Showing 120 items

matching manual tool

-

Moorabbin Air Museum

Moorabbin Air MuseumManual (Item) - (SP) AAP RAAF Pub 717:01 Vol 3 Part 1 Sect 1 Chap 1 1st Edition RAAF Schedule of Spare Parts Equipment and Scales for De Havilland and Hamilton Propeller and Constant Speed Control Unit Spares and Tools

-

Moorabbin Air Museum

Moorabbin Air MuseumManual (Item) - (SP) Wright Cyclone 9 - Tool Catalog

-

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Fire Beater - Canvas, c 1930s

Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. This canvas hose beater was based on a century-old design which used lengths of canvas fire hose rivetted together and lashed with wire to a broom handle. The hose was be soaked in water to improve its effectiveness. If the flames were more than a metre or so the user was generally not able to get close enough to extinguish the fire It's recommend that users lift no more than above knee height to conserve energy and let the beater to the work. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts and later RakehoesEarly firefighting toolBushfire beater - Canvas with wooden handleR P PWD (Public Works Department) The handle has painted markings which indicate which FCV District it belonged to.bushfire, forests commission victoria (fcv) -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Fire Beater - Leather, c 1940s

Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. This leather beater was based on a century-old stockman's design which used green cow hide leather lashed to a broom handle. It's recommend that users lift no more than above knee height to conserve energy and let the beater to the work. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts and later RakehoesEarly firefighting toolBushfire beater - Leather with wooden handlebushfire, forests commission victoria (fcv) -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Manual, United States Army, Direct And General Support Maintenance Manual Including Repair Parts And Special Tools List For Machine Gun Mount M66 With Installation Kit

A cream coloured cardboard cover with black details on the front.At the top of the manual reads TM 9-1005-300-34 Department of the Army Technical Manual. There are three punch holes and two metal staples down the left hand side. the manual is kept in a plastic cover for protectionunited states - armed forces - service manuals, machine gun mount m66, installation kit -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bellows, 1862-1875

This bellows was used at the Warrnambool Racecourse by Master Farrier, Brian Chapman (1931-2017), during the 1970s but its history before then is still being investigated. The bellows have continued to be used from 1978 at Flagstaff Hill's blacksmith's workshop. Even today, in 2021, this same bellows are used by a volunteer blacksmith as he demonstrate the skills and tells of the importance of the blacksmith trade to colonial Australia. This 1860s double-action bellows is a typical form of blacksmith's or shipsmith's bellows. The end is forge-fitted with an iron nozzle or tube, called a tuyere or Tue iron, which concentrates the air to fan the fire or furnace. Tuyeres were traditionally made of cow horn. The double-action design of this bellows efficiently moves air both in and out of the chambers in the one movement of the long handle. The bellows was manufactured by John C. Onions of Birmingham, England, between 1862 and 1875. The stamp with the text, Gold Medal 1862, was also used on the business’ advertising. In 1875 the company was registered and began using the name John C. Onions Limited. JOHN C. ONIONS - John C. (Collingwood) Onions (1841-1904) was the son of a bellows maker of the same name. Onions (born 1841) and his wife Helen married in 1867 and they named one of their children John Collingwood Onions (1868-1913), as was the family tradition. He was well known as a Birmingham manufacturer of patented bellows and other forge-related equipment. He sold to the wholesale and retail markets for both local and overseas customers, including the British colonies. An 1862 advertisement points out that John C. Onions was a “Bellows manufacturer and contractor to Her Majesty’s Honourable Board of Ordinance” and His Imperial Majesty the Emperor of the French [Napoleon Bonaparte]”. The advertisement includes a sketched portrait of the Emperor Napoleon III, and an Imperial Autograph Letter dated May 23, 1854, from Napoleon, Palace of the Tulleries to Mr J C Onions of Bradford Street, Birmingham. In 1863 the company registered a patent on portable forges. In 1871 there were eight employees. John C. Onions Limited became a registered company in 1875. In 1876 an advertisements included that the company were smiths for hearths and tools in general and showed a row of six medallions including one with “Napoleon III, Emperor” and his portrait, and another “ _ _ _ 1862 MEDAL”. Their advertising motto was “For Excellence of Quality”. In 1885 the company merged with William Allday and Sons to become Allday and Onions. This mid-19th century bellows has local historical significance as it were once used by blacksmiths at the Warrnambool Racecourse in the annual racing event that continues today. This bellows is significant as a working example of equipment used in the 1800 and 1900s in the trace of blacksmiths and other metal working smiths. The bellows is technologically significant as it shows the progress from simple bellows to the double-action bellows, a time saving and efficient improvement. The manufacturer John C. Onions is historically significant as a family business that began in the 1600s and continued up until the 1980s.Bellows; large, oval, mechanical double-action smith’s bellows, manually operated, in working condition. The paddles of wood that form the top, middle sections and base of the bellows have flexible leather pieces attached firmly between them, forming airtight double lungs. Cut-outs in the panels allow the bellows to fill with air then force it out. A long handle is connected to pump the bellows and control the quantity and force of the air. The blasts of air are forced through the metal nozzle or tuyere at the end of the bellows and into the forge’s fire. Inscriptions are impressed into the wood on the upper paddle or board of the bellows. There are three circular stamps containing text. Text impressed in the wooden upper paddle of the bellows has been assumed to read “JOHN C. ONIONS, PATENTEES & MANUFACTURERS, BIRMINGHAM””?” “EXTRA” “AWARDED FOR EXCELLENCE OF QUALITY”, made from the following readable text :- “JOHN C ONIONS“ “PATENT - - - & MAN - - - - - - - - -“, “BIR - - - - HAM“, “ _ ERA - - - - “- XTRA-“, “- - - - - - - FOR EXCELL-“ “OF - - - - ITY” Text in the stamp “ - - ECE - - “, “ - - - - - / 1862 / MEDAL”, “- ITY” flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, john collingwood onions, john c onions, allday and onions, bellows, smith’s bellows, 19th century bellows, double-action bellows, double-acting bellows, double lung bellows, double chamber bellows, blacksmith tools, blacksmith trade, blacksmith craft, blacksmith equipment, forging equipment, john c onions patented double-action bellows, brian chapman, warrnambool racecourse, blacksmith, shipsmith, iron smith, mechanical bellows -

Clunes Museum

Clunes MuseumTool - SEED SOWER

THIS SMALL MANUAL SEED SOWER WAS USED IN THE SEBASTOPOL GARDEN, THE SEED BOX HAS THREE SETTINGS ALLOWING THE OPERATOR TO SOW VERY FINE, MEDIUM OR LARGE SEEDS.PLANET J Rlocal history, tools, rural, tools -

Ballarat Tramway Museum

Ballarat Tramway MuseumManual, Warren Doubleday, "Scrubber No. 8 Training Manual", Jun. 2006

Ten page plus cover sheet document titled "Scrubber No. 8 Training Manual", detailing Controls, Auxiliary equipment of ex MMTB Scrubber No. 8 ( 8W), with photographs of the controls, scrubbing blocks, pipework, preparation, operation, stabling, appendix showing cut out switches and tool box and Scrubber car operator competency sheet. Version 1, dated 8/6/1001. (has been replaced since). Prepared by Warren Doubleday 6/2001.trams, tramways, scrubber tram, btm, manual, instructions -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionRakehoe (McLeod Tool)

Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts. However, its believed the now common Rakehoe is an Australian variation of the American McLeod Tool which was developed in 1905 by forest ranger Malcolm McLeod of the Sierra National Forest. The late Athol Hodgson advised that predecessors, Reg Torbet who had been the Chief Fire Officer for the Forests Commission from 1948-1956, along with his QLD counterpart Clive Price, went in late 1951 as Australian delegates on a 10 week fire study tour of Nth America organised by the United Nations. They came back with a couple of McLeod tools from Canada. Cam MacLeod (different spelling) had been the Head of Fire Research for the Canadian Forest Service at the time and had supplied them. The tools were ideal for deciduous forests in the eastern provinces and Clive arranged to have them manufactured in QLD. The Rakho, as it was then spelled, was first issued to FCV crews 65 years ago in 1955-56. The American Pulaski had been trialled, but never found favour with Australian firefighters.Rakhoeforests commission victoria (fcv), hand tools, forest harvesting, bushfire -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionFire beater (canvas)

Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts. However, its believed the now common Rakehoe is an Australian variation of the American McLeod Tool which was developed in 1905 by forest ranger Malcolm McLeod of the Sierra National Forest. The late Athol Hodgson advised that predecessors, Reg Torbet who had been the Chief Fire Officer for the Forests Commission from 1948-1956, along with his QLD counterpart Clive Price, went in late 1951 as Australian delegates on a 10 week fire study tour of Nth America organised by the United Nations. They came back with a couple of McLeod tools from Canada. Cam MacLeod (different spelling) had been the Head of Fire Research for the Canadian Forest Service at the time and had supplied them. The tools were ideal for deciduous forests in the eastern provinces and Clive arranged to have them manufactured in QLD. The Rakho, as it was then spelled, was first issued to FCV crews 65 years ago in 1955-56. The American Pulaski had been trialled, but never found favour with Australian firefighters.Fire Beater (canvas) 1930s designforests commission victoria (fcv), hand tools, forest harvesting, bushfire -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionBook - Book - Manual of Practical Office Short Cuts, National Office Management Association - Manual of Practical Office Short Cuts, 1947

A manual of practical office short cuts to improve office functions.Dark navy bound book with silver embossed writing. 267 pages. non-fictionA manual of practical office short cuts to improve office functions.town of portland, office, instructional manual -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionPulaski

Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts. However, its believed the now common Rakehoe is an Australian variation of the American McLeod Tool which was developed in 1905 by forest ranger Malcolm McLeod of the Sierra National Forest. The late Athol Hodgson advised that predecessors, Reg Torbet who had been the Chief Fire Officer for the Forests Commission from 1948-1956, along with his QLD counterpart Clive Price, went in late 1951 as Australian delegates on a 10 week fire study tour of Nth America organised by the United Nations. They came back with a couple of McLeod tools from Canada. Cam MacLeod (different spelling) had been the Head of Fire Research for the Canadian Forest Service at the time and had supplied them. The tools were ideal for deciduous forests in the eastern provinces and Clive arranged to have them manufactured in QLD. The Rakho, as it was then spelled, was first issued to FCV crews 65 years ago in 1955-56. The American Pulaski had been trialled, but never found favour with Australian firefighters.Pulaski Fire Tool Combines an axe and a grubbing hoe. Digging end and cutting end with short wooden handleforests commission victoria (fcv), hand tools, forest harvesting, bushfire -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Rakehoe, McLeod Tool (American)

Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts. However, its believed the now common Rakehoe is an Australian variation of the American McLeod Tool which was developed in 1905 by forest ranger Malcolm McLeod of the Sierra National Forest. The late Athol Hodgson advised that predecessors, Reg Torbet who had been the Chief Fire Officer for the Forests Commission from 1948-1956, along with his QLD counterpart Clive Price, went in late 1951 as Australian delegates on a 10 week fire study tour of Nth America organised by the United Nations. They came back with a couple of McLeod tools from Canada. Cam MacLeod (different spelling) had been the Head of Fire Research for the Canadian Forest Service at the time and had supplied them. The tools were ideal for deciduous forests in the eastern provinces and Clive arranged to have them manufactured in QLD. The Rakho, as it was then spelled, was first issued to FCV crews 65 years ago in 1955-56. The American Pulaski had been trialled, but never found favour with Australian firefighters.First used in 1955Rakehoe Combination of a heavy-duty six-toothed (each 9cm long) rake with a large, sturdy (25cm) hoe.bushfire, forests commission victoria (fcv) -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - bale hook small, c1900

A hook as a hand tool is used for securing and moving loads. It consists of a round wooden handle with a strong metal hook projecting at a right angle from the centre of the handle. The appliance is held in a closed fist with the hook projecting between two fingers. This type of hook is used in many different industries, and has many different names. It may be called a box hook, cargo hook, loading hook, or a docker's hook, and a baling hook, bale hook, or hay hook in the agricultural industry. Other variants exist, such as in forestry, for moving logs, and a type with a long shaft, used by city workers to remove manhole covers. A hay hook is slightly different in design in that the shaft is typically longer. It is used on farms to secure and move bales of hay, which are otherwise awkward to pick up manually. A small bale hook with a wooden handle and 2 curved steel hooks pioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, graziers, wool bales, hay bales, -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesTool - Garden tool, Scythe

Long handle scythe used by the college to maintain gardensManual scythe blade with long wooden handle painted orange. Used by Burnley Students for garden maintenance,Metal stamped 1285garden maintenance, burnley, grass control, weed control, students -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Aircraft propellers, Aircraft Propeller Tools and Test Equipment

... Catalogue of tools & testing equipment for Hamilton standard ...Catalogue of tools & testing equipment for Hamilton standard reversing propellersSpiral bound catalogue non-fictionCatalogue of tools & testing equipment for Hamilton standard reversing propellerslist & illustrations of equipment -

Flagstaff Hill Maritime Museum and Village

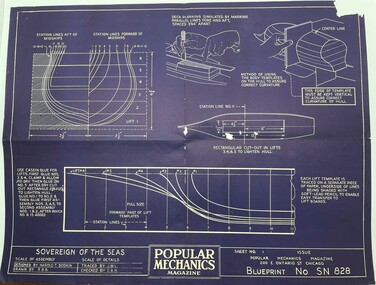

Flagstaff Hill Maritime Museum and VillageWork on paper - Sovereign of the Seas Model Blueprints, Popular Mechanics Press, "Sovereign of the Seas", 1933

... advertised for purchase in the “Sovereign of the Seas” Book/Manual ...A complete set of 8 blueprints from “Popular Mechanics Magazine”, Chicago. The blueprints are on a royal purple coloured paper with white print. Each print displays labelled diagrams to assist the hobbyist to assemble the ship model “Sovereign of the Seas”. The designer is Harold T. Bodkin. Distinct fold creases divide the documents into quarters. There is some silverfish damage leaving holes, however, all instructions are visible. flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum and village, shipwreck coast, great ocean road, model ship, vessel sovereign of the seas, jim williams, james bernard williams, the forth tasmania, freda williams, heather williams, phyllis bowditch, fletcher jones staff 1936, 17th century sailing ship, cramond and dickson, sovereign of the seas, royal sovereign, sovereign, charles 1, fletcher jones, warrnambool breakwater, popular mechanics magazine -

Flagstaff Hill Maritime Museum and Village

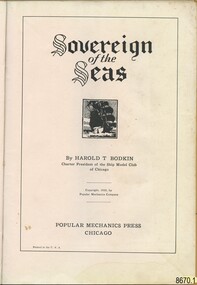

Flagstaff Hill Maritime Museum and VillageBook - "Sovereign of the Seas" book or manual for the ship model hobby enthusiast, Harold T. Bodkin, 1933, "Sovereign of the Seas", Popular Mechanics Press

Jim (James Bernard) Williams, who was the owner of this manual, was a long-time resident of Warrnambool having the opportunity to work at two notable historical businesses of the town. The first, Cramond & Dickson a drapier store established around 1852-1855 and which remained a store that traded under the same name for the longest in Victoria, before it closed its doors in 1974. The second business was Fletcher Jones a highly successful textile and clothing Australian business. Some of Jim’s spare time was devoted to the model ship making which would conjure up many fascinating stories of maritime history. In addition to Jim witnessing the tail end of ships at port in Warrnambool, his "father was as sea captain and operated his vessel in Bass Strait coastal trade between Tasmania and Victoria". The intricately detailed model made by Jim is full of precise detail. The manual and the blueprints held by Flagstaff Hill Maritime Village also reflect the intricate process and devotion to the task completed by Jim. The history of the shipwreck and maritime stories of the Victorian Southwest coast surrounding Warrnambool would have continued to inspire his passion. Three photos of the model and Jim, like the photo of Harold T. Bodkin in the manual, attest to the enthusiasm and enjoyment that was gained by him through this hobby. The manual opens to a photo of “Mr. Harold T. Bodkin adding finishing touches to model of the “Sovereign of the Seas”. The “Forward to Reader” which is on the next page is written by “E. R. HAAN, Technical Editor, Popular Mechanics Magazine. The forward explains the methodology used to achieve the fine detail that is part of the body of the model, by “applying imitation carvings”, and is cited as “a museum type of model”. The following page “Blueprints and Craftmats on the ‘Sovereign of the Seas’” discusses the availability of a set of blueprints to purchase separately. Followed by a description of the moulding process for the “miniature carvings”. “Historical Notes of Interest on the “Sovereign of the Seas (1637)” follow on the next page. The manual is divided into the following parts from pages 8 to 71: “Part I – Shaping the Hull/Part II – The Rudder, Quarter Galleries and Gunports/Part III Wales, Gunport Covers and Initial Ornamentation/Part V – Beakhead Decoration, Bulkhead and Rails, Etc./Part VI Carvings, Lanterns, Knights, Bitts and Painting/Part VII – Details of Mast Construction/Part VIII – Standing Rigging/Part IX – Running Rigging and Final Details. All of these instructions include photographs and detailed graphs. Then instructions on “How to Read and Use Ship-Model Drawings”, “The Shop-Model Maker’s Tools”, and “Simplified Ship-in-a-Bottle”. This is finished off with “Helpful Hints….” And numerous pages of advertising. Some adverts include aids for completing the “Sovereign of the Seas” model. Part I uses blue and black ink to illustrate a dramatic picture of the “Sovereign”, otherwise all print is in black ink on buff paper. This book in significant to the collection as it was donated along with other tools and blueprints which have been used by the donor of the "Sovereign of the Seas" model ship. It also connects with the wider community in that it is related to historical maritime interest and the donor, Jim Williams is also connected to other significant retail and manufacturing businesses of the past in Warrnambool. This manual has been covered with brown paper, including an extra strip for the spine. The front has a watermark at the top middle, some pencilled compass circles segmented into eight parts across the area and a small amount of script writing. The back also has the same type of compass circles and some other small shapes. There are also grease marks. The cover has a patina adding to variations of colour to the paper indicative of the book being handled often. The title page reads “Sovereign of the Seas” in an Old English font. This is followed by a lithograph print around 1 inch square of a ship at full sale. By HAROLD T. BODKIN/Charter President of the Ship Model Club of Chicago/Copyright, 1933, By Popular Mechanics Company/POPULAR MECHANICS PRESS/CHICAGO/Printed in the U.S.A. By HAROLD T. BODKIN/Charter President of the Ship Model Club of Chicago/Copyright, 1933, By Popular Mechanics Company/POPULAR MECHANICS PRESS/CHICAGO/Printed in the U.S.A.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, model ship, vessel sovereign of the seas, jim williams, james bernard williams, the forth tasmania, freda williams, heather williams, phyllis bowditch, fletcher jones staff 1936, 17th century sailing ship, cramond and dickson, sovereign of the seas, royal sovereign, sovereign, charles 1, fletcher jones, warrnambool breakwater -

National Vietnam Veterans Museum (NVVM)

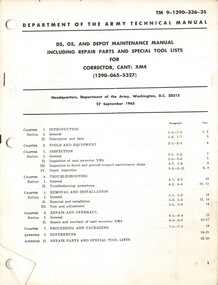

National Vietnam Veterans Museum (NVVM)Manual, DS,GS, and Depot Maintenance Manual including Repair Parts and Special Tool Lists for Corrector, CANT, XM4 and Gateway Army Ammunition Plant

... Tools Tools Maintenance Manual US Army DS,GS, and Depot ...DS,GS, and Depot Maintenance Manual including Repair Parts and Special Tool Lists for Corrector, CANT, XM4 and Gateway Army Ammunition Plant. These are held in a plastic bag.united states - armed forces - service manuals, special tools, tools, maintenance manual, us army -

Moorabbin Air Museum

Moorabbin Air MuseumBook - Aircraft construction, Rigging and Airframes. A Manual for Riggers and Students

General outline of the principles of aircraft construction & maintenance, circa 1936non-fictionGeneral outline of the principles of aircraft construction & maintenance, circa 1936tools & instruments, materials, assembly of component parts, flying & taxiing faults -

Arapiles Historical Society

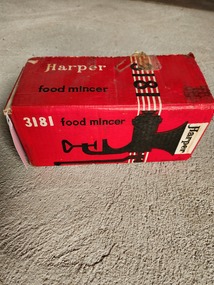

Arapiles Historical SocietyDomestic object - Greta HOGART Collection - 3181 Harper Food Mincer

The Harper 3181 Food Mincer was manufactured in England and designed for domestic kitchens in the mid-20th century. These devices allowed users to manually mince meats, vegetables, and other foods before the widespread use of electric appliances. Harper was a well-known British manufacturer of kitchen tools, and their tinned food mincers were valued for their durability and effectiveness. The mincer represents an era of hands-on food preparation and is an example of practical kitchen technology from the time.This item is a vintage Harper Food Mincer, Model No. 3181, housed in its original red and black branded cardboard box. The food mincer itself is made of heavy-duty metal with a polished finish. It features a wide hopper at the top for feeding meat or vegetables, a robust handle for manual turning, and a clamp mechanism for securing it to a countertop or table. The box displays the Harper logo and an illustration of the mincer, advertising its use for home food preparation.Box: Printed with “Harper Food Mincer No. 3181,” “Made in England,” and “Fully Tinned.” Mincer: Stamped with “3181 HARPER” on the body, and likely additional markings on handle or clamp sections (not fully visible in photo).household item, food, mincer, kitchen -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Manual, United States of America War Office, Organizational Maintenance Manual Including Repair Parts And Special Tool Lists Radio Set AN/PRC-25, 1965

... Manual Repair Parts Special Tools Radio Set AN/PRC-25 ...A cream coloured cardboard cover with black information on the front. Top right hand corner reads TM 11-5820-398-12. Nar the botton of the cover there is an United States of America War Office insignia with Headqyarters, Department Of The Armu November 1965. There are five punch holes down the left hand side and the manual is held together with two metal staples.manual, repair parts, special tools, radio set an/prc-25, united states of america war office -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Avon engines RAAF, Royal Australian Air Force Avon Mk 109 Repair and Reconditioning Instructions

Instructions for repair & reconditioning of Avon Mk 109 engine, circa 1957. Includes amendment listnon-fictionInstructions for repair & reconditioning of Avon Mk 109 engine, circa 1957. Includes amendment listreconditioning, tools & equipment, dismantling & cleaning, inspection, rebuilding, rig testing, bench testing -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Avon engines RAAF, Royal Australian Air Force Avon Mk 109 Repair and Reconditioning Instructions

Instructions on Avon Mk 109 for repair & reconditioning , circa 1957. Including amendment sheetsnon-fictionInstructions on Avon Mk 109 for repair & reconditioning , circa 1957. Including amendment sheetsschedule of fits & clearances, reconditioning instructions, tools & equipmemt, inspection -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Avon engines, Royal Australian Air Force Avon Mks 20 &26 Repair and Reconditioning Instructions

Instructions for the repair & reconditioning of Avon Mk 20 & 26 engines, circa 1957non-fictionInstructions for the repair & reconditioning of Avon Mk 20 & 26 engines, circa 1957list of schedules, reconditioning instructions, tools & equipmemt, distmantlng & cleaning, inspection -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Avon engines RAAF, Royal Australian Air Force Avon Mks 20 &26 Repair and Reconditioning Instructions

Repair & reconditioning instructions for RAAF Avon Mk 20 & 26 engines, circa 1957non-fictionRepair & reconditioning instructions for RAAF Avon Mk 20 & 26 engines, circa 1957tools & equipmemt, replacement / adjustment & rectification, major repairs, workshop processes, main rotating assembly, general repars, main casings & housings, miscellaneous maintenance matters -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Rolls Royce Derwent engines, Rolls Royce Derwent OHM Microfilm Print Workshop Copy

Microfilm copies of Derwent Overhaul Manual pages, circa 1953Faded microfilm copy of original overhaul manualnon-fictionMicrofilm copies of Derwent Overhaul Manual pages, circa 1953dismantling engine to sub-assemblies, dismantling sub assemblies, cleaning engines, rebuilding engine from sub assemblies, rig testing sub assemblies, engine testing, tools & equipment -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Rolls Royce Derwent engines, Derwent Overhaul Manual

Overhaul instructions for Derwent turbo jet engine, circa late 1950snon-fictionOverhaul instructions for Derwent turbo jet engine, circa late 1950sdismantling engine to sub-assemblies, dismantling sub assemblies, cleaning engines, inspection of engines, rebuilding sub assemblies, rig testing sub assemblies, rebuilding engine from sub assemblies, engine testing, packing the engine, testing, tools & equipmemt -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Griffon Engines, Griffon Mk. 61, 65, 66, 67 and 74 Aero Engines

Instructions for repair & conditioning Griffon Mk 61,65,66,67 &74 engines, circa 1949Spring back binder, Photocopies. Full title inside manualnon-fictionInstructions for repair & conditioning Griffon Mk 61,65,66,67 &74 engines, circa 1949servicing engine repair equipment, tools, dismantling & cleaning, inspection, engine rebuilding, general arrangement drawings -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Griffon Engines, Griffon 74-7 Maintenance Manual

Instructions for maintenance of Griffon 74-7 engine, circa1950s3 ring bindernon-fictionInstructions for maintenance of Griffon 74-7 engine, circa1950sgeneral description, transportation & storage, installation & removal, starting & operating, inspection & servicing, unit replacement, tools & equipment