Showing 2730 items

matching hand made

-

Ballarat Fire Brigade

Ballarat Fire BrigadeCertificate, just prior to December 10th, 1867

Certificate is of the pledge that the brigade made to His Royal Highness the Duke of Edinburugh at a dinner that the Duke attended at the Ballarat Fire Station on 10th December 1867 during a royal visit to the district. White timber framed pledge from the Ballarat Fire Brigade to His Royal Highness the Duke of Edinburugh during his royal visit in December 1867. Pledge is on white paper with a coat of arms near the centre at the top of the page. Lettering is mainly in black ink with some red coloured letters being used. Certificate has a light brown coloured border around it with a hand drawn scrolled decorative edge made in gold colour. To His Royal Higness / The Duke of Edinburugh / May It Please Your Royal Highness / We Othe fficers and Members of the Ballaarat Fire Brigade, an institution based upon pure philanthropic / principles, our motto being "We Strive to Save" bear to approach your Royal / Highness with feelings of devotion and attachment, and deep felt gratitude to the Almighty, for this / opportunity of envicingour loyalty to Her Most Gracious Majesty Queen Victoria, your Royal / Mother: and, of tendering a hearty Firemans welcome to Your Royal Highness, in the land of our / adoption, and the good town of Ballaarat East, our residence. / We are deeply impressed with the great honor and importance of your Royal Higness's visit to the / Australian Colonies, and beg to express our fervent wishes for your Royal Highness's safe return / to our mother country. / We have the privilege and honor, to subscribe ourselves your Royal Higness's most obedient and humble / servants. / On behalf of the Brigade / Charles Dunn, Captain Carl Franz, Lieutenant / R. Geilhofer, Hon. Secretary / Ballaarat, December, 1867ballarat fire brigade, queen victoria, his royal higness, the duke of edinburugh, december 1867, 1867, captain charles dunn, captain dunn, lieutenant carl franz, lieutenant franz, honourary secretary r geilhofer, his royal highness the duke of edinburugh -

Ballarat Fire Brigade

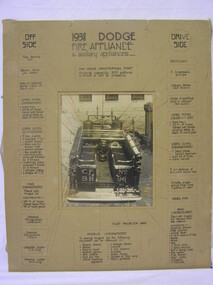

Ballarat Fire Brigadeposter

Poster was probably made as a training aide for newer members or display purposes for public talks. Original vehicle still owned by brigadeB&W photograph of brigades 1938 Dodge pumper taken from rear of appliance. Photograph shows appliance fully stowed and has an inventory of stowed equipment listed down both sides of poster with photo located in centre. aroows from item list to position on photograph appear to be hand drawn (possibly at later date) in red pen. 1938 Dodge fire appliance & auxiliary appliances, (numerous further inscriptions as per photograph of poster) -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Pliers, Henry Boker, late 19th to early 20th century

This unusual set of pliers was made in Germany by Henry Boker (Heinrich Boker). Boker hand tools were being produced in the 18th century in Remscheid, Germany. Boker tools were known for good quality and value for money. George A. Fox & Co., of 250 Victoria Street North Melbourne, were agents for Boker tools in the 1950s. Museums Victoria has a Boker catalogue in its collection dated circa 1954.These pliers are significant as an example of hand tools used in the early 20th centry or earlier. Pliers like this would typically be used in maritime trades.Pliers, double headed. This hand tool has two sets of jaws on its pair of handles. It was made by Henry Boker, Germany. Impressed into metal "HENRY BOKER / GERMANY"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, pliers, double headed pliers, henry boker, boker hand tool, german tool, german pliers, antique pliers, vintage pliers, victorian pliers, heinrich boker, tradesmen's tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to late 19th Century

... tools. Tools that were themselves hand made shows ...A jack plane (or fore plane) is a general-purpose woodworking bench plane, used for dressing timber down to the correct size in preparation for truing and/or edge jointing. It is usually the first plane used on rough stock, but in exceptional cases can be preceded by the scrub plane. Jack planes are 300–460 mm long and 64–76 mm wide, with wooden-stocked planes sometimes being slightly wider. The blade is 44–57 mm wide that is often slightly convex (or ground with rounded corners) to prevent digging in to or marking the work. The cut is generally set deeper than on most other planes as the plane's purpose is to remove stock rather than to gain a good finish (smoothing planes are used for that). In preparing stock, the jack plane is used after the scrub plane and before the joiner plane and smoothing plane. The carpenters' name for the plane is related to the saying "jack of all trades" as jack planes can be made to perform some of the work of both smoothing and joiner planes, especially on smaller pieces of work. Its other name of the fore plane is more generally used by joiners and may come from the fact that it "is used before you come to work either with the Smooth Plane or with the Joiner". Early planes were all wood, except for the cutter, or combined a wood base with a metal blade holder and adjustment system on top. Although there were earlier all-metal planes, Leonard Bailey patented many all-metal planes and improvements in the late 19th century. A jack plane came to be referred to as a "No. 5" plane or a "Bailey pattern No. 5" at the end of the 19th century. A vintage tool made by an unknown company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could remove large amounts of timber. These jack or dressing planes came in various shapes and sizes to achieve a flat and even finish to timber surfaces before the use of smoothing planes and came in many sizes. A significant tool from the mid to late 19th century that is still in use today with early models sought after by collectors. It gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting edged hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items. Jack Plane handle is attached by large screw there is a round piece of wood tacked to front. noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jack plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Broad Axe, Prior to 1950

A cooper's broad axe (or Cooper's side axe) is a short one-handed axe that has a long cutting edge intended for initial dressing of staves and heading pieces used in the making of barrels and other associated items made from wood.A tool of the cooper and other woodworking tradesmen that has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used.Broad head axe with wooden handle with handle on an angle to allow use. Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, maritime village, coopers tools, broad axe, barrel making, cutting staves -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Groove Plane, Prior to 1950

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. The subject planes blade is designed to cut a groove and it's blade maker (M Gilmour) is not listed by collectors of vintage planes as a known plane makers of the 19th or 20th century.A vintage tool made by an unknown maker, this item was made commercially for firms and individuals who worked in wood and needed a tool that could produce an ornamental finish to timber. These profiled planes came in various shapes and sizes to achieve the required decorative finish. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Grooving PlaneM Gilmour stamped on bladewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, moulding plane, groove plane, joiners tools, hand plane, carpenters tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Chair, 1890s

These oak and rattan arm chairs were previously used in the old Warrnambool Museum and Art Gallery, opened on 29th July 1886 with Mr Joseph Archibald as Curator, demolished in 1960. Chairs are significant to local history as they were originally purchased for use in the Warrnambool Museum and Art Gallery. The chairs were part of the social and cultural history of WarrnamboolChair, oak wood arm chair (set of 9), cureved back with decorated wooden edges, shield carved into top and protective metal plates on top at rear. Padded leather seat studded at edge, over rattan cane seat. Rattan cane is stitched onto wooden frame through drilled holes. Front and side legs each have two spindles between them. back legs have one. Legs are turned and slightly cambriol. Some chairs have written on back leg "1486". Made in England, c. 1896Some of the chairs have hand written black pen on back leg "1486"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, chair, arm chair, rattan chair, warrnambool museum, warrnambool art gallery, 1890s chair, 19th century furniture, domestic furniture -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plough, Syracuse Chilled Plow Co, 1876-1900

The Syracuse Chilled Plough Company was created in 1876 and specialised in the manufacture of agricultural ploughs. Harry Wiard invented the chilling process in plough manufacture. The company was originally founded as the Robinson Chilled Plough Company in 1876 and changed its name 3 years later. At its peak, in the early 20th century. The company made more than 100,000 horse-drawn ploughs and road scrapers of various designs that were sold from the Syracuse plant each year and exported around the world. The company slogan of the day was, “The sun never sets on a Syracuse plough." Eventually, other farming implements were added to the line. The company employed more than 300 people in its local plant, which covered a square block on the cities Near West Side. In 1910-11, Deere and Company began expanding its holdings, and with the success of the Syracuse Chilled Plough Company, Deere sought to acquire the company. The management of the Syracuse operation after John Deere took over remained in the hands of Wiard and Chase, and the manufacturing operations were left in Syracuse. The only change from previous Syracuse operations was the selling of the companies products through Deere retail outlets instead of directly to the trade. The factory in Syracuse continued to produce ploughs until 1955. The subject item in the Flagstaff collection is an early model Syracuse Chilled plough with a wooden beam frame it is very much lighter in weight and was adapted to work sandy or light loamy soil. This plough has a sloping landside, which tends to keep the clods and dirt from falling into the furrow, making the ploughman's work much more comfortable and easy. This design was made in eight sizes for both right and left-handed ploughing and became very popular in the far West and South of the USA. Note: The definition of a chill plough means : a plough having the share and mould-board of chilled semi steel or cast iron.The subject item is believed to be a very early plough given its wooden beam frame and was made before 1900 probably around 1880. This makes it a significant example of the types of plough that early settlers were using in Victoria. There would not be very many of this type of vintage plough left with a wooden beam and frame, making it today a desirable collector's item. Syracuse Wood Beam Chilled single furrow plough metal wheel in front. Syracuse Chiller Co Syracuse & 50 L stamped on ploughshare.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plough, syracuse chiller co, chiller plourh, farm equipment, furrow -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Musical, Piano, Aucher Freres, circa 1880-1920

This piano was made by Aucher Freres of Paris, said to be famous for its pianos in the mid-late 1800s. Aucher Freres (Aucher Brothers) produced a model of piano that was built specifically for use on sailing vessels, the upright yacht-style piano. Pianos were amongst the domestic goods brought to Australia by many colonial immigrants. They were also imported by Australian distributors by the shipload and sought after by settlers. A piano was often found in a Missions to Seamen club room, where visiting seafarers would entertain or be entertained by music and song as part of their relaxation in port. A sarcastically written news article of January 2nd 1869 reported that the Secretary of the Loyal Liberals of Ballarat, Mr Henry Bell, was presented both with a “illuminated address” and a piano. The piano was made by Aucher Freres of Paris and was purchased for sixty guineas (which converts to around $7,500 Au in 2019). The gift was criticised for encouraging foreign industry rather than native Australian products, thus going against what the Loyal Liberals own protectionist policy. The writer goes on to state that several pianos made in the Colony compared very favourably at the International Exhibition with those manufactured by the English or French. He then says that “… the secretary … might learn a lesson from his piano ... the name Aucher Freres, Paris emblazoned on its front should be … a perpetual reminder of the hollowness of that protectionist imposture …” [Refer to Intercolonial News, Victoria, originally published in The Argus, was repeated in the Wallaroo Times and Mining Journal of South Australia 2-1-1869.] Aucher Freres pianos were still around in 1930. A second-hand model was advertised for sale as a good practice piano. The advertisement was placed by the Mount Gambier, SA, agents for Saver’s Pianos Ltd of Adelaide. The piano was described as “a sound little instrument of good tone and appearance”. The asking price in November 1930 was 32 pounds and ten shillings (which converts to about $2,500 Au in 2019). [Refer to Savery’s advertisement, Mt Gambier Border Watch 11-11-1930]This piano is significant for its connection with the time period of chapel and club room at Flagstaff Hill's St Nicholas Seamen's Church. It represents the form of entertainment enjoyed by seafarer's world wide, which is appropriate for a maritime village. The maker of the piano is famous for its quality pianos of the 19th and early 20th century.Piano, upright, polished wood. The wooden hinged keyboard cover lifts up to allow access to the keyboard. The piano also has two brass candlesticks. The top of the piano is hinged and lifts up to allow access to the piano mechanic's inside for tuning and maintenance. The inside flap has a music stand incorporated into it. It also has the usual two hard-soft pedals at the base. There are two brass decorated hooks at each end to allow for ease of movement when the position of the piano is changed. Maker's name inscribed inside keyboard lid in gold lettering. Made in Paris by Aucher Freres (Aucher Brothers)."AUCHER FRERES / Paris" (NOTE: the "C" is sometimes mistaken for a "G")flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, piano, music, upright piano, paris, france, aucher freres -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageChair, 1907-1914

The design of this set of four lightweight chairs is based on Thonet’s bentwood designs, which are still some of the best-selling designs for café and restaurant owners. It is elegant, sophisticated and durable. Some of these chairs still have their original seat, under which the letters “TH” or “RSL” are hand written. Flagstaff Hill has several bentwood chairs with these letters on them, in either chalk, black paint, or both. It is believed that the chairs were used in the original Warrnambool Town Hall, and later the RSL. The Town Hall was completed in 1891, built on the corners of Timor and Liebig Streets. (In 1977 the Town Hall was declared unsafe and was later replaced by the Warrnambool Performing Arts Centre.) Some of the chairs have marks, paper labels and symbols on them that show that the maker was Josef Jaworek, who had a small furniture factory in east Sinensia, which was at that time in Austria, from 1907 - 1914. Bentwood chairs are made by a process of wetting wood in water, bending it into curved shapes, then allowing it to dry so that the shape becomes permanent. This process originated by Michael Thonet, who had been given the right to bend wood into desired curves by the Austrian Courts in 1842. In 1856 he was granted a 13 year patent to manufacture chairs and table legs of bent wood treated by steam or boiling water. In 1859 his company Gebruder Thonet produced his original design. Thonet’s early designs also featured hand carved or laminated wooden seats. His Model No. 14 was produced in the 1850’s and his most popular design. After Michael’s death in 1871 the family went on designing and producing chairs. These bentwood chairs are believed to be associated with the original Warrnambool Town Hall. The Warrnambool Town Hall played a significant role in the both the local government and the social events of local and district areas. It was a place for Council meetings, community events and entertainment, theatrical and musical.Bentwood chair (4 of 4), painted black, inner back is curled loop, seat has leather cover attached with studs, ventilation holes under seat, legs are splayed and have a bracing ring. Marks: under seat, handwritten and stamped into wood.Marked with handwritten "TH", in both black paint & white chalk. Under rim is label printed "65" Stamped into wood on rim under chair "95".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bentwood chair, café chair, restaurant chair, josef jaworek, austrian chairs, furniture -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Box plane, Stewart Spiers, mid-1900s

This small metal plane was manufactured in 1909 by Spiers-Stewart, Ayr, Ayrshire, Scotland. Stewart Spiers began making planes in Ayr in around 1840. The business continued successfully as a small operation until the mid-1930s.This plane is an example of tools made overseas and used in the 1900's. Box plane; hand operated small metal plane with round wooden knob. Plane has separate blade and blade cap. Inscription on blade cap is indecipherable. Originally marked as made by Spiers."SPIERS"flagstaff hill, warrnambool, maritime-museum, maritime village, shipwreck coast, tradesman's tool, plane, box plane, tool, spiers-stewart, early 20th century, scotland, hand tool, stewart spiers, spiers, woodworking -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, 1920s-1950s

This drill once belonged to Goodall and Sons, who were blacksmiths in Terang. The smith was called upon to do a variety of work. In the early 1900s he was often the nearest person to be able to perform an engineer’s services for many miles around. The Dawn Ball-bearing Post Drill no. 611 is described in McPherson’s Catalogue as a “drilling machine with adjustable automatic feed, with improved Dawn coupler and ball-bearing thrust’. The heavy design of the flywheel enables it to maintain momentum” and is “fitted with pulleys for belt drive if desired” The hand crank drives an automatic feed to work off a cam-follow system opposite a large wheel. Made by Dawn Manufacturing Co. Australia 1920-1950. DAWN MANUFACTURING CO. Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. In 1959 the company was taken over by G.N. Raymond Group, then in 1973 the Siddons Ramset Limited acquired Dawn. In December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. In November 1998 Dawn became 100 per cent Australian owned. HENRY GOODALL & SONS Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The drill is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the 1920s-1950s.Dawn Ball-bearing Post Drill no. 611, made by Dawn of Melbourne, model no 611. Hand operated drill press. Self-feeding blacksmiths’ drill-press. This drill once belonged to Harry Goodall & Sons, blacksmiths of Terang. Dated 1920s-1950s. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. "Dawn", "Melbourne"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall, terang 1900s, warrnambool district 1900s, post drill, blacksmith’s drill, dawn post drill, dawn ball-bearing post drill no. 611, blacksmiths, dawn of melbourne -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSeparator

Separator machine. Hand-crank operated milk separator, Crown Separator Co Pty Ltd. Multi-part separator stand with bowls (2) and attachments including a spanner small cone shaped objects on homemade stand. ."42D022" stamped on 2x separator chutes.Manufacture's plate "MADE IN SWEDEN" , "CROWN SEPARATOR / HEAD OFFICE 547 FLINDERS ST MELBOURNE". ."42D022" stamped on 2x separator chutes. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, milk separator, farm machinery, dairy machinery, dairy industry, crown spearator co, cream -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, 1869-1920

... of how furniture was made predominately by hand and with tools ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane Hollow type Marked Routledge No.8 Blade Stamped JAS Burden (owner). flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Between 1869 early 20th century

... of how furniture was made predominately by hand and with tools ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Plane, Moulding, Hollow Size No 18 Routledge Maker (Owner "J.A.S.Burden")flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Richard Routledge, Late 19th to early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use to produce a decorative moulding for a piece of furniture, door trims etc, or other timber items that had to be accomplished by using hand tools and in particular one of these types of planes. Profiled planes came in various shapes and sizes to achieve the required decorative finish. A significant tool from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Rebate Moulding plane Size 1/2"Maker R Routledge Birmingham also marked Owner Jas Burdenflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Richard Routledge, Late 19th to early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use to produce a decorative moulding for a piece of furniture, door trims etc. or other timber items that had to be accomplished by using hand tools and in particular one of these types of planes. Profiled planes came in various shapes and sizes to achieve the required decorative finish. A significant tool from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Plane Moulding type size 1/8" Maker stamped R Routledge & JAS Burden (owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Late 19th Century

... of how furniture was made predominately by hand and with tools ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane. Stamped JAS Burden (owner) also No 2flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageScale, 1920

Inventor Biography: Percival Everitt was a Norfolk-born engineer and regarded as the father of the coin-op industry. in 1884 he patented one of his many inventions the coin-operated scales. For many people, it was their first exposure to coin-operated machines. As a young man in 1877, Everitt invented a hay and corn pitcher, a turnip thinner in 1878 and an “Automatic Travelling Anchor” in 1880. But he hit his stride in 1883 with the first postcard-vending machine over a hundred of which he distributed around London. Everitt went on to invent the one penny scale which prompted the formation of the Weighing Machine Company in 1885. Further inventions followed a blow tester in 1887 also the machine for testing a person grip in 1888 and the dispensing machine that opera glasses could be hired from in 1889 also the fortune-telling machine in 1890. He also invented a mechanism to shut coin slots when vending machines were empty, but then as now vandals posed a problem by jamming paper into the slot. Everitt sadly did not make his fortune he died suddenly in February 1893, in his late forties with £71 to his name. Penny Slot Weighing Machine: When the Australian colonies federated to form the Commonwealth of Australia in 1901 their post and telegraph departments were merged to form the national Postmaster General's (PMG) Department. The subject scale is an automatic public weighing machine, No.387, made in England by George Salter and Co. of West Bromwich. The Australasian Automatic Weighing Machine Co. Ltd in 1923 tendered for the right to place Automatic Weighing Machines on railway and tram premises throughout New South Wales subsequently for five-year terms in return for a fixed payment per machine and a portion of the revenue to the NSW Government. The company also made arrangements with the Postmaster General's Department to place machines outside post offices across the country. Weights were measured in stones and pound's up to 20 stone (127 kg) and average weights were shown separately for men, women, boys and girls by various heights in feet and inches. The subject item has had its scale change by the Eastern Scale Company to metric and it is believed to have occurred shortly after April 2000 as the company was first registered and began trading on this date. This weighing machine was originally installed by the Australasian Automatic Weighing Machine Co. Ltd at Warrnambool Post Office and was made by the firm, George Salter and Company, in West Bromwich, England to the Percival Everitt patent. Salter advertised that these machines were suitable for hotels, pleasure gardens, theaters, exhibition halls, clubs, baths and places of public resort. The company had been established in 1760 by the brothers, Richard and William Salter, manufacturing springs and pocket steelyards (spring balances). After several generations, the company was taken over by a nephew, George, and in 1884 the Salter trademark was registered to show a Staffordshire knot pierced by an arrow. The company's expanded range of products included the first coin-operated public weighing machines in the 1880s and in 1895 the first English made typewriter. When the last George Salter died in 1917, the company passed into the hands of other relatives but continued to grow before being bought out by Staveley Industries in 1973. Despite several subsequent mergers, the Salter name continues today on home ware products such as digital scales.A very rare example of a penny in the slot weighing machine imported into Australia and used in public places the item is significant as it gives a snapshot into community life at the time where the public could go and get weighed given there were no personal weighing machines or equipment that people could use at home. So if they needed to post a letter or go on a train journey they could use a machine to check their weight. Whats interesting is that this patent by Percival Everitt was the worlds first slot machine and the start of casino, arcade and other types of slot machines. Personal weighing scale metal large silver painted penny coin operated. Weight measurements are in stones and pounds. Australian Automatic Weighing Machine 60 lb Everitt Patent. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCrusher

Crusher for coke and charcoal, Made by T.Howie of Whitehall St Footscray (ca. 1930's) metal hand turned handleflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Auburn Tool Company, 1870 to 1893

... by hand and with tools that were themselves hand made shows ...Moulding Plane: A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. Auburn Tool Company: The Auburn Tool Company is known to exist from 1864 to 1893. George Casey reorganized the firm of Casey, Clark and Company as a joint-stock company in 1864, under the company name of Auburn Tool Company. The 1865 New York State Census noted the firm as a manufacturer of the plane, plane irons, and skates. The production that year was listed as 30,000 pairs of skates and 35,000 planes along with 25,000 dozen plane irons. The plane irons carried the trademark "Thistle". Both skates and plane irons were made from welded wrought iron and cast steel. The Auburn Tool Company was among the five leading plane manufacturing firms existing in the mid to late 19th century USA. Others were: H. Chapin's Son; Greenfield Tool Company; and Sandusky Tool Company. Auburn Tool Company, with these others, was also a founding member of the Plane Makers Association, organized around 1858 to fix prices. Most of the companies tools were manufactured by prisoners and in 1866 the firm was outbid for prison labour by J M Easterly and Co. After losing the contract with the prison authority they constructed a new building and continued in the plane manufacturing business with private labour. The 1870 US Census reported the firm had 21 machines, driven by water power, employing 66 males, producing annual products valued at us$70, 000. After A. Howland and Company was dissolved in 1874, the Auburn Tool Company again resumed using contract labour at the State Prison until 1877. The Auburn Tool Company merged with the Ohio Tool Company of Columbus, Ohio, on Nov 14, 1893. Although plane manufacturing was continued at Auburn until after 1907, after this merger the firm went under the name of the Ohio Tool Company. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. It also gives an insight into how many manufacturing companies bid for the rights to use prison labour to make their products at this time in our history. Decorative wood Moulding, plane Round type Auburn New York. Owner A Neudt Size 14 flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Malleys Ltd, 1930-1950

This is a steel, bench-mounted, hand-operated (60 rpm) butter churn for making small amounts of butter from cream in the home. It was made by the Sydney firm of Malleys Ltd from the 1930s until the 1950s and came in 3 and 5 quart sizes. Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. Butter churns were machines used to produce butter by the violent agitation of separated cream. Depending on the design of the churn, the agitation would be variously achieved by a repetitive thrashing, centrifugal motion or internal paddles. Churns were typically constructed from wood, glass and cast-iron; with tin or steel commonly used for some fixtures. The subject item gives an insight into domestic life where butter was made in the home.Heavy red cast iron base, with a long handle, wooden grip, connected to a shaft along the base, thence, to a cog wheel, and gear, to a second shaft and paddle in a metal basin. Basin has lid, and hole in base with a screw cap to allow the draining of the butter milk. Designed to be placed on a bench, with the handle over the edge. Malleys is written in raised letters on the base, and on the handle, '60 rev. pr. min.'warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, malleys, butter churn, domestic object, dairy machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1922

In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Sewing machine, treadle operated, "Branded Premier" 5-7-9-2-0-0-" Serial Number Y6243048 (denotes 1922 year of manufacture) flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand operated, dressmaking, textile machinery, portable, premier sewing machine, premier, singer treadle sewing machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Mincer, late 19th or early 20th Century

A meat grinder, commonly known as the meat mincer, is used for chopping meat into fine pieces. Alternatively, it can be used for the mixing of raw or cooked meat, fish and vegetables. It is the best way to process meat, and is a widely used piece of equipment by butchers and in the home.. Butchers have been known to use either mincing knives or meat cleavers in the kitchen for years to produce a quantity of minced meat. This was a slow and laborious process. The advent of the meat mincer has not only made the mincing process easier but also faster. The meat mincer has slowly evolved over the years into what it is today. The first meat mixer or meat mincer was invented in the 19th century by a German inventor named Baron Karl Drais. Although some versions of the device date back to much earlier. The oldest form of meat mincer was hand cranked which forced meat through a metal plate with several small holes in it, which resulted in long and thin strands of the meat. The meat was fed into the funnel that was placed at the top of the mixer. This meat would pass through a hand cranked screw conveyor that would squash and mix the meat before passing it through the metal plate. Needless to say, this was again a slow and laborious procedure to follow to produce large quantity of meat. With passage of time, this hand cracked machine became powered by electricity. The meat mincer has a great adaptability and efficiency now. The huge variety in mincer plates allows a butcher to produce different types of minced meat in any shape desired. However, traditional manual meat mincers have not really changed a lot. They are manually operated and made of cast iron, as earlier. They are similar to the original mincer designs, dating back to the early 1900s. Some butchers still prefer using a variety of mincer knives. Adapted from: https://brennan-group.com/blogs/news/history-of-the-meat-mincerThe development of the meat mincer enabled both butchers and home cooks to process and grind meat effectively.Clamp on meat mincer with handle for rotating the mincing apparatus inside.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, meat mincer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Spectacles and case, Fred and Geoff Bennett (F.T. and P.G. Bennett), mid-29th century

This pair of spectacles was prescribed and made in Warrnambool by brothers Fred and Geoff Bennet from about 1946 when they established their optometrist business at 192 Liebig Street Warrnambool. The business moved to 152 Liebig Street in 1988, by which time it had already changed hands to become McMahon and Owen Optometrists. Jayson Ward and Mathew Bucks purchased the business in 2012, then changed the name to Warrnambool Eyecare in 2016. They also own and practice at Portland Eyecare.This pair of glasses is significant as an example of locally owned and manufacture red eyewear from the mid 290th century. Spectacles, Pince-nez with oval shaped tinted lenses, metal bridge and rubber nose pads. Hard surfaced blue velvet lined spectacle case. Inscription on case. Made by F.G. & P..G. Bennett in Warrnambool."F.G. & P.G. Bennett Warrnambool"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, pince-nez, glasses, eyewear, seeing aids, vision, optician, f.g. & p.g. bennett warrnambool, eye care, magnifiers, reading glasses, fred and geoff bennett, personal effects -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pill Maker Board

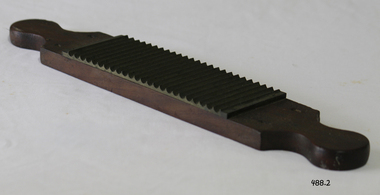

... a sore throat to fever, headaches or constipation, was made... throat to fever, headaches or constipation, was made laboriously ...Before factory production became commonplace in medicine, dispensing was considered an art and pill machines such as these were a vital component of any chemist’s collection. This machine dates back to the days when your local chemist or apothecary bought, sold, and manufactured all his own drugs and medicines to everybody who lived within the local community. In Victorian times, there was no such thing as off-the-shelf medicine. Every tablet, pill, suppository, ointment, potion, lotion, tincture and syrup to treat anything from a sore throat to fever, headaches or constipation, was made laboriously by hand, by the chemist. Pill machines such as these first appeared in the mid-1700s and quickly became a staple of the Victorian chemist’s shop. A ‘pill mass’ of medicinal powders mixed with a binding agent would be hand-rolled into a pipe on the tile at the back of the machine. This would then be placed across the grooved brass plate and cut into equal-sized pills using the corresponding side of the roller. Once all the necessary ingredients for the pills had been measured and ground with a pestle and mortar a final ingredient was poured in, syrup – this acted as a binding-agent. You could then roll it into a sausage shape. The largest part of the machine is the board. This is set at an angle and is comprised of the rolling surface, the cutting grooves, and the collection-tray. The large flat surface is for rolling out the pill-paste into the sausage shape. This is then rolled towards the brass cutting-grooves. The paddle (the second piece) is flipped over so that the grooves there line up with the grooves on the board. Rollers on the ends of the paddle roll against the brass edges of the board, and they guide the paddle straight across the grooves, taking the pill-mass with it. The grooves on the paddle and the board slice up the pill-mass and, after rolling the thing back and forth a couple of times like a rolling-pin, the circular pills roll off the grooves and into the tray at the bottom. https://galwaycitymuseum.ie/blog/collections-spotlight-victorian-pill-making-machine/?locale=en The collection of medical instruments and other equipment in the Port Medical Office is culturally significant, being an historical example of medicine from late 19th to mid-20th century. Pill making device including a grooved base board and grooved sliding board with two pill moulds.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, pills, pill maker, medicine, health -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pill Rolling Pin

... , headaches or constipation, was made laboriously by hand... throat to fever, headaches or constipation, was made laboriously ...Used as tBefore factory production became commonplace in medicine, dispensing was considered an art and pill machines such as these were a vital component of any chemist’s collection. This machine dates back to the days when your local chemist or apothecary bought, sold, and manufactured all his own drugs and medicines to everybody who lived within the local community. In Victorian times, there was no such thing as off-the-shelf medicine. Every tablet, pill, suppository, ointment, potion, lotion, tincture and syrup to treat anything from a sore throat to fever, headaches or constipation, was made laboriously by hand, by the chemist. Pill machines such as these first appeared in the mid-1700s and quickly became a staple of the Victorian chemist’s shop. A ‘pill mass’ of medicinal powders mixed with a binding agent would be hand-rolled into a pipe on the tile at the back of the machine. This would then be placed across the grooved brass plate and cut into equal-sized pills using the corresponding side of the roller. Once all the necessary ingredients for the pills had been measured and ground with a pestle and mortar a final ingredient was poured in, syrup – this acted as a binding-agent. You could then roll it into a sausage shape. The largest part of the machine is the board. This is set at an angle and is comprised of the rolling surface, the cutting grooves, and the collection-tray. The large flat surface is for rolling out the pill-paste into the sausage shape. This is then rolled towards the brass cutting-grooves. The paddle (the second piece) is flipped over so that the grooves there line up with the grooves on the board. Rollers on the ends of the paddle roll against the brass edges of the board, and they guide the paddle straight across the grooves, taking the pill-mass with it. The grooves on the paddle and the board slice up the pill-mass and, after rolling the thing back and forth a couple of times like a rolling-pin, the circular pills roll off the grooves and into the tray at the bottom. https://galwaycitymuseum.ie/blog/collections-spotlight-victorian-pill-making-machine/?locale=enhe companion item to pill-maker base, item 488.2The collection of medical instruments and other equipment in the Port Medical Office is culturally significant, being an historical example of medicine from late 19th to mid-20th century.Pill making device including a grooved base board and grooved sliding board with two pill mouldsNone.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, pill making, pill mould, medicine, health -

Flagstaff Hill Maritime Museum and Village

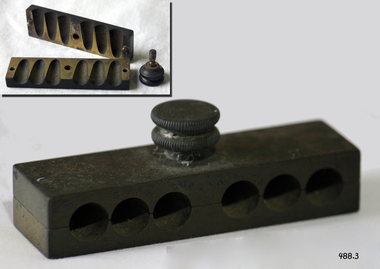

Flagstaff Hill Maritime Museum and VillageEquipment - Suppository Mould

... a sore throat to fever, headaches or constipation, was made... a sore throat to fever, headaches or constipation, was made ...Before factory production became commonplace in medicine, dispensing was considered an art and pill and suppository machines such as these were a vital component of any chemist’s collection. This mould dates back to the days when the local chemist or apothecary bought, sold, and manufactured all his own drugs and medicines to everybody who lived within the local community. In Victorian times, there was no such thing as off-the-shelf medicine. Every tablet, pill, suppository, ointment, potion, lotion, tincture and syrup to treat anything from a sore throat to fever, headaches or constipation, was made laboriously by hand, by the chemist. Some medicines are formulated to be used in the body cavities: the suppository (for the rectum), the pessary (for the vagina) and the bougie (for the urethra or nose). History Suppositories, pessaries and bougies have been prescribed for the last 2000 years but their popularity as a medicinal form increased from around 1840 - suppositories for constipation, haemorrhoids and later as an alternative method of drug administration, pessaries for vaginal infections and bougies for infections of the urethra, prostate, bladder or nose. Manufacture The basic method of manufacture was the same for each preparation, the shape differed. Suppositories were "bullet" or "torpedo" shaped, pessaries "bullet" shaped but larger and bougieslong and thin, tapering slightly. A base was required that would melt at body temperature. Various oils and fats have been utilised but, until the advent of modern manufactured waxes, the substances of choice were theobroma oil (cocoa butter) and a glycerin-gelatin mixture. The base was heated in a spouted pan over a water-bath until just melted. The medicament was rubbed into a little of the base (usually on a tile using a spatula) and then stirred into the rest. The melted mass was then poured into the relevant mould. Moulds were normally in two parts, made from stainless steel or brass (silver or electroplated to give a smooth surface). To facilitate removal the moulds were treated with a lubricant such as oil or soap solution. To overcome the difficulty of pouring into the long, thin bougie mould, it was usual to make a larger quantity of base, to partially unscrew the mould, fill with base and then screw the two halves of the mould together thus forcing out the excess. When cool, any excess base was scraped from the top of the mould, the mould opened and the preparations removed, packed and labelled with the doctor's instructions. https://www.rpharms.com/Portals/0/MuseumLearningResources/05%20Suppositories%20Pessaries%20and%20Bougies.pdf?ver=2020-02-06-154131-397The collection of medical instruments and other equipment in the Port Medical Office is culturally significant, being an historical example of medicine from late 19th to mid-20th century.Proctological mould for making suppositories.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, suppositories, medicine, health -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Suppository Mould

... a sore throat to fever, headaches or constipation, was made... a sore throat to fever, headaches or constipation, was made ...Before factory production became commonplace in medicine, dispensing was considered an art and pill and suppository machines such as these were a vital component of any chemist’s collection. This mould dates back to the days when the local chemist or apothecary bought, sold, and manufactured all his own drugs and medicines to everybody who lived within the local community. In Victorian times, there was no such thing as off-the-shelf medicine. Every tablet, pill, suppository, ointment, potion, lotion, tincture and syrup to treat anything from a sore throat to fever, headaches or constipation, was made laboriously by hand, by the chemist. Some medicines are formulated to be used in the body cavities: the suppository (for the rectum), the pessary (for the vagina) and the bougie (for the urethra or nose). History Suppositories, pessaries and bougies have been prescribed for the last 2000 years but their popularity as a medicinal form increased from around 1840 - suppositories for constipation, haemorrhoids and later as an alternative method of drug administration, pessaries for vaginal infections and bougies for infections of the urethra, prostate, bladder or nose. Manufacture The basic method of manufacture was the same for each preparation, the shape differed. Suppositories were "bullet" or "torpedo" shaped, pessaries "bullet" shaped but larger and bougieslong and thin, tapering slightly. A base was required that would melt at body temperature. Various oils and fats have been utilised but, until the advent of modern manufactured waxes, the substances of choice were theobroma oil (cocoa butter) and a glycerin-gelatin mixture. The base was heated in a spouted pan over a water-bath until just melted. The medicament was rubbed into a little of the base (usually on a tile using a spatula) and then stirred into the rest. The melted mass was then poured into the relevant mould. Moulds were normally in two parts, made from stainless steel or brass (silver or electroplated to give a smooth surface). To facilitate removal the moulds were treated with a lubricant such as oil or soap solution. To overcome the difficulty of pouring into the long, thin bougie mould, it was usual to make a larger quantity of base, to partially unscrew the mould, fill with base and then screw the two halves of the mould together thus forcing out the excess. When cool, any excess base was scraped from the top of the mould, the mould opened and the preparations removed, packed and labelled with the doctor's instructions. https://www.rpharms.com/Portals/0/MuseumLearningResources/05%20Suppositories%20Pessaries%20and%20Bougies.pdf?ver=2020-02-06-154131-397The collection of medical instruments and other equipment in the Port Medical Office is culturally significant, being an historical example of medicine from late 19th to mid-20th century.Proctological mould for making suppositories.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, suppositories, medicine, health