Showing 1220 items

matching carved

-

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Clare Gervasoni, Ballarat School of Mines Technical Art School, c2008, 29/07/2020

The former Ballarat Circuit Court Building, later the first building of the Ballarat School of Mines, was demolished to make way for a new custom built Art School building. Sir Alexander Peacock opened the Ballarat Technical Art School in July 1915. It cost 10,000 pounds and was constructed by the Public Works Department from plans drawn by the then Art School Principal, Herbert H. Smith. The building contractors were Messrs Gower and Eddards. According to the SMB Annual Report of 1914 'the internal upholstering and fittings have all been carried out in Australian timbers, with Queensland maple largely used throughout.' Before this building was constructed art and craft classes were held in various buildings around Ballarat. The building could be described as federation-art deco in style. It features sandstone insertion with sandstone string coursing. The base of the building is rusticated sandstone. The relief stone panel on the front with the words "Technical Art School" features stone pilaster brackets and corbels. In the centre front can be seen rectangular sandstone pediment with decorative stonework incorporating the date of construction. The windows in the lower floor feature five supporting keystones whereas the upper windows have sandstone lintels. The building also features decorative cast iron downpipes. The entrance on the northern side has attractive leadlight glazing in an art deco style. Above the door a miner's lamp and pick are featured in the design. The building is functional in design with large metal windows in the south wall to ensure good light into the studios. The northern wall has standard double hung windows. The interior of the building features a carved wooden staircase and cast iron ceiling vents. The rear drawing studios can be made into one large studio by opening panelled timber doors. This opening features classical plaster pilasters with a pediment above.Colour photograph of a sandstone detail on a double storey, red brick building - the Ballarat Technical Art School, a division of the Ballarat School of Minesballarat school of mines, ballarat technical art school, architecture, art, gribble building -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Liz Pidgeon, Heritage Excursion; Eltham Lower Park Walk and Talk, 1 July 2017, 1 July 2017

Transcription of plaque: Not Just a Pretty Place acknowledges the cultural significance of this site for residnets of the Nillumbik Shire and for the Wurundjeri community. Historically the confluence of rivers have particular importance as these were sites where rituals and ceremonies took place. The carved bluestone form presents an oversize river pebble that echoes the spirit of the water and draws attention to this location as a meeting place and landmark. The oval shape of a coolamun (Wurundjeri dish or basket) is referenced in the sculpture as a reminder of the indigenous heritage and as a gesture to reconciliation Danko describes the work as a contemporary message stick or sign, that can be read as a merker of time, nature and human existance. 2000 Nillumbik Art in Public Places Award. Heritage Excursion - Saturday 1st July - Eltham Lower Park - Walk and Talk Eltham Lower Park has played an important part in the history of our area since the early days of European settlement when it was used by local residents as an informal racecourse. Prior to that its location at the junction of the Diamond Creek and the Yarra River made it an important meeting place for the Wurundjeri people. The park combines formal elements and sporting facilities with remnant bushland that is of environmental significance. It is home to sporting and horse riding clubs, popular play spaces and the Diamond Valley Miniature Railway, which attracts large numbers of visitors. The park will be the venue for our July excursion which will comprise a walk of about 3.5 km around the park and adjacent areas. Along the way we will discuss the history and natural history of the area. The path along the creek and the river provides a pleasant and scenic walk. This walk on Saturday 1st July is about 3.5 km in length and will take 2 to 2.5 hours. It will start at 2pm at the Main Road car park at the front of the park. (Melway ref 21 H 10). From Newsletter No., 234, June 2017 Born Digitalelection day, heritage excursion, activities, eltham district historical society, eltham lower park, not just a pretty place, public art, plaque -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDeadeye, circa 1873

This example of a sailing ship’s ‘dead-eye’ is from the wreck of the LOCH ARD, which sank near Port Campbell in 1878. The vessel was an iron hulled clipper ship constructed for the Loch Line in 1873. It was part of a fleet of similar merchant ships owned by that company, which specialised in bringing passengers and goods from London via the Great Circle route to Melbourne, and returning to Britain via Cape Horn with the colony’s wool clip. Deadeyes were a common feature of sailing ship technology in the nineteenth century. They were a simple, cheap, and hard-wearing device that, in conjunction with another deadeye, provided an effective means of levering, or tightening, attached ropes and stays. Lower deadeyes were fixed to the sides of the ship by an encircling metal collar (inset in a flattish groove chiselled around the outer circumference of the disc), which was bolted to iron bars attached to the hull (called chain-plates). Upper deadeyes were looped by a strong hemp or wire rope (inset in a rounded groove carved around the outer circumference of the disc), which was joined to the bottom ends of the rigging which reached up to secure the masts into position (called shrouds or stays). Connecting a Lower deadeye to its corresponding Upper deadeye was a rope (called a lanyard) which looped up and down through the three “eyes” of each disc, to form a pulley system. The hitching of the two deadeyes with a looped lanyard provided the means of tightening, or loosening, the tension on the mast rigging ― essentially by pulling against the chain-plates bolted to the outside of the hull. It was a procedure that could be performed by sailors at sea and in emergencies. For example, after a gale the stays may have stretched and the masts worked loose, requiring retightening. Or, in the extreme circumstance of shipwreck, the lanyards might need to be released on the weather side, so that the masts fall away from the stricken vessel. The shipwreck of the LOCH ARD is of State significance. Victorian Heritage Register S417.A well-preserved ship’s deadeye with wire loop rope still attached. The original tar coating for water-proofing still remains, colouring the entire artefact black. It is wrapped in hessian cloth and hemp cord and is currently in storage under secure and stable conditions. This deadeye was recovered from the wreck of the LOCH ARD. The artefact is a typical deadeye, comprising a thick round wooden disc, pierced by 3 similarly sized and shaped holes from one flat side through to the other, in a triangle formation. The survival of the wire cable loop-rope suggests it was an Upper Deadeye, connected to the shrouds (mast rigging). Previous number PWO 2388.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, deadeye, loch ard, rigging -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Clare Gervasoni, Ballarat School of Mines Technical Art School, c2008, c2008

The former Ballarat Circuit Court Building, later the first building of the Ballarat School of Mines, was demolished to make way for a new custom built Art School building. Sir Alexander Peacock opened the Ballarat Technical Art School in July 1915. It cost 10,000 pounds and was constructed by the Public Works Department from plans drawn by the then Art School Principal, Herbert H. Smith. The building contractors were Messrs Gower and Eddards. According to the SMB Annual Report of 1914 'the internal upholstering and fittings have all been carried out in Australian timbers, with Queensland maple largely used throughout.' Before this building was constructed art and craft classes were held in various buildings around Ballarat. The building could be described as federation-art deco in style. It features sandstone insertion with sandstone string coursing. The base of the building is rusticated sandstone. The relief stone panel on the front with the words "Technical Art School" features stone pilaster brackets and corbels. In the centre front can be seen rectangular sandstone pediment with decorative stonework incorporating the date of construction. The windows in the lower floor feature five supporting keystones whereas the upper windows have sandstone lintels. The building also features decorative cast iron downpipes. The entrance on the northern side has attractive leadlight glazing in an art deco style. Above the door a miner's lamp and pick are featured in the design. The building is functional in design with large metal windows in the south wall to ensure good light into the studios. The northern wall has standard double hung windows. The interior of the building features a carved wooden staircase and cast iron ceiling vents. The rear drawing studios can be made into one large studio by opening panelled timber doors. This opening features classical plaster pilasters with a pediment above.Colour photographs of a double storey, red brick building built - the Ballarat Technical Art School, a division of the Ballarat School of Minesballarat school of mines, ballarat technical art school, architecture, art, gribble building -

Federation University Historical Collection

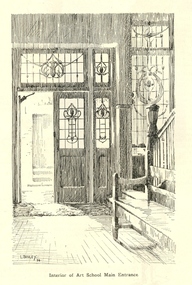

Federation University Historical CollectionArtwork, other - Artwork, Artwork from the Ballarat School of Mines Students' Magazine, 1934, 1934

Sir Alexander Peacock opened the Ballarat Technical Art School in July 1915. It cost 10,000 pounds and was constructed by the Public Works Department from plans drawn by the then Art School Principal, Herbert H. Smith. The building contractors were Messrs Gower and Eddards. According to the SMB Annual Report of 1914 'the internal upholstering and fittings have all been carried out in Australian timbers, with Queensland maple largely used throughout.' Before this building was constructed art and craft classes were held in various buildings around Ballarat. The building could be described as federation-art deco in style. It features sandstone insertion with sandstone string coursing. The base of the building is rusticated sandstone. The relief stone panel on the front with the words "Technical Art School" features stone pilaster brackets and corbels. In the centre front can be seen rectangular sandstone pediment with decorative stonework incorporating the date of construction. The windows in the lower floor feature five supporting keystones whereas the upper windows have sandstone lintels. The building also features decorative cast iron downpipes. The entrance on the northern side has attractive leadlight glazing in an art deco style. Above the door a miner's lamp and pick are featured in the design. The building is functional in design with large metal windows in the south wall to ensure good light into the studios. The northern wall has standard double hung windows. The interior of the building features a carved wooden staircase and cast iron ceiling vents. The rear drawing studios can be made into one large studio by opening panelled timber doors. This opening features classical plaster pilasters with a pediment above. This building is now the Gribble Building on the Federation University Australia SMB Campus.Artwork by students of the Ballarat Technical Art School from the 1934 Ballarat School of Mines Students' Magazine .1) Stairs to the Ballarat Junior Technical School from Grant Street .2) Caricatures by Nornie Gude .3) work by Colin S. Hunt .4) A girl and a rooster by Gilda Gude .5) Self Portrait .6) Main entrance to the Ballarat Technical Art School by Lorna Bailey .7) Artwork from the magazineballarat technical art school, gribble building, gribble, stained glass, white flat, hopwood, bailey, gude, ballarat junior technical school, visual arts -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Photograph, B/W Stefanie Rennick nee Rietman c1999; Newspaper clipping 1996, 1996, 1999

August Rietmann (1877-1951) of Lustdorf ,Switzerland, married Maria Frieda Oesschlager (1878-1942) of Baden Baden, in Germany on 6/8/1910 8/8/1915 August and his wife Frieda migrated to Melbourne, Victoria, Australia sailing on the Steam Ship ‘Osterley’ from Marseilles to Melbourne They leased Box Cottage, Ormond in 1917 and raised two children, Stefanie (1918 -2006) and William (1920- 1997). 1935 August purchased the property and the family used the Cottage during the day and slept in the Front House. August was a monumental mason, potter and sculptor, and was employed at Corbens Ltd Clifton Hill, to carve war memorials in Victoria post WW1 c 1915-1922. During the 1920's August set up his own business in pressed cement making pot plants, columns,paving slabs and lampstands. His son William joined the business and and the family continued to use the site after August died in 1951. Rietmann Landscaping Ltd moved to Bay Road Highett in 1953 and later to Carrum. The land, containing the Box Cottage, was sold to Lewis Timber Pty Ltd in 1970 and Mr Lewis proposed that Moorabbin City Council should preserve the heritage Cottage. Stefanie Rietman, grew up living in Box Cottage until 1935 when she began a Teaching career. Stefanie married Alan Francis 1941 but he was killed in WW2 Air operations over Germany 1944. Two sons were born 1942, 1944. Stefanie returned to live at the cottage until 1958. She married Herbert Rennick 1946 and two sons were born 1947, 1952. Stefanie also established a native grasses garden in Joyce Park, and designed and made resin jewellery. Stefanie died 2006 In 1984 the Cottage was dismantled and reconstructed in the adjacent Joyce Park. The Rietman family is an example of the diverse nationalities that lived and worked productively in Moorabbin Shire 1871–1933 , the City of Moorabbin 1934-1994 and continues today in the Cities of Glen Eira, Kingston, Bayside, and Monash. Stefanie was a talented artist , school teacher, and jewellery designer and raised 4 sons. August, a sculptor and stone mason, was employed by Corben Pty Ltd Clifton Hill to carve WW1 Memorials before establishing his own successful masonry business in the Box Cottage during the latter 1920s. After becoming interested in pressed cement casting, he took on apprentices (1930s Depression) and among his products were garden furniture, pots and also street lamp standards, some of which were installed in St Kilda Road. After August’s death in 1951, his family continued the business ‘Rietman’s Landscaping Ltd.’, at Highett and a) Newspaper clipping, Moorabbin Standard 17/9/1996 Stefanie Rennick ( nee Rietman) by N. Strahan b) Photograph Black & White, Stefanie Rennick ( nee Rietman) 1999a) printed article b) handwritten informationresin jewellery, australian native grasses, schools, education, craftwork, pottery, ceramics, ormond state school, rietmann august, rietman august, rietmann frieda, rietman frieda, stonnington city town hall, war memorials, world war 1 1914-1918, rietman stefanie, rennick stefanie, francis stefanie, rietman william, rietman ray, montford paul, malvern city town hall, box cottage museum ormond, box william, box elizabeth, joyce park ormond, rietman's landscaping pty ltd, bay road highett, macrobertson pty ltd, coleraine soldier memorial 1921, box cottage ormond -

Bendigo Historical Society Inc.

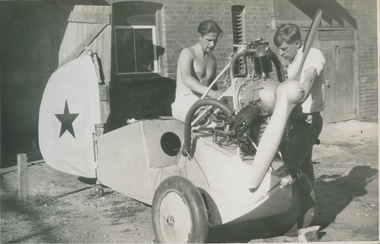

Bendigo Historical Society Inc.Photograph - Gliding in Bendigo, Late 1930s

These are the recollections of Alan Menere (1915 – 2001). Alan grew up in Moonee Ponds, Victoria, and moved to Bendigo while in his early 20s. There he met some like-minded young men who enjoyed challenges and matters mechanical. Flying was the adventure of the time, and they decided to give it a go. There was no intention to be on the leading edge of gliding technology. The challenge was to fly, and by their own efforts. They were aided in this by the embryonic regulatory arrangements covering light aircraft construction and flying, a sense of optimistic can-do, and the cavalier estimation of risks that goes with being in your early 20s. The events described here took place against a darkening political background. Alan and his mates were politically aware, very left wing, and viewed the gathering storm in Europe with apprehension. They could see from early on that war was coming, and it would change everything. Prevented from joining the Air Force by his red-green colour blindness, Alan joined the Army the day after the Pearl Harbour attack. He served in an Armoured Reconnaissance Unit in Western Australia, then with the Army Education Service in New Britain. After the War he joined the Commonwealth Public Service. He moved to Canberra, but his Bendigo habits stayed with him, as he built sailboards and carved propellers, to the admiration of his sons. Alan developed macular degeneration in his mid-60s. He retired to Port Stephens, fishing and socializing when he wasn’t tinkering with wing-sails for his catamaran. As he could touch-type, he quickly learned to use a computer. Very aware that he was the last member of the Bendigo group still alive, he resolved to set down his flying experiences. The images he selected are included, but there are many more from the Bendigo days.A CD entitled "Alan Menere - Recollections of Gliding in Bendigo in the late 1930s". The CD contains 33 documents consisting of one word file, one PDF file (entitled "The Urge to Fly") and the rest are of either photos of the Bendigo Gliding club or generally around Bendigo itself. Also included are some paper clippings of accidents that happened and description of flights.history, bendigo, bendigo gliding club, alan menere -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, John Kendrick Blogg carving, pulpit of St Stephen's Presbyterian Church, Surrey Hills

John Kendrick Blogg was born in Canada and migrated to Victoria in 1877. In 1884 he established a successful industrial chemistry business, which included extracting perfume from Australian native trees and plants.liquid ammonia for refrigeration, acetic acid, perfumes, shoe polish, baking powder and non-alcoholic drinks. Other products were He lived at 'Balmoral' in Albany Crescent, Surrey Hills; his woodwork was produced here. Family oral history has that he took up woodcarving after his 1st wife, Annie, died in 1893. His earliest known piece is a music cabinet of 1901; the latest is a panel of 1932 when Blogg was 81 years of age. He was a member of the Victorian Artists Society and exhibited there between 1920 and 1924. Much of his work incorporates motifs of Australian flora, particularly gum leaves. John and his family were members of St Stephen's Presbyterian Church, Surrey Hills. The present church building was dedicated in December 1910 and J K Blogg's contribution to the new building was the Hogg Memorial pulpit which is comprised of 13 panels. Blogg carved more than 300 pieces for churches, schools, royalty, family and friends. Many of J K Blogg's pieces remain with family members, but he is represented in municipal (City of Whitehorse), state and national collections. In addition to work in the St Stephen's Presbyterian Church within the Surrey Hills area his work was produced for Surrey Hills Primary School, Surrey Hills Bowling Club and Surrey Hills Methodist Church, however perhaps his most famous local work is the honour board at the Shrine in the Surrey Gardens. Blogg was also a poet. Ref: Legacy in Sculptured Wood - An appreciation of the work of John Kendrick Blogg, 1851-1936 by Marjorie Morgan, 1993.Colour photo of the central panel of the pulpit at St Stephen's Presbyterian Church in Canterbury Road, Surrey Hills. It depicts the burning bush.hogg memorial pulpit, st stephens presbyterian church, churches, woodcarving, church furniture, john kendrick blogg, john blogg -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, John Kendrick Blogg carving, pulpit of St Stephen's Presbyterian Church, Surrey Hills

John Kendrick Blogg was born in Canada and migrated to Victoria in 1877. In 1884 he established a successful industrial chemistry business, which included extracting perfume from Australian native trees and plants.liquid ammonia for refrigeration, acetic acid, perfumes, shoe polish, baking powder and non-alcoholic drinks. Other products were He lived at 'Balmoral' in Albany Crescent, Surrey Hills; his woodwork was produced here. Family oral history has that he took up woodcarving after his 1st wife, Annie, died in 1893. His earliest known piece is a music cabinet of 1901; the latest is a panel of 1932 when Blogg was 81 years of age. He was a member of the Victorian Artists Society and exhibited there between 1920 and 1924. Much of his work incorporates motifs of Australian flora, particularly gum leaves. John and his family were members of St Stephen's Presbyterian Church, Surrey Hills. The present church building was dedicated in December 1910 and J K Blogg's contribution to the new building was the Hogg Memorial pulpit which is comprised of 13 panels. Blogg carved more than 300 pieces for churches, schools, royalty, family and friends. Many of J K Blogg's pieces remain with family members, but he is represented in municipal (City of Whitehorse), state and national collections. In addition to work in the St Stephen's Presbyterian Church within the Surrey Hills area his work was produced for Surrey Hills Primary School, Surrey Hills Bowling Club and Surrey Hills Methodist Church, however perhaps his most famous local work is the honour board at the Shrine in the Surrey Gardens. Blogg was also a poet. Ref: Legacy in Sculptured Wood - An appreciation of the work of John Kendrick Blogg, 1851-1936 by Marjorie Morgan, 1993.Colour photo of the some of the 13 panels forming the pulpit at St Stephen's Presbyterian Church in Canterbury Road, Surrey Hills.st stephens presbyterian church, churches, hogg memorial pulpit, woodcarving, church furniture, john kendrick blogg, john blogg -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, Golden Wattle: Flower arrangement used for J K Blogg carving

John Kendrick Blogg was born in Canada and migrated to Victoria in 1877. In 1884 he established a successful industrial chemistry business, which included extracting perfume from Australian native trees and plants.liquid ammonia for refrigeration, acetic acid, perfumes, shoe polish, baking powder and non-alcoholic drinks. Other products were He lived at 'Balmoral' in Albany Crescent, Surrey Hills; his woodwork was produced here. Family oral history has that he took up woodcarving after his 1st wife, Annie, died in 1893. His earliest known piece is a music cabinet of 1901; the latest is a panel of 1932 when Blogg was 81 years of age. He was a member of the Victorian Artists Society and exhibited there between 1920 and 1924. Much of his work incorporates motifs of Australian flora, particularly gum leaves. John and his family were members of St Stephen's Presbyterian Church, Surrey Hills. The present church building was dedicated in December 1910 and J K Blogg's contribution to the new building was the Hogg Memorial pulpit which is comprised of 13 panels. Blogg carved more than 300 pieces for churches, schools, royalty, family and friends. Many of J K Blogg's pieces remain with family members, but he is represented in municipal (City of Whitehorse), state and national collections. In addition to work in the St Stephen's Presbyterian Church within the Surrey Hills area his work was produced for Surrey Hills Primary School, Surrey Hills Bowling Club and Surrey Hills Methodist Church, however perhaps his most famous local work is the honour board at the Shrine in the Surrey Gardens. Blogg was also a poet. Ref: Legacy in Sculptured Wood - An appreciation of the work of John Kendrick Blogg, 1851-1936 by Marjorie Morgan, 1993.Black and white photo of an urn on a pedestal contianing stems of wattle with leaves and blooms.woodcarving, surrey hills shrine, monuments and memorials, john blogg, john kendrick blogg, r falconer -

Flagstaff Hill Maritime Museum and Village

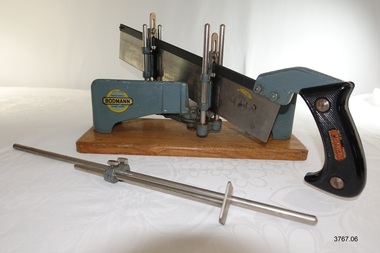

Flagstaff Hill Maritime Museum and VillageTool - Mitre Saw Set, 1930-1955's

This Bodmann mitre saw set was used in the making of components for the ship model Sovereign of the Seas. It is part of a collection of objects used by Jim Williams, maker of fine ship models from about 1930-1955. Most of the components for the models, as well as many of the tools, were handmade by Jim Williams. Jim’s family has donated the ship model “Sovereign of the Seas” and many tools, accessories and documents used in the making of this and other ship models have been donated to Flagstaff Hill Maritime Village. ABOUT the BRAND NAME ON THE SAW - BODMANN and CO, Germany In 1927 the Brisbane Courier Mail described Bodmann and Co of Reinscheid, Germany as "manufacturers of guaranteed tools and hardware. It appears that at least the saw has been re-badges and sold by Bodmann because (1) there are remnants of a label on the saw blade similar in shape to the Bodmann label on the mitre set (2) the removed label reveals the name and logo of "ULMIA Schutz OTT Marke" (3) one of the "Bodmann" labels on the saw handle has been applied in a crooked manner, almost leaving off the last "N". ULMIA is a German manufacturer of high quality woodworking tools. A drawing of a very similar mitre bset with saw can be seen on the ULMIA website. In 2002 the long established company ANKE of Swabian Alb, Germany (makers of cut timber, workbenches and countertops) bought out the name and trademark rights of ULMIA. HISTORY OF SOVEREIGN OF THE SEA (brief) Ship model of HMS Sovereign of the Seas, scale model of 17th Century English war ship, was handmade and carved from plans, enclosed in airtight glass case. All components of that model, including even the smallest pulleys, were hand crafted using tools designed and made by Jim. Outstanding details include functional rigging and moving cannons. Please see our record 3732 of the mode Sovereign of the Seas for further details of the ship and the Jim Williams. This mitre saw set is connected with the hobby and skill of ship model making that has been crafted as a leisure activity for many generations. The hobby is often chosen by serving and retired mariners who appreciate the connection with maritime history. This mitre saw set was used by local Warrnambool man, Jim Williams, who was employed at Cramond and Dickson clothing store, and then at Fletcher Jones menswear for 27 years. It was used in making components for the model of the historic ship, the Sovereign of the Seas. The Sovereign of the Seas was a historic 17th century English war ship with important maritime heritage. Bodmann Mitre Saw set model 348, comprising metal, adjustable mitre saw on timber stand, and metal hand saw with Bakelite handle. The mitre saw is labelled with the trademark of Bodmann, Germany, and stamped with the model number 348. The saw has Bodmann trademark badges on each side of the handle; the text on one of these badges is not quite aligned. The saw blade has remnants of a label under which the stamped logo of ULMIA Schutz OTT Marke is clearly visible. Saw is fitted with two metal guides that slide onto vertical posts on the mitre saw. Metal measuring guide holds the wood job to the correct length. Saw has a protective brown paper wrapper. This mitre saw set is part of a collection of tools and accessories once used by Jim Williams, maker of a series of ship models 1930-1955 including “HMS Sovereign of the Seas”.On mitre saw- 2x logos "REGISTERED / BODMANN / TRADE MARK" and embedded stamp “348”. On saw - Remnant of logo on blade “ULMIA Schutz OTT Marke” with image of a church-like tall building, and 2x , "BEST QUALITY / BODMANN / MADE IN GERMANY” flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jim williams, james bernard williams, ship model hobby, ship model tools, ship model making equipment, ship model making accessories, wood working tool, model making tool, mitre box set, mitre saw, bodmann and co reinscheid, germany, ulna ott of of swabian alb, germany, anke of swabian alb, germany, sovereign of the sea, ship model, hobby, ship model tool, mitre saw set -

Wycheproof & District Historical Society Inc.

Wycheproof & District Historical Society Inc.Photo, Mrs Elaine Storey, Wycheproof School Honour Roll 1914 - 1919, 1919

This plaque recognises the Wycheproof servicemen from State School No1757 who served in the 1914-1919 War. The actual large Honour Roll hangs in the old historic Wycheproof State School building.This Honour Roll contributes to and is part of the nation's collection of War Records; it is unique,believed to be the only one of its kind.PHOTO of large Wycheproof School Honour Roll WW1, on wall at the former Wycheproof S.S. No.1757 building - now the Mount Wycheproof Museum. The plaque of solid wood has cylindrical wooden pillars each side of the 55 gold inscribed names - 12 FALLEN servicemen and marked with a +. Raised wooden carved grapes and leaves adorn the top edge. In the centre, on the scroll are dedication words in Honour of the Brave Men From Wycheproof State School. A small wooden cupboard is attached underneath for War Service Records. This photo is in a display Book registered number 02089 at the Court House. Anderson, E. , Anderson, N. , Boyce W. , Bruce R. , Brotherson, H. , + Brotherson, L. , Barker, D. , Beardon, G., Currie N. , Currie, G. , Cutts, R. , Cutts, A. , Chisholm, A. , Cooper, C. , Duckmanton, S. , Dooley, N. , Dooley, J. , Donnelly, T. , Gibb, J.R. +Gregson A. , Hurcules, W. , Hurcules, C. , Hurcules, N. , + Hayes, L. , Hayes, G. , +Hotham, J. , Hindson, E. , Heap, A. , Holloway, V. , Headley, J. , + Kearney, P. , Matheson, H., Matheson, J. , Miles, H. , McDonald, G., McDonald, W., +W., McElphinney, D. , McElphinney, D. , Pratt, A. , + Orrock, P. , + Orrock, A. , + Robinson, S. , Redgen, J. , + Ryan, J.F. , + Slocombe, R. , Stewart, C. , Stewart, R. , Stavely, W. ,+ Sayers, W. , Secombe, W. , Taylor, R. , Tucker, C. , Thomas, R. , Wilson, S. , Ward, P. + Supreme Sacrifice Anderson, E. , Anderson, N. , Boyce W. , Bruce R. , Brotherson, H. , + Brotherson, L. , Barker, D. , Beardon, G., Currie N. , Currie, G. , Cutts, R. , Cutts, A. , Chisholm, A. , Cooper, C. , Duckmanton, S. , Dooley, N. , Dooley, J. , Donnelly, T. , Gibb, J.R. +Gregson A. , Hurcules, W. , Hurcules, C. , Hurcules, N. , + Hayes, L. , Hayes, G. , +Hotham, J. , Hindson, E. , Heap, A. , Holloway, V. , Headley, J. , + Kearney, P. , Matheson, H., Matheson, J. , Miles, H. , McDonald, G., McDonald, W., +W., McElphinney, D. , McElphinney, D. , Pratt, A. , + Orrock, P. , + Orrock, A. , + Robinson, S. , Redgen, J. , + Ryan, J.F. , + Slocombe, R. , Stewart, C. , Stewart, R. , Stavely, W. ,+ Sayers, W. , Secombe, W. , Taylor, R. , Tucker, C. , Thomas, R. , Wilson, S. , Ward, P. + Supreme Sacrifice wycheproof - school, honour roll, world- war-one, wycheproof- servicemen -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, Steele family members at 'Dalriada' (formerly 'Clifton'), 77 Union Road, Surrey Hills

At ‘Dalriada’, previously ‘Clifton’, 77 Union Road, corner Bona Vista Avenue (dem.) Home of Charles and Sarah Steele pictured with Bertrand Steele and wife Amy, daughter of John Woodhead of ‘Kirklands’. ‘Dalriada’ was built on Woodhead’s land. In 1892 Bertrand purchased the pharmacy on S.W. corner Canterbury/Union Road and moved it to the ‘new’ Surrey Hall. By 1894 he had returned it to its former site where he remained in business until 1900 when he married Amy and went overseas. In 1910 Bertrand Steele became Professor of Chemistry in Brisbane. As his son-in-law, Bertrand was executor of the estate of John Woodhead of ‘Kirklands’. Charles Henri Dillon Steele (1869-1935) - Parents: Samuel Madden Steele and Harriet Sarah Acock. He married Sarah Margaret Russell. They had 2 daughters Margaret Dillon Steele who married William Brayshay Woodhouse, dentist, and Harriet Vevers Steele. From Dentistry Museum site: “Charles Henry Dillon Steele was one of the pioneers of Dentistry in Victoria. He was born in England in 1869 and came to Melbourne in 1889. He was registered by the Dental Board in 1890 and practiced in Collins Street until his death in 1935. His daughter Margaret Dillon (Nancy) Steele graduated BDSc Melbourne in 1929 and obtained the degree of DDS in Toronto in 1931. She returned to Melbourne and rejoined her father in practice at 90 Collins Street and later at 147 Collins Street. In 1935 she married William Brayshaw Woodhouse (BDSc, DSc Melbourne) who bought the practice of Mr. Steele in that year and continued in practice there until 1980. Their son Anthony Dillon Woodhouse graduated BDSc (Melb) 1958 and DDS (Toronto) in1966 and continued in the old family practice established by Mr. Steele." (Dr. Tony Woodhouse, May 1984) Sarah Steele - Born Sarah Margaret Russell, after her marriage to Charles Henry Dillon Steele was very active in community work, notably as President of the local Patriotic League. It was she who persuaded John Kendrick Blogg to carve the Honour Roll for The Shrine in the Surrey Gardens. A black and white photograph of a family group seated on the grass. (mr) bertrand steele, (mr) john woodhead, house names, pharmacists, dentists, clothing and dress, union road, surrey hills, (mr) charles henri dillon steele, 'kirkland', 'clifton', 'dalriada', (miss) amy woodhead, (miss) sarah margaret russell, (mrs) sarah margaret steele -

Flagstaff Hill Maritime Museum and Village

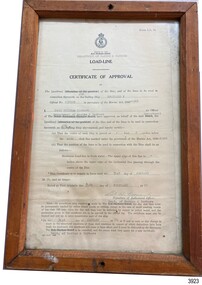

Flagstaff Hill Maritime Museum and VillageDocument - Certificate of Approval, Load Line, 25-02-1970

This Certificate, Load-Line, gave approval for the vessel Reginald M to load cargo up to a certain line, marked by a disc attached to the ship and inspected by the South Australian Harbors Board. The vessel had a long and varied life of service. This Certificate relates to early 1970, before the ship was sold to the Lyall Mining and Rail Company. The Load Line on the Reginald M was carved on the ship, inside the hull and not removeable. The REGINALD M - The vessel “Reginald M” was a two-masted coastal ketch, owned and built by Mr. Jack (John) Murch of Birkenhead, Port of Adelaide, South Australia. Its construction took approximately 6 months and it was launched at Largs Bay in 1922. The Reginald M’s purpose was to serve the coastal trade of South Australia, to carry cargo cheaply and efficiently. It is believed that the keel was in fact hewn from two telegraph poles! Its builder frequented all the salvage yards for materials and fittings. Reginald M had a very shallow draft and a flat bottom that enabled it to come close to shore and to sit high and dry at low tide or to be beached on sand. The flat bottom was also to make the ship able to skim over reefs. Wagons could load and unload direct from her side. Her cargo included Guano, Barley, Wool, Horses, Cattle, Timber, Explosives, Potatoes, Shell Grit and Gypsum. After a variety of services, in late 1970 Reginald M was sold to the Mt. Lyell Mining and Railway Company and was used by them as a barge to carry explosives. In 1972 the Navy League of Strahan, Tasmania, purchased her for use by the Strahan Sea Cadet Unit to use at Macquarie Harbour and renamed her T.S. Macquarie. However this plan for use of Reginald M did not come to pass. In 1974 Mr. Andrew Rennie, of East Brighton, Melbourne, bought her for a similar purpose. , paying $5,000 and donating a ‘Cadet of the Year” trophy to the Sea Cadets. He sailed her from Strahan to Melbourne, planning to use her for pleasure sailing. Also in 1975 Reginald M was sold to Melbourne Ferry Company at auction. Later in 1975 the Reginald M was bought by Flagstaff Maritime Museum for $20,000 . She has been restored and is now one of the exhibits in the Village lagoon or lake. It was restored in 2006 using funds from a $4,000 government grant.This Certificate is significant because of its association with the last working days of REGINALD M. REGNIALD M was a coastal trading ketch from South Australia built in 1922. It was one of very few sailing coastal trading vessels still existing until 2016, and its flat bottom, single chine shape illustrated a very simple but robust method of construction, compared to other round bilged examples of trading vessels. The vessel is listed on the Australian Register of Historic Vessels (ARHV Number: HV000562.)Certificate, rectangular, behind glass in wooden frame. Certificate is an official printed form, some information is over-typed, other information is hand written and signed. Frame has a central hole in top and bottom. The Certificate relates to Load Level of the vessel Reginald M and refers to the exact placement of a disc within the vessel that indicates the maximum load in fresh water. . Issued to the vessel 'Reginald M', Official Number 137228. . Issued by the Sough Australian Harbors Board . Valid from 25-02-1970 to 31-01-1974. . Signed by Neil Cormack, 25th February 1970Certificate of Approval - Load Line for sailing vessel Reginald M, Official Number 137228. Logo of the South Australian Harbors Board. Issued by Department of Marine & Harbors, Port Adelaide, 25th February 1970. In force until 31st January 1974. Signed by Neil William Cormack, authorised officer for Department of Marine & Harbors. Typed onto form: "AUX [SAILING SIP]" "REGINALD M" "137228" "1968" " Neil William Cormack" "Department of Marine & Harbors" "1 [foot] 3 [inches below the] main [deck]" "31st JANUARY 74" "25th FEBRUARY 70" Signature: "Neil W Cormack"flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, coastal trader, reginald m, ketch, john murch, ch murch, reg webb, carribie station, mt lyell copper company, melbourne ferry company, certificate of approval, load line, 137228, load line disc, 25-02-1970, neil w cormack, neil william cormack, south australian harbors board, department of marine and harbors, harbours -

Federation University Art Collection

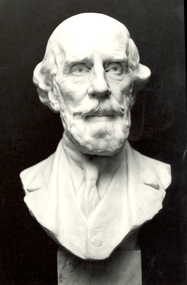

Federation University Art CollectionSculpture - Marble sculpture, 'Professor Alfred Mica Smith' by Paul Montford, 1924

Paul Raphael MONTFORD (1868 - 1938) Paul Montford moved to Australia to carve four buttress groups in granite for the Melbourne Shrine of Remembrance. In 1924 he was teaching at Geelong Technical College. Professor Alfred Mica Smith was a long term lecturer at the Ballarat School of Mines. The sculpture was commissioned by former Students of the Ballarat School of Mines working in Western Australia. One of those former students, William Corbould, remembered his first encounter with the professor fondly:- 'From the Registrar's Office I was led to be introduced to the Professor of Chemistry, one Mica Smith. The initial encounter gave me little encouragement - his large laboratory was filled with hundreds of bottles bearing strange labels with queer symbols on them. My heart sank. At the first opportunity I grabbed my hat and made for the door, but the good professor called me back. I pointed out that I was never any good at school ... so it was no use pretending to be clever enough to understand all those weird symbols! The Professor told me not to worry about that and took me to one of the benches where he found a blowpipe and a charcoal block. Mixing together two powders from bottles on the shelf he transferred a sample to the charcoal and directed the bunsen flame onto it. Soon it began to melt and a white bead appeared in front of my eyes. He then took a test tube and added a little colourless liquid from each of two bottles. A beautiful dark blue colour appeared. My interest was won.' Alfred Mica Smith was the well-loved Professor of Chemistry and Metallurgy at the Ballarat School of Mines between 1881 and 1922. Upon reaching the age of 78 Mica Smith retired having influenced generations of miners. At the time of his death Ballarat School of Mines Students’ Magazine reported: "In the annals of the School, the year 1922 will be noted chiefly as the last year in which Professor Mica Smith taught here. With his retirement, a memorable epoch closed. The Professor has served the School for 42 years with a service, the length and thoroughness of which are unique. … It is not quite realised in this city how famous the School became throughout the world, nor to what extent the Professor was responsible for its high position in the mining and metallurgical world. … This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.Marble bust of Ballarat School of Mines Professor Alfred Mica Smith by Paul Montford. The bust is mounted on a jarrah pedestal made from timber donated by the Millar Timber and Trading Company. The bust was formally presented to the Ballarat School of Mines on Saturday 13 December1924 in front of Alfred Mica Smith and a large gathering. It is signed 'Paul R. Montford, Sc, 1924' at the back.Professor A. Mica Smith, 1924, Presented by His Old Students Associated with Western Australia as a Token of Affectionate Esteemart, artwork, ballarat school of mines, montford, paul montford, alfred mica smith, mica smith, marble, bust, sculpture -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Plant Stand, Late 19th Century (1898)

During the years 1869-1935 there were well over 250 registered bamboo furniture producers in Britain. The earliest recorded firm was Hubert Bill of 14 Little Camden St, London N.W., who claimed to have been established in (1869) while Daniel Jacobs & Sons of Hackney Road, London, were still in business in 1915, after 45 years of production. Design, quality, price and methods of construction were fairly consistent throughout the whole period, but it was the imaginative and often eccentric choice of subject matter that marked differentiation between the various firms. While most produced standard tables, stands and fire-screens, the more adventurous offered for sale items such as corner shelve units, charcoal barbecue grills and musical tea tables. Shelves were often covered with embossed leather paper designs, at first imported from Japan and then later produced in England. Some firms incorporated the knobbly roots of the bamboo stems into their designs, generally to form feet. Occasionally handles to drawers and cupboards were made with these roots although they were more commonly carved as imitations. Handles were mostly of cheap metal or brass. The ends of the bamboo canes were capped with stamped metal or turned bone, ivory or wooden discs. Methods of construction fell into three categories. First and most common is that of pegging. Bamboo stems being hollow, thick dowels can easily be glued into the joints. Some firms farmed out this work of `plugging' the ends of the canes to part-time workers at home. The second method, that of pinning, was far less satisfactory as bamboo tends to split lengthwise and therefore the jointed pieces eventually disintegrated. The most efficient method was that patented in 1888 (patent No 2383) by the firm of W. F. Needham in Birmingham. It consisted of metal shoes and covers for all joints which were made by wrapping a metal strip around the stems and soldering the overlapping ends. Some joints were further strengthened by a small pin or screw. Needham was by far the largest and most successful manufacturer and their individual and superior method of construction undoubtedly gained them their reputation. A. Englander & Searle of 34 Gt Eastern St and 31 Mare St, Hackney, London, were a firm particularly concerned with methods of construction. Although they seem to have entered the bamboo furniture market at a comparatively late date, about 1898, they produced inexpensive' bamboo, aimed particularly at the export trade. Stating in their catalogue that bamboo furniture “can be exported in one piece or it can be exported in pieces and put together again. The fixing up is much facilitated by a system of marking and numbering. Further, no glue is required for putting together as the screw system only is applied”. This method of construction best fits the Etagere and this item in the flagstaff collection and it is believed to have been made by A Englander & Searle, exported in a knock down form to Australia, purchased in kit form from a dealer here and put together by the purchaser. The bamboo plant stand is a significant item as it highlight furniture fashion of the late Victorian era. This item was highly sort after in its time and although mass produced, not many examples remain because the item is so fragile so this example is a valuable addition to the Flagstaff collection. It is believed,the construction method used is by a notable and respected maker in England of bamboo furniture that was aimed specifically at the export market and probably came to Australia in kit form to be assembled by the purchaser.Bamboo plant stand with octagonal top edged with tortoise shell bamboo the top is of wood and supported by four tortoise shell bamboo legs joined at the base by a square cane covered shelf. The tortoise shell appearance is brown lacquer. Item is part of the Giles Collection. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, furniture, plant stand, bamboo furniture, etagere, victorian furniture, simulated bamboo, tortise shell, a englander & searle, domestic furniture, giles collection, henry giles, cooramook, mailor’s flat, wangoom, 19th century household goods -

Victorian Interpretive Projects Inc.

Victorian Interpretive Projects Inc.Photograph - colour, Clare Gervasoni, St Peter's Catholic Church, Daylesford, 2015, 14/06/2015

"The fine structure of St. Peter's, with its prettily-decorated interior, which holds crowded congregations at Holy Mass on Sundays, is alone an eloquent testimony of the piety and devotion which permeates the whole parish. Attached to the church is a circulating library, and Catholic papers and other literature are distributed at the church door. Branches of the H.A.C.B. Society and Catholic Federation are doing much good work. (Melbourne Advocate, 17 January 1914) "OPENING AND CONSECRATION OF THE NEW CATHOLIC CHURCH OF ST. PETER’S, DAYLESFORD Cross on St. Peter'sNotwithstanding the inclemency of the weather, the opening of the new Catholic Church of St. Peter’s, yesterday (Sunday), attracted a crowded congregation. Although the rain, which has poured almost incessantly for some days past, had left our roads and streets in the condition for which Daylesford is celebrated in winter weather, and although he storm and rain seemed to increase as the hour announced for the ceremonies approached, the church was filled by a large congregation, comprising all sects and denominations of Christians in and around the district. The beautiful edifice, erected mainly through the zeal, liberality and energy of the respected pastor, presented a most imposing appearance, and reflects infinite credit upon the Rev. Mr. Slattery, and the flock committed to his charge. The church was commenced in November 1863 and has been in the hands of the workmen up to the present time, work being uninterruptedly carried on. On commencing the foundations, it was necessary to excavate until solid clay was reached, which in consequence of the deep rich chocolate soil on the site of the building, had to be carried down to an average depth of 6 feet 6 inches. The foundations were laid with massive stones in courses of 12-inch, and four feet thick, reducing to 3 feet below the floor line. The style of the building is decorated Gothic, and consists of a nave, 80 feet by 30 feet in the clear, and a chancel 18 feet high; from floor line to apex of roof, 47 feet, which is elegantly constructed, consisting of six spans or frames with puncheons resting on carved corbels, low down between the windows. The north side consists of a handsome entrance, near the north-west angle, approached by nine steps of cut stone, and four bays of windows on nave, and a small door on side of chancel, intended as an entry from the sacristy. The south side presents a very handsome view to Victoria street, a beautiful porch entrance giving access to the building on the south-east end of nave; and on the south-west angle a handsome octagonal spire, terminating in an iron cross, with gilt floriations; the height of top of cross, from floor line, is 88 feet. A stone stairs gives access to the organ gallery and the belfry. The whole of the windows are of a handsome geometrical design, and carved in stone, with mullions and tracery, and glazed with amber-tinted glass, the chancel window being 15 feet high, and 8 feet wide. The chancel arch is unusually large, 27 feet St. Peter's interiorhigh and 18 feet wide, and handsomely moulded, and presents a fine appearance from the body of the church. The roof is stained a rich oak, with heavy cornice, and all the walls are smoothly plastered, and colored peach color, giving the amber-tinted glass a beautiful soft cathedral appearance to the interior. The altar is of a very chaste design, the panels being moulded with Gothic heads, and finished in white and gold; the altar rail was not completed, but is intended to be of polished cedar, with carved pillars. The interior fittings will be proceeded with immediately, and to complete the design, an organ gallery, with sittings for about 100 persons besides the choir, will be constructed on the west end. It is intended also to place pillar gaslights on each side of the main entrance, for lighting during vespers in winter. The style of architecture has been strictly carried out, and in the best and most substantial manner. The building has been erected under the superintendence of the architect Mr. John Townsend Brophy, a member of the congregation, and who has discharged his duty with great ability and care. The hour of half-past eleven has scarcely passed when from the sacristy entered His Lordship the Right Rev. Dr. Gould, Bishop of Melbourne, preceded by the Very Rev. Dean Hayes (Sandhurst), the Rev. P. J. Slattery, and a number of boys dressed in white surplices. The Right Reverend Prelate proceeded to the foot of the altar, the Very Rev. the Dean on his right, and the Rev. P. J. Slattery on the left. The prayers usual upon the occasion were read by the Bishop. A procession was then formed, and went around the church in the following order. Several youths bearing wax candles first, next the Very Rev. the Dean, then the Bishop and his train bearers, and following were the Rev. Mr. Slattery and acolytes. Having returned to the altar in the same order, the Deacon (Dean Hayes) and Sub-Deacon (Rev. P. J. Slattery) proceeded to robe his Lordship, who had taken his seat at the epistle side of the altar, for the solemn High Mass, at appropriate times wearing his mitre and bearing his crozier. The mass, which was chanted by the Bishop with touching simplicity and earnestness, was then commenced. The choir, under the direction of Mr. Meunsch, organist, was full and most effective. Mrs. Testar, of Melbourne, having generously offered her valuable services, took the leading soprano solos, and it is scarcely necessary to add, rendered them with exquisite taste and feeling – her beautiful voice being heard with great effect throughout the entire building. The choir consisted of the following ladies and gentlemen who volunteered to aid in the ceremonies upon this most interesting occasion. Ladies: Mrs. Tresar, soprano; Mrs. J.J. McCormick, alto; Miss Julia Conry, soprano; Mrs. Vincent, soprano; Mrs. Aitken, soprano. Gentlemen: H. Guthiel, tenor; Master John Murphy, tenor; James Knox, bass; J. M. Murphy, bass; Mr. Staunton, baritone; Mr. Sourby, alto; Mr. Short, bass. The chant, “Let us adore,” during the procession, was given by Mrs. Vincent with considerable power. The selection of the “Imperial Mass” (Haydn’s No. 3) was felicitous, and the highly artistic and finished manner in which the different parts were sustained, demonstrated that great and persevering care must have been bestowed on the preparation for “the opening day.” The “Kyrie” was given with the full strength and power of the choir. The swelling of the voices in complete harmony, and the pealing of the organ in the midst of incense and prayer, produced a most marked effect upon the congregation. In the “Gloria,” the solos of Mrs. Testar were really beautiful and Mrs. McCormick rendered the alto solos with considerable merit. Mr. Knox sang the part commencing with the words “Qui tolles” with much taste and power. The “Credo” than which we believe there is not a more magnificent piece of sacred music extant, was most successful in its rendering, nor do we ever remember to have heard anything more touching than the manner in which the line “Vetam Venturi in Seculi,” was given by Mrs. Testar. The offertory hymn “Come unto Me all ye that labor,” was given by Mrs. Testar with the most thrilling effect. The “Sanctus” having been sung, in which Mr. Sourby ably rendered an alto solo, the “Agnus Dei” was commenced with a solo by Mrs. McCormick and was given with great taste and feeling, Mrs. Testar, at the conclusion of the “Agnus,” taking up the soprano part. Mass being concluded, the Very Reverend Dean Hayes ascended the altar and proceeded to preach the opening sermon, taking as his text Second Paralipomenon [Chronicles II], 7th chapter and 16th verse – “For I have chosen and have sanctified this place that My hand may be there for ever, and My eyes and My heart may remain there perpetually.” St Peter's manseAt the close of the sermon a collection was made by the very reverend preacher, assisted by John Egan, Esq., Corinella, on behalf of the church, and about fifty pounds were contributed. When it is remembered that 500 tickets had been issues at 10s each, and the inclemency of the weather taken into consideration, the collection may be regarded as a large one. Benediction was sung by the Rev. P. J. Slattery, assisted by Dean Hayes, the choir singing the “O! Salutaris Hostia” and “Laudate.” Handel’s Hallelujah Chorus was sung at the termination of the ceremonies. The vestments issued at Benediction, as well as at the Mass, were of the most gorgeous and beautiful character. When the Benediction was over, the Rev. P. J. Slattery, standing at the front of the altar said– “I wish to say one or two words before the congregation leave. I feel most deeply indebted to all of you who have attended here today for the honor and glory of God, not withstanding the difficulties you had to encounter from this most inclement season. I am truly delighted at such a manifestation of feeling, and will not easily forget it.” The rev. gentleman having disrobed, thanked the members of the choir for their kindness in assisting at the ceremonies, and more especially Mrs. Testar, who had braved all the storm and rain to be present at, and give the advantage of her great musical abilities on, the “opening day.” (Daylesford Mercury, 15 May 1865.)A number of photographs of St Peter's Catholic Church, Daylesford, taken at the 150th anniversary celebration. st peter's catholic church daylesford, decoration, altar decoration, anniversary, daylesford, religion, painting, interior, slattery, gough, d'alton, mcmahon -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wooden Bread Board, Not known

In the high tech, fast paced society that we live in, it’s easy to take some things for granted. Case in point: the wood cutting board on which you’ll probably be preparing the evening’s dinner. Have you ever taken the time to think about the history of the cutting board? Where did it come from, and what did ancient civilizations use to cut their meats, fruits and vegetables? Wood throughout the ages Since the dawn of time, wood has been one of the most available materials used by mankind to build tools and lodgings, so it’s not really surprising to know that wood has been used in the preparation of food since the prehistoric ages. Of course, back then, cavemen probably used an unpolished slab of tree trunk to cut the kill of the day on and they probably didn’t think twice about saving it once the meal was over. Chances are they probably threw it in the fire with the rest of the wood needed to kindle it. Advances in technology Throughout the centuries, mankind evolved and started creating machines from steam, electricity and metal. When the circular saw was invented, nicer, cleaner slabs of wood were cut and used as cutting boards. Since soft wood was the most available type of wood at the time, it was the material of choice for to be used for cutting boards. Boards were made smaller since the slab of wood could now be cut to any desired size. Since they were made smaller, they were also used to eat off of and some people referred to them as trenchers. Trenchers were originally pieces of stale hard bread that were used as substitute plates. Wood trenchers quickly became the replacements of the eatable dinnerware. The butcher block: the cutting board’s larger cousin In the industrial ages, many industries rapidly developed, and the butchery industry followed this trend as well. Before the invention of the cutting board, butchers used tree rounds to carve their meat on. The rounds were often too soft and they rapidly became unsanitary. Hard maple wood butcher blocks were the preferred choice of the industry. They were made to be extremely thick and durable, so durable in fact, that a butcher could use the same block for almost his entire career. Cutting boards around the world As cutting boards began to be more and more used in kitchens around North America, the rest of the world crafted such boards from different materials. The East used thick bamboo as their material of choice. Despite its frail appearance, bamboo is quite strong and made durable cutting boards and butcher blocks. Europe used maple in the crafting of their cutting boards while Persia used flat pieces of polished wood in their kitchens. The world then saw cutting boards that were being made from other materials like plastic and they came in all shapes and sizes, but they always served the same purpose, to provide a household with a safe, clean surface on which to prepare meals for their friends and family members. https://www.woodcuttingboards.com/news/quick-history-of-the-cutting-board-47.aspxThe use of the wooden chopping board over time. Wooden Rectangular Bread board . Worn (concave in centre). Raw wood.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, chopping board, cooking -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bread Board

In the high tech, fast paced society that we live in, it’s easy to take some things for granted. Case in point: the wood cutting board on which you’ll probably be preparing the evening’s dinner. Have you ever taken the time to think about the history of the cutting board? Where did it come from, and what did ancient civilizations use to cut their meats, fruits and vegetables? Wood throughout the ages Since the dawn of time, wood has been one of the most available materials used by mankind to build tools and lodgings, so it’s not really surprising to know that wood has been used in the preparation of food since the prehistoric ages. Of course, back then, cavemen probably used an unpolished slab of tree trunk to cut the kill of the day on and they probably didn’t think twice about saving it once the meal was over. Chances are they probably threw it in the fire with the rest of the wood needed to kindle it. Advances in technology Throughout the centuries, mankind evolved and started creating machines from steam, electricity and metal. When the circular saw was invented, nicer, cleaner slabs of wood were cut and used as cutting boards. Since soft wood was the most available type of wood at the time, it was the material of choice for to be used for cutting boards. Boards were made smaller since the slab of wood could now be cut to any desired size. Since they were made smaller, they were also used to eat off of and some people referred to them as trenchers. Trenchers were originally pieces of stale hard bread that were used as substitute plates. Wood trenchers quickly became the replacements of the eatable dinnerware. The butcher block: the cutting board’s larger cousin In the industrial ages, many industries rapidly developed, and the butchery industry followed this trend as well. Before the invention of the cutting board, butchers used tree rounds to carve their meat on. The rounds were often too soft and they rapidly became unsanitary. Hard maple wood butcher blocks were the preferred choice of the industry. They were made to be extremely thick and durable, so durable in fact, that a butcher could use the same block for almost his entire career. Cutting boards around the world As cutting boards began to be more and more used in kitchens around North America, the rest of the world crafted such boards from different materials. The East used thick bamboo as their material of choice. Despite its frail appearance, bamboo is quite strong and made durable cutting boards and butcher blocks. Europe used maple in the crafting of their cutting boards while Persia used flat pieces of polished wood in their kitchens. The world then saw cutting boards that were being made from other materials like plastic and they came in all shapes and sizes, but they always served the same purpose, to provide a household with a safe, clean surface on which to prepare meals for their friends and family members. https://www.woodcuttingboards.com/news/quick-history-of-the-cutting-board-47.aspxThe bread board is an example of kitchen equipment used during Victorian times and similar to those used today.Bread board. Wooden, octagonal, plain sanded light wood. Has decoration around edge and indented circular line to delineate round cutting board section.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bread board, cutting board, pastry board, kitchen utensil, kitchen equipment, baking equipment, food preparation -

Federation University Art Collection

Federation University Art CollectionPrint - Printmaking, Artwork from Dong Ho Village, c1970-2010

Dong Ho is on the Duong River in Bắc Ninh Province, Vietnam. The woodcut painting (Tranh khắc gỗ dân gian Dong Ho is a line of Vietnamese folk painting originating in Dong Ho village. The traditional themes of Dong Ho painting are good luck signs, historical figures, folk allegories, popular stories, and social commentaries. Elements of everyday life are well integrated in Dong Ho paintings to express the thoughts and wishes of people. (Wikipedia - https://en.wikipedia.org/wiki/%C4%90%C3%B4ng_H%E1%BB%93_painting, accessed 11 April 2017.) Craftsmen in Dong Ho use a special type of paper named giấy điệp. The bark of dó tree, which normally is grown in Tuyên Quang Province, is soaked in water for months, then mixed with powders of seashells (sò điệp), which is the origin of the paper's name, and glutinous rice to make sheets of paper. The s seashell and glutinous rice results in paper with an exotic sparkling hard background which is able to conserve the durability of colours. The colours are refined from natural materials which are easily found in Vietnam. For instance, the red colour is taken from red gravel in Thiên Thai Mountain, while the black comes from charcoal of burned bamboo leaves. The hand carved woodblock is applied with paint and pressed on a sheet of paper like a stamp. The process is repeated with different colours until the craftsman is satisfied with the outcome. One woodcut is for outline and several others are for each colour printed. The finished picture is covered with a layer of rice paste (hồ nếp) to strengthen the durability of its illustration and colours and afterwards dried under the sun. From beginning to end the process takes six to seven months. (Wikipedia - https://en.wikipedia.org/wiki/%C4%90%C3%B4ng_H%E1%BB%93_painting, accessed 11 April 2017.) The tradition of Đông Hồ painting dates back to the 11th century during the reign of the Lý Dynasty. Originally, Đông Hồ paintings were made with black-and-white prints of woodcuts, but from the 15th century, different colours were introduced by craftsmen in the village. As a village specialized in making woodcuts and paintings, almost all Đông Hồ villagers were involved in the manufacturing of paintings from carving the woodblocks, producing điệp papers, obtaining natural colours to creating new themes, and printing.(Wikipedia - https://en.wikipedia.org/wiki/%C4%90%C3%B4ng_H%E1%BB%93_painting, accessed 11 April 2017.) Before 1945 over 150 families in Đông Hồ village were making pictures, but the tradition has rapidly faded. Villagers can no longer make a living based on this production so only a few households in the village still make pictures, while many others have switched to producing joss paper and votive paper object.(Wikipedia - https://en.wikipedia.org/wiki/%C4%90%C3%B4ng_H%E1%BB%93_painting, accessed 11 April 2017.)Asian ArtA framed collection of work by children from Dong Ho Village, Vietnam.dong ho, vietnam, woodcut, printmaking, dong ho art, dong ho painting, dong ho village, vietnam. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCraft - Ship Model, S.S. Nelson, 1877 - 1984

This beautifully made ship model is a side relief of the steam ship “S.S. Nelson”, which was launched in 1877. The model’s case stands out because of its ornately carved internal frame. Relief models of ships, sometimes called half models, were often built by the shipbuilders as an exact scale model of the finished ship. The shipbuilders would use the model to ensure that the design was balanced. They would use the model as a point of reference during building. Also, ship models were used to demonstrate the designs to prospective buyers. It is not known whether this model of the “S.S. Nelson” was made for these purposes. HISTORY of the “S.S. Nelson” During the period 1840-1890 shipping was the cheapest and most practical means of carrying produce and goods to and from coastal towns such as Warrnambool. In the 1850s regular domestic steamer services began and by 1870 the passenger trade was booming. Passengers were taken to the ship’s side in small boats called lighters, which took it to ships at anchorage in Lady Bay, then climbed aboard up ladders or gangways. Their fare covered accommodation Saloon/Cabin section (higher class and more expensive) or the Steerage section (lower class and less expensive, below deck level). Produce included livestock such as pigs and fowls, and dairy products, bales of wool, and potatoes. The goods were loaded from the Warrnambool Jetty into the lighters. The S.S. Nelson was built by Messrs Blackwood and Gordon of Port Glasgow for a cost £25,000 in 1877. She was an iron screw steamer with an overall length of 200 feet, beam 25.5 feet and a depth of hold of 19.4 feet, which gave her a gross measurement of 649 tons. Her engines gave her a best speed of 13 knots and a maintainable speed of 12 knots. She was described as a handsome, star decked, efficient steamship, fitted with accommodating for 75 first class passengers in a saloon, and 40 second class passengers in a cabin. The S.S. Nelson arrived in the colony of Victoria on March 9th, 1877. She was first registered in Warrnambool by the Warrnambool Steam Packet Company under the management of Mr William Evans, and employed in the coastal trade of south west Victoria. She was very popular in 1878, registered under the new ownership of the Western Steamship Navigation Company, trading between Melbourne, Warrnambool and Portland. Captained John Nicholson commanded the S.S. Nelson after the previous captain, Thomas Smith, was suspended in 1882 for six months by the Victorian Steam Navigation Board following the collision between the S.S. Nelson and the S.S. Julia Percy. Other Captains include S Drewet and John Thompson. The S.S. Nelson was sold to Messrs. Huddart, Parker and Co. and re-registered in Melbourne on June 23rd, 1890. The new owners intended to use her for their Bass Strait crossing between Melbourne, Victoria and Launceston, Tasmania. On the night of Friday, June 27th 1890, under the command of Captain Carrington, she was on her way to Launceston on her first crossing for her new owners. She had no passengers and very little cargo and was to return to Melbourne with passengers the following morning. She was only 21 hours out of the dock when she struck Porpoise Rock in the Tamar River. All crew of 25 were saved but the bulkheads gave way and she rapidly filled before keeling over and disappearing in approximately 130 feet of water. The new owners had fully insured the almost 14-year-old S.S. Nelson with the Australian Alliance Insurance Company and she had only been in their possession for four days. This ship model of the S.S. Nelson is significant for its connection with the steam screw ship S.S. Nelson, one of a fleet of vessels owned by the Warrnambool Steam Packet Company. The S.S. Nelson was specifically built and purchased for the Victorian coastal trade business of the late 19th century, when shipping was the cheapest and most practical means of transporting goods and passengers between Victoria’s coastal towns and the major port at Melbourne. Once the railway came to Warrnambool in 1889, the steam shipping industry began to decline.Ship model; relief of the S.S. Nelson, showing deck superstructure, ventilators and single funnel. Ship's name is painted on the bow "NELSON". Wood model, varnished finish over natural wood and black painted areas. Timber case with ornate edging and glass front and sides."NELSON" painted on bowflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, s.s. nelson steam ship 1877, screw steamer, 1877 vessel, ship model s.s. nelson, blackwood and gordon port glasgow, warrnambool steam packet company, western steam navigation company, south west coast trader, sea transport melbourne to portland, victorian steam navigation board, s.s. julia percey, captain john nicholson, captain thomas smith, captain s drewet, captain john thompson, captain carrington, huddart, parker and co, bass strait crossing 1890, sea transport melbourne to launceston, porpoise rock tamar river, australian alliance insurance company, ship model making, vessels, victorian coastal trader -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Historical, Warrnambool, C. 1854-1871

This is an image of the Warrnambool Lighthouse Complex on Middle Island in 1854. The Store, Lighthouse Keeper's Quarters, Lighthouse and Flagstaff are in the background. The foreground shows a covered buggy drawn by two horses and a person in attendance, and another wheeled vehicle behind it with a figure nearby. There is a saddled horse to the right with two males in conversation nearby. The ground is soft, perhaps the riverbed or sandy shore. THE LIGHTHOUSE KEEPERS Lighthouse Keepers were responsible for keeping their Lighthouse’s lights shining at night. They kept a lookout for passing vessels and changes in weather. They were expected to clean, polish and maintain the equipment and buildings. They kept regular and detailed records of who was on watch, and the time the light was lit, trimmed and extinguished. They kept a journal about other events that occurred. They keep regular, accurate Meteorological Logs. It was expected that they were competent in Morse code signalling. They would be called to help in times of disasters and shipwrecks and to give official statements about these events. Many Lighthouse Keepers also volunteered as members of the lifeboat crew. The Lady Bay lighthouses were officially classified as small, so the Keepers had the official titles of Senior Assistant Lighthouse Keeper and Assistant Lighthouse Keeper. They were employed by the Public Service and paid rent to live in the Lighthouse Quarters. They were compulsorily retired at the age of 60, with most receiving a superannuation payment. Despite their time-consuming duties, there was time to follow hobbies and crafts such as growing vegetables, playing musical instruments, making models of buildings including lighthouses, and crafting furniture pieces. An example of a keeper’s skills is the carved fire screen made by /assistant Keeper Thomas Hope in the late 19th century and displayed in the Lighthouse Keeper’s cottage at Flagstaff Hill. Both Alexander and Farncombe had served under Senior Keeper Robert Deverell, who was the first and only Senior Lighthouse Keeper at the Middle Island Complex. John Alexander was the Assistant Keeper in the 1850s. Andrew Farncombe was the last Assistant Keeper at Middle Island, serving there with his family from 1864 to 1871. During 1871 and 1872 the Lighthouse Complex was moved to Flagstaff Hill on Merri Street. Farncombe and Deverell then became the first Keepers and occupants of the Lady Bay Lighthouse Complex at Flagstaff Hill. They continued their service together; overall, Deverell served from 1859 to 1885 and Farncombe from 1864 to 1974. WARRNAMBOOL'S LADY BAY LIGHTHOUSE COMPLEX - The original Lighthouse Complex was built on Middle Island in 1858-1859 then transferred stone-by-stone to Flagstaff Hill in 1871. The Complex comprised the Lighthouse, the Lighthouse Keepers’ Quarters and a Privy. The bluestone Keeper’s Quarters was a cottage divided into two compartments, one for the Senior Keeper and his family, the other for the Assistant Keeper and his family. The bluestone Store was divided into three; a store, a workshop, and an oil store (or office). The Privy comprised a small building also divided into two separate, back-to-back toilets, one for each Keeper and his family. In the 1970s the Flagstaff Hill Planning Board was set up under the chairmanship of John Lindsay. The Board was to make recommendations to the Warrnambool City Council regarding the use of the buildings and the rest of the Crown Land on the site. The Flagstaff Hill Maritime Village opened in 1975 and began renovating the Cottage in stages, during which time evidence of a 1920s fire was found in the eastern section of the cottage. Additions of a porch on the west and a washroom on the east were made in the 1980s. The western part of the building is now a Shipwreck Museum and the east has returned to a late 19th-century Lighthouse Keeper’s cottage and includes the screen made by Assistant Lighthouse Keeper Thomas Hope in the late 19th century. Hope served two periods of time at the Lighthouse. This photograph is significant as a visual record of the original Warrnambool Lighthouse Complex on Middle Island, the origin of what is now the Lady Bay Lighthouse Complex. The photograph is significant for its connection to the Complex, which is now listed on the Victorian Heritage Register, H1520, for being of historical, scientific (technological) and architectural significance to the State of Victoria. The Complex is significant as an example of early colonial development. The photograph is significant for its connection with the important navigational function of the Lighthouses, a function still being performed to this day. The photograph is also significant as it shows an example of buildings organised by the Public Works Department in Victoria in the mid-to-late 19th century. The structures tare still stand strong. Photograph of horses, a buggy and three gentlemen in the foreground and the background shows a lighthouse and accompanying buildings. Printed in black and white. (Another two horse-drawn vehicles are partially visible). The subject is the Lighthouse Complex on Middle Island, Warrnambool, dated between 1854 and 1871.An inscription is handwritten in black pen on the back of the mounting board."The lighthouse and accompanying buildings were / established on Middle Island in 1854, as this / picture shows. In 1871 they were moved to their / present site on Flagstaff Hill."flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, warrnambool, maritime museum, shipwreck coast, lighthouse keeper's cottage, lighthouse residence, lighthouse, chart room, quarters, privy, middle island, beach lighthouse, obelisk, lighthouse complex, lady bay complex, warrnambool port, warrnambool harbour, lady bay, keepers, lighthouse keeper, upper lighthouse, lower lighthouse, assistant keeper, ports and harbours, cottage, meteorological record, 1854, 1871 -

Eltham District Historical Society Inc

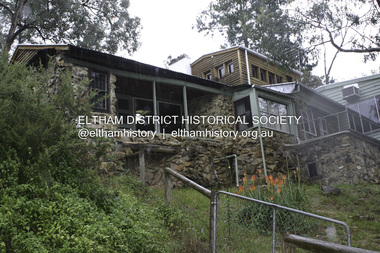

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Stonygrad, 34 Hamilton Road, North Warrandyte, 30 January 2008