Showing 689 items

matching splitter's

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Newspaper - Photograph, Newspaper 'Reconstruction Box Cottage' celebration 1987, 1987

The original small, pioneer cottage was built in the late 1840s to early1850s, by an unknown pioneer. It was located on part of a 30 Acre allotment that was originally part of Dendy’s Special Survey granted in 1841. The doors and window sashes, (made of red deal joinery timber), as well as the brass locks and fittings, are from the original cottage, and were imported from England. The fire-place bricks are from the original cottage, and are sun-dried, (not kiln fired), and are hand-made. Convict marks can be seen on two bricks. There is a small display of external cladding shingles from the original pioneer cottage. These shingles were hand-split, and most likely made from locally collected timber The nails included in this display were used to fasten the shingles on the original cottage, and are also hand-made. The cottage was occupied by William Box and family from 1865 until 1914 when it was sold to William Reitman who resided there until 1950. The enamel nameplate, “Colonial”, on the wall of the cottage, was the name chosen for the original pioneer cottage by Mr William Reitman, when he purchased the property in around 1915, for 1200 Pounds approximately. In 1974 Mr Lewis, a timber specialist, found the dilapidated building on property he had recently purchased in Jasper Rd and suggested it be reconstructed and relocated. Moorabbin Council agreed and the cottage was rebuilt just about 250 metres from its original site. The cost of the rebuild was met by 'Victoria's 150th Committee, plus a small grant from the City of Moorabbin, and Mr Laurie Lewis donated much of the timber for the reconstruction. The re-constructed cottage plan has followed faithfully the original dimensions, and plan of the original pioneer cottage, and as many original items from that cottage’s long occupation have been incorporated. The photographs in Album 1 record the progress of the reconstruction from February 1984 to the First Public Open Day November 18th 1984 and this Celebration in October 1987This Newspaper photograph of Frank Thatche,r CMHS Vice President, riding a penny - farthing during a display by the Vintage Bicycle Club in 1987 is an example of the community events held at Box Cottage after the Reconstruction was completed. The Moorabbin Standard Newspaper was the local paper for the City of Moorabbin until it was absorbed by The Leader Newspaper Group Ltd. late 20thCentury. Mrs H. Deam and Mr A. Smith, CMHS members, took these photographs to record the progress of the ‘Reconstruction’ from February 1984 to November 1984. Although 'Box Cottage' is a re-construction, it is an unique museum that, being located in the midst of a modern community in Ormond Victoria, can educate and demonstrate many aspects of the early settler’s way of life in Victoria. As such, it is an invaluable resource for students and all kinds of visitors. 1 Black and white photograph in the Moorabbin Standard Newspaper October 1987 of Frank Thatcher , CMHS Vice-President, riding a 107 year old Penny- farthing bicycle at Box Cottage Joyce Park Ormond. He is assisted by Mr Harry Clarke, President of the Vintage Cycle Club of Victoria.brighton, moorabbin, highett, ormond, mckinnon, cottages, pioneers, colonial, dendy henry, box william, box elizabeth, reitman william, convicts lewis timber co. ltd., deam h, smith arthur, museums, box alonzo, moody & smith builders highett, the moorabbin standard newspaper, the leader newspaper pty ltd., thatcher frank, clarke harry, vintage bicycle club victoria, bicycles, penny-farthing bicycles -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Photograph, Colour ' Reconstruction Box Cottage' Moorabbin Pipe Band 1992, 1992

The original small, pioneer cottage was built in the late 1840s to early1850s, by an unknown pioneer. It was located on part of a 30 Acre allotment that was originally part of Dendy’s Special Survey granted in 1841. The doors and window sashes, (made of red deal joinery timber), as well as the brass locks and fittings, are from the original cottage, and were imported from England. The fire-place bricks are from the original cottage, and are sun-dried, (not kiln fired), and are hand-made. Convict marks can be seen on two bricks. There is a small display of external cladding shingles from the original pioneer cottage. These shingles were hand-split, and most likely made from locally collected timber The nails included in this display were used to fasten the shingles on the original cottage, and are also hand-made. The cottage was occupied by William Box and family from 1865 until 1914 when it was sold to William Reitman who resided there until 1950. The enamel nameplate, “Colonial”, on the wall of the cottage, was the name chosen for the original pioneer cottage by Mr William Reitman, when he purchased the property in around 1915, for 1200 Pounds approximately. In 1974 Mr Lewis, a timber specialist, found the dilapidated building on property he had recently purchased in Jasper Rd and suggested it be reconstructed and relocated. Moorabbin Council agreed and the cottage was rebuilt just about 250 metres from its original site. The cost of the rebuild was met by 'Victoria's 150th Committee, plus a small grant from the City of Moorabbin, and Mr Laurie Lewis donated much of the timber for the reconstruction. The re-constructed cottage plan has followed faithfully the original dimensions, and plan of the original pioneer cottage, and as many original items from that cottage’s long occupation have been incorporated. The photographs in Album 1 record the progress of the reconstruction from February 1984 to the First Public Open Day November 18th 1984 and this event in 1992These 3 photographs show the 'Box Cottage' in 1992 after the 'Reconstruction' . The Moorabbin Pipe Band is shown performing at an Open Day with Cr. Flavell, Moorabbin City Council and Mr Reid CMHS. Mrs H. Deam and Mr A. Smith, CMHS members, took these photographs to record the progress of the ‘Reconstruction’ from February 1984 to November 1984 and this event in 1992 Although 'Box Cottage' is a re-construction, it is an unique museum that, being located in the midst of a modern community in Ormond Victoria, can educate and demonstrate many aspects of the early settler’s way of life in Victoria. As such, it is an invaluable resource for students and all kinds of visitors. 2 x colour photographs of The Moorabbin Pipe Band performing at an Open Day in 1992, with Cr. Flavell, Moorabbin City Council and Mr Reid CMHS , at the 'Reconstructed Box Cottage' in Joyce Park. Ormond 1 x colour photograph of the 'Reconstructed Box Cottage ' c 1992written on back ; a) Moorabbin Pipe Band / Mr Reid & Cr. Flavell / 1992 ; b) Moorabbin Pipe Band 1992 ; brighton, moorabbin, highett, ormond, mckinnon, cottages, pioneers, colonial, dendy henry, box william, box elizabeth, reitman william, convicts lewis timber co. ltd., deam h, smith arthur, museums, box alonzo, moody & smith builders highett, the moorabbin standard newspaper, the leader newspaper pty ltd., fox max cr. , lewis laurie, moorabbin city council, national trust, connard geoff mlc, lawson geoff mlc, flavell robert cr. moorabbin city council, joyce park, jasper road, moorabbin pipe band, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Photograph, colour 1984 Box Cottage dismantled, 1984

The original small, pioneer cottage was built in the late 1840s to early1850s, by an unknown pioneer. It was located on part of a 30 Acre allotment that was originally part of Dendy’s Special Survey granted in 1841. The doors and window sashes, (made of red deal joinery timber), as well as the brass locks and fittings, are from the original cottage, and were imported from England. The fire-place bricks are from the original cottage, and are sun-dried, (not kiln fired), and are hand-made. Convict marks can be seen on two bricks. There is a small display of external cladding shingles from the original pioneer cottage. These shingles were hand-split, and most likely made from locally collected timber The nails included in this display were used to fasten the shingles on the original cottage, and are also hand-made. The cottage was occupied by William Box and family from 1865 until 1914 when it was sold to William Reitman who resided there until 1950. The enamel nameplate, “Colonial”, on the wall of the cottage, was the name chosen for the original pioneer cottage by Mr William Reitman, when he purchased the property in around 1915, for 1200 Pounds approximately. In 1974 Mr Lewis, a timber specialist, found the dilapidated building on property he had recently purchased in Jasper Rd and suggested it be reconstructed and relocated. Moorabbin Council agreed and the cottage was rebuilt just about 250 metres from its original site. The cost of the rebuild was met by 'Victoria's 150th Committee, plus a small grant from the City of Moorabbin, and Mr Laurie Lewis donated much of the timber for the reconstruction. The re-constructed cottage plan has followed faithfully the original dimensions, and plan of the original pioneer cottage, and as many original items from that cottage’s long occupation have been incorporated. The photographs in Album 1 record the progress of the reconstruction from February 1984 to the First Public Open Day November 18th 1984These 3 photographs show the 'Box Cottage' dismantled in the Lewis Timber Co Ltd property at the commencement of the 'Reconstruction in February 1984. Mrs H Deam and Mr A. Smith, CMHS members, photographed the progress of the 'Reconstruction' from February 1984 to November 1984. Although 'Box Cottage' is a re-construction, it is an unique museum that, being located in the midst of a modern community in Ormond Victoria, can educate and demonstrate many aspects of the early settler’s way of life in Victoria. As such, it is an invaluable resource for students and all kinds of visitors. 3 x Colour photographs of the 'Box Cottage' dismantled in sections, lying on the floor of the storage building of the Lewis Timber Co Ltd Jasper Road Ormond c 1984nilbrighton, moorabbin, cottages, pioneers, ormond, colonial, mckinnon, dendy henry, box william, box elizabeth, reitman william, convicts lewis timber co. ltd., deam h, museums, box alonzo, smith a, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Photograph, Colour, 'Box Cottage' in Lewis Yard 1977, 1977

The original small, pioneer cottage was built in the late 1840s to early1850s, by an unknown pioneer. It was located on part of a 30 Acre allotment that was originally part of Dendy’s Special Survey granted in 1841. The doors and window sashes, (made of red deal joinery timber), as well as the brass locks and fittings, are from the original cottage, and were imported from England. The fire-place bricks are from the original cottage, and are sun-dried, (not kiln fired), and are hand-made. Convict marks can be seen on two bricks. There is a small display of external cladding shingles from the original pioneer cottage. These shingles were hand-split, and most likely made from locally collected timber The nails included in this display were used to fasten the shingles on the original cottage, and are also hand-made. The cottage was occupied by William Box and family from 1865 until 1914 when it was sold to William Reitman who resided there until 1950. The enamel nameplate, “Colonial”, on the wall of the cottage, was the name chosen for the original pioneer cottage by Mr William Reitman, when he purchased the property in around 1915, for 1200 Pounds approximately. In 1974 Mr Lewis, a timber specialist, found the dilapidated building on property he had recently purchased in Jasper Rd and suggested it be reconstructed and relocated. Moorabbin Council agreed and the cottage was rebuilt just about 250 metres from its original site. The cost of the rebuild was met by 'Victoria's 150th Committee, plus a small grant from the City of Moorabbin, and Mr Laurie Lewis donated much of the timber for the reconstruction. The re-constructed cottage plan has followed faithfully the original dimensions, and plan of the original pioneer cottage, and as many original items from that cottage’s long occupation have been incorporated. The photographs in Album 1 record the progress of the reconstruction from February 1984 to the First Public Open Day November 18th 1984 This photograph shows the 'Box Cottage' in the Lewis Timber Co Ltd property in 1977 where it is being used as a storage room for timber. Mrs H Deam and Mr A. Smith, CMHS members, photographed the progress of the 'Reconstruction' from February 1984 to November 1984. Although 'Box Cottage' is a re-construction, it is an unique museum that, being located in the midst of a modern community in Ormond Victoria, can educate and demonstrate many aspects of the early settler’s way of life in Victoria. As such, it is an invaluable resource for students and all kinds of visitors.A colour photograph of the ‘Cottage’ in the yard of the Lewis Timber Co P/L Jasper Road, Ormond, in 1977 where it is being used as a storage area for timber.brighton, moorabbin, cottages, pioneers, ormond, colonial, mckinnon, dendy henry, box william, box elizabeth, reitman william, convicts lewis timber co. ltd., deam h, museums, box alonzo, smith a, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)A laminated , photocopy of the ‘Plan of Box Cottage c 1865 ‘, 1985

The original small, pioneer cottage was built in the late 1840s to early1850s, by an unknown pioneer. It was located on part of a 30 Acre allotment that was originally part of Dendy’s Special Survey granted in 1841. The doors and window sashes, (made of red deal joinery timber), as well as the brass locks and fittings, are from the original cottage, and were imported from England. The fire-place bricks are from the original cottage, and are sun-dried, (not kiln fired), and are hand-made. Convict marks can be seen on two bricks. There is a small display of external cladding shingles from the original pioneer cottage. These shingles were hand-split, and most likely made from locally collected timber The nails included in this display were used to fasten the shingles on the original cottage, and are also hand-made. The cottage was occupied by William Box and family from 1865 until 1914 when it was sold to William Reitman who resided there until 1950. The enamel nameplate, “Colonial”, on the wall of the cottage, was the name chosen for the original pioneer cottage by Mr William Reitman, when he purchased the property in around 1915, for 1200 Pounds approximately. In 1974 Mr Lewis, a timber specialist, found the dilapidated building on property he had recently purchased in Jasper Rd and suggested it be reconstructed and relocated. Moorabbin Council agreed and the cottage was rebuilt just about 250 metres from its original site. The cost of the rebuild was met by 'Victoria's 150th Committee, plus a small grant from the City of Moorabbin, and Mr Laurie Lewis donated much of the timber for the reconstruction. The re-constructed cottage plan has followed faithfully the original dimensions, and plan of the original pioneer cottage, and as many original items from that cottage’s long occupation have been incorporated. The photographs in Album 1 record the progress of the reconstruction from February 1984 to the First Public Open Day November 18th 1984Mrs H Deam and Mr A. Smith, CMHS members, photographed the progress of the 'Reconstruction' from February 1984 to November 1984. Although 'Box Cottage' is a re-construction, it is an unique museum that, being located in the midst of a modern community in Ormond Victoria, can educate and demonstrate many aspects of the early settler’s way of life in Victoria. As such, it is an invaluable resource for students and all kinds of visitors. A laminated , photocopy of the ‘Plan of Box Cottage c 1865 ‘ Hand drawn layout of 2 houses with shrubs, trees, plants, wells, gardens on the Box Cottage site c1930 as recalled by Stefanie Rietman Rennick. brighton, moorabbin, cottages, pioneers, ormond, colonial, mckinnon, dendy henry, box william, box elizabeth, reitman william, convicts lewis timber co. ltd., deam h, museums, box alonzo, smith a, -

Puffing Billy Railway

Puffing Billy RailwayVictorian Railways 2'6" Transporter wagon 129Q, 1926

The Q class were introduced as bogie flatwagons in the 1870's. Large Q wagons as shown were built to the 1920's In the early 1900's, some Q wagons were modified for Pintsch Gas traffic with a small pump motor cabin at one end and a tank for carrying the gas. Other conversions for traffic were as required. Examples were: sheet glass, skeletal underframes between workshops In 1926 the railways built two narrow gauge Garratt locomotives. As normal wagons were unsuitable for moving these locomotives a special skeletal wagon was built. The engines were split into units for transportation. It featured axle bearings and boxes from steam engines, had hinged buffers that could drop out of the way during loading/unloading. It also featured 'strap' rail along the deck. The wagon was Q 129. This wagon was also available for general narrow gauge rolling stock. Q wagons were numbered from 1 to 136. Service History: *Q 129.VA - 1/ 6/1926 NWS Built new H/brake & drop buffers. For traffic of Narrow Guage stock 31/ 1/1931 NWS Into Workshops - 16/ 6/1931 NWS Out of Workshops (50 days) 6/11/1931 NWS Into Workshops - 27/11/1931 NWS Out of Workshops (22 days) 24/ 8/1936 NWS Into Workshops - 10/ 9/1936 NWS Out of Workshops (18 days) 27/11/1936 NWS Into Workshops - 26/ 2/1937 NWS Out of Workshops (Light repairs) circa 1960 - Photograph SL20 p32, loaded with 7NA / /1975 - Photograph #393 / /1976 - Photograph #553, #554 19/ 3/1979 - Condemned - 10/ 4/1979 - Off Register - 10/ 4/1979 - Sold (to) ETR, Belgrave / /1989 EME Body [GRE]. [SXC]: 29/3/92, MEL127E5, Puffing Billy at station Historic - Victorian Railways - Transporter wagon used to carry and transfer 2' 6" Narrow gauge rolling stock over Victorian broad gauge (1,600 mm (5 ft 3 in) main lines to the narrow gauge lines. Q 129 was unique, it was built to transport narrow gauge locomotives. Transporter Wagon made of Steel and wrought Iron129Q129q, puffing billy, transporter wagon -

Melbourne Legacy

Melbourne LegacyFilm, Firewood

15 min black and white 16 mm film, no sound. Begins with shots of trees in the bush and piles of cut logs beside a track before moving to a group of men standing by a car with 'Operation Firewood' on the boot. A road sign indicates 'Nathalia 6 1/2', 'Numurkah 22', 'Picola 3'. 'Katunga' and 'Barmah'. Shots of an empty Austin flat bed truck with 'Legacy Operation Firewood', poster on the drivers door covering the truck company name,and other empty flat bed trucks parked along a country town street which looks unsealed. A shot of a wooden sign saying 'Euroa Please slow down' follows with the Legacy car travelling very slowly past it before we see a large group of men throwing up logs onto a nearly fully loaded truck, and then a partially loaded truck with men on the flat bed stacking the logs. Five trucks are shown fully loaded and a crowd of men are gathered around a table. A circular saw (with no safety guards!) is being used to cut the bigger logs into a manageable size for splitting before being loaded by a lot of men of varying ages. The film then moves to the city where we see three men riding on the back of a moving fully loaded truck, before it stops to deliver the cut but unsplit logs to a delighted widow and her children. The logs are hurled into her front garden as a well dressed man photographs the proceedings. Other deliveries follow to further widows, but it is not clear who is going to split the logs, some of which are extremely large. The film ends showing a line of empty trucks, and a fenced city area with a sign saying 'Melbourne Legacy Firewood' holding further a supply of logs. 15 mins 07 sec. Legatees delivered firewood annually until 1995 to widows to help them through the winters in a project called 'Operation Firewood' . See also Cat. No. 000848.A record of Legacy helping widows with supplying and stacking firewood. When open fires were the main source of heating a load of firewood, and help moving it, would have been very important to the widows.Metal Kodak film cannister, silver coloured, with 'Firewood' label on outer casing.No inscriptions on internal film. operation firewood, widows -

National Wool Museum

National Wool MuseumClothing - Shirt, 1925-1938

Male wool shirt made in Bradford, U.K. The shirt is cut from first fabric woven from 100% traceable Australian wool. Bradford Mills differ to Australian mills in that the entire process of producing worsted material does not take place at the one firm/factory. Rather it is split between many firm/factories specialising in their task in the production of worsted material. For example, the wool goes from merchants to combers to produce tops, the tops to spinners to produce yarn and then the yarn is sold to manufactures who weave it into cloth. After the weaving is done the cloth has to be sent to the dryers and finishers, who scour, dye and finish the cloth. Finally, the finished cloth is purchase by a fresh set of merchants, who will later sell the cloth elsewhere in England or abroad. At each these steps a new firm is handling the wool/cloth making it hard to track lineage of wool through this process and hence hard to guarantee 100% Australian wool. This shirt was purchased and worn by the donor’s husband, George H. Gerber, an Australian Wool Buyer. The shirt was purchased on one of George’s trips to Bradford in the U.K. on company business. Gerber was a second-generation Wool Traders in his family. His father, also named George H. Gerber, worked for Kreglinger & Furneau. He worked for them in Boston, U.S.A. before he died from the Spanish Flu in 1918. The company then promised a job to his oldest son (donor’s husband) once he finished school. Thus, George came to be trained as a Fine Wool Classer by Kreglinger & Furneaux (Aust.) Pty Ltd where he was employed as a Wool Buyer all his working life. He retired in 1969 as the head of their Australian office when the company was taken over Also of note, the shirt was sold with 2 add-on collars. Having additional collars was advantageous as changing only the collar increased the number of days the shirt could be worn without washing. Cream coloured shirt with black and red single thread verticle stripes.“Grandpa” collar (with 1 of its 2 supplied add-on collars included). French cuffs. Sold with 2 add-on collars, hence both ends of the collar have buttonholes to take a stud, and a partially-opened button-hole is at the centre of the neck on the outside of the collar for a second stud.Letering label on shirt: GENT’S OUTFITTER Herbert Winfield 23 CHEAPSIDE, BRADFORDbradford, u.k, kreglinger & furneaux (aust.) pty ltd, 100% australian wool -

Bendigo Military Museum

Bendigo Military MuseumUniform - JACKET, TROUSERS, SHIRT, NECKTIE, BELT, SERVICE DRESS - ARMY, Australian Defence Industries, 2016

1. Jacket, Khaki wool/polyester fabric. Service Dress style. Gold colour plastic buttons with shank and metal split ring. Buttons have raised emblem - Rising Sun Emblem. Collar, shoulder epaulettes, four front pockets with button down flap. Left sleeve - oval patch Rising Sun Badge, patch crossed Rifles, patch Australian Coat of Arms - Warrant Officer. Right sleeve - patch - Parachute Wings, patch, Australian Coat of Arms - Warrant Officer, 1st Class. Khaki colour polyester fabric lining with white cotton manufacturers label inside left side. 2. Trousers, khaki wool/polyester fabric. Service Dress Style, with fob pocket, two side pockets, one back pocket with button down flap. Plastic buttons, metal zipper fly, Khaki colour polyester fabric waist and pocket lining. White manufacturers label back pocket. 3. Shirt, Khaki colour cotton/polyester fabric, long sleeves, shoulder epaulettes, two front pockets with button down flap. Plastic buttons. White cotton manufacturers label, back, below collar. 4. Necktie - khaki colour wool/polyester fabric with polyester fabric lining tie. Two manufacturers labels - black and white cotton with black ink print. 5. Belt - black webbing with brass buckle and keepers. Emblem on reverse sides of buckle. Manufacturers Information on label - black ink print. 1. ADA/MADE IN CHINA/ OCT 2016/ CC30BK/ ^/ NSN: 8405 66 162 6289/ SIZE 105S/ NAME:/ PM KEYS NO:/ OUTER 60% WOOL/ 40% POLYESTER/ LINING/ 100% POLYESTER/ DRY CLEAN ONLY/ DO NOT WASH/ IRON UNDER DAMP CLOTH/ WARM IRON". 2. As above with NSN: 8405 66 162 6077" 3. 'ADA/100M/ NSN 8405 66 088 7104/ SIZE??/ NAME/ SERVICE NO./65% POLYESTER/ 35% COTTON/ MADE IN AUSTRALIA" 4. "ADA" ADA/ MADE IN CHINA/ MAY 2016/ 60% WOOL/ 40% POLYESTER/ DRY CLEAN ONLY" 5. Etched emblem on buckle "^". uniform, army, service dress -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - LONG SLEEVED FULL LENGTH DRESSING GOWN

This gown dated to c. 1910-1910Long sleeved full length dressing gown of cream coloured satin. Front opening with three passementerie buttons at centre front with fabric ties at waist (60cm). Ties split into two parts at halfway point Each tie is tied at the end with a thin cord and finished with two tassels with cord covered beads. Garment, including long sleeves, is fully lined with cream coloured satin with decorative stitching pattern.Rounded neckline at back with stand up collar (5cm) decorated with lace. Lace fabric panel across shoulders at front and back. Both sides of front opening have a border (7cm) from shoulder to hem. Neckline dips to V shape above waist. Panels decorated with piping. Front panels lined with cream coloured embroidered lace netting to top button. A different patterned lace lines the top part of the opening panels and extends across the neckline at the back.Two hanging loops attached inside shoulders at top of sleeves. Long sleeves of cream coloured lace fabric with double layer of satin lining. Each sleeve has a panel of decorative fabric from the top of the shoulder to the wrist (same decorative fabric as that used for border of front opening). Satin cuff (12 cm) scalloped edge above wrist. Inside cuff edge of sleeve is lined with lace fabric with a row of pleated net inserted at hemline at wrist. Front inside on LHS has a pocket handstitched to the lining, (30cm X 24 cm). Pocket has decorative pleated ribbon edging.costume, female, long sleeved dressing gown -

National Wool Museum

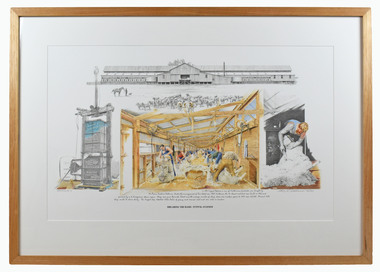

National Wool MuseumPrint, Chris McClelland, Shearing the Rams – Tuppal Station, 210

Chris was invited to be artist in resident for the historic re-enactment of “Shearing the Rams” at the North Tuppal Station woolshed held on the 4th and 5th June 2010. The celebration attracted record crowds to witness the shearing of the station rams by 72 blade shearers. Over a single weekend in 2010, thousands of people queued for hours to see a piece of Australian history recreated at North Tuppal Station near Tocumwal, NSW. In 1900, Francis Faulkner invested a staggering £4000 to extend his shearing shed on Tuppal Station, making it the biggest in the country. Over the next decade more than three million sheep trod its pine boards and were shorn in its 72 stands. After years of drought and the Great Depression, the property fell into disrepair and the station was split up. When North Tuppal Station was sold to the Atkinson family in 1928, just five of the 72 stands were in operation. In 2010, Sport Shear Australia approached the Atkinson family about holding an event in the historic shearing shed to raise money for a team of Australian shearers to go to the world shearing title in Wales. An army of volunteers restored the T-shaped shed and yards and organised a weekend of events. Over two days, 6,000 sheep were shorn and all 72 stands of the restored North Tuppal shed were brought back to life. A total of 117 shearers shared the boards with 90 wool handlers who skirted 19 fleeces every minute. For a period on each day of this historic weekend, the machines were then silenced, and 72 shearers picked up their old blade shears to recreate past shearing methods. “When they fired up and got the blades out there was deathly silence on the board - you could hear a pin drop because normal shearing you have all the machines and it is quite noisy. Here you could just hear the click, like in the song Click Go the Shears Boys. People had tears in their eyes. It was quite an emotional thing to see that and very proud to be here.” George Falkiner, grandson of Francis FalkinerColoured framed print of shearing scene in the Tuppal station, Ferrrier’s wool press on the left-hand side and station on the top. Print in framed in a light-coloured wooden frame with white coloured matte.Under artwork - In 1891 Tuppal Station, a sum of 176,000 acres threshold, was bought by Mr Fiane Sadlies Falkines, Under the management of his eldest son F.B.S. Falkines, the 72 stand woolshed was build in 1900 and powered by a 16 horsepower steam engine. Sheep were pure Boonoke blood and the average numbers of sheep shorn over nineteen years to 1909 was 152,780. Around 7200 sheep could be shorn daily. The largest clip totalled 3326 baled of greasy and scoured wool and was sold in London. Bottom right corner - Chris McClelland 181/720 Shearing The Rams – Tuppal Station -

Parks Victoria - Point Hicks Lightstation

Parks Victoria - Point Hicks LightstationCorbel

In architecture a corbel serves a decorative as well as structural function as a solid piece of stone, wood or metal that is built into a wall and juts out like a bracket to carry a weight. The smoothly shaped corbel was formerly built into the external wall of the lighthouse facing the sea. It consists of two cupped, rounded forms, one bigger than the other, which are attached to a damaged flat base. Made of cast concrete, it is the same fabric as the lighthouse and shows evidence of white paint on its surface. An early architectural drawing of the tower shows the corbel as a projecting, decorative moulding underpinning the balcony floor associated with the auxiliary light. It indicates the original corbel was a much larger architectural feature which started as a solid rectangular block and terminated with a smaller block and then two tapering, rounded forms. Prepared in mid-1888, the architectural drawings for the lighthouse by Victorian Public Works Department architect, Frederick Hynes, were amended in 1888-89 to provide for an auxiliary light, which comprised an arched opening and door in the tower wall below the lantern room and small balcony. In the late nineteenth century all of Victoria’s lightstations installed a red auxiliary light to serve as a danger warning to mariners sailing too close to shoare. Existing lightstations, like Cape Otway, built a pavilion below their lighthouse facing out to sea, but newly constructed towers like Point Hicks and Split Point incorporated them into their designs. The efficacy of auxiliary lights became a controversial issue and all were discontinued on 1 January 1913. The Point Hicks balcony was removed from the face of the tower in 1971 after it was found to be badly rusted. This resulted in the complete removal of the corbel, from which the rounded moulding and part of the base survives. The auxiliary light and door were subsequently removed in 1975 and glass blocks now fill the opening. Cape Schanck Lightstation retains four cast iron brackets from its auxiliary light balcony which are currently stored in the lighthouse on the ground floor. No other architectural fabric associated with the auxiliary light has been identified at Point Hicks Lightstation. The fragment of corbel has first level contributory significance for its historic and architectural values as a relic of the auxiliary light and as an original moulding from the fabric of Victoria’s first concrete lighthouse.A masonary corbel. -

Dandenong/Cranbourne RSL Sub Branch

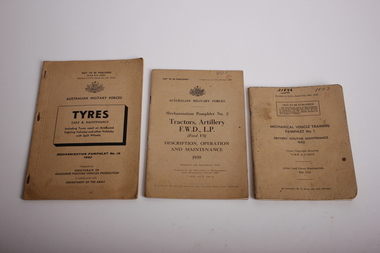

Dandenong/Cranbourne RSL Sub BranchBooklet - Military operation and maintenance handbooks, The Specialty Press Pty Ltd, 1939-1945

Three military operation and maintenance handbooks including Mechanical Vehicle Training, Tractors, Artillery and Tyres Care and Maintenance.1. "Notified in G.O's, dated 31st July, 1942/ *NOT TO BE PUBLISHED/The information given in this document is not to be communicated, either directly or indirectly, to the Press or to any person not holding an official position in His Majesty's Service/ MECHANICAL VEHICLE TRAINING/PAMPHLET No.1/DRIVER'S ROUTINE MAINTENANCE/1942/Crown Copyright Reserved/*A.M.R. & O 1588 B./Allied Land Forces Headquarters,/May 1942/ By Authority: W.A Hamer Pty. Ltd, Printers." 2. "NOT TO BE PUBLISHED Notified in A.A.Os, October 1939/AUSTRALIAN MILITARY FORCES/ Mechanization Pamphlet No.2/Tractors, Artillery, F.W.D., L.P (Ford V8)/DESCRIPTION, OPERATION/AND MAINTENANCE/1939/ (Reprinted with Amendments, 1940)/ Prepared by the Directorate of Mechanization, Army Headquarters, October 1939./ *A.M.R and O. 1588 B./ Bu Authority: The Specialty Press Pty Ltd., 174 Little Collins Street, Melbourne" 3. "NOT TO BE PUBLISHED/ (A.M.R. & O. 1588B)/Notified in G.O's dated 31st July, 1942/ AUSTRALIAN MILITARY FORCES/ TYRES/CARE & MAINTENANCE/ Including Tyres used on Armoured Fighting Vehicles and other Vehicles with Split Wheels/ MECHANIZATION PAMPHLET No. 19/1942/ Prepared by/ DIRECTORIATE OF ARMOURED FIGHTING VEHICLES PRODUCTION/in collaboration with/DEPARTMENT OF THE ARMY"handbooks, maintenance, mechanical, training -

Woodend RSL

Woodend RSLKnife sheath

This knife and scabbard belongs to Lindsay Fankhouser, who wore it on his ankle when he served as an engineer/ crewman in the RAAF (Iroquois and Hercules) during the Vietnam war. He used this knife many times a day while he was serving. It is a brown leather knife sheath, with a decorative front and two canvas straps attached at the back. The shorter strap is located at the bottom of the sheath and the longer strap is located just below the belt loop. Both straps are fixed in place with stitching. The top strap has a square of stitching, while the bottom strap has two lines of stitching that follows the stitching of the sheath. The belt loop is at the top of sheath and is a fixed flap of leather that is folded across the top and also holds the handle of the knife in place using a circular hole that fits around the butt of the knife. The bottom canvas strap has three adjustable brass male press studs on the left side as well as the fixed female one on the right. The top canvas strap has four adjustable brass male press studs on the right side as well as as the fixed female one on the right. The sheath is held together by stitching and five iron rivets. There is one on the point of the sheath, two on either side of the top, and two more 51mm below the top two. 46mm above the sheath, there are another two iron rivets on either side. Above that on the holding flap, there are two iron rivets just above the circular hole on either side. On the flap, around the hole there are three brass flat-headed split pins, one on either side and one on the front. At the top of the sheath, above the decorative embossing, there is a dark brown jagged cut strip of fixed leather. All the leather on the object is a reddish-brown, while the canvas and stitching is light beige. The end stitching on the canvas straps is dark grey. The front of the sheath is polished leather, while the back is rough.On back of belt loop flap, there is an embossd manufactuing patent number; PATENT Nr152.463 On face of the sheaf there embossed decoration. It depicts a lion with stylised decorative foliage and above the lion there is a fleur de lise. Above that it reads Soallingen Norge.norway, norge, soallingen, knife, small knife, hunting, scabbard, sheath, vietnam, lindsay fankhouser, raaf -

Ballarat Heritage Services

Ballarat Heritage ServicesDigital Photograph, Dorothy Wickham, Filming Fingal's Finest Day, Malahide Castle, 2016, 09/2016

Generations of the Talbot family have called Malahide Castle home. They played significant roles in Irish political and social life. Set in 260 acres the castle is only 10 minutes from Dublin airport. https://www.malahidecastleandgardens.ie/ According to wikipedia See https://en.wikipedia.org/wiki/Easter_Rising#Fingal In Fingal (or north County Dublin), about 60 Volunteers mobilised near Swords. They belonged to the 5th Battalion of the Dublin Brigade (also known as the Fingal Battalion), and were led by Thomas Ashe and his second in command, Richard Mulcahy. Unlike the rebels elsewhere, the Fingal Battalion successfully employed guerrilla tactics. They set up camp and Ashe split the battalion into four sections: three would undertake operations while the fourth was kept in reserve, guarding camp and foraging for food. The Volunteers moved against the RIC barracks in Swords, Donabate and Garristown, forcing the RIC to surrender and seizing all the weapons. They also damaged railway lines and cut telegraph wires. The railway line at Blanchardstown was bombed to prevent a troop train reaching Dublin. This derailed a cattle train, which had been sent ahead of the troop train. The only large-scale engagement of the Rising, outside Dublin city, was at Ashbourne. On Friday, about 35 Fingal Volunteers surrounded the Ashbourne RIC barracks and called on it to surrender, but the RIC responded with a volley of gunfire. A firefight followed, and the RIC surrendered after the Volunteers attacked the building with a homemade grenade. Before the surrender could be taken, up to sixty RIC men arrived in a convoy, sparking a five-hour gun battle, in which eight RIC men were killed and 18 wounded. Two Volunteers were also killed and five wounded, and a civilian was fatally shot. The RIC surrendered and were disarmed. Ashe let them go after warning them not to fight against the Irish Republic again. Ashe's men camped at Kilsalaghan near Dublin until they received orders to surrender on Saturday. The Fingal Battalion's tactics during the Rising foreshadowed those of the IRA during the War of Independence that followed. Volunteer contingents also mobilised nearby in counties Meath and Louth, but proved unable to link up with the North Dublin unit until after it had surrendered. In County Louth, Volunteers shot dead an RIC man near the village of Castlebellingham on 24 April, in an incident in which 15 RIC men were also taken prisoner.filming fingal's finest day, malahide castle, ireland -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Photograph, B/W Laminated of August Rietman Family c 1918, c1918

August Rietmann 1877-1951 and his wife Frieda 1878-1942 leased the Box Cottage in 1917 and raised 2 children Stefanie 1918-2006, and William 1920– 1997. August was a Monumental Mason / Potter / Sculptor and he was employed at Corbens Ltd Clifton Hill, to make the War Memorials for many towns post WW1. August purchased the property 1935,and established a pressed concrete business using the cottage as a workshop and storeroom After August died in 1951, William, his son, continued to work in the business from the site until the land was sold to Lewis Co. Ltd Timber Merchants in 1970. Rietman's Landscaping Ltd , managed by William's family, moved to Bay Road Highett 1953 and later to Carrum. The original small, pioneer cottage was built in the late 1840s to early1850s, by an unknown pioneer. It was located on part of a 30 Acre allotment that was originally part of Dendy’s Special Survey granted in 1841. The doors and window sashes, (made of red deal joinery timber), as well as the brass locks and fittings, are from the original cottage, and were imported from England. The fire-place bricks are from the original cottage, and are sun-dried, (not kiln fired), and are hand-made. Convict marks can be seen on two bricks. There is a small display of external cladding shingles from the original pioneer cottage. These shingles were hand-split, and most likely made from locally collected timber The nails included in this display were used to fasten the shingles on the original cottage, and are also hand-made. The cottage was occupied by William Box and family from 1865 until 1914 when it was sold to August Rietman . The enamel nameplate, “Colonial”, on the wall of the cottage, was the name chosen for the original pioneer cottage by Mr August Rietman, when he purchased the property in around 1915, for 1200 Pounds approximately. In 1974 Mr Lewis, a timber specialist, found the dilapidated building on property he had recently purchased in Jasper Rd and suggested it be reconstructed and relocated. Moorabbin Council agreed and the cottage was rebuilt just about 250 metres from its original site. The cost of the rebuild was met by 'Victoria's 150th Committee, plus a small grant from the City of Moorabbin, and Mr Laurie Lewis donated much of the timber for the reconstruction. The re-constructed cottage plan has followed faithfully the original dimensions, and plan of the original pioneer cottage, and as many original items from that cottage’s long occupation have been incorporated. The photographs in Album 1 record the progress of the reconstruction from February 1984 to the First Public Open Day November 18th 1984After the death of Elisa Box in 1914 the house was leased to August Rietmann, a potter / sculptor who with his wife Fieda raised their family there 1917 - 1951. Stefanie Rennick nee Rietman lived at the house until she left to study teaching 1937. August's son, William Rietman and family managed Rietman's Landscaping Ltd after moving to Bay Road Highett 1953 and later to Carrum. The Lewis Timber Company Ltd purchased the land with The Cottage c1970. i) A laminated, black and white, photograph of August Rietmann and Family c1918 at Box Cottage, Ormond, Molly the house cow is in foreground ii) Colour photograph of Rietman's Landscaping Ltd. Bay Road Highett c 1990brighton, moorabbin, cottages, pioneers, ormond, colonial, mckinnon, dendy henry, box william, box elizabeth, reitman august, convicts lewis timber co. ltd., deam h, museums, box alonzo, smith a, rietmann august, rietman august, rietmann frieda, rietman frieda, stonnington city town hall, war memorials, world war 1 1914-1918, rietman stefanie, rennick stefanie, francis stefanie, rietman william, rietman ray, mountford paul, malvern city town hall, box cottage museum ormond, joyce park ormond, rietman's landscaping pty ltd, bay road highett, macrobertson pty ltd, coleraine soldier memorial 1921, dendy, rietman agust, convicts, macrobertson, war memorial -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Plant Stand, Late 19th Century (1898)

During the years 1869-1935 there were well over 250 registered bamboo furniture producers in Britain. The earliest recorded firm was Hubert Bill of 14 Little Camden St, London N.W., who claimed to have been established in (1869) while Daniel Jacobs & Sons of Hackney Road, London, were still in business in 1915, after 45 years of production. Design, quality, price and methods of construction were fairly consistent throughout the whole period, but it was the imaginative and often eccentric choice of subject matter that marked differentiation between the various firms. While most produced standard tables, stands and fire-screens, the more adventurous offered for sale items such as corner shelve units, charcoal barbecue grills and musical tea tables. Shelves were often covered with embossed leather paper designs, at first imported from Japan and then later produced in England. Some firms incorporated the knobbly roots of the bamboo stems into their designs, generally to form feet. Occasionally handles to drawers and cupboards were made with these roots although they were more commonly carved as imitations. Handles were mostly of cheap metal or brass. The ends of the bamboo canes were capped with stamped metal or turned bone, ivory or wooden discs. Methods of construction fell into three categories. First and most common is that of pegging. Bamboo stems being hollow, thick dowels can easily be glued into the joints. Some firms farmed out this work of `plugging' the ends of the canes to part-time workers at home. The second method, that of pinning, was far less satisfactory as bamboo tends to split lengthwise and therefore the jointed pieces eventually disintegrated. The most efficient method was that patented in 1888 (patent No 2383) by the firm of W. F. Needham in Birmingham. It consisted of metal shoes and covers for all joints which were made by wrapping a metal strip around the stems and soldering the overlapping ends. Some joints were further strengthened by a small pin or screw. Needham was by far the largest and most successful manufacturer and their individual and superior method of construction undoubtedly gained them their reputation. A. Englander & Searle of 34 Gt Eastern St and 31 Mare St, Hackney, London, were a firm particularly concerned with methods of construction. Although they seem to have entered the bamboo furniture market at a comparatively late date, about 1898, they produced inexpensive' bamboo, aimed particularly at the export trade. Stating in their catalogue that bamboo furniture “can be exported in one piece or it can be exported in pieces and put together again. The fixing up is much facilitated by a system of marking and numbering. Further, no glue is required for putting together as the screw system only is applied”. This method of construction best fits the Etagere and this item in the flagstaff collection and it is believed to have been made by A Englander & Searle, exported in a knock down form to Australia, purchased in kit form from a dealer here and put together by the purchaser. The bamboo plant stand is a significant item as it highlight furniture fashion of the late Victorian era. This item was highly sort after in its time and although mass produced, not many examples remain because the item is so fragile so this example is a valuable addition to the Flagstaff collection. It is believed,the construction method used is by a notable and respected maker in England of bamboo furniture that was aimed specifically at the export market and probably came to Australia in kit form to be assembled by the purchaser.Bamboo plant stand with octagonal top edged with tortoise shell bamboo the top is of wood and supported by four tortoise shell bamboo legs joined at the base by a square cane covered shelf. The tortoise shell appearance is brown lacquer. Item is part of the Giles Collection. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, furniture, plant stand, bamboo furniture, etagere, victorian furniture, simulated bamboo, tortise shell, a englander & searle, domestic furniture, giles collection, henry giles, cooramook, mailor’s flat, wangoom, 19th century household goods -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - HELEN MUSK COLLECTION: CREAM SILK BODICE AND SKIRT

Ivory coloured silk bodice. Part of wedding ensemble with matching skirt with train. (11400.513B). The silk fabric has an all over pattern of scattered leaves. The bodice has long sleeves and is fully lined with cotton fabric with a front opening. The cotton lining at the front forms a separate bodice with a front opening fastened with fifteen hooks and eyes from throat to waist. The lining is edged at centre front on both sides with a border of the silk fabric. The border narrows from 7 cm at the throat to 3 cm at the waist. In the lining of the bodice are two casings on either side of the front opening containing boned segments. Across the lining of the back are seven casings containing boned segments. The front LHS of the bodice has an outer layer of silk fabric with a squared neckline. The RHS of the bodice overlaps the centre opening of the bordered lining to attach across the left shoulder. From the left shoulder the front tapers diagonally to the waistline 4cm to the left of centre. This cross over section is fastened with ten hooks and eyes – seven of the eyes are attached to the bodice lining and three are on the LHS outer silk fabric layer. This section crosses full width to the edge of the LH sleeve, across the top of the shoulder to the neckline. The LHS outer section crosses back over the edge of the centre section. There is a third layer on the RHS with a squared neckline to form a symmetrical appearance. The two side sections are edged with ruffles of fine silk ribbon. The centre section of the crossover part has vertical pintucks extending from the throat for 9 cm. The fullness created by the pintucks is gathered to centre front where the waist dips to a shallow V shape. The back of the bodice has vertical pintucks extending 12 cm from across the shoulders, narrowing to a single vertical strip of pintucks (4 cm) ending at centre waist. The waist is edged with a border of silk ribbon with a horizontal tuck. Inside the back of the bodice above the waist cotton tape ties are attached. These ties extend to the front of the bodice and the ends are fastened with a metal buckle. On this cotton tape at centre back there are to metal hooks for attaching the skirt. Attached to the neckline of the front section of the bodice is a 7 cm stand up collar. The collar extends from the RH shoulder in front of the neck and across the LH shoulder and continues unattached around the back of the neck to attach to the edge of the collar at the RH shoulder. The edges of the collar are fastened with three hooks and eyes. The collar has three full width horizontal pleats and the top edge is trimmed with a frill of fine gathered silk ribbon. On the waistline at centre front and centre back are decorative buttons (3.5 cm) of pearl coloured beads. The buttons have a centre pearl bead bordered by small glass beads surrounded by 9 smaller pearl beads and nine small pearl beads. Each button is edged with a row of tiny class beads with 18 points. The long sleeves are fully lined and made of two sections. The underneath section of the sleeve is ungathered and shaped at the elbow. The upper section of each sleeve is gathered at the shoulders and attached to the underneath section with a series of small pleats down to the elbow creating fullness. There is a small cap sleeve at each shoulder over the top of the gathered sleeve. The cap sleeves are edged with a frill of gathered silk ribbon with a decorative row of gathered silk ribbon parallel to the edge. At each wrist is a gathered frill of silk fabric edged with silk ribbon. Each sleeve has an 8 cm split at the wrist on the back seam. Full length ivory coloured silk skirt. The silk fabric has an all over pattern of scattered leaves. The skirt is fully lined with cotton fabric. The skirt is made of 5 pieces. The centre front panel has two darts at the waistline. The two side panels are cut on the bias and wrap around to form a centre back seam gathered into the waistband and finishing 44 cm below the waist line. Two triangular pieces of fabric are inserted at the back below the centre seam to complete the full circle of the skirt. There is 30 cm back opening. The waistband is made of cotton tape (3cm) fastened with two hooks and eyes with a 2 cm crossover. There is another hook and eye fastener halfway along the opening split. There is one upward facing hook on either side of the centre back opening to attach the matching bodice. The LHS of the back opening has a cotton fabric pocket inserted along the seam. The hem of the skirt is edged with two 5 cm frills of gathered silk fabric.costume, female daywear, silk bodice -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Screen, Thomas Hope, 1905-1913

The fire screen was part of the original furnishings of the Lighthouse Keeper's Quarters in Merri Street, Warrnambool. It was made by Lighthouse Keeper, Thomas Hope. Thomas served two terms as an assistant lighthouse keeper in Warrnambool. His first term was from 1905 to 1907. He later returned from 1910 to 1913, when he was appointed as Keeper five months after the untimely death of his predecessor Peter Quinn. Woodworking was one of Thomas Hope’s hobbies, and the three-panel fire screen he made as a lighthouse keeper is now in the Flagstaff collection and is displayed in the Lighthouse Keeper’s Cottage. Thomas Hope 1857 - 1928 Thomas James Hope was born in Camden, Surrey, England in 1857. His father, also called Thomas, was reputed to be a member of the Royal Family, and Thomas Hope Junior his illegitimate son. Thomas was subsequently brought up on the estate of the Earl of Hopetoun in Somerset and it was thought that Thomas was the Earl’s grandson. Against the wishes of those in charge of Thomas, he joined the navy at an early age, seeing much of the world until he settled in New Zealand at the age of twenty-four. After some years in New Zealand, he came to Australia to live. One of the jobs Thomas Hope had prior to becoming an assistant lighthouse keeper in 1896 was as a cook in the Lunatic Asylum at Sunbury, Victoria. He served as an assistant keeper at Shortlands Bluff, Gabo Island, Split Point and Warrnambool, retiring in 1918. He bought a house in Nicholson St, Warrnambool and died in March 1928. He is buried in the Warrnambool cemetery. Thomas Hope is recorded in family history as being of short stature and, not surprisingly given his alleged aristocratic connections, possessed a beautiful speaking voice. He and his wife Elizabeth nee Waters, whom he married in New Zealand, had six children (Thomas, killed in World War One), Ellen (Nell), Nora (who was married at the Warrnambool lighthouse keepers cottage), William (who died in Warrnambool), Marion and Alan. Joseph Hoover (Dec 29, 1830, to Aug 7, 1913) Joseph Hoover, the printer of the pictures on the screen, was born in Baltimore, of Swiss-German heritage. He was trained as an architectural woodturner. In 1856 Hoover moved to Philadelphia and began producing elaborate wooden frames in his wood-turning and framing business. By 1865 Hoover had started to produce popular prints for publishers and artists, which included noted Philadelphia artist James F. Queen. In the 1880s Hoover set up a complete plant specialising in chromatography, the process of producing colour prints from lithographic plates. The coloured prints he produced were affordable to business and private customers. In 1893 his son Henry L., a trained lithographer, joined the company as overseer and it was called J. Hoover & Son. It became one of the largest in America by the turn of the century. Hoover won a medal for Excellence for his Chromolithographs of James Queen’s works. In 1904 Joseph’s other son, Joseph W, joined the business as a partner and the company was called Jos. Hoover & Sons. Hoover died of a heart attack in 1913. He was survived by his wife and six children: two sons who were also his business partners, and four daughters. The firm continued in production until around 1985. Hoover’s prints included scenes, still life and landscapes of America and other locations. They were sold in America and overseas to countries including Canada, Germany, Mexico and England. The three-panelled screen in the Lighthouse Keeper’s Cottage was made by the Assistant Lighthouse Keeper, Thomas Hope during one of his two terms at the Lighthouse Keepers' Quarters. It is the only object in the collection known to be connected to Hope. The Lighthouse Keeper's Cottage is part of the Lady Bay Lighthouse Complex, which is listed on the Victorian Heritage Register for being of historical, scientific (technological) and architectural significance to the State of Victoria.Fire screen comprising three black wood framed panels hinged together. Each panel contains a glass-encased print depicting a rural landscape. Ornate stencil cut wood edging and quilt-inspired parquetry sits above each panel. The central panel is taller than those either side. Screen is lined in black-painted cardboard.Printed at the base of each of the three prints “COPYRIGHT 1896 BY J. HOOVER & SON, PHILAD’’A.”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, firescreen, thomas hope junior, ellen (nell) hope, nora hope, william hope, marion hope, alan hope, jos. hoover & sons of philadelphia, lighthouse keeper, assistant lighthouse keeper, carved screen, merri street, lighthouse keeper's cottage, lighthouse residence, lighthouse, wood carving, lighthouse complex, lady bay lighthouse, fire screen -

Victorian Interpretive Projects Inc.

Victorian Interpretive Projects Inc.Photograph - digital, LJ Gervasoni, Murtoa Stick Shed 00031, 13/08/2011

From the Victorian Heritage Register statement of significance H0791 The Marmalake/Murtoa Grain Store, originally the No.1 Murtoa Shed, is located within the Murtoa Grain Terminal, adjacent to the grain elevator tower and railway line. The shed is 280m long, 60m wide and 19m high at the ridge with a capacity of 3.4 million bushels. The hipped corrugated iron roof of the shed is supported on approximately 600 unmilled hardwood poles set in a concrete slab floor and braced with iron tie rods. These poles are the reason for use of the term "stick shed". With its vast gabled interior and the long rows of poles the space has been likened to the nave of a cathedral. An elevator at one end took wheat from railway trucks to ridge level where it was distributed by conveyor along the length of the shed, creating a huge single mound of grain. Braced internal timber bulkheads on either side took the lateral thrust of the wheat, and conveyors at ground level outside the bulkheads took wheat back to the elevator for transport elsewhere. Wheat had been handled in jute bags from the start of the Victorian wheat industry in the mid nineteenth century. Bulk storage had been developed in North America from the early 1900s. NSW began building substantial concrete silos from 1920-21. In Western Australia, farmers' co-operatives, who had to supply their own bulk storage from 1934-5, pioneered the use of low-cost horizontal sheds of timber and corrugated iron for bulk storage. Following its establishment in 1935 the Victorian Grain Elevators Board (GEB) planned a network of 160 concrete silos in country locations, connected by rail to the shipping terminal at Geelong. By the outbreak of the Second World War there was a worldwide glut of wheat, and Australia soon had a massive surplus which it was unable to export. Only 48 silos had been established under the Victorian Silo Scheme so far, and wartime material and labour restrictions prevented progress with this scheme. The storage deficit had become an emergency by 1941 as Britain obtained its imports from North America, rather than over the lengthy and difficult shipping route from Australia. In 1941 the GEB, under chairman and general manager Harold Glowrey, proposed large temporary versions of the horizontal bulk storage sheds already in use in Western Australia. The proposal was approved by the Victorian Wheat and Woolgrowers Association, who considered the use of shed storages as a longer term proposition. After initial resistance from the Australian Wheat Board, some of whose members represented wheat bagging interests, the Commonwealth and Victorian governments agreed to split the costs, and Murtoa was chosen as a suitable site for the first emergency storage. The main contractor, Green Bros, commenced work on the No.1 Murtoa Shed in September 1941, deliveries of bulk wheat began in January 1942, and the store was full by June of the same year. In the following years the Council for Scientific and Industrial Research (later CSIRO) conducted valuable research and experiment on the impacts and control of insect pests at the Murtoa No.1 shed. With these discoveries, and the development of more effective pesticides, use of the No.1 shed and the larger No.2 shed, erected in 1942/43, continued for many years. The No.2 shed was demolished in 1975. By the 1990s, pest resistance to pesticides and requirements for both pest free and insecticide free grain rendered open storage of this type unviable. The No. 1 store was also becoming increasingly expensive to maintain, and its use was phased out from 1989.Image of the Marmalake/Murtoa Grain Store which is of historical, architectural, scientific (technical) and social significance to the State of VictoriaDigital colour image of the interior of the Marmaduke . Murtoa grain storage facility better known as the Stick Shed. The shed was constructed in World War Two to store grain. The supporting columns are trees.marmalake, murtoa grain store, wheat store, stick shed, murtoa -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . J Moseley. maker and R Knight & J Heath also stamped stamped (Owners)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . Stamped HB on one end and 8 on otherflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Wood Moulding Plane J Moseley & Son maker also stamped (Previous Owners) HIT & E Dunstan, RA Dixon with an N inside a W flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century