Showing 10197 items

matching 1960-1964

-

National Wool Museum

National Wool MuseumArchive - The Australian Sheep Flock, c.1990s

Part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.One sided A4 sized leaflet showing different breeds of sheep used for the production of wool in Australia.front: THE AUSTRALIAN SHEEP FLOCKstuart ascough, international wool secretariat, victoria wool processors, port phillip mills pty ltd, topmaking, career, wool industry, mills, leaflet -

National Wool Museum

National Wool MuseumArchive - Wool Processing, c.1990s

Part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.One sided A4 sized leaflet showing images and text relating to the processing of wool from fibre into fabric.front: WOOL / PROCESSING / Two main systems are used to process wool from fibre into fabric.stuart ascough, international wool secretariat, victoria wool processors, port phillip mills pty ltd, topmaking, career, wool industry, mills, leaflet -

National Wool Museum

National Wool MuseumArchive - Wool in Australia, 1990s

Part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.Concertina A4 sized leaflet outlining the history of wool in Australia from 1788 to 1988 in four pages with colour graphics and black text.page 1: Wool in Australia / 1 7 8 8 - 1 8 3 8 / Within 50 years of settlement sheep had moved into / every colony, the annual wool clip was over two / million kg, and wool had become our main export page 2: Wool in Australia / 1 8 3 8 - 1 8 8 8 / The first 100 years saw Australia become the / world's leading producer of wool. Our economy's / strength depended on the wool clip. page 3: Wool in Australia / 1 8 8 8 - 1 9 3 8 / By the late 1930's, wool represented over 62% of / the total export value of primary products. Australia's / fine wool was in great demand worldwide. page 4: Wool in Australia / 1 9 3 8 - 1 9 8 8 / In the 50 years leading up to our Bicentenary, / many developments in the sheep and wool / industry have maintained Australia's place / as the leading producer of wool.stuart ascough, international wool secretariat, victoria wool processors, port phillip mills pty ltd, topmaking, career, wool industry, mills, leaflet -

National Wool Museum

National Wool MuseumArchive - About Wool, International Wool Secretariat, 1995

Part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.A series of ten A4 information leaflets with various titles on the theme of 'About Wool...'. Some leaflets are single sheets double sided, some are folded four sided leaflets. All have different colours and titles, including 'Australian Wool Industry Statistics', 'History of the Australian Wool Industry', 'Guide to Wool Textiles', 'Wool the Fibre', 'Trademarks of Wool', 'Wool and the Environment', 'The Australian Sheep Flock', 'Care of Wool', 'The Natural Properties of Wool' and 'The Processing of Raw Wool into Yarn'. Leaflets show illustrations, logos, images and text.8394.1: No.1 / AUSTRALIAN / WOOL INDUSTRY / STATISTICS 8394.2: No. 2 / HISTORY OF THE / AUSTRALIAN WOOL / INDUSTRY 8394.3: No. 3 / GUIDE TO WOOL TEXTILES 8394.4: No. 4 / WOOL THE FIBRE 8394.5: No. 5 / TRADEMARKS OF WOOL 8394.6: No. 6 / WOOL AND THE ENVIRONMENT 8394.7: No. 7 / THE / AUSTRALIAN SHEEP / FLOCK 8394.8: No. 8: / CARE OF WOOL 8394.9: No. 9 / THE NATURAL / PROPERTIES OF WOOL 8394.10: No. 10 / THE PROCESSING OF / RAW WOOL INTO YARNstuart ascough, international wool secretariat, victoria wool processors, port phillip mills pty ltd, topmaking, career, wool industry, mills, leaflet -

Federation University Art Collection

Federation University Art CollectionPainting - Portrait, Laurence Scott Pendlebury, 'The Artist's Wife' by Laurence Scott Pendlebury, 1978

Laurence SCOTT PENDLEBURY (1914 - 1986) Born Melbourne Laurence Scott Pendlebury studied at the National Gallery of Victoria School between 1932 and 1938 and then at Swinburne Technical College. He served during World War Two with the AIF between 1941 and 1945. Teaching at Swinburne Technical College between 1946 and 1963 Laurence Scott Pendlebury was head of the art school from 1963 until his retirement in 1974. He was president of the Victorian Artists’ Society from 1961 to 1963. Awards include: Dunlop Prize in 1950, 1951, 1953 and 1954; Gibson Prize, Victorian Artists’ Society in 1956; Wynne Prize in 1956, 1957, 1960 (shared with John Perceval) and 1968; Caltex Prize in 1957; Victorian Artists’ Society Artist of the Year (shared) in 1975. Portrait of Nornie Gude, the artist's wife, holding a violin. Nornie Gude was a student of the Ballarat Technical Art School, a division of the Ballarat School of Mines. Nornie Gude was the daughter of Walter Gude, a leding musician, and highly regarded teacher. She grew up in Ballarat and was educated at Loreto College. From 1931 to 1936 Nornie Gude attended the Ballarat Technical Art School, a division of the Ballarat School of Mines. She was accepted into the School at the age of 15 because she was so advanced in painting. Nornie Gude studied at Ballarat for five years before progressing to Melbourne’s National Gallery of Victoria School. As a violinist Nornie Gude played for more than a decade with the Zelman Orchestra. This work was a finalist in the 1978 Archibald Prize.artists, artwork, laurence scott pendlebury, pendlebury, nornie gude, gude, available, alumni -

Federation University Art Collection

Federation University Art CollectionCeramic, Gwyn Hanssen Pigott, Woodfired Bowl by Gwyn Hanssen Piggot, c1986, c1986

Gwyn HANSSEN PIGGOT (1935-2013) Born Ballarat Gwyn Hanssen Piggot completed a Bachelor of Fine Arts at Melbourne University in 1954. She spent three years apprenticed to Ivan McMeekin at Sturt Pottery, Mittagong, New South Wales. Between 1958 and 1965 Gwyn Hanssen-Pigott worked at various potteries in the United Kingdom, including Winchcombe Pottery in Gloucestershire, Leach Pottery at St Ives, and Wenford Bridge Pottery and Aldermaston Pottery in Berkshire. In 1960 she established her own studio in London. The essence of her work is purity, simplicity and form. She worked with porcelain for strength and for its translucent nature, and fired with wood to add a dine ash bloom to glazes. In 1992 Gwyn Hanssen Piggot was artist in residence at the Ballarat School of Mines.A small woodfired bowl by internationally renown ceramicist Gwyn Hanssen Piggot. gwyn hanssen-pigott, ceramics, gippsland campus, bowl, jan feder memorial ceramics collection, woodfire 86 -

Federation University Art Collection

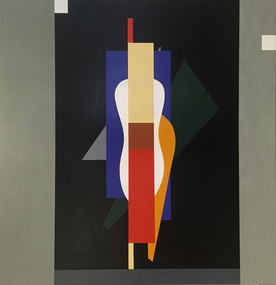

Federation University Art CollectionOil & acrylic on linen, 'Guitar 2003' by Robert Jacks, 2006

Robert JACKS (1943-2014) Jacks studied sculpture at Prahran Technical College from 1958–1960 and painting at RMIT in 1961–62. His first solo exhibition was held to great acclaim in 1966 and in 1968 his work was included in the landmark exhibition, The Field, at the National Gallery of Victoria. Beginning in 1968, Jacks spent ten years living and working in Canada and the United States. It was during this period that his unique visual language matured, incorporating influences from the major exponents of contemporary abstraction, minimalism and conceptual practice. In 2001 the Bendigo Art Gallery established the Robert Jacks Drawing Prize. In 2006, he was named an Officer of the Order of Australia (AO) This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.art, artwork, robert jacks, the field, abstraction, contemporary art -

City of Greater Bendigo - Civic Collection

City of Greater Bendigo - Civic CollectionPhotograph - Portrait, Vincent Kelly, Mrs J.A. Michelsen Mayoress 1935 -36, c. 1936

Prior to the election of female Councillors and Mayors from the 1960’s onwards the Mayoress role was one of the few ways women could be active in civic life. Mayoresses made important contributions to their local communities through their charity work and as ambassadors for their region on a state and at times, international level. They also undertook some Mayoral duties on occasions when the Mayor was unavailable. Annie Irene Michelsen (nee Tussup) born Huntly (1870-1955). Mayoress 1926/1927, 1935/1936, 1942/1943. Wife of Cr John Andrew Michelsen OBE. Pioneer in the field of social work and regarded as a woman of tremendous vitality and versatility. Known as an outstanding horse woman and breeder of standardbreds for harness racing. Member numerous sporting clubs and foundation president of the Bendigo Nurses Association. Framed, oval photographic studio portrait. Hand coloured detail. Mrs. Michelsen wore a gown of black crepe eros, cut to mould the figure and fall into a train at the back. A cascade eflect of gold lame from one shoulder to the hem in front gave graceful movement to the front of the gown, and wing draperies lined with gold lame were shirred to the shoulders of the square neckline. She wore a shoulder spray of golden orchids and carried a bouquet of old gold roses and golden leaves (1). The Argus (Melbourne, Vic. : 1848 - 1957) Wed 3 Jun 1936 annie tussup, mayoress michelsen, mayor michelsen, vincent kelly photographer, city of bendigo, city of greater bendigo portraits -

City of Greater Bendigo - Civic Collection

City of Greater Bendigo - Civic CollectionPhotograph - Portrait, Vincent Kelly, Mrs H.W. Snell Mayoress 1955 - 56, c 1956

Prior to the election of female Councillors and Mayors in the 1960’s, the Lady Mayoress role was one of the few ways women could be active in civic life. Mayoresses made important contributions to their local communities through their charity work and as ambassadors for their region on a state and at times, national level. Mayoresses were also required to undertake Mayoral duties on occasions when their husband was unavailable. Mayoress Snell was born in Durham UK. Mayoress Snell was the first Mayoress to wear the gold medallion which came with the office. It was presented on April 11th 1956 at the municipal centenary dinner at the Shamrock and was a gift from Sir George Lansell who followed in the tradition of his late father George Lansell in making a mayoral presentation in gold. (1) p 209 Jackman.Framed, oval photographic studio portrait. Hand coloured detail. Image is flat, glass is domed.cl; Mrs H. W. Snell / Mayoress 1955 - 56 1958 - 59 / 1959 - 60vincent kelly, studio photography, edith margaret snell, city of bendigo mayoress, city of greater bendigo portraits, lansell pendant -

Mont De Lancey

Mont De LanceyPeg Tool

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Peg Tool for shoe-making. Metal tool with leather handle, pointed one end and round disc on other end.bootmaking tools -

Mont De Lancey

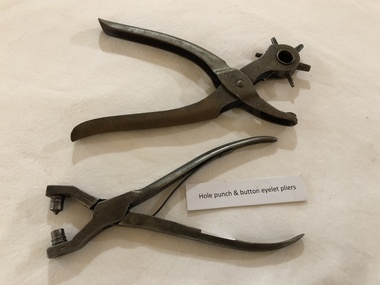

Mont De LanceyHole Punch and Button Eyelet Pliers

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.A metal hole punch, and metal button eyelet pliers, both used for shoe-making.AMG Darholeybootmaking tools -

Mont De Lancey

Mont De LanceyLegging

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade leather legging with 4 metal clips.boot covers, leggings -

Mont De Lancey

Mont De LanceyLasts

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.2 x wooden Lasts (Adult size) with metal screws. 1 x cast iron Last (Child size) with holes in base and a removable elevated top.Wooden: Size 6 (80) Cast Iron: Size 9 Dbootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Last on a four-footed base/stand. Last is removable from stand, and can be moved into different positions on top of the stand.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron double-ended Lap Last.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyBootmaker's Repair Stand

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden bookmaker's repair stand, opens slightly at one end. Two pieces of wood connected by two screws.bootmaking tools -

Mont De Lancey

Mont De LanceyHeel and Sole Cutters, Mobbs & Lewis

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron pieces - 1 Heel cutter and 1 Sole cutter.bootmaking tools -

Mont De Lancey

Mont De LanceyNail Bag, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Brown leather handmade nail bag, with strap.tool bags -

Mont De Lancey

Mont De LanceyHalf-Moon Knife

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron handmade knife with a wooden handle, attached by a nail.bootmaking tools, cutting tools -

Mont De Lancey

Mont De LanceyCircular Welt Cutter, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Welt Cutter with a wooden handle. -

Mont De Lancey

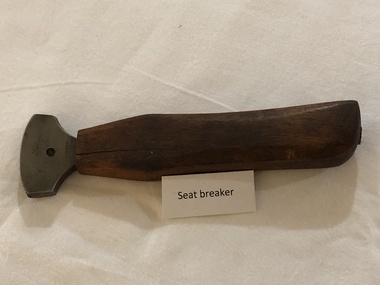

Mont De LanceySeat Breaker

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Seat Breaker with a wooden handle. -

Mont De Lancey

Mont De LanceyFudge Wheel

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Fudge Wheel with a wooden handle. -

Mont De Lancey

Mont De LanceyFoot Measure/Ruler

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden, folding, foot measure/ruler with brass clasps.bootmaking tools, measures, rulers -

Mont De Lancey

Mont De LanceyHammer and 2 Knives/Cutters

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron hammer with a wooden handle. Larger Cutter/knife, cast iron with a wooden handle. Smaller Cutter/knife, cast-iron with a wooden handleHammer: "London" Larger knife: "Pettys Sheffield".bootmaking tools, hammers, cutting tools -

Mont De Lancey

Mont De LanceyBootmaking Equipment

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Heel plate. Miscellaneous Sole plates. Hobnails and a tin of wooden sprigs.bootmaking tools, nails -

Mont De Lancey

Mont De LanceyHeel Shave and 2 Heels

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Heel Shave. 1 larger Leather heel piece. 1 smaller Leather heel piece.bootmaking tools, shaves -

Mont De Lancey

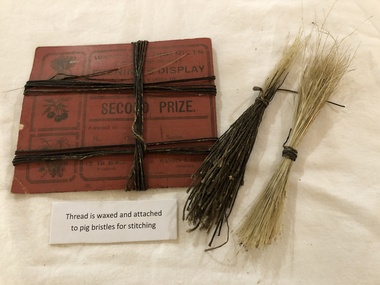

Mont De LanceyBootmaking Equipment, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade Waxed Thread attached to pig bristles, for boot stitching .bootmaking tools, thread waxers, threads -

Mont De Lancey

Mont De LanceyAwls and Awl Tips

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.5 x Cast iron Awls, all with wooden handles. 1 x container of spare Awl metal tips.bootmaking tools, awls, piercing tools -

Parks Victoria - Gabo Island Lightstation

Parks Victoria - Gabo Island LightstationFlags

Used to signal ships from lightstation. White flags are semaphore flags used for signalling alphabet letters. Salvaged from junk pile and mounted on wooden block. The identical, white hand held flags, which were used as a pair, are each stapled to a dowel. Information on both items indicates they were made by a well known flag, pennant and banner makers, Evan and Evans who were then located at 680 Elizabeth Street, Melbourne and are now in Spencer Street West Melbourne. Founded in 1877, the firm was a co designer of the Australian Flag in 1901. The flags are likely to date from c.1960 - 70 and are currently displayed in the former Keepers' quarters/ weather room mounted on a wooden block. Similar pairs of semaphore flags are held in Wilsons Promontory and Cape Nelson collections. The flags have second level contributory significance for their provenance to the lightstation and flag makers Evan & Evans. Thet have historic value for increasing our understanding of the semaphore signalling system formally used at the lightstation.Two identical white fabric flags stapled to a wooden dowel and secured to a wooden base on an angle.They have blue writing, on tags, on the flags.On tags on both flags, "EVAN & EVANS FLAGS P/L / FLAGMAKERS / 680 ELIZABETH ST / MELB. 3000 3475755" -

Melbourne Legacy

Melbourne LegacyJournal - Newsletter, Melbourne Legacy Widows' Newsletter, 1991 - 1992

Examples of Melbourne Legacy Club newsletters, covering the activities of Melbourne Legacy Widows' Club. Information includes a notice from the Chairman of the Widows' Committee, dates of meetings, possible day trips and theatre outings, and cruises. The ladies were welcome to attend monthly meetings, card afternoons, indoor bowls competitions, outings and tours, plus the annual fete and Christmas concert. The first edition of the newsletter was in 1960, previously there had been a quarterly magazine but the distribution was limited, they changed to a 4 page newsletter format to reach more of the widows. By 1990 it had grown to 12 pages, then 16 pages in May 1991 with the introduction of black and white photos, and then to 20 pages in November 1991. Various pages of interest have been added to show different news items. Other editions haven't been scanned.Brings to life the activities provided for the widows and the work of Melbourne Legacy in the early years.Black typed newsletter x 10 editions from 1991 to 1992, each edition 12, 16 or 20 pages. No 185, January 1991 No 186, March 1991 No 187, May 1991 (photos started appearing) No 188, July 1991 No 189, September 1991 No 190, November 1991 No 191, January 1991 No 192, March 1992 No 193, April 1992 No 194, July 1992newsletter, activities