Showing 146 items

matching precision

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Scales,Spring Balnce Imperial ‘Household’ Salter, 20thC

In the 18th century, spring scales appeared. To produce these scales, a manufacturer would use the resistance of a spring to calculate weights, which could be read automatically on the scale’s face. The ease of use of spring scales over balance scales is what led most post offices to outfit their clerks with spring postal scales. One of the most common types of spring scales was the kitchen scale—also known as a family or dial scale. Designed for horizontal surfaces, these scales used the weight of goods in a pan at the top of the scale to force the spring down. Such scales were common in early-20th-century households and were sold by Sears and Montgomery Ward. Many had flat weighing surfaces but some were topped by shallow pans. Companies such as Salters, Chatillon, and Fairbanks made both. SALTER HOUSEWARES began in the late 1760 in the village of Bilston, England. At this time Richard Salter, a spring maker, began making 'pocket steelyards', a scale similar to the fisherman's scale of today. By 1825 his nephew George had taken over the company, which became known as George Salter & Co. and later established a large, well equipped manufacturing site in the town of West Bromwich. The business thrived throughout the 1900s, and in 1972 the company was purchased by Staveley Industries Plc. In 2002, the management team at Salter Housewares Ltd, backed by Barclays Private Equity, bought the company out from the group, to concentrate on its consumer businesses. In 2004 was sold to the US-based HoMedics company, and in 2006, Salter Housewares USA and Taylor Precision Products Inc (also owned by HoMedics) merged. Salter Brand No. 44 Household Spring Balance Kitchen Scales made of green painted metal with a large clock face dial marked in 1oz graduations and with a shallow metal bowl placed on the flat top connected to the mechanism. An adjustable screw tightened or loosened the spring to bring the pointer to zero, prior to adding the material to be weighed.. A common piece of kitchen equipment as most families used this type of scale when measuring goods for cooking or storing.On Clock face ; NO. 44 / HOUSEHOLD SCALE / TO WEIGH 14LB X 1OZ / Pro. Pat. No. 30819 / 32 / MADE IN ENGLAND / SALTER / S in trademark rope with arrow market gardeners, early settlers, fruit, vegetables, farmers, cooking, recipes, scales, weights, measures, brass, balance beam, moorabbin, cheltenham, bentleigh, kitchen scales, dairy products, cereals, wheat flour, salter housewares pty ltd, west bromwich england -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Black and White, The University of Ballarat Mace, 1996, 1996

The University's mace was carried in procession for the first time during the Graduation ceremonies in May 1996. The mace was presented to the University by former Chief Commissioner of the Ballarat City Council, Vern Robson, at a ceremony on 02 February, following a national competition for its design, sponsored by the Council. (The Flag, Issue 2, July 1996) Nineteen artists responded to the competition which called for a design that would embody a distinctive Australian image reflecting the heritage of the city and in relationship with gold, an Aboriginal element and the history of the University. The winning entry, dominated by a poppet head, was submitted by Central Victorian artist/sculptor Trefor Prest, a sessional lecturer in sculpture at the University.(The Flag, Issue 2, July 1996) The Herald Sun of 03 February 1996 reported 'the new mace shows importance elements of Ballarat's heritage as well as the university's focus on the future. The artist emphasises the egalitarian nature of Australia as embodied in Ballarat's famous slice of history - the Eureka uprising. ... The mace has a poppet head at the top of the shaft - an unusual element for a mace - but it represents Ballarat's mining history and the University's evolution from the Ballarat School of Mines. An opening egg at the top stands for the nurturing of development and learning. The mace's straight shaft is depicted as the tree of knowledge and, incorporating a bark canoe scar, Ballarat's Aboriginal heritage. At the end of the shaft is a surveying device, which represents precision and accuracy ads embodied in the university's academic pursuits.' Bob Morrell of the University organised the national competition to design the mace and said 'It is in keeping with the university's logo, 'proudly flying the flag', which incorporates the Southern Cross.' Trefor Prest lectured in Sculpture at the University of Ballarat from 1995-1996.Black and white photograph showing three men holding the new University of Ballarat (now Federation University) mace. From left to right they are Vern Robson (Chief Executive Officer City of Ballarat), Trefor Prest (Sculptor) and Professor David James (Vice Chancellor).university of ballarat, mace, trefor prest, vern robson -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Brass balance 'Salters', c1900

In the 18th century, spring scales appeared. To produce these scales, a manufacturer would use the resistance of a spring to calculate weights, which could be read automatically on the scale’s face. The ease of use of spring scales over balance scales is what led most post offices to outfit their clerks with spring postal scales. One of the most common types of spring scales was the kitchen scale—also known as a family or dial scale. Designed for horizontal surfaces, these scales used the weight of goods in a pan at the top of the scale to force the spring down. Such scales were common in early-20th-century households and were sold by Sears and Montgomery Ward. Many had flat weighing surfaces but some were topped by shallow pans. Companies such as Salters, Chatillon, and Fairbanks made both. SALTER HOUSEWARES began in the late 1760 in the village of Bilston, England. At this time Richard Salter, a spring maker, began making 'pocket steelyards', a scale similar to the fisherman's scale of today. By 1825 his nephew George had taken over the company, which became known as George Salter & Co. and later established a large, well equipped manufacturing site in the town of West Bromwich. The business thrived throughout the 1900s, and in 1972 the company was purchased by Staveley Industries Plc. In 2002, the management team at Salter Housewares Ltd, backed by Barclays Private Equity, bought the company out from the group, to concentrate on its consumer businesses. In 2004 was sold to the US-based HoMedics company, and in 2006, Salter Housewares USA and Taylor Precision Products Inc (also owned by HoMedics) merged. A portable, brass balance scale , 'Salters' for weighing items. A steel ring holds a brass plate marked with graduations 0 – 26 to which is attached a steel hook. ( rope & arrow TM ) / SALTER / POCKET / BALANCE / MADE IN ENGLAND Graduated 0 – 26 / PATENT / No. 8 Base rope & anchor S (trade mark) pioneers, early settlers, market gardeners, moorabbin, brighton, cheltenham, tools, craftsman, balance, scales, weights, imperial measure,, salter housewares pty ltd, west bromwich, england, salter george, salter richard, bilston england, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Hydrometer, 1878 to 1930s

This Sikes brass hydrometer was manufactured by the optical and scientific instrument makers Kasner & Moss of 17 Collins Street West, Melbourne, in the latter part of the nineteenth century. The firm adverted hydrometers, as well as optical instruments, as early as August 13th, 1864, in The Age, Melbourne. This hydrometer set was donated to Flagstaff Hill in 1979 by local wine and spirits merchants Lynch Bros of Fairy Street, Warrnambool. Giffen Russell had established the business in 1878, and Harry Lynch took it over in the 1930s, and after he passed away in 1953 Kevin Matthew Lynch became proprietor of K M Lynch Food and Liquor. The business closed in the 2010s. The hydrometer may date back to the establishment of the business in 1878, as Kasner & Moss were selling hydrometers in Melbourne from 1864. Hydrometers were used to measure the density, or relative density, of liquids from the late 1600s. In 1816 Bartholomew Sikes won the competition for the most useful accurate hydrometer. Hydrometers were commonly used by distillers, vintners, and brewers to establish accurate measures of alcohol concentration in their beverages. Following this manufacturing process, government inspectors and excise officers used them to check that the labelled indications of alcohol-proof were correct and that the right amounts of duty were being paid. This hydrometer and its fitted and hinged wooden container show signs of heavy and protracted use in a working environment. Although the instrument has some parts missing and has been recently repaired, the original quality of the inlaid box and the fine engraving on the instrument and the attachable weights, are indications of the hydrometer’s very real value when new. This Sikes hydrometer, bearing the maker's mark of “Kasner & Moss Melbourne” and the registered number “20373”, was presented to the purchasing public as a precision-made instrument designed for professional use. The Sikes hydrometer is of local significance because of its implied association with the alcohol trade in the southwest region of Victoria. It was donated by a family member of Lynch Bros, a local licensed outlet for wines and spirits in the period before the general relaxation of liquor licensing laws in the State of Victoria. It may have belonged to Griffin Russell who established the liquor store in 1878.Hydrometer; original Sikes brass hydrometer in a polished wooden case with an inlaid plaque on the lid. The brass float is a sphere with a thin flat upper stem and a short, lower stem with a bulb-shaped end. The upper stem is engraved scale on both sides with the numbers 1 to 10, and five divisions between each number. There are ten fixed pegs in the base to secure the thick brass horseshoe-shaped, numbered, various-sized weights (20, 30, 40, 80, 90); the free pegs would have originally stored another five weights (10, 50, 60, 70, and 100). The empty compartment in the box suggests another part in the initial set, probably a thermometer. The fitted, fabric-lined box has two brass closures and two brass hinges. The scientific instrument shows signs of heavy use and repairs. The Serial Number on the float matches the Serial Numbers on the weights. The plaque on the lid, the float and the weights have inscriptions. Made by Kasner & Moss, Melbourne. Plaque: “SIKES HYDROMETER / KASNER & MOSS / MELBOURNE” On float's lower stem: “SIKES 20373” On one thin edge of the float's scale, engraved in script “Kasner & Moss” and stamped “MELBOURNE”, and symbol“P” rotated 90 degrees. On the opposite thin edge of the float: “N20.373”, “SIKES”, “I P % II O” (in ornate capitals). Each weight has s unique number, and the same serial number “20373”.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, sikes hydrometer, scientific instrument, pressure measurement, measuring instrument, ullage tool, customs, excise duty, tax, alcohol content, proof, calibrate, standard weights and measures, tariff, kasner & moss, scientific instrument makers, specific gravity, liquid density, alcohol testing, technology, alcohol measurement, proof spirit, wine and spirits merchants, local business, brass measuring instrument, k m lynch, giffen russell, harry lynch -

Puffing Billy Railway

Puffing Billy RailwaySmiths Setric Electric Clock, circa 1937

Electric Clock - Smiths Setric Clock From 1937 the trademark "Sectric" appears on their synchronous models.Usually on the dial but sometimes also on the back cover. Early clocks had a prominent "T" in sectric. Smiths English Clocks 1931 Smiths, then called S. Smith and Sons (Motor Accessories) Ltd, entered the domestic clock market and formed a new company, Smiths English Clocks Ltd, as the Clock and Watch division with Cricklewood as the main factory. Smiths were one of the first companies to produce synchronous electric clocks. These were put on the market towards the end of 1931. Smiths formed a subsidiary company called Synchronous Electric Clocks to produce these clocks as the first models carry this name. 1932 Smiths purchased English Clock and Watch Manufacturers of Coventry, and acquired the trade names Astral and Empire. 1934 Smiths produced a synchronous alarm clock which they named the Callboy. 1934 They bought the Enfield Clock Co. The Smith's 8 day Calotte clock made its debut at the British Industries Fair in 1934. Prior to this date calottes had been exclusively of foreign manufacture. Also that year, Smiths introduced the Batriclock which was intended for areas where the synchronous clock could not be used. 1935 They introduced the Synfinity, which Smiths described as "the clock that never stops". They said it was "the remarkable combination of a synchronous electric movement with the essential elements of a fine precision lever escapement". If the electric supply failed the clock would run for up to six hours and rewind when the power returned. Apparently the synchronous motor also corrected the mechanical time train at intervals. Smiths produced a synchronous electric chiming clock. 1937 The trade name Sectric appears on Smiths electric clocks. Also the introduction by Smith's of a calotte clock with an alarm movement.Historic - Smiths English Setric Electric Clock Electric Clock - Smiths Setric Clock It is round with the numbers one to twelve, three hands with a white face. Smiths Sectricpuffing billy, clock, time, smiths sectric -

National Wool Museum

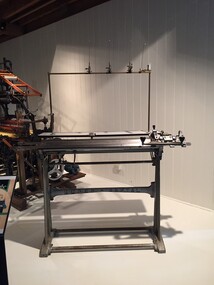

National Wool MuseumMachine - Knitting Machine, Coppo, 1960s

The knitting machine is a recently designed instrument, especially when it is compared with its ancient counterpart, the loom. It enables the creation of many metres of fabric very quickly. A knitting machine is composed of a series of needles which mimic the process of manual knitting. The mechanism engages numerous mechanical elements simultaneously and enables the creation of many metres of fabric very quickly. In addition, a knitting machine can be setup to produce unique bolts of fabric. The density of the fabric may be modified and a knitting machine can produce double-faced effects. A doubled-faced effect creates colour combinations through the introduction of an additional colour to the knitting pattern. This knitting machine is a Coppo brand. It contains over five hundred needles and was produced in the 1960s. It is a representation of the best available in the world at that time. Originating from Italy, it was designed for commercial use. Through both precision and capacity, Italian artisans were seen to be the best in the world of textiles and knitwear. Through emigration, globalisation and the regularly available quantities of wool, Australia came to compete on this stage. The owner of this particular machine migrated from Italy in 1959. When she did, she brought with her a Dubied knitting machine. She later replaced it with this Coppo. When in Australia the owner began work as a piece worker, knitting jumpers and worked for some of the iconic names in the Australian knitting trade including ES Poratt and Alpin Manufacturing. The owner’s role progressed from a piece worker to a wool garment designer and she won many Wool Industry Awards in the 1970s and 1980s. Her high quality of work using and her individual custom designs were spoken about by many of her customers and she had a very large private clientele. She designed and knitted fully fashioned tailored jumpers for people for around 30 years.Knitting table sits on a stand with wide metal legs. Legs contain lettering 'COPPO torino'. Legs are connected via three thin metal poles as well as a metal band and the bed of knitting table at top. The connecting metal band has the lettering 'SUPER - COPTAL' attached. The Knitting table itself contains two beds and a bench at the rear. Attached to the bench is a thin metal structure for the elevation of yarn. It has four crane esk structures above on this metal structure. The bench is covered in a pale grey laminate in the imitation of wood. Attached to the knitting bed is a sliding contraptions containing two handles at the front followed by a complex semi-circle sliding mechanism used to move the knitting mechanism front and back.Left Stand. Lettering: Coppo Torino Right Stand. Lettering: Coppo Torino Centre Stand. Lettering SUPER - COPTALcoppo, knitting machine, design, italy, wool, business, migrants -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw gauge, Henry Disston, 1890-1920

Disston Saw Works of Philadelphia was one of the better known and highly regarded manufacturers of handsaws in the United States. During the Machine Age, the company was known as Henry Disston & Sons, Inc. a supplier of industrial saw blades. History: The story of handsaws in the United States mirrors the technical and development of steel in Sheffield, England, which was the center of handsaw production during the 18th century and through most of the 19th century. England's political and economic lock-on steel making in the colonies held American saw makers at bay until well after the Revolutionary War. American steel producers were unable to compete until the US government introduced import tariffs to level the playing field in 1861. Henry Disston: Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He had emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world, the Keystone Saw Works. Some five years later, Disston built a furnace—perhaps the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons began to set the standards for American saw makers, both in terms of producing high-quality saws and files in 1865 through his development of innovative manufacturing techniques. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets. It took over 25 years to move the entire facility to Tacony. Henry Disston was renowned for having one of the first industries that exhibited environmental responsibility, as well as a paternalistic view towards his employees. For example, he had thousands of homes built in Tacony for his workmen. Funds to purchase these homes were made available through a building and loan association set up by the Disston firm. His caring influence on the community was evident in everyday life. To meet employees' cultural needs, a hall and a library were built with Henry Disston agreeing to pay a fixed sum towards its maintenance. The Tacony Music Hall was erected in 1885, also with the assistance of Disston money. Henry Disston had fallen ill by 1877 and never truly recovered; he suffered a stroke and died the next year. This came only one and a half years after seeing his products receive the highest honors at the great Philadelphia Centennial Exposition of 1876. His vision of a working-class community and the completion of the transfer of his enormous saw plant was carried out by his wife and his sons. The company, by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's armor-plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A tool used to set and sharpen cross cut saws used to fell trees for building construction made by a well known American maker whos firm pioneered the making of saws and their related items including files.combination cross cut saw raker and gauge/jointerDisston USA in the castingflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Ballarat Tramway Museum

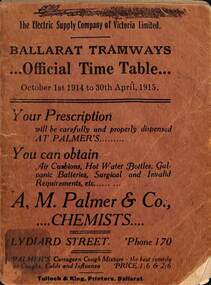

Ballarat Tramway MuseumEphemera - Ballarat, Electric Supply Co. of Vic (ESCo), "Official Time table", 1914

Timetable published by the Electric Supply Co of Victoria (ESCo) for Ballarat Tramways - dated 1/10/1914 to 30/4/1915. Provides times for each route, ticket prices, school tickets, fare box routes, fares, transfer tickets, and route colours both for day and night. Also has notes to passengers and places of interest for each route. Has contact phone numbers for the Company. Manager Mr Pringle. See item 9131 for a 1915 Winter timetable. Has many adverts - from the front page: A M Palmer Chemist Hodgson - optical Snows - department store Summerscales - postcards W E Thomas - Dentist L Casper - optician E Jermyn - feed merchant Standsfield & Smith - Decorators Briant's Red shop tea rooms A E White - tailor Ellingsen & Co - furniture Southern Cross Hotel H P Stevens & Co - fur coats Frank Williams - painter and decorator Longhurst's bread factory G Buchanan - metal ceilings Robert Hutchinson - electrical engineer and contractor G Ludbrook - furnishing undertaker A Cant - plumber, gasfitter and ironmonger Huddart Parker and Howard Smith coal merchants Precision Big 4 - motor cycles and bicycles H W Channing - Tram drivers' training school T H Richards - butcher C Ellis - furniture exchange Levecke's motor garage Frank Penhalluriack - electrical work Nankervis - store Taffy King Fred A Reed - tobacconist F & J W Gower - builder E E Hobson - decorator Walter Cornell - liver pills Irvines - wines G Warner - Ironmonger J A Reynolds - Wall papers W J Robson - leadlights Porter's - boots and shoes Holman & Fiscalini - stables and motor garage Butler & Co - blinds Mrs Kerby - clothing reseller Rose Cosmetic - H Binzer & Co Mrs Busfield - laundry Mrs J H Dogson - registry office for servants B G Tucker's Water Cure Electric Supply Co Rowlands drinks On the bottom of most pages - Sidar products and on the top the Coliseum Picture Palace. Demonstrates and ESCo timetable and provides information about fare systems and local businesses.Time table - booklet - 40 pages + brown light card covers centre stapled with tabbed or cut pages.tramways, ballarat, timetables, esco, advertisements, fares, tickets, fare boxes -

Ballarat Tramway Museum

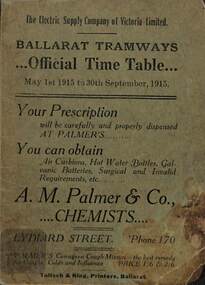

Ballarat Tramway MuseumEphemera - Ballarat, Electric Supply Co. of Vic (ESCo), "Official Time table", 1915

Timetable published by the Electric Supply Co of Victoria (ESCo) for Ballarat Tramways - dated 1/5/1915 to 30/9/1915 - winter. Provides times for each route, ticket prices, school tickets, issue and use of tokens, fares, transfer tickets, and route colours both for day and night. Also has notes to passengers and places of interest for each route. Has contact phone numbers for the Company. Manager Mr Pringle. See item 9132 for a 1914 Summer timetable. Has many adverts - from the front page: A M Palmer Chemist Hodgson - optical Snows - department store ESCo - show room in Sturt St L Casper - optician E Jermyn - feed merchant Standsfield & Smith - Decorators Briant's Red shop tea rooms A E White - tailor Ellingsen & Co - furniture Southern Cross Hotel H P Stevens & Co - fur coats Frank Williams - painter and decorator Longhurst's bread factory G Buchanan - metal ceilings Robert Hutchinson - electrical engineer and contractor G Ludbrook - furnishing undertaker A Cant - plumber, gasfitter and ironmonger Huddart Parker and Howard Smith coal merchants Precision Big 4 - motor cycles and bicycles H W Channing - Tram drivers' training school T H Richards - butcher C Ellis - furniture exchange Levecke's motor garage Frank Penhalluriack - electrical work Nankervis - store Taffy King Fred A Reed - tobacconist F & J W Gower - builder E E Hobson - decorator Walter Cornell - liver pills Irvines - wines G Warner - Ironmonger J A Reynolds - Wall papers ESCo Electric lighting Holman & Fiscalini - stables and motor garage Butler & Co - blinds Mrs Kerby - clothing reseller Rose Cosmetic - H Binzer & Co Mrs Busfield - laundry Mrs J H Dogson - registry office for servants Summerscales - stationary and postcards W J Robson - glass Porter's Boots and Shoes B G Tucker's Water Cure Electric Supply Co Rowlands drinks On the bottom of most pages - Sidar products and on the top the Coliseum Picture Palace. Demonstrates and ESCo timetable and provides information about fare systems and local businesses.Time table - booklet - 40 pages + green light card covers centre stapled with tabbed or cut pages.tramways, ballarat, timetables, esco, advertisements, fares, tickets, tokens -

Kew Historical Society Inc

Kew Historical Society IncPhotograph, Kew Flyer Team, c.1912

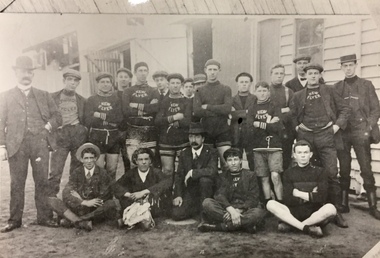

In 1903, an article in the Box Hill 'Reporter' noted that the Kew Flyer Cycle business had been started in 1893 by Harry F. Cooper, who was "the oldest cycle maker in the district". By 1903, the Kew Flyer business was located at 8 (later 14) Cotham Road where it was to remain an institution until its closure. Seven years later, W.D. Vaughan, in his 'Jubilee History of Kew, Victoria' (1910) wrote that: "Several cycling clubs have been born and died, suffering chiefly from the migration of the leading spirits in the organisations, but since 1900 the ‘Kew Flyer’ road race, instituted by Mr. H. F. Cooper, has been the cycling event of the year among local riders. It is run on the White Horse Road at Blackburn." Early newspaper reports record that distance of the Race was initially 10 miles but by 1906, the event was 15 miles, starting from the Travellers' Rest Hotel in Blackburn. Cooper's Kew Flyer business in Cotham Road introduced new technologies and models throughout its 56-years of operation. By 1908, it was claimed that the shop had been enlarged with new "workshops and [the] latest lathes and cycle building tools. [It] Is now one of the most up-to-date Cycle Works in Victoria". By the First World War, Cooper had expanded his business to include motorbikes with "Precision Engines". The Kew Flyer business and the annual road races continued through the War, even though a number of its staff left for the front. One of these was [Pte] Robert Charles Field Richardson, who joined the 6th Battalion, fought and was wounded at Gallipoli, and died of his wounds in a hospital in Alexandria, Egypt in 1915. In 1917, the death of Private H.S. Herbert was announced. He had been the winner of the Kew Flyer Cycle Road Race in 1913. He died in action in France, having fought at Gallipoli and in France at the Battle of Pozieres. The majority of bicycles advertised by Cooper were designed for men, although bikes for women and 'juveniles' were advertised as early as 1918, so they were probably manufactured throughout the period. Harry Cooper was to sell his Kew Flyer business in 1936, after 39 years of trading. The business he began continued until 1949.This is a very rare image [the location of the original is now unknown] of a Kew Flyer team. The photo was sourced and remained in the possession of the historian Dorothy Rogers, whose brother was an early member of staff in the firm. The photo is historically significant as it is the only known photograph of a Kew Flyer Team, and possibly the only known photo of Harry F. Cooper, the founder of the firm and a key figure in Victorian cycling history. Photograph, the first of two, of an earlier album photograph of the Kew Flyer Team in uniform with trainers and workers of the company. One of the men in the photograph is probably Harry Cooper, the proprietor of the Kew Flyer business in Cotham Road, Kew. Harry Cooper was the sponsor of one of the best known trader cycle races in Melbourne. The photograph remained in the possession of the Rogers family until its donation to the Society by John Rogers in 2015.Handwritten annotation by the historian Dorothy Rogers on reverse: "Kew Flyer Team about 1912-13. Coopers Cycle Shop Cotham Rd opp. Kew Post Office".kew flyer, harry f cooper, trader bike races - victoria - kew, kew flyer team -

Kew Historical Society Inc

Kew Historical Society IncPhotograph, Kew Flyer Team, c.1912

In 1903, an article in the Box Hill 'Reporter' noted that the Kew Flyer Cycle business had been started in 1893 by Harry F. Cooper, who was "the oldest cycle maker in the district". By 1903, the Kew Flyer business was located at 8 (later 14) Cotham Road where it was to remain an institution until its closure. Seven years later, W.D. Vaughan, in his 'Jubilee History of Kew, Victoria' (1910) wrote that: "Several cycling clubs have been born and died, suffering chiefly from the migration of the leading spirits in the organisations, but since 1900 the ‘Kew Flyer’ road race, instituted by Mr. H. F. Cooper, has been the cycling event of the year among local riders. It is run on the White Horse Road at Blackburn." Early newspaper reports record that distance of the Race was initially 10 miles but by 1906, the event was 15 miles, starting from the Travellers' Rest Hotel in Blackburn. Cooper's Kew Flyer business in Cotham Road introduced new technologies and models throughout its 56-years of operation. By 1908, it was claimed that the shop had been enlarged with new "workshops and [the] latest lathes and cycle building tools. [It] Is now one of the most up-to-date Cycle Works in Victoria". By the First World War, Cooper had expanded his business to include motorbikes with "Precision Engines". The Kew Flyer business and the annual road races continued through the War, even though a number of its staff left for the front. One of these was [Pte] Robert Charles Field Richardson, who joined the 6th Battalion, fought and was wounded at Gallipoli, and died of his wounds in a hospital in Alexandria, Egypt in 1915. In 1917, the death of Private H.S. Herbert was announced. He had been the winner of the Kew Flyer Cycle Road Race in 1913. He died in action in France, having fought at Gallipoli and in France at the Battle of Pozieres. The majority of bicycles advertised by Cooper were designed for men, although bikes for women and 'juveniles' were advertised as early as 1918, so they were probably manufactured throughout the period. Harry Cooper was to sell his Kew Flyer business in 1936, after 39 years of trading. The business he began continued until 1949.This is a very rare image [the location of the original is now unknown] of a Kew Flyer team. The photo was sourced and remained in the possession of the historian Dorothy Rogers, whose brother was an early member of staff in the firm. The photo is historically significant as it is the only known photograph of a Kew Flyer Team, and possibly the only known photo of Harry F. Cooper, the founder of the firm and a key figure in Victorian cycling history. Photograph, the second of two, from an earlier album photograph of the Kew Flyer Team in uniform with trainers and workers of the company. One of the men in the photograph is probably Harry F. Cooper, the proprietor of the Kew Flyer business in Cotham Road, Kew. Harry Cooper was the sponsor of one of the best known and oldest trader cycle races in Melbourne. The photograph remained in the possession of the Rogers family until its donation to the Society by John Rogers in 2015.Handwritten annotation by the historian Dorothy Rogers on reverse: "Kew Flyer Team from very old photo".kew flyer, harry f cooper, trader bike races - victoria - kew, kew flyer team -

Kew Historical Society Inc

Kew Historical Society IncVehicle, Kew Flyer, Women's Roadster, c.1920

In 1903, an article in the Box Hill 'Reporter' noted that the Kew Flyer Cycle business had been started in 1893 by Harry F. Cooper, and that he was "the oldest cycle maker in the district". By 1903, the Kew Flyer business was located at 8 (later 14) Cotham Road where it was to remain an institution until its closure. In 1910, W.D. Vaughan, in his 'Jubilee History of Kew, Victoria' wrote that: "Several cycling clubs have been born and died, suffering chiefly from the migration of the leading spirits in the organisations, but since 1900 the ‘Kew Flyer’ road race, instituted by Mr. H. F. Cooper, has been the cycling event of the year among local riders. It is run on the White Horse Road at Blackburn." Early newspaper reports recorded the distance of the race as initially 10 miles but by 1906, the event extended to 15 miles, starting from the Travellers' Rest Hotel in Blackburn. Cooper's Kew Flyer business in Cotham Road introduced new technologies and models throughout its 56-years of operation. By 1908, it was claimed that the shop had been enlarged with new "workshops and [the] latest lathes and cycle building tools. [it] Is now one of the most up-to-date Cycle Works in Victoria". By the First World War, Cooper had expanded his business to include motorbikes with "Precision Engines". The Kew Flyer business and the annual road races continued through the War, even though a number of its staff left for the front. One of these was [Pte] Robert Charles Field Richardson, who joined the 6th Battalion, fought and was wounded at Gallipoli, and died of wounds in Alexandria, Egypt in 1915. In 1917, the death of Private H.S. Herbert was announced. He had been the winner of the Kew Flyer Cycle Road Race in 1913. He died in action in France, having fought at Gallipoli and at the Battle of Pozieres. The majority of bicycles advertised by Cooper were designed for men, although bikes for women and 'juveniles' were advertised as early as 1918, so they were probably manufactured throughout the period. Harry Cooper was to sell his Kew Flyer business in 1936, after 39 years of trading. The business he began continued until 1949.This is an historically significant and rare 1920s Kew Flyer Cycle in intact condition, with most of the original paintwork preserved on the frame. Harry F Cooper, who was the manufacturer of the cycle had a retail business and a factory in Kew. He promoted the Kew Flyer Road Race which was the most important trader-run cycle event in Victoria from 1900 to his retirement in 1936.An unrestored Kew Flyer Women's Roadster ca 1920, donated to the Kew Historical Society by John Wyatt in 2017. Original paint work and logo on the loop frame in navy blue, blue and gold, featuring Egyptian influences in the painted design . The rubber sprung saddle was made by Dunlop and has a serial number on a plate at the rear. The loop frame is original. Most of the cycle, on an initial evaluation following the donation were judged to be original, but with the addition of a later mudguard, reflector and chain guard. These have now been removed.Kew Flyerwomen's roadster, kew flyer, harry f cooper, businesses - kew, cycling -

Victorian Aboriginal Corporation for Languages

Victorian Aboriginal Corporation for LanguagesBook, Native Title Research Unit AIATSIS, Proof and management of native title : summary of proceedings of a workshop : conducted by the Native Titles Research Unit, Australian Institute of Aboriginal and Torres Strait Islander Studies at University House, Canberra 31 January - 1 February 1994, 1994

Introduction - Jim Fingleton - Outlines history and problem aspects to do with the formulation of the Native Title Act 1993 and subsidiary /? consultative bodies (eg National Native Title Tribunal and Regulations; Native Title Implementation Task Force); Note: Talks &? discussion papers annotated separately by author/?title/?workshop title; SESSION GROUP DISCUSSIONS ONLY annotated here; First Session: Claims - Matters raised in discussion - timing; restraining orders; requirement for claim acceptance; researching claims; disputes; representative bodies; native title /? compensation claims; Second Session: Hearings - "Main matters raised in discussion" - 1.gender issue in hearings; 2.subjective /? objective tests of native title; 3.use of maps; 4.practice directions; 5. mediation; 6. what precision is needed to prove ownership; Third Session: Determinations - "Matters raised in discussion" - 1.what is a community; 2.the legal process for proof of communal title(i-iv); Fourth Session: New Management Regimes - Main matters raised in discussion - 1. need for new development models; 2. need for new administrative models; 3. is self-sufficiency a realistic goal; 4. actve/?passive income; 5. direct funding of Indigenous bodies; 6. towards self-government; Fifth Session: New Management Decisions - Main matters raised in discussion - 1. different models for money management; 2. local government laws and native title; 3. restrictions on the enjoyment of native title rights; 4. need for flexibility in investigating native title; Sixth Session: Conclusions and Recommendations - Papers as requested; discussion; Main New Matters raised by panel in discussion - 1. recommendations from the Aboriginal caucus; 2. requirements for an application; 3. issues for funding; 4. role of representative bodies; 5. double dipping; 6. role of AIATSIS; 7. trustees or agents; 8. land management issues; Annexes: annotated separately under author /? title.tablesnative title, land tenure -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1900's

In August 1884, Alfred Hirst who had started his trade as a watch repairer and was described as a watchmaker extraordinaire established Hirst Brothers and Company, on Union Street in Oldham Manchester. He took his two stepbrothers into the business and the company was set up to produce timepieces and jewellery as well as importing “Limit company” Swiss watches and precision machine tools for the watch and clock trade. By 1902 Hirst Brothers. had become a limited company and was still growing, adding other businesses in Manchester in 1904 and at Birmingham in 1907. The quality of the clocks and watches was such that Alfred Hirst realised his greatest ambition in 1912 with a range of watches which carried the "Limit" trademark. These watch movements had originally been made in Switzerland and shipped to Hirst Bros. to be put into British made “Dennison” cases. This trade brought even more growth with additional sales offices opening in London and Glasgow. At the outbreak of the First World War in 1914 found them manufacturing aircraft parts including revolution counters and optical instruments. The firm had been tasked by the Ministry of Munitions to solve the problem of pilots dropping bombs by hand and as a result, they effectively created the first bomb rack. After the war, the company once again began to prosper and with the demand for their products increasing they looked to build a new purpose-built factory to manufacture their products. In 1917 they purchased a seven-acre field site at Tame Side Dobcross, the designing of the new factory was passed onto local architect AJ Howcroft. His brief for the design of the clockworks would have been prompted by Alfred Hirst who having visited modern factories in the United States was inspired by the latest factory designs providing as much daylight as possible during working hours. The factory was eventually completed in 1920, by the mid-1920s there were cheap clock imports from Germany and production turned to radio sets and other components as well as counter and gas meters for the "Parkinson and Cowan" company who was later to take over the business. In 1926 came the cotton crash and the District Bank who had loans with the company foreclosed on the Hirst loan. The company did survive and throughout the second World, War II were involved in munitions work at the factory as well as making instruments for various aircraft. In the 1950’s they were producing meters and high grade measuring equipment but by the 1970's the business had closed and the factory was demolished in the mid-1980 "s The item is a good example of the later use of an early mechanism “Fusee” that was originally invented around 1525 in Prague. This type of clock mechanism was replaced as watchmakers looked for mechanisms that could reduce the size of clocks and watches, it appears England was the only country to continue making clocks with a Fusee device until around 1900,s of which our clock is an example. The use of a Fusee movement eventually became obsolete in 1970,s. The item is significant for the collection as it is a clock with a movement that has long since been made obsolete. Fusee type gallery wall clock made by Tame Side with an 8-day mechanical fusee movement. The white enamel dial is a little crazed and some of the Roman Numeral numbers are fading due to over-cleaning. The movement has a hexagonal iron pendulum bob hooking onto a pendulum rod with a spring-wound anchor escapement.Only mark is stamped on the movement believed to be a production number "13490" and made in Tame Side. (If the clock had been made after 1912 it would have had a trade mark "Limit")flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, wall clock, fusee, gallery clock, alfred hirst, tame side -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1940's

Smiths began with a craftsman named Samuel Smith who in 1851 opened a shop in Newington Causeway, London, where he made and sold watches, clocks and precision instruments. Samuel had a son, Samuel Jnr who was apprenticed in his fathers business. Samuel Jnr eventually opened his own business at 85 Strand and later opened other premises at 9 Strand, Trafalgar Square and 68 Piccadilly. In 1899 he turned his business into a private limited company, S. Smith & Son Ltd. Samuel Jnr son, Sir Allan Gordon-Smith, joined him as Manager at 9 Strand in 1903 and laid the foundation of the vast Smiths organisation of the future, leading the company towards the supply of accessories for the then developing motor industry making car clocks and the first speedometers patented in 1904. In July 1914 a new company was formed under the name S. Smith & Sons (Motor Accessories) Ltd., to take over the motor accessory business of S. Smith and Son Ltd. and this became the main company of the group which eventually grew to become Smiths Industries Ltd. The original company S Smith and Sons Ltd., continued as jewelers and clock and watchmakers until 1930 when the company was taken over by Bravingtons retail jeweller chain. In 1931 Smiths decided to enter the domestic clock market and formed a new company, Smiths English Clocks Ltd., as the Clock and Watch division of S Smith & Sons (Motor Accessories) Ltd. This is the start of "Smiths Clocks" because this is when they began to manufacture domestic clocks in quantity. Moreover, they set out to produce these clocks at a price that the average householder could afford. S Smith & Sons (Motor Accessories) was at this time was the main company in the Smiths group of companies and their business developed both in the motor vehicle field and outside it. Smiths began to make automatic pilots for aircraft and, through the acquisition of a majority interest in Henry Hughes & Sons Ltd., entered the field of marine instruments. During the war from 1939 to 1945, Smiths' production expanded. There was a demand for motor, aircraft and marine instruments for the Services and the production of industrial instruments and it is at this time that our item was made. In 1944 many changes were made to the Smiths' organisation. The name of the principal company was changed from S Smith & Sons (Motor Accessories) to S. Smith & Sons (England) Ltd. and four new subsidiary selling companies were set up. These were Smiths Motor Accessories Ltd., Smiths Aircraft Instruments Ltd., Smiths Industrial Instruments Ltd., and Smiths English clocks Ltd. The manufacture of clocks and watches ceased in 1979 and 1983 saw Smiths withdraw from producing items for the motor industry.An item that is now regarded as a vintage, sought by horology collectors worldwide and is in excellent condition. The item is unique in that it was made specifically for ships by the Smith company a well known British clock manufacture. Its provenance is well established and it was made during the world war II era specifically for merchant and naval vessels of the time. Naval brass ships bulkhead clock. The clock face is of white enamel with black Roman numerals, an outer minutes ring and black steel hands. There is a subsidiary seconds dial with sweeping hand just above the centre and a fast/slow adjustment lever above that. There is no manufactures name on the dial. There are a beveled glass and brass hinged lid to the front of the clock. The clock is housed in a heavy brass case with screw holes around the circumference for mounting. There are no markings on the clock or mechanism flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, s smith and sons, clock, maritime clocks, clock makers, bulkhead clock -

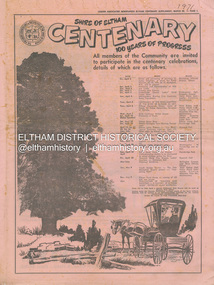

Eltham District Historical Society Inc

Eltham District Historical Society IncNewspaper - Supplement, Leader Associated Newspapers, Shire of Eltham Centenary; 100 Years of Progress, March 30, 1971

Poduced as a supplement to the Diamond Valley News in celebration of the centenary of the Shire of Eltham in 1971. Contains stories of historical note about people and places of the shire as well as numerous advertisng by local businsesses. Also on page 1 lists the program of events commencing Friday, April 2 commencing with a dinner and previewing of paintings by Justus Jorgensen at Montsalvat attended by the Prime Minister, the Rt. Hon. W. H. McMahon running through to the publication of Pioneers & Painters edited by Alan Marshall. Contents: Page 1 Program of Events Page 2 Wingrove . . man of Eltham Page 3 Council people of 100 years Page 5 Capt. Sweeney, Eltham’s first Irish settler Page 6 Station a tribute to ex-concillor Page 7 Eltham 25 Years Ago just a street Page 9 Kangaroo Ground – once the hub of the shire Page 10 Festival of Arts and Crafts at Montsalvat Page 11 Obelisk honours their memory Page 11 Henry Dendy – an Eltham venture Page 12 Free by rail – if they worked Page 12 The long shadow of Ween Cameron Page 13 McMahon’s – a momentous era Page 14 50 Years Ago . . . Lyon Bros Ford Page 15 Beer at 3d. a pint Page 17 Oldest Home Built in 1850 Page 19 History in black and white . . . . Page 20 Historical Pigeon Bank Page 22 Bridge over log crossing Page 22 Pioneer shot by outlaw Page 23 Milestone for Smith Family Page 24 The Eltham Chamber of Commerce Mardi Gras Advertisers: F.J. & R. Favier (Butcher & Delicatessen Lower Plenty) Eltham Hotel Country Art Store (Eltham) A.R. Warren (Eltham) Heidelberg Travel Service Williams Butcher (Lower Plenty) Greensborough Bulk Store Mac’s Meats (Eltham) Buxton Garden Ornaments (Eltham) Hugh Fisher Photographer (Eltham) Para (Mach. Trading Co. (Greensborough) Westfield Shoppingtown (Doncaster) Clinton’s (Eltham) Gillespie & Lewis P/L (Soft Furnishings Greensborough) T. Hutchinson’s Engineers (Greensborough) Knox & Hellemons Pty Ltd (Builders) Angliss Butchers (Eltham) Rainbow Real Estate (Research) Research Licensed Supermarket Gibsons Research Meat Supply Owen Holmes Motors (Greensborough) Research Pharmacy R. & P. Humphries Delicatessen (Eltham) Montsalvat Eltham Apex Mowerama (Eltham) R.H. Dean & Son Real Estate (Greensborough) L.J. & J.D. Avery Butchers (Eltham) Deylen & Torikov (Motor Engineers Eltham) George Lovitt & Co. Pty Ltd Precision Engineers and Toolmakers Montmorency) Fred’s Mower Repairs (Lower Plenty) Gray’s Milk Bar (Montmorency) Maranne Beauty Salon (Montmorency) Evans Bros. & Newell Pty Ltd (Printing Greensborough) La Ronde Restaurant (Eltham) Terry & Margaret’s Garage (Caltex Lower Plenty) Kevin Dawson Building & Joinery Contractors (Eltham) Montmorency Authorised Newsagency Eltham Produce Store (W.J. Cameron) Consolidated Aluminium (Aust.) Pty Ltd (Eltham) Briar Hill Timber & Trading Co. Pty Ltd Diamond Valley Coaches (Eltham) Lyon Bros Ford (Eltham) The Natural Development Association (Eltham Shire) Alan Whitmore R.E.S.I. (Eltham) Keith Wilkie’s Mensland (Montmorency) Eltham Home Supplies (Eltham) Safeway (Greensborough) Lower Plenty Fish Supply Blue Gum Milk Bar (Eltham) W. Hutchinson Sand Soil & Gravel Suppliers (Greensborough) Keyzers Milk Bar (Greensborough) P.J. Timber & Trading Pty Ltd (Eltham) Diamond Valley Motocycles (Honda Macleod) Neville F. Emerson Real Estate (Lower Plenty) Edon Engineering (Eltham) Mobil Service Centre (Eltham) C.A. & J.M. Kohlman (Panton Hill General Store) C.A. & J.M. Kohlman (Smiths Gully General Store) ANZ (Eltham) Diamond Valley Demolition (Eltham) Volkswagen Specialists (D. Young Greensborough) N.F. Thorpe Pty Ltd Precision Engineers (Briar Hill) Ashley’s Milk Bar (Montmorency) J. Turnbull (General Blacksmith Greensborough) Airlook Service Station (Montmorency) A. & L. Mallios (Grocer Hurstbridge) United Refrigeration Pty Ltd (Greensborough) Peter McDougall & Associates Real Estate (Eltham) Hurstbridge Bus & Taxi Service Pty Ltd Browne Bros. Safeway (Eltham) St Andrews Hotel Eltham Real Estate Pty Ltd Eltham Chamber of Commerce B.P. Evergreen Service Station (Eltham) A.R. Warren Fuel Merchant (Eltham) W. Penna Chemist (Eltham) PPH Produce Paint Hardware (Eltham) Eltham Cake Kitchen (Eltham) Fred Ramak Continental Hairdresser (Eltham) Clinton’s (Eltham) Thompson’s Pharmacy (Eltham) Tillings Timber Supermarket (Eltham) Lyon Bros Ford (Eltham) Bob Clarke’s Men’s Wear (Eltham) Eltham Glen Service Station (Eltham) Miss V. Rampton Naturopath (Eltham) Eltham South Milk Bar (Eltham) Eltham Jewellers (Eltham) Baines Supa-Valu Supermarket (Eltham) Sibbel Builders P/L (Eltham) G. & E. Reivers Fly and Shower Screens (Eltham) Kenton Shoeland (Eltham) Eltham Newsagency (Eltham)One copy marked '1971' on fronta. & l. mallios (grocer hurstbridge), a.r. warren (eltham), a.r. warren fuel merchant (eltham), airlook service station (montmorency), alan whitmore r.e.s.i. (eltham), angliss butchers (eltham), anz (eltham), ashley’s milk bar (montmorency), b.p. evergreen service station (eltham), baines supa-valu supermarket (eltham), blue gum milk bar (eltham), bob clarke’s men’s wear (eltham), briar hill timber & trading co. pty ltd, browne bros. safeway (eltham), buxton garden ornaments (eltham), c.a. & j.m. kohlman (panton hill general store), c.a. & j.m. kohlman (smiths gully general store), clinton’s (eltham), consolidated aluminium (aust.) pty ltd (eltham), country art store (eltham), deylen & torikov (motor engineers eltham), diamond valley coaches (eltham), diamond valley demolition (eltham), diamond valley motocycles (honda macleod), edon engineering (eltham), eltham apex, eltham cake kitchen (eltham), eltham chamber of commerce, eltham glen service station (eltham), eltham home supplies (eltham), eltham hotel, eltham jewellers (eltham), eltham newsagency (eltham), eltham produce store (w.j. cameron), eltham real estate pty ltd, eltham south milk bar (eltham), evans bros. & newell pty ltd (printing greensborough), f.j. & r. favier (butcher & delicatessen lower plenty), fred ramak continental hairdresser (eltham), fred’s mower repairs (lower plenty), g. & e. reivers fly and shower screens (eltham), george lovitt & co. pty ltd precision engineers and toolmakers montmorency), gibsons research meat supply, gillespie & lewis p/l (soft furnishings greensborough), gray’s milk bar (montmorency), greensborough bulk store, heidelberg travel service, hugh fisher photographer (eltham), hurstbridge bus & taxi service pty ltd, j. turnbull (general blacksmith greensborough), keith wilkie’s mensland (montmorency), kenton shoeland (eltham), kevin dawson building & joinery contractors (eltham), keyzers milk bar (greensborough), knox & hellemons pty ltd (builders), l.j. & j.d. avery butchers (eltham), la ronde restaurant (eltham), lower plenty fish supply, lyon bros ford (eltham), mac’s meats (eltham), maranne beauty salon (montmorency), miss v. rampton naturopath (eltham), mobil service centre (eltham), montmorency authorised newsagency, montsalvat, mowerama (eltham), n.f. thorpe pty ltd precision engineers (briar hill), neville f. emerson real estate (lower plenty), owen holmes motors (greensborough), p.j. timber & trading pty ltd (eltham), para (mach. trading co. (greensborough), peter mcdougall & associates real estate (eltham), pph produce paint hardware (eltham), r. & p. humphries delicatessen (eltham), r.h. dean & son real estate (greensborough), rainbow real estate (research), research licensed supermarket, research pharmacy, safeway (greensborough), shire of eltham centenary, sibbel builders p/l (eltham), st andrews hotel, t. hutchinson’s engineers (greensborough), terry & margaret’s garage (caltex lower plenty), the natural development association (eltham shire), thompson’s pharmacy (eltham), tillings timber supermarket (eltham), united refrigeration pty ltd (greensborough), volkswagen specialists (d. young greensborough), w. hutchinson sand soil & gravel suppliers (greensborough), w. penna chemist (eltham), westfield shoppingtown (doncaster), williams butcher (lower plenty), a. roy ford, a.g. thomas, agnes bell, albert h. price, andrew ross, anton w. brinkkotter, arthur brindley, b. bessant, b.w. plant, bell family, charles wingrove, culla hill, dave lyon, david w. bell, e.j. andrew, edwin smith, eltham court house, eltham obelisk, ewen hugh cameron, f.e. griffith, f.v. squire, frank mcmahon, george green, george stebbing, h. eric rundle, harold e. bartlett, henry dendy, henry hurst, henry stooke, herbert a. davies, herbert hewitt, i.g. smedley, j.a. mcdonald, jack baker, jack williams, james k. brice, james rossiter, john lyon, john s. smedley, justus jorgensen, kangaroo ground, larry burke, martin mcmahon, menzies jackson, mott family, mrs andrew, mrs harper, p. harmer, p.j. lester, patrick joseph mcmahon, r.j. galbraith, robert burke, robert charles harris, rosehill, s. willey, shillinglaw cottage, shire of eltham war memorial tower, thomas sweeney, tiny carroll, tom orford, w.b. thomas, william morris -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Stevenson Screen, Thomas Stevenson, ca. 1910

Stevenson screens were first introduced in Australia in the 1880s and were widely installed by 1910. The screens have been used to shelter and protect thermometers and other meteorological instruments from rain and direct heat while the holes and double-louvre walls allowed air to flow around them. Sometimes other meteorological instruments were included in the weather stations, so there were different Stevenson Screen sizes. This authentic, original Stevenson screen was previously owned by the Australian Bureau of Meteorology and was used for many years for weather readings at the Cape Otway Light Station in southwest Victoria. The Lighthouse Keepers recorded the readings for minimum and maximum temperatures at 9 a.m. every day from January 1865 until April 1994. The equipment was sheltered in a Stevenson Screen from 1902 until April 15 1994, when the mercury thermometer was replaced by a platinum resistance probe within an Automatic Weather Station (AWS). This Stevenson screen is one of the two screens that then became redundant. The other Stevenson screen was kept to display to visitors. Lightkeepers were no longer required at the Cape Otway Light station either, due to the automated system. The meteorological instruments donated with the screen were used for measuring temperature and humidity. They are mounted on a metal bracket that fits across the screw holes on the screen’s internal frame. The glass-covered Relative Humidity (RH) sensor was made by the renowned precision instrument maker, Rotronic AG of Switzerland, which was founded in 1965. The firm made its first electronic temperature and humidity instrument in 1967. Meteorological records have been collected in Australia from the 1800s. The records were collated, published and used as a basis for weather forecasts. Many sectors, such as maritime and agriculture industries, have relied on these figures for making important decisions. The quality and placement of the meteorological instruments used to measure temperature and humidity are of utmost importance for accuracy. In early colonial times, there were no national standards for meteorological instruments that would allow for accurate figures and comparisons. Once the Bureau of Meteorology was established (around 1908 to 1910) the department installed Stevenson screens throughout Australia, many at lighthouses and light stations, and the measuring instruments were standardised. The Stevenson Screen was named after its inventor, Scottish Civil Engineer Thomas Stevenson (1818-1887) who was also the father of Robert Louis Stevenson, author. Stevenson developed the small thermometer screen around 1867. It had double-louvred walls around the sides and a top of two asbestos sheets with an air space between them and was thickly painted with a white coating that reflected the sun’s rays. This design was modified in 1884 by Edward Mawley of the Royal Meteorological Society. Standards were set for the locations of the screens and instruments, including their distance above ground level and the direction the door faced.Stevenson screens played a significant part in providing a standardised shelter for all meteorological instruments used by the Australian Bureau of Meteorology from about 1910 until 1994. The readings from the instruments gave the meteorological statistics on which weather forecasts throughout Australia were based. This Stevenson screen was used locally at Cape Otway, along the Great Ocean Road in southwest Victoria, so contributed towards our local forecasts and weather warnings.Stevenson screen, original, from the Australian Bureau of Meteorology’s weather station at the Cape Otway Lighthouse. The screen is a white wooden cupboard with a slanted cover raised above the top. The top has ten drilled ventilation holes, and the sides and door are made of downward-slanting double louvres. Two brass hinges join the door to the lower edge of the screen and a metal fitting at the top edge allows for a padlock closure. The screen is supported on four short legs, each with a hole drilled from side to side for fitting to a frame. Inside the screen are two wooden frames fitted with hooks and screws. The floor has three boards; one across the back and one across the front at the same level, and a board wider than the space between these boards is fitted higher, overlapping them slightly. Inside the screen, a pair of electronic instruments with short electric cables is mounted on a metal bracket with drilled holes in it. One of the instruments is a Relative Humidity (RH) probe. It is 26 cm long and is a glass tube with a filter on one end and an electrical connection on the other. It has inscriptions on its label, showing that was made by Rotronic AG, Switzerland. The other instrument is a Resistance Temperature Device (RTD) thermometer. It is 22.5 cm long and has a narrow metal probe joined to a hexagonal metal fitting. A brass plate on the front of the screen has impressed inscriptions. The screen is Serial Number 01/C0032, Catalogue Number 235862.Stamped into brass plate "CAT. NO. / 253862 / SERIAL NO. 01/C0032" On instrument’s electrical fitting; “CD2” [within oval ‘+’ above S] “Serie693 op65 / 220/380V~16A” On instrument’s glass; “rotronic ag” “SWISS MADE” “CE / CH-8303 / Bassersdorf” Symbol for [BARCODE] “ART NO MP 101A_T4-W4W” “POWER 4.8.30VDC“ “OP. RANGE: 0-100%RH/-40+60° C” “OUT H 0-100% 0-1V” “OUT T -40+60°C -0.4..+0.6V” “SERIE NO 19522 009”flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, cotton region shelter, instrument shelter, thermometer shelter, thermoscreen, thermometer screen, measuring instruments, meteorological instrument, weather recording, weather station, lighthouse equipment, light station equipment, stevenson screen, marine instruments, mercury thermometer, platinum resistance probe, aws, automatic weather station, rotronic ag, swiss made, meteorological device, weather forecast, weather prediction, weather records, meteorological forecast, meteorological record, australian bureau of meteorology, bureau of meteorology, bureau, bom, relative humidity, rh, relative humidity probe, resistance temperature device, rtd, thermometer, temperature, humidity, cape otway, cape otway lighthouse, cape otway light station, rotronic, switzerland, swiss instrument, thomas stevenson, double-louvered walls, edward mawley, royal meteorological society, 01/c0032, serial number, cat. no. 235862, serial no. 01/c00323 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sharpening Steel

A honing steel, sometimes referred to as a sharpening steel, whet steel, sharpening stick, sharpening rod, butcher's steel, and chef's steel, is a rod of steel, ceramic or diamond-coated steel used to restore keenness to dulled blade edges. They are flat, oval, or round in cross-section and up to 30 centimetres (1 ft) long. The steel and ceramic honing steels may have longitudinal ridges, whereas the diamond-coated steels are smooth but embedded with abrasive diamond particles. Non-abrasive honing rods such as smooth ceramic or ribbed steel are able to remove small amounts of metal via adhesive wear. In normal use, the rod is applied to the blade at a slightly higher angle than that of the bevel, resulting in the formation of a micro-bevel. The term "hone" is associated with light maintenance performed on a blade without the effort and precision normally associated with sharpening, so the name "hone" was borrowed. In the 1980s, ceramic abrasives became increasingly popular and proved an equal, if not superior, method for accomplishing the same daily maintenance tasks; manufacturers replaced steels with ceramic (and later, manufactured diamond abrasive) sharpening "steels" that were actually hones. Use Honing steels are used by lightly placing the near edge of the blade against the base of the steel, then sliding the blade away from yourself along the steel while moving it down – the blade moves diagonally, while the steel remains stationary. This should be done with the blade held at an angle to the steel, usually about 20°, and repeating on the opposite side at the same angle. This is repeated five to ten times per side. Steeling It is often recommended that steeling be performed immediately before or after using a knife and can be done daily. By contrast, knives are generally sharpened much less frequently. A traditional smooth honing steel is of no use if the edge is blunt, because it removes no material; instead it fixes deformations along the edge of a sharp blade, technically known as burnishing. There has long been speculation about the efficacy of steeling (re-aligning the edge) vs honing (removing minor deformation with abrasives); studies tend to favour abrasives for daily maintenance, especially in high-carbide-volume "stainless" steels (such as the popular CPM S30V steel, which tends to "tear out" when steeled rather than re-forming an edge.) Small honing steel for outdoor activities Usage trends Steels have traditionally been used in the West, especially in heavy-use scenarios (e.g. butchering, where the edge deforms due to forceful contact with bone). These scenarios also lead Western trends toward blades tempered to a lower level of hardness (and thus lower brittleness). In East Asia, notably Japan, harder knives are preferred, so there is little need for steeling intra-day, as the edge does not deform as much. Instead, the blade is honed as needed on a waterstone. While tradition has kept the practice of steeling alive in Western kitchens, the majority of honing steels sold are abrasive rather than smooth, and knives are harder and more frequently made of stainless steel, which does not respond to traditional steeling techniques as well as high-carbon/low alloy tool steels.The sharpening steel is essential to maintain the sharpness of carving and other knives.Steel knife sharpener with bone handle. Part of a carving set.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sharpening steel, carving set, kitchen equipment -

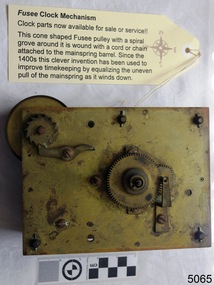

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Fusee Clock Mechanism, early 20th Century

The origin of the fusee is not known. Many sources credit clockmaker Jacob Zech of Prague with inventing it around 1525. The earliest dated fusee clock was made by Zech in 1525, but the fusee appeared earlier, with the first spring-driven clocks in the 15th century. The idea probably did not originate with clockmakers, since the earliest known example is in a crossbow windlass shown in a 1405 military manuscript. Drawings from the 15th century by Filippo Brunelleschi and Leonardo da Vinci also show fusee mechanisms. The earliest existing clock with a fusee, also the earliest spring-powered clock, is the Burgunderuhr (Burgundy clock), a chamber clock whose iconography suggests that it was made for Phillipe the Good, Duke of Burgundy about 1430. Springs were first employed to power clocks in the 15th century, to make them smaller and portable.[1][5] These early spring-driven clocks were much less accurate than weight-driven clocks. Unlike a weight on a cord, which exerts a constant force to turn the clock's wheels, the force a spring exerts diminishes as the spring unwinds. The primitive verge and foliot timekeeping mechanism, used in all early clocks, was sensitive to changes in drive force. So early spring-driven clocks slowed down over their running period as the mainspring unwound. This problem is called lack of isochronism. Two solutions to this problem appeared with the first spring-driven clocks; the stack freed and the fusee. The stack freed, a crude cam compensator, added a lot of friction and was abandoned after less than a century. The fusee was a much more lasting idea. As the movement ran, the tapering shape of the fusee pulley continuously changed the mechanical advantage of the pull from the mainspring, compensating for the diminishing spring force. Clockmakers empirically discovered the correct shape for the fusee, which is not a simple cone but a hyperboloid. The first fusees were long and slender, but later ones have a squatter compact shape. Fusees became the standard method of getting constant force from a mainspring, used in most spring-wound clocks, and watches when they appeared in the 17th century. Around 1726 John Harrison added the maintaining power spring to the fusee to keep marine chronometers running during winding, and this was generally adopted. The fusee was a good mainspring compensator, but it was also expensive, difficult to adjust, and had other disadvantages: It was bulky and tall and made pocket watches unfashionably thick. If the mainspring broke and had to be replaced, a frequent occurrence with early mainsprings, the fusee had to be readjusted to the new spring. If the fusee chain broke, the force of the mainspring sent the end whipping about the inside of the clock, causing damage. The invention of the pendulum and the balance spring in the mid-17th century made clocks and watches much more isochronous, by making the timekeeping element a harmonic oscillator, with a natural "beat" resistant to change. The pendulum clock with an anchor escapement, invented in 1670, was sufficiently independent of drive force so that only a few had fusees. In pocketwatches, the verge escapement, which required a fusee, was gradually replaced by escapements which were less sensitive to changes in mainspring force: the cylinder and later the lever escapement. In 1760, Jean-Antoine Lépine dispensed with the fusee, inventing a going barrel to power the watch gear train directly. This contained a very long mainspring, of which only a few turns were used to power the watch. Accordingly, only a part of the mainspring's 'torque curve' was used, where the torque was approximately constant. In the 1780s, pursuing thinner watches, French watchmakers adopted the going barrel with the cylinder escapement. By 1850, the Swiss and American watchmaking industries employed the going barrel exclusively, aided by new methods of adjusting the balance spring so that it was isochronous. England continued to make the bulkier full plate fusee watches until about 1900. They were inexpensive models sold to the lower classes and were derisively called "turnips". After this, the only remaining use for the fusee was in marine chronometers, where the highest precision was needed, and bulk was less of a disadvantage until they became obsolete in the 1970s. Item is an example of clock mechanisms used until 1910 for many different styles of clocks and went out of fashion in the 1970s due to improvements in clock and watch making.Brass fusse clock movement, It has very heavy brass plates and wheels, high-count machined pinions, and a fusee. The mounting of the pendulum is missing and It has a recoil escapement. A fusee is a conical pulley driven through a chain by the spring barrel. As the spring runs down, the chain acts at a larger and larger radius on the conical pulley, equalising the driving torque. This keeps the rate of the clock more even over the whole run. It has motion work to drive an hour hand as well as a minute hand and the centre arbor is extended behind the back plate to drive some other mechanism.Inscription scratched on back"AM 40" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock mechanism, fusee mechanism, horology -

Federation University Historical Collection

Federation University Historical CollectionBook - Booklet, The Institute of Physics Handbook: Exhibition of Scientific Instruments and Apparatus, 08/1960

The Exhibition of Scientific Instruments and apparatus was set up to show the professional scientist the latest tools of trade and glimpses of future developments in the field of instrumentation .Cream soft covered book of 198 pages relating to an exhibition of scientific instruments and apparatus held at the School of Chemistry, University of Sydney. Exhibitors in the exhibition include: Advance components, Airmec, Akashi, Aladdin Industries, Amalgamated Wireless, Applied Physics Corporation, Ardente, Austral Engineering Supplies Pty Ltd, Avo Limited, Baird Atomic, Baker, Baldwin Instrument Co., B. and Relays, Barnstead Still and Steriliser Co., Beckman, Bender, Boonton Radio Corporation, Bosch, British Electric Resistence, British Physical Laboratories, Buccho, Bundenberg, Buehler, Bureau of Analysed Samples Ltd, Business Equipment Pty Ltd, Cambridge Instrument Co, Casella, Chamberlain and Hookham, Cossar, Cooke Troughton, Counting Instruments Co, CSIRO, Dawe Instruments, Difco, Duff and Macintosh, Dumont, Dupree, Dynatron Rodio Ltd, East Lancashire Chemical Co., Edwards High Vacuum Ltd, Eletircal Equipment Australia, Electronic Industries, Electroscientific Industries, Electrothermal Heating, Elema Schonanda, EMI, Englehard, Epprect, ERD Engineering, Ericsson Telephones, Esdaile, Ether Ltd, Evershed and Vignoles, Faraday Electronic Instruments, Federal Products, Filtron, Fischer, Fluke, Foot, Fortiphone, PX Fox, Foxall Instruments, Gambrell Bros, Gardener and Salmon, Garlick, Gelman , Gossen, Griffen and george, Gurr, Guthrie. Hasler, Headland Engineering Developments, Heraeus, Hersey Sparling Meter Co, Hewlett Packard, Heyneco, Hilger and Watts, Instron Engineering, Institute of Physics, Intermetal, Internation Resistance Corporation, Jacoby Mitchell and Co, Janke and Kinkel, JENA-er Glasswerke Schott and Gen, Keithly Instruments, Kelvin and Hughes, Kent, Kipp and Zonene, Kovo, Krautkramer, Kruss, Lambrecht, Land Pyrometers Leeds and Northrup, Leeds Meter Co, Leybold, Liddle and Epstein, Long Industrial Equipment, macdougall, McKinlay Fletcher, McLellan, Marconi Instruments, Masruements, Metrimpex, Metrohn, Metron, Mettler, Mica Corporation, Minneapolis Honeywell Regulator Company, Moisture Regulator, Morganite, Morris, Moseley, Muirhead, Mullard- Australia, Nagard, National Instrument Co, National Standards Laboratory, Negretti and Zamba, Nira, Northeastern Engineering, Nuclear Equipment Ltd, Ronald payne, Philbrick, Philips, Physik Instruments, Pincombe, Precision Tools and Instrument Co., Printed Electronics, Pye, Quicfit, Radion Corporation of Amerixa, Radio Frequency Laboratories, Radiometer, Rank Cintel, record Electric Co., Reichert Optische Werke, Rhode and Schwarz, Ridsdales and Co, Rocol, Rotameter, Rototherm, Rowe, George Sample, Santon, Sanders, Sartorious-Werke, Sauter August, Schneider, Scruttons, SEFRAM, Selby, Sensitive Research, Servomax Controls, shckman, Shimadzu, Siemens, Simpson, Sodeco, Soiltest, Solartorn, Southern Instruments, Albert Speck, Stanford X-Ray, Sunvic Controls, Sweda, Sydney County Council, Tamson, techne Cambridge, Tektronix, Telefunken, Telequipment, Andrew Thom, Thompson J, Langha,, Thronethwaite, Tinsley, Tokyo Opptical co., Townsen and Mercer, Treacerlab, Tylors, Unicam, Union OPtical Co, Varian Associated, Venner Electronics, Vidler Thornethwaite Engineering, Crosweller, Wandel and Golterman, Watson Victor Limited, Wayne Kerr Laboratories, waveforms, West Instruments, Herman Wetzer, Wild Instrument Supply Co, Yokagawa Electrical Works, Carl Seiss, Zwick.science, instruments, apparatus, scientific objects -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923