Showing 220 items

matching plant and machinery

-

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING REPORTS - EXTRACTS IRONBARK SOUTH MINE MANAGER'S REPORTS

Handwritten extracts from the Manager's Reports Ironbark South Mine on the Sheepshead Line for the Hlaf-Year ended Feb. 4th, 1936. Report mentions work carried on the mine,crushings, gold yield and development work carried out. H. E. Jones, Gen. Manager and P. I. Wellington, Mine Manager. Also a profit and loss account 1/2 year to 31st Dec. 1935. Details expenses such as wages firewood, etc. Value of gold and plant and machinery. Aslo for the 1/2 year ending 19/1/1937, crushing and gold yield. H. E. Jones. M. Manager.document, gold, mining reports, mining reports, ironbark south mine, h e jones, p i wellington -

National Wool Museum

National Wool MuseumTextile - Onkaparinga Blanket, Waffle Collection, Unknown

Onkaparinga started in South Australia in 1869. Migrating from Germany, two brothers, Heinrich and Edward Kramm, both weavers, purchased and brought with them some machinery and established themselves in Hahndorf in a mud hut. Their original plant consisted of one carding machine, one spinning mule of 30 spools and 2 hand looms. The spinning mule was horse driven, the others all hand operated. The wool was washed by hand and dried in the sun then teased by hand. Now 145 years later the brand name Onkaparinga, is known all over the world, the products reflect the experience, passion and ingenuity of over a century's tradition in providing luxurious home wares. Donated to the National Wool Museum by Joyce GrayLight orange waffle weave woolen blanket, with nylon trimming. Product tag included with plastic case. On product tag - The better way to sleep. Onkaparinga onkaparinga, blanket, wool, kramm -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - NEW CHUM & VICTORIA TRIBUTE COY - EXTRACT OF MEETING

New Chum and Victoria Tribute Coy. Formation of Coy. Extract from Bendigo Advertiser Saturday July 22, 1871. Meeting held at Sterry's Gold Mines Hotel. Mr Sterry in Chair. 18 shareholders representing 504 shares present. Extracts from Director's Report. After striking water which appeared to be of a permanent nature, it was decided to purchase a plant. Machinery consisting of a 14 inch dia. Cylinder with double winding drums, winding engine, plus boiler etc from Buningong. Same erected for 750 pounds. Everything going well. It was decided, the best place to erect it was on Burrows and Sterry's ground. Permission was granted.document, gold, new chum & victoria lines of reef, new chum & victoria tribute coy, extract of meeting new chum & victoria tribute coy, bendigo advertiser, mr sterry, gold mines hotel, mr burrows -

Bendigo Historical Society Inc.

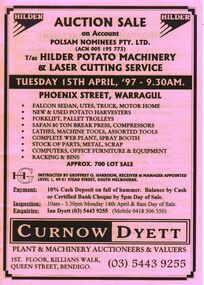

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - POLSAM NOMINEES PTY LTD

Pink paper catalogue with black printing for a sale on account of Polsam Nominees Pty. Ltd. T/as Hilder Potato Machinery & Laser Cutting Service on 15th April '97 at Warragul. For sale were vehicles, potato harvesters, forklift, pallet trolleys,80 ton press, compressors, lathes, machine tools, assorted tools, complete web plant, spray booth, parts, metal, scrap, computers, office furniture & equipment, racking and bins. Announcement printed in the front of catalogue mentions that J. H. Curnow & Son Pty. Ltd. Are combining their name with the Dyett family and trading as Curnow Dyett, Real Estate Agents, Auctioneers and Qualified Valuers.business, auctioneers, curnow dyett, ian dyett collection - auction catalogue - polsam nominees pty ltd, hilder potato machinery & laser cutting service, geoffrey o harrison, ian dyett, curnow dyett, j h curnow & son pty ltd, occupational health and safety act 1985, noel dyett, ian dyett, fred dyett -

Bendigo Historical Society Inc.

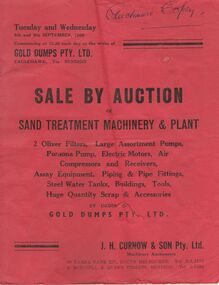

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - GOLD DUMPS PTY LTD

Red covered auction catalogue for a sale held at the works of Gold Dumps Pty. Ltd., Eaglehawk on the 8th and 9th September, 1959 of Sand Treatment Machinery & Plant. Sale held at the Devonshire Sands Site and the New Moon Site. Included in the sale were 2 Oliver Filters, Large Assortment of Pumps, Pomona Pump, Electric Motors, Air Compressors and Receivers, Assay Equipment, Piping & Pipe Fittings, Steel Water Tanks, Buildings, Tools, Huge Quantity Scrap & Accessories. J. H. Curnow & Son Pty. Ltd. Were the Auctioneers. Catalogue, a Bolton Bros. Print. Auctioneers Copy written on the top of the front cover. Prices of lots have been written near the lots.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - gold dumps pty ltd, j h curnow & son pty ltd, devonshire sands site, new moon site, bolton bros print -

Bendigo Historical Society Inc.

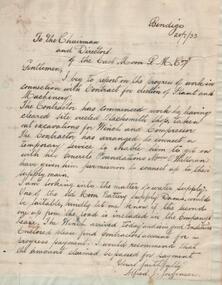

Bendigo Historical Society Inc.Administrative record - East Moon Gold Mining Company Mine Manager's Report Book, 1919 - 1920

February 1933: East Moon Gold Mining Co. N.L. has been formed with a capital of £25,000 in 36,000 shares of 10/- each issued at 1/-. The company will work an extensive lease on the Paddy’s Gully and Derby lines of reef at Eaglehawk. A shaft was sunk on the Paddy’s Gully line in the property of the New Moon Co. some years ago to a depth of 380 ft. and another shaft was sunk by the same company on the Derby line of reef to 134 ft. In the Paddy’s Gully shaft a large body of spurs 10ft wide at the 256ft plat was exposed and continued downward for 36 ft (56ft?) before passing out of the shaft to the east. A little gold was seen in the stone but no work was done. The development of this formation will be the first work undertaken by the new company. (The Sun News Pictorial Monday 20th February 1933, page 23) Black hard cover book, red binding on spine, one hundred and eighty eight pages of which sixty five are used. Label on front cover: 'East Moon G.M.C . N.L.' Book contains: a. handwritten reports from Alfred Jorgensen regarding the installation of the plant and machinery at the mine b. reports from E.G. Robertson, the Manager of the East Moon Gold Mining Company. Typed report by E.G. Robertson, 8th July 1935 reports on the Paddy's Gully shaft, the Derby shaft and the Hustlers shaft. Entries date from 20th July 1933 to 22nd. August 1935. Mine Manager's book forms part of the Margaret Roberts Collection of Mining records.bendigo, margaret roberts, legal managers, mine manager, east moon gold mining company n.l., e.g. robertson mine manager, alfred jorgensen contractor, paddy's gully shaft, derby shaft, hustler's shaft, -

Bendigo Historical Society Inc.

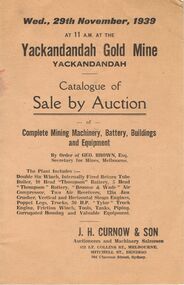

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - YACKANDANDAH GOLD MINE

Light tan coloured auction catalogue for a sale at the Yackandandah Gold Mine, Yackandandah on 29th November, 1939 of Complete Mining Machinery, Battery, Buildings and Equipment, By Order of Geo. Brown, Esq, Secretary for Mines, Melbourne. The Plant Includes:- Double 8in Winch, Internally Fired Return Tube Boiler, 10 Head Thompson Battery, 5 Head Thompson Battery, 'Broome & Wade' air Compressor, two Air Receivers, 12in Jaw Crusher, Vertical and Horizontal Steam Engines, Poppet Legs, Trucks, 30 H.P. 'Tylor' Truck Engine, Friction Winch, Tools, Tanks, Piping, Corrugated Housing and Valuable Equipment.J.; H. Curnow & Son were the auctioneers. Catalogue printed by The Cambridge Press.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - yackandandah gold mine, geo brown esq, j h curnow & son, the cambridge press -

Wodonga & District Historical Society Inc

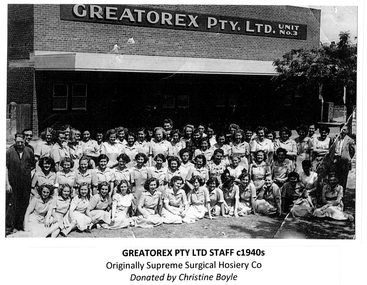

Wodonga & District Historical Society IncPhotograph - Greatorex/ Supreme Surgical Hosiery Co. Wodonga

The Greatorex company came to Wodonga in August 1945 under the Cain Government decentralisation policy. It initially had premises in Beechworth Road, around the corner from Tallangatta Road (now Thomas Mitchell Drive). Due to expansion they later relocated to the corner of Tallangatta Road and Anne Street Wodonga in 1952. Greatorex had its main manufacturing plant in Melbourne, Victoria. At their peak Greatorex Pty Ltd. which also operated as Supreme Surgical Hosiery Co., manufactured brassieres, swimsuits, elastic thread, surgical hosiery and employed 90 staff in Wodonga. The company which was operated by Thomas Greatorex with Mr M. P. Brain as Manager, also owned Fulflex Yarns Pty. Ltd. Fulflex produced elastic yarns to be used in the manufacture of garments at Supreme Surgical Hosiery. In 1960, due to the increasing cost of freight charges for moving raw materials and manufactured goods to and from Melbourne, the company was forced to close down. Plant and machinery valued at over £30,000 was moved to Melbourne. Some personnel were given the opportunity to also transfer to the parent company. In 2024, the company still operates as Greatorex Textile Industries P/L in Moorabbin, Victoria.These images are significant because they document an industry which operated in Wodonga in the 1940s and 1950s.A collection of black and white photos of workers at the Greatorex / Supreme Surgical Hosiery Co. in Wodonga.Names listed beneath one of the images.greatorex industries, wodonga industries -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - NEW CHUM & VICTORIA LINES OF REEF - MINING MACHINERY, NEW CHUM LINE, EAGLEHAWK

Handwritten notes on mining machinery sold at auction. South St Mungo - Winding Engine. Pair of 15 ? Cyl. Winding Engines. 7 ft Winding Gear. Also Jackass Boiler. Feed Pump, Trucks, Rails, Flat Sheets, Poppet Heads, Housing, etc. Sold for 270 pounds. Purchaser H Ralph for Austral Drill Co. Lady Barkly Company - 12 inch Cylinder Winding Engine. 8 ft Winding Gear. Cornish Flue Boiler, Feed Pump, Rails,Poppet Heads, Housing, etc. Sold for 162 pound 10 shillings. Purchaser W. J. Sever, Mining Merchants, Melb. Crushing Battery - Complete 40 Head Battery. Tandem Compound Engine. 11 in & 22 in Cylinders. High Press, Boilers, Electric Lighting Plant. 6 in Cyl. High Speed Engine, Fire-proof, Feed Pump, Rails, Flat Sheets, Tools & Sundries. 1000 pound to R. Ralph. These three mining plants, complete. Sold by Messrs Bell, Lambert and Nixon - Auctioneers. Ref; Bendigo Advertiser. July 14th 1910 Page 2.document, gold, new chum & victoria lines of reef, new chum & victoria lines of reef, mining machinery new chum line eaglehawk, south st mungo, h ralph, austral drill co, lady barkly company, w j sever, crushing battery, messrs bell, lambert and nixon, bendigo advertiser july 14th 1910 page 2 -

Kiewa Valley Historical Society

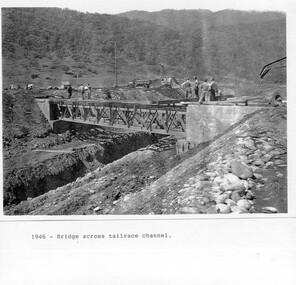

Kiewa Valley Historical SocietyPhotograph - Folder of Photographs – Photocopied set of black and white photographs (pages 9 - 18) from the display folder put together by KVHS to document life on the Kiewa Valley Hydro-electric Scheme

Although the Kiewa Hydro-Electric Scheme was first proposed in 1911, construction did not commence until 1938. As part of the push to cut electricity costs and diversify supply, the Victorian Government (circa 1930) initiated the conversion from primarily brown coal supply to hydro – electricity. Field investigations during the 1940’s resulted in a new proposal for a scheme that had more than double the capacity of the 1938 scheme. The Kiewa Hydroelectric Scheme became the largest scheme of its kind in the State Of Victoria and the second largest scheme in Australia. The number of personnel involved in the planning and construction of the scheme increased dramatically. During the late 1940’s, most activity centred around the construction of the West Kiewa Power Station, Rocky Valley Reservoir, McKay Creek Power Station and the Bogong Creek Aqueduct.A common thread across all the larger hydro scheme constructions was the need for workers, both qualified and unqualified who came from around the world seeking a new life for themselves and their families. New accommodation and facilities were required for the army of workers engaged in construction in often remote and wild areas. The SEC had a high demand for timber, and set up the first of a number of sawmills at Bogong Creek in 1939 and set up the first hardwood logging in the headwaters of the Kiewa River. These new ‘towns’ such as Mt Beauty and Bogong, survived, serving the needs of operational personnel and their families, and expanding with growth of new industries. Mount Beauty, and to a lesser extent Bogong, are among these places. PHYSICAL: Large A3 size spiral bound display folder containing 21 pages of photocopied black and white photographs of various aspects of the early days of the Kiewa Valley Hydro-electric scheme including equipment, various work sites and photographs of workers and their families. 1-Bridge across Tailrace Channel 1946 2-New Mess building, Mt Beauty 3-Homan’s Gap Saw Mill 4- Diamond Drilling Plant – Big Hill 5-Rocky Valley Camp-Mess Building 6-Parlimentary Party at Rocky Valley 7-No.4 Headrace Tunnel 8- Allis-Chalmers Tractor School 9- SECV Heavy Machinery lined up by road 10- No. 5 Raceline – Balasting Track with improvised truck 1-1946 – Bridge across tailrace channel Page number 9 2-New mess building, Mt Beauty 6.4.46 Page number 10 3- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 10.1.47 Time: 11.40am No K2271 Kiewa Hydro Electric Works Homan’s Gap Saw Mill – Rip Saw Page number 11 4- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 5.10.47 Time: 11am No K4111 Kiewa Hydro Electric Works Diamond Drilling Plant – Big Hill Page number 12 5- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 11.2.48 Time: 3pm No K4277 Kiewa Hydro Electric Works Rocky Valley Camp-Mess Building Page number 13 6- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 15.4.48 Time: 4.30pm No K4397 Kiewa Hydro Electric Works Parlimentary Party at Rocky Valley Page number 14 7- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 22.8.48 Time: 9am No K4668 Kiewa Hydro Electric Works General view of No.4 Headrace Tunnel Page number 15 8-STATE ELECTRICITY COMMISSION OF VICTORIA Date: 5.9.49 Time: 10am No K5180 Kiewa Hydro Electric Works Allis-Chalmers Tractor School – HD 19, Mr I Crossthwaite at Controls Page number 16 9- No markings Page number 17 10- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 7,12.49 Time: 4pm No K5423 Kiewa Hydro Electric Works No. 5 Raceline – Balasting Track with improvised truck. Page number 18 secv; kiewa hydro electric scheme; mt beauty; bogong; construction area -

Bendigo Historical Society Inc.

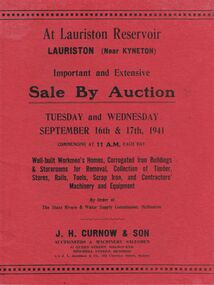

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - LAURISTON RESERVOIR

Two red covered auction catalogues for an Auction Sale at Lauriston Reservoir, Lauriston (Near Kyneton) on 16th and 17th September, 1941. Sale consisted of Well-built Workmen's Homes, Corrugated Iron Buildings & Storerooms for Removal, Collection of Timber, Stores, Rails, Tools, Scrap Iron, and Contractors' Machinery and Equipment By Order of The State rivers & Water Supply Commission, Melbourne. Auctioneers were J. H. Curnow & Son. Contains description of buildings. Has a loose page of Additional Plant to be sold at the Lauriston Reservoir Auction on 17/9/1941. Also has two black and white photos, the first one of the Lauriston Reservoir showing the concrete bank during construction and the other, a Section of Residential Area. In the background is the bank and a tower each side of the bank.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - lauriston reservoir, state rivers & water supply commission, j h curnow & son, j l jamieson & co, r g knight, e d shaw, h h c williams, hon a a dunstan, cambridge press -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Textile - Woollen Blanket, Warrnambool Woollen Mill, Circa 1949

The first Warrnambool to Melbourne cycling race was held in October 1895. 24 riders started with only 7 finishing the race. W. Nicol was the winner of the inaugural race. Two months later on 14/12/1895 the race was run in reverse. For the ensuing 43 years it was mainly Melbourne to Warrnambool. Since 1939 it has been run mainly Melbourne to Warrnambool. The prize of this blanket was 2nd prize to E. Ion of Tasmania in October 1949. The prize itself, A Warrnambool Blankets Tartan rug was made at the Warrnambool Woollen Mill in Harris St Warrnambool Early efforts to establish a woollen Mill in Warrnambool commenced with an early mill on the Merri at Woodford in 1874 but the site proved unsuitable and was financially struggling. The decision was made to move plant and and machinery to the old meat preserving factory in South Warrnambool The plant and equipment was sold to Mr Robert Hood of Sherwood on the Hopkins River East Warrnambool who carried on the venture until fire destroyed the building in 1882, The site lay idle until a group of local businessmen raised 40000 pounds to establish the mill in 1910. It continued to trade well through the early and mid 20th century. Dunlop brought the mill in 1968 and there was a slow downturn with numerous owners until it closed in 2000. The site passed into private hands in 2003.Both the Warrnambool Woollen Mill and the Melbourne to Warrnambool Road Race are a significant part of local history. The Melbourne to Warrnambool Cycling road race remains one of the premier sporting events in Australia. It commenced in 1895 Maroon and red block check with black and white check lines on front with plain maroon back. Fringed on two sides. Grey cotton label with The Warrnambool Woollen Mill Co Limited in top Left hand side of label, Victory Rug diagonally in blue Guaranteed All WOOL Made in Australia in bottom RH corner of label. Owner M bottom of label. 1949 Mr. Ernie Ion” handwritten in black pen.warrnambool, warrnambool woollen mill, marcus saltau, w. nicol -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Bradford Kendall, Wodonga

Bradford Kendall was established in 1922 by Lesley Bradford and Jim Kendall, investing their winnings on a race horse. They both previously worked at the BHP Steel Works. They gained contracts with the railways and mining industry. During World War II they also manufactured armaments. During the boom of the 1950s they established several foundries in South Australia, Western Australia, Queensland and Victoria. Bradford Kendall Ltd Wodonga foundry was established in 1954. It melted down old railway wheels, rails and redundant machinery to produce a range of low-alloy steel products, especially for earth-moving vehicles, railways, oil rigs and sugar factories. Wodonga was ideally placed as a change point between the different rail gauges of Victoria and New South Wales, close to the Hume Highway and the Snowy Mountain Scheme. The first sod for the site was turned on 2nd June 1954 and the first melt and pour of molten metal at Wodonga took place on 7th July 1954. Bradford Kendall Plant No.5 in Wodonga became one of the most profitable foundries in the Bradford Kendall group. Bill Black became the first plant Manager, a position he held for 30 years. Another long term employee was Pat Gooding who began work at a 15 year old and retired for the position of Bradken foundry Manufacturing Manager 51 years later. In the early 1980s, Australian National Industries Ltd bought Bradford Kendall and other heavy engineering companies. The Wodonga foundry with its (then) 170 or so staff became part of Bradken Consolidated along with nine other foundries in Australia and New Zealand. In 1989, Kerry Packer’s Consolidated Press Holdings Ltd took control of ANI. In January 1999, Smorgon Steel Group acquired ANI, which included the Bradken business. The company changed hands again in 2001 when Smorgon Steel Group sold Bradken to Castle Harlan Australian Mezzanine Partners (CHAMP). In 2016 negotiations began for Bradken to be taken over by Hitachi Construction for A$689 million. In April 2017 Bradken became a wholly owned subsidiary of Hitachi Construction Machinery Co. Limited.A collection of black and white images and advertising for Bradford Kendall (Bradken) Wodonga.bradford kendall, wodonga industries, wodonga businesses -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - NORTH DEBORAH GOLD MINING CO N. L. - COPY OF CORRESPONDENCE, NORTH DEBORAH GOLD MINING CO N. L

Handwritten copy of correspondence dated 18th January 1950. Mentioned arer: Dividends, 9 pound 6 shillings per Share, Commenced Mining operations on Deborah Line of Reef, October 1937 and worked continuously since that date, amount of gold from the ore, Pyrites Concentrates treated todate, produced gold to a nett value of 53,000 pounds. Mine Plant Machinery, Buildings and Battery Equipment at Book value 25,420 pounds. Shaft to 1,300 feet. 90 men employed at Mine and Batteries, Annual Wages Sheet 32,000 pounds. Directors: Mr E . H. Noske (Chairman), Messrs G. W. Lansell, A. E. Dowling, G. A. Pell, T. Swinburne, W. J. Donovan. Legal Manager Mr J. J. Stanistreet. General Manager Mr S. ScDonald. Albert Richardson Collection. document, gold, north deborah gold mining co n. l., north deborah gold mining co n. l., copy of correspondence north deborah gold mining co n. l., deborah line of reef, mr e h noske, g w lansell, a e dowling, g a pell, t swinburne, w j donovan, mr j j stanistreet, mr s mcdonald -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - NORTH JOHNSONS MINE - HAPPENINGS AT THE NORTH JOHNSONS MINE AND NORTH GARDEN

Handwritten page and typed copy of same, of happenings at the North Johnsons and on the back North Garden. Written on page: North Johnsons, Copy our from M/M Reports. Cage stuck 26/10/1900, Scarcity of water 6/1/1899 9/11/1900, Boiler at Rose taken down etc 28/10/1899, Old workings giving trouble 14/10/1898, 8/7/1898 No ladderway, slack ropes fouled - cage etc at 485 ft., 7/6/1901 Water 3,000 gals a day, 2360 feet 2/3/1900 Miner burnt Candle (Gas?). On the back: North Garden, G. Armstrong ?, E'House open, Machinery, 16/6/1881 Old W. Wigley as watchman. 3/11/1881 Engine man Toy let 5 men into the well through carelessness. (Discharged.) Got another man - Grey. He could not manage it. Now have Syme ? Cannot say much about him yet. Half Yearly Report. 26/1/1882. New Plant. All work suspended to put in new machinery. Pair of 20'' cyl. For winding. 12 inch Ford Compressor, New Poppet Legs & Brace & Quartz shoots. Av. Of 13 1/2 dwts from new reef at 1320 '. Albert Richardson Collection. document, gold, north johnsons mine, north johnsons mine, north garden, happenings at the north johnsons mine and north garden, m/m reports, g armstrong, w wigley, engine man toy, grey, syme?, ford compressor -

Seaworks Maritime Museum

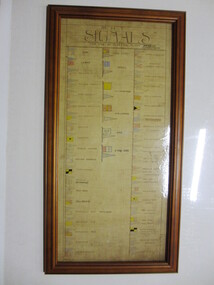

Seaworks Maritime MuseumList of Pennants

Has recently been framed and laminatedFramed list of pennants signifying ships and signals hand drawn with coloured pencil in 1915 on paper. Later corrections made in 1933 in black penM. H. T./SIGNALS/FOR THE USE OF FLOATING PLANT OCT 1915 1915/Corrected Feb 1933/ HUME/ J. A. BOYD/WILLIAM PITT/WILLIAM STRONG/CHAS DUCKETT/EDWARD NORTHCOTE/ H C PIGGOTT/BATMAN/FAWKNER/FRANCIS DUNCAN/WILLIAM ANDREWS/COMMISSIONER/PENGUIN (at Geelong)/ RED BIRD/GELLIBRAND/MOTOR BOAT NO 2 TATEGAMI/MOTOR BOAT NO 3/MOTOR BOAT NO 4/ENGINEER/HARBOR MASTER/LADY STANLEY/HOVELL/ W. S. MOUNTAIN/W.M. COWPER/G.F.H./D. YORK SYME/ SUPER of DREDGING/ASSISTANT/HARBOR MASTER/SUPER of MACHINERY/ELECTRICIAN/INSP of DREDGING/INSP of MACHINERY/INSPECTOR WHARVES/(F WILLIAMS)/INSPECTOR DOCKING/& SHIPWRIGHTS/DIVERS WANTED/ACCIDENT SEND/MEDICAL ASSISTANCE/WAITING FOR/EMPTY BARGES/DREDGING STOPPED/WEATHER UNFAVOURABLE/TAKE AWAY/EMPTY BARGES/TUG WANTED/DERRICK PUNT/WANTED/TAKE DERRICK/PUNT AWAY/TAKE AWAY/COAL BARGE/BUCKETS FOULED/OBSTRUCTION SEND/DERRICK PUNT &/DIVERS/ DREDGING STOPPED/REPAIRING/DREDGING RESUMED/ B. Harris 16.8.15/ Drawing No 3415melbourne harbour trust (mba) -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Newsletter - City of Moorabbin Historical Society Jun 2011, June 2011

The City of Moorabbin Historical Society was formed c 1960 by a group of Moorabbin residents who were concerned that the history of the area should be preserved. A good response to a call for items related to the historical area of Moorabbin Shire brought donations of a wide variety of artefacts which are now preserved by the current members of CMHS at Box Cottage Museum . Helen Stanley, Secretary of CMHS, began producing a Newsletter for members in April 2007 to provide current information and well researched items of historical interestHelen Stanley has produced a bi-monthly Newsletter, 2007 - 2013, for the members of the City of Moorabbin Historical Society that contains well researched interesting historical items, notification of upcoming events, current advice from Royal Australian Historical Society , Museums Australia Victoria and activities of Local Historical Societies. The Newsletter is an important record of the activities of the CMHS. Mrs Nance Blackman’s notes in 1978 for the Centenary of The Cheltenham Church of Christ.. The Blackman family were early settlers in Moorabbin Shire. 5 x A4 paper printed on 1 side Issue 22 of the bi-monthly, City of Moorabbin Historical Society Newsletter produced by Society member and Secretary, Mrs Helen Stanley in June 2011. Notice of meeting June 26th and CMHS members exhibited some artefacts at the ‘Fun4over50’s’ event at Kingston (Moorabbin ) Town Hall June 5th. Glen Eira City Council Building Dept. Officers inspected erosion along the North side of the Barn floor, members have planted seedlings in the garden and Helen and Joan are entering data about our ‘Collection’ onto the MAV website while Jim Dale has photographed some of the farm machinery. Small paragraphs about early local Religious groups – Salvation Army, Methodist and Presbyterian Ministries – with 2 photocopied photographs. Helen also provides the notes penned by Mrs Nance Blackman in 1978 for the Centenary of The Cheltenham Church of Christ. CITY of MOORABBIN HISTORICAL SOCIETY / JUNE 2011 NEWSLETTER city of moorabbin historical society, stanley helen, melbourne, moorabbin, brighton, cheltenham, ormond, bentleigh, mckinnon, market gardeners, pioneers, early settlers, moorabbin shire, box cottage museum, city of moorabbin, box william, glen eira city council, museums australia victoria, knott peta, church of christ cheltenham, baptist church, presbyterian church. salvation army, jasper road, point nepean road, brewer’s road, redmore rev. james, methodist mission to chinese market gardeners, blackman nance, lydia street bentleigh -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BENDIGO AMALGAMATED GOLDFIELDS NO LIABILITY - PROSPECTUS OF BENDIGO AMALGAMATED GOLDFIELDS N. L

1. Printed Prospectus of Bendigo Amalgamated Goldfields No Liability dated 1917. The Company was being formed amongst other things to acquire 38 of the principal Mining Properties contiguous to one another and situated in the heart of the Bendigo Goldfield. Properties are listed. Itmes include List of Assets, Liabilities, Future of Company, a short report on the Central Area of the Bendigo Goldfield by E C Dyason, B. Sc., B M E, Yields from Bendigo Goldfields, Financial Results from Bendigo Mining, The Bendigo Goldfield-Resources of the 'Central Area' (Abridged) by V Pabst, Report on Plant and Machinery by Andrew Harkness, Summarised Report on the Properties within the'Central Area' Bendigo Goldfield, Schedule of Properties to be Acquired, Plan of Leases and a Form of Application. 2. Share Certificate ( photocopy of original ) : ' Flora McKell of Melbourne is a member of the above named Company ' and has forty shares paid up to ten shillings each. Signed Angus Mackay Director, W. Stanfield, Secretary. Dated 24th June 1921.document, gold, bendigo amalgamated goldfields n l, bendigo amalgamated goldfields no liability, prospectus of bendigo amalgamated goldfields no liability, l v lansell, h m leggo, w angliss, e c dyason, commonwealth bank of australia, ward & co, furner & brownhill, laurie & hodgetts, corrie & co, w stennard, h hawkins, clarke & co, f douglas jones, arthur phillips, j h craig, a capper moore, j g stanfield, norman picot, v pabst, h y north, walter weddell, lea butler birch, george h green, mccoll rankin & stanistreet, elden h kirkwood, geo j keogh -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - VICTORIA HILL - THE BENDIGO DIGGINGS, PRELIMINARY DRAFT FOR BROCHURE

BHS CollectionNine typed pages of notes on a preliminary draft for a brochure on the Bendigo Diggings. First part is the objective which is to preserve the mining history and to have exhibits in the places they were used, e.g. quartz mining machinery exhibited in a quartz mining area, not on an alluvial field. Part B is historical notes on the area. Part C is the Site - Victoria Hill area. Part D is Stage One which consists of carpark area, technological museum, restaurant, mineral haulage line, picnic ground, earthworks and planting over the area. Part E is Stage Two which will consist of the open-air exhibits, in the area surrounded by the mineral haulage line, and the Central Nell Gwynne mine on the west side of the site. Part F is Stage Three which will consist of the winery, the steam tram track, the lake, the wildlife sanctuary and various buildings associated with gold mining. Part G is Costing with the prices to be filled in. Parts H and I are the Appeal and the Committee. Details to be filled in. Notes prepared by Albert Richardson.mining, marketing, victoria hill, victoria hill, the bendigo diggings - preliminary draft for brochure, aust national travel association, tullamarine jetport, emu bottom homestead, kyneton historical museum, chinese joss house, eaglehawk museum, whipstick scrub, cairn curran reservoir, castelmaine historical museum and market hall, national trust, ballarat hiatorical park, echuca's hopwood gardens, swan hill folk museum, gibson's mount alexander no 2 squatting run, captain brown, chief commissioner wright, hustler's reef, thomas hustler, mining board, drainage of reefs act 1862, first world war, bendigo amalgamated goldfields, second world war, sandhurst, w c vahland, battery trams, horse trams, steam trams, electric trams, central nell gwynne mine, theodore ballerstadt, george lansell, new chum hill, ballerstadt's open cut, 180 mine, new chum syncline battery, william rae, victoria quartz, wittscheibe's 'jeweller's shop', luffsman and sterry, gold mines hotel, adventure, bendigo and district tourist association, bendigo city council, bendigo branch of the royal historical society of victoria, professor brian lewis, school of architecture and building at the university of melbourne, taylor horsfield, lord robert cecil, south australian gold commissioner -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - DRAINAGE PROBLEMS - DRAINAGE PROBLEMS 1910

Handwritten notes from Bendigo Advertiser reports. (1) Mr J. H. Craig reports- Victoria Reef Quartz - Cleaned and tested No 3 boiler. Have bailed 3,905 tanks. Water now 2.953 feet from surface. At Lazarus - Bailed 4,828 tanks. At New Chum Railway - Cleaned and tested boilers and flues, effected repairs to machinery and shaft, and started bailing at 3 pm on Friday 29th inst, and bailed 965 tanks. Bendig Advertiser 3/8/1910 Page 2 Mining Intelligence. (2) New Chum Mines - Better progress is now being made in lowering the water in the deep level workings at the New Chum Mines. At the Victoria Quartz, the water which on Monday stood at 3073feet, has been lowered 70 feet during the past four days. The pumping service at the New Chum Railway was in operation yesterday, and the winding plant is fully occupied. There is a considerable quantity of water toraise, and the companies have a difficult task before them. Bendigo Advertiser 5/8/1910 Page 2. Document from Albert Richardson Collection of mining history.gold, drainage problems, new chum drainage association, new chum mines drainage problems 1910, bendigo advertiser 3/8/1910 page 2, mr j h craig, victoria reef quartz, lazarus, new chum railway, bendigo advertiser 5/8/1910 page 2, albert richardson -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Letter - MCCOLL, RANKIN AND STANISTREET COLLECTION: QUOTE FROM MILLER AND CO. MACHINERY, 25th May 1931

Five-page letter and quote, 25th May 1931, from Miller & Co Machinery, 27 Queen Street, South Melbourne. Bendigo office phone 50. Quote for Central Nell Gwynne shaft: steam winch, straight line steam drive air compressor, air receiver, Cornish flue boiler, Worthington duplex steam pump. Price for foregoing 740 pounds. Delivery of boiler at Redan shaft, poppet legs standing at Buttrey's Reward Mine and the whole of the balance of the plant F.O.R. Melbourne Monument Hill Shaft: steam winch double cylinder, straight line single stage steam driven air compressor, air receiver crown flanged ends, Cornish flue boiler, steam pipes, air pipes, iron chimney stack 26'0' x 3'.6' diameter, black steel wire ropes 1000' length Price for foregoing 610 pounds. If preferred, self-contained boiler in lieu of Cornish type offered, the following is offered: return tube boiler, by Roberts and Sons Bendigo. This boiler is self-contained Deborah shaft: straight line steam driven air compressor, air receiver. Price 200 pounds.bendigo, gold mining, mccoll rankin and stanistreet, miller and co., machinery., central nell gwynne gold mine, monument hill gold mine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Hand operated embossing document press, 1910

The woollen mill was a vital part of Warrnambool for all but 22 years of the town’s history since it's the establishment in 1847 when the first land sales were held and white settlement began. In 1869 the Warrnambool Meat Preserving Company began operations on the mill site, in 1875, shareholders of the then defunct Warrnambool Meat Preserving Company happily sold the land and buildings on the Merri river to Warrnambool Woollen Mill Company Ltd for £5,000. The site was sold again in 1876 to grazer Robert Hood of Sherwood, who was chairman of directors of the failed company, which couldn’t raise sufficient capital to keep the works operating. The entrepreneurial Hood then used the existing plant to turn his own wool into tweed cloth. But just as the mill was starting to show a profit, a fire destroyed the building and plant on the night of 25 March 1882. So again, the mill was operational for six short years. Insurers only paid a fraction over 10% of the damage, Hood couldn't raise sufficient capital to rebuild on his own, and so the site lay unused until 1910. In 1908 Marcus Saltau and Peter John McGennan convinced the Warrnambool Chamber of Commerce to invest in a secondary industry with local capital. A public meeting in September 1908 agreed to raise £40,000, electing Saltau chairman of directors, a post he held for 34 years. A year later, using mostly local money, the Warrnambool Woollen Mill Company dispatched its first manager, John E. Bennett, to buy a plant and recruit 20 experienced staff from the Yorkshire woollen industry in December 1909. Another year more, the new mill was officially opened on 14 November 1910 by Marcus Saltau as company chairman and town mayor. Eighteen months on, in May 1912, the mill paid its first half-yearly dividend of 2 ½%. It was now working two shifts, with a year's orders to fill. In 1914 the mill ordered its own generator, providing the town with electricity and effectively doubling its plant size by October 1915, six months after Gallipoli. Thereafter, government orders for cloth and military supplies assured the mill’s success right through the First World War and on until 1923. A plant upgrade in 1922 for machinery to make worsted fabric drained profits, which, with a fall in demand, led to a loss in 1925. Profits were restored by the 1930s, despite the Depression, mostly due to tight management and robust marketing. Production boomed again during the Second World War, but soon foreign competition bit into profits, forcing the company to consolidate operations. The ‘50s and ‘60s were golden years for the mill. Security and growth gave the company confidence to trial Australia’s first electric blanket in 1958 and to install Swiss Sulzer looms in 1965. Over time, the building facades took on the modern look that the mill presented until it closed. The Dunlop company bought the mill in 1968, fending off a challenge from Onkaparinga in South Australia, and continued to expand by adding Wendouree Woollen Mill in the same year and Dream-spun Textiles a decade later, in 1979. Soon after that purchase, however, the mill began its slippery slide into decline. Dunlop sold to its former rival bidder Onkaparinga Woollen Co. Ltd in 1982, which in turn was taken over by Macquarie Worsted's only a year later, in 1983. Operations remained stable for a decade until 1994 when the Macquarie Group signaled that its newly rationalised operations left no room for the Warrnambool investment. The final operator of the mill was The Smith Family charity group, which ran the site by agreement with the Warrnambool City Council and a state government grant in that same year, 1994. The mill became more of a fabric recycler than a manufacturer. The site was sold to private operators in February 2003 and rezoned four months later to allow for the mixed housing development. The embossing press is significant for its association with the Warrnambool Woollen Mills 1910-1968, a major employer in the Warrnambool district. The press is also significant as an example of commercial office equipment used in the 19th and 20th century.Press, metal, for Company seal of Warrnambool Woollen Mill, stamping their brand as Western District Worsted Mills Pty Ltd. Metal is black with red and gold floral markings. Inscription of stamp reads "WESTERN DISTRICT WORSTED MILLS PROPRIETRY LIMITED" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, warrnambool woollen mills, western district worsted mills proprietry limited, worsted fabric, printing press, logo printing press, stamp printing press, shipwreck-coast, flagstaff-hill-maritime-village -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph - Photograph: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Monochrome photograph depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'J. Caldwell and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Tarnagulla History Archive

Tarnagulla History ArchivePostcard - Photographic postcard: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Photographic postcard, front image depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'A Merry Christmas and a Happy New Year, E. Bool' and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesBooklet, Michele Adler, Studies in Horticulture, 1998-2007

Royalties from the sale of booklets donated to the Friends of Burnley GardensPlants in Print price labels on some of them. Display Copy Not for Sale on some of them.studies in horticulture, horticulture, t.a.f.e., rod mcmillan, michele adler, plant recognition, workplace requirements, industry requirements, workplace communication, peter esdale, workplace maintenance, peter sheppard, teamwork, soil characteristics, lanscape drawing, graphics, ken wallace, scott watson, ron barrow, operate tractors, operate machinery, ken james, work environment, john stanley, promotional program, oh & s procedures -

Federation University Historical Collection

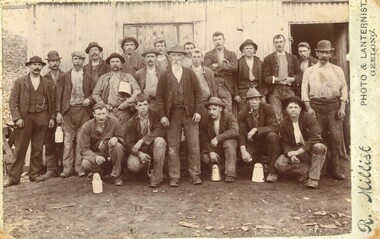

Federation University Historical CollectionPhotograph, R. Millist, Hanlon Consols Mine Rokewood, 1901

The photo depicts one shift of mine hands at Hanlon Consols Mine Rokewod in 1901. ist on the left is George Edgar Yung. George was born in Ararat the son of Yohann Godlip and Christina (b Weller)Yung. They lived at Happy Valley near Linton. and Piggoreet. Yohann was a miner and died in the All Nations Mine collapse at Derwnt Jack's in 1877. Interesting to note in the following information that the Hanlon Consol mamager, William Maughan was also the manager of the Try Again Mine in Piggoreet. He was also on the six man school committee of Piggoreet Common School No. 726. (Is this why George Yung ended up working in Rokewood because of a previous connection at Piggoreet? George married Clara Emma Smith from Happy Valley and worked in a mine at Allendale. They later moved to Yendon) About the Hanlon gold mining company near Rokewood. 1901 - Information Bendigo Prospecting Club, 21/08/2020. Information provided once again by Peter McCarthy. Christopher Hanlon had put down a line of bores south of the Rokewood main street, looking for a continuation of the Break O’Day lead which had been worked for two or three miles with highly payable results, though in a primitive manner. Ground was being paddocked 30 feet deep and made to pay. The bores suggested the sinking would be about 70 feet and a shaft site was selected at the back of Stanbrook’s Hotel. The Hanlon Gold Mining Company was formed in March 1895 and the shaft was bottomed at 68 feet, getting just over an ounce of gold from the shaft bottom. By January 1896, the poppet heads were up, and steam plant was nearly ready. The mine produced 846 oz by September, which was not as good as expected, but they installed a second puddling machine. The mine was profitable for the next three years, with periods of prospecting and the need to install steam pumps in 1897. A second shaft was sunk in 1899, which bottomed at 86 feet on good wash and was sunk on to 109 feet. 1743 oz of gold had been produced in six months to September 1899, but the No1 shaft was let on tribute as the No2 workings were opened and machinery installed the following year. The No1 shaft tributors broke even in 1900 and in 1901 the shaft was shut down, with the No1 shaft machinery sold late in 1902. By September 1901, the mine had produced gold worth £66,124 and the No2 shaft main drive was in 346 feet, with gold being found mainly in crevices in the hard floor. Mining continued, but once the No2 shaft workings met up with the old No1 shaft workings at the end of 1902 there was not much wash remaining. The mine was let on tribute in June 1903 and a drive was put in to test deeper ground. The company was wound up in February 1904 and the plant sold. From what they discovered, the manager concluded that the mine sat at the edge of an ancient coastline and the gold was in a beach deposit. The total gold production from the mine was worth £73,294. J Lee Archer JP, shareholder, was the manager of the Bank of Victoria in Ballarat. Born in Tasmania, he came to Victoria with his parents and first came to Ballarat in 1855 as a junior clerk with the bank. He died in 1902 aged 64. Alexander J. Peacock was a legal manager and a share broker. In 1897 Peacock, born in Creswick, had been elected as one of the Victorian delegates to the Constitutional Convention which wrote the Australian Constitution. He later became a politician, state treasurer and three times state premier of Victoria and was knighted KCGM. He died in 1933 aged 72. William Maughan, director, was an English miner who came to Victoria in the 1850s and became a mine manager, managing the Try Again at Piggoreet, Ryan’s Freehold and the Madam Berry, among others. He died in Williamstown in 1915 aged 85. Sepia photographRhs front of photo: R. Millist Phto & Lanternist Geelong Verso (upside down): ONE SHIFT OF MINE HANDS HANLON CONSOLS MINE ROKEWOOD 1901 Grandfather Yung 1st on left rokewood, hanlon consols mine, shift of mine workers 1901, gold mines, george edgar godlip yung, william maughan -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBolt Cutter, 1878

Cyrus Chambers was a self-described mechanic who started out winding bobbins in his father's woollen mill and went on to invent machines that changed their industries. Cyrus Chambers came from Quaker parents the ninth of thirteen siblings, he once said a year before his death. “I believe I have succeeded because, first, I was industrious; second, because I made a study of the subject that was before me.” At age 7, Chambers went to work in his father’s mill. His job was to monitor bobbins—wooden spindles around which thread was wound and to remove and replace them as they became full. "There was no child labour law at that time," he later recalled. Chambers loved machinery and always regarded himself as a mechanic rather than an inventor. At age 16, Chambers was sent to learn dentistry with an older brother, (Edwin) who was already in the field and willing to take him on as an apprentice. Chambers was talented at working with small parts. He used his brother's dental instruments to build a miniature high-pressure steam engine of silver. It ran at 3,000 revolutions per minute and weighed less than a half-ounce. At that time it was the smallest engine that had ever been constructed. The engine was displayed at the 1876 Centennial and is now in a permanent collection at the Franklin Institute USA. Chambers major invention was the paper folding machine and came from reading that school teachers made less than the young girls who were employed to fold book pages as they came off the press. He told friends that his first efforts were to make the machine that would fold newspapers after demonstrating his device he met with Horace Greeley of the New York Tribune who advised Chambers would never invent the machine that would be able to fold his newspaper or books. In less than a year Chambers had built a full-size machine capable of folding large newspapers and books and was installed at J B Lippincott & Co folding pages for the "Comly Speller" this machine ran successfully for twenty-five years until the printing works burnt down. Chambers then went into partnership with a brother and they established the firm "Chambers, Brother & Co" at a plant in Philadelphia. It was also observed in 1910 and a fact that there was not a periodical or newspaper printed or recently published book that had not gone through one of Chambers inventions. Chambers went on to produce many mechanical inventions and improvements to existing tools and machinery most notable was his invention for the machine that would make clay bricks. This machine made forty bricks per hour and by the end of Chambers life after many improvements, it could make more than four hundred. Although there were a large number of bold cutters made of this patent at Cyrus Chamber’s foundry in Philadelphia, the item is associated with a notable American inventor of the nineteenth century. This particular patent for a bolt and rivet cutter won Chambers the prestigious Elliott Cresson Medal. This cutter is just one of the many inventions and mechanical improvements that Cyrus Chambers made during his lifetime, contributing to the ongoing development of mechanical improvements that were occurring in American industry of the time and therefore a notable addition to the Flagstaff collection.Cast iron bolt cutter with removable tempered steel cutter. Chambers New No. 2.Raised embossed lettering on cast body of cutter "New No 2" on one side, "Chambers Bros & Co" on the other sideflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cyrus chambers, bolt cutter, paper folding machine, brick making machine, elliot cresson, elliot cresson medal, franklin institute, gold medal, rivet cutter -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1922

In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Sewing machine, treadle operated, "Branded Premier" 5-7-9-2-0-0-" Serial Number Y6243048 (denotes 1922 year of manufacture) flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand operated, dressmaking, textile machinery, portable, premier sewing machine, premier, singer treadle sewing machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1907 -1920 (see note section this document for further information regards model identification)

In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Singer sewing machine treadle type wooden stand with six drawers plus instruction manual Lotus decoration to machinewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing-machine, clothes repair, singer sewing machine -

Ringwood and District Historical Society

Ringwood and District Historical SocietyDocument, Packet: Ringwood Coolstore Cuttings, Historical Notes, Equipment Sale, Rule Book. 1911-1959

Miscellaneous documents relating to the Ringwood Coolstore and Horticultural Society.Packet includes: . 3793(f): Hand written notes on the development of Ringwood Cool Stores in the early 1900's. . 3793(h): Typed document titled 'Fruit Cool Storage Symposium' dated 1963, produced by the Department of Agricultue and the Orchardists and Fruit Cool Stores Association. . 3793(g): Hand written minutes and general notes of the Ringwood Horticultural Society meetings and Shows, from 1899 to 1902. . 3793(e): Small booklet- 'Rules of The Ringwood Co-operative Cool Stores Society Limited, 1934.' . 3793(b),(c),(d): Typed documents: 1. How to lay out a packing shed. 2. Notice of the Forty-third Ordinary General Meeting of The Ringwood Co-operative Cool Stores Society Limited held in the Ringwood Town Hall on 31st March, 1959. 3. Notice of Important Auction Sale of 'Cool Stores Machinery and Plant Buildings for Removal' on December 2nd, 1959. . 3793(a): 2 Newspaper articles by J. K. McCaskill, J.P. on the Early History of Parish of Ringwood and Official Opening of the Ringwood Cool Stores in 1911. (Mail 3/12/1950 and 10/12/1959).