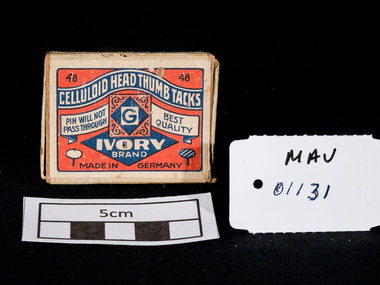

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Objects, Thumb Tacks 'Ivory', 20thC

A thumb tack, push pin or drawing pin is a short nail or pin used to fasten items to a wall or board for display and intended to be inserted by hand, generally without the assistance of tools. A variety of names are used to refer to different designs intended for various purpose. Edwin Moore invented the "push-pin" in 1900 and founded the Moore Push-Pin Company. Moore described the push-pin as a pin with a handle. Later, in 1904, in Lychen, German clockmaker Johann Kirsten invented flat-headed thumb tacks for use with drawings. A thumb tack has two basic components: the head, often made of plastic, metal or wood, and the body, usually made of steel or brass. The head is wide to distribute the force of pushing the tack in, allowing only the hands to be used. Many head designs exist: flat, domed, spherical, cylindrical and a variety of novelty heads.Cardboard box with sliding insert that contained 48 'IVORY' Brand celluloid head Thumb Tackson Box ; 48 / 48 / CELLULOID HEAD THUMB TACKS / 'G' / PIN WILL NOT / PASS THROUGH / BEST / QUALITY / IVORY / BRAND / MADE IN GERMANYdrawing pins, thumb tacks, brass tacks, moore edwin, kirsten johann -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

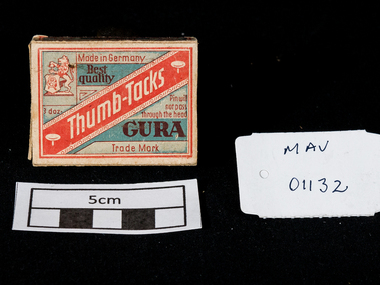

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Objects, Thumb Tacks 'GURA', GURA Pty Ltd

A thumb tack, push pin or drawing pin is a short nail or pin used to fasten items to a wall or board for display and intended to be inserted by hand, generally without the assistance of tools. A variety of names are used to refer to different designs intended for various purpose. Edwin Moore invented the "push-pin" in 1900 and founded the Moore Push-Pin Company. Moore described the push-pin as a pin with a handle. Later, in 1904, in Lychen, German clockmaker Johann Kirsten invented flat-headed thumb tacks for use with drawings. A thumb tack has two basic components: the head, often made of plastic, metal or wood, and the body, usually made of steel or brass. The head is wide to distribute the force of pushing the tack in, allowing only the hands to be used. Many head designs exist: flat, domed, spherical, cylindrical and a variety of novelty heads. Cardboard box with sliding insert that contained 3 Doz. GURA Brand Thumb Tacks On box ; MADE IN GERMANY / BEST / QUALITY / 3 doz. / THUMB-TACKS / Pin will / not pass / through the head / GURA / Trade Mark -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)WW11 1939-1945 Australian Army Soldiers Sewing Kit, c1939

1939 - 1945 Australian Army Sewing Kit. This kit is just one of many different brands of sewing kit - issued to Australian troops during the Second World War. Containing the standard requirements for uniform/clothing repair in the field. Items include:- assorted sewing needles,spare metal (quad hole) buttons and spare cotton/wool thread. Originally the "hold-all" (or pouch) was manufactured using leather, which was in plentiful supply in Australia and is quite durable. The major problem with leather however, especially in tropical or damp conditions - is it's susceptibility to moisture. This will then have an adverse affect upon the metal items contained within the kit, obviously resulting in corrosion to the metal sewing needles and buttons. This sewing kit hold-alls was manufactured from a khaki cotton or similar material. The metal thimble is missing.Standard issue sewing kit for Australian Soldiers serving in WW2 1939-45 in New Guinea and tropical areasA rectangular khaki cotton pouch containing wool and cotton threads, needles, metal buttons, folding stainless steel scissors that rolls up and is tied by two cotton bands.world war 11 1939-1945, cotton, khaki, soldier field kit, sewing kit, new guinea, army supply department, australian army, moorabbin, bentleigh, cheltenham, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured objects, metal paper fasteners, c1950

... brass piercing paper fasteners size 46 Manufactured objects ...c1950 The family of Ailsa Hunt used these brass paper piercing fasteners at home and in office to secure sheets of paper.lThese paper fasteners would have been use in most Offices and home during the mid 20th C in City of MoorabbinRectangular green cardboard box with sliding insert that contains many brass piercing paper fasteners size 46Box front THE / QUICK / PIERCING / PAPER/ FASTENER / 1 GROSS No. 46 - illustrations of various pin sizes - / EACH FASTENER / IS A PIERCER / IN ITSELF -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Objects, x 6 buttons, white metal filigree, c1900

c1900 These white metal buttons could be attached to a dress or jacket to possibly match or enhance decorative silver, pewter or brass buckles that were attached by ribbons or straps to plain shoes for evening and special occasions . These buttons were worn by a lady in the family of Ailsa Hunt in Moorabbin Shire These decorative white metal buttons were a common accessory for early settler women in Moorabbin Shire c19006x square white metal buttons with filigree design and attachment loop at backdetachable silver buttons, footwear, shoes, buckles, clothing, silver, pewter, brass, white metal, victorian fashion, edwardian fashion, market gardeners, early settlers, moorabbin shire, bentleigh, mckinnon, moorabbin, cheltenham, wedding dresses, evening wear, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Objects, 2x buckles white metal, c1900

c1900 Decorative silver, pewter or brass buckles were attached by ribbons or straps to plain shoes for evening and special occasions . These buckles were worn by the a lady in the family of Ailsa Hunt in Moorabbin ShireThese decorative shoe buckles were a common accessory for early settler women in Moorabbin Shire c19002 x rectangular white metal buckles with floral filigreefootwear, shoes, buckles, clothing, silver, pewter, brass, victorian fashion, edwardian fashion, market gardeners, early settlers, moorabbin shire, bentleigh, mckinnon, moorabbin, cheltenham, wedding dresses, evening wear, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Object, 2 x oval metal filigree buckles

... metal filigree buckles Manufactured Object, 2 x oval metal ...2 x oval metal filigree buckles