Showing 525 items

matching use of machinery

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageShip Log Rotor, 1930s

Thomas Walker & Son was internationally renowned in the manufacturing of ships logs, founding father, Thomas Walker (1805–1871), an engineer in Birmingham, patented a mechanical log in 1878 which was a recording instrument that attached to a rail at the stern of a vessel connected by a long cord with a rotor which was towed behind the ship. The instrument dial recorded the distance travelled. Thomas Walker first went into business to manufacture stoves at 58 Oxford Street Birmingham. Walker’s self-feeding stove was widely lauded at the Paris Exhibition of 1855, winning a prize medal and kick starting the first of many notable innovations for the Walker family's manufacturing business. However, it wasn’t until working on an earlier ships log model invented by his Uncle that Thomas Walker became interested in the further development of this device, used to ascertain a ship’s speed. Walker continued to improve on the common log for the company of Massey & Sons and these improvements were deemed revolutionary. This log became a firm favourite of the West India Association (British-based organisation promoting ties and trade with the British Caribbean). and the most common log in use for two generations. It took till 1861 for Thomas Walker and his son, Thomas Ferdinand Walker (1831-1921) to patent the first Walker log of many. Together, with the introduction of the A1 Harpoon Log two years later, they established the Walker Log Business as a force to be reckoned with. By the time of his passing in 1871, Thomas Walker Snr had not only founded a family business with considerable staying power but also instilled a tradition of public service. Having sat as a representative on the Birmingham Town Council for 15 years and played an active role in public works, he was soon given the nickname of ‘Blue Brick Walker’. Much like his father, Thomas Ferdinand Walker changed the face of the maritime industry. His patent of 1897, the ‘Cherub’ log, was a notable departure from the past providing a far more accurate reading and replacing the majority of logs of the age. They were the first to produce an electric log and the Walker factory was one of the first to introduce the 48 hour work week for employees. This ship log rotor was invented and made by a significant marine instrument maker and innovator of machinery. It demonstrates the huge leap taken to improve navigational accuracy at sea with an instrument that was in use for decades and still is today. Therefore it is a worthy addition to the Flagstaff Maritime collection as it demonstrates another aspect of maritime navigation.A Walkers Cherub III Patent mechanical ship brass rotor with with four vane's one marked with an anchor and "T. W. Cherub 441", The log is attached to a brass swivel with a short length of rope. Has T W Cherub 441 marked on a vane.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, log rotor, taffrail log, thomas walker, marine technology, marine instrument, navigation, ship speed, measurment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Copper Sheet, circa 1878

In 1984 the Commonwealth Government made available to Flagstaff Hill a collection of lead ingots and copper sheets recovered from the wreck-site of the LOCH ARD. They were presented to the Warrnambool City Council by the Hon. Tom Uren MHR, Minister for Territories and Local Government: “The Commonwealth recognises that shipwrecks like the LOCH ARD are our national heritage with important educational, recreational and tourist applications” (The Standard, Tuesday 8 May 1984). The LOCH ARD was wrecked in 1878. Unsuccessful salvage operations were then undertaken with the 90 ton paddle steamer NAPIER. In sudden bad weather this vessel too was sunk. The precise position of the LOCH ARD in the exposed and dangerous waters off Mutton Bird Island became lost to memory. The underwater location of the LOCH ARD was rediscovered in 1967 by a Warrnambool skindiver, Stan McPhee. In the two years following his find, the vessel was systematically pillaged by unauthorised salvagers. This led to the State and Federal Governments’ intervention in 1969. A roundup and seizure of recovered lead ingots and copper sheets was conducted by Commonwealth and Victorian Police. Offenders were charged and convicted. The “repossessed loot of the Tassie Boys” was placed into secure storage (Jack Loney, 1978, Wrecks & Reputations). The LOCH ARD manifest of cargo lists “Pig lead 50 tons, 994 pig & 37 rolls” and “Copper 33 plates, 53 bolts”. While the lead ingots have been subsequently described as “ballast”, the copper sheets are unlikely to have been associated with the ship’s normal complement in that way. Similar product lines in the cargo manifest are “Bar and rod iron 102 tons”, “Plate iron 3 tons” and “Zinc 12 tons”. These raw materials were used by colonial artisans such as blacksmiths and metal smelters to fashion, and repair, agricultural implements and industrial machinery. Copper was valued for its non-corrosive properties and its malleability, or ease of working. Both these qualities were useful, for example, in laying underground gas pipes that supplied lighting to residences, businesses and streetscapes in the mid-nineteenth century. As the nineteenth century progressed, the metal was also increasingly valued for its conductivity, with copper wiring linking colonial communities to each other, and the wider world, via the Telegraph system. The average weight of the copper sheets is 216 kilograms, calculated by "volume 0.1936m³ X Cu density 8930kgs/m³".The shipwreck of the Loch Ard is of significance for Victoria and is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulation of artefacts from this notable Victorian shipwreck. The collections object is to also give us a snapshot into history so we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. The collections historically significance is that it is associated unfortunately with the worst and best-known shipwreck in Victoria's history. Large heavy sheets or panels of copper metal raised from the wreck of the LOCH ARD. The 10 sheets are of roughly similar dimensions and rectangular shape. They bear signs of prolonged submersion in seawater, with various degrees of limestone accretion, adhered marine growth, and green oxidisation. Three of the sheets are severely buckled, demonstrating the force of underwater explosives used in their salvage. One sheet appears cut or severed in a diagonal line downwards from its top left hand corner. One sheet has a 10cm X 10cm square cut out of its top right hand corner. All sheets are in sturdy, stable condition. No maker’s marks are visible.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, sailing ship, copper sheet, manutacturing materials, metal imports, muntz -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Calendar

This calendar has been distributed as a advertising item for Earl’s agricultural machinery and oil depot. The business was situated at the corner of Lava and Kepler Streets in Warrnambool. The name, Acmino’ stood for Allis-Chalmers, Mitchell’s Implements, Neptune Oils’. Distributing calendars at Christmas time for the following year was, and still is, a popular advertising tool for businesses. This calendar is of minor interest as an example of the use made by businesses in the 1940s of calendars as advertising tools. It also has a local Warrnambool connection, the agricultural machinery business of F. Earl. This is a 1946 calendar with a buff-coloured sheet of crinkled paper with a brown border. It has a coloured photograph of two men droving cattle near a river and it ispasted on to the paper with a brown border around the photograph. The calendar for 1946 is printed on to the paper and also in monthly sheets pasted on to the paper on top of each other. The printing on the calendar is brown. On the back of the calendar is written in black ink, ‘French Bros’. The calendar has a red piece of string at the top for hanging the calendar up on a wall or cupboard. The calendar is torn at the edges and somewhat stained.‘With Compliments from the “Acmino” House, F.Earl (Prop.)Warrnambool Phone 484 Private 75’ ‘Allis-Chalmers Tractors Mitchell’s Implements Neptune Oils’ ‘Sales, Service and Satisfaction Guaranteed’ ‘French Bros’ ‘acmino’ house, warrnambool, f. earl, history of warrnambool -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhoto - Mountain Creek Logging Camp, 1955

... record of the general working conditions, type of machinery ...Hume and Hovell discovered the area in 1824 and by the end of the 19th century the valley was transformed by logging, dairy and beef cattle properties and tobacco farms. The logs could have been milled for timber at the State Electricity Commission's mill at Howman's Gap which provided a much needed source of timber for construction of McKay Creek Power Station which began construction in 1951 and also the camps and houses for the workers and their families. There was a need for housing and infrastructure for an increasing population of workers for the hydro-electric scheme as there was a general shortage of this commodity. A timber mill was started in Tawonga by Mates, of Albury, in 1945, and electricity became available in 1946 the S.E.C. bought the mill, and enlarged it. In 1960 it was purchase by a local family, they also started a timber mill in Mt Beauty worked both until 1980 when they closed it. The Tawonga mill and enlarged the mill called Mt. Beauty Timbers Pty Ltd employed approximately 50 people. An historical pictorial record of the general working conditions, type of machinery and vehicles in use in the 1950’s. Note the lack of protective clothing!Black and white photograph of the logging camp at Mountain Creek. November 1955Handwritten on the back of photograph - MOUNTAIN CREEK LOGGING CAMP NOV 55mountain creek logging camp, timber industry, tawonga -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhoto - Logging. Mountain Creek, November 1955, November 1955

... record of the general working conditions, type of machinery ...Hume and Hovell discovered the area in 1824 and by the end of the 19th century the valley was transformed by logging, dairy and beef cattle properties and tobacco farms. The logs could have been milled for timber at the State Electricity Commission's mill at Howman's Gap which provided a much needed source of timber for construction of McKay Creek Power Station which began construction in 1951 and also the camps and houses for the workers and their families. There was a need for housing and infrastructure for an increasing population of workers for the hydro-electric scheme as there was a general shortage of this commodity. A timber mill was started in Tawonga by Mates, of Albury, in 1945, and electricity became available in 1946 the S.E.C. bought the mill, and enlarged it. In 1960 it was purchase by a local family, they also started a timber mill in Mt Beauty worked both until 1980 when they closed it. The Tawonga mill and enlarged the mill called Mt. Beauty Timbers Pty Ltd employed approximately 50 people An historical pictorial record of the general working conditions, type of machinery and vehicles in use in the 1950’s. Black and white photograph of logging at Mountain Creek November 1955Small typed note attached to the back of photo - Logging Mountain Creek November 1955mountain creek logging camp, tawonga, timber industry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph – Photocopy of black and white photograph of Bogong Creek Race Line. 17/1/51, 17/01/1951

... . An historical record showing the machinery used during this time ...A start on the construction of Bogong Creek race line was made at the commencement of winter in 1948. Work proceeded in the following years when work on the High Plains was not practicable. In January, 1951 the special trimming machine, the special slip form and concrete mixing and placing equipment was put into service. A shortage of cement caused some delays as well as a sudden financial recession. The race line was completed and put into service in 1952.An historical record showing the machinery used during this time, the number of workers and supervisors involved and the mountainous terrain where they worked. It also demonstrates the OH&S of the period with workers mostly in street clothing with no hard hats or other safety equipment. Several workers can be seen working shirtless or in singlets.Photocopy of a black and white SECV photograph No: K 6209 labelled Bogong Creek Race Line ch. 1700. Depicting large group of workers and supervisors working at the site. Dated 17/1/52Printed underneath the photograph: STATE ELECTRICITY COMMISSION OF VICTORIA Date: 17/1/51 Time: 10.30am No: K 6209 Kiewa Hydro-Electric Works Bogong Creek Race Line ch. 1700 bogong creek raceline; secv; kiewa hydro electric scheme; -

Kiewa Valley Historical Society

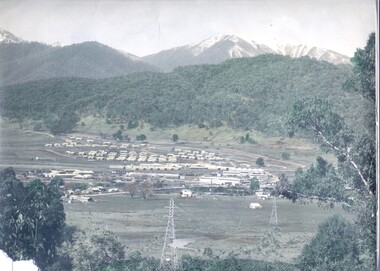

Kiewa Valley Historical SocietySet of 2 hand coloured photographs of early Mount Beauty, photographs of Mount Beauty, 1947/48

Construction of the town of Mount Beauty commenced in 1946 and continued until 1952. It was built to provide family accommodation for workers engaged in the construction of the hydro electric power scheme. As well as housing, there was an administration building, staff hostel, merchandising centre, workmen's camps, base stores and workshops and the Mount Beauty Terminal Station. The first house was occupied in November, 1946 by the then manager of the trading store, with a frontage onto Hollonds Street. The total number of houses erected was 488, 162 custom built and 326 prefabricated. The main workmen's camp can be seen just left of the centre of the photograph and accommodated 144 men at the time of the photograph. By 1950 it could accommodate 1200men. Photo No. 1 is taken in 1947/early 1948 as there is no evidence of the staff hostel under construction. This hostel was commenced in August/September 1948 and is clearly shown in photograph No. 2, dating this photo as 1948 as it is before the completion of the bypass road connecting to the main (high plains) road. This road was constructed in 1939 and in 1948 followed the route of Tawonga Crescent. This remained in use until the bypass construction was completed in early 1949 and does not appear to be finished in this photograph.. Both photographs are taken from the power line easement adjacent to the Bright road.Significant historical pictorial record of the development of a town from grazing land. The type of terrain that had to be surveyed and then to construct roads and other infrastructure, with very little machinery, is also of prime significance in the development of the Kiewa Hydro Electric Scheme.Two photographs, both hand painted to show colours, and both of Mount Beauty c 1947/48 not long after commencement of construction of homes and facilities for workers.Photo No.1 - on back of photo, left upper corner, faintly in pencil, SPIKE, underneath this is written T Pay,. Photo No. 2 - on back of photo, left upper corner, faintly in pencil, Jmount beauty, housing, accommodation -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPapers - Centenary Bright-Tawonga Road, 19th March 1996

The Bright-Tawonga Road was built in 1896, connecting the Ovens and Kiewa valleys. The article gives an description of the event.The Bright - Tawonga road connected Tawonga to the larger town of Bright and the closest railway service. This road provided the Upper Kiewa Valley with access to larger markets, alternative transport and increased facilities not available in the Kiewa Valley in the early, pre SEC days. It describes how roads were built in 1896 with little machinery. The KVHS has in its collection the dray used to help build the road. One page article from the 'Shire News' dated 19th March 1996bright-tawonga road, road works, kiewa valley, ovens valley, dray -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotographs - 2 Colour photographs of logs being harvested and milled for timber in the Kiewa Valley

... at a timber mill 2. Colour photograph of heavy machinery being used... pictorial record of the type of machinery and vehicles in use ...: Hume and Hovell discovered the area in 1824 and by the end of the 19th century the Kiewa Valley was transformed by logging, dairy and beef cattle properties and tobacco farms. The logs could have been milled for timber at the State Electricity Commission's mill at Howman's Gap which provided a much needed source of timber for construction of McKay Creek Power Station which began construction in 1951 and also the camps and houses for the workers and their families There was a need for housing and infrastructure for an increasing population of workers for the hydro-electric scheme as there was a general shortage of this commodity. A timber mill was started in Tawonga by Mates, of Albury, in 1945, and electricity became available in 1946 the S.E.C. bought the mill, and enlarged it. In 1960 it was purchase by a local family, they also started a timber mill in Mt Beauty worked both until 1980 when they closed the Tawonga mill and enlarged the mill called Mt. Beauty Timbers Pty Ltd which employed approximately 50 people. An historical pictorial record of the type of machinery and vehicles in use in the 1950’s to harvest and mill the logs from surrounding forested areas.1. Colour photograph of large logs being milled for timber at a timber mill 2. Colour photograph of heavy machinery being used to harvest large logs for milling timber; timber mill; kiewa valley; forests; logging -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPot Melting, circa mid to late 1900's

Before 1908 the words "melting pot" was a term relating to a "crucible" with a meaning of "a pot in which metals and other substances are melted (fused) to provide metal items of varying shapes and uses. From the mid 1900's this term changed and became more related to the "mixing" of social and ethnically diverse populations. The description used here is that of pre 1908. This melting pot was used in the early to late 1900's when produce and hardware shops were too far away from the Kiewa Valley and time was at the essence. The ability to manufacture as many "crucial " items at the home property was the difference between running a successful rural business or not. The isolation of the Kiewa Valley (before the 1950's), hindered the "time down" of machinery and important "widget" replacements. The ability of self sufficiency on properties is still a boon to rural properties as time lost is never really recovered.This melting pot is highly significant to the Kiewa Valley as it provides evidence that the graziers and cattle stations required to be self sufficient in all aspects of day to day maintenance and replenishment of worn materials requiring to be "manufactured " at the property and lack of replacements from commercially shelved products. This aspect of "survival" in the "bush" can be seen in the "huts" built on the Bogong High Plains to accommodate the seasonal grazing of cattle from the Kiewa Valley.This black melting pot is made of cast iron. The lid is missing. The top rim of the pot has three lips for poring accuracy. The formation of these lips are in a "triangle" formation. The top section of the body has a curve inwards reducing the pot diameter from 270mm at the base to 135mm.at the top. The handle is made from heavy gauge wire which is fastened to the body through two lugs (welded onto the top section of the pot) and fasten through a hole at the top of each lug. The handle has a "U" shape as it goes through the lug hole, ensuring no accidental fixture to any side thus allowing free swiveling from one side to the other . "BH" indented within a diamond shape. Opposite "No 3"camp fire cooking utensils, hot plate, cast iron cooking appliance, drovers kitchen -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBook - Miscellaneous - Pictorial - Snow, Georgian House, The Australian Snow Pictorial, c1952

This book records the history of skiing in Victoria with photos of places and people showing equipment used in the snow fields and used by skiers.Falls Creek and the Bogong High Plains are included in this book showing photos of local people and machinery etc. Dorothy Anderson (nee Ryder) owned and used this book. She lived at Tawonga.This is a bound pictorial book with a blue cover and white printed title.. The subject is Alpine resorts and ski areas in the Australian High Country in the 40s and 50s. 'To our very dear friends, Mr and Mrs Ryder, with our best wishes for a Merry Christmas & a Happy New Year from Harold and 'Rel / Ril ?' 'snow, skiing, photography, pioneers, enthusiasts, heritage, st elmo, secv machinery, ryder family, bogong high plains, rope tow -

Kiewa Valley Historical Society

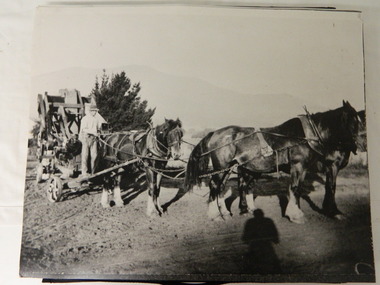

Kiewa Valley Historical SocietyPhotos - Horse team working on farm x3

Horses were coupled together to form a team to pull farm machinery to work on farms. Later, petrol and kerosene equipment was used and then diesel. The Kiewa Valley consisted of farming families before the Kiewa Hydro Electric Scheme was constructed in the late 1940's at the upper end of the valley. Three large black & white photos of a horse team pulling farm equipment. 1. Mouldboard plough 2. header 3. thresher or chaff cutter. 1.& 2. are working on the farm 3. is pulling the machinery to a nearby farm. No labelsfarm equipment. horse teams. farming. crops. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMilking Cups - Dairy

This milking equipment was used in the early days of milking using machines. The dairy industry is and has been one of the major industries of the Kiewa Valley. This equipment was used on local farmers, P & R. Creamer's dairy farm.Set of early mechanical milking cups. 4 cups - 2 each side of 2 hollow metal (steel) rods which are attached to hollow rubber tubes that lead towards the main milking machine. The metal cups have black ends at the opening where they are attached to the cow. The outlet from the cups is via 2 metal tubes that lead into the rods that in turn lead to the tubes.At opening at end of cups: "Utility" possibly more but too difficult to read. milking machinery; dairy; kiewa valley; creamer family; -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Ledger, Ledger and Correspondence (Swinton), 1930s

.1 This is a ledger which was originally printed for the recording of agricultural and pastoral sales but has been used by the Warrnambool firm of Swintons Pty Ltd. to record sales of farm products and machinery from 1934 to 1945. .2 These are 13 items of correspondence, receipts, insurance documents, agreements etc. associated with the Warrnambool business firm of Swintons Pty Ltd. These were contained within the ledger referred to above. William and Ann Swinton migrated to Australia in 1854 and William Swinton worked as a builder and carpenter for a decade, erecting many buildings in the Warrnambool area, including the Wangoom Presbyterian Church. In 1865 he opened a shop in Timor Street, Warrnambool selling groceries, glassware and china. In 1888 the business was known as William Swinton and Sons. Branch stores were opened in Wangoom, Cudgee, Nullawarre, West Warrnambool and South Warrnambool. When William died his son Robert became the first managing director of Swintons Pty Ltd. In 1934 the business split in two with George Swinton and Sons selling furnishings, clothing and glassware and Swintons Pty Ltd selling produce, hardware and seeds. Today the Swinton family still operates a furniture and bedding store in Timor Street. This ledger and the accompanying paper material are of considerable importance as they are associated with the Swinton businesses in Warrnambool. The ledger contains lists of customers of the Swinton business in the 1930s and 40s and provides names, addresses and the cost of the product sold. This is very useful to researchers. The current Swinton business in Timor Street is the oldest family business in Warrnambool and, with the Swinton name associated with businesses in Timor Street for 152 years, is among the oldest family businesses in Australia..1 This is a hard cover ledger. It is beige-coloured with red leather edging on the corners and a red and gold label on the front cover. The pages are held in the folder with metal studs. The pages are white with red and blue printed lines and red leather tabs numbering 1 to 9. The entries are handwritten in blue and black ink. The ledger cover is slightly scuffed. .2 These are 13 items of correspondence from the 1930s and 40s. There is both handwritten and printed material. ‘The Perpetual Income Tax Recorder. No 5. Agricultural and Pastoral’. swinton family warrnambool, history of warrnambool -

Eltham District Historical Society Inc

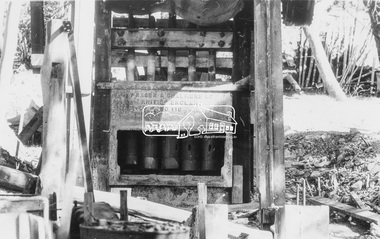

Eltham District Historical Society IncPhotograph, Fraser & Chalmers LD. Erith England No 110 Stamp Mill for processing gold ore, possibly used at Diamond Creek Gold mine

Black and white copy of photo printed on glossy photographic paper 30.5 x 40.5 cm (12 x 16 inch); image size approx. 18.5 x 28 cmengland, erith, fraser and chalmers, gold mining, machinery, stamp mill -

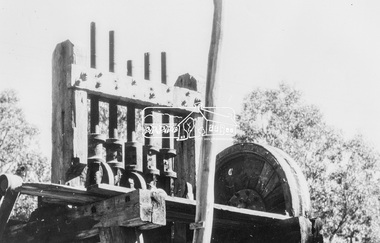

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Fraser & Chalmers LD. Erith England No 110 Stamp Mill for processing gold ore, possibly used at Diamond Creek Gold mine

Black and white copy of photo printed on glossy photographic paper 30.5 x 40.5 cm (12 x 16 inch); image size approx. 18.5 x 28 cmengland, erith, fraser and chalmers, gold mining, machinery, stamp mill -

Federation University Historical Collection

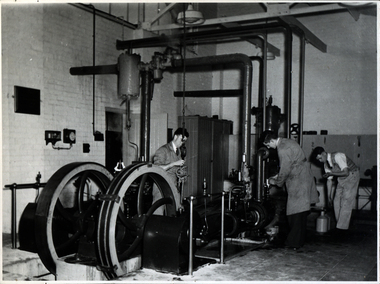

Federation University Historical CollectionPhotograph - Black and white photograph, Ballarat School of Mines Model Steam Engine

The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.Black and white photograph of the Davey Paxman Experimental Steam Engine. On the brake is returned serviceman Norman WIlliam Ludbrook (Diploma Electrical Engineering, 1952). Far right is Roy E. Mawby (Diploma Electrical Engineering, 1950)steam engine, model steam engine, davey paxman, electrical engineering, laboratory, scientific instrument, norman ludbrook, norman william ludbrook, roay mawby, roy e. mawby -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBolt Cutter, 1878

Cyrus Chambers was a self-described mechanic who started out winding bobbins in his father's woollen mill and went on to invent machines that changed their industries. Cyrus Chambers came from Quaker parents the ninth of thirteen siblings, he once said a year before his death. “I believe I have succeeded because, first, I was industrious; second, because I made a study of the subject that was before me.” At age 7, Chambers went to work in his father’s mill. His job was to monitor bobbins—wooden spindles around which thread was wound and to remove and replace them as they became full. "There was no child labour law at that time," he later recalled. Chambers loved machinery and always regarded himself as a mechanic rather than an inventor. At age 16, Chambers was sent to learn dentistry with an older brother, (Edwin) who was already in the field and willing to take him on as an apprentice. Chambers was talented at working with small parts. He used his brother's dental instruments to build a miniature high-pressure steam engine of silver. It ran at 3,000 revolutions per minute and weighed less than a half-ounce. At that time it was the smallest engine that had ever been constructed. The engine was displayed at the 1876 Centennial and is now in a permanent collection at the Franklin Institute USA. Chambers major invention was the paper folding machine and came from reading that school teachers made less than the young girls who were employed to fold book pages as they came off the press. He told friends that his first efforts were to make the machine that would fold newspapers after demonstrating his device he met with Horace Greeley of the New York Tribune who advised Chambers would never invent the machine that would be able to fold his newspaper or books. In less than a year Chambers had built a full-size machine capable of folding large newspapers and books and was installed at J B Lippincott & Co folding pages for the "Comly Speller" this machine ran successfully for twenty-five years until the printing works burnt down. Chambers then went into partnership with a brother and they established the firm "Chambers, Brother & Co" at a plant in Philadelphia. It was also observed in 1910 and a fact that there was not a periodical or newspaper printed or recently published book that had not gone through one of Chambers inventions. Chambers went on to produce many mechanical inventions and improvements to existing tools and machinery most notable was his invention for the machine that would make clay bricks. This machine made forty bricks per hour and by the end of Chambers life after many improvements, it could make more than four hundred. Although there were a large number of bold cutters made of this patent at Cyrus Chamber’s foundry in Philadelphia, the item is associated with a notable American inventor of the nineteenth century. This particular patent for a bolt and rivet cutter won Chambers the prestigious Elliott Cresson Medal. This cutter is just one of the many inventions and mechanical improvements that Cyrus Chambers made during his lifetime, contributing to the ongoing development of mechanical improvements that were occurring in American industry of the time and therefore a notable addition to the Flagstaff collection.Cast iron bolt cutter with removable tempered steel cutter. Chambers New No. 2.Raised embossed lettering on cast body of cutter "New No 2" on one side, "Chambers Bros & Co" on the other sideflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cyrus chambers, bolt cutter, paper folding machine, brick making machine, elliot cresson, elliot cresson medal, franklin institute, gold medal, rivet cutter -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Smoothing Plane, Heinrich Boker, Mid 19th to late 19th Century

... be used to remove marks left by woodworking machinery. When used... machinery. When used effectively alongside other bench planes ...A smoothing plane is typically used after the work piece has been flattened and trued by the other bench planes, such as the jack, fore, and joiner planes. Smoothing planes can also be used to remove marks left by woodworking machinery. When used effectively alongside other bench planes, the smoothing plane should only need a handful of passes removing shavings as fine as 0.002 inches (0.051 mm) or less. The work piece is then ready to be finished, or can be further refined with a card scraper or sandpaper. The smoothing plane is usually held with both hands, and used in a similar manner to the other bench planes. Though designed for smoothing, a smoothing plane can be used as an 'all-round' bench tool and for rougher work depending on how it is set up. Being smaller than other bench planes, the smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more manoeuvrable. It has also been claimed that the coffin design exposes more end grain, enabling the plane to better adjust to changes in humidity. Henry Boker Maker: Heinrich "Henry" Böker of Reimschied-Solingen, Germany and his family was making tools in the 17th century. In 1829 Hermann and Robert Böker added sabres to the company's offerings, in 1837 they emigrated to New York City and established a firm to import German cutlery. H. Boker sabres would be eventually supplied to some American soldiers during the Civil War. Heinrich Boker in 1869 , a relative of Hermann and Robert, established a cutlery firm in Solingen, a centre of industry and cutting tool manufacturing in Germany. The company became a leader in the manufacture of razors, scissors and eating utensils. As early as 1900 the majority of tools produced by Boker were distributed in the U.S. market by the New York branch of the family, and pocket knives became the company's most important product line. During WWII the Solingen factory was destroyed and all the equipment and inventory was lost. After the war the factory was rebuilt and the company resumed operations, but in the early '60s the company was sold to the scissors manufacturer Wiss & Sons, and in the early 70s Wiss sold out to Cooper Industries. At some point Heinrich Boker adopted the Americanised version of his name, Henry Boker and was used as a brand name for the company's products. A vintage smoothing plane of the coffin pattern made by Henry Boker the item is a rare and significant example of vintage woodworking tools used in the manufacture of wooden items.Smoothing Plane Coffin design. Blade marked Henry Bokerflagstaff hill, warrnambool, maritime-museum, shipwreck-coast, smoothing plane, heinrich boker, carpenters tool, cabinet makers tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing Plane, Mid to Late 19th Century

... be used to remove marks left by woodworking machinery. When used... machinery. When used effectively alongside other bench planes ...A smoothing plane is typically used after the work piece has been flattened and trued by the other bench planes, such as the jack, fore, and joiner planes. Smoothing planes can also be used to remove marks left by woodworking machinery. When used effectively alongside other bench planes, the smoothing plane should only need a handful of passes removing shavings as fine as 0.002 inches (0.051 mm) or less. The work piece is then ready to be finished, or can be further refined with a card scraper or sandpaper. The smoothing plane is usually held with both hands, and used in a similar manner to the other bench planes. Though designed for smoothing, a smoothing plane can be used as an 'all-round' bench tool and for rougher work depending on how it is set up. Being smaller than other bench planes, the smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more maneuverable. It has also been claimed that the coffin design exposes more end grain, enabling the plane to better adjust to changes in humidity. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a smooth finish to timber. The tool was used when timber items needed to have a smooth finish these types of planes were used in conjunction with profiled planes that provided a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Smoothing Plane coffin design Maker J Moseley & Son London & 2 1/4"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Technical Reference, Henry J Webb, author, Advanced Agriculture, 1894

The author Henry John Webb (1846-1893) was an English botanist and agriculturalist who worked in scientific ways, described as thorough, to improve many aspects of farming, such as promoting a scientific system for making butter. He became a very successful Principal of Aspatria Agricultural College in northern England, which was set up for the training and education of farmers and farm labourers. He also held world records as a cyclist and tricyclist. This book is part of Flagstaff Hill's Pattison Collection. Longmans, Green & Co. published several of Webb's technical books. The publisher firm, Longmans, Green & Co, was originally founded in 1724 in London by Thomas Longman under the name Longman. In August of that year, he bought the two shops and goods of William Taylor and set up his publishing house there at 39 Paternoster Row. The shops were called Black Swan and Ship, and it is said that the 'ship' sign was the inspiration for Longman's Logo. After many changes of name and management, the firm was incorporated in 1926 as Longmans, Green & Co. Pty Ltd. The firm was acquired by Pearson in 1968 and was known as Pearson Longman or Pearson PLC. Interestingly, the logo in some books, such as “Steam Turbines 2nd edition, published in 1922” has the year “1724” but the logo in books such as “Advanced Agricultur, published in 1894” has the year “1726” in the logo.The book is significant for showing the technical advancement in agriculture att the end of the 19th century and can be used to trace the evolution of agricultural methods and machinery since that time. The book is significant for its connection to the publisher Longmans, Green and Co., of London, a firm that has been established for over two centuries, renowned for publishing encyclopedias, dictionaries, books on English grammar, textbooks, poetry, reference books, novels, magazines and more. The book has additional importance for its connection to the Pattison Collection, which, along with other items at Flagstaff Hill Maritime Village, was originally part of the Warrnambool Mechanics' Institutes’ Collection. The Warrnambool Mechanics’ Institute book collection has historical and social significance for its strong association with the Mechanics Institute movement and its important role in people's intellectual, cultural and social development throughout the latter part of the nineteenth century and the early twentieth century. The collection of books is a rare example of an early lending library and its significance is enhanced by the survival of an original collection of many volumes. The Warrnambool Mechanics' Institute’s publication collection is of both local and state significance.Advanced Agriculture Author: Henry J Webb Publisher: Longmans Green & Co Date: 1894 The green hardcover book includes tables, drawings and diagrams. There are inscriptions on the spine label, front endpaper sticker and stamp. The logo of Longmans, Green & Co. is on the fly page. It is a line drawing of a shield above a leafy wreath border surrounding a sailing ship at sea with a plaque below. Inscriptions are on the shield and plaque. It is part of the Pattison Collection.Label: "PAT 631 WEB" Sticker: "Corangamite Regional Library Service" Stamp: 'Warrnambool Public Museum" Logo shield: "L & Co" [Longman Green & Co.], Logo plaque: "1726" [in this book]flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, pattison collection, ralph eric pattison, warrnambool mechanics’ institute, mechanics’ institute library, warrnambool library, free library, corangamite regional library service, longmans green and co., l & co., 1724, thomas longman, paternoster row london, henry j webb, agriculture, farming, botanist, lecturer, english scholar, aspatria agricultural collage principal, technical farming, zoology, chemistry, physics, geology, 1984 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Codd neck bottle, E. Rowlands, 1921

... was to secure a supply of pure water. Using mineral Waters... with the most up-to-date machinery then in use. By 1870 their business ...The design of the bottle is called a Codd, sometimes referred to as a marble bottle or "Codd's patent bottle". During the mid-to-late 1800s, there were many inventions to keep the fizz in carbonated drinks such as ginger ale, soda water, and fruit drinks. Hiram Codd, an English engineer invented a successful process that he patented as "Codd's patented globe stopper bottle" in 1872. The Codd-neck bottle (commonly called Codd or marble bottle) is manufactured in two parts. The body of the bottle is cast in two sections. At the time of joining the sections, glass marble and rubber seal are inserted into the neck section. The lip is then applied to the top of the bottle. The Codd bottle is filled upside down as the pressure of the gas from the carbonated liquid holds the marble up and out of the way. When the bottle stands upright the gas pushes the marble up against the washer, creating a firm seal to keep the fizz inside. The bottle is opened by pushing the marble down firmly to allow some of the gas to escape. The marble drops down and is caught in a depression formed in the neck. When the bottle is tilted to pour or drink the liquid the marble rests in a dimple. Two Ballarat miners, Evan Rowland and Robert Lewis started manufacturing mineral and aerated waters, bitters, cordials, and liqueurs in 1854, in a tent on the shores of Lake Wendouree Ballarat. Another 13 firms at that time employed manual operations, whereas they introduced Taylor's No. 1 machine that speeded up the process and laid the foundation for their fortune. Evan Rowland was a pioneer in the aerated water trade in Australia. He was born on August 2, 1826, in North Wales. In 1852, during the gold rush, he emigrated to Melbourne, and in 1854 he went to Ballarat and formed a partnership with Robert Lewis, the firm being called ‘‘Rowlands & Lewis’’. Their next step was to secure a supply of pure water. Using mineral Waters that they found via a natural spring at Warrenheip, Victoria. From the outset, the beverages made from this water gained repute and were in great demand. Their business prospered so well that in 1858 they were able to build a factory at the corner of Sturt and Dawson Streets, Ballarat, and to fit with the most up-to-date machinery then in use. By 1870 their business had increased so much and demand had grown to such an extent that Mr. Rowlands erected another factory, covering over an acre of ground at the corner of Dana and Doveton Streets, costing £13,000. The factory was fitted with the most modern equipment of the time to manufacture cordials and aerated water. In 1873 Rowlands established an agency at 116 Collins St, Melbourne, because the demand for the products of the Melbourne factory became so large. The company expanded to Sydney opening a factory at the corner of Burns & Hay Streets Darling Harbour obtaining spring water to supply this plant from Katoomba in the Blue Mountains. The water was brought to Sydney by rail. In the meantime, the Melbourne concern had progressed so rapidly that in 1888 a magnificent factory embodying all the latest ideas and equipment was built in King Street Melbourne. Robert Lewis was a fellow Welshman born in 1816, and he arrived in Port Phillip in 1853 and became a partner in the early day with Evan Rowland but with lesser and shorter involvement in the firm, from which he retired in 1876. Robert Lewis was perhaps better known as Ballarat's first mayor and a Member of the Legislative Assembly. He was a strong supporter of local charities, president/treasurer of the Eisteddfod Committee, a major force in the development of the Ballarat Hospital, and he was the mayor of Ballarat five times, the first in 1863, (having been a counsellor as early as 1859) and for the last time in 1881. Lewis died in 1884 of a stroke in Ballarat. Rowlands continued in the firm and invented and patented an improved soda water bottle. The water used in Rowlands products was filtered four times but his attempts to use local corks failed on quality grounds. He was a stickler for quality, which was so good that many outside Victoria were prepared to pay the 'premium' imposed by inter-colonial customs duty payable at that time. By the 1890s, Rowlands had factories in Ballarat, Melbourne, Sydney, and Newcastle. He died in 1894 but his company continued until well after the Second World War when it was sold to Schweppes.An early manufacturing process producing the first mineral waters in Australia was invented and developed by an early Welsh migrant to Australia. The Evan Rowlands story gives an insight into the early development of manufacturing industries in Australia that allowed their workers and the towns they were situated in to prosper and develop into what they are today. Bottle; clear glass Codd neck bottle with small marble in top. Once contained soda water or soft drink. Manufactured in 1921 by E. Rowlands of Ballarat, Melbourne, Katoomba and Sydney. The bottle is 'recyclable' - the message on the base says that it remains the property of E. Rowlands Pty Ltd."E. ROWLANDS BALLARAT MELBOURNE KATOOMBA AND SYDNEY". Imprinted into bas "1921" "THIS BOTTLE REMAINS THE PROPERTY OF E. ROWLANDS PTY LTD"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bottle, codd bottle, hiram codd, glass marble bottle, e. rowlands bottle manufacturer, soda bottle australia, early recyclable bottle, codd's patent bottle, marble bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink bottle, MABIE TODD & Co. (Aust.) Pty. Ltd, Second half of 19th Century or first half of the 20th Century

A Brief History Of Mabie Todd Ltd The company originated in America from the beginnings during the 1860s when a Mr. Todd and a Mr. Mabie began making pencil cases and pen holders in New York. Later they were joined by the Bard Brothers who made Gold nibs and by 1873 the company of Mabie Todd and Bard were established in New York. By 1878 the first patent was filed for the design and manufacture of a fountain pen, achieved under the design leadership of one William Washington Stewart. The first Swan fountain pen followed just 6 years later in 1884 with an over-under feed with ink delivery assisted by a twisted silver wire. This same year an office had been established in the UK with a showroom in Cheapside, London. The UK was being supplied with a steadily increasing supply of pens from New York and by 1905 new, larger showrooms were established in High Holborn. By this time the Swan pen had become synonymous with fountain pens at large. In 1906 the name of Bard was dropped in the US and the UK company subsequently adopted the title Mabie Todd & Co. New York. In 1907 British production began, using imported nibs from New York and whilst the company in the UK flourished, the business in the US started to diminish under stiff competition from new manufacturers.. By 1915 manufacturing was doing well in England from a factory in Weston Street, London and the New York company agreed to sell the rights to all European and Colonial business to Mabie Todd & Company Ltd of England. From then onwards, the development of the range mostly followed, rather than led the interests of the markets they were supplying. Even during the First World War the business continued to flourish. with factories in both London and Liverpool. At the end of 1919 a new expansion plan saw the establishment of a new Headquarters in Oxford Street, London. Throughout this period, some components were continuing to be imported from America, but gradually these diminished and during the 20s and 30s manufacturing facilities were expanded and by the end of the 1930s Mabie Todd were in full production, manufacturing pens in its London factory, gold nibs in Birmingham and ink in Liverpool. Another new headquarters grew out of this period of abundance and market domination. when in 1936 they moved into Sunderland House in Mayfair, London, a highly prized mansion building. Disaster struck early in the Second World War. Its prestigious Sunderland House headquarters was destroyed during the blitz, followed by destruction of its main factory in Harlesden, North London. Some machinery was saved and able to be used at another factory premises in the City, but like many other 'non essential' manufacturing, the main production was centred on wartime components such as rocket fuses and ammunition. After The War, in 1945 they moved out of their City premises to Park Royal and eventually in 1946 proper fountain pen production was resumed. In 1948 the company decided to go public. But at the time they had no plans to enter into the market for the now growing interest in ballpoint pens, the result was the beginning of their slide into obscurity and subsequent demise. They became Biro Swan in 1952 following a large share purchase by Biro Pens. Even though at this time they had just launched their new high profile Calligraph range to join the competition for the new market associated with a craze for italic writing, fountain pen manufacture under the new company was to suffer a lack of real support. The restyled ranges of 1956 failed to ignite market interest and with diminishing quality, the end of the Mabie Todd story was inevitable. After 80 years of Swan pens, the book was closed.This bottle of ink would have been supplied to schools. After a child was deemed old enough to progress from just using slate and board, he/she would have been supplied with a pen shaft made of wood and with a very basic metal nib. The ink bottle would be used to fill up the individual inkwells. This operation would have been conducted by the teacher him/herself, or by an older pupil under the close eye of the teacher.Ink bottle clear glass with 'Swan Ink' paper label. Has rusted screw on top & black ink inside.Label has 'Mabel Todd' manufacturer's logo at top,; 'Swan Ink' name clearly shown; 'Made in England' printed clearly; and 'Mable Todd & Co Ltd, London & Liverpool' printed at base of label.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ink, bottle, mabie todd ltd -

Seaworks Maritime Museum

Seaworks Maritime MuseumShipbuilders model, R W Miller

Original ship - 11,741 gross tons. 589' x 70' x 30' (179.5 x 21.34 x 9.14m). Oil tanker built by Eriksberg Motor Vessels at Gottenburg, Sweden in 1951 for Hjalmar Bjorge of Norway as the Storheim. Purchased November 1964 and renamed R W MILLER. Had a crew of 39 seamen, including the officers. 1973 sold to Independent Shipping Company Pty Ltd of Singapore. Renamed Cherry Victor. Scrapped 1979. Robert Miller traded under the name R W Miller and Company from early 1912. One of Miller's first contracts was to pick up overburden and spoil from the sinking of the Balmain Colliery shaft and dump it at sea. Miller saw the opportunity to sell this material and he ended up getting a sixpence a ton from a local council and other contractors for use as road bases and building foundations. This close association with coal led to Robert W Miller on 15th January 1913 being given the contract for coal distribution from Sydney Harbour Colliery (Balmain mine). So began a long association with coal. Miller built a fleet of lighters that were used to transport blue metal, sand and coal around Sydney Harbour. This introduction into coal transport opened a prospect for him to enter the larger coal shipping transport. During 1917 Miller purchased a vessel, the taking over 1985 by Howard Smith Industries Pty Ltd, Melbourne. Build date 1951-1979. Ship builders model of the tanker R W Miller in a glass case. The body is painted in colours of maroon, green and grey, the deck with detailed fittings and superstructure, an Australian merchant flag flying from the stern, within a mahogany framed glazed display casePlaque at foot of model: M/T R.W. MIILRT/ BUILT GOT. 1951/ OWNERS R.W. MILLER & CO. PTY. LTD/ LENGTH OVERALL 559.04"/ LENGTH BETWEEN P.P 526.06"/ EXTREME BREADTH 70.00"/ MOULDED DEPTH 39.03"/ DEADWEIGHT TONNAGE 18,500/ MACHINERY B & W TYPE A I.H.P 7, 600" on model: "R.W Miller" painted in black -

Seaworks Maritime Museum

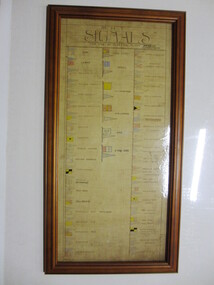

Seaworks Maritime MuseumList of Pennants

Has recently been framed and laminatedFramed list of pennants signifying ships and signals hand drawn with coloured pencil in 1915 on paper. Later corrections made in 1933 in black penM. H. T./SIGNALS/FOR THE USE OF FLOATING PLANT OCT 1915 1915/Corrected Feb 1933/ HUME/ J. A. BOYD/WILLIAM PITT/WILLIAM STRONG/CHAS DUCKETT/EDWARD NORTHCOTE/ H C PIGGOTT/BATMAN/FAWKNER/FRANCIS DUNCAN/WILLIAM ANDREWS/COMMISSIONER/PENGUIN (at Geelong)/ RED BIRD/GELLIBRAND/MOTOR BOAT NO 2 TATEGAMI/MOTOR BOAT NO 3/MOTOR BOAT NO 4/ENGINEER/HARBOR MASTER/LADY STANLEY/HOVELL/ W. S. MOUNTAIN/W.M. COWPER/G.F.H./D. YORK SYME/ SUPER of DREDGING/ASSISTANT/HARBOR MASTER/SUPER of MACHINERY/ELECTRICIAN/INSP of DREDGING/INSP of MACHINERY/INSPECTOR WHARVES/(F WILLIAMS)/INSPECTOR DOCKING/& SHIPWRIGHTS/DIVERS WANTED/ACCIDENT SEND/MEDICAL ASSISTANCE/WAITING FOR/EMPTY BARGES/DREDGING STOPPED/WEATHER UNFAVOURABLE/TAKE AWAY/EMPTY BARGES/TUG WANTED/DERRICK PUNT/WANTED/TAKE DERRICK/PUNT AWAY/TAKE AWAY/COAL BARGE/BUCKETS FOULED/OBSTRUCTION SEND/DERRICK PUNT &/DIVERS/ DREDGING STOPPED/REPAIRING/DREDGING RESUMED/ B. Harris 16.8.15/ Drawing No 3415melbourne harbour trust (mba) -

Greensborough Historical Society

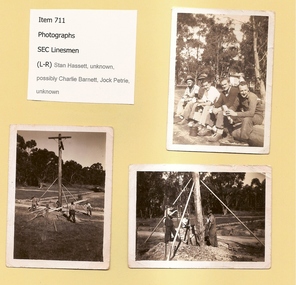

Greensborough Historical SocietyPhotographs, Linesmen 1950s, 1950c

... power poles before heavy machinery was used. sec linesmen power ...Photograph 1 shows 5 men (linesmen) on lunch break. (L-R) Stan Hassett, unknown, possibly Charlie Barnett, Jock Petrie, unknown. Photos 2 and 3 show the crew erecting power poles.These photos are significant as they show some Greensborough men at work, and the method of erecting power poles before heavy machinery was used.3 black and white photographs. Subject is electrical linesmen and the erection of electricity poles.sec, linesmen, power poles, state electricity commission, stan hassett, charlie barnett, jock petrie -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Watches, pocket watch, c1900

A pocket watch is a watch that is made to be carried in a pocket, as opposed to a wristwatch, which is strapped to the wrist.. They were the most common type of watch from their development in the 16th century until wristwatches became popular after World War I The first stem-wind and stem-set pocket watches were sold during the Great Exhibition in London in 1851 and the first owners of these new kinds of watches were Queen Victoria and Prince Albert. Stem-wind, stem-set movements are the most common type of watch-movement found in both vintage and modern pocket watches.In 1857 the American Watch Company in Waltham, Massachusetts introduced the Waltham Model 57, the first to use interchangeable parts which cut the cost of manufacture and repair. Most Model 57 pocket watches were in a coin silver. Watch manufacture was becoming streamlined; the Japy family of Schaffhausen, Switzerland, led the way in this, and soon afterwards the newborn American watch industry developed much new machinery, so that by 1865 the American Watch Company (afterwards known as Waltham) could turn out more than 50,000 reliable watches each year.This silver plated pocket watch with an open glass face has black roman numerals on a white dial , gold hour hands and a blue second hand. The winding stem is at 12 o’clock and has a metal ring for attachment to a chain. Back: of case ; a shield inside 2 circleswatches, brighton, cheltenham, moorabbin, bentleigh, early settlers, pioneers -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Opening of Andrew Ross Museum, Kangaroo Ground, 20 Nov 1994, 20/11/1994

In 1992 Shire of Eltham Historical Society member and Kangaroo Ground resident, Bruce Ness became aware that the old school teacher residence at Kangaroo Ground School was no longer being used. Over the years Bruce had been storing a growing collection of the Society's artifacts and objects including various machinery and farm tools. He proposed that this might present an opportunity to set up a museum with the Society's objects. It was proposed that a board be appointed containing representatives of the Society, the School Council, Shire of Eltham and "Friends of the Andrew Ross Museum." As a consequence, most of the Society's objects were transferred to the museum and the Society became more focused on documents, maps and photographs, etc.Roll of 35mm colour negative film, 3 stripsFuji 100shire of eltham historical society -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Opening of Andrew Ross Museum, Kangaroo Ground, 20 Nov 1994, 20/11/1994

In 1992 Shire of Eltham Historical Society member and Kangaroo Ground resident, Bruce Ness became aware that the old school teacher residence at Kangaroo Ground School was no longer being used. Over the years Bruce had been storing a growing collection of the Society's artifacts and objects including various machinery and farm tools. He proposed that this might present an opportunity to set up a museum with the Society's objects. It was proposed that a board be appointed containing representatives of the Society, the School Council, Shire of Eltham and "Friends of the Andrew Ross Museum." As a consequence, most of the Society's objects were transferred to the museum and the Society became more focused on documents, maps and photographs, etc.Roll of 35mm colour negative film, 3 stripsFuji 100shire of eltham historical society -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Opening of Andrew Ross Museum, Kangaroo Ground, 20 Nov 1994, 20/11/1994

In 1992 Shire of Eltham Historical Society member and Kangaroo Ground resident, Bruce Ness became aware that the old school teacher residence at Kangaroo Ground School was no longer being used. Over the years Bruce had been storing a growing collection of the Society's artifacts and objects including various machinery and farm tools. He proposed that this might present an opportunity to set up a museum with the Society's objects. It was proposed that a board be appointed containing representatives of the Society, the School Council, Shire of Eltham and "Friends of the Andrew Ross Museum." As a consequence, most of the Society's objects were transferred to the museum and the Society became more focused on documents, maps and photographs, etc.Roll of 35mm colour negative film, 3 stripsFuji 100shire of eltham historical society