Showing 919 items

matching billy

-

Puffing Billy Railway

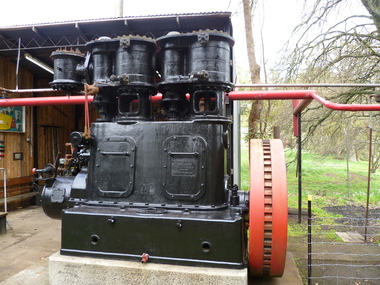

Puffing Billy RailwayTwin Cylinder Engine - Belliss & Morcom Ltd, Patent Self Lubricating Engine , Birmingham, 1926

Belliss & Morcom Ltd, Patent Self Lubricating Engine , Birmingham It was used to operate the Fairfield No. 2 Mill Paper Making machine by a rope and pulley drive.Historic - Industrial Twin Cylinder Engine - stationary engine used to operate the Australasian Paper and Pulp Co Ltd. - Fairfield No. 2 Mill Paper Making machine by a rope and pulley drive.Twin Cylinder Engine - stationary engine made of steel, wrought iron, brassBelliss & Morcom Ltd, Patent Self Lubricating Engine , Birminghamtwin cylinder, engine, stationary engine, industrial stationary engine, puffing billy, fairfield no. 2 paper mill, australian paper manufactures ltd, belliss & morcom -

Puffing Billy Railway

Puffing Billy RailwayDrill Press, Hand operated

Built by the Buffalo Forge Company in New York, USA. It is of a typical hand operated design used in workshops.Historic - Industrial drill - typical hand operated design used in workshops.Steel - Black and red paintBuffalo Forge Company Drill Press No. 611puffing billy, drill press, hand tools, buffalo forge -

Puffing Billy Railway

Puffing Billy RailwayPlatform Trolley

Used on the railway platforms to transform luggage and small goods items between the trains that arrived at the station and the parcels office on the platform. They were often seen on railway platforms with suitcases, chicken boxes and other small boxes.Historic - railway platform typical of those used on station platformsPlatform Trolley made of Wood and Steel and wrought ironplatform, trolley, transport, luggage, railway, puffing billy -

Puffing Billy Railway

Puffing Billy RailwayMachine - Steam Hammer, G James, 1841

Steam hammers, invented by Englishman John Naysmith in 1841, made possible the forging of heavy iron bars and greatly reduced the physical labour required in forging. The hammers could vary in capacity (drop-force) from 400 pounds [lbs.] (181 kg) to 400 Tons (406.3 tonnes) and were once a part of most major engineering works. The Victorian Railways, from where the Museum exhibit came, used many hammers of varying sizes, their largest being at Newport Workshops measuring 30 feet (9.1 metres) high by 15 feet (4.6 metres) wide. Steam Hammers have made forging of heavy iron bars possible and has greatly reduced the physical labour required in forging. Historic - Victorian Railways - Industrial Steam Hammer Large metal mechanical steam hammer. made of iron & wrought ironC James Maker Melbournelarge, mechanical, steam, hammer -

Puffing Billy Railway

Puffing Billy RailwayHand Winch

Imported by Cameron, Sutherland & Seward Ltd. Machinery Merchants, Melbourne & Sydney, this example is of the type of hand winch used by the Australian Industries and timber workers in the Australian bush. The central rotating drum is operated by three interacting cog wheels. The metal cable is wound onto the central drum.Historic - Hand Winch type of hand winch used by the Australian Industries and timber workers in the Australian bush.Hand Winch made of wrought iron, metal and ironhand, winch -

Puffing Billy Railway

Puffing Billy RailwayCheetham Salt Hopper Truck No12

Trucks of this type were built to carry salt from the saltpans of Cheetham Salt Company works, at Laverton, Moolap and Geelong. Made from wood and steel, it was found that the wood would not erode as much as steel from the salt and this is the reason these vehicles have metal on the exterior of the wagon. Later new stainless steel hopper trucks were used at the works. Historic - Industrial narrow Gauge railway - Cheetham Salt Company at Laverton, Moolap and Geelong.Two Cheetham Salt Hopper Trucks Gauge 2'0" Made from Wood & Steel No. 12 on metal frame of one of the Cheetham Salt Hopper truck A second hopper truck is not numbered.puffing billy, industrial narrow gauge railway, cheetham salt company, gauge 2' 0", salt -

Puffing Billy Railway

Puffing Billy RailwayH Class Bogie Flat Wagon

This vehicle was used on the Innisfail tramway line in Northern Queensland and given the "H" Classification. It was later sold to Howard Smith Industries. The wagon has been donated to the Museum and sees use on the Museum's 2'0" gauge line. Historic - Industrial Narrow gauge Railways - Rolling stock - Innisfail tramway line in Northern Queensland H Class Bogie Flat Wagon made of Iron, wrought iron and steelh class, bogie, flat wagon, 2'0" gauge -

Puffing Billy Railway

Puffing Billy RailwayFour Wheel Long Wheel Base Flat Wagon

Built for use at Bachus Marsh on a Cementation contract, these 3 long wheel base vehicles arrived at the Museum in 1982 and are used on the Museum's 2'0" gauge lines.Historic - Industrial Narrow Gauge Railway - Flat WagonFour Wheel Long Wheel Base Flat Wagon made of Steel and Metal puffing billy, bachus marsh, four wheel flat wagon, two foot, 2'0" gauge -

Puffing Billy Railway

Puffing Billy RailwayMaribyrnong Cordite Wagon

Cordite Wagon - 18½-inch (460mm) gauge wagons came from the Commonwealth Explosives factory at Maribyrnong in Melbourne’s western suburbs. Both have gun-metal wheels, as avoiding sparks was understandably a priority in an explosives factory. Both wagons also have water tanks to drip water on the wheels as an added precaution. Cordite, an explosive used in artillery, was manufactured and pressed into thin sheets, which still contained a quantity of acetone solvent from the manufacturing process. The sheets of cordite were laid in racks of perforated trays in the cordite wagons, which were hand-pushed to the cordite drying-house where the trucks were coupled together in rakes and warm air was blown through them. The acetone, being very volatile, was evaporated out of the cordite and recovered to be re-used in the manufacturing process. Historic - Industrial Narrow Gauge Railway - Commonwealth Explosives factory, Maribyrnong, Victoria, AustraliaCordite Wagon - Rectangular yellow wagon made of wood and brass with aluminium traysThe number 77 is on the endspuffing billy, wooden wagon, 18½-inch gauge, explosives, maribyrnong cordite factory, maribyrnong explosives factory, puffing billy museum, industrial narrow gauge railway -

Puffing Billy Railway

Puffing Billy RailwayWonthaggi Coal Skip, Early 20th century

One of two types of four wheel skips widely used on the Wonthaggi Coal Fields for transportation from the underground workings to the surface screening and loading areas. Haulage underground was accomplished by the use of pit ponies, whilst an endless rope system was used to bring the skips to the surface areas. Much of the coal for the colony of Victoria was sourced from Newcastle and the Hunter Region in New South Wales, along with local supplies from private and co-operative coal mines at Outtrim, Jumbunna and Korumburra in Gippsland. After the 1909–1910 strike by coal miners in the Hunter Valley, the Victorian state government were determined to ensure stability in local supplies of coal. The State Coal Mine and the town of Wonthaggi came into being in 1910 to supply coal for the Victorian Railways. It was one of the largest and most dangerous collieries in Australia. At its peak in 1926 the mine produced 2,435 long tons (2,474 t) per day, with the Victorian Railways buying 90% of production. In 1928, Wonthaggi coal accounted for around 60% of Victorian Railways coal consumption.Historic - Industrial - Victorian Railways - Narrow Gauge Railway rolling stock - Wonthaggi Coal Fields, Victoria, AustraliaRectangular steel bin with wood frame and steel wheelspuffing billy, coal skip, wonthaggi, wonthaggi coal fields, 2'0" gauge, brown coal -

Puffing Billy Railway

Puffing Billy RailwayFour Wheel Brick Skip

Typical of many small four wheel skips constructed to transport raw bricks from the moulding press to the kilns for firing.Historic - Industrial Narrow gauge railway - Fritsch, Holzer & Company Brick works, Hawthorn, Victoria, Australiatwo Wooden skips with steel wheels "JF 12" & "SB 34"puffing billy, fritsch, holzer & company, brick skip, fritsch, holzer & company brickworks, pressed red brick -

Puffing Billy Railway

Puffing Billy RailwayN Model Fordson Tractor, 1930s

Fordson Henry Ford set up the company Ford and Son in 1917, it later became known as Fordson. Henry had previously tried to interest the directors of the Ford Motor Co in producing agricultural machinery, but when this met with no success he set up the new company to market the tractor he had created. Fordson: Model N 1929-32 Produced at Cork 1932-1945 Produced at Dagenham The Fordson Model N replaced the Fordson Model F. Production of the Model N started in Cork in 1929. Production of the Fordson Model N was transferred from Cork to Dagenham in 1932. The Model N featured a 27 HP engine, standard rear fenders (mudguards), a higher voltage ignition system, and optional pneumatic tires. In 1935 power take-off (PTO) was available as an option on the Model N. Historic - Farm Machinery - TractorSteel Tractor - Orange with black wheels.Fordsonpuffing billy, fordson, tractor -

Puffing Billy Railway

Puffing Billy RailwaySide Tipping Timber Skip, circa 1900?

Side Tipping Timber Skip Wooden Contractors Wagon. Gauge 17 inch (430mm) Typical of the many side tipping wagons used for soil and rock disposal in construction work and mining throughout Australia and the world. The wagon would be loaded with soil and pushed along a short line to the end of track where the load would be emptied out to either side. By using a central pivot the wagon’s body can be tipped either side to allow the contents to be easily removed ready for the next load.Historic - Industrial Narrow Gauge RailwayWooden bodied, steel framed side tipping skip.puffing billy, side tipping skip, industrial narrow gauge railway -

Puffing Billy Railway

Puffing Billy RailwayEnd Opening Wagon, 1900?

End opening Wagon Gauge: 17 inch (430mm)Historic - industrial Narrow gauge RailwayEnd Opening Wagon - Made from wood and steel with one end that openspuffing billy, four wheel wagon -

Puffing Billy Railway

Puffing Billy RailwayHeinrici Hot Air Motor, 1900s

Louis Heinrici, Germany, circa 1900 a small Stirling type hot air engine in which a body of air is worked constantly, being alternately heated and cooled during each revolution of the crankshaft. Heinrici hot air engines are of the valveless, closed cycle type, generally called Stirling cycle engines, after Robert Stirling, the Scottish Presbyterian minister who pioneered their development in the early 1800's. They operate by alternately heating and cooling a quantity of air, called the working fluid, contained in the engine's internal spaces. Heat is applied externally and passes through the cylinder wall, heating the working fluid, which is then expanded against a piston to do mechanical work. After heating and expanding, the working fluid is moved to a cool space where it cools and contracts before being returned to the hot space for the cycle to repeat. It has a displacer (just a loose piston), below and in the same cylinder as the power piston to which it is connected via cranks and linkages so as to lead by 90degrees of crankshaft angle. The displacer space and the piston space are connected by the annular gap around the loose fitting displacer so that the working fluid moves between these spaces and changes volume by the appropriate ratio as the engine rotates. Because they have no valves and experience no sudden pressure changes, Stirling engines are noted for quietness and reliability. Heinricis use air at atmospheric pressure for their working fluid, but for higher specific output (power for size) and better efficiency, modern Stirling cycle engines use pressurised gas- air, nitrogen, helium or hydrogen.Historic - Hot Air Engine - MotorHot Air Motor made of Steel with two drive wheels. a small Stirling type hot air engine in which a body of air is worked constantly, being alternately heated and cooled during each revolution of the crankshaft. Heinrici Motorheinrici hot air motor, puffing billy -

Puffing Billy Railway

Puffing Billy RailwayVictorian Railways Station Fruit & Rubbish Bin, 1920's

Historic - Victorian Railways Station Rubbish Bin - used at the time of Mr Clapp, Chairman of the Victorian Railways Commissioners "Eat More Fruit" campaignHistoric - Victorian Railways Station Rubbish Bin - used at the time of Mr Clapp, Chairman of the Victorian Railways Commissioners "Eat More Fruit" campaignTin lined wooden box with sign writing on two sides.Fruit skins and rubbish must be deposited here (hand sign written on two sides ).victorian railways, rubbish bin, puffing billy railway -

Puffing Billy Railway

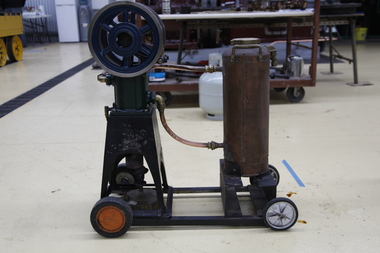

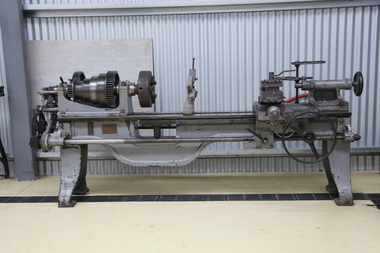

Puffing Billy RailwayLathe - Gap Bed, early 1900s

Possibly ex Victorian Railways Newport workshops Supplied by Bevan & Edwards Machinery Merchants, Melbourne Sebastian Lathes Described by its makers as the Utility School, Garage and Repair-shop Lathe, the machine immediately below, a Sebastian 15" (circa 1910 - 1926) was the Company's cheapest offering and, in its basic form, lacked a compound slide rest, the tailstock did not set over for taper turning and the bed lacked a gap. However, a friction-type countershaft unit was included in the price as well as a tool post, faceplate, drive plate, changewheels for screwcutting and a small tool kit. As with modern cars (especially BMW) everything worthwhile was on the options' list and by spending more it was possible to specify all those small but important extras. Although in its lowest-cost form this model was reduced to the fundamentals required for a useable, screwcutting centre (engine) lathe it was still reasonably specified and would certainly have fulfilled many requirements when installed in a school or training workshop. The true swing was 15.25", it was properly backgeared and screwcutting was through a conventional tumble-reverse mechanism that allowed both left and right-hand powered movement to the carriage by altering the position of just one lever. As standard it accepted 40" between centres, but any capacity could be ordered, in foot intervals, up to a maximum of 88" - when it is hoped that a central bed support might have been included …… The spindle, which ran in white-metal bearings, had a useful 15/8" hole and a No. 3 Morse taper centre. Some models appear to have had the leadscrew clasp-nut lever on the right-hand side of the apron, while on others it was positioned to the left.. Early Sebastian 13-inch lathe Typical of the Centre or "Engine" lathe made by many manufacturers from the late 1800s until the late 1930s, the basic flat-belt drive Sebastian, with separate countershaft, was eventually relegated to the economy end of the Company's range by the introduction of geared headstocks and self-contained motor-drive systems.Historic - Industrial Machinery - Gap Bed Lathe - Possibly ex Victorian Railways Newport workshops - Purchased and supplied from Bevan & Edwards Gap Bed Lathe - Grey with raw steel parts and a timber cupboard with gears and tools. Bevan & Edwards PTY,LTD Machinery Merchants Melbourne (possible government tag) 365bevan & edwards pty,ltd machinery merchants melbourne, puffing billy -

Puffing Billy Railway

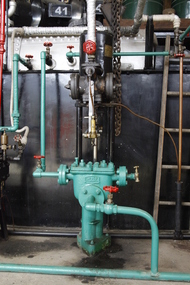

Puffing Billy RailwaySteam Driven Weir Pump, 1900s

Weir Pumps - these types of vertical pumps were used extensively with both land and marine steam pumps. The pumps were also used for various duties from pumping oil fuel and feed water for boilers, to draining bilges on steam ship[s They are a single cylinder, double acting vertical pumps used by G. & J. Weir Ltd. , of Cathcart, Glasgow Historic - Weir Vertical PumpSteam Driven Weir Pump Green and Black with metal parts.No. B49717puffing billy, weir, steam pump -

Puffing Billy Railway

Puffing Billy RailwaySteam Driven Weir Pump, 1900s

G. and J. Weir of Holm Foundry, Cathcart, Glasgow and now known as the Weir Group. The company was established in 1871 as an engineering firm by two brothers, George and James Weir, founding G. & J. Weir Ltd. The Weir brothers produced numerous groundbreaking inventions in pumping equipment, primarily for the Clyde shipyards and the steam ships built there. These pumps became extremely well known for their use as boiler feedwater pumps, and for ship's auxiliary equipment such as evaporators. Under W D Weir, the company turned to producing munitions and war material in the First World War. As well as shells, they manufactured aircraft including the Royal Aircraft Factory F.E.2 fighter and bomber. James George Weir (aviator, son of James Galloway Weir) a director of the company formed the Cierva Autogiro Company. G & J Weir would be a financial supporter of the company during its existence. In 1943, they provided the finances for the construction of the W.9, an experimental helicopter, to Air Ministry requirements. It was first listed on the London Stock Exchange in 1946. Double-acting Weir steam pumps were virtually standard fitment on British-built steamships, being used for pumping water, fuel, air and much else well into the 1950s, as well as being used on other ships worldwide. Historic - Double-acting Weir steam pumpSteam Driven Pump made of iron & steel puffing billy, weir pump, weir, steam driven pump -

Puffing Billy Railway

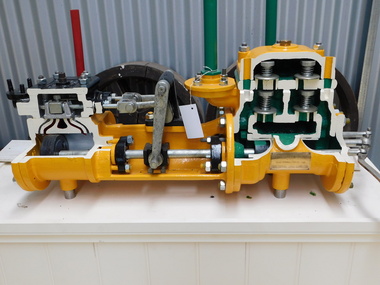

Puffing Billy RailwaySectioned Tangye Steam Operated Water Pump, 1900s

Sectioned steam pump so that the pump workings can be seen. Inscriptions & Markings: Tangye Birmingham, This steam pump was presented by the colonial gas Assn Ltd (brass plaque) The Colonial Gas Association was originally formed in London on 2 February 1888, as The Australasian Gas Association Limited. The primary objective of the company was to provide investment capital to help finance the construction and management of gasworks being established by the London engineering firm John Coates & Co in metropolitan cities and regional towns throughout Australia and New Zealand. By 1890, the Australasian Gas Association had acquired gasworks at Benalla, Shepparton, Wangaratta, Warragul, Maldon and Seymour, and had constructed a large gasworks at Box Hill to supply the eastern suburbs of Melbourne. In 1893, the company's name was changed to the Colonial Gas Association Limited. During the 1890s, the company acquired regional gasworks in Queensland, Western Australia and South Australia, followed by its first gasworks in New South Wales, in 1911. In 1914, the company consolidated its metropolitan supply area by purchasing the Oakleigh and Footscray gasworks. Further expansion occurred in the 1920s with the purchase of established gasworks at Williamstown, Frankston and Dandenong and the acquisition of ten further gas undertakings in Queensland and New South Wales, making the firm the fifth largest gas producer in Australia. info from The Colonial Gas Association Limited, circa 1893 https://collections.museumvictoria.com.au/items/1553322 Originally formed by the five Tangye brothers from Cornwall as James Tangye & Brothers in 1857, this Birmingham engineering firm grew to become one of the largest suppliers of jacks, pumps, steam and oil engines, hydraulic presses, gas producers and machine tools in the late 19th and early 20th centuries. The successful sideways launching of I.K. Brunel's 'Great Eastern' from the mud of the Thames in 1857 using Tangyes hydraulic jacks gave the firm much needed publicity and new orders flowed in. To finance expansion, George Price provided additional capital and the company name became Tangye Brothers & Price in 1859. A new factory known as the 'Cornwall Works' was built in Clement Street, Birmingham. In 1872, the firm became Tangye Brothers and in about 1879- 1880 began production of internal combustion stationary engines based on Horace Robinson's patents, later using the Otto four-stroke design for its Soho range of gas engines. Examples of the Soho engine were exhibited by the firm at the 1880 Melbourne International Exhibition. Petrol and oil engines were made from the 1890s onward, and by 1910 had developed into the Model B, BR and AA series engines. Tangyes supplied custom-built pumps and presses for particular applications, becoming a major exporter of engineering equipment. In 1884, Tangye Brothers opened a custom-built branch office, showroom and warehouse in Melbourne at Cornwall House in Collins Street West, advertising the full range of engineering products. These lantern slides images are taken from Tangyes product catalogues from the 1910-1925 period and are believed to have been used as sales promotional aids in Australia by the Tangye Brothers. info from https://collections.museumvictoria.com.au/articles/4670 Historic - Industrial Steam Operated Water Pump built by Tangye Bros and used by the Colonial Gas Company - Melbourne, Victoria, AustraliaSectioned steam pump so that the pump workings can be seen. Tangye Birmingham, This steam pump was presented by the colonial gas Assn Ltd (brass plaque)puffing billy, steam pump, sectioned, tangye bros -

Puffing Billy Railway

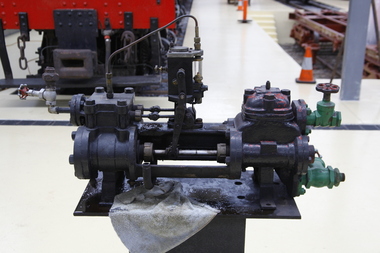

Puffing Billy RailwaySteam Pump, Worthington - Simpson steam driven pump, circa 1917

Worthington Steam Pump This type of horizontal duplex steam pump was most commonly made by Worthington-Simpson Ltd., England. It was really two double-acting pumps placed side by side. Worthington pumps of this size would feed a small boiler with water whilst larger similar pumps up to six feet long would be used to pump bulk liquids. This type of horizontal duplex steam pump was most commonly made by Worthington-Simpson Ltd., England. It was really two double-acting pumps placed side by side. Worthington pumps of this size would feed a small boiler with water whilst larger similar pumps up to six feet long would be used to pump bulk liquids.Historic - horizontal duplex steam pump made by Worthington - SimpsonSteam Pump made of Steel, bronzeWorthington-Simson ltd Newark-on-trent England No 5073449 Size 4 1/2 x 2 3/4 x 4puffing billy, worthington steam pump, worthington - simpson -

Puffing Billy Railway

Puffing Billy RailwayThe Quasi Arc Co Ltd Generator - Flat Belt Driven D.C, 1900s

QUASLARC Generator Built by the Quasi-Arc Co. Ltd. Victoria London SW.1, This generator is believed to have been used for welding purposes. The generator is driven by a belt from a nearby steam plant. The quasi-arc co ltd 6 kw. d.c generator 60/30 volts 0/200 amps 1200 rpm comp cont rating No 4696 Historic - Industrial Generator Large casting with a drive pulley on one end, cast aluminum covers, bronze makers plaque. The quasi-arc co ltd 15,grasyenor ????ens. Victoria,London,S.W.1 This machine is designed for use with ????? Arc electrodes 6 kw. d.c generator 60/30 volts 0/200 amps 1200 rpm comp cont rating No 4696puffing billy, generator, welding, quasi - arc -

Puffing Billy Railway

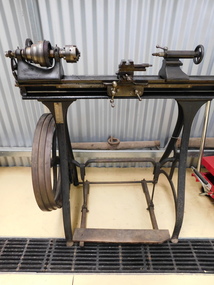

Puffing Billy RailwayTreadle Lathe

Industrial Treadle Lathe Possibly a Star Treadle LatheHistorical - Industrial Treadle Lathe Treadle Lathe made of Steel and wrought irontreadle lathe, puffing billy -

Puffing Billy Railway

Puffing Billy RailwaySteam Powered Water Pump, 1900s

Steam Powered Water Pump in active use on George & George BoilerHistoric - Industrial Steam Powered Water Pump in active use on George & George Boiler Steam Powered Water Pump Blue with steel rods and brass valves.Snow steam Pump works Bufflalo, N.Y.,U.S.A Size 3x2x3 Number 51520puffing billy, water pump, steam, blue, snow steam pump works -

Puffing Billy Railway

Puffing Billy RailwaySmiths Setric Electric Clock, circa 1937

Electric Clock - Smiths Setric Clock From 1937 the trademark "Sectric" appears on their synchronous models.Usually on the dial but sometimes also on the back cover. Early clocks had a prominent "T" in sectric. Smiths English Clocks 1931 Smiths, then called S. Smith and Sons (Motor Accessories) Ltd, entered the domestic clock market and formed a new company, Smiths English Clocks Ltd, as the Clock and Watch division with Cricklewood as the main factory. Smiths were one of the first companies to produce synchronous electric clocks. These were put on the market towards the end of 1931. Smiths formed a subsidiary company called Synchronous Electric Clocks to produce these clocks as the first models carry this name. 1932 Smiths purchased English Clock and Watch Manufacturers of Coventry, and acquired the trade names Astral and Empire. 1934 Smiths produced a synchronous alarm clock which they named the Callboy. 1934 They bought the Enfield Clock Co. The Smith's 8 day Calotte clock made its debut at the British Industries Fair in 1934. Prior to this date calottes had been exclusively of foreign manufacture. Also that year, Smiths introduced the Batriclock which was intended for areas where the synchronous clock could not be used. 1935 They introduced the Synfinity, which Smiths described as "the clock that never stops". They said it was "the remarkable combination of a synchronous electric movement with the essential elements of a fine precision lever escapement". If the electric supply failed the clock would run for up to six hours and rewind when the power returned. Apparently the synchronous motor also corrected the mechanical time train at intervals. Smiths produced a synchronous electric chiming clock. 1937 The trade name Sectric appears on Smiths electric clocks. Also the introduction by Smith's of a calotte clock with an alarm movement.Historic - Smiths English Setric Electric Clock Electric Clock - Smiths Setric Clock It is round with the numbers one to twelve, three hands with a white face. Smiths Sectricpuffing billy, clock, time, smiths sectric -

Puffing Billy Railway

Puffing Billy RailwayHand Operated Drill Press, 1900s

Historic - Industrial drill - typical hand operated design used in workshops.Historic - Industrial drill - typical hand operated design used in workshops.Hand operated drill press. Bench mounted type hand drill press. drill, press, workshop, hand operated, puffing billy -

Puffing Billy Railway

Puffing Billy RailwayWorkshop Safety Sign - Wearing Of Goggles, 1944

Workshop Safety Sign - Wearing Of Goggles SignHistoric - Safety Sign Workshop Safety Sign - Wearing Of Goggles Sign Timber framed notice board printed by the Victorian Railways of wearing safety goggles.Workshop Safety Sign - Wearing Of Goggles Signpuffing billy, victorian railways, safety sign -

Puffing Billy Railway

Puffing Billy RailwayHand Operated Drill Press, 1900s

Historic - Industrial drill - typical hand operated design used in workshops.Historic - Industrial drill - typical hand operated design used in workshops.Hand Operated Drill Press Bench mounted type hand drill press. puffing billy, tools, hand tools, drill press -

Puffing Billy Railway

Puffing Billy RailwayPlatform Kerosene Lamp, 1900s

Platform Lamp - Kerosene Platform Lamp Station Lamp When Made - 1900s Typical of the lights that lit a lonely railway station in the days before electricity.Historic - Early Railway Platform Kerosene LampLarge Kerosene Platform Lamp made of tin, brass and glasslamp, puffing billy, station lamp -

Puffing Billy Railway

Puffing Billy RailwayV. R. Krupp 1888. IV. Rail, 1888

60lbs rail that was used throughout the Victorian rail network. In 1887 Gibbs, Bright and Co. had a contract with Victorian Railways for railway and canal construction and supply of Krupp Rails. Gibbs, Bright and Co were merchant bankers and shipping agents and merchants who where also Directors of the GWR ( Great Western Railway ) and the Ship The "Great Britain" in England Gibbs, Bright and Company had principally been involved in shipping and trading, mainly in the West Indies, but following the discovery of gold in Victoria they established an office in Melbourne and soon became one of the leading shipping agents and merchants in the Colony. They expanded into passenger shipping and soon established offices in Brisbane, Sydney, Newcastle, Adelaide and Perth as well as launching passenger services between England, Mauritius and New Zealand. Gibbs, Bright also held a number of financial agencies from British mortgage, finance and investment companies as well as representing several British insurance companies in Australia. In addition they conducted a growing import business as well as an export business that included livestock, dairy produce, wool and flour. Also the company played a substantial part in the development of Australia's mineral resources, starting with lead in 1895, and later venturing into tin, gold, copper, cement and super phosphates. In Australia, after WWI, many of the larger companies were managing their own import and export so Gibbs, Bright and Company tended to focus its Agency business on smaller companies while expanding their interest into other markets such as timber, wire netting, zinc, stevedoring, road transport, marine salvage, gold mining as well as mechanical, structural, electrical and marine engineering. The Company's shipping interests continued to grow as well and still formed a major part of its business. In 1948 the parent company in England took the major step from tradition when they changed the business from a partnership into a private limited company. The name was the same, Antony Gibbs and Sons Limited, and in practice the effect of the change was very little. Some of the firm's branches and departments had already become limited companies and the formation of a parent company simplified the structure. The Australian operation was in time changed to Gibbs Bright & Co Pty Ltd in 1963. In 1848 Alfred Krupp becomes the sole proprietor of the company which from 1850 experiences its first major growth surge. In 1849 his equally talented brother Hermann (1814 - 1879) takes over the hardware factory Metallwarenfabrik in Berndorf near Vienna, which Krupp had established together with Alexander Schöller six years earlier. The factory manufactures cutlery in a rolling process developed by the brothers. Krupp's main products are machinery and machine components made of high-quality cast steel, especially equipment for the railroads, most notably the seamless wheel tire, and from 1859 to an increased extent artillery. To secure raw materials and feedstock for his production, Krupp acquires ore deposits, coal mines and iron works. On Alfred Krupp's death in 1887 the company employs 20,200 people. His great business success is based on the quality of the products, systematic measures to secure sales, the use of new cost-effective steel-making techniques, good organization within the company, and the cultivation of a loyal and highly qualified workforce among other things through an extensive company welfare system. From 1878 August Thyssen starts to get involved in processing the products manufactured by Thyssen & Co., including the fabrication of pipes for gas lines. In 1882 he starts rolling sheet at Styrum, for which two years later he sets up a galvanizing shop. The foundation stone for Maschinenfabrik Thyssen & Co. is laid in 1883 with the purchase of a neighboring mechanical engineering company. In 1891 August Thyssen takes the first step toward creating a vertical company at the Gewerkschaft Deutscher Kaiser coal mine in [Duisburg-]Hamborn, which he expands to an integrated iron and steelmaking plant on the River Rhine. Just before the First World War he starts to expand his group internationally (Netherlands, UK, France, Russia, Mediterranean region, Argentina). info from The company thyssenkrupp - History https://www.thyssenkrupp.com/en/company/history/the-founding-families/alfred-krupp.htmlHistoric - Victorian Railways - Track Rail - made by Krupp in 1888Section of VR Krupp 1888 Rail mounted on a piece of varnished wood. Rail made of ironpuffing billy, krupp, rail, victorian railways