Showing 1198 items

matching rememberance

-

Eltham District Historical Society Inc

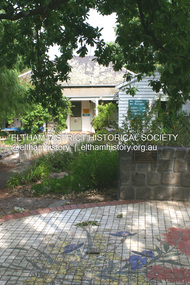

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, Former home of Professor William MacMahon Ball, York Street, Eltham, 24 May 2007

Situated at the eastern end of York Street, Eltham, 'Shinrone', the former home of Professor William (Mac) MacMahon Ball was one of the first in the Shire of Eltham to incorporate mud-brick. Professor MacMahon Ball, a political scientist, writer, broadcaster and diplomat and family moved to York Street, Eltham in 1945 into a timber cottage built around the 1890s and in poor repair. Mac asked Alistair Knox to renovate the home and he expanded the living area and added verandahs. In 1948 Montsalvat artist and sculptor Sonia Skipper supervised the building of most of the mud-brick studio. Neighbour Gordon Ford made the mud-bricks. Mac also asked John Harcourt, who had worked with him as a journalist in shortwave broadcasting, to build a pise (rammed earth) and stone addition to the largely timber house. Harcourt built two bedrooms - including an attic bedroom - a balcony with a shower and toilet, a nd a fireplace and chimney of local stone. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p141 At the eastern tip of York Street, Eltham, stands Shinrone, the former home of one of Australia’s intellectual leaders. Professor William Macmahon Ball, was one of the first to bring Asia as a foreign policy issue to the Australian public.1 He was a political scientist, writer, broadcaster and diplomat. The house was one of the first in Eltham Shire to incorporate mud-brick,2 because of the acute shortage of building materials after World War Two. Its novice builders later become leaders in Eltham’s built and garden design. Mac (as he was usually called), who was the son of a Church of England minister, was born in Casterton, Victoria in 1901 and died in 1986. In 1945 he helped establish the United Nations, as political consultant to the Australian Delegation at the San Francisco Conference.3 Then in 1946 Mac was appointed British Commonwealth Representative on the Allied Council for Japan, which is recorded in detail in his diary.4 In 1948 Mac led an Australian Government Goodwill Mission to South East Asia. However, Mac was perhaps most successful as an academic and public speaker.5 He was a commentator on the Australian Broadcasting Commission, from the early 1930s to the early 1960s. He was also Controller of the Short-Wave Broadcasting Unit during World War Two, which later became Radio Australia. From 1923 he taught at The University of Melbourne, then became foundation Professor of Political Science in 1949 and was Chair until his retirement in 1968.6 In 1942, as the government expected a Japanese invasion, Mac’s wife Katrine and their only child Jenny, moved from Kew to Eltham as temporary evacuees. However Mac and Katrine lived in Eltham for almost the rest of their lives. After staying with friends, they rented a house in Reynolds Road, where, as it was wartime, they needed to keep horses for transport and a cow and poultry for milk and eggs. In 1945 the family moved to the house at York Street, which was then a timber cottage, built around the 1890s and in poor repair. The underground well, cellar and part of the garden are all that remain of what stood on the original 18 acre (7.3ha) allotment. Thanks largely to Katrine’s hard work, the house was gradually renovated and extended. The long rambling house was partially built by several young neighbours, who were inspired by the cheap mud-brick and stone building style of Montsalvat, the Eltham artists’ colony. Mac asked Alistair Knox to renovate Shinrone, named after an Irish village near Katrine’s family home. Knox later popularised the mud-brick style of house construction, for which Eltham became known. He expanded the living area and added verandas. In 1948 Montsalvat artist and sculptor Sonia Skipper supervised the building of most of the mud-brick studio. Another neighbour, Gordon Ford, who was to have a major influence on the Australian garden style, made the mud-bricks. Mac also asked John Harcourt, who had worked with him as a journalist in short-wave broadcasting, to build a pisé (rammed earth) and stone addition to the largely timber house. Harcourt built two bedrooms – including an attic bedroom – a balcony with a shower and toilet, and a fireplace and chimney of local sandstone. With pioneering work naturally came mistakes, including one particularly dramatic incident when Harcourt was building walls with unsupported sections. Jenny Ellis, Mac’s daughter, remembers being awakened from sleep by a thundering shudder. The wall of her room had fallen down – fortunately away from her! In 1950 artist Peter Glass – another neighbour and later landscape designer – built Katrine a mud-brick pottery. As a result, the house features at one end Harcourt’s characteristic steep gable roof, while at the other the flatter construction characteristic of Knox. Mac referred to the home as the Eltham ‘experimental building site’.7 Surprisingly, the combination works, perhaps partly because it has the warm inviting feel of timber, mud-brick and stone.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, eltham, alistair knox, gordon ford, john harcourt, mudbrick construction, pise construction, professor macmahon ball, shinrone, sonia skipper, york street -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Memorial Arch Gateway, Nillumbik Cemetery, Diamond Creek, 23 January 2008

The Nillumbik Cemetery is of historical, architectural, aesthetic and social significance at a Regional level (North-east Melbourne). The memorial arch is of State significance. Nillumbik Cemetery, which was established in 1867, is of historical and social significance for its association with the early history of Diamond Creek and as a record of the pioneering families of the district. Significant graves include those of the famous writer Alan Marshall, author of 'I Can Jump Puddles', footballer Gordon Coventry, and William Ellis, notable early settler and benefactor. The 1897 Tudor/Gothic revival memorial arch, bequeathed by William Ellis, is a rare design in ornamental gateways and is relatively large for the size of the cemetery. It is unique in Victoria as a cemetery gateway arch. The burial ground has associated structures, such as the hexagonal timber sexton's office, post and wire fence and picket hand gate along Main Street, all probably built in the early twentieth century. Covered under Heritage Overlay, Nillumbik Planning Scheme. National Trust of Australia (Victoria) - Regional significance Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p83 Entering Nillumbik Cemetery through an ornamental gateway and shaded by the Monterey Cypress hedge helps one leave the busy world outside and contemplate yesterday’s Diamond Creek. The gateway, classified by the National Trust of Australia (Victoria), and inscribed with ‘JANVA VITAE’ (gate of life), was a gift from a distinguished pioneer, William Ellis. Ellis, who was an original trustee of the Nillumbik Cemetery representing the Primitive Methodists and a successful farmer, bequeathed £100 to build the red-brick and carved stone gateway in 1887. In 1867 surveyor Edward Bage had set aside two acres (0.8ha) now 35 Main Street, for this cemetery, in what was then called the village of Nillumbik. Several earlier burials on private lands in the district might have been exhumed and re-interred in the new cemetery. The first burials in the cemetery are thought to be of ‘a Chinaman who hanged himself from a tree behind the Church of England’ and ‘another man who was drowned in a water-hole behind the same church’.1 The 1000 or so graves in the cemetery are grouped into five denominational sections: two Anglican and one each for the Methodist (the largest), Catholic and Presbyterian Churches. It is believed that several unmarked graves are of Aborigines and Chinese miners.2 Perhaps the most famous person buried in the cemetery was author Alan Marshall, who died in 1984 and wrote, among other books, I Can Jump Puddles. Surprisingly his grave is particularly modest consisting of only a grassed plot with a tiny boulder and a simple bronze plaque. It lies about halfway down the main path, at the west and third row back. The first European, interred at the cemetery on July 9, 1869, was Hannah, aged 13 years eight months, daughter of local orchardist John Lawrey and wife Honor.3 Each grave has a story which reflects a rich history. Phillip Cummings, who died in 1884, provided the barn for Diamond Creek’s first school, run by the Primitive Methodist Church. The barn stood at the corner of Phipps Crescent and the main road.4 Former Eltham Shire councillor George Stebbings, who died in 1896, built several prominent buildings in the district, including Shillinglaw Cottage in Eltham.5 The grave of miner James Joseph Whyte, who died in 1908, is a reminder of Diamond Creek’s gold mining history. At age 51, Whyte died from a rock fall in the Diamond Mine, Diamond Creek. Diamond Creek’s first butcher, Patrick Ryan, became President of the Shire of Heidelberg and Chairman of the Eltham Hurstbridge Railway Trust. A former gold miner, he was grandfather of local historian Reverend Jock Ryan. He was buried in an unmarked grave halfway down the central path. His son John Lawrence, who is buried elsewhere, had been a Mayor of the City of Heidelberg. George Martin Pizzey gave a hall, for what was to become The St John’s Anglican Church in Diamond Creek. He was a Crimean War veteran, mason and leather goods manufacturer in Melbourne, who died in 1915. The two world wars took a heavy toll of locals with 54 personnel buried here, two thirds of whom served in World War One. A sporting pioneer was Greensborough District Cricket Club founder, Andrew Webb, who was buried in 1971. Politician Roy Mountford Vale (Monte), who died in 1977, was a Member of the Legislative Assembly of Greensborough, and a founding councillor and president of the Diamond Valley Shire. Modern-day residents are also remembered in this cemetery. The tragic Ash Wednesday bushfires took their toll on the district: William Marsden of Panton Hill CFA died, aged 39, fighting bushfires at Upper Beaconsfield in 1983.6 Several graves tell of those who held distinguished positions overseas, including William Constable, who died in 1989. Constable was artistic director of a ballet company, art director of more than 30 films for London-based film productions, and was awarded best Film Art Director at the Moscow Film Festival in 1960.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, diamond creek, memorial arch, gateway, nillumbik cemetery, william ellis -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Rob Roy Hill Climb, 24 November 2007

The Rob Roy Hill Climb originated in 1935 on the property of former Heidelberg Mayor, William Clinton, where he reared the Rob Roy breed of miniature ponies. He established Pleasure Grounds on part of the property attracting groups of Sunday visitors from Melbourne's inner suburbs. Visitors enjoyed a picnic area, pony rides, a dance hall and a tap room. Young men would ride their BSA or Harley Davidson motorcycles to the property which led to regular club-organised hillclimb meetings between 1930 and 1936. In 1935 Clinton offered the use of his property to the Light Car Club of Australia for their hillclimbs. The track was sealed that same year and the hillclimb at Clintons Road was one of only three specially designed bitumen surface hillclimbs in the world, the others being Shelsey Walsh and Prescott Hillclimbs in the UK. The first Light Car Club of Australia hillclimb was held at Rob Roy in February 1937. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p133 About six times a year the unlikely sound of car engines emerges from deep in the heart of Christmas Hills.* Usually a quiet retreat, the Hills are home to one of the world’s oldest purpose-built motor sport venues - the Rob Roy Hillclimb. When sealed in 1939, the hillclimb at Clintons Road was one of only three specially designed bitumen surface hillclimbs in the world, the others being Shelsley Walsh and Prescott Hillclimbs in the UK.1 The Rob Roy Hillclimb originated in 1935 on the property of former Heidelberg mayor, William Clinton, where he reared the Rob Roy breed of miniature ponies. Rob Roy was the Scottish folk hero and outlaw. On part of his property Clinton established Pleasure Grounds, attracting Sunday parties from Melbourne’s inner suburbs. Visitors enjoyed a picnic area, pony rides, a dance hall and a tap room.2 Young men riding on their BSA or Harley Davidson bikes led to club-organised regular hillclimb meetings, between 1930 and 1936. In 1935 Clinton offered his property to the Light Car Club of Australia for their hillclimbs. In February 1937, the first Light Car Club of Australia hillclimb meeting was held at Rob Roy. Jack Day achieved the fastest time that day for the 760 yard (695m) track at 36 seconds in a Ford V8 engined Bugatti Special. At first the climb was just a dusty gravel track, but in 1939 it was up-graded and bituminised. Today the 695 metre track begins on a slight incline, proceeds through a sharp right turn, which formerly passed a rusty iron shed, now remembered by the name Tin Shed Corner. The track continues down a slight incline to a level stretch along the top of an embankment holding back a half-acre (0.2ha) dam, then up to a one-in-three gradient. The track then winds uphill through several left turns to the finish line. In 1939 Frank Kleinig reduced the record to 29.72 seconds in an MG Hudson. Throughout World War Two the Rob Roy Hillclimbs were suspended, but were resumed in 1947. The hillclimbs consistently attracted crowds averaging 500 to 600 people, peaking at 2000, until the hillclimb was destroyed by the 1962 bushfires. The meetings included nine Australian Hillclimb Championships, with the first in 1938 won by Peter Whitehead in his ERA. Eight of the Outright and Class record holders were Australian Grand Prix winners including Jack Brabham, who became a triple F1 World Champion. The Light Car Club of Australia held 61 meetings at Rob Roy. Events usually included Touring, Gran Turismo, Production, Sports, Racing and Vintage cars and in the latter years Go-carts. These meets suddenly stopped after the 1962 bushfire destroyed the access bridge on the property leading to the track area, although fortunately Clinton saved his home. The club then established the Lakeland Hillclimb venue close to Lilydale.3 From 1979 to 1987 the MG Car Club ran hill climbs at the Templestowe Hillclimb until the land was to be sub-divided. In 1991 the MGCC approached the Shire of Nillumbik about using the derelict Rob Roy venue. In 1992, after much lobbying, the club signed a ten-year lease from Melbourne Water, which has been renewed. The original track was faithfully reconstructed. Access roads were improved and guard rails were installed on the causeway. Permanent structures were rebuilt and tonnes of rubbish removed. This was made possible by an immense amount of voluntary work by MGCC members and financial support from the newly formed Friends of Rob Roy. In February 1993 the first Return to Rob Roy Historic Meeting was run with a huge spectator attendance of around 1000 enthusiasts. In September 2007, the Nillumbik Shire Council gave the hillclimb heritage protection. This acknowledged the property’s significant contribution to early Australian motor sport with its social connection to William Clinton and the local community.4 *Christmas Hills was named after emancipated convict and shepherd David Christmas, lost in these hills.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, rob roy hill climb, clintons road, light car club of australia, william clinton -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - ROYAL PRINCESS THEATRE COLLECTION: EIGHT FIRST BIRTHDAY SOUVENIR PROGRAMME, c1955

Royal Princess Theatre Eight First Birthday Souvenir Programme, 31st August, 1955. 1874 - 1955. Manager: Don Vincent. Price - Sixpence. Proceeds: Cinematograph Trade Benevolent Fund. The Royal Princess Theatre. In May, 1874, the late John Crowley, at a cost of 12,000 pounds the Royal Princess Theatre. It was opened on 31st August, 1874, on which occasion the 'Grand Duchess of Gerolstein' was performed. It was in January, 1904, that the Theatre was closed until April, 1905, for re-construction at a cost of 5,000 pounds. Further alterations were made I 1936 when the old circle and the gallery was converted into the present circle and loge, the cost on this occasion was 14,000 pounds. At the Royal Princess has been seen every form of entertainment known in the world. Operas, including Gilbert and Sullivan, Shakespearean plays, Minstrels, Pantomime, Circus (Wirth's making their first appearance in1887), Drama, Revues, Magicians, and the latest medium of entertainment Ice Revue. Of the many shows presented on stage of the theatre, I feel none has survived as long, or as well, as 'Charley's Aunt.' The companies to present their performances have been many and varied, but among an imposing list, the names of Charles Holloway, The Royal English Opera Company, J. C. Williamson Co., and Royal Comic Opera Coy., will long be remembered. The line of notable personalities who have appeared on the stage is long also, and includes such names as John McCormack, Clara Butt, Harry Lauder, Peter Dawson and more recently Jessie Mathews and John Calvert. But of all these and many others, I am sure none can ever compare with the wonderful performances by the late Dame Nellie Melba, who gave her farewell performance in September, 1921. It is interesting to note that Dame Nellie Melba, gave two farewell performances. The first was in February, 1886, when she made a last appearance as Mrs Armstrong, to later become Madame Melba. The first competition of the Austral Society was held in the Theatre in May, 1897, and the first living pictures were seen in August, 1899. The London Bioscope Co. presented 'Struck Oil,' with Maggie Moore, in February, 1901 (Maggie Moore had appeared in the stage play or the same name many times earlier). However, it was not until 1910 that the Royal Princess was mainly used for pictures, and of course, since that year, that has been the principle form of entertainment presented. It was Easter, 1930, that the first talkie, 'The Desert Song,' was screened and then followed coloured films, and now in 1955 the latest in film development - Cinemascope has been installed. This installation caused, for the first time in many years, alterations to the back stage to enable the large 30ft. Screen to be quickly removed ready for any 'live' performances. In 1937 the Royal Princess came under the Management of Northern Amusements Pty. Ltd., a unit of the Woodrow Corporation Ltd., whose policy it is to bring in entertainment to Bendigo, and I, as their representative will carry on the traditions of the past, and make the Royal Princess truly a Home of Entertainment. Don Vincent, Manager. Wednesday, 31st August, 1955 on the stage. Eagelhawk Brass Band. Official cutting of the Bithday Cake and its presentation to the Matron of the Benoevolent Home by His Worship the Mayor of Bendigo (The cake kindly donated by Friedrich & Bassemir). Presentation of the Travel Voucher for a 10 day Luxury Coach Tour on behalf of Pioneer Coaches Ltd., to the licky couple winning the recent 25th Wedding Anniversary Contest, by His Worship the Mayor of Eaglehawk. 'Progress of Fashion by Bendigo Fashion House including A Tableaux of 7 Bridal Ensembles. Miss 1874 Gertrude Perry, Misses 1955 Rosemary Lorenz, Lorraine Foley, Joan Pinder, Pauline Kim, Shirley Morgan, Pat Ferrari, Wilma Breerton. Make - up by Helen Lang Beauty Salon. 81st Birthday Performance on the screen. Newsreels, Cartoons, Shorts, Seven Brides for Seven Brothers. Photograph: The Staff of the Royal Princess, under the Management of Mr Don Vincent, who are at your service. Hearing Aids are now installed in all parts of the Theatre, Doctors or Nurses on call may leave their names at the pay-box. Advertisements for Bendigo businesses: Radio Taxis, Kings Dry Cleaners, John V. Schenck Art Florist, Morley Johnsons everything for the home, Ron Meurer fridges, The Melody Bar, music. Program comprises of two sheets of paper.program, theatre, royal princess theatre, royal princess theatre eight first birthday souvenir programme, 31st august, 1955. 1874 - 1955. manager: don vincent. price - sixpence. proceeds: cinematograph trade benevolent fund. the royal princess theatre. in may, 1874, the late john crowley, at a cost of 12, 000 pounds the royal princess theatre. opened on 31st august, 1874, 'grand duchess of gerolstein' was performed. 1904, the theatre was closed until 1905, for re-construction. further alterations 1936 when the old circle and the gallery was converted into the present circle and loge, 14, 000 pounds. seen every form of entertainment known in the world. operas, including gilbert and sullivan, shakespearean plays, minstrels, pantomime, circus (wirth's making their first appearance in1887), drama, revues, magicians, and the latest medium of entertainment ice revue. 'charley's aunt.' the companies have been many and varied, charles holloway, the royal english opera company, j. c. williamson co., and royal comic opera coy., john mccormack, clara butt, harry lauder, peter dawson and more recently jessie mathews and john calvert. dame nellie melba, who gave her farewell performance in september, 1921. it is interesting to note that dame nellie melba, gave two farewell performances. the first was in february, 1886, when she made a last appearance as mrs armstrong, to later become madame melba. the first competition of the austral society was held in the theatre in may, 1897, the first living pictures in august, 1899. the london bioscope co. presented 'struck oil, ' with maggie moore, in february, 1901 (maggie moore had appeared in the stage play or the same name many times earlier). by1910 that the royal princess was mainly used for pictures, has been the principle form of entertainment presented. it was easter, 1930, that the first talkie, 'the desert song, ' was screened and then coloured films, now 1955 the latest in film development - cinemascope has been installed, alterations to the back stage to enable the large 30ft. screen to be quickly removed 'live' performances. in 1937 the management of northern amusements pty. ltd., a unit of the woodrow corporation ltd., 1955. eagelhawk brass band. official cutting of the bithday cake and its presentation to the matron of the benoevolent home by his worship the mayor of bendigo (the cake kindly donated by friedrich & bassemir). presentation of the travel voucher for a 10 day luxury coach tour on behalf of pioneer coaches ltd., to the licky couple winning the recent 25th wedding anniversary contest, by his worship the mayor of eaglehawk. 'progress of fashion by bendigo fashion house including a tableaux of 7 bridal ensembles. miss 1874 gertrude perry, misses 1955 rosemary lorenz, lorraine foley, joan pinder, pauline kim, shirley morgan, pat ferrari, wilma breerton. make - up by helen lang beauty salon. 81st birthday performance on the screen. newsreels, cartoons, shorts, seven brides for seven brothers. photograph: the staff of the royal princess, under the management of mr don vincent, who are at your service. hearing aids are now installed in all parts of the theatre, doctors or nurses on call may leave their names at the pay-box. advertisements for bendigo businesses: radio taxis, kings dry cleaners, john v. schenck art florist, morley johnsons everything for the home, ron meurer fridges, the melody bar, music. royal princess theatre eight first birthday souvenir programme, 31st august, 1955. 1874 - 1955. manager: don vincent. price - sixpence. proceeds: cinematograph trade benevolent fund. the royal princess theatre. in may, 1874, the late john crowley, at a cost of 12, 000 pounds the royal princess theatre. opened on 31st august, 1874, 'grand duchess of gerolstein' was performed. 1904, the theatre was closed until 1905, for re-construction. further alterations 1936 when the old circle and the gallery was converted into the present circle and loge, 14, 000 pounds. seen every form of entertainment known in the world. operas, including gilbert and sullivan, shakespearean plays, minstrels, pantomime, circus (wirth's making their first appearance in1887), drama, revues, magicians, and the latest medium of entertainment ice revue. 'charley's aunt.' the companies have been many and varied, charles holloway, the royal english opera company, j. c. williamson co., and royal comic opera coy., john mccormack, clara butt, harry lauder, peter dawson and more recently jessie mathews and john calvert. dame nellie melba, who gave her farewell performance in september, 1921. it is interesting to note that dame nellie melba, gave two farewell performances. the first was in february, 1886, when she made a last appearance as mrs armstrong, to later become madame melba. the first competition of the austral society was held in the theatre in may, 1897, the first living pictures in august, 1899. the london bioscope co. presented 'struck oil, ' with maggie moore, in february, 1901 (maggie moore had appeared in the stage play or the same name many times earlier). by1910 that the royal princess was mainly used for pictures, has been the principle form of entertainment presented. it was easter, 1930, that the first talkie, 'the desert song, ' was screened and then coloured films, now 1955 the latest in film development - cinemascope has been installed, alterations to the back stage to enable the large 30ft. screen to be quickly removed 'live' performances. in 1937 the management of northern amusements pty. ltd., a unit of the woodrow corporation ltd., 1955. eagelhawk brass band. official cutting of the bithday cake and its presentation to the matron of the benoevolent home by his worship the mayor of bendigo (the cake kindly donated by friedrich & bassemir). presentation of the travel voucher for a 10 day luxury coach tour on behalf of pioneer coaches ltd., to the licky couple winning the recent 25th wedding anniversary contest, by his worship the mayor of eaglehawk. 'progress of fashion by bendigo fashion house including a tableaux of 7 bridal ensembles. miss 1874 gertrude perry, misses 1955 rosemary lorenz, lorraine foley, joan pinder, pauline kim, shirley morgan, pat ferrari, wilma breerton. make - up by helen lang beauty salon. 81st birthday performance on the screen. newsreels, cartoons, shorts, seven brides for seven brothers. photograph: the staff of the royal princess, under the management of mr don vincent, who are at your service. hearing aids are now installed in all parts of the theatre, doctors or nurses on call may leave their names at the pay-box. advertisements for bendigo businesses: radio taxis, kings dry cleaners, john v. schenck art florist, morley johnsons everything for the home, ron meurer fridges, the melody bar, music. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.White earthenware dinner plate. Crazing evident all over.Backstamped ‘Made in England S LTD’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Johnson Bros