Showing 780 items

matching knife-grinder

-

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPhotograph - Black and white photographs, James (Jim) Pleasance, Pruning Display

Black and white photographs of various sizes pasted on cardboard for display purposes. Some annotated. (1) (2) Difference between leaf and fruit buds. (3) "The 'rod' or whip is most suitable plant to commence training." (4) Planted and pruned fruit tree. "School of Horticulture and Primary Agriculture Burnley B. 1 " stamped on reverse. (5) "Pear Tree-Unpruned (1) June." (6) "Same Pear Tree-Pruned (2) June." (7) Young unpruned "William bon Chretien". Reverse, Burnley Stamp. (8) Same tree pruned. Reverse, Burnley Stamp. (9) Unpruned pear tree. (10) "Narrabben" plum before inserting branch spreaders. (11) With branch spreaders. (12) Close up of some of its branches without spreaders. (13) Close up of branch with seaders. (14) Plum tree with spreaders. (16) Close up of fruiting spurs. (17) "Apple Blossom Oct. Reverse, p 163(Oct." )(18) Same photograph enlarged. (20) Close up of fruiting buds. (21) Old unpruned apricot tree. (22) "Unpruned branch of apricot tree." (23) Close up of apricot branch. (24) "Same branch-apricot-pruned June Reverse, p99 (June)."(25) Pruned branch stump of mature fruit tree.(26) "Clean saw cuts with sharp knife." (27) "Treat all large wounds on trees to avoid infection by wood rotting fungus." (28) "Apply coating of lead paint or grafting mastic." (29) "Branch of lemon-unpruned Aug. Reverse, p157 (Sept.)." (30) "Same branch of lemon-pruned Aug. Reverse, p 157 Aug."(31) "Young climbing rose-ready for planting-July." (32, 33) Grape vine before pruning. (34) Same vine pruned and trained. (35) Older vine pruned.fruit bud, rod, whip, school of horticulture and primary agriculture, burnley, pear tree, spreaders, plum tree, apricot tree, fungus, lead paint, lemon, roses, grape vine, leaf bud, training, fruiting spurs, apple blossom, grafting mastic, teaching, a w jessep -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Guillotine, c. 1880's

This guillotine is a hand operated machine specifically designed to cut through multiple sheets of paper or card. It has a very heavy and sharp single blade knife mounted between vertical guides or runners. The main users of a machine like this is in by the printing and publication binding industry. Book binding companies use a guillotine to evenly trim the pages of a book after it has been bound. The way the guillotine is used is - paper or card is stacked squarely on the flat table and pushed firmly against the back guide - the handle below the table at the front of the machine is wound around, which brings the back guide forward, pushing the paper stack forward and positioning the centre of the stack below the vertical frame - the upper wheel is wound around, which brings the clamp and firmly in position on top of the paper, to hold it very firmly - the large wheel on the side of the machine is turned around to lower the long sharp blade down onto the pages and cut them through. The sharp edge of the blade is protected somewhat from becoming blunt; a block of wood sits in the table under the stack of paper An early model of a guillotine was patented in 1837 by Thirault, who built a model with a fixed blade. Guillotines similar in principal to this one were patented by Guillaume Massiquot in 1844 and 1852. Over the years many improvements have been made and operation has moved from man power to electricity. Oscar Friedheim Ltd. was the importer and wholesaler of a large range of machinery and equipment for the printing and bookbinding industry. He sold most of his equipment under his own name. On this guillotine or paper cutter he refers to the origin of the guillotine’s manufacture only as “German Manufacrure”. A reference book “Commercial Bookbinding: a description of the processes and the various machines used" by Geo. Stephen, 1910, recommends Oscar Friedheim, amongst others, for the supply of “reliable cutting machines for hand or power”. It also recommends Oscar Friedheim’s for a wide range of other printing machinery and processes. OSCAR FRIEDHEIM LIMITED, LONDON Oscar Friedheim Ltd. was established in 1884 and operated from Ludgate in London. The company was an importer and wholesale supplier in the 1880’s, offering machinery and equipment for the printing and packaging industry for the UK and Ireland. The company became incorporated in 1913. An advertisement of 1913 includes a telegraphic code plus two telephone numbers for Oscar Friedheim Ltd and invites readers to call at the Ludgate, London, showrooms to see the machines working. The company later became Friedheim International Ltd. The book titled “Friedheim, A Century of Service 1884-1984 by Roy Brewer, celebrates Oscar Friedheim’s achievements. Friedheim International currently operates from Hemel Hempstead, on the northern outskirts of London UK. It promotes itself as “… the leading supplier of finishing, converting and packaging machinery to the printing, graphic arts, and highly varied packaging industries in the UK and Ireland. The company’s policy is simple – “employ the best people, work with the best equipment manufacturers in the world, and treat our customers as partners!” The company still sells guillotines. The guillotine is significant for its ability to represent aspects of the printing trade in Warrnambool and in a typical port town circa 1850 to 1910. It represents communication methods and processes used in the time before electrically powered equipment became common in industry.Guillotine (or paper cutter), hand operated. Metal framework with vertical guides, stand and metal mechanical parts including wheels and gears. Table with back guide; handle below front of table winds to move the back guide. A wheel at top of machine winds to adjust pressure of the clamp on the work on the table below it. The cutting blade fits between vertical guides; a timber insert in the table below the blade helps minimise the loss of sharpness of the blade. A handle on the side of the machine turns a large spoked wheel, which rotates a large gear, causing the blade to move up and down. Makers details are on a small oval plaque with embossed maker’s details is screwed onto main body. Maker is O Friedheim, London, and the machine is of German manufacture, circa late 1880’s.Maker’s plaque inscribed "O. FRIEDHEIM / London / German Manufacture"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, printing machinery, printer’s guillotine, paper guillotine, paper cutter machine, oscar friedheim ltd london, friedheim international ltd, bookbinding industry, printing industry -

Vision Australia

Vision AustraliaEquipment - Object, Telesensory Systems, Optacon, 1974

The Optacon OPtical-to-TActile-CONverter is a compact, portable reading aid for the blind. It is about the size of a textbook, and weighs less than 2kg. It works by converting a printed image into a tactile image that a blind person can feel with one finger. After a period of training and practice, a blind person can use the Optacon to read ordinary books, magazines, newspapers, and other printed materials. The Optacon was developed after intensive research at Standford University, California, USA and was trialed by clients of the Royal Victorian Institute for the Blind (now part of Vision Australia) in 1973. It has three main sections: 1 a miniature camera, 2 an electronics section, and 3 a tactile stimulator array. The miniature camera, about the size of a pocket knife, is mounted in a housing that has rollers for easy movement along a line of print. The camera is connected to the electronics section by a lightweight cable. The electronics section and the tactile stimulator array are in the main chassis. The array consists of 144 tiny metal rods arranged in six vertical columns and 24 horizontal rows. Each of the rods can vibrate independently. The tips of these rods protrude through holes in a concave finger plate where the index finger is placed flat in order to read. These three components act together to convert the image of a printed letter or other shape into a pattern of vibrating rods, a tactile image of the letter or shape. The letter shape is tactually perceived as an image that moves from right to left on the finger, showing the left or leading edge of the letter first. Letters are felt sequentially rather than all at once, and the image should be kept moving. The Optacon converts a printed O into a tactile form that resembles a crater with a vibrating rim -- a completed circle. C would have a gap or opening on the right side of the curve. The letter F would be felt, sequentially, as a vertical line with two trailing horizontal lines. Because it can convert any ordinary printed image into a corresponding tactile image, the Optacon is not restricted to any special typestyle or language. The camera has a zoom lens that compensates for differences in the size of type. The standard Optacon lens can accommodate type sizes from 6 point to 20 point. With the optional F4A magnifier lens, type sizes as small as 4 point can be read. Powered by a rechargeable battery, and comes with its own battery charger. The battery is contained within the main chassis, and is not removable by the user. There are four basic controls on the Optacon: the Magnification Adjustment zoom button located on the camera section on the side opposite the rollers; and the On-Off switch, the Stimulator Intensity Adjustment knob, and the Threshold Adjustment knob located on the right side of the front panel. The Circuit Breaker protrudes from the right-hand wall inside the chassis compartment. From left to right when the back panel is facing you, are located: the jack for connecting the battery charger; the Battery Check button; the Normal-Invert switch; and the Input/Output I/O connector for use with the Visual Display, when using the Repeater Cable to connect two Optacons to one another or with other accessories. Designed not be removed from the leather case during normal operation, the On-Off switch is a slide switch located on the right side of the front panel. It slides up and snaps into place in the on position. 1 black with orange front, rectangular device in leather case assistive devices, audio equipment -

Melbourne Tram Museum

Melbourne Tram MuseumAlbum - Ron Scholten Slide Collection, Ron Scholten

Photo - see pdf file for further information. Number Brief Description RSC1 PCC 1041 at the gates of Preston Workshops on a test run without it’s trolley retriever RSC2 PCC 1041 in Glenhuntly Road on Route 67 en route to Carnegie crossing the Railway Gates at Glenhuntly Station RSC3 W2 482 stored at Malvern Depot with Olympic Park on the Destination RSC4 Cable Car Set 64 in Swanston St outside Princess Bridge Station in Bound with open top Double Deck Bus, Trak Motors ? Departing from Flinders St Station RSC5 W3 669 in St George Rd at Sumner St en route to Preston Workshops for scrapping RSC6 Cable Car in Lygon St en route to Carlton RSC7 PCC 1041 turning from St Georges Rd into Miller St to enter Preston Workshops RSC8 Flinders St Station with cable cars RSC9 PCC 1041 in strife on it’s maiden day in service. Trams on route 88 delayed in Queens Parade Clifton Hill RSC10 Flinders St at William St with Cable Cars RSC11 L 104 on the fan of the new shed at Malvern Depot on a TMSV tour RSC12 Cable Set 1 after it’s restoration at Preston Workshops on the fan near the front gate RSC13 X1 466 at a suburban terminus of the Footscray System RSC14 X2 680 at Point Ormond Terminus RSC15 An ex Launceston Tram at the outside terminus of the Penny Royal Complex Tramway in Launceston RSC16 Q 148 at Preston Workshops awaiting disposal RSC17 Elizabeth St with Cable Cars RSC18 Elizabeth and Bourke St corner outside the GPO with cable cars RSC19 Collins St with Cable Cars RSC20 A photo taken from the observation deck of the ICI building showing a view of Parliament house with a w class tram in Nicholson St RSC21 Auburn Horse car with a posed photo of all the tramwaymen employed RSC22 Cheltenham Double Deck Horsecar with a full load of passengers RSC23 City of Northcote cable trailer 3 at a terminus RSC24 City of Northcote Cable cars passing in High St Northcote RSC25 St Kilda Rd at Princes Bridge with Cable Cars RSC26 Flinders St with Cable Cars RSC27 Cable Cars RSC28 Bourke St looking towards Elizabeth St from Queen St RSC29 Cable cars in Bourke St at Elizabeth St looking East RSC30 Cable cars in Elizabeth St at the terminus at Flinders St RSC31 Cable cars in Bourke St at Swanston St looking west RSC32 Cable cars in Swanston St at Flinders St looking North RSC33 Cable cars in Collins St near Russell St RSC34 Cable cars in Elizabeth St at Bourke St RSC35 Cable cars in Collins St at Elizabeth St RSC36 Cable Cars in Swanston St at Flinders St RSC37 Cable cars in Collins St RSC38 Cable Cars RSC39 Cable cars in St Kilda Rd near Princes Bridge RSC40 Cable cars in Collins St East of Swanston St RSC41 Cable cars in Spring St outside Parliament house RSC42 K 92 in M&MTB Chocolate and cream livery but with a P&MTT Destination box on Route 14 RSC43 Thornbury depot viewed from Miller St and St Georges rd. Two W2 class cars are laying over between the peaks RSC44 Z3 201 in Met Livery passes D1 3510 in new M Tram livery. A Staff member in uniform stands in the doorway. Dandenong Rd RSC45 D1 3530 advertising Heinekin Super Golf on Route 55 in Royal Park RSC46 D1 3504 in M Tram livery on the reserved track in Matthews Ave near Essendon Airport showing Route 81 Travancore . I suspect it is a private enthusiasts charter due to the Malvern W class run number in the rear windscreen RSC47 D1 3504 on Route 64 in Dandenong Rd in M Tram Livery RSC48 D1 3504 in M Tram Livery at Airport West Terminus RSC49 D1 3504 in M Tram Livery in Union Rd outside the Showgrounds RSC50 D1 3504 at West Maribyrnong Terminus in M Tram Livery RSC51 D1 3503 in M Tram Livery in Malvern Depot RSC52 SW6 960 and VR 53 in Harbour Esplanade for the NMEL&T Co Centenary RSC53 Hawthorn Tramways Trust 32 in Harbour Esplanade for the NMEL&T Co Centenary RSC54 VR 53 & B 2042 in Harbour Esplanade for the NMEL&T Co Centenary RSC55 VR 53 & C 3016 in Harbour Esplanade for the NMEL&T Co Centenary RSC56 NMEL&T Co 13 usually V214 in Harbour Esplanade for the NMEL&T Co Centenary RSC57 NMEL&T Co 13 usually V214 at Preston Workshops for the NMEL&T Co Centenary RSC58 Hawthorn Tramways Trust Lettering on HTT 32 in Harbour Esplanade for the NMEL&T Co Centenary RSC59 Hawthorn Tramways Trust 32 in Harbour Esplanade for the NMEL&T Co Centenary RSC60 Hawthorn Tramways Trust 32in Harbour Esplanade for the NMEL&T Co Centenary RSC61 Hawthorn Tramways Trust 32 in Harbour Esplanade for the NMEL&T Co Centenary RSC62 NMEL&T Co 13 usually V214 at Preston Workshops for the NMEL&T Co Centenary RSC63 W2 516 and another on route 59 wait to shunt at Essendon Airdrome Terminus as W2 571 on route 49 departs. This was the last day of operation. RSC64 Australia’s First Electric Tram at Box Hill with Tramwaymen including H J Hilton who is in the centre RSC65 W2 484 en route to St Kilda Junction and another wait for passengers after a race meeting at Caulfield Racecourse RSC66 X1 463 on the Footscray system en route to Russell St RSC67 Geelong 35 on Chilwell Route, Formerly HTT 13, M&MTB 119, then Bendigo 1 and Ballarat 37 RSC68 P&MTT 4 on Opening Day of the system in Glenferrie Rd RSC69 Bendigo 6 in McCrae St near the Depot end route to North Bendigo RSC70 P&MTT 4 in Glenferrie on opening day of the System RSC71 Scrubber 3 stripped and awaiting scrapping at Preston Workshops RSC72 Scrubber 4 at South Melbourne Depot RSC73 Q 191 & 139 at Preston Workshops awaiting scrapping RSC74 Rail Grinder 3 at Preston Workshops as purchased from Sydney RSC75 Y 469 waits to shunt at Wattle Park Terminus as Y1 613 departs on driver training duties RSC76 VR 53 on the outside roads at Essendon Depot RSC77 W5 796 with three doors and square windows running out of Brunswick Depot in Cameron St, with a supplementary destination board showing “City via Swanston St” RSC78 W2 258 on the wheel grinder road at Brunswick depot RSC79 X2 676 on a TMSV tour, W5 817 & 836 & VR 53 on the open roads at Essendon Depot RSC80 PCC 1041 on test, passes W71035 in High St Preston RSC81 D1 class production number 7 as delivered on test in Matthews Ave RSC82 W2 383 on route 5 turning from the reserved track in Dandenong Rd into St Kilda Rd at St Kilda Junction RSC83 Z3 204 as advertising tram for Vodaphone Grand Prix running into Malvern Depot new shed RSC84 Z1 4 on test in St Georges Rd RSC85 PCC 1041 on Route 96 in Burke St near Exhibition St RSC86 Z1 3 without numbers on test turning from Miller St in St Georges Rd RSC87 Track components stored in Coldblo Rd at Malvern Depot with Z class cars adjacent RSC88 D1 3501 in M Tram Livery on Route 55 in Peel St at Franklin St RSC89 C 3001 in Yarra Trams Livery Porto 018 & D13502 in M Tram Livery on Display in Harbourside Esplanade RSC90 D1 class tram production number 7, in as delivered condition on test in Matthews Ave RSC91 D1 3503 inside Malvern Depot RSC92 SW6 955 and W6 974 in St Kilda at City Rd at Dusk RSC93 Freight Car 19 at Preston Workshops in green Livery RSC94 Rail Grinder 3 in green Livery at South Melb Per Way Yard RSC95 A SW6 class car on route 50 shunting at Elizabeth St Terminus at night, taken from Flinders St Station RSC96 W2 588 & 435 in St Kilda Rd at Batman Ave RSC97 Y1 613 in service at Wattle Park Terminus RSC98 W2 588 in Wellington Parade en-route to the City with a Grand Final Load of passengers followed closely by 384 RSC99 W2 558 on a MCG Footy Special entering the Simpson St sidings RSC100 W3 657 & an L Class in the new shed at Malvern Depot RSC101 Y1 613 in St Kilda Rd on an enthusiasts tour in St Kilda Rd south of St Kilda jun RSC102 Y1 613 on an enthusiasts tour in Clarendon St with the two extra tracks on the Viaduct under construction RSC103 W6 976 on the fan of the new shed at Malvern Depot RSC104 W7 1024 as an advertising car for Bank of NSW at the route 1 terminus at South Melb Beach RSC105 PCC 980 on route 96 in Nicholson St near North Fitzroy Depot RSC106 SW6 890 with dash canopy lighting in Market St on the opening day of William St Services RSC107 W2 444 with big numbers heads a line of footy specials in Simpson St Sidings RSC108 Cable Cars in Elizabeth St RSC109 NMEL&T co 2 with a trailer outside the power station in Mount Alexander Rd RSC110 Alf Twentyman’s cable car set in his Northcote backyard RSC111 Cable Cars in Queens Parade Clifton Hill RSC112 Cable cars in Collins St outside the Townhall RSC113 PCC 1041 at Carnegie terminus RSC114 Cable cars in Elizabeth St RSC115 Cable cars in Collins St near Swanston St RSC116 HTT 19 turns from Riversdale Rd into Camberwell Rd at Camberwell Junction RSC117 W1 419 official builders photo of first car of the class RSC118 Cable car with a full load of passengers RSC119 W1 422 illuminated for the visit of T.R.H. The Duke and Duchess of York RSC120 PCC 1041 in strife on it’s maiden day in service. Trams on route 88 delayed in Queens Parade Clifton Hill RSC121 Bendigo birney in Finn St near North Bendigo terminus RSC122 SW6 in St Kilda Rd at Domain Rd at night RSC123 All 3 of Alf Twentyman’s cable cars in his Northcote backyard RSC124 Cable trailer 256 being unloaded into the shed at Bylands RSC125 Cable grip car 1 being removed from the Melbourne Museum RSC126 Alf Twentyman's cable cars in his Northcote Backyard RSC127 Alf Twentyman's cable cars in his Northcote Backyard RSC128 Alf Twentyman's cable cars in his Northcote Backyard RSC129 Alf Twentyman's cable cars in his Northcote Backyard RSC130 W class car in Swanston St at Collins St RSC131 Y1 469, L & W3 on the run out of Glenhuntly Depot on a tour RSC132 W7 1024 as an advertising tram for Bank of NSW at Clifton Hill RSC133 W2 496 on a footy special in Simpson St Sidings RSC134 W2 as originally converted to a test car at Preston Workshops RSC135 W3 667 in Brunswick Depot with Ellen Butland at the controls RSC136 W3 669 on it’s final run at Victoria Prd & Brunswick St RSC137 W2 571 in Wellington Prd at Clarendon St with a Footy Final load of Passengers RSC138 Y1 613 shunts at Spencer St Terminus as X217 waits on Australia Day Pageant RSC139 PCC 1041 on Rt 96 in Burke St outside the Southern Cross Hotel RSC140 890 with accident damage on the outside roads at Preston Workshops c1978 RSC141 535 on Rt 4 at the old St Kilda Jun c1967 RSC142 1041 on Rt 88 turns from Bourke St into Spring St 1973 RSC143 102 on a tour at Albert Park Beach Terminus Feb 1972 RSC144 833, 835 & 834 in the shed at Malvern Depot c1976 RSC145 281 in Wellington Parade on a football very crowded special c1974 RSC146 464 Ballarat Rd 1960 RSC147 181 Explosives Fty - at Footscray Station - July 1960 RSC148 181 Williamstown Road 1960 RSC149 Cable car set at Alf Twentyman’s c1970 RSC150 X 217 at Malvern Depot c1970 RSC151 X1 465 and T181 Footscray Football ground in Barkly St. c1960 RSC152 Scrubber 5 at South Melbourne depot c1960 RSC153 X1 465 Footscray to Russell St, c1960 RSC154 X1 467 Leeds St Footscray 1960 RSC155 PMTT 4 Glenferrie Road, 1910 RSC156 S 164 at Malvern Depot c1970 RSC157 T178 Footscray c1960 RSC158 Cleaner No. 7 at South Melbourne depot c1960 RSC159 Two Y classes at Princes Bridge / Batman Ave mid 1950s RSC160 Swanston St – Nu color vue slide – M142 Demonstrates the work of Ron Scholten in photography, collection and/or production of duplicate slidesAssembled album in a black presentation folder of 160 colour slides, 8 slide sleeves, collected or produced by Ron Scholten. Many are TMSV or Windsor Publications slides. All photographs have been scanned and placed on the Museum's G drive. A list of all photographs with details has been compiled. melbourne, tramways, trams, cable trams -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Domestic object - Dressing bag, Mary Glass Dickson, Circa1885

John Glass Cramond 1829 and James Dickson 1831-1910 were founders of a large drapery store. Both were Scots and both came separately to Australia in 1852. Cramond initially came for gold but soon opened a store in St Kilda with a post Office attached and he was the first post master there. Dickson was a farmer’s son but became a draper and while he was unsuccessful on the Bendigo diggings and then returned to Melbourne where he met Cramond and soon after they opened a store on Lonsdale Street. They opened their business in Warrnambool in 1855 as a general store with groceries, drapery and ironmongery. Both partners were involved with the community and James Dickson was an original director of the Warrnambool Woollen Mill 1909 and the Warrnambool Cheese and butter factory. He also served on the committee of management of Warrnambool Base Hospital. This case was a wedding gift from James Dickson Jnr to his wife Mary Glass Cramond on the occasion of their wedding. This item has significance on a number of levels. It belonged to a member of one of Warrnambool’s earliest pioneering families and it marks the occasion when the two families of Cramond and Dickson were linked through the marriage of James Dickson jnr and Mary Glass Cramond. The firm played a significant part in the development of the city and traded for nearly 150 years. It therefore has social significance to Warrnambool. The item is well provenance with the case initialed and items within the case monogrammed. The case and its items are aesthetically quite beautiful as well as being typical of travelling or dressing cases of the more well to do, of the time. Mappin & Webb were manufacturers of some standing with the Mappin name appearing in manufacturing as early as 1775.The company has held a royal warrant as silversmiths since 1897 to the present day and as crown jeweler since 2012. Throughout this time, they have manufactured quality items for the luxury market. It provides an insight into the way ladies travelled and the items which they considered essential. This consists of a black leather with leather handle attached with brass fittings. Middle opening with side pocket on one side with metal catches. Inside has removable sections for holding the numerous containers and items belonging to the case. Interior of the case is dark blue satin. The items contained within the case are as follows: 321.1 Luggage case 321.2 Glass bottle rectangular, silver monogrammed lid, empty. 321.3 Tall round glass bottle, silver monogrammed lid, empty. 321.4 Small glass bottle with pink powder, silver monogrammed lid. 321.5 Small multi sided bottle with stopper and brass hinged lid. 321.6 Tall round bottle with silver monogrammed lid. 321.7 Tall thin multi sided bottle with brass lid. 321.8 Cream coloured monogrammed jar cotton wool inside. 321.9 Clothes brush rectangular cream back. 321.10.1Glove stretcher bone coloured .10.2 Case black leather. 321.11.1 hair comb cream with silver edge .11.2 Case black leather 321.12 Hair brush cream handle 321.13Spatula cream monogrammed 321.14 Mirror, silver round with handle. 321.15 Writing compendium .1 Case black leather .2 Pen with nib .3 Lead pencil .4 Navy satin covered blotting book 321.16 Inkwell glass bottle in small black leather case. 321.17 Match striker in leather case. 321.18 Mirror in black leather case rectangular 321.19 Small case for visiting cards. 321.20Sewing kit rectangular, contains threads and needles pkts x 3 321.21Container, small, hinged tortoise shell patterned. 321.22.1 Manicure set .2 Scissors small .3 Scissors large .4Corkscrew with Mother of pearl handle .5 Pocket knife with Mother of pearl handle .6Tweezers with Mother of pearl handle .7 File with Mother of pearl handle .8 Fine hook Mother of pearl handle .9 Bodkin .10 Bodkin 321.23 Hairbrush oval silver backed 321.24 Mirror silver handled hand mirror. 321.25 Hairbrush wooden handled with Mother of pearl inlay. 321.26 Cylinder, silver with removable lid and small phial of iodine labelled Felton’s pocket iodine. 321.27 Phial small glass with gold decorations. 321.28 Inhaler with insert 321.29 Thimble, metal. 321.30 Silver backed hair brush 321.31 silver backed clothes brushEngraved on side pocket: M.G.D. Mappin and Webb Sheffield and London. Some of the items are monogrammed as per the list above. A number of the glass bottles have lids hallmarked Mappin & Webb London and Sheffield makers stamped inside lid with hall marks history of warrnambool, cramond and dickson, mary glass cramond, dressing bag, woman's toiletry bag 1880 -

The Beechworth Burke Museum

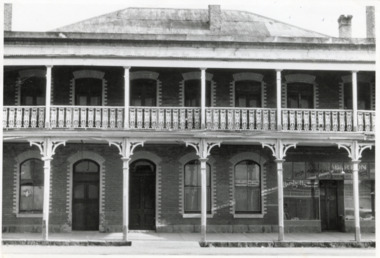

The Beechworth Burke MuseumPhotograph - Two Photographs, Saunders, 1864-1972

Taken some time after 1864, these photographs depict the Star Hotel both directly (8674.1) and from the Hotel north west down Ford Street (8674.2). The images depict the building with its modern exterior, having settled for this brick form after several other building designs. The Star Hotel was the first hotel opened in Beechworth, and would go through a series of dramatic changes under its first three owners. The original timber structure was built by W.H. Neuber, though at the time it was only known as ‘The Beechworth Hotel’. The site was later purchased in 1855 by mining entrepreneur, and prolific business owner, John Alston “Six Stars” Wallace. He would go on to extend the established hotel, rebuilding much of it with weatherboard and a shingled roof, adding a two storey structure with a verandah and a theatre capable of supporting 400-500 people, which was often used for international performances. Renamed as the Star Hotel, it was the second in a chain franchise, eventually leading to the “Six Stars” moniker Wallace went by, with hotels at Rutherglen, Chiltern, Yackandandah, Bright, Snake Valley, and of course, Beechworth. Under his ownership, it developed into a popular location for merchants, wayfarers, and locals alike, with the help of his brother Peter as manager. Situated on a road once synonymous with Melbourne to Sydney roadtrips, and the allure of the gold mines, the popularity of the Star drew all manner of clientele from across the country. As such a central hub, the ‘Star Assembly Rooms’ were used as a meeting place for debates, discussions, festivities, and problem solving among the various working sects of the area. These meetings included shareholder discussions for prospecting companies, railway planning, council meetings, and discussions surrounding the interactions between European and Chinese miners, both good and bad. By late 1856, John had the Beechworth at auction through J.H. Grey & Co. It was most likely due to the high profile murder of the manager, Robert Murdoch, during an altercation in relation to a dine and dash event by a Swedish miner, Charles Jansen, who had been ‘excited by drink’ on November 17th. He had refused to pay for his meal and waiter James Mitchell failed to persuade him otherwise. Mitchell, or possibly Murdoch himself, forced him out as tempers and threats escalated. As the photos tell, there are a number of doors which may be entered through, and Jansen used an alternate entrance to access the building. Murdoch was investigating the noise when he encountered the furious man. He was subsequently stabbed with no warning by a small clasp knife, as he tried to stop the intrusion. His exclamations, "I’m stabbed, I’m stabbed!” alerting other occupants, and Jansen was restrained and arrested. Murdoch died the next day from his injuries, with the inquest carried out on the theatre stage. Some 3000 members of the town attended the funeral, and the Star hung black cloth in memory of Robert and his death. Afterwards, an auction caw the property pass to Messrs Robertson and Quirk, though would return shortly thereafter to Six Stars’ portfolio. Six Stars would later sell off his properties from 1862, with the Beechworth Star purchased by 1864 by John Sitch Clark. This allowed Clark to redevelop a significant portion of the Hotel, stripping a central section and constructing the brick structure that survives today, reopening the Star in July that year. It was after this time that our photographs were taken. Clark would later sell the property to Frank Mitchell, shortly before his own death. The next owner, Frederick Allen, lived on the property before the deed was sold to him in the 1880s. He would later sell the property to William Carroll in 1890, with proprietorship eventually moving to Mr. W.H. Porter, and transferring to a Mr. Marendaz by 1913 and Mr. Holly in 1915. Licensing disputes would arise 1917 between Margaret Carroll and a Mrs. McDonald, before it became delicenced some years prior to 1935. It was around this year that the property was bought by Mr. W.J. Pemberton at the meagre price of £500, down from the £13,000 Six Stars originally auctioned it for. It served as a Youth Hostel for a period of time around 1972, and currently the building serves as a private accommodation on the second floor, with shops taking up the ground floor level.These photographs of the Beechworth Star Hotel as they depict a form of Beechworth's first hotel, and also the site of a high profile murder. Two black and white rectangular photographs printed on matte photographic paper.8674.1 (reverse) Beechworth/ 734/ Tanswell’s Hotel [crossed out]/? Old Star/ Hotel,/[small pencil scratching]/ Saunders/ BMM 8674.1 8674.2 (reverse) Beechworth/ 60%[circled]/ Old Star Hotel/Building etc.,/ 12 ½ cm/ 3"[circled, arrows extending horizontally to edges]/[arrows extending top to bottom mid-right of reverse]/ Saunders/ 734[circled]/ BMM 867.2,/ [thin scribbled bordering around top, right, and bottom edges]star hotel, beechworth hotel, john alston wallace, ja wallace, john sitch clark, frederick allen, robert murdoch, meeting place, tragedy, theatre, mining town -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, Australian Commonwealth Engineering Standards Association, "Flame proof air break switches for Voltages Not Exceeding 600Volts"s", 1926-1932

.1 - Book - 20 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Air-break knife switches and laminated brush switches for voltages not exceeding 660Volts" - C23 - 1926, August 1926" .2 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Flame proof air break switches for Voltages Not Exceeding 600Volts", C25-1926, October 1926. .3 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Flame proof air break circuit breakers for Voltages Not Exceeding 600Volts", C26-1926, October 1926. .4 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Totally Enclosed air-break Circuit Breakers for Voltages not exceeding 660 Volts" - C27 - 1926, September 1926. .5 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Totally Enclosed air-break Switches for Voltages not exceeding 660 Volts" - C28 - 1926, December 1926. .6 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard "Metallic Resistance Materials for Electrical Purposes" - C29-1926, November 1926. .7 - Book - 28 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Face Plate controllers and resistances for use therewith Electric Motors (DC and AC Slip ring)" - C31-1926 - December 1926. .8 - Book - 28 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Australian Standard "Contactor Controllers and Resistances for use therewith Electric Motors (DC and AC Slip ring)" - C32-1926 - December 1926. .9 Book - 36 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Electrical Performance of Industrial Electric Motors and Generators with class A insulation" - C34-1927, October 1927 with a green label dated September 1932 advised that the tentative standard has been endorsed as a Standard with amendment. .10 - Book - 56 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Electrical Performance of Large Electric Generators and Motors - Rating permitting overloads" - C35-1927, April 1927 with a green label dated September 1932 advised that the tentative standard has been endorsed as a Standard with amendment. On top right hand corner has the date stamp of the "The Electric Supply Co. of Victoria Ltd Ballarat" trams, tramways, power station, standards, materials, electrical systems -

Flagstaff Hill Maritime Museum and Village

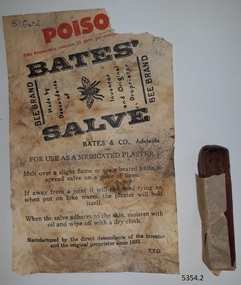

Flagstaff Hill Maritime Museum and VillageArticle - Ointment, Bates & Co. (William Usher), 1851 - mid-1900s

Bates' Salve has been used as a home remedy for the treatment of boils, skin infections, splinters, pimples and insect bites for decades, from the mid-1800s to the mid-1900s. It is a drawing application for bringing out foreign bodies and pusses from a wound. There are still many families who remember using it and others who have been using it and are down to their last ‘inch’. One comment from a reader from Queensland tells how his Dad was a sleeper cutter in the 1950s and on school holidays his brother and he used to help their Dad. When doing this task after a wet season they would be confronted with spear grass about a metre high. Sometimes the spears would enter their skin, and when the spears were wet they would screw like a corkscrew into their flesh. If they left them for too long it was impossible to dig them out with a needle. That's when the Bates Salve was put into action to draw the spearhead out. "It worked wonders. It was a marvellous invention." Many people say that they would love to be able to purchase more of it today and hope that someone will produce a ‘safe’ version of it. There are several versions of a recipe for the salve available online. It appears that the salve is named after Daisy Bates, wife of the Bates’ Salve proprietor, William Usher. William’s son Victor continued making Bates’ Salve well into the mid-1900s, with the business being carried on by Victor’s only son, Alan. There are still descendants in the family home in Norwood, Adelaide. William’s great-grandchild has stated that, despite being subject to the salve during childhood, there have been no noticeable ill effects. A small notice in the Adelaide Advertiser in 1915 made a suggestion “It is said that Bates’ Salve is the popular line with OUR BOYS in Gallipoli. They recently sent to the Adelaide Red Cross for a supply, so it would be a good line to put in soldiers’ Christmas Billies.“ Over 700 ‘Christmas Billies’ were sent from generous Warrnambool citizens to our soldiers in the trenches in Gallipoli. The average cost of filling a billy with gifts was Ten Shillings, calculated at about Fifty-four Dollars in 2021. The contents included Christmas puddings and tobacco. The huge project was coordinated by a local Committee and involved generous businesses and hundreds of kind-hearted community members, with recognition sown by naming many of those involved in an article in the Warrnambool Standard. The project’s idea was initiated by Australia’s Department of Defence and all states were involved in supporting the soldiers in this way. Mr Bates (Theopholis) of Hull, England, was the original owner of the Bates’ Salve recipe. When he died he left his business to William Usher, his son-in-law. William arrived in South Australia in 1851 after he had sold his recipe to an English firm, giving them the rights to make and sell it all over the world, except in Australia. Bates then became the registered proprietor of Bates’ Salve for the Commonwealth and still had a large market for his product. William Usher made the salve at his Norwood home, in a wood-fired copper in the garden within a three-sided enclosure. The ointment was then taken to a room in the house where it was divided, labelled and packaged. It was then sent to Faulding’s Wholesale Chemist for distribution. William and his wife May (or Mary) had three children; Jack, Victor and Ivy. When May died, William married Mary Williams (May’s maid, from Tasmania, twenty years younger than William) and had seven more children. The treatment’s packaging labels it as a POISON. It seems that its active ingredient was lead oxide (22 per cent), which is no longer considered unsafe. A member of the public mentioned that in 2016 they found some Bates’ Salve in an old family medicine chest. Its label stated that the product “contains a minimum of 25.8 per cent of red lead oxide”. That particular sample was made at 470 Wallon Road, West Molesey, Surrey, England. Some people would love to be able to use the product still and even take the risk of poisoning. Instructions for its use are included on the wrapper. Here is a transcription - "Bates' Salve. Bee Brand. POISON. This Preparation contains 22 parts per centum [lead oxide]… Made by Descendants of the Inventor and Original Proprietor. For use as a medicated plaster. Melt over a slight flame or use a heated knife to spread the salve on a piece of linen. If away from a joint it will not need tying as, when put on lukewarm, the plaster will hold itself. When the salve adheres to the skin moisten it with oil and wipe it off with a dry cloth. Manufactured by the direct descendants of the inventor and the original proprietor since 1833."This package of Bates' Salve has been used as a home remedy since the mod-1800s and even up to now in 2019 by those who consider themselves lucky to still have some at home. It was promoted as a 'cure all' treatment and kept handy for use at home and away. It represents our early industry and health management when medical treatment was often difficult to access. The product is the part of many childhood memories of those alive today.Bates’ Salve ointment; oblong stick of firm, brown waxy substance wrapped in waxed paper, with an outer printed wrapper. Text on wrapper warns that it is POISON and includes instructions for use as a medicated plaster, to be heated and spread onto linen then applied to the injury. Made by Bates & Co., Adelaide. The wrapper shows an emblem of a bee. The formula has been used since 1833.Text on wrapper includes "POISO[N]", "BATES' SALVE", "BEE BRAND", "BATES & CO., ADELAIDE". "This Preparation contains 22 parts per centum [lead oxide]" There is an emblem of a bee with wings outstretched.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bates’ salve, bates’ salve medicated plaster, bates and co adelaide, bee brand, medicated plaster, medical treatment, remedy, drawing treatment for infection, medicine cabinet, home remedy, pharmacy treatment, mid 1800s – mid 1900s remedy, topical application, treatment for boils, bites, splinters and infections, poison, preparation for treatment, ointment -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - HELEN MUSK COLLECTION: WEDDING BODICE AND SKIRT

Ivory coloured waist length silk wedding bodice with front opening. Silk fabric has alternating striped pattern of chequerboard pattern, running stitch pattern and diagonal woven pattern. The bodice is made of two layers of the silk fabric with cotton fabric lining. The front inner layer has two darts from the waistline. The back inner layer has a centre seam and three darts from the waist on either side. The outer layer on both front and back has three knife pleats falling from the shoulders creating a gathered effect. These side panels of pleated fabric create a deep V neckline by crossing over 5cm above the waist. The V shape neckline is filled with an insert of cream and dark green lace with a floral pattern. The lace insert extends to the throat to form a high round neckline. The neckline is edged with cream coloured woven cotton braid. The side edges of the outer layers are trimmed with cream lace with a floral pattern and 5cm zig zag peaked edges that extends from centre waist at the front, over the shoulders and to the crossover section at centre back where there is a decorative silk fabric flower stitched at the crossover point just above the waist. The front opening is fastened with fourteen hooks and eyes plus another hook and eye offset 5 cm above the waist at the crossover point. Set in long sleeves are in two sections. An inner layer of silk fabric widens to the elbow where two five cm frills of gathered tulle are attached. Each frill is edged with a row of silk stitching. Attached below the frills are two 7 cm strips of lace stitched together to form the lower part of the sleeve. The edge of the lace forms the hem at the wrist. Each sleeve has a 5 cm hemmed V shaped split from the hem at the wrist. The outer layer of the sleeve is bell shaped falling from the shoulder to the elbow. This section of the sleeve is edged with cream lace with a floral pattern and 5cm zig zag peaked edges that are stitched to the fabric of the sleeve. Ivory coloured full-length wedding skirt with train. The skirt is made in two layers. The under layer is made from cotton from the waist with a wide border of silk fabric - 18 cm wide at centre front, widening to 37 cm at the side seams. The back of this skirt extends to a train and the border widens to 48 cm. The border section is lined with cotton fabric. At the centre back, the border has two godet inserts to create fullness in the train. The outer layer of the skirt is of ivory silk fabric with alternating vertical stripes of a chequerboard pattern, a running stitch pattern and a diagonal woven pattern. The lower edge of the skirt is edged with an 18 cm border of lace patterned with embroidered circles. The edge of the lace forms a zig zag pattern of elongated V shaped peaks (7 cm). The front of the skirt dips to a V shape at centre front with the point of the V reaching the hemline. The back of the skirt dips below the front hemline in a U shape over the train. The waist band is made of cotton tape. The centre front of the waistband has an embroidered pattern in silk thread. The centre back opening is fastened with seven metal hooks with six cotton loops plus one metal eye on the waistband. There are two cotton tape hanging loops on either side of the inner waistband. Hand and machine stitched.costume, female ceremonial, wedding bodice -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - ANDREW - MONSANT COLLECTION: LADIES DRESS - BODICE AND SKIRT, 1909

BHS CollectionWaist length dark green cotton bodice. Fabric has alternating stripes of pulled thread pattern and wider stripes of small dot pattern. Front opening with deep V to waist with lined lace insert extending from throat to waist. LHS of bodice fastened to lace insert with five press studs. Stand up collar of lined black lace (%cm) fastened with two hook and eyes. The bodice is made from five pieces. The two front sections have three knife pleats facing out and falling from the shoulder. The pleats are stitched down for twenty cms from the shoulders. On either side of the front opening is decorative embroidered black lace that extends across the shoulders to the back of the collar. There are two side panels from under the arm. The back section has three box pleats falling from the collars and tapering to the waist. The hem of the bodice is fastened with black cotton tape. Leg of mutton sleeves are trimmed with black embroidered brais at elbow and wrist. Lower sleeves have pintucks from elbow to wrist. The sleeves are lined with black cotton fabric. The back of the bodice is lined with black cotton fabric almost to the hem. A three cm piece of white and blue cotton tape is attached across the lower back with cotton ties at either end. The underarm panels are lined with brown cotton fabric and green satin inserted sections. The front has a separate lining with front opening and shaped with darts. Fastened with six buttons and buttonholes. Two shoulder pads on each side- one white piece under the shoulder and a green satin piece under the gathered section of each sleeve. Dark green full length skirt. Cotton fabric with alternating stripes of pulled thread pattern and wider stripe of small dot pattern. Skirt is made of three sections. Centre front panel widens slightly to hemline. Side panels continue around to join at centre back. Darts at both hips to shape sides. Panels widen to hemline. Inverted pleats at either side of back opening create fullness. Back opening(30cm) has insert of black satin joined to LHS of opening to enlarge the opening. Insert attached to waist band with two press studs. Two other press studs attach skirt to RHS of insert. Brown cotton waistband hand stitched to skirt. Ties attached to waistband at back opening- one cotton tape, one satin ribbon. Front centre panel has a piece of black satin stitched as lining from eighteen cm below waist (57cm deep). Stitched across and attached to side seams. Lower edge trimmed with black lace. Second piece of satin lining stitched to centre seam and stitched around the hip to partway across back.(Looks like a nylon petticoat cut in two pieces and stitched inside skirt as a lining). Hemline has fifteen cm piece of cotton lining attached and lower edge of hem has fringed cotton binding attached.. Side seams of front panel have decorative trim of embroidered braid extending seventy-six cms from waist. Braid then turned ninety degrees and continued in a horizontal zig zag line around to centre back seam (both sides) twenty cms above hem. Hand and machine stitched.costume, female, ladies dress- bodice. -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Photograph - Colour, Sunnyside Mill Bridge over the Yarrowee, Hill Street, Ballarat, 2016, 17/09/2016

"A joint meeting of city and town ratepayers, convened by Messrs Francis Jago and Henry Johns, interested in the formation of a cart bridge in Hill street, over the Yarrowee Creek, was held on Saturday evening, in the Societies Hall, corner of Skipton and South streets, with the view of taking united action in the matter. Mr Morris was voted to the chair, : and about 60 persons were present. The chairman stated that the object of the meeting was that united influence should be brought to bear upon the City and Town Councils, so that a cartbridge should be erected. He said that Mount Pleasant would no doubt be thickly populated in a few years, and the bridge would prove a great boon to the inhabitants of the locality. By means of a cart bridge drays, would be enabled to save on their journeys to and fro between the mount and the batteries, at least a mile and a half each time. He hoped that the councillors for the south ward would assist them in this matter. Mr Jago, as one of the conveners of the meeting, said that united action on the part of both eastern and western ratepayers was requisite, so as to exert a strong pressure upon the City and Town Councils, in order that the work should be carried but. Mr Grainger moved the first resolution as follows;—“ That the construction of a cart bridge over the Yarrowee Creek at Sunnyside, to facilitate communication between the residents of the city and town, is urgently necessary, and that in the interests of both municipalities the two councils be asked to at once jointly carry out the work. In doing so he said that the necessity of a cart-bridge for the residents of Mount Pleasant would be apparent when the number of batteries, tanneries, and also the Woollen Mill, in the district were considered. The place was of growing import ance, and ready communication should at once be established. Another reason was that an immense saving in time would be effected. It was quite a common occurrence to see one, two, or three drays stuck in the bed of the creek which had gone that way to make a short cut. Now, what with the horses floundering about and breaking their harness, it seemed a wonder to him that life had not been destroyed before now, just through the want of a cartbridge. Mr Johns seconded the resolution. Mr Robert Calvert supported the resolution, and said that it was disgraceful action on the part of the representatives of the south ward that the work had not been executed long ago. They should come together like men and demand that the work should be done, and if not done they should not pay rates until it was. (A voice—“But they’ll make us.” Laughter.) The wooden footbridge across the creek was “only a wooden fabric, not fit for a Christian to walk across, and steps should be taken to remedy this also. Mr Blight, a resident of Mount Pleasant, said that, in common with others, he had been opposed to the erection of the bridge two years ago, but his views had since been altered. Cr. Morrison, who was present, said that the fault of the cartbridge not being erected over the Yarrowee at Hill street lay not with the City Council, but with their neighbors, who had always been opposed to its erection there. In 1874 a motion was carried at a meeting of ‘the City Council" by which the sum of £5OO had been voted to carry but the work. As the bridges over the Yarrowee were joint undertakings of the city and town, they had, by the provisions of an act of Parliament, called upon the Town Council to assist them in the erection of the bridge. In consequence, a conference of the two corporate bodies had taken place, when a motion was moved by Cr Howard, the representative of the south ward, and seconded by Cr Turpie, of Ballarat East—“ That the bridge should be erected at Hill street.” The motion was rejected, principally through the eastern representatives, who wanted the bridge lower down. Since then the two councils had often met to consider, the question of bridges over the Yarrowee Creek, but nothing had been done at the meetings, as the Eastern Council wanted the bridge in one place and the City Council in another. He had himself, when first elected to the council, given notice of motion affirming the desirability of a bridge, at the place now fixed upon. The Woollen Company was growing in importance, and a direct, road to its works would greatly advance its interests. For the working, expenses of each ward £400 was annually, appropriated; and this amount would not be sufficient carry out the work. They would have to obtain a special grant of about £900, as Hill street would require a culvert to be erected therein, as now it was virtually an open drain which carried the drainage of the western plateau to the Yarrowee. He advised that strong pressure should be exerted, specially upon the Eastern Council, and then the work might be carried out. He thought that if the foot bridge was repaired, and large stones thrown into the creek, it would do until the bridge could be erected. The chairman then put the resolution, and it was unanimously carried. Mr Hamilton moved the second resolution— “That Messrs Fern, Greenwood, Peirce, and Jago be deputed by the meeting to wait upon the City and Town Councils and present the first resolution; also that petitions in its favor be signed by all ratepayers interested.” Mr Haigh seconded the resolution, which was carried. Votes of thanks to Cr Morrison for his attendance, and to the chairman for presiding, were passed, and the proceedings terminated." (Ballarat Star, 9 August 1881, page 3) "WOOLLEN MILL BRIDGE YARROWEE IMPROVEMENTS Though brief the official ceremony of opening the bridge across the Yarrowee Creek, near the Sunnyside Woollen Mills, was of an interesting character. It took place at noon yesterday in the presence of the Mayors and councillors of the City and Town. Hon. F. Hagel thorn (Minister of Agriculture).Hon Brawn. M.L.C., Lt-Col Morton (Acting City Clerk). Mr J. Gent (Town Clerk of Ballarat East), Mr A. Farrer (City Engineer), Lt. L. Finch (who is about to leave for the Front, and who assisted Messrs A. Farrer and G. Maughan in carrying out the project, Mr W. Hurdsfield (Clerk of Works) and others. An apology was received from Mr J. McClelland, contractor for the work. Mayor Hill expressed pleasure in Introducing Mr Hagelthorn, who had at great personal sacrifice and inconvenience come from Melbourne to perform the opening ceremony of that beautiful bridge, which was of great improvements that had been effected.When Mr Hagelthorn was Minister of Pubic works he visited Ballarat specially to see the condition of the creek, which at that time was in a disgusting state from a sanitary standpoint. After viewing the position, and realising the justice of the claim. Mr Hagelthorn made strong representations to the Government of which the was a member with the result that it voted £17,000 for the work. That action had been the means of turning a plague spot into a thing of beauty. They therefore owed a deep debt of gratitude to Mr Hagelthorn and the Government of which he was a member, and they were particular grateful to Mr Hagelthorn for coming to Ballarat to perform the open ceremony. Mayor Levy said he could bear testimony to the good work Mr Hagelthorn had always done for Ballarat. In him Ballarat and district always had a good friend. He thought Mr Hagelthorn would feel amply gratified at seeing the good work that had been done. It would serve as some reward for the expenditure, on behalf of the residents of Bal larat, of the amount of money made available through Mr Hagelthorn's instrumentality for the two municipalities. Otherwise the City and Town councils would not have been able to carry out so necessary and so beneficial a work. There was a great amount of work yet to be done, and when the financial market became low stringent Mr Hagelthorn would no doubt be pleased to take the necessary steps to have money provided for further works which could not be undertaken at the present time. The adjacent woollen mill was a standing monument to what was being done in Ballarat, and what ever the City and Town Councils or the Government could do to encourage such manufacturing enterprise should be done, and he was glad to be able to say that was being done as far as finances would permit. He concluded by presenting Mr Hagelthorn with a gold mounted pocket-knife with which to cut the ribbon stretched across the centre of the structure as a bar to traffic. The Hon. F. Hagelthorn, who was greeted with applause said before him was a good work well done in the interests of the public. Real prosperity could only be achieved by a movement carried out by the people to increase natural productiveness. Most of them had been made aware, on account of the war par tiularly, that the people who were best equipped, the industries that were best organised, and the Governments that were most intelligently controlled would get the most of this world's goods and some of its luxuries that Would be denied other people less efficient. Any thing the Government could do to promote industry and to increase the reward of those engaged in it, both employer and employee, would be done. Most Governments would do but little in that regard. ... " (Ballarat Courier, 13 September 1916, page 4)Bluestone and iron bridge over the Yarrowee River at Hill Street, Ballarat.sunnyside mill, sunnyside woollen mill, ballarat woollen mill, bridge, yarrowee creek, francis jago, mount pleasant, yarrowee river, robert calvert -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village