Showing 1034 items

matching drills

-

Bendigo Military Museum

Bendigo Military MuseumPhotograph - PHOTOGRAPHS OF SOLDIERS, 38th BATTALION, 38 Bn, c1950-1962

38 Bn was raised in Bendigo in 1916. Post War it was the CMF Unit until 1967. The Mollison St Drill Hall was built by Contractor Mr. Midgley. First used Jan 1916. Shut down Circa 2002. The 38 Bn Colours are held within the RSL Military Museum, Bendigo.1. Photo of 4 Senior NCO's in battle dress in front of the Mollison Street Drill Hall. 38 Bn Northern Victorian Regiment. The four soldiers have .303 rifles. WO Burrell has the red sash of a Colour Sgt. His MM can be seen. 2. Photo of Regiment Colours 38 Northern Vic Regiment in front of Mollison St Drill Hall. Two Officers, Capt. Emonde holding Queens Colours - 4 Snr NCO's have rifles at the slope with ceremonial tips on their bayonets.1. On rear is written - Cenotaph party/ Warrant Officer 3 sets Guards. 2. On rear is written - '" ANZAC DAY" .38 bn, mollison st, drill hall, photographs -

Clunes Museum

Clunes MuseumManual - AGRICULTURAL MACHINERY MANUAL, International Harvester of Aust P/L, 1950-1960

... Drills ....1 McCormick International GL-223 3pt linkage Tractor Mower .2 McCormick International GL-225 Post Hole Digger .3 Engineering Bulletin: EB17, Fordson Tractors .4 Massey-Ferguson 536 Side Delivery Rake Instruction Book .5 Massey-Ferguson 500 series drills, (fitting of the small seed boxes)owners manuals, mccormick international, massey ferguson, moore hydraulics, mower, tractor, drills -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0471 for another 1/8th inch hole.A number 5 stamped on the flat sideauger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0470 for another 1/8th inch hole.auger, hand drill, fencing, tool, rural trades, brace & bit -

Bendigo Military Museum

Bendigo Military MuseumPhotograph - PHOTOGRAPHS, TRUCKS FROM 1970's, RACT, 1970's

3. 2 trucks have the 3rd MD TAC Sign, 1 truck has the TAC sign with 7 on it. Passchendaele Barracks was the name of the Army Drill Hall, Mollison Street, Bendigo. The drill hall was in use 1916 - abt 2004.1. Side view of international MK3 Army Truck 4 x 4 set up for troop or general service work. Canvas cover is on. Coloured photo taken in the Mollison Street Depot yard. Photo is mounted on stiff cardboard. 2. Side View of Army Commercial Ford Truck. Cabin tilted forward to enable access to engine (Ford CL 400). 3. Group photo in colour, of 5 MN3 trucks lined up on the road beside the Mollison Street Drill Hall,. 1. On the rear is a 'stuck on' label "International 2 1/2 tons GS MN3 Bendigo Deport Yard". 3. On the rear is written "Convoy Inter MK3's in Mollison Street Bendigo. trucks, cmf, passchendaele barracks trust -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph, drilling rig and stack of drill pipe used to drill for iron ore near Nowa Nowa Victoria 1957, 1957

Black and white photograph showing drilling rig and stack of drill pipe used to drill for iron ore near Nowa Nowa Victoriaengineering -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - DRILL BRACE

Brace for holding drill bits for drilling holes in wood or steel, with wooden handles.tools, multipurpose, drill -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncDrill

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.drill, bow -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncDrill

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.drill, hand -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncDrill

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.drill, bow -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncDrill

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.drill, archimedean -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncDrill

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.drill, archimedean -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncDrill

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.drill, archimedean -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncGauge

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.gauge, drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Puffing Billy Railway

Puffing Billy RailwayDrill Press, Hand operated

Built by the Buffalo Forge Company in New York, USA. It is of a typical hand operated design used in workshops.Historic - Industrial drill - typical hand operated design used in workshops.Steel - Black and red paintBuffalo Forge Company Drill Press No. 611puffing billy, drill press, hand tools, buffalo forge -

![Photograph - Construction of the F19 [Eastern Freeway], Ron Setford, March 1973](/media/collectors/550653872162f11fb04854aa/items/67ff9b3d3b378d43a2a8aa3c/item-media/67ff9b7a3b378d43a2a8ab93/item-fit-380x285.jpg) Kew Historical Society Inc

Kew Historical Society IncPhotograph - Construction of the F19 [Eastern Freeway], Ron Setford, March 1973

Ron Setford and his wife Grace Setford lived in Tanner Avenue, East Kew, from c.1946 to c.1995. A keen photographer, he recorded the changing face of Kew over a 20 year period. Apart from 30 photographs of built structures and places in Kew dating from 1960 and 1961, 145 of his 35mm colour slides chronicle the development of the F19 (later renamed Eastern) Freeway through the Yarra Valley in Kew over a five year period from c.1972 to c.1977. This important collection was donated to the Society by his granddaughter in 2025.This collection of 175 35mm slides is of local and statewide significance, owing to its subject matter, particularly the major development of road transport infrastructure during the 1970s with the construction of the Eastern Freeway. The photographer also took care to annotate and date most of his slides which enable the researcher to pinpoint temporal and spatial locations."Eastern Freeway / Drilling for blasting 3/73"ron setford, eastern freeway, f19 freeway -

Kiewa Valley Historical Society

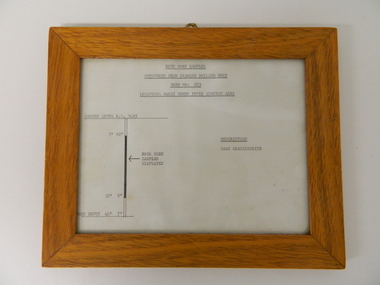

Kiewa Valley Historical SocietySketch Rock Core Display, circa mid to late 1900's

This framed sketch details, in graphic form, where the core samples in the display cabinet were removed. The drilling was a precursor to the decision where to locate, in this case, the McKay Creek Power Station. The information gained by structural engineers from the core samples would be used also for the placements of underground tunnels entry and exit points and the overall effective size of the plant. This would have included drill and blast techniques(rock characteristics play an import part of explosion control), requirements for support structures and reinforcing cement/steel forms. The use and replenishment of diamond drill bits(the strongest available, see KVHS 0280) was dependent on the "type" of rock found. Support beams for reinforced ceilings and floors was also a necessity.The visual derails of where the rock core samples were removed is very significant in the formulation and placement of the underground Power Stations and their maze of tunnels(in and out) for a successful implementation of the Hydro Scheme. The amount of pre-planning and scientific studies required for such a large scheme must be undertaken to ensure that a "white elephant" was not the result.This framed and glass front rock core display sketch has type written information of the rock samples displayed in KVHS 0279 (A). It has a softwood stained and glossed frame with a fixed(nailed) back board and a brass fixture for mounting onto a wall.The paper and type are slighted faded (sunlight affected). The sign heading "ROCK CORE SAMPLES RECOVERED FROM DIAMOND DRILLED BORE" underneath this "BORE NO: 883" and below this "LOCATION: McKAY CREEK POWER STATION AREA" to the left a sketch incorporating the ground level point "GROUND LEVEL R.L.3493", and the core depth point "CORE DEPTH 40' 7". In between and representing( in visual form) the core location areain question.alternate energy supplies, alpine feasibility studies temperature, rainfall, sec, kiewa hydro scheme, electricity -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchCartridge

20mm Drill Roundammunition, 2014, army -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchShirt

Shirt Green Drilluniform, 1984, army -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchCoveralls

Coveralls Green Drilluniform, 1986, army -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchShorts

Shorts Green Drilluniform, 1981, army -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumShort drill

8493.1 - Short drill. -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch303 Round

.303 Drill roundammunition, ww2, army -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchAmmunition

.303 drill roundammunition, ww2, army -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchCartridge, Combat Disabled Vets

Made by Combat Disabled Vets20mm Drill Roundammunition, 2000, army -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchBullet

7.62cal Drill roundammunition, ww2, army -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchBullet

5.56mm Drill Roundammunition, vietnam, general -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncHandle

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.handle for drill bit -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncHandle

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.handle for drill bit