Showing 1332 items

matching the clerk

-

8th/13th Victorian Mounted Rifles Regimental Collection

8th/13th Victorian Mounted Rifles Regimental CollectionTrophy, McClure Cup

Battery Quartermaster Sergeant Harold Bauerle served with the Albury Battery in the 1920s and 1030s. Shortly following Federation the military unit in Albury was redesignated No 4 New South Wales Battery Australian Field Artillery (AFA). It was under the command of Major John Wilkinson, an Albury solicitor and comprised about 100 citizen soldiers, 4 guns and about 40 horses. Training centred on the Albury Drill Hall located in Victoria Street. A reorganisation in 1912 resulted in the Battery being named No 17 Battery AFA. When war broke out in 1914 the Battery then under the command of Major Joseph Shellshear, and Albury doctor, offered its services as a trained artillery battery to the Australian Imperial Force (AIF). The Battery cooled its heels and continued to train till July 1915 when a second division was raised in the AIF and trained artillery was needed. When the call came 150 officers and men of the 17th Battery went into the AIF, many to the 13th Battery with Major Shellshear in command and others to other AIF batteries of the 4th and 5th Artillery Brigades. The 13th Battery was adopted immediately by the townsfolk of Albury as the Albury Battery. The Battery served in France and Belgium and was involved in all the major battles fought by the Australians perhaps most notably at Noreuil where the Battery found itself surrounded but continued to fight till eventually the enemy was driven back. Following the war members of the Battery nominated this battle as their most significant achievement and consequently a newly developed recreational reserve on the Murray River foreshore was named Noreuil Park. In 1919 the Battery resumed training as part of the Citizen Military Forces or Militia. Changes of title were frequent, first 27th Battery, then 60th Battery and finally 40th Battery AFA. Battery commanders included Captain Leslie Colquhoun, an Albury real estate agent, Captain Roy Collings, Albury town clerk and Captain Clifton Mott a newspaper editor. The Depression of the early 1930s almost brought about the closure of the Albury Battery but it survived through the intervention of the mayor, Alderman Alfred Waugh, who made direct representation to the Minister for Defence. When the Second World War erupted in 1939, the Battery was at full strength and a rich source of officers and trained men for the second AIF. Militia training of the few remaining officers and Albury adopted the 2/23rd Infantry Battalion which had been raised at the Showground. Following WWII, CMF soldiering recommenced in the form of an armoured regiment, the 8th/13th Victorian Mounted Rifles. After nearly a half a century of service in war and peace the Albury Battery has faded and exists now in this collection of objects and images. This trophy is representative of community support for a Citizen Military Forces unit drawn from a regional NSW Town in the period between the World Wars.Silver cup with two handles mounted on Bakelite base being the McClure Cup for most efficient NCO in Albury Battery 1935-36 . inscription on side of cup."McClure Cup / for / Most efficient NCO / 1935-36 / won by / BQMS H.C. Bauerle"bauerle h c bqms, albury battery, mcclure cup -

Melton City Libraries

Melton City LibrariesNewspaper, Get the good oil here…, 2001

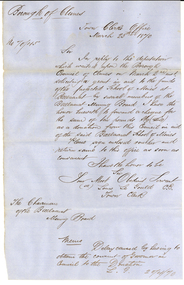

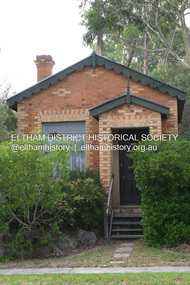

"A court was established in Melton by 1864, when the first recorded case was heard before Mr BA Porter JP, with Mr A Carroll as the Clerk of Courts. John James was convicted of being drunk, for which he was fined five shillings or 24 hours imprisonment. The court was held in the ‘long room’ of the old Melton Hotel, before moving to rented accommodation at the Raglan Hotel, and finally to the Roads Board office. Tenders for construction of the present building were called for by the Public Works Department on 13th February 1892. The architect Samuel Edward Brindley was born in Birmingham, England, in 1842. He was articled to the local architect, J.R. Botham, FRIBA, before emigrating to Victoria where he was employed as an architect in the Education Department from 18 August 1873. With the amalgamation of the architectural branch of the Education Department with the Public Works Department in 1884, Bindley was placed in charge of Victorian government building design for the North-Western District. In 1975, the Melton and District Historical Society became concerned at hearsay that the court house was to be demolished to make way for carparking space. Melton had been declared a ‘satellite city’ and was developing rapidly. A new shopping centre had recently been built at a setback of 60 feet (c.18 metre) from 323-329 High Street, and the court house, together with the adjacent weatherboard police station, had been left standing alone. A new police station was planned, and the weatherboard police station was subsequently demolished. In its nomination of the building for National Trust classification the Society argued that the Court House was ‘the best of two early buildings left in the main street’ (the other being a bluestone hotel) and that its loss would be ‘tragic’. However the nomination was unsuccessful, the National Trust at the time judging that it was of no particular ‘distinction’ or ‘antiquity’. The building continued to be used as a court house at least until 1991 when the Department of Housing and Construction (formerly the PWD) conducted a heritage study of court houses. By this time Federation-era architecture had achieved acceptance within the heritage movement. The building was recognised as being ‘the only surviving example in brick of the Federation Queen Anne style which was used for court houses only twice.’ Twenty years later when it was proposed to modify the eastern façade of the building to accommodate a café, the M&DHS was again concerned. This time the National Trust objected that the proposed extension would be an over-development of the site, and questioned the changes to the interior court room furnishings and fittings. The site never appears to have been nominated to the Victorian Heritage Register. It has since been converted into the Shire of Melton Tourist Information Centre". Opening of the Visitor Centre in Meltoncouncil, local architecture -

Eltham District Historical Society Inc

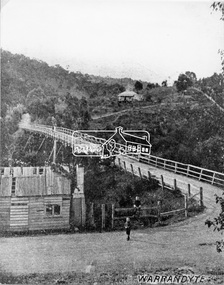

Eltham District Historical Society IncNegative - Photograph, Warrandyte Bridge over River Yarra, c.1910

View of the 1875 timber trestle bridge over the Yarra River reproduced from a newsprint image. Also known as Anderson's Creek (Road) Bridge A contract was accepted for William Elliot to erect a bridge over the Yarra River at Warrandyte on Anderson's Creek Road and other improvements for £1,331.6.2 - Gazette No. 143. Tuesday, November 13th 1860 - http://gazette.slv.vic.gov.au/view.cgi?year=1860&class=general&page_num=2161&state=V&classNum=G143&id=). The bridge was washed away by floods in 1863. It was replaced with a taller timber trestle structure in October 1875, designed and built by C.S. Wingrove, Shire Clerk, Engineer and Surveyor for Eltham Shire Council. A replacement for this bridge was commenced in 1955 to cope with increasing traffic and this structure was widened in 2018 to meet further traffic demands. Argus (Melbourne, Vic. : 1848 - 1957), Thursday 23 September 1875, page 7 ________________________________________ THE WARRANDYTE BRIDGE. The ceremony of formally opening the newly erected bridge over the Yarra at Ander-son's Creek was performed on Monday last, in the presence of the members of the Eltham and Bulleen shire councils whose territories it joins, and a goodly number of the residents of the district. The task was delegated to Mr. Cameron, M.L.A., who, after a few introductory remarks declared the bridge to be opened, and christened it the " Warrandyte Bridge." The party then adjourned to Grant's Hotel, where a cold collation had been prepared. The chair was taken by the president of the Eltham shire (Mr. John Bell) and the vice chair by Mr. Kent, a member of the Bulleen council. Mr Robert Williamson proposed "Success to the bridge," coupling with it the name of Mr. Cameron, to whose exertions was in the main to be attributed the erection of that structure which was an ornament to the district and would prove of great service to both sides of the river. Mr. Cameron, in responding, alluded to the great difficulties, mainly of a pecuniary nature, that had been encountered in carrying out the project, and which had only been got over by their united efforts and by the liberal spirit in which the late Commissioner of Roads had dealt with the case. The healths of the contractor and the engineer were also drunk. The bridge is a trussed timber one, resting on yellow box piles sunk into the solid rock, each pier being weighted with 50 tons of stone. The abutments consist of dry stone walls, 6ft. thick at the base, and tapering to 3ft. on the top, the face of the work having a batter of 1 to 1. The length of the bridge is 308ft., there being four openings in the centre of 66ft. each, and two at the ends of 20ft. each. The width in the clear is 9½ft., and the height from the bed of the river about 33ft. The approaches comprise 1,100 cubic yards of earthwork, and the formation of 48 chains of sideling, the whole cost of the work, which was carried out under the direction of the engineer to the Eltham Shire Council, being £1,413.This photo forms part of a collection of photographs gathered by the Shire of Eltham for their centenary project book,"Pioneers and Painters: 100 years of the Shire of Eltham" by Alan Marshall (1971). The collection of over 500 images is held in partnership between Eltham District Historical Society and Yarra Plenty Regional Library (Eltham Library) and is now formally known as the 'The Shire of Eltham Pioneers Photograph Collection.' It is significant in being the first community sourced collection representing the places and people of the Shire's first one hundred years.Digital image 4 x 5 inch B&W Neg B&W Print 12.5 x 9 cmsepp, shire of eltham pioneers photograph collection, warrandyte, bridge -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Photograph - Colour, Sunnyside Mill Bridge over the Yarrowee, Hill Street, Ballarat, 2016, 17/09/2016

"A joint meeting of city and town ratepayers, convened by Messrs Francis Jago and Henry Johns, interested in the formation of a cart bridge in Hill street, over the Yarrowee Creek, was held on Saturday evening, in the Societies Hall, corner of Skipton and South streets, with the view of taking united action in the matter. Mr Morris was voted to the chair, : and about 60 persons were present. The chairman stated that the object of the meeting was that united influence should be brought to bear upon the City and Town Councils, so that a cartbridge should be erected. He said that Mount Pleasant would no doubt be thickly populated in a few years, and the bridge would prove a great boon to the inhabitants of the locality. By means of a cart bridge drays, would be enabled to save on their journeys to and fro between the mount and the batteries, at least a mile and a half each time. He hoped that the councillors for the south ward would assist them in this matter. Mr Jago, as one of the conveners of the meeting, said that united action on the part of both eastern and western ratepayers was requisite, so as to exert a strong pressure upon the City and Town Councils, in order that the work should be carried but. Mr Grainger moved the first resolution as follows;—“ That the construction of a cart bridge over the Yarrowee Creek at Sunnyside, to facilitate communication between the residents of the city and town, is urgently necessary, and that in the interests of both municipalities the two councils be asked to at once jointly carry out the work. In doing so he said that the necessity of a cart-bridge for the residents of Mount Pleasant would be apparent when the number of batteries, tanneries, and also the Woollen Mill, in the district were considered. The place was of growing import ance, and ready communication should at once be established. Another reason was that an immense saving in time would be effected. It was quite a common occurrence to see one, two, or three drays stuck in the bed of the creek which had gone that way to make a short cut. Now, what with the horses floundering about and breaking their harness, it seemed a wonder to him that life had not been destroyed before now, just through the want of a cartbridge. Mr Johns seconded the resolution. Mr Robert Calvert supported the resolution, and said that it was disgraceful action on the part of the representatives of the south ward that the work had not been executed long ago. They should come together like men and demand that the work should be done, and if not done they should not pay rates until it was. (A voice—“But they’ll make us.” Laughter.) The wooden footbridge across the creek was “only a wooden fabric, not fit for a Christian to walk across, and steps should be taken to remedy this also. Mr Blight, a resident of Mount Pleasant, said that, in common with others, he had been opposed to the erection of the bridge two years ago, but his views had since been altered. Cr. Morrison, who was present, said that the fault of the cartbridge not being erected over the Yarrowee at Hill street lay not with the City Council, but with their neighbors, who had always been opposed to its erection there. In 1874 a motion was carried at a meeting of ‘the City Council" by which the sum of £5OO had been voted to carry but the work. As the bridges over the Yarrowee were joint undertakings of the city and town, they had, by the provisions of an act of Parliament, called upon the Town Council to assist them in the erection of the bridge. In consequence, a conference of the two corporate bodies had taken place, when a motion was moved by Cr Howard, the representative of the south ward, and seconded by Cr Turpie, of Ballarat East—“ That the bridge should be erected at Hill street.” The motion was rejected, principally through the eastern representatives, who wanted the bridge lower down. Since then the two councils had often met to consider, the question of bridges over the Yarrowee Creek, but nothing had been done at the meetings, as the Eastern Council wanted the bridge in one place and the City Council in another. He had himself, when first elected to the council, given notice of motion affirming the desirability of a bridge, at the place now fixed upon. The Woollen Company was growing in importance, and a direct, road to its works would greatly advance its interests. For the working, expenses of each ward £400 was annually, appropriated; and this amount would not be sufficient carry out the work. They would have to obtain a special grant of about £900, as Hill street would require a culvert to be erected therein, as now it was virtually an open drain which carried the drainage of the western plateau to the Yarrowee. He advised that strong pressure should be exerted, specially upon the Eastern Council, and then the work might be carried out. He thought that if the foot bridge was repaired, and large stones thrown into the creek, it would do until the bridge could be erected. The chairman then put the resolution, and it was unanimously carried. Mr Hamilton moved the second resolution— “That Messrs Fern, Greenwood, Peirce, and Jago be deputed by the meeting to wait upon the City and Town Councils and present the first resolution; also that petitions in its favor be signed by all ratepayers interested.” Mr Haigh seconded the resolution, which was carried. Votes of thanks to Cr Morrison for his attendance, and to the chairman for presiding, were passed, and the proceedings terminated." (Ballarat Star, 9 August 1881, page 3) "WOOLLEN MILL BRIDGE YARROWEE IMPROVEMENTS Though brief the official ceremony of opening the bridge across the Yarrowee Creek, near the Sunnyside Woollen Mills, was of an interesting character. It took place at noon yesterday in the presence of the Mayors and councillors of the City and Town. Hon. F. Hagel thorn (Minister of Agriculture).Hon Brawn. M.L.C., Lt-Col Morton (Acting City Clerk). Mr J. Gent (Town Clerk of Ballarat East), Mr A. Farrer (City Engineer), Lt. L. Finch (who is about to leave for the Front, and who assisted Messrs A. Farrer and G. Maughan in carrying out the project, Mr W. Hurdsfield (Clerk of Works) and others. An apology was received from Mr J. McClelland, contractor for the work. Mayor Hill expressed pleasure in Introducing Mr Hagelthorn, who had at great personal sacrifice and inconvenience come from Melbourne to perform the opening ceremony of that beautiful bridge, which was of great improvements that had been effected.When Mr Hagelthorn was Minister of Pubic works he visited Ballarat specially to see the condition of the creek, which at that time was in a disgusting state from a sanitary standpoint. After viewing the position, and realising the justice of the claim. Mr Hagelthorn made strong representations to the Government of which the was a member with the result that it voted £17,000 for the work. That action had been the means of turning a plague spot into a thing of beauty. They therefore owed a deep debt of gratitude to Mr Hagelthorn and the Government of which he was a member, and they were particular grateful to Mr Hagelthorn for coming to Ballarat to perform the open ceremony. Mayor Levy said he could bear testimony to the good work Mr Hagelthorn had always done for Ballarat. In him Ballarat and district always had a good friend. He thought Mr Hagelthorn would feel amply gratified at seeing the good work that had been done. It would serve as some reward for the expenditure, on behalf of the residents of Bal larat, of the amount of money made available through Mr Hagelthorn's instrumentality for the two municipalities. Otherwise the City and Town councils would not have been able to carry out so necessary and so beneficial a work. There was a great amount of work yet to be done, and when the financial market became low stringent Mr Hagelthorn would no doubt be pleased to take the necessary steps to have money provided for further works which could not be undertaken at the present time. The adjacent woollen mill was a standing monument to what was being done in Ballarat, and what ever the City and Town Councils or the Government could do to encourage such manufacturing enterprise should be done, and he was glad to be able to say that was being done as far as finances would permit. He concluded by presenting Mr Hagelthorn with a gold mounted pocket-knife with which to cut the ribbon stretched across the centre of the structure as a bar to traffic. The Hon. F. Hagelthorn, who was greeted with applause said before him was a good work well done in the interests of the public. Real prosperity could only be achieved by a movement carried out by the people to increase natural productiveness. Most of them had been made aware, on account of the war par tiularly, that the people who were best equipped, the industries that were best organised, and the Governments that were most intelligently controlled would get the most of this world's goods and some of its luxuries that Would be denied other people less efficient. Any thing the Government could do to promote industry and to increase the reward of those engaged in it, both employer and employee, would be done. Most Governments would do but little in that regard. ... " (Ballarat Courier, 13 September 1916, page 4)Bluestone and iron bridge over the Yarrowee River at Hill Street, Ballarat.sunnyside mill, sunnyside woollen mill, ballarat woollen mill, bridge, yarrowee creek, francis jago, mount pleasant, yarrowee river, robert calvert -

Ringwood and District Historical Society

Ringwood and District Historical SocietyMemorabilia - Envelope, Packet: Ringwood Methodist Church - Anniversary Pamphlets, Cuttings, Pictures, Hand written notes

Churches - Ringwood Methodist Church3785.1 A hand written notes of the early history of the church. Several to the Town Clerk from the Ringwood Church trust and thr Public health department. 2. Minutes of meeting of the Ringwood Parsonage Trust 1909 and 1910 3. The Record of the Box Hill and Ringwood Methodist Circuits. Hand writen list of members of Ringwood Circuit. 4. Flyer for Back to Ringwood Methodist Church Jubilee, March 9th to 17th. 1929. Letter to Richard Carter from Aub (sic) who was eight years old at the time and can remember the Jubilee 4 Booklets about the Church Also a name tag for Miss V. Watson Assist. Secretary. Several cuttings, one full page spread from the newspaper about the Jubilee. 5. Ringwood Methodist Sunday School Tea and Meeting. Cutting from the Ringwood & Croydon Mail. The Wigley family were greatly represented. 6. Diamond Jubilee 17-28th. March ,1939 Program of Events 7. Six pages of hand written letters from the Methodist Circuit, letter to the Ringwood Councillors inviting them to the Centennary Celebrations of the Church,letter to the Town Clerk from Methodist Sunday School Surrey Hills regarding a picnic in Ringwood. 8. Ringwood United Churchmen's Association syllabus 1937 9. Pamphlet about Sunday Sport and the Christian Duty to Vote. 10.Ringwood Methodist Church news July 1963 11. Two Ringwood Methodist Church pamphlets for the 75th. Anniversary March 17th.-28th. 1954. 12.Copy of lease from the Methodist Church Trust for 30 years to use land in Ringwood 13. Carols by Candlelight (no year) and the Ringwood Methodist Church News March 1958, With memories of Christmas. 14.Pamphlet of the Laying of the Foundation Stone Saturday 18th. May 1963 and two pamphlets of the Opening and Dedication of the Ringwood Methodist church 9th. november 1963. 15.'The Messenger' Journal of the Ringwood Methodist Church December 1963. 16'. Forward in Faith' Review Stewardship Canvass August 1961. 11 pages outlining the plans for the proposed new Church. 17. Foolscap sheet typed with the Evening Service Sunday 6th. December 1970 with the Combined Circuit Choirs .Excerpts from 'The Messiah' 18. 'Recollections of Ringwood Methodism' issued at the celebration of the 98th. Anniversary of the Church 29th. may 1977. Compiled by Alf. Clark 19.Syllabus for the Uniting Church Fellowship Ringwood 1984 20.' Methodist Pioneers in the Croydon Area'. Work in Progress by Rev. Barry Brown 21.two page history of the ' Pipe Organ in the Ringwood Uniting Church' which was built by the Melbourne firm of Geo. Fincham & Sons. Plus a pge with' A Few Facts about the Organ' 22. Two Church Christmas cards (no year). one in envelope -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Memorial Tower, Kangaroo Ground c.1934, 1934c

Sepia photograph of Joyce McMahon and 'Tiny' Carroll at the War Memorial Tower, Kangaroo Ground c.1934. The guns were installed in 1934 and removed in 1942. Taken in the early 1930s, the photograph ... shows the Kangaroo Ground Tower of Remembance with Joyce McMahon, daughter-in-law of Mr. P. J.McMahon, the then Shire of Eltham Secretary, her horse and a very tall person patting the horse. He is ex-serviceman W. "Tiny" Caroll who was the council's caretaker of the surrounding War Memorial Park. He lived in the stone cottage which still stands in the park. "Tiny" is seen as the fictional character "Tiny Bourke" who, in author Alan Marshall's book "This is the Grass", "was a giant of a man, well over six feet high, with huge hands that completely encircled the cup of tea". The bronze casting, which shows the 79 names of those who paid the "supremen sacrifice" in World War 1 (1914-1918), was erecfed above the entrance to the Tower in September, 1930. The Monterey cypress trees which now form the windbreak around the park's fenceline, were just knee high in this photograph. They were planted in August 1926, with all the plantings paid for, and done, by the public as the Tower was being erected. The two field guns have been identified as of German origin, Krupp 77 mm calibre captured on October 4, 1918 at Geneve, France. They were removed in 1943/44 as a wartime requirement of the Australian Govenment. A public notice dated October 16, 1926 by Cr. H Rutter, Chairman of the Eltham Soldiers War Memorial League stated: "On the summit of that central and conspicuous landmark, Garden Hill, there is being erected a massive memorial tower which will, for all time, remind every passerby of the part played by the men of the Shire of Eltham in the Great War. The work has been undertaken by the people of the Shire a a tribute of love and admiration for those who were known and dear to use in the days of their youth and early manhood, who went out from amongst us, never to return, and whose self-sacrifice has made us, each and all, thier ever-lasting debtors" Harry Gilham, Eltham District Historical Society Kangaroo Ground Tower of Remembrance, A Journey in Time: a column about Nillumbik's history, Nillumbik Mail, 9th August, 2000 Since that research the following has been sourced from Eltham and Whittlesea Shires Advertiser and Diamond Creek Valley Advocate, April 8, 1921, p. 3 Retrieved April 25, 2020, from http://nla.gov.au/nla.news-article57639687 Eltham Shire Council From Town Clerk, Melbourne, stating that a light machine-gun captured by the 22nd battalion, A.I.F. at La Motte Farm, near Beaurvoir, on Oct. 3rd, 1918, during the operations which won the Beauvoir line and completed the smashing of the great Hindenburg defence-system, has been alloted to the Shire of Eltham. - On the motion of Crs Hubbard and Smedley, it was decided to have the gun placed in the Memorial Park. Sepia Photographgarden hill, gun, joyce mcmahon, kangaroo ground, memorial tower, shire of eltham war memorial tower, tiny carroll, war memorials, war trophy, william carroll -

Federation University Historical Collection

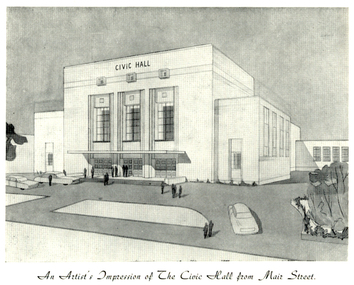

Federation University Historical CollectionProgramme, The Opening of Civic Hall, 1956, 1956

The City of Ballarat unanimously resolved to erect a Civic Hall in Mair Street in 1951. The architects, Gordon Murphy, of Melbourne, and H.L. and L.J. Coburn, of Ballarat, were commissioned in 1952. The Council constructed the foundations and footings for the building under the supervision of the former City engineer, Mr L.H. Finch, in 1953. These footings are of massed concrete. The design for the building took advantage of the cross fall of the land, providing for the Small Hall to be entered from the Doveton Street frontage through a foyer under the Main Stage, the structure is steel with brick panels, with accommodation for 1,592 persons in the Main Hall and 440 persons in the Lower Hall. The front facade faces Mair Street, set back from the building line to provide for the entrance drive-ways and kerbed gardens. Tenders were invited on a firm price basis. A young Ballarat master Builter, Walter Benbow Trahar was the successful tenderer, the contract price being 139,841 pounds. the work was commenced in 1953 and has proceeded in spite of material and labour difficulties until its completion. The following statistics are of interest:- * The foundations contained 200 cubic yards of concrete. * The constructional steel work weighs approximately 270 tons. * The reinforcing steel 47 tons. * Reinforced concrete in the structure, 1,100 cubic yards. * The approximate number of bricks in the building, 580,000. * The flooring is of selected kiln-dried hard wood and totals 40,000 lineal feet. * The dimensions of the Main Auditorium, 100ft by 86 ft, including the side promenades each 82ft by 13ft. *The Main stage, of reinforced concret with parquette finish measures 62 ft by 40ft. *The floor area of the Lower Hall is 74 ft by 38 ft, and has a stage dimensions of 40ft by 20 ft. * Each hall has independent heating and ventillating systems. Where possible the material in the building was furnished from local business houses. The public address installation, which provided for additional microphones, is on the main Stage. There is inter-communication throughout the building connecting the front office, with the bioscope box, the stages in both the large and lower halls, and the Hallkeeper's residence. Local craftsmen have completed the painting, plaster work, and the electrical installation; local produced materials being used in the construction of the buildings with the exception of the timber for the Main Floor, the roofing and the structural steel. The City of Ballarat Councillors in 1956 were Councillors N. T. Callow, F.J. Cutts, K.C. Webb, W.E. Roff, O.W. Curnow, F.T. Woodward, Allan C. Pittard, A.W. Nicholson, J.A. Chisholm, G.L. Scott, F.W. Oliver, A.D. Mason. The Town clerk was H.R. Maddern and the City Engineer was G. Murrowood. A City of Ballarat Council meeting of 25 September 2013 voted to demolish the Ballarat Civic Hall. The Council heard from nearly 50 members of the public during a marathon six-hour meeting. Councilors John Birt, Des Hudson, Amy Johnson, Josh Morris, Peter Innes, John Philips supported the motion to demolish Civic Hall. Councillors Samantha McIntosh, Vicki Coltman and Belinda Coates voted against the motion.Six page souvenir Program of citizens' entertainment on the occasion of the Opening of Ballarat Civic Hall on in August 1956. The front cover features the City of Ballarat Coat of Arms. The programme starts with a message from the Mayor, Cr Neil T. Carrow. It includes the Concert Programme directed by James H. Davey, an asrtist's impression of the Civic Hall from Mair Street, and information relative to the New Civic Hall. The programme features images of the City of Ballarat Coat of Arms, Cr N.T. Callow, , James H, Davey, and an artist's impression of the Ballarat Civic Hall. Mayor Neil Callow's Message: "To-day, our citizens witness the fulfilment of the most extensive Municipal undertaking in the City's period of recent prosperity and development. Their Hall now fills a requirement of which they have been deprived since the Coliseum building was destroyed by fire over 20 years ago. The building has been designed as an all purpose structure and I am hopeful the citizens will use it and enjoy it to its fullest extent. Your Council and its Architects have planned as broadly as possible for the benefit of all to-day and for years to come. We are proud of the work executed by a Ballaarat Master Builder whose work is a monument to the City's craftsmen. I feel I should also remind this assembly that the women of Ballaarat, back in 1951, provided funds which have been applied in the purchase of a Grand Piano and two Upright Pianos which are now installed in this building. The sincere hope of myself and your Councillors is that this Hall and its amenities will prove of immense value to the development of the cultural and artistic tastes of this community and that it will be freely used for these and many other purposes. From now on this magnificent building and its furnishings and equipment will be available to all. I strongly exhort you to use and protect it. My hope is that the citizens will, for many years to come, enjoy the amenities which it has to offer. ballarat civic hall, civic hall, architecture, finch, art deco, city of ballarat, coat of arms, city of ballarat coat of arms, callow, shugg, lemke, oates, gullan, tuuri, john, robertson, sorrell, antonio, gordon murphy, walter benbow trahar, trahar, coburn, h.l. coburn, l.j. coburn, n.t. callow -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, Mr Charles Ansell Smith and family

Mr Charles Ansell Smith of 3 Vincent Street with his family – Roy, Stan and Frank Smith and Dorothy (Mrs Cromwell). Photo is without Kenneth or Harold so possibly taken during WW1; Kenneth enlisted in 1914, Harold in 1915 and killed in 1917. The boys went to Surrey Hills State School and Dorothy to Milverton Girls School, first at 192 Union Road, it later moved to ‘Nilgard’, 221-223 Union Road. Helen Malvira Mackenzie (1865-1956) married Charles Ansell Smith (c1861-1934) in 1891. He was baptised 23 April 1861 in Tintinhull, Somerset - son of William Maxwell & Louisa Claudina Smith (nee Ansell). His father was curate of the church at the time. Helen Malvira (or Malvena) MacKenzie, known as Nellie, was the second daughter of the John Mackenzie J.P., of Westernport, and Wilcannia, N.S.W., and great granddaughter of the late Admiral Pasco, R.N. They lived at 'Devon', 3 Vincent Street from at least 1910 but perhaps earlier until 1915. Charles Ansell and Helen Malvina Smith’s children: 1. Kenneth Ansell – b 1892 d 3 May 1977 at Lancefield SERN 819 Enlisted AIF on 17/8/1914 giving his occupation as book seller Assigned to 8th Battalion, G company Enlisted 17 August 1914 Embarked A24 Benalla on 19 October 1914 Returned to Australia on 23 October 1918 Obituary describes him as eldest child of the late Charles Ansell & Helen M Smith of Surrey Hills and Lancefield. 2. Stanley Charles – b 1893 (Carlton) - lived Surrey Hills 3. Dorothy Louisa – b 1894 - 1988 4. Harold Maxwell Pasco – b 1897 Oakleigh SERN 3268 Educated Surrey Hills State School Religion Cof E Occupation: Clerk Served with 48th Infantry CMF, Kooyong Enlisted 23 July 1915 – parents living at Vincent Street at the time Assigned to 24th Battalion, 7th Reinforcement Embarked HMAT A73 Commonwealth on 26 November 1915 KIA 4 October 1917 at Passchendaele, Ypres No known grave. Parents at ‘Cloverdale’, Lancefield 5. Francis W D (Frank) – b 1898 – 1972 Obituary: Frank (FWD) Smith on Feb 14 (suddenly) Francis Wm Douglas Smith, son of Charles Ansell & Helen M (Surrey Hills & Lancefield) and brother of Kenneth (Lancefield), Dorothy (Mrs Cromwell), Harold (KIA) Roy & Stanley. 6. Roy MacKenzie – b 1901 – 1988 m Ruby Olive Laity in 1931 So, the children were all born before the family came to Surrey Hills but Vincent Street was where they grew up. Charles and Helen are buried in Box Hill Cemetery (CE-NS-1266) Stan Smith was most helpful to the History group of the S.H. Neighbourhood Centre with his research into S.H. History and in particular for the vast amount of detail he gave on people and happenings. His observations have been very accurate and he has very precise recollections of the old days. A black and white photograph of 3 young men, a lady and an older man. The men are dressed in suits and the lady in a below-the-knee dress. The young men are carrying hats whilst the older one is wearing his.(mr) charles ansell smith, (mr) roy smith, (mr) stan smith, (mr) frank smith, (mrs) dorothy cromwell, (miss) dorothy smith, milverton girls school, union road, surrey hills, nilgard, francis william douglas smith, stanley charles smith, roy mackenzie smith -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionProgramme - Ephemera, Chatham Primary School Fathers' Club 'Trial by Jury' programme, 16/11/1929

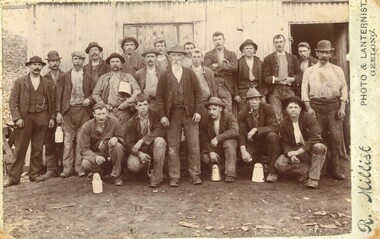

The program describes the performance as 'original burlesque' and was written, composed and produced by A E Woffinden and A W Sutton, members of the Chatham Fathers' Club, to raise money for the school. There were 250 programs printed at a cost of one pound fifteen shillings. This performance starred 21 of the fathers with Mr W Crellin as the only female character, Miss Eileen Flapper. The Chatham Fathers' Club became renowned locally for the quality of its performances, repeats being given to other community organisations. In the publication 'Chatham Past & Present: A Patchwork of People' there is also a photo of the cast taken in the quadrangle of the school. The original program and photo were lent to the school at the time of the 70 year reunion in 1997 by Mrs Jean Lacy (nee Walker), whose father took part as a member of the jury. Many of the performers were also in the formal photo of the Father's Club, taken in February 1928 on the front steps of the school. The original hangs in the school entry foyer and is reproduced in 'A Patchwork of People: Chatham Past and Present'. In relation to names, these are better identified and the following identifications have been reached by referencing this and the 1931 electoral roll. The geographic spread of addresses reflects that when Chatham opened in August 1927, surrounding schools were overcrowded and some families chose to relocate their children. Albert Ernest Woffinden (manufacturer) lived at 14 Banool Road, Surrey Hills. Alfred William Sutton (clerk) lived at 528 Whitehorse Road, Surrey Hills. Mr A Davidson - not found in electoral roll. Walter Dallas Kinross (mechanic) lived at 72 Empress Road, Surrey Hills. Gilbert Leslie (Bert) Rae (sales) lived at 63 Empress Road, Surrey Hills. Mr Joseph P Braddick (mechanic) lived at 1 Northcote Avenue, Canterbury; now Balwyn (NB/ Name is miss-spelt Braddock in the program). Norman Patrick Smart (bt opr) lived at 61 Sir Garnet Road, Surrey Hills. Henry Albert Wysham (show card writer) lived at 9 Northcote Avenue, Canterbury. Mr Sidney Bessant (labourer) lived at 191 Mont Albert Road, Canterbury. William Morrison (teacher) lived at 37 Chatham Road, Canterbury. William Charles Crellin (breadcarter) lived at 59 Empress Road, Surrey Hills. Mr F Parsons - taken as Fred Parsons (bricklayer) lived at 2 Kaarumba Grove, Balwyn. Mr MacDougal (incorrectly spelt in program) is Dougall MacDougall (gas collector) lived at 5 Wells Street, Surrey Hills. Mr A V Webb - not found. Mr McKie - not found. Victor Harold Theodore Clow (civil servant) lived at 4 Talbot Avenue, Balwyn; listed as T. Clow. Mr M Walker (donor's father) not found in electoral roll for 1931; thought to have lived in Sir Garnet Road. Mr McLeod - a number listed in the 1931 electoral roll. Richard Frost (carriage builder) lived at 341 Mont Albert Road, Surrey Hills. Mr Allen - a number listed in the 1931 electoral roll. Mr J Tulloch - not found in the 1931 electoral roll. This is an example of 'home-spun' entertainment and creativity of the era when the sense of community was very real. It is an example of the fundraising efforts undertaken by school communities to provide 'extras' that would later be regarded as 'basics'. For many years the sense of community in this part of Surrey Hills revolved around Chatham school, the Benson Street Methodist Church and the football club, located at the Canterbury Recreation Ground.A photocopy of the programme for the Chatham Primary School Fathers' Club "Trial by Jury" performance on 16 November 1929. It includes the words of the song 'Carry me back to dear old Chatham'. It lists the performers by character and some details regarding the Chatham Primary School Fathers' Club.chatham primary school, chatham primary school fathers' club, theatrical productions, entertainment, albert ernest woffinden, fundraising, alfred william sutton, walter dallas kinross, gilbert leslie (bert) rae, joseph p braddick, norman patrick smart, henry albert wysham, sidney bessant, william morrison, william charles crellin, fred parsons, dougall macdougall, mr a v webb, mr mckie, victor harold theodore clow, mr m walker, mr mcleod, richard frost, mr allen, mr j tulloch -

The Beechworth Burke Museum Research Collection

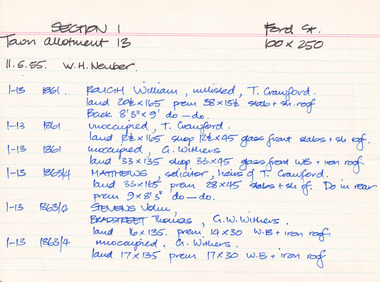

The Beechworth Burke Museum Research CollectionCard (Series) - Index Card, George Tibbits, Ford Street, Beechworth, 1976

George Tibbits, University of Melbourne. Faculty of Architecture, Building and Town & Regional PlanningIndex system that support the research for Beechworth : historical reconstruction / [by] George Tibbits ... [et al]Arranged by street names of BeechworthEach index card includes: street name and number of property, image of property, allotment and section number, property owners and dates of ownership, description of the property according to rate records, property floor plan with dimensions.beechworth, george tibbitsbeechworth, george tibbits -

Bendigo Historical Society Inc.

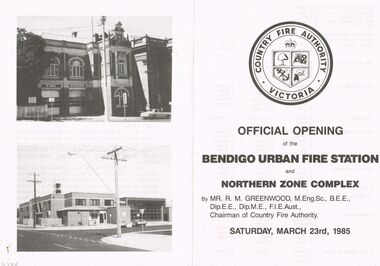

Bendigo Historical Society Inc.Document - OFFICIAL OPENING OF THE BENDIGO URBAN FIRE STATION AND NORTHERN ZONE COMPLEX, 23 March 1985

Official Opening of the Bendigo Urban Fire Station and Northern Zone Complex by Mr R M Greenwood, M.Eng.Sc., B.E.E., Dip.E.E., Dip.M.E., F.I.E.Aust., Chairman of Country Fire Authority. Saturday, March 23rd, 1985. Northern Zone Complex Staff: Assistance Chief Officer: A Graham. Regional Officers: W Walker, R Morrall. Deputy Regional Officers: D Barber, J Ray. Typist Clerks: H Harrison, A Connelly. Bendigo Urban Fore Brigade: Station Officer in Charge: M Gray. Station Officers: J Chapman, J Clark, R Ellis, S Knight, R Langridge, K Pinner, D Vecht, E Walder. Volunteer Officers: Chairman: Geoff Flack. Foreman: J Turner. Apparatus Officer: P Sheers. Secretary: L Rodda. Senior Firefighters: J Absalom, R Allott, L Anglin, P Brereton, P Brown, B Cole, A Dennis, G Ellis, J Griffiths, A Harrington, R Lindsay, A Hartland, J Meagher, G Monro, T Nolan, W Watters, J Wellard. Firefighters: R Barry, A Boromeo, A Crosthwaite, A Hand. Volunteer Firefighters: P Bouwmeester, M Bracey, E Carruthers, D Dunlop, G Ellis, M Ellis, I Ellis, George Flack, I Johnson, C Lapsley, P Mundy, G Nadort, M Nabbs, J Phillips, T Rosewall, R Schintler, B Sandlant, G Watson, R Watt, R Wee Hee. Reserve Firefighters: D Anderson, P Barker, P Chapman, C Clayton, S Guest, D McCarroll, A Maes, S Pearson, M Ruff, N Wastell, G Wilkinson, D Dean, A Rogers. Life Members: Perc Terrill, Max Ellis, George Ellis, Ron Wee Hee, Stan Price, S/O Vin Lapsley (retired). Ladies Auxiliary: President: Mary Dillon, Secretary: Ruth Turner, Treasurer: Karen Watt. J Clark, T Graham, M Gray, M Gray, Y Yore, M Letts, J Nadort, J Vecht, M Lapsley, D Dunlop, A Flack, L Graham. Junior Brigade Members: M Graham, G Hore, T Hore, D Spiers, A Hore, P Holloway, S Turner. Short History on the Bendigo Fire Brigade which was established on 1st May 1899, taking the form of an amalgamation of the 3 Fire Brigades in existence in Bendigo. . . Back cover 2 photographs original Bendigo Station and new Bendigo Station.event, official, country fire authority, official opening of the bendigo urban fire station and northern zone complex by mr r m greenwood, m.eng.sc., b.e.e., dip.e.e., dip.m.e., f.i.e.aust., chairman of country fire authority. march 23rd, 1985. staff: assistance chief officer: a graham. regional officers: w walker, r morall. deputy regional officers: d barber, j ray. typist clerks: h harrison, a connelly. bendgio urban fore brigade: station officer in charge: m gray. station officers: j chapman, j clark, r ellis, s knight, r langridge, k pinner, d vecht, e walder. volunteer officers: chairman: geoff flack. foreman: j turner. apparatus officer: p sheers. secretary: l rodda. senior firefighters: j absalom, r allott, l anglin, p brereton, p brown, b cole, a dennis, g ellis, j griffiths, a harrington, r lindsay, a hartland, j meagher, g monro, t nolan, w watters, j wellard. firefighters: r barry, a boromeo, a crosthwaite, a hand. volunteer firefighters: p bouwmeester, m bracey, e carruthers, d dunlop, g ellis, m ellis, i ellis, george flack, i johnson, c lapsley, p mundy, g nadort, m nabbs, j phillips, t roasewall, r schintler, b sandlant, g watson, r watt, r wee hee. reserve firefighters: d anderson, p barker, p chapman, c clayton, s guest, d mccarroll, a maes, s pearson, m ruff, n wastell, g wilkinson, d dean, a rogers. life members: perc terrill, max ellis, george ellis, ron wee hee, stan price, s/o vin lapsley (retired). ladies auxiliary: president: mary dillon, secretary: ruth turner, treasurer: karen watt. j clark, t graham, m gray, m gray, y yore, m letts, j nadort, j vecht, m lapsley, d dunlop, a flack, l graham. junior brigade members: m graham, g hore, t hore, d spiers, a hore, p holloway, s turner. short history bendigo fire brigade established 1st may 1899, amalgamation of the 3 fire brigades in existence in bendigo. . .2 photographs original bendigo station new bendigo station. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Federation University Historical Collection

Federation University Historical CollectionDocument, Establishment of the Ballarat School of Mines, 1870, 1870