Showing 791 items

matching coffee

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Chair, early 29th century

The Bentwood chair has been called ‘the world’s most popular chair’. The original Bentwood chair, was designed by German-Austrian cabinet maker and Master Joiner, Michael Thonet (b.1796 - d.1871) and introduced to the market in 1859. Thonet started his business in his home town of Boppard as an independent cabinet maker in 1819. In the 1830’s he began trying to make furniture from glued (laminated) and bent wooden slats. Over the next few years his attempts to patent this process failed in Germany, Great Britain, France, and Russia. He then began using lightweight, strong wood and bending it into elegant, comfortable furniture. The Bentwood technology took Thonet years to perfect. In simple terms, the wooden rods or lengths were wet by soaking or steaming, bent into shape and then held in place until they hardened into the moulded curved shape or pattern. The wood usually chosen for the bentwood chairs was maple or beech. Thonet had revolutionised an older process by industrialising the process. The dowels of wood were cut and prepared as components of furniture, treated by the ‘bentwood’ process, then ready immediately for assembling with very little extra workmanship needed. Thonet held 2 patents for this process, the second one ended on 10th July 1869 and was non-renewable. At the Trade Fair at Koblenz of 1841 Prince Klemens Wenzel von Mettemich was very impressed with Thonet’s furniture, especially the chairs. In 1842 Thonet sold his Boppard business and emigrated to Vienna, and began working, along with his sons, on the interior decoration of the Palais Leichtenstein, for the Carl Leistler establishment. In 1849 he began his own business again, the Gebruder Thonet to include his sons (translated “Brothers Thonet”). He produced the “No. 1” Bentwood chair. He received a bronze medal for his Vienna bentwood chairs at the World Fair in London in 1851, and a silver medal in Paris in 1855. In 1856 he opened a new factory in Koritchan (Moravia), where there were extensive woods of beech trees available for his enterprise. In the next years, five more Eastern European production sites were established in Bystritz (1862), Nagy-Ugrócz (1866), Wsetin (1867), Hallenkau(1867) and Nowo-Radomsk(1880). Thonet’s 1859 No. 14 “chair of chairs” (or “Konsumstuhl Nr. 14” – coffee shop chair no. 14) was the most famous of all of Thonet’s Bentwood chairs. In 1867 he received a gold medal at the Paris World Fair. This new style of furniture making became very popular. Up until 1830 50 million of these chairs had been produced. By the 1870’s Thonet owned offices in almost 20 countries, with sales locations across Europe, in Chicago and New York. In 1889 he set Thonet set up a head office in Frankenberg, Hesse. Bentwood models designed in the mid to late 19th century featured hand-caned or laminated wood seats and were usually stamped with the country of origin. The Bentwood elements were the backrest, seat rim and legs. Typically the seat was covered with ‘bucket’ leather. After the Patent ran out in 1869, companies such as Jacob & Josef Kohn began the production of bentwood furniture.The popularity of the Bentwood chair that was introduced by Michael Thonet in the 1850s is due to its versatility and timeless quality. Its style, whether varnished or painted, suits any room in the house. The lightweight chairs are also popular for café and restaurant seating, as well as for public gatherings. They can be easily moved around and grouped in a variety of ways to suit any occasion.Chair, bentwood, pair of two. Backrest has full length inverted U inside frame. Support rail and wire reinforcing between legs. 3692.01 seat has floral pattern pressed into wood 3692.02 seat is plain (replacement seat). Made by Harnison & Co.3692.01 chair's marks; Label ""HARNISON & CO./ NEUSOL / BUDAPEST" and "WIENER NOBEL" and "(symbol) N inside circle, under Crown" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, domestic furniture, dining furniture, bentwood chair, harnison & co., neusol, budapest, wiener nobel -

Eltham District Historical Society Inc

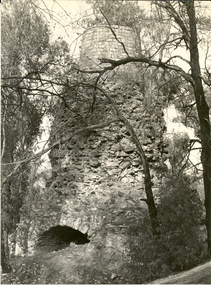

Eltham District Historical Society IncPhotograph, Slab hut, Warrandyte, Warrandyte Mystery Tour, 29 May 1994, 29/05/1994

[article by Bettina Woodburn in EDHS Newsletter No. 97, July 1994:] THE WARRANDYTE MYSTERY TOUR MAY 29TH 1994 - Members of the Eltham Historical Society met at the Old Post Office, now converted into the Warrandyte Historical Museum, for a picnic lunch on the sunny back verandah overlooking the shimmering Yarra River. Interesting photographs and artefacts filled various rooms outlining the history of this area, and told tales of Aboriginal and more recent neighbours of the Eltham Shire. The weather was calm, cloudy mostly with only occasional sunny patches, but it wasn't cold, although the autumnal leaf colours had changed to wintry brown. "All Aboard" and we set off in the Warrandyte Community Bus (with the School Bus sign displayed at the rear) to learn about local places of "Pride and Joy” from Bruce our guide and Tom the driver. Almost directly opposite we entered Whipstick Gully to explore the first of the district's hidden treasures - the Victory, one of the largest of the six or so major mines, past the old quarry now used for abseiling practice. By torchlight we entered the rocky hillside and saw the seams of quartz the miners had followed in their search for gold. Stamping batteries, and there was one in this gully, converted discarded rock into 'road metal'. Warrandyte is proud to be the first declared Goldfield in 1851, and one of the longest surviving, into the 1920s. A pleasant drive across the Bridge and along Bradley's Lane to Norman's Reserve brought us to see another Tunnel at Pound Bend through which the Yarra was diverted to allow about three miles of river-bed to be used for prospecting for alluvial gold. Still on this side of the river we visited the Old Slab Hut in Castles Road. This remnant of miners' housing is preserved because it had been incorporated into a weatherboard house, and saved from the bulldozers - a last minute reprieve, for preservation, by the National Trust. Devastating bush fires have destroyed other old cottages built of wattle and daub, with bark roofs and stone fire-places. The Cairn commemorating the disclosure of Gold Discovery at Warrandyte on June 30th 1851 beside Anderson's Creek Road was our next point of historical interest. We drove on to South Warrandyte and circled back to above the ford on Anderson's Creek to the entrance of the 4th Hill Mine. Again we crept along with our torches, careful of the low roof-rock, and side shafts. At a junction in a large cavity we were able to stand, look up a long air-vent which some 'cavers' climb down, and marvel at, and experience an aspect of a miner's life. Outside we heard the same bird songs, the trills and bell-pealing, saw the same straggly eucalypts, and a silver leafed wattle in flower, native grasses and ferns, and the neat present day houses, often of Warrandyte stone, perhaps veneered only. The day ended pleasantly, seeing more of the Yarra from Everard Drive, and the water rushing out of the Tunnel at Pound Bend, before returning to afternoon tea or coffee at the Museum. A great day for all concerned - many thanks to the Organisers.Colour photographslab hut, warrandyte, "warrandyte miner's cottage" -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pound Bend tunnel, Warrandyte, Warrandyte Mystery Tour, 29 May 1994, 29/05/1994

[article by Bettina Woodburn in EDHS Newsletter No. 97, July 1994:] THE WARRANDYTE MYSTERY TOUR MAY 29TH 1994 - Members of the Eltham Historical Society met at the Old Post Office, now converted into the Warrandyte Historical Museum, for a picnic lunch on the sunny back verandah overlooking the shimmering Yarra River. Interesting photographs and artefacts filled various rooms outlining the history of this area, and told tales of Aboriginal and more recent neighbours of the Eltham Shire. The weather was calm, cloudy mostly with only occasional sunny patches, but it wasn't cold, although the autumnal leaf colours had changed to wintry brown. "All Aboard" and we set off in the Warrandyte Community Bus (with the School Bus sign displayed at the rear) to learn about local places of "Pride and Joy” from Bruce our guide and Tom the driver. Almost directly opposite we entered Whipstick Gully to explore the first of the district's hidden treasures - the Victory, one of the largest of the six or so major mines, past the old quarry now used for abseiling practice. By torchlight we entered the rocky hillside and saw the seams of quartz the miners had followed in their search for gold. Stamping batteries, and there was one in this gully, converted discarded rock into 'road metal'. Warrandyte is proud to be the first declared Goldfield in 1851, and one of the longest surviving, into the 1920s. A pleasant drive across the Bridge and along Bradley's Lane to Norman's Reserve brought us to see another Tunnel at Pound Bend through which the Yarra was diverted to allow about three miles of river-bed to be used for prospecting for alluvial gold. Still on this side of the river we visited the Old Slab Hut in Castles Road. This remnant of miners' housing is preserved because it had been incorporated into a weatherboard house, and saved from the bulldozers - a last minute reprieve, for preservation, by the National Trust. Devastating bush fires have destroyed other old cottages built of wattle and daub, with bark roofs and stone fire-places. The Cairn commemorating the disclosure of Gold Discovery at Warrandyte on June 30th 1851 beside Anderson's Creek Road was our next point of historical interest. We drove on to South Warrandyte and circled back to above the ford on Anderson's Creek to the entrance of the 4th Hill Mine. Again we crept along with our torches, careful of the low roof-rock, and side shafts. At a junction in a large cavity we were able to stand, look up a long air-vent which some 'cavers' climb down, and marvel at, and experience an aspect of a miner's life. Outside we heard the same bird songs, the trills and bell-pealing, saw the same straggly eucalypts, and a silver leafed wattle in flower, native grasses and ferns, and the neat present day houses, often of Warrandyte stone, perhaps veneered only. The day ended pleasantly, seeing more of the Yarra from Everard Drive, and the water rushing out of the Tunnel at Pound Bend, before returning to afternoon tea or coffee at the Museum. A great day for all concerned - many thanks to the Organisers.Two colour photographswarrandyte, activities, pound bend -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlaque - Nameplate, James & Alexander Brown, 1849 – 1931

This is one of two cast brass nameplates of James & Alexander Brown in our collection. The Newcastle, NSW, firm was renowned for its coal mining and exporting business established in colonial Australia in 1843. The firm had an office in Melbourne and sold coal for commercial use and from the Wharf for the domestic market. The coal was then distributed along the southwest coast of Victoria in steamships or steam packets and into the regional areas of Victoria by cart and wagon. In 1890 there was a strike of coal workers but the Geelong Advertiser, September 1, 1890, announced that “a firm of coal merchants only recently received some large cargoes from Newcastle”. This supply of coal could have originated at the colliery of James & Alexander Brown. About James & Alexander Brown: - James (1816-1894), John (1823-1846) and Alexander Brown (1827-1877) migrated with their parents from Scotland to Sydney, Australia, in 1842. The next year James leased land and was assisted by his brothers Alexander and John in mining coal in the area near Maitland. The market was very competitive, with the government controlling prices. James was instrumental in a legal battle that resulted in the introduction of open competition for coal mining. James and Alexander had become business partners by 1852 and moved south of Newcastle where they established and worked a profitable mining enterprise. Their assets by 1857 included a ships’ chandlery, a fleet of steamships and an overseas trading business. They were the first firm to import rum, sugar and coffee into Newcastle. By 1892 they were exporting coal to New Zealand, China, North America, and various colonial ports. They had elaborate workshops to service their own steam engines and steamships. They were the first to use a steam collier vessel in Australian waters and they set up the second tug boat in Newcastle, the beginning of being owners of many more tug boats and performing a towing business. By 1868 James & Alexander Brown was the largest coal producer in the colony. James focused on managing the colliery and Alexander on overseas trade. It was estimated that the firm had produced over eight per cent of coal in New South Wales by 1914. James & Alexander Brown advertised in the Melbourne Herald in the early 1900s and kept an office at Queen Street, Melbourne as well as at the Wharf, stating their telephone numbers for both places. The coal was available for ‘Immediate Delivery’ for household and industrial purposes. The advertising claimed that their Pelaw Main coal was the famous household coal that met the highest test in Australia and burned bright and clean. Domestic customers could purchase the coal at the wharf or pay for delivery. Commercial customers could load their purchases into their steamships or wagons for further distribution into regional Victoria. After James’s death in 1894 his son John managed the firm, which was also known as J & A Brown. John passed away in 1930 and his sons took over. In 1931 the firm amalgamated with Abermain Seaham and the new name was J & A Brown & Abermain Seaham Collieries Ltd. commonly abbreviated to JABAS, which merged with Caledonian Collieries Ltd in 1960 and Coal & Allied Industries Ltd. was formed. The pair of nameplates is significant for its connection with the firm James & Alexander Brown. The firm was established in 1845 and became one of the largest collieries in colonial Australia. It was involved in trading within Australia and overseas. James was involved in the introduction of open competition for coal mining prices. They were the first to use a steam colliery in Australian waters and the first to import goods such as rum, sugar and coffee into New South Wales. The firm had a Melbourne office in the early 1900s, selling and distributing coal throughout Victoria, which likely included the Port of Warrnambool, which opened in 1890. The nameplates are likely to have originated from the Melbourne location.Brass Entrance Name Plate, one of a pair. Eight holes are formed through the plate; one in each corner, and four more holes are within the inscription area. The cast plate has three rows of text with the company’s name and type of business. The plate was owned by James & Alex. Brown. "JAMES & ALEXR. BROWN / COLLIERY PROPRIETORS / & STEAMSHIP OWNERS"flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, nameplate, james & alexander brown, j & a brown, james & alexr brown, colliery proprietors, steamship owners, ship chandlers, coal mine, coal export, australian import, australian export, newcastle, colliers, coastal trade, steamships -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlaque - Nameplate, James & Alexander Brown, 1849 – 1931

This is one of two cast brass nameplates of James & Alexander Brown in our collection. The Newcastle, NSW, firm was renowned for its coal mining and exporting business established in colonial Australia in 1843. The firm had an office in Melbourne and sold coal for commercial use and from the Wharf for the domestic market. The coal was then distributed along the southwest coast of Victoria in steamships or steam packets and into the regional areas of Victoria by cart and wagon. In 1890 there was a strike of coal workers but the Geelong Advertiser, September 1, 1890, announced that “a firm of coal merchants only recently received some large cargoes from Newcastle”. This supply of coal could have originated at the colliery of James & Alexander Brown. About James & Alexander Brown: - James (1816-1894), John (1823-1846) and Alexander Brown (1827-1877) migrated with their parents from Scotland to Sydney, Australia, in 1842. The next year James leased land and was assisted by his brothers Alexander and John in mining coal in the area near Maitland. The market was very competitive, with the government controlling prices. James was instrumental in a legal battle that resulted in the introduction of open competition for coal mining. James and Alexander had become business partners by 1852 and moved south of Newcastle where they established and worked a profitable mining enterprise. Their assets by 1857 included a ships’ chandlery, a fleet of steamships and an overseas trading business. They were the first firm to import rum, sugar and coffee into Newcastle. By 1892 they were exporting coal to New Zealand, China, North America, and various colonial ports. They had elaborate workshops to service their own steam engines and steamships. They were the first to use a steam collier vessel in Australian waters and they set up the second tug boat in Newcastle, the beginning of being owners of many more tug boats and performing a towing business. By 1868 James & Alexander Brown was the largest coal producer in the colony. James focused on managing the colliery and Alexander on overseas trade. It was estimated that the firm had produced over eight per cent of coal in New South Wales by 1914. James & Alexander Brown advertised in the Melbourne Herald in the early 1900s and kept an office at Queen Street, Melbourne as well as at the Wharf, stating their telephone numbers for both places. The coal was available for ‘Immediate Delivery’ for household and industrial purposes. The advertising claimed that their Pelaw Main coal was the famous household coal that met the highest test in Australia and burned bright and clean. Domestic customers could purchase the coal at the wharf or pay for delivery. Commercial customers could load their purchases into their steamships or wagons for further distribution into regional Victoria. After James’s death in 1894 his son John managed the firm, which was also known as J & A Brown. John passed away in 1930 and his sons took over. In 1931 the firm amalgamated with Abermain Seaham and the new name was J & A Brown & Abermain Seaham Collieries Ltd. commonly abbreviated to JABAS, which merged with Caledonian Collieries Ltd in 1960 and Coal & Allied Industries Ltd. was formed. The pair of nameplates is significant for its connection with the firm James & Alexander Brown. The firm was established in 1845 and became one of the largest collieries in colonial Australia. It was involved in trading within Australia and overseas. James was involved in the introduction of open competition for coal mining prices. They were the first to use a steam colliery in Australian waters and the first to import goods such as rum, sugar and coffee into New South Wales. The firm had a Melbourne office in the early 1900s, selling and distributing coal throughout Victoria, which likely included the Port of Warrnambool, which opened in 1890. The nameplates are likely to have originated from the Melbourne location.Brass Entrance Name Plate, one of a pair. Eight holes are formed through the plate; one in each corner, and four more holes are within the inscription area. The cast plate has three rows of text with the company’s name and type of business. The plate was owned by James & Alex. Brown. "JAMES & ALEXR. BROWN / COLLIERY PROPRIETORS / & STEAMSHIP OWNERS"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, nameplate, james & alexander brown, j & a brown, james & alexr brown, colliery proprietors, steamship owners, ship chandlers, coal mine, coal export, australian import, australian export, newcastle, colliers, coastal trade, steamships -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph Album, Photographs of Ballarat Buildings, 1967, 1967

When these photos were taken Geoffrey Biddington was highly involved with the Ballarat Branch of the National Trust. At one time Her Majesty's Theatre was known as the Memorial Theatre. Lenaghan of Tourello "Master Dan Lenaghan, eldest son of Mr. and Mrs. R. Lenaghan, of Tourello, has been successful in obtaining a Government scholarship, tenable for four years at St. Patrick's College, Ballarat.(Melbourne Advocate, 02 March 1939) Two Black folders of Ballarat photographs as follows: .1) Interior of Ballarat Railway Station .2) Interior of Ballarat Railway Station .3) Craig's Hotel .4) Craig's Hotel .5) Craig's Hotel .6) Craig's Hotel .7) Ballarat Fine Art Gallery later Art Gallery of Ballarat .8) Cuthberts, corner Lydiard and Mair Streets .9) Golden City Hotel (GCs) .10) Golden City Hotel (GCs) .11) Reid's Coffee Palace .12) Alexandria Tea Rooms, neighbouring Old Colonists' Club, Ballarat, Lydiard Street North .13) ? .14 Caste iron drink fountain, corner of Strurt and Drummond Streets, October 1967 .15) Lal Lal Blast Furnace .16) Ballarat Botanical Garden Gates .17) Ballaarat Old Cemetery Gates .18) Novar gate .19) Ballaarat Old Cemetery Gates .20) ? .21) Webster Street .22) Doveton Street South .23) ? .24) ? .25) .26) .27) Iron hitching Rail .28) Iron hitching Rail .30) Postal Box, Corner or Armstrong Street South and Eyre Street, October 1967 .31) Iron Drinking Fountain in the Ballarat Botanical Gardens .32) Iron Drinking Fountain in the Ballarat Botanical Gardens .33) Killarney, Warrenheip .34) Killarney, Warrenheip .35) Killarney, Warrenheip .36) Killarney, Warrenheip .37) Bailey's Mansion, Drummond Street .38) Bailey's Mansion, Drummond Street .39) Beaufort House .40) Beaufort House .41) ? .42) ? .43) ? .44) ? .45) ? .46) ? .47) ? .48) Lenaghan's Tourello, February 1968 .49) Lenaghan's Tourello, February 1968 .50) ? .51) ? .52) ? .53) ? .54) ? .55) ? .56) ? .57) ? .58) ? .59) ? .70) Her Majesty's Theatre, Lydiard Street .71) Her Majesty's Theatre, Lydiard Street .72) Dana Street Primary School, September 1967 .73) Ballarat School of Mines Administration Building, September 1967 .74) Eureka Street Primary School ? .75) Selkirk Brick Chimney? .76) Grigsby's Foundry, Mair Street, September 1967 .77) Pratt's Warehouse, Camp Street .78) Premises of R. And R.A. Williams, Mair Street, September 1967 .79) City Oval Grandstand, with fire training tower in the background, .80) City Oval Grandstand .81) City Oval Grandstand .82) Smythesdale Post Office, October 1967 .83) Court House Hotel. Smythesdale, October 1967 .84) Smythesdale, October 1967ballarat, buildings, bluestone, iron, architecture, biddington, geoff biddington, railway, old colonists, lal lal blast furnace, beaufort house, her majesty's theatre, craig's hotel, botanical gardens, bailey, cuthbert, lenaghan, tourello, smythesdale post office, court house hotel, smythesdale, smythesdale, alexandria tea rooms, cast iron, eureka street primary school, dana street primary school, ballarat school of mines administration building, grigsby brass founder, foundry, pratt's warehouse, selkirk bricks, grandstand, court house hotel -

Federation University Historical Collection

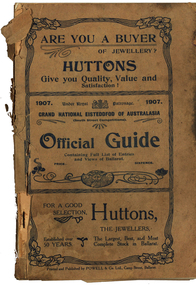

Federation University Historical CollectionBook - Programme, South Street Eisteddfod Official Guide, 1907, 1907

South Street competitions have been held in Ballarat since 1991.Official guide to the 1907 South Street competitions. Images include: Prince of Wales, Lord Northcote, W.D. Thomas, South Street Competition Executive Committee (W.H. Pearson, W.H. Chandler, A. Prichard, W.H. Richards, W.D. Hill, Col. Williams, W.D. Thomas, F. Besemeres, F.J. Martell, J.T. Morris. F.J. Williams, R. Maddern, R.J. Gribble), Sir John Madden, Lord Tennyson, W.D. Hill, Frederick Bevan, Ballarat (Sturt Street), Lake Wendouree (Yachts), J.W. Beswick, Lawrence Campbell, City of Ballarat Mayor and Councillor (Mayor Brawn, E. Williams, E. Morey. Cr Brokenshire, J. Whykes, J.M. Barker, G. Crocker, W.D. Hill, R. Pearse, T. Hollway), Ballarat East Mayor and Councillors (J. Gent, Cr Glendenning, J.N. Dunn, I. Pearce, C. Bunting, A. Levy, J. Ritchie, J. McNeil, A. McKenzie, Cr Penhalluriak), Sturt Street Looking West, Old Curiosity House, Entrance to the Ballarat Fine Art Gallery, Interior of the Ballarat Fine Art Gallery, Ballarat East Town Hall and Gardens, Lake Wendouree Ferry, W.E. Swenson, S.B. Swenson, J.G.M. Swenson, Rev. T. Flynn, Edwards' Pyrites, Lestor's Hotel, Sunshine Sheild, W to W Shield, Frank Herman, W.F. Coultman, Marks' Trophy, Lighthouse Port Fairy, R. Correll Music Seller, James Smith, Isaac Pitman, Arthur Brumfield, Hugh Leschen, John Robson, St Augustine's Band Geelong, Moorabool Falls, Kirks Dam, Ballarat Choral Society, Alfred Deakin, James Long, Hugh McKay Advertisements include: Huttons the Jewellers, Sam Jamieson, Sun Foundry, City Saw Mills, Blomeley Bros Iron and Brass Founders, G. Bongiorno- Railway Fruit Palace, Henry Brind & Co., Andrew Cant, Harrison's Foundry, Umbrella and Sunshade Emporium, Ballarat City Baths, Ballarat Coffee Palace, Irwin's Provincial Hotel, Victa Studio; D. Lem Chinese Medical Practitioner, Bosisto's Eucalyptus Oil, Ronaldson Bros & Tippett, Unicorn HOtel, Mrs F. Allen Caterer, Coles & Pullum, J.C. Dillon & Co., Surrey Tannery, Coulthard's Ballarat Business College, George Farmer, MrBride's Boots, L.J. Austin, Dyason's, Ballarat Brewing Company, Phoenix Brewery, Royal Standard Brewery, Edwards' Pyrites, Lestor's Hotel, Robson's College of Music, James A. Gear, Williams Shoemen, Tekardo Brothers, Powell & Co.south street competitions, eisteddfod, chinese herbalist, south street, r.b. lemmon, g. bongiorno, w.d. thomas, john madden, lord tennyson, w.d. hill, frederick bevan, j.w. beswick, lawrence campbell, boer war memorial, queen victoria statue, curiosity shop, m.b. john foundry, ballarat east town hall and gardens, sunshine shield, hugh victor mckay, w to w shield, w.j. coltman, frank herman, j. hutton-jones, t. downer, j. marks, hutton and co trophy, marks trophy, hugh leschen, john robson, st augustine's band, geelong, downer trophy, trekardo brothers, moorabool falls, kirks dam, ballarat choral society, alfred deakin, challenge cup, james long, grand national eisteddfod of australasia, ballarat east gardens, ballarat east town hall -

Ballarat Tramway Museum

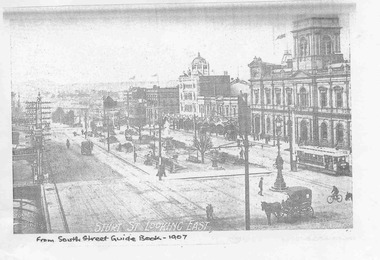

Ballarat Tramway MuseumDocument - Photocopies, Royal South Street Society, Royal South Street Society Guide, 2008

Has a strong association with the work of the Royal South Street Society, who published a handbook/guide or manual for their competitions. Used a photograph published at about the same time.Set of 15 photocopies of pages from the Royal South Street Society Guide showing trams in Sturt St Ballarat. .1 - Sturt St Looking East - with an ESCo tram outside the town hall and other horse drawn vehicles - 1907 .2 - Sturt St Looking West - same image as in Reg item 2688 - 1907 .3 - Sturt St Looking East - with many vehicles and people - 1910 and the "Chef" kitch range stove advertisement sold by Middleton and Morris of Sturt St. .4 - Sturt and Lydiard St, with a tram turning from Sturt into Lydiard St, 1910 with the post office in the background - 1910 and an advertisement for Woderine medicine sold by Jas. A. Gear, herbalist. .5 - Sturt St looking West - tram turning from Sturt into Lydiard St, taken from near post office corner - 1911 and a advertisement for Williams the Shoeman. .6 - Sturt St. West - with an ESC0o tram outbound - the only vehicle - 1913. .7 - same photo as .3, with a Monster Military Carnival Advertisement for Nov. 8th - 1913 .8 - Sturt and Lydiard St from next to post office, looking west with two trams, one horse trailer and many people - a busy scene - 1914 .9 - Sebastopol tram No. 21 at Grenville St - 1928 - with the Ballarat Gas Company Show rooms in the background, the Sturt St shelter. The tram has a Suttons Organs roof advertisement. .10 - View of Sturt Street, showing City Hall Buildings, with an ESCo Sebastopol type tramcar crossing the street, taken from the post office stops. - 1928 - Advertisements for G. Ludbrook Furnishing Undertaker (Motor Service and Horse drawn vehicles) and R. Young Grocer. .11 - Sturt St looking West, looking west, with a Sebastopol type tram at Grenville St and the big shelter removed. Has many buildings and many people in the background - 1928. .12 - same photo as for .10 and Clarendon Presbyterian Ladies Collection, Ballarat photograph - 1929. .13 - Advertisement for Ballarat Tramways - cars for Coliseum, fare box, route numbers and route colour scheme - 1929. .14 - as for above, no date, but opposite is the is an item for the Mouth Organ Band Contest, "A" Grade - c1933, notes the Coburg Tramway Athletic Club Harmonica Band and the Malvern Tramways Harmonica band amongst the contestants. .15 - same as .9, with a advertisement for the Melbourne Coffee Palace - Bourke St. Photocopies made by Neville Hasket for the BTM 10/2008. See also Reg item 675 for alternative source details.Handwritten note on photocopiestrams, tramways, ballarat, sturt st., royal south street society, lydiard st, town hall, post office, esco -

Eltham District Historical Society Inc

Eltham District Historical Society IncFilm - Video (VHS), Nillumbik Shire Council, The Nillumbik Story, 1996

PART 1 – NILLUMBIK (00:00-07:17) Opening features various scenes around Nillumbik Shire. For 40,000 years Nillumbik was the home of the Wurundjeri people. Robert Hoddle gave the district its name. Jock Ryan, then president of Nillumbik Historical Society discusses the names Nillumbik and Diamond Creek. In the late 1830s white occupation began with gold found in Warrandyte in 1851 and 12 years later at Diamond Creek -the Diamond Reef which led to the Caledonian gold rush. Jock Ryan discusses the Diamond Creek mine, which was thriving until it burnt out in 1915. Large numbers of workmen moved into area in late 1870s to construct the Maroondah Aqueduct. With growing population of Melbourne, the nearby Yan Yean system had severely disrupted the flow of the Plenty River, forcing the closure of three flour mills there. The aqueduct came to the rescue carrying water 66km from Healesville to Preston. When the Diamond Creek gold mine burnt down the local economy suffered but fruit growing industry had already been established and Diamond Creek became a thriving fruit growing centre. Interview with Jack Powell, a long-time fruiterer at St Andrews market, his family had lived in the area for a hundred years, 3 to 4 generations, “a lot of hard work”. By the time the railway arrived fruit growing was no longer competitive. The railway brought the city closer and day trippers. The Green Wedge separates the shire from the more densely developed neighbours such as Whittlesea, Doncaster, Templestowe, Bulleen and Greensborough. Population at the time (1996) was 19,000 but links to the past remain strong. Mudbrick houses along the Heritage Trail The saving of Shillinglaw Cottage from demolition in 1963 and relocation brick by brick. PART 2 – ENVIRONMENT (07:18-14:44) Peter Brock (with Bev Brock in background) at St Andrews market discusses his childhood growing up in the district and the environment and the values it instilled upon him and his own family. The Brocks have been in the district since the 1860s. Nillumbik Shire responsible for managing three catchment areas; Diamond Creek, Arthurs Creek and Watsons Creek. Follows the course of the Diamond Creek commencing in Kinglake through the district to its confluence with the Yarra River at Eltham at Eltham Lower Park. Highlights Eltham Lower Park community revegetation program and the newly constructed (1996) viewing platform built of new and recycled timbers at the confluence of the Diamond Creek and Yarra River. Also featured are outdoor recreation on the river and at Eltham Lower Park including the Diamond Valley miniature railway. Sugarloaf reservoir and recreational activities and fishing. Aerial view of Memorial Park and Shire of Eltham War Memorial tower at Garden Hill, Kangaroo Ground. Significant tourism opportunities for the shire with 3 million potential day-trippers in metropolitan Melbourne. Council and community working together to find a way to promote the shires natural and artistic assets. At Arthurs Creek, the Brock family and neighbours working together to take care of their waterway. Peter Brock’s uncle, Sandy Brock talks about environmental management and the Arthurs Creek Landcare group and actions to eradicate blackberry problem. Having previously planted Cypress rows they are replacing them with indigenous species to improve the water supply, keeping cattle out of the creek bed to improve the quality downstream flowing into the Yarra. Eltham East Primary School Band playing “All things bright and beautiful” merges into scenes of the bushland sanctuary set aside by the school in 1980 with unidentified teacher discusses the sanctuary and their education program and school children’s comments. Plight of a family of Wedgetail eagles nesting in the path of a developer’s bulldozer at North Warrandyte and actions to save their nesting areas. PART 3 – ARTS (14:45-22:00) Arts and Jazz festival at Montsalvat featuring interviews with Sigmund Jorgensen discussing Montsalvat and its principles. Also Matcham Skipper. Clifton Pugh’s funeral at Montsalvat and his legacy at Dunmoochin near Cottlesbridge with artists in residence, at the time, Chicago artist Charles Reddington who discusses the benefits of the experience. An unidentified female artist also talks about the program and why people are drawn to the area. Unidentified man on street talking about the amount of talent in the area, artists, poets, musicians, authors. Artist Ming Mackay (1918-2009) interviewed talking about the people she mixes with on “the Hill”. Works of local artists are displayed Eltham Library Community Gallery and Wiregrass gallery with a new coffee shop at the Wiregrass making it an even more popular destination. Music at St Andrews Hotel (may be a little bit country) and the Saturday market where likely to hear anything. Sellers and patrons at the market asked about what attracts them to the market and where they came from. Scenes of poets/authors giving readings. CREDITS Music by John Greenfield from the CD Sweet Rain “The Snow Tree”, Uncle Music UNC 2001 Cameras - David Mirabella and Peter Farragher Editor – Olwyn Jones Written and Produced by Jason Cameron A Jason Cameron Proction for Nillumbik ShireProvides a record of the relatively newly created Shire of Nillumbik at the time and the features and attactions of the shire in its people arts, culture and environmentVHS Cassette (two copies) Converted to MP4 file format 0:22:00, 1.60GBvideo recording, arthurs creek, arthurs creek landcare group, artists, artists in residence, arts, arts festival, authors, blackberry, brock family, bulldozer, bulleen, bushland sanctuary, caledonian gold rush, charles reddington, clifton pugh, cottlesbridge, cypress rows, developer, diamond creek, diamond creek mine, diamond reef, diamond valley miniature railway, doncaster, dunmoochin, education program, eeps, eltham, eltham east primary school, eltham east primary school band, eltham library community gallery, eltham lower park, environment, fishing, flour mill, fruit growing, fruiterer, garden hill, gold mining, green wedge, greensborough, heritage trail, hurstbridge railway line, jazz festival, jock ryan, kangaroo ground, kangaroo ground tower, kinglake, maroondah aqueduct, matcham skipper, memorial park, ming mackay (1918-2009), montsalvat, mudbrick houses, music, musicians, nesting area, nillumbik historical society, nillumbik shire, north warrandyte, old timer, orchards, peter brock, plenty river, poets, population, recreation, recreational activities, revegetation, robert hoddle, sandy brock, shillinglaw cottage, shire of eltham war memorial, sigmund jorgensen, st andrews hotel, st andrews market, sugarloaf reservoir, templestowe, the hill, tourism, viewing platform, warrandyte, water catchment area, watsons creek, wedgetail eagle, whittlesea, wiregrass gallery, wurundjeri, yarra river, jack powell -

Ballarat Clarendon College

Ballarat Clarendon CollegeBook, The watches of the trails

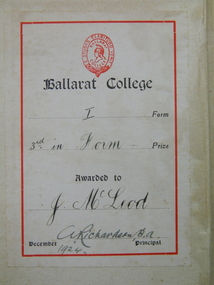

John Anning MacLeod John was born in Ballarat as the second generation of Ballarat MacLeod’s, with his grandfather arriving in Geelong on the Hornet in 1857 as an 11 year old child with his 60 year old father John and mother Mary aged 37 years and 5 brothers and one sister. He grew up on the corner of Drummond Street and Mair Streets, opposite what became St John of God hospital, at his parents house of Dunvegan. John entered Ballarat College as a junior student in 1923. He received 3rd in Form prizes in both 1924 and 1925. His sister Margaret, attended Clarendon Ladies College. The household employed a chauffeur, a cook, a gardener and a ladies maid to care for them. In the 1930’s his father lost his fortune in the collapse of the jute future’s market so the staff were dismissed and he left Ballarat to go to Geelong College as a boarder. He was an officer in the Geelong College cadet corps and joined the Army as a private and rose to the permanent rank of Major after meritorious performance in the intelligence area of operations. He served in North Africa, in Palestine, Egypt, Moratai, the Philippines, Java and New Guinea. He was awarded his Military MBE by King George VI for exceptional devotion to duty and for brilliant coordination work amongst the allied intelligence team. During the war he met Mary Monica Carrol Bateman, a lietenant in the 2/4th Army General Hospital at a dinner party in Brisbane. The couple had four children, Hamish John Torquil born in 1945, Rory Hugh Alexander born in 1947 and twins Ian Donald and Katriona Margaret born in 1948. After the Second World War he worked for Lumley’s Insurance Brokers in London for a couple of years to follow up his accountancy training and then returned to Ballarat due to his father’s failing health and took over the management of John MacLeod and Co, Wholesale grocers and Merchants in Lydiard Street, Ballarat. The business had been started by his great grandfather and they produced the famous Sirdar brand of products and a special tea blend called Afternoon Cup. There was a spice mill in nearby Market Street and there they roasted peanuts, coffee and ground spices for packaging and distribution to the small corner shops who were the mainstay of commercial grocery. In the 1950’s John MacLeod and Co merged with James McKay and Sons to form McKay MacLeod Pty Ltd., wholesale tobacco, wine and spirits and grocery merchants who also manufactured the Sunny South brand of sweet mustard pickles, brewed vinegar and tomato sauce. He introduced the semi-automated system for extensions and financial records on the Bradma plates that saved staff the problems of sorting out the calculations for sales tax, miscellaneous charges etc. that greatly sped up the transactions at the checkout points. A new warehouse and office complex was built in Mair Street east up near Humffray Street, with the manufacturing factory on the opposite side of the street. They had a shop in St Arnaud and one in Geelong which was the local wholesaler for supplying to the corner shops of the greater Geelong area. With the development of supermarkets the demise of the corner store began and so the sales profiles began to diminish. He unsuccessfully stood for Liberal Party pre-selection for the seat of Ballarat in 1948 and served on the Liberal state finance and executive team for many years before resigning over the issue of conscripts being sent to Vietnam. He was instrumental in leading a group of Ballarat academics in opposition to the Vietnam war and publicly resigned from the Liberal Party over their foreign policy. John MacLeod saw the writing on the wall of the business in the early 1970’s and suggested that the firm restructured with focusing on tobacco, wine and spirits. His partners did not agree and so he sold out and retired to Barwon Heads. After a few years of golfing and surfing he became frustrated and joined SCORE, the Service Corp of Retired Executives. In this role he worked for ten years in the Geelong area solving accounting problems for Geelong small businesses and so helped Beaumont’s bakery back onto its feet. He worked gentlemen’s hours of 10 am to 3 pm which allowed him to have time for a round of 9 holes on the golf course at the end of the day and to have a surf before breakfast. He fully retired at the age of 65 and had ten years of voluminous reading of local library books before dying of burns at the age of 75. His war record has been documented in other archives at the College. He was a member of the Naval and Military Club and of the Barwon Heads Golf Club. He had good crafting skills and built a series of steam driven boats for his four children that used to be sailed at home on Lake Wendouree, Lake Learmonth and on the sheltered waters of the Barwon River. The boats are now being restored to operational order to be sailed by his great grandson Grayson Girardi. Red cloth bound book with title printed in gold lettering on spine, embossed publisher's mark centre of front cover and school crest in gold relief on front cover; book plate inside front cover. Book plate inside front cover: School crest / Ballarat College / I form / 3rd in form Prize / Awarded to / J MacLeod / December 1924 A Richardson B A Principaljohn-macleod, ballarat-college, book-prize, 1924 -

Ballarat Clarendon College

Ballarat Clarendon CollegeBook, The school across the road

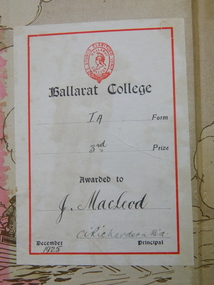

John Anning MacLeod John was born in Ballarat as the second generation of Ballarat MacLeod’s, with his grandfather arriving in Geelong on the Hornet in 1857 as an 11 year old child with his 60 year old father John and mother Mary aged 37 years and 5 brothers and one sister. He grew up on the corner of Drummond Street and Mair Streets, opposite what became St John of God hospital, at his parents house of Dunvegan. John entered Ballarat College as a junior student in 1923. He received 3rd in Form prizes in both 1924 and 1925. His sister Margaret, attended Clarendon Ladies College. The household employed a chauffeur, a cook, a gardener and a ladies maid to care for them. In the 1930’s his father lost his fortune in the collapse of the jute future’s market so the staff were dismissed and he left Ballarat to go to Geelong College as a boarder. He was an officer in the Geelong College cadet corps and joined the Army as a private and rose to the permanent rank of Major after meritorious performance in the intelligence area of operations. He served in North Africa, in Palestine, Egypt, Moratai, the Philippines, Java and New Guinea. He was awarded his Military MBE by King George VI for exceptional devotion to duty and for brilliant coordination work amongst the allied intelligence team. During the war he met Mary Monica Carrol Bateman, a lietenant in the 2/4th Army General Hospital at a dinner party in Brisbane. The couple had four children, Hamish John Torquil born in 1945, Rory Hugh Alexander born in 1947 and twins Ian Donald and Katriona Margaret born in 1948. After the Second World War he worked for Lumley’s Insurance Brokers in London for a couple of years to follow up his accountancy training and then returned to Ballarat due to his father’s failing health and took over the management of John MacLeod and Co, Wholesale grocers and Merchants in Lydiard Street, Ballarat. The business had been started by his great grandfather and they produced the famous Sirdar brand of products and a special tea blend called Afternoon Cup. There was a spice mill in nearby Market Street and there they roasted peanuts, coffee and ground spices for packaging and distribution to the small corner shops who were the mainstay of commercial grocery. In the 1950’s John MacLeod and Co merged with James McKay and Sons to form McKay MacLeod Pty Ltd., wholesale tobacco, wine and spirits and grocery merchants who also manufactured the Sunny South brand of sweet mustard pickles, brewed vinegar and tomato sauce. He introduced the semi-automated system for extensions and financial records on the Bradma plates that saved staff the problems of sorting out the calculations for sales tax, miscellaneous charges etc. that greatly sped up the transactions at the checkout points. A new warehouse and office complex was built in Mair Street east up near Humffray Street, with the manufacturing factory on the opposite side of the street. They had a shop in St Arnaud and one in Geelong which was the local wholesaler for supplying to the corner shops of the greater Geelong area. With the development of supermarkets the demise of the corner store began and so the sales profiles began to diminish. He unsuccessfully stood for Liberal Party pre-selection for the seat of Ballarat in 1948 and served on the Liberal state finance and executive team for many years before resigning over the issue of conscripts being sent to Vietnam. He was instrumental in leading a group of Ballarat academics in opposition to the Vietnam war and publicly resigned from the Liberal Party over their foreign policy. John MacLeod saw the writing on the wall of the business in the early 1970’s and suggested that the firm restructured with focusing on tobacco, wine and spirits. His partners did not agree and so he sold out and retired to Barwon Heads. After a few years of golfing and surfing he became frustrated and joined SCORE, the Service Corp of Retired Executives. In this role he worked for ten years in the Geelong area solving accounting problems for Geelong small businesses and so helped Beaumont’s bakery back onto its feet. He worked gentlemen’s hours of 10 am to 3 pm which allowed him to have time for a round of 9 holes on the golf course at the end of the day and to have a surf before breakfast. He fully retired at the age of 65 and had ten years of voluminous reading of local library books before dying of burns at the age of 75. His war record has been documented in other archives at the College. He was a member of the Naval and Military Club and of the Barwon Heads Golf Club. He had good crafting skills and built a series of steam driven boats for his four children that used to be sailed at home on Lake Wendouree, Lake Learmonth and on the sheltered waters of the Barwon River. The boats are now being restored to operational order to be sailed by his great grandson Grayson Girardi. john-macleod, ballarat-college, 1925, book-prize -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaFurniture - Pews x 18 with kneelers and pew fronts, c. 1917

The pews (18 small and 1 large) with 3 fronts were donated by Mrs E.W. Outhwaite in memory of her father, Nicholas Maine, who died in 1915. Nicholas Maine biography was published in the Australian on 11 September 1915 : "Nicholas Maine, whose paternal grandfather was rector of the Church of England and Ireland, parish of Dunaghy, County Antrim, came of a family of very considerable repute as merchants in Belfast. He was born at Ballymena on New Year's Day, 1826, and received his earlier education at the Diocesan School, Ballymena, and at Dr. Bryce's Academy, Belfast. After a three years' apprenticeship in a merchant's office, in Belfast, he ventured forth into the world as supercargo in a vessel belonging to one of his brothers, and so performing two voyages to Brazil. Ashore once more, he joined a broker's office in Liverpool, and whilst there was specially chosen out of a large staff as the man to take charge of a fleet of ships on a guano quest on the coast of Patagonia. Having determined on a suitable rendezvous for his ships, he sailed for the River Plate in a handy vessel, and from Monte Video south- wards minutely searched and examined the coast, chiefly in boats, as far as Santa Cruz, near the Straits of Magellan. At Sea Bear's Bay, in lat. 48deg. S., he landed his men, and pitched his tents, &c. After 10 months of extreme hardship and risky adventure on the coast in open boats, and loss of many men from scurvy, he loaded up all the ships sent to him, and returned to the River Plate. While there he met Captain Hotham, R.N., of H.M.S. Gordon (afterwards Governor of Victoria), and also saw Garibaldi, who was then making himself famous by his daring adventures against the enemy, though with inadequate means. (There was war going on in the river at the time.) From Monte Video he returned to Brazil, where he opened a direct trade with Russia, by shipping the first cargo, of sugar and cotton from Pernambuco to St. Petersburg. For so doing the Emperor Nicholas allowed his vessel (the Urgent), belonging to his brothers, trading under he name of N. Maine and Sons, to enter Russia free of port charges. Shortly after this Nicholas Maine went ashore, spending three years in a Liverpool brokers office, when, sailing again as super cargo, he went on a trading voyage to Chili and Peru. He was present at Panama for six months during the rush to California, and crossed the isthmus on muleback and by canoe, a severe journey in those days. Thence he went to Jamaica, his ship's company carrying with them the cholera, which decimated the population. Then home again, visiting the United States by the way. After another year in Liverpool, he sailed again for Brazil, at one day's notice, bought a cargo of coffee at Rio Janeiro, took it to San Francisco, and settled there, where he had three years of a most exciting life — 1851-2-3 —also making speculative voyages down the coast to Mexico and Nicaragua, at which latter place he took the fever and so on to the South Sea Islands, where he suffered shipwreck, and thence on to Chili. He arrived in Melbourne from New Zealand in 1854; made one more voyage to Chili (his last venture at sea), and on his return sold his vessel. After refitting a dismasted clipper ship, called the Flying Arrow for his brother Crawford, with what was considered in those days unusual dispatch, when the port had not many conveniences for the purpose, he quietly went again into harness ashore. He managed Mr. T. S. Martin's large business in Melbourne for five years, till he broke down, from excessive work and anxiety. After winding up the business, he sailed for England in 1862, and idled at home, in Italy, and other parts of the Continent till, his health being restored, he returned to Melbourne in 1867, and went to Queensland to buy into a station along with his brother and others; but, not being satisfied, came back to Melbourne, and began to work as a mercantile broker. Soon after this he was induced to apply for the resident secretaryship of the Australian Mutual Provident Society, and got it in 1868, though, at the time, several professionals thought him unfit, and prophesied failure. He retired after a long term of eminently profitable business transactions in 1895, owing to a rule of the society to retire secretaries at the age of seventy. He accordingly left on the 1st January, 1896, after twenty-seven years' service unbroken by a single holiday, save for a trip to Europe in 1891. A letter was written him by Sir Joseph Abbott, chairman of the board, in which he said:- "I need hardly assure you that the board is extremely sorry that the, society is obliged to lose your services, which have been so highly appreciated by us during your long connection with the society," and enclosed a grateful resolution passed by the board." Margaret Isabella Maine was born in 1871 and was the only daughter of Nicholas Maine. In 1897, she married Edward Walter Outhwaite, a layer from New South Wales who had studied at the University of Melbourne. Edward was the brother of Arthur Grenbry Outhwaite, husband of artist Ida Rentoul. Margaret and Edward had three children: a son, Maine Outhwaite and two daughters, Helen Margaret and Jocelyn. The pews on the left side of the nave have been moved to make room to a baby grand piano (date tbc.) therefore 2 of them have to be moved elsewhere in the mission and the pew front has been brought backwards..gifts, st peter chapel, pews, edward walter outhwaite, margaret isabella outhwaite nee maine (1871-1964), arthur grenbry outhwaite (1875-1938), nicholas maine (1826-1915), heritage listed, gifts-1917, kneelers, genuflection, praying -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Diamond ring, about 1855

In 1975, 120 years after the sailing ship Schomberg was wrecked, Flagstaff Hill divers (Peter Ronald, Colin Goodall and Gary Hayden) found an ornate communion set amongst the wreckage. The set comprised a jug, ciborium, lid, chalice and plate. The items, apart from the lid, were then displayed at Flagstaff Hill Maritime Village. The lid had etchings that did not match the chalice and sat in storage for several years. Then in 1978, while the marine concretion inside the lid was being examined, a surface layer came loose and revealed a glint of gold that was assumed to be a piece of brass. The layers of concretion were carefully removed and a ring-like band emerged. Further treatment exposed a 'large faceted stone in an intricate gold setting. Weeks later a detailed examination estimated the value of the ring, known as the Schomberg Diamond, to be $7000. When the Schomberg was launched in 1855, she was considered the "Noblest” ship that ever floated on the water. Schomberg's owners, the Black Ball Line had commissioned the ship for their fleet of passenger liners. She was built by Alexander Hall of Aberdeen at a cost of £43,103 and constructed with 3 skins. One planked fore and aft and two diagonally planked, fastened together with screw-threaded trunnels (wooden rails). Her First Class accommodation was simply luxurious with velvet pile carpets, large mirrors, rosewood, birds-eye maple and mahogany timbers throughout, soft furnishings of satin damask, an oak-lined library with a piano. Overall she had accommodation for 1000 passengers. At the launch, the Schomberg's 34-year-old master, Captain 'Bully' Forbes, had promised to reach Melbourne in sixty days stating, "with or without the help of God." Captain James Nicol Forbes was born in Aberdeen in 1821 and rose to fame with his record-breaking voyages on the famous Black Ball Line ships; Marco Polo and Lightning. In 1852 in the Marco Polo, he made the record passage from London to Melbourne in 68 days. Unfortunately there were 53 deaths on the voyage, but the great news was off the record passage by Captain Forbes. In 1854 he took the clipper “Lighting” to Melbourne in 76 days and back in 63 days, this record was never beaten by a sailing ship. He often drove his crew and ship to breaking point to beat his previous records. He cared little for the comfort of the passengers. On this, the Schomberg's maiden voyage, he was determined to break existing records. Schomberg departed Liverpool on her maiden voyage on 6th October 1855 flying a sign that read "Sixty Days to Melbourne". She departed with 430 passengers and 3000 tons cargo including iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, 90,000 gallons of water for washing and drinking. She also carried 17,000 letters and 31,800 newspapers. The ship and cargo were insured for $300,000 a fortune for the time. The winds were poor as she sailed across the equator, slowing Schomberg's journey considerably. Land was first sighted on Christmas Day, at Cape Bridgewater near Portland, Captain Forbes followed the coastline towards Melbourne. Forbes was said to be playing cards when called by the third mate Henry Keen, who reported land about 3 miles off. Due in large part to the captain's regarding a card game as more important than his ship, it eventually ran aground on a sand spit near Curdie's Inlet (about 56 km west of Cape Otway) on 26th December 1855, 78 days after leaving Liverpool. The sand spit and the currents were not marked on Forbes's map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to Schomberg and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted the SS Queen at dawn and signaled the steamer. The master of the Queen approached the stranded vessel and all of Schomberg’s passengers and crew disembarked safely. The Black Ball Line's Melbourne agent sent a steamer to retrieve the passengers' baggage from the Schomberg. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Later one plunderer found a case of Wellington boots, but alas, all were for the left foot. Local merchants Manifold & Bostock bought the wreck and cargo but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. In 1864 after two of the men drowned when they tried to reach Schomberg, salvage efforts were abandoned. In 1870, nearly 15 years after the wreck parts of the Schomberg had washed ashore on the south island of New Zealand. The wreck now lies in 825 meters of water and although the woodwork is mostly disintegrated the shape of the ship can still be determined due to the remaining railway irons, girders and the ship’s frame. A variety of goods and materials can be seen scattered about nearby. The actual lid in which the ring was found has not yet been completely identified and could belong to a coffee pot, sugar bowl or maybe a jug or something similar. Although all survived the wreck no-one came forward to claim the valuable diamond. The Schomberg Diamond is currently on display in the Great Circle Gallery. Flagstaff Hill Maritime Village along with the rest of the communion set. Other artefacts salvaged from the wreck include ship fittings and equipment, personal effects, a lithograph, tickets and photographs from the Schomberg. One of the Schomberg bells is in the Warrnambool Library.The Schomberg Diamond is particularly significant in that it played a crucial part in having the legislation changed to protect shipwrecks, with far tighter control over the salvaging of items from wreck sites. This ring is registered as Artefact S/105 in the Schomberg collection, the Schomberg collection as a whole is of historical and archaeological significance at a State level. Flagstaff Hill’s collection of artefacts from the Schomberg is also significant for its association with the Victorian Heritage Registered shipwreck (VHR S 612). The collection is of prime significant because of the relationship between the objects salvaged, as together they help us to interpret the story of the Schomberg. The collection as a whole is historically significant for representing aspects of Victoria's maritime history and its potential to interpret social and historical themes. A mid-Victorian gentleman's solitaire diamond dress ring with a Brazilian cut diamond (cushion cut), one and one-third carat set within an 18 carat yellow gold ring consisting of four claws within an open scroll setting and a divided scroll shank. Colour is classified as 'J', clarity SII. The setting is handmade. warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, schomberg, shipwrecked-artefact, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, ciborium, ring, schomberg-diamond, schomberg-ring, gentleman's ring, dress ring -

Melbourne Legacy

Melbourne LegacyLetter, Intermediate Legacy Club, 1975

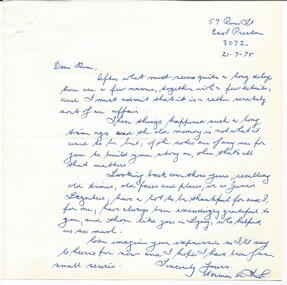

A letter written by Norm Smith and addressed to Kem Kemsley on 21 July 1975. It outlines recollections compiled by Norm Smith about the Intermediate Legacy Club (ILC) and individual members. His letter mentions 'Looking back over those years, recalling old time, old faces and places, we as Junior Legatees have a lot to be thankful for and I, for one, have always been exceedingly grateful to you, and those like you in legacy, who helped us so much.' Graham Billiet's letter dated 23 Mar 1974, mentions taking Frank Doolan to the reunion in 1974. Graham felt the ILC was winding down and was only running on half steam. He gives ILC members' addresses. Norm Smith's letter includes: Ted Kennedy, was the first president of the ILC, he was 'tall rangy lad with fiery red hair' who worked for United Distillers Ltd for 40 years (mostly in Brisbane where he joined Brisbane Legacy). Had been a keen junior legatee and taken part in Literary and Debating group and the Dramatic group where he met his future wife, Florence Pittard - which was the first marriage between junior legatees. He had been a naval cadet in the 1928 compulsory training and later joined the CMF where he was closely associated with L/ Stan Savige. He rose to rank of Major in AIF. Jack and Tom Kennedy, his brothers were in the Lacrosse team and his sister Molly in the JLC for years. G Billiet, a first nighter, very well known to legatees of the time. Bill Johnston, a studious type, went to MHS and university, became a Solicitor. Served in the RAAF as a Flight Lieut. Frank Corrie, prominent Junior Legatee in the Literary and Debating group, a fitter and turner by trade, was on JLC cricket and lacrosse teams, joined the AIF. Fred Hollingsworth, a motor mechanic, he joined CIG. He joined the AIF and served in the Middle East, and was one of the Rats of Tobruk as a sergeant. Bert Hollingsworth (brother of Fred) also in AIF and rank of Lieut. Is a past president of ILC. Bert Wood, a past president, worked for Victorian Railways, moved to Coolangatta. Dan Fitzgerald, active in the Drama group of JLC, worked as an announcer at the ABC. Alan Davidson, keen gymnast - particularly wrestling, helped with Alan Beattie (instructor of boys classes). Roy Davidson (brother of Alan) joined the AIF, afterwards joined M&MTB as a driver, married a Junior Legacy girl. Their younger brother Arthur was also in the lacrosse team. Roy Gilbert, keen junior legatee took part in Literary and Debating group and the Dramatic group and lacrosse team. Worked for Vacuum Oil Co., a past president of ILC and also married a Junior Legatee, Miss Lil Edmunds. Served in the AIF and was a Lieutenant in the Middle East. 'Jimmy' MacGregor, a colourful and handsome Junior Legatee, born in Collingwood, was one of L/ Stan Savige original contacts. Keen JLC gymnast and member of the football team. Worked at the Ret. Soldiers Woollen Mills in Geelong and was in the Geelong ILC. Frank 'Happy' Holliday, was in the lacrosse team, foundation member of ILC and past president. Served with the RAAF as an air frame fitter. Worked for L/ Con Fahle in the printing workshop for 40 years. Howard Auterey, joined the RAAF during the war and returned work for the State Saving bank before retiring in Warrnambool. Norman Smith, was working as an apprentice with M&MTB, took interest in Literary and Debating group and was in the lacrosse team. Was ILC president in 1946. Enliseted in the RAAF as airframe fitter. Retired from M&MTB after serving 50 years, married for 40 years to a daughter of an original Anzac who has also been an active member of the Ladies ILC for many years. Background: The ILC was formed in 1929. The idea of the club sprang from those boys who had outgrown the Junior Legacy Club. In the early days it fielded a lacrosse team and it was this that mainly held the members together (formed under guidance of L/ Jimmy Downing). Enthusiasm wained after a few years as it lacked a solid objective. The answer came from one of its members and in 1938 they founded the Don Esses Club. This was a club for the children of incapacitated ex-servicemen which met every Thursday night at 7.30 run by the ILC members. The name came from the signallers' code Disabled Servicemen's Sons. During the second world war 80% of the members of the ILC enlisted in the services. Leaving only 8 members that could not join due to ill health or reserved occupations. They continued the Don Esses and whatever aid they could to Legacy. ILC members had always helped Legacy where possible including being camp leaders or camp staff, with the annual demonstrations, and coffee stalls at the ANZAC dawn service. Post second world war some ILC members were nominated into Legacy, others drifted away in civil occupations. It was found difficult to recruit new blood into the ILC and eventually membership waned when the boys from the Don Esses clubs found other youth activities to join. The ILC ceased to meet regularly in the mid fifties. However a strong comradeship still existed between members and they would meet in one anothers homes. Members were always ready to help the senior Legacy Club in any way in their power and still helped at Christmas parties and summer camps. ILC was a service rendering organisation and was self governing. Non-sectarian and non-political, the members were ex-junior legatees over 18 years of age. After serving in World War 2 members were eligible to become members of Legacy. Was in a folder of material collated about the ILC by an early archive committee. A record of a Junior Legatee recording what he knew about ILC members and their life outside of Legacy in response to a request from L/ Kem Kemsley. It could have been part of the early archive committee working to capture Legacy history.White note paper x 18 pages handwritten by Norm Smith about the ILC members and a handwritten letter x 3 pages from Graham Billiet about ILC members with addresses.ilc, membership, junior legatee -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener