Showing 2184 items

matching machinery.

-

Tarnagulla History Archive

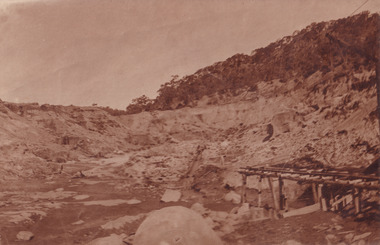

Tarnagulla History ArchivePhotograph - Photograph: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Monochrome photograph depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'J. Caldwell and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Tarnagulla History Archive

Tarnagulla History ArchivePostcard - Photographic postcard: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Photographic postcard, front image depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'A Merry Christmas and a Happy New Year, E. Bool' and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Federation University Historical Collection

Federation University Historical CollectionDocument, Contract for the Madame Bent Gold Mining Company, 1886, 1886

Handwritten on foolscap paper, with red seal on last page.1) The Subcontractor is also to remove the following [ ? ] from Mr Webb's paddock ... to the Madame Bent Mine Grenville ... .2) Specification for the taking doan, removal and reerection 2 Engines 2 boilers pumping gear, Bob, Poppett heads and Capstone etc, for teh Mdame Bent G.M.Cy Grenville. The company will provide ... .3) Morey's Coys yard, together with holding down bolts, and the following ... .4) to the extent of Bed ... Carpentry Work - To carefully take down the poppet heads and co... and erect the same on the claim complete ... .5) Engine Framing as shown for the winding engines and pumping engines. Properly fitted to get ... .6) The boilers to be fed in front. The contractor to cut and drill all necessary holes in the boilers and pipes - to fire blow ... The contractor to make good any damage or breakage or loss to machinery or any part hereof that may occur to it during the removal of the reerection of same. The loss or damage, if any, not being made good by the contractor, or in the event of the works not being proceeded with to the satisfaction of the Company;s Engineer, The company's Engineer hereby ... .7) of the whole of the works, and in default thereof the COntractor shall forfeit the sum of two pounds ... Signed James Malcolm Witness L. Menz The Common seal of the company was affixed this thirteenth day of December:/86 by its manager James Burrell in the presence of [illegible] managers Seal - Madame Bent Gold Mining Company Durham Lead Buninyongmadame bent gold mining company, richard squire, james malcolm, james burrell -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Copper Sheet, circa 1878

In 1984 the Commonwealth Government made available to Flagstaff Hill a collection of lead ingots and copper sheets recovered from the wreck-site of the LOCH ARD. They were presented to the Warrnambool City Council by the Hon. Tom Uren MHR, Minister for Territories and Local Government: “The Commonwealth recognises that shipwrecks like the LOCH ARD are our national heritage with important educational, recreational and tourist applications” (The Standard, Tuesday 8 May 1984). The LOCH ARD was wrecked in 1878. Unsuccessful salvage operations were then undertaken with the 90 ton paddle steamer NAPIER. In sudden bad weather this vessel too was sunk. The precise position of the LOCH ARD in the exposed and dangerous waters off Mutton Bird Island became lost to memory. The underwater location of the LOCH ARD was rediscovered in 1967 by a Warrnambool skindiver, Stan McPhee. In the two years following his find, the vessel was systematically pillaged by unauthorised salvagers. This led to the State and Federal Governments’ intervention in 1969. A roundup and seizure of recovered lead ingots and copper sheets was conducted by Commonwealth and Victorian Police. Offenders were charged and convicted. The “repossessed loot of the Tassie Boys” was placed into secure storage (Jack Loney, 1978, Wrecks & Reputations). The LOCH ARD manifest of cargo lists “Pig lead 50 tons, 994 pig & 37 rolls” and “Copper 33 plates, 53 bolts”. While the lead ingots have been subsequently described as “ballast”, the copper sheets are unlikely to have been associated with the ship’s normal complement in that way. Similar product lines in the cargo manifest are “Bar and rod iron 102 tons”, “Plate iron 3 tons” and “Zinc 12 tons”. These raw materials were used by colonial artisans such as blacksmiths and metal smelters to fashion, and repair, agricultural implements and industrial machinery. Copper was valued for its non-corrosive properties and its malleability, or ease of working. Both these qualities were useful, for example, in laying underground gas pipes that supplied lighting to residences, businesses and streetscapes in the mid-nineteenth century. As the nineteenth century progressed, the metal was also increasingly valued for its conductivity, with copper wiring linking colonial communities to each other, and the wider world, via the Telegraph system. The average weight of the copper sheets is 216 kilograms, calculated by "volume 0.1936m³ X Cu density 8930kgs/m³".The shipwreck of the Loch Ard is of significance for Victoria and is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulation of artefacts from this notable Victorian shipwreck. The collections object is to also give us a snapshot into history so we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. The collections historically significance is that it is associated unfortunately with the worst and best-known shipwreck in Victoria's history. Large heavy sheets or panels of copper metal raised from the wreck of the LOCH ARD. The 10 sheets are of roughly similar dimensions and rectangular shape. They bear signs of prolonged submersion in seawater, with various degrees of limestone accretion, adhered marine growth, and green oxidisation. Three of the sheets are severely buckled, demonstrating the force of underwater explosives used in their salvage. One sheet appears cut or severed in a diagonal line downwards from its top left hand corner. One sheet has a 10cm X 10cm square cut out of its top right hand corner. All sheets are in sturdy, stable condition. No maker’s marks are visible.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, sailing ship, copper sheet, manutacturing materials, metal imports, muntz -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Smoothing Plane, Heinrich Boker, Mid 19th to late 19th Century

A smoothing plane is typically used after the work piece has been flattened and trued by the other bench planes, such as the jack, fore, and joiner planes. Smoothing planes can also be used to remove marks left by woodworking machinery. When used effectively alongside other bench planes, the smoothing plane should only need a handful of passes removing shavings as fine as 0.002 inches (0.051 mm) or less. The work piece is then ready to be finished, or can be further refined with a card scraper or sandpaper. The smoothing plane is usually held with both hands, and used in a similar manner to the other bench planes. Though designed for smoothing, a smoothing plane can be used as an 'all-round' bench tool and for rougher work depending on how it is set up. Being smaller than other bench planes, the smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more manoeuvrable. It has also been claimed that the coffin design exposes more end grain, enabling the plane to better adjust to changes in humidity. Henry Boker Maker: Heinrich "Henry" Böker of Reimschied-Solingen, Germany and his family was making tools in the 17th century. In 1829 Hermann and Robert Böker added sabres to the company's offerings, in 1837 they emigrated to New York City and established a firm to import German cutlery. H. Boker sabres would be eventually supplied to some American soldiers during the Civil War. Heinrich Boker in 1869 , a relative of Hermann and Robert, established a cutlery firm in Solingen, a centre of industry and cutting tool manufacturing in Germany. The company became a leader in the manufacture of razors, scissors and eating utensils. As early as 1900 the majority of tools produced by Boker were distributed in the U.S. market by the New York branch of the family, and pocket knives became the company's most important product line. During WWII the Solingen factory was destroyed and all the equipment and inventory was lost. After the war the factory was rebuilt and the company resumed operations, but in the early '60s the company was sold to the scissors manufacturer Wiss & Sons, and in the early 70s Wiss sold out to Cooper Industries. At some point Heinrich Boker adopted the Americanised version of his name, Henry Boker and was used as a brand name for the company's products. A vintage smoothing plane of the coffin pattern made by Henry Boker the item is a rare and significant example of vintage woodworking tools used in the manufacture of wooden items.Smoothing Plane Coffin design. Blade marked Henry Bokerflagstaff hill, warrnambool, maritime-museum, shipwreck-coast, smoothing plane, heinrich boker, carpenters tool, cabinet makers tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Smoothing Plane, Heinrich Boker, late 19th to early 20th Century

A smoothing plane is typically used after the work piece has been flattened and trued by the other bench planes, such as the jack, fore, and joiner planes. Smoothing planes can also be used to remove marks left by woodworking machinery. When used effectively alongside other bench planes, the smoothing plane should only need a handful of passes removing shavings as fine as 0.002 inches (0.051 mm) or less. The work piece is then ready to be finished, or can be further refined with a card scraper or sandpaper. The smoothing plane is usually held with both hands, and used in a similar manner to the other bench planes. Though designed for smoothing, a smoothing plane can be used as an 'all-round' bench tool and for rougher work depending on how it is set up. Being smaller than other bench planes, the smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more manoeuvrable. It has also been claimed that the coffin design exposes more end grain, enabling the plane to better adjust to changes in humidity. Henry Boker Maker: Heinrich "Henry" Böker of Reimschied-Solingen, Germany and his family was making tools in the 17th century. In 1829 Hermann and Robert Böker added sabres to the company's offerings, in 1837 they emigrated to New York City and established a firm to import German cutlery. H. Boker sabres would be eventually supplied to some American soldiers during the Civil War. Heinrich Boker in 1869 , a relative of Hermann and Robert, established a cutlery firm in Solingen, a centre of industry and cutting tool manufacturing in Germany. The company became a leader in the manufacture of razors, scissors and eating utensils. As early as 1900 the majority of tools produced by Boker were distributed in the U.S. market by the New York branch of the family, and pocket knives became the company's most important product line. During WWII the Solingen factory was destroyed and all the equipment and inventory was lost. After the war the factory was rebuilt and the company resumed operations, but in the early '60s the company was sold to the scissors manufacturer Wiss & Sons, and in the early 70s Wiss sold out to Cooper Industries. At some point Heinrich Boker adopted the Americanised version of his name, Henry Boker and was used as a brand name for the company's products. A vintage smoothing plane of the Bismark pattern made by Henry Boker the this plane is now regarded as a collectors item and is an example of vintage woodworking tools used in the manufacture of wooden products.Smoothing Plane Bismark design. Blade marked Henry Bokerflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, smoothing plane, heinrich boker, carpenters tool, cabinet makers tool -

Bendigo Historical Society Inc.

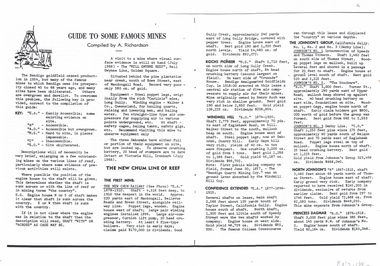

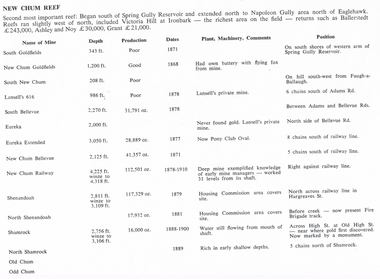

Bendigo Historical Society Inc.Document - LONG GULLY HISTORY GROUP COLLECTION: GUIDE TO SOME FAMOUS MINES

Three pages titled Guide to Some Famous Mines. Compiled by A Richardson. Each mine is listed as on the reef it is situated on. Reefs are The New Chum Line of Reef and the Garden Gully Line of Reefs, and the Devonshire Group. Mentioned is the mine's location, depth of shaft, poppet legs, machinery, location of engine house, gold yield, dividends and owners of mine. The mines are: The New Chum Line of Reef. The New Chum Railway, Kochs Pioneer, Windmill Hill, Confidence Extended, Johnson's No 1, Johnson's No2, Johnson's No 3, North Johnson's, Princess Dagmar, Golden Age, Johnson's Reef Extended, Golden Pyke, Constellation, Great Northern, Virginia, Specimen Hill United, New Argus, Clarence United, North Argus, South New Moon, New Chum Hill, The New Chum and Victoria, Catherine Reef United. Garden Gully Line of Reefs. The Great Southern, Ulster United, Londonderry, South Garden, The Sea Amalgamated, Garden Gully United, Victory and Pandora, Unity Mine, Carlisle United, Cornish United, Eureka Extended, South Belle Vue United, Shenandoah, Shamrock, New Chum Consolidated, New Chum United, Lansell's 222, Rae's Open Cut, Great Central Victoria, Victoria Consols, The Ironbark, Hercules and Energetic, Pearl, The Devonshire Group. North of Staley,The Duke of Edinburgh, New St Mungo, Duchess Tribute, South Devonshire, Duchess of Edinburgh, Princess Alexandra, West United Devonshire, Hopewell, Phoenix. Yhe Mungo Mines. Unicorn, South St Mungo, Lady Barkly, The St Mungo, Sadowa, Eastwood. Snobs Hill Group. The Ellenborough, The Belmont and Saxby, York and Durham, The Acadia, William's United, The Victoria Hill - Ironbark, The North Old Chum, Lansell's Big 180, Ballerstadt's Open-Cut and The Victoria Quartz.bendigo, history, long gully history group, the long gully history group - guide to some famous mines, a richardson, the new chum railway, kochs pioneer, windmill hill, confidence extended, johnson's no 1, johnson's no2, johnson's no 3, north johnson's, princess dagmar, golden age, johnson's reef extended, golden pyke, constellation, great northern, virginia, specimen hill united, new argus, clarence united, north argus, south new moon, new chum hill, the new chum and victoria, catherine reef united, the great southern, ulster united, londonderry, south garden, the sea amalgamated, garden gully united, victory and pandora, unity mine, carlisle united, cornish united, eureka extended, south belle vue united, shenandoah, shamrock, new chum consolidated, new chum united, lansell's 222, rae's open cut, great central victoria, victoria consols, the ironbark, hercules and energetic, pearl, the duke of edinburgh, new st mungo, duchess tribute, south devonshire, duchess of edinburgh, princess alexandra, west united devonshire, hopewell, phoenix, unicorn, south st mungo, lady barkly, the st mungo, sadowa, eastwood, the ellenborough, the belmont and saxby, york and durham, the acadia, william's united, the victoria hill - ironbark, the north old chum, lansell's big 180, ballerstadt's open-cut, the victoria quartz -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph - Photograph - Reproduction, Unknown

This image is a reproduction of an 1899 original depicting the 'Williams Good Luck Mine' on the Mopoke Reef (also called 'Morepork Gully') in the Dingle Ranges, approximately three miles from Beechworth. The foreground of the image is littered with piles of smashed rock and detritus, known as ‘mullock’, beside a reinforced mine shaft, a vertical access passageway allowing miners to enter the mine and haul ore out using lifting technology such as a poppet heads, whims or windlasses. A group of miners and a dog appear close to an open-sided miner’s hut. Following the discovery of gold at Beechworth in 1852, rushes quickly followed at surrounding creeks and gullies in the district. In the late nineteenth and early twentieth centuries, small syndicates of miners continued to work old or abandoned quartz reefs, often persisting without the assistance of heavy machinery to remove the large amounts of rock, in order to obtain yields at ever greater depths. The group of miners in this photograph are Mr. Roger Williams and Sons, who revived operations at the ‘Old Good Luck’ mine on the Mopoke Reef in the Dingle Range near Beechworth around 1892, working the site for more than two decades. An emigrant from Cornwall with experience in the tin mining industry, 19 year old Roger Williams senior sailed to New Zealand in 1840, then to Australia where he spent time in the Bendigo Gold Fields before settling in Beechworth in the early 1860s. Mr Williams senior worked on various mining activities in the district, including the Rocky Mountain Tunnel project. Conversant with the character of gold-bearing reefs in the area, the syndicate dug an eight hundred foot tunnel, digging down as far down as two hundred feet with little capital save their labour, to connect and provide better working access to the mass of reefs and veins in the vicinity. Progress was hampered by poor air quality charged with fumes from dynamite and large quantities of rock had to be crushed to obtain payable yields. The Victorian Goldfields are filled with ruins and remnants of the area's rich mining history, ranging from small alluvial diggings to the remains of huge mining companies. Site names often changed several times throughout the nineteenth and twentieth centuries. Some sites were abandoned and forgotten, others were worked continuously over many decades. The names of mines were often repeated at different locations throughout the Victorian Goldfields. For example, there is a Mopoke Gully heritage mine near Fryers Creek, Victoria. 'Mopoke' is a common onomatopoeic name for Morepork and Australian Boobook owls. This image has historical, social and research significance for patterns of emigration during of the Victorian Gold Rush, and the historical, social and environmental impacts of mining at Beechworth at the turn of the nineteenth and twentieth centuries. As gold became scarce and government support and large company investment waned, poor hard-working miners laboured intensively to make a living through periods of high unemployment. This image can be compared and studied alongside other historical mining photographs and objects in the Burke Museum Collection. It has potential to improve our understanding of miners working conditions and the shifting character of mining in the Beechworth district. Black and white rectangular reproduction photograph printed on matte photographic paper.Obverse: Williams Good Luck Mine Beechworth / Roger! / Reverse: 6858 / burke museum, beechworth museum, beechworth, gold fields, gold rush, victorian gold rush, gold ming history, colonial australia, australian gold rushes, mining technology, beechworth historic district, indigo gold trail, migration, indigo shire, good luck gold mine, victorian goldfields, mining syndicates, gold fever, quartz-mining, small-scale mining, old good luck mine, mopoke gully, quartz reefs beechworth -

The Beechworth Burke Museum

The Beechworth Burke MuseumBook - 1875 Catalogue, William Detmold, RULES / CATALOGUE OF BOOKS / INVENTORY OF PICTURES, DRAWINGS, / MAPS, CHARTS, FURNITURE, SPECIMENS / OF THE / PUBLIC LIBRARY AND BURKE MUSEUM / BEECHWORTH, 1875

This large, leather bound journal was made for the Public Library and Burke Museum in Beechworth by book manufacturer, William Detmold in 1875. It was commissioned by the President of the Library and Burke Museum committee, Dr Antoine Mousse, for the purpose of cataloguing all the items in the collection. The cataloguer was the curator at that time, William Morton, whose hand-writing appears in the journal today. When William Morton first started recording in this journal in 1875, there were already a number of existing items in the institution. The Public Library and Burke Museum in Beechworth had actually been operating since the 1850s; first as a Young Men’s Association in 1856, then as Beechworth Athenaeum in 1858, then as the Beechworth Public Library in 1860. Then in 1861 when news of the death of Beechworth’s former police superintended, Robert O’Hara Burke, reached the town, it was agreed that the Public Library would also become a museum to tribute his legacy, renaming it as the ‘Public Library and Robert O’Hara Burke Memorial Museum, Beechworth’. Many of the items from the early institutions would have been used to form the nucleus of this new organisation. Plus, the additional items that were either collected or donated to develop it into a museum. The catalogue is extensive. There are exactly 461 pages of recorded items, each page detailing the various collections the museum acquired in the late 19th century. Collections recorded in this catalogue include a large collection of geological specimens, that were given to the museum in 1868 by the Geological Survey Department of Victoria. A large collection of taxidermy mounts, that were given to the museum as skins by the Museum of Australia in 1865. An extensive collection of Aboriginal artefacts that were purchased from amateur anthropologist R. E . Johns in 1868. As well as artworks, charts, photographs, machinery, maps etc., all of which have been held in the museum since. This catalogue also details the governance and management of the organisation. There were originally 30 rules that governed the actions for the management committee and, while anyone could read in the free library, only subscribers could borrow two books and one periodical. At first, subscriptions rates were 7/6 a quarter. This was later changed to £1 per annum, paid quarterly in advance. This was a considerable amount; 7/6 per quarter meant that the annual fee was £1.10. This was equivalent to about £650.00 or about $1,182.00AUD today, while the reduced subscription fee of £1 a year was the equivalent to £450.00 or about $818.00AUD today. Membership of the athenaeum would have been the reserve of the town's notable citizens. The vale of the catalogue lies not only in its historical connect with the establishment of the Athenaeum and the current museum, but also in its record of the names and positions of all members of the institution's committees of management from 1875-1876. This is a unique object that contains important records for a notable country town. Large brown leather bound book made in 1875 for the Beechworth library and museum by William Detmond. Inside is a comprehensive and detailed itemised listing of the paintings, drawings, charts, photographs, specimens and books that entered the institution from 1850 -1882. non-fictionCover: RULES / CATALOGUE OF BOOKS / INVENTORY OF PICTURES, DRAWINGS, / MAPS, CHARTS, FURNITURE, SPECIMENS / OF THE / PUBLIC LIBRARY AND BURKE MUSEUM / BEECHWORTHburke museum, beechworth, catalogue, museum catalogue, 1875, william morton, william detmold, exposition universelle, ferdinand von mueller, public library, collection, book, leather bound, restored, digitised, robert o'hara burke, hand-written -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, 1907-8

The photo from 1907-8 is a sepia print, depicting a small valley with building at base. There are flumes visible above areas of water, trees on hills and a few small cottages on the hillside. Cock's Pioneer Gold & Tin Sluicing Co NZ No 2 Site. The photo was taken of Matthews Gully looking west. Sluicing was undertaken in the area from 1900 to 1942 with some short breaks between these periods. The image depicts a location mined by Cocks Pioneer Gold and Tin Sluicing Company (as recorded on the annotation on the card mount) The Cocks Pioneer Gold and Tin Mines N.L was one of El Dorado's two largest open cut sluicing mines of the 20th Century. The other was named the Cocks El Dorado Gold Dredging Company. The Cocks Pioneer Mines operated from 1901 until 1941 and found a total of 117,378 ounces of Gold and 1,673 tones of tin concentrates over these years. The Cocks company was formed in 1898 and operated until 1941. Open cut sluicing involved the use of high-powered hoses which used the centrifugal sand pump system (known as hydraulic sluicing) which broke down the soil which was then processed for gold and other precious metals. From 1914 , four years after this image was captured, the company reformed to Cocks Pioneer Gold and Tin Mines NL (previously it was known as Cocks Pioneer Sluicing Co) and undertook large scale sluicing operations until 1929 and then 1934-1941. El Dorado is located on Reedy Creek and is surrounded by forested country to the north and east. It is 20 km east of Wangaratta in Victoria's regional north-east. John Cock was the son of a Cornish minor who arrived in El Dorado in 1858. Cock founded his gold and tin mining company which ran successfully for many years in the El Dorado region. It was an open cut sluicing company because of the abandonment of underground mining after this was deemed too dangerous. In 1935 Cock's El Dorado Company commissioned the floating dredge which is still visible in El Dorado today. The dredge was built by the Thompson engineering works, Castlemaine, and weighed over 2,000 tones and today has a place on the Victorian Registers of historic buildings. Interestingly, the name El Dorado does not derive from the gold in the region, but from the Barambogie pastoral run completed by William Baker in 1840-1841. Gold was discovered in El Dorado 1854 but the gold was too deep for individual prospectors to find, it required the use of heavy machinery.The search for gold is ingrained into the history of Victoria and therefore, images like this one which portray an open cut sluicing site can reveal important information for society and technology for the date when the photograph was taken. This image is of important historical significance for its ability to convey information about sluicing and the methods used to find gold in 1910. It also shows a location where sluicing was undertook which provides insight into the impact of sluicing on the environment at a time when it was done. This image is important for current research into the history of El Dorado, a small regional location near Wangaratta in Victoria's North East. Therefore, this image has the capacity to be beneficial for research into society and the motivations of those living and working in this region during this period and therefore, has social significance. The Beechworth Burke Museum has additional images relating to gold sluicing and El Dorado which can be analysed and studied alongside images like this one.Sepia coloured rectangle photograph printed on gloss photographic paper Reverse: 1997. 2613/ A02613/ No2 site/ Matthews Gully/ Cocks Pioneer G&T. ?? Co NZ/ No2 Site looking West/ 1907-8/ (7)sluicing, hydraulic sluicing, 1907, 1908, mining, cock's pioneer gold & tin sluicing co nz, nz, site no 2, matthews gully, west, valley, building, cottages, hillside, trees, water, gold and tin mine -

Puffing Billy Railway

Puffing Billy RailwayGreenbat Battery Loco, Greenwood & Batley ltd

Greenbat Battery Loco Built by Greenwood & Batley Ltd Builders No. 420363/2 This Greenbat Battery Loco has been loaned to the Museum by the Walhalla Goldfields Railway, who had acquired it in 2013 along with a large quantity of narrow gauge trollies and light rail from Orica’s now closed munitions factory in Melbourne’s western suburbs. The trolley on display was one of two in use from the 1970s. Orica - Deer Park Munitions factory Orica Deer Park in Melbourne’s west has been used since circa 1875 for various forms of manufacturing and storage of chemicals. Although the site is bounded by Ballarat Road, Station Street, Tilburn Road and the Western Ring Road, the current entry point for industrial operations is situated at Gate 6 off Tilburn Road. Operations include: • a specialty chemicals facility producing products for mining services operations • quarry services • other chemical manufacture activities. The Deer Park factory complex is of historical significance as the location of the first plant for the manufacture of high explosives in Australia and has been, for its entire history, the most important, if not only, commercial manufacturer of high explosives in Australia. It commenced operation under the importer Jones Scott and Co, and then the Australian Lithofracteur Company (Krebs Patent), a rival to Nobel's dynamite patent. The factory was producing nitro-glycerine based explosives in Australia only a couple of years after Nobel's Ardeer factory began operating in Scotland. The explosives factories complex is of historical significance for the association with the Australian Lithofracteur Company, Australian Explosives and Chemicals, the Nobel company and later ICIANZ, which grew to become one of the largest explosives, chemical and plastics manufacturers in Australia. It was the pioneer of the industry and retained its dominance through monopolistic practices, taking over most of its competitors in the Australasian region. Substantial parts of the pre-Second World War layout of the site remain which, with a number of significant buildings dating back to the 1920s and '30s, indicate past and present processes of manufacturing, the necessary safety measures required and the integrated nature of the explosives and chemical industry. The narrow gauge tramway, which ran through the explosives section, was a rare survivor of nineteenth century materials-handling methods into the 21st Century. Greenwood & Batley were a large engineering manufacturer with a wide range of products, including armaments, electrical engineering, and printing and milling machinery. They also produced a range of battery-electric railway locomotives under the brand name Greenbat. The works was in Armley, Leeds, UK. Greenbat was the trade name for the railway locomotives built by Greenwood & Batley. The company specialised in electric locomotives, particularly battery-powered types for use in mines and other hazardous environments. Historic - Industrial Narrow Gauge Railway - Battery Locomotive - Orica - Deer Park Munitions factory - Deep park, Victoria, Australia Battery Locomotive - made of iron puffing billy, greenbat battery loco, battery locomotive, industrial narrow gauge railway, orica - deer park munitions factory -

Federation University Historical Collection

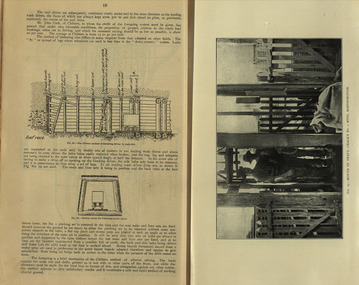

Federation University Historical CollectionBook, Stanley B. Hunter, Memoirs of the Geological Survey of Victoria No 7., The Deep Leads of Victoria, 1909

Pink paper covered book by Stanley Hunter, Engineer in Charge of Boring Operations. Contents include tunnelling, deep sinking, the Chiltern Method, the Ballarat Method, Stawell, Ararat, Moyston, Raglan, Wimmera, Landsborough, Avoca, Ballarat West Leads, Berry-Moolort-Loddon Lead System, Clunes, Creswick, Bullarook Affluent, Corinella, Daylesford-Castlemaine Tributary, Majorca-Carisbrook tributary, Huntly, Coliban, Campaspe, Rutherglen., Smythesdale, Durham Lead, Tanjil, Evolution of Mining Machinery, size of claims, Definition of a Deep Lead, Discovery of Gold in Victoria, Geographical Position of Deep Leads, Water in Deep Leads, Methods of Deep Lead Mining, Cost of Deep Lead Mining, Stawell, Ararat, Moyston, Raglan, Wimmera, Landsborough, Avoca, Ballarat West, Berry, Springs Hill, Loddon Valley, Charlotte Plains, , Timor, Burn Creek, Huntly, Colinan, Goulburn, Ovens Valley, Chiltern, Indigo, Morrison's Lead, Plans include: geological Map of Stawell, ararat, Raglan and Landsborough; Kempson's Freehold Mine, Stawell; Geological Map of Beaufort, Avoca, Maryborough, Ballarat west, Berry-Moolort, Loddon, Creswick, Marong, &c; Cardigan Propriety Gold Mine; Working Miners United Gold Mine, Homebush; Hepburn Deep Lead Plan; Madame Berry West Mine; West Berry Consols Mine; Spring Hill and Central Leads; Berry Consols Extended Mine; Loddon Valley Goldfields; Chalk's No 3 Mine; Charlotte Plains Considated Mine; Duke United Mine; Geological Map of Bendigo, Huntley, Campaspe, Malmsbury, Kyneton, trentham, &c; Geological Map of Chiltern, Rutherglan, Eldorado, Beechworth, &c; Chiltern Valley Gold Mine; Wallace Chiltern Valley Consols Mine; great Southern and Chiltern Valley United Mine; great Northern extended Consols; Prentice and Southern deep Leads; Glenfine South Gold Mine; Geological map of Pitfield, Rokewood, Mt Mercer, Ballark, Meredith, &c.; McEvoy Mine; Dargo . . . . . . . . . . . . . . . . . . . . . . . mining, deep leads, squire, tools, gold panning, gold cradle, cradling, puddling, tubbing, mining shaft, shaft sinking, whip, horse whip, whim, horse whim, chalk's no. 1 mine, maryborough, mining cage, shaft, mining trucks, maryborough, washdirt, puddler, tunnelling, deep sinking, chiltern method of working, ballarat method of working, sampling washdirt. gravels, balmoral, mt william, stawell, moyston, great western, ararat, raglan, wimmera valley, landsborough, cardigan, haddon, beaufort, waterloo, avoca, lamplough, caralulup, ballarat west, ballarat, smythesdale, glenfine, illabarook, durham lead, morrison's lead, bullengarook, berry-moolort-loddon system, clunes, creswick, spring hill, bullarook, castlemaine - daylesford, majorca, carisbrook, timor, burnt creek tributary, tarnagulla, marong, rheola, inglewood, huntly, coliban, campaspe, goulburn lead system, ovens valley system, mitta mitta, kiewa valley, tarago, tanjil, moondarra, bogong, dargo high plains -

Federation University Historical Collection

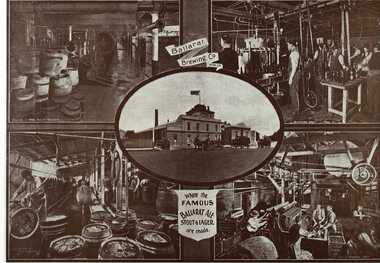

Federation University Historical CollectionBook, Ballarat Illustrated : Under the Seals of the City & Town Councils, c1920

This book was a donation to Federation University Australia's Professor David Battersby from Vice-Chancellor Professor Scott Bowman of Central Queensland University.Soft cover. Front cover with some red. 80 pages. Back cover Plan of Ballarat Map. Photographic plates. Brief history of Ballarat and the topics photographed. . Ballarat City Municipal Chambers . The Ballarat Banking Company Limited . Art Gallery Ballarat . The Ballarat Trustees, Executors & Agency Company Limited . John MacLeod & Coy Pty Ltd . The Ballaarat Gas Coy . Ballarat's Homes . J. J. Goller & Co. . Ballarat East Views . Star Office . The Ballarat Courier . Morshead's . M. B. John Ballarat - The largest Inland Brass Foundry in Australia . Rowlands Koomah Spa . Huttons the Jewellers . Botanical Gardens Ballarat . Millers the Clothiers . Jas Smith Agricultural Machinery . Views of Lakes Learmonth & Burrumbeet . Coles & Pullum Stock & Station Agents . Harry Davies & Co. . Views about the City . Benoit's Sun Foundry . Ballarat College (for Boys) . Wm Paterson's . Lydiard Street Views . Eureka Terra-cotta & Tile Co. of Australia Limited . Churches of Ballarat . The Ballarat Woollen & Worsted Co. Ltd Sunnyside Mills . Red Shop Tea Rooms . Tyler's - Bridge Street, Ballarat . Allchin Bros Ballarat . Loreto Abbey Mary's Mount Ballarat . Brinds - Dunnstown . Ballarat Brewing Co. . Turnbridge's Arcade . Zoological Gardens Ballarat . A. Cant Plumber & Gasfitter . Interiors of some Ballarat Churches . Hugh Jones & B . W. F. Coltman . Views in Eureka Reserve . Loveland & Haslem, Moter Engineers . Public Institutions Ballarat . G. Warner & Co. Prop. Ltd . The Electric Supply Company of Victoria Limited . Ballarat East Views . Longhurst's Specialities . P. C. Thornton Proprietor Sturt St Ballarat . Cowley's Eureka Ironworks Pty Ltd . W. Owen Sports Depot & Tobacconist . Clarendon Ladies' College . Crocker's . Evening Echo Office . London Bank Chambers . Proprietors of Business . Broadbent Bros & Co. Gifted by Vice-Chancellor Professor Scott Bowman Central Queensland University, 2014.ballarat, school of mines, evening echo, john scullin -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - MINING IN BENDIGO COLLECTION: MINING PHOTOGRAPHS

BHS CollectionFolded paper with copies of photos of mines and various mining buildings. On the front is a view from New Chum Hill, looking south in 1890's. Pictured is the Lazarus Crushing Plant and boiler house, Lansell's '222'. Amd the new Chum Mines in the background. On the inside at the top is the New Chum Railway, Golden Square. Pictured is the mine and its buildings, two chimneys, two large wood stacks and other mines in the background. On the left, a man is standing on the side of the railway line beside the mine. The next picture is the United Hustlers and Redan Mine, west of Comet Hill State School, Sandhurst Road. It shows the mine and its buildings, chimney, ore bins, mullock heap and tramway. The middle picture is the Central Deborah, Violet Street, near Bendigo Creek, Golden Square. It shows the poppet legs, buildings and some machinery behind the large building. The large building has eight ventilators in the roof. The buildings are made of corrugated iron. The bottom left picture is the Deborah Mine, Quarry Hill. The picture shows the poppet legs on the hilltop, the buildings beside it, a square chimney behind the poppet legs and some vegetation and a peppercorn tree in the foreground. The far building also has ventilators in the roof. The picture on the right is underground at 1000 feet level in the Deborah Mine. Pictured are three men with a rock drill. On the back, at the top is a picture of a First Motion Winding Engine at Deborah - later at Central Deborah. The picture shows the engine and driver. The middle picture is the South New Moon Mine, Eaglehawk - leading mine in State in 1903. The picture shows the poppet legs, buildings, chimney and a high tramway. In the foreground is a dam. The bottom picture is Victoria Hill looking south to New Chum Hill. In the foreground is Lansell's '180' Mine and Ballerstedt's Open Cut and in the background are the 'New Chum and Victoria', 'Old Chum' and the 'North Old Chum'.photo, mining in bendigo, mining photographs, lazarus crushing plant, lansell's 222, new chum mines, new chum railway, united hustlers and redan mine, comet hill state school, central deborah, deborah mine, first motion winding engine, south new moon mine, lansell's 180, ballerstedt's open cut, new chum and victoria, old chum, north old chum, square chimney -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, 1910 - 1911

This photograph depicts Cock's Pioneer G & T Sluicing site No. 4 in El Dorado. Looking eastwards, the photo captures a wooden and tin building with various mining equipment strewn in the foreground. Underneath the verandah, figures can be seen. These are believed to be a Mr. Hollister (left), Mrs. Breustedt (4th from left), children Min and Chris Breustedt, and Kate Timmons holding a girl's hand. The Cocks Pioneer Gold and Tin Mines N.L was one of El Dorado's two largest open-cut sluicing mines of the 20th Century. The other was named the Cocks El Dorado Gold Dredging Company. The Cocks Pioneer Mines operated from 1901 until 1941 and found a total of 117,378 ounces of Gold and 1,673 tones of tin concentrates over these years. The Cocks company was formed in 1898 and operated until 1941. Open cut sluicing involved the use of high-powered hoses which used the centrifugal sand pump system (known as hydraulic sluicing) which broke down the soil which was then processed for gold and other precious metals. From 1914, four years after this image was captured, the company reformed to Cocks Pioneer Gold and Tin Mines NL (previously it was known as Cocks Pioneer Sluicing Co) and undertook large-scale sluicing operations until 1929 and then 1934-1941. The Cocks Pioneer was an extremely successful mining company during the 20th century. In the Annual Report of the Secretary for Mines for the year 1915, the Cocks Pioneer was the largest producer of gold and tin collecting 5,535 ozs. of gold and £7,500 of tin. Twenty years later in 1935, Cocks Pioneer was still one of the most profitable mines in Victoria, ranking as the second-highest dividend paying mine. The company produced a total of 3,650 kg of gold. El Dorado is located on Reedy Creek and is surrounded by forested country to the north and east. It is 20 km east of Wangaratta in Victoria's regional northeast. John Cock was the son of a Cornish miner who arrived in El Dorado in 1858. Cock founded his gold and tin mining company which ran successfully for many years in the El Dorado region. It was an open-cut sluicing company because of the abandonment of underground mining after this was deemed too dangerous. In 1935 Cock's El Dorado Company commissioned the floating dredge which is still visible in El Dorado today. The dredge was built by the Thompson engineering works, Castlemaine, and weighed over 2,000 tones and today has a place on the Victorian Registers of historic buildings. Interestingly, the name El Dorado does not derive from the gold in the region, but from the Barambogie pastoral run completed by William Baker in 1840-1841. Gold was discovered in El Dorado in 1854 but the gold was too deep for individual prospectors to find, it required the use of heavy machinery.The search for gold is ingrained into the history of Victoria and therefore, images like this one which portray an open cut sluicing site can reveal important information for society and technology for the date when the photograph was taken. This image is of important historical significance for its ability to convey information about sluicing and the methods used to find gold in 1910. It also shows a location where sluicing was undertook which provides insight into the impact of sluicing on the environment at a time when it was done. This image is important for current research into the history of El Dorado, a small regional location near Wangaratta in Victoria's North East. Therefore, this image has the capacity to be beneficial for research into society and the motivations of those living and working in this region during this period and therefore, has social significance. The Beechworth Burke Museum has additional images relating to gold sluicing and El Dorado which can be analysed and studied alongside images like this one.A black and white copy of a sepia coloured rectangular photograph printed on matte photographic paper mounted on boardObverse: COCKS PIONEER G + T SL CO, N.L. / 1910 - 11 / NO 4 SITE LOOKING EAST / 4 Reverse: 1997.2508 / AUG 29 1909cocks pioneer gold and tin sluicing company, el dorado, mining, sluicing, hydraulic mining, hollister, breustedt, timmons, gold, tin, gold rush, victoria -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, 1910

This photograph dating to 1910 depicts an open cut sluicing site located in El Dorado captured looking east up the open cut from the number 3 Barge site. Sluicing was undertaken in the area from 1900 to 1942 with some short breaks between these periods. The image depicts a location mined by Cocks Pioneer Gold and Tin Sluicing Company (as recorded on the annotation on the card mount). It portrays open cut rocks with a crevice in the center of the image where the sluicing was being undertaken. There is a small timber structure on the right of the image which could be an entrance to a mine or supports made of wood to prevent a cave in at the open cut site and above the cut rock there is bush. The timber structure has rail tracks on top of the bridge which could suggest the identification of this structure as a mine entrance. The rail tracks were used for little carts which hauled soil from the mine. The Cocks Pioneer Gold and Tin Mines N.L was one of El Dorado's two largest open cut sluicing mines of the 20th Century. The other was named the Cocks El Dorado Gold Dredging Company. The Cocks Pioneer Mines operated from 1901 until 1941 and found a total of 117,378 ounces of Gold and 1,673 tones of tin concentrates over these years. The Cocks company was formed in 1898 and operated until 1941. Open cut sluicing involved the use of high-powered hoses which used the centrifugal sand pump system (known as hydraulic sluicing) which broke down the soil which was then processed for gold and other precious metals. From 1914 , four years after this image was captured, the company reformed to Cocks Pioneer Gold and Tin Mines NL (previously it was known as Cocks Pioneer Sluicing Co) and undertook large scale sluicing operations until 1929 and then 1934-1941. El Dorado is located on Reedy Creek and is surrounded by forested country to the north and east. It is 20 km east of Wangaratta in Victoria's regional north-east. John Cock was the son of a Cornish minor who arrived in El Dorado in 1858. Cock founded his gold and tin mining company which ran successfully for many years in the El Dorado region. It was an open cut sluicing company because of the abandonment of underground mining after this was deemed too dangerous. In 1935 Cock's El Dorado Company commissioned the floating dredge which is still visible in El Dorado today. The dredge was built by the Thompson engineering works, Castlemaine, and weighed over 2,000 tones and today has a place on the Victorian Registers of historic buildings. Interestingly, the name El Dorado does not derive from the gold in the region, but from the Barambogie pastoral run completed by William Baker in 1840-1841. Gold was discovered in El Dorado 1854 but the gold was too deep for individual prospectors to find, it required the use of heavy machinery.The search for gold is ingrained into the history of Victoria and therefore, images like this one which portray an open cut sluicing site can reveal important information for society and technology for the date when the photograph was taken. This image is of important historical significance for its ability to convey information about sluicing and the methods used to find gold in 1910. It also shows a location where sluicing was undertook which provides insight into the impact of sluicing on the environment at a time when it was done. This image is important for current research into the history of El Dorado, a small regional location near Wangaratta in Victoria's North East. Therefore, this image has the capacity to be beneficial for research into society and the motivations of those living and working in this region during this period and therefore, has social significance. The Beechworth Burke Museum has additional images relating to gold sluicing and El Dorado which can be analysed and studied alongside images like this one.Sepia coloured rectangular photograph printed on gloss photographic paper mounted on board.Obverse: COCKS PIONEER Q + T SL CO, N.L. / 1910 / LOOKING EAST UP OPEN CUT / FROM NO3 BARGE SITE / Reverse: 1997 . 2611 / A02611el dorado, north east gold, sluicing, gold sluicing, hydraulic sluicing, 1910, gold and tin mine, open cut mining, mining, gold mining, north-east victoria, beechworth, burke museum -

Eltham District Historical Society Inc

Eltham District Historical Society IncFilm - Video (VHS), Phil Burke et al, Shire of Eltham Grants Commsission Submission (Series 69, Item 7), 1993

Shire of Eltham Archives: Series 69, Item 7 Opens with aerial views of the Shire, 85% of the shire covered by the Green wedge principal. Discusses the obligations required of the Shire to maintain the Green Wedge. The Shire covers over 27,000 hectares with a population in excess of 45,000 residents, more than 70% living in the southern 10% of the Shire in suburbs of Eltham, Montmorency, Lower Plenty and Research. 85% of the Shire in the more sparsely populated northern area which is covered by the Green Wedge. Council is committed to providing a parity of services to all residents such as garbage collection and maintenance of roads. Views of rubbish collection trucks in Montmorency. It is emphasised that the cost of these services in highly populated areas is relatively low whereas in the sparsely populated Green Wedge areas, considerable. There are hundreds of kilometres of roads throughout the Shire, many unmade and maintenance is high to check overhanging trees and erosion especially on the steep hills is expensive and disproportionate to servicing the population in the dense urban areas. Shows views of hilly gravel roads and graders at work maintaining them. Shows scenes of assessing planning applications in these rural areas which takes significantly more time as well as other services provided such as Meals on Wheels, building permits, Ranger services. Provision of recreational facilities in hilly areas requires the acquisition of expensive river flats (views of cricket ground surrounded by hills) and where not possible, costly earthmoving required. Also, views highlighting extensive tracks of natural habitat home to significant bird, animal and plant life. Shire emphasises its commitment highlighted by the Eltham Copper Butterfly which the Shire maintains small pockets of bushland to ensure its survival at significant expense (views of Pauline Toner Copper Butterfly Reserve.) Short interview with Pat Vaughan, Environmental Officer for the Shire discussing the Eltham Copper Butterfly who also mentions many other species in the Shire of high significance from bats to mammals to plants as well as the importance of the Green Wedge to Melbourne – the lungs of Melbourne - and ensuring the protection of very important habitat which requires a great deal of planning and management to look after. Views of Wingrove Park to emphasise this maintenance by machinery in some areas is too damaging and introduced species, etc must be removed by hand. Balancing the services and facilities expected by the community with the needs of the environment requires careful planning demands requires careful planning and the principals of the Green Wedge require constant attention in the face of growing need for housing. Director of Planning & Environment, Richard Allen advises there are approximately 1,300 planning permits and development applications each year ranging from simple subdivision, boundary realignments to further complicated non-urban developments for agricultural pursuits and the level of expertise required from architectural and engineering to land degradation, flora and fauna. Video finishes with aerial views and parklands, streetscapes and rural areas. VHS Video cassette Converted to MP4 file format 00:07:39; 89MBshire of eltham, video recording, shire of eltham archives, eltham shire council, eltham, building permits, cricket ground, development applications, eltham copper butterfly, garbage collection, graders, green wedge, lower plenty, meals on wheels, montmorency, pat vaughan, pauline toner reserve, planning applications, planning permits, ranger services, recreational facilities, research, richard allen, roads, rural areas, wingrove park, victoria grants commission -

Federation University Historical Collection

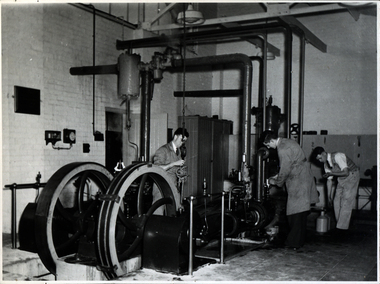

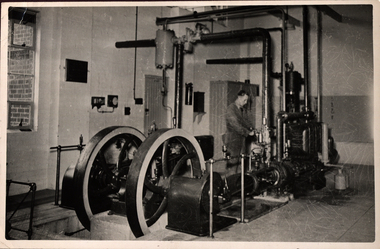

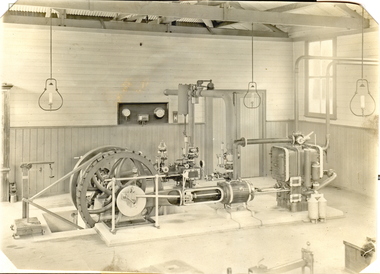

Federation University Historical CollectionPhotograph - Black and white photograph, Ballarat School of Mines Model Steam Engine

The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.Black and white photograph of the Davey Paxman Experimental Steam Engine. On the brake is returned serviceman Norman WIlliam Ludbrook (Diploma Electrical Engineering, 1952). Far right is Roy E. Mawby (Diploma Electrical Engineering, 1950)steam engine, model steam engine, davey paxman, electrical engineering, laboratory, scientific instrument, norman ludbrook, norman william ludbrook, roay mawby, roy e. mawby -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph - Black and white, Ballarat School of Mines Model Steam Engine

The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.Black and white photograph of the Davey Paxman Experimental Steam Engine installed at the Ballarat School of MInes. steam engine, model steam engine, davey paxman, thomas bath, experimental steam engine -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Ballarat School of Mines Davey Paxman Experimental Steam Engine, c1902

The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only. Black and white photograph of an experimental steam engine which was produced for the Ballarat School of Mines. It was designed for experimental purposes, such as testing of efficiency, etc. The laboratory which housed the steam engine was lit with gas lighting. davey paxman experimental steam engine, model steam engine, davey paxman, steam, thomas bath, thermodynamics -

Federation University Historical Collection

Federation University Historical CollectionLetter - Correspondence, Letter on Bendigo United Pyrites Company Letterhead, 1898, 1898

"The United Pyrites Company's Works are situated about three quarters of a mile from Spargo Brothers, and are on the northern side of the Marong road, in Pinch-gut Gully. Two processes are followed at these works, viz., the amalgamating process and the treatment by means of chlorine gas. The latter is called the Newbery-Vautin system, and the mode pursued is that laid down by Mr. Cosmo Newbery and Mr Vautin, whose names have been given to the process. Mr. Edwards manages these works. Three reverbatory furnaces are used to roast the pyrites, which is weighed in the truck before being put into the furnaces. At this weighbridge a sample of each lot is kept, and if the yield is not equal to expectation, the works are carefully gone over to see where the fault occurs. Care is taken at the furnace to regulate the heat, otherwise the pyrites might slag instead of roasting evenly right through. An immense revolving furnace (made of boiler iron) was used at these works. It was found to be suitable for treating blanket sand, but was not a success for roasting coarse pyrites. The process of amalgamating by means of Chilian mills is the same in these works as at the Western Works, but the United Works are on a larger scale, and eleven mills are utilised. It is the chlorine gas process which is most interesting here. The gas is made from sulphuric acid, black oxide of manganese, and common salt, and the gas is introduced into huge vats, where it works its way through a filter of pieces of quartz and then through the bed of roasted pyrites lying above. The action of the gas transforms the gold into chloride of gold. This is easily dissolved in water, and in that form is drawn off into huge delf jars, where the use of sulphate of iron precipitates the gold to the bottom. A small battery—eight head of stamps in two boxes—is in use here to crush small consignments of stone sent for trial. Test crushings come from all the Australasian colonies, and even from India. The jars used are manufactured at Epsom, and some of the salt used is also of home manufacture, from the Salt Lakes on the Northern plains. Mr. Edwards took us over a new building in course of erection, and in which the chlorine gas is to be generated in the midst of the pyrites— a still further advancement in the new process. There is some very good machinery in this new building, and the tailings from the ordinary pyrites works will also be treated by this chlorine gas system, which has been found to work well at Mount Morgan, in Queensland. The purest of gold is obtained by this process, the gold passing in solution into a charcoal filter, from which it emerges in the shape of metallic gold. We saw some nice cakes of retorted gold at the works. One of 26oz. was from some New Zealand pyrites (2½ tons), and assayed over 23 carats. There were also cakes of Avoca gold, of silver, and of the tremulous amalgam." (The Argus, 4 February 1887)Two handwritten letters to the Ballarat School of Mines on Bendigo United Pyrites Company Letterhead.bendigo united pyrites company, pyrites, ballarat school of mines, j.j. deeble, joel deeble, joel james deeble, a.m. dean, fred j. martell, martell, s.h. cowan, letterhead -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Rudder Pintles and Gudgeons, Alexander Hall and Son, ca. 1855