Showing 2178 items

matching machinery

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pump, circa 1930's - 1940's

This pump is an Ajax Type L2 Series A model, made and sold by McPherson’s Pty Ltd of Melbourne circa 1930’s to 1940’s, is a mechanical, hand operated, constant flow pressure pump. It would have been used to pump fluids from one area to another, for example from a dam to a tank or used as a bilge pump on a small vessel, mounted on the vessel’s bulkhead, floor or deck. This type of hand pump is sometimes called a ‘Reciprocating Suction Pump’. It has a mechanical pumping action of the lever moves the piston inside the pump up and down. The water is lifted from below the pump through the inlet pipe and into the pump’s cylinder. This action causes the lower valve to close and the piston’s valve opens and the pressure within the pump forces the water out of the pump through the exit pipe. The limitation of this type of pump is that it can only raise the water a maximum of about 7 metres from beneath the ground and yields 24-26 Litres per minute. This type of pump could be used for many purposes such as pumping water or fuel. McPherson’s 1940’s advertisement proclaims “For all jobs on the land – irrigation, spraying, tank, plumbing, fire-fighting – there’s a suitable “Ajax” pump. Send us the details of you pumping problem. Our Expert’s advice will help you choose the right pump – the one that will give you most years of PROFITABLE PUMPING.” (The Australasian (Melbourne) Sat. 26th October 1940.) McPherson’s Pty Ltd, the manufacturer, advertised a similar pump to this one in The Australasian (Melbourne) in 1936, calling it the Ajax Double Acting Hand Pump. In 1942 another advertisement advised that a representative for a fire-fighting equipment supplier was visiting the western district of Victoria. The company could now supply double-action two-spray Ajax pumps at lower prices than similar pumps the district had recently purchased from Adelaide. McPHERSON’S FOUNDER and COMPANY TIMELINE 1860 – Thomas McPherson, a Scottish immigrant (c. 1853 ), founded McPherson’s in Melbourne, supplying pig iron (lead ingots imported as ballast in ships) to local manufacturers. 1882 – Thomas McPherson established a warehouse in Collins St Melbourne and included tools, steam fittings and machinery in his wares. The business expanded to include steam saw mills and became known as Thomas McPherson and Sons (William Murray and Edward). 1888 – Thomas passed away and his sons inherited the business. In 1896 William Murray became the sole proprietor after his brother Edward’s death. 1900 – The firm expanded, establishing Acme Bolt Company to manufacture nuts and bolts. 1912 – McPhersons Pty Ltd established a machinery warehouse and showroom in 554-556 Collins St Melbourne. McPherson’s went on to establish branches in Sydney (1911), Adelaide (1921) and Perth (1930) 1917 - McPherson’s supplied ‘dog spikes’ for the transcontinental railway, running from Eastern to Western Australia. 1918 – A tool works set up in Kensington, Melbourne, manufacturing Macson lathes and made machine tools that previously had to be imported. 1924 – The Bolt Works was transferred to a new building in Melbourne. McPhersons began making pumps. 1929 – McPherson retired. His son (Sir) William Edward McPherson (known as ‘WE’), was born in Hawthorne, Melbourne, in 1898. After his education he began work in his father’s Melbourne hardware and machinery business He took over as governing director when his father retired. 1929-1932 – McPherson’s supplied thousands of tons of rivets from its Richmond (Melbourne) Bolt Works for the construction of the Sydney Harbour Bridge. 1936 – McPherson’s Pty Ltd is advertising Ajax Pumps in newspapers 1934 – McPhersons purchased the property adjoining the warehouse in Collins Street, and during 1935-1936 built a new office and showrooms on the site of 546-445 Collins St. 1939 - McPherson’s acquired the Tool Equipment Co. Pty. Ltd and Associated Machine Tools Australia Pty Ltd was formed to separate McPherson’s machine-tool manufacturing and merchandising interests. 1939 – Ajax Pump Works, a foundry and pump manufacturing plant, was established in Tottenham, Melbourne, and the Ajax Bolt and Rivet Co Pty Ltd began manufacturing in New Zealand. 1944 - McPherson’s became a public company, McPherson’s Ltd. 1948 - The Ajax Pump Foundry opened at Kyneton, Victoria and in the post war years it grew to became a large manufacturer. 1980’s – Ajax Pumps brochure lists the address as 6 Buckhurst St, South Melbourne, Vic 3205 with the Telephone number 03 669 3588 1988 - Ajax Pumps acquired the Forrers Company, which was established in 1921. Manufacturing in Ipswich, Queensland, specialising in submersible sewage pumps. 1991 – KSB Ajax was formed, bringing together the companies KSB and Ajax Pumps 1993 – Manufacturing was moved to state-of-the-art premises in Tottenham, Victoria 2001 - The Forrers facility was moved to Tottenham. 2007 - Company name KSB Ajax Pumps was changed to KSB Australia Pty Ltd. 2009 - KSB Australia opened a branch in Townsville, Queensland. 2011 - KSB Australia moved to its dedicated Water and Waste Water Competence Centre in Bundamba, Queensland. DISPLAY OF THIS AJAX PUMP This pump was installed at Flagstaff Hill Maritime Village as part of a working display in the village by the Friends of Flagstaff Hill, in acknowledgement of the dedicated involvement of one of its long serving members, Bob Crossman. The display was officially opened 31st March 2018 and incorporates a restored Furphy Tank and Water Pipe Stand. The pump is used to draw water from the lake, through the water stand pipe and into the reconditioned Furphy Tank. This Ajax pump made by McPherson’s Pty Ltd is significant for its association with McPherson’s, a prominent manufacturer of hardware in Victoria. McPherson’s is famous for supplying ‘dog-spikes’ for the transcontinental railway (eastern to western Australia, 1917) and rivets for the Sydney Harbour Bridge (1929-1932). The Ajax pump is also of significance because of its association with McPherson’s Governing Director (Sir) William McPherson, former premier and treasurer in Victoria 1928-1929. The former McPherson’s Pty Ltd building in Collins Street Melbourne is now on the Victorian Heritage Register VHR H0942 This pump is representative of mechanical pumps popular in the early to mid-1900’s and still used today. Hand operated pressure pump, double acting. Cast metal case, painted red, with steel hose attachments and long metal lever. Pump is bolted to wooden plank. Model of pump is AJAX, Type L2, Series A pump. Embossed on lower section of pump "L2 - 10", "L2 - -1", "AJAX" “(?) –2-1” Embossed on lower handle “3-7” “L – 4” Embossed on attached plate “FOR SPARE PARTS / TYPE L2 / SERIES A / PUMP ASSEMBLED BY T R” Manufactured by McPherson’s Pty Ltd of Melbourne circa 1930’s - 1940’s.flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ajax pump works tottenham melbourne, ajax pump factory kyneton, william edward mcpherson, thomas mcpherson of melbourne, mcpherson’s pty ltd melbourne, acme bolt company, tool equipment co. pty. ltd, associated machine tools australia pty ltd, ajax bolt and rivet co. pty ltd new zealand, forrers company ipswich queensland, ksb ajax pumps, ksb australia pty ltd, macson lathes, tool manufacturer early to mid- 20th century, ajax double acting hand pump, ajax type l2 series a pump, qisjax pumps, water pump 1940’s, fuel pump 1940’s, hand operated constant flow pressure pump, reciprocating suction pump, agricultural hand pump, plumber’s hand pump, portable hand pump -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, Jelbart home, 93 Arthur Street, Eltham, 11 November 2006

Situated at the top of the hill in Arthur Street, the former Jelbart residence and barn were part of a major change that transformed Eltham's character in the late 1960s. Built from the mid 1940s through mid 1950s when Eltham was a rural community, the Jelbrat residence and barn are all that remain of a family property of some 250 acres (100 ha). With growing population pressures, in the late 1960s, owners Ron and Yvonne Jelbart decided to subdivide their property creating the Woodridge Estate in the early 1970s, a major factor towards the transformation of Eltham to the suburb it is today. The Jelbarts had moved to Eltham in the early 1940s when they purchased a poultry farm in New Street, now Lavendar Park Road. (The local Black Friday bushire of January 13, 1939 had started at C.A. (Clarrie) Hurst’s Eltham Poultry Farm and Hatchery in New Street.) Jelbart was primarily a businessman importing office machinery but desired farm beef and dairy cattle so the couple purchased the virgin bushland at what was then at the end of a dirt road, Arthur Street. With post war shortages of most building materials, they followed the example of the Eltham Artists' Colony (later called Montsalvat) and built thier home from mud-bricks and recyclked materials. The barn was first to be completed in 1945 which they made their home whilst building the main residence. It took eight years to complete the two buildings. Both the main residence and the barn are now separate homes, and along with the remaining property being sub-divided further in 1998 are now part of the Kinloch Gardens Estate at 93 Arthur Street. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p139 Standing on a hilltop at Arthur Street, Eltham, the Jelbart residence and former barn were part of a major change that transformed Eltham’s character in the late 1960s. Built from the late 1940s to the mid 1950s when Eltham was a rural community, they are all that remain of what was once a family property of around 250 acres (100 ha). As population pressure increased in the late 1960s, owners Ron and Yvonne Jelbart, decided to subdivide their property. The break-up of this property into the Woodridge Estate in the early 1970s, was a major factor towards transforming Eltham into the suburb it is today.1 Although standing only a few minutes from Eltham’s busy hub and hundreds of houses in Woodridge, scarcely any urban sound disturbs the peace. Views from the two buildings are almost exclusively of trees and extend to Mt. Dandenong to the south-east, the Great Divide to the north, and Melbourne city to the south-west. The Jelbarts had lived in Eltham since the early 1940s when they bought a poultry farm in New Street, now Lavender Park Road. Although Jelbart was primarily a businessman importing office machinery, he was keen to farm dairy and beef cattle, so the couple bought rough bushland at what was then the end of Arthur Street. But a shortage of building materials following World War Two hampered their plans to build their new home, so they followed the example of the Eltham Artists’ Colony (later called Montsalvat) and used mud-bricks and recycled materials.2 With great determination the family and friends constructed their house. Massive timber frames and huge quantities of mud-bricks were made on site. The barn was built first in 1945, and two years later, while camping inside, the Jelbarts started building their house. It took eight years to construct the two buildings, even with the help of professional tradesmen. The buildings, with timber frames infilled with mud-brick and plastered, are reminiscent of the English Tudor style. The Jelbarts are of Cornish stock. Much of the timber framework came from demolished bridges or warehouses, and recycled slate was used for roofs and floors. Quality second-hand materials were readily available in the late 1940s and 1950s when there was much demolition in Melbourne and little respect for heritage. A former 19th century Toorak mansion Woorigoleen provided the magnificent stone fireplace, the timber panelling and the parquetry floor in the living room. The large stone gateposts at the entry of the property came from Melbourne University. Almost no mechanical equipment was used to build the 55 square house and the 25 square barn. Massive timber frames were erected using block and tackle pulleys and timbers were shaped, sawn and drilled by hand. Son and architect Ian, with his family, have lived in and extensively renovated both buildings since the early 1970s. Ian transformed the steep ridge of the property into a plateau, where the main house Kinloch stands, surrounded by terraces and lawns. The grounds retain many native plants, including massive yellow boxes – some nudging 80 years. Ian attached 70 metres of pergolas draped with wisteria, roses and grape vines, to three sides of the house. The beautiful garden is featured in the book Through the Rose Arbour by Rosemary Houseman. The two-storey barn – now a house – retains traces of its original use. The cow-shed with milking and feed-rooms, and the machinery-shed remain. The house, separated on the ground floor by a breeze-way, soars two storeys and includes a mezzanine. These are connected by spiral staircases, to timber-beamed and plaster-lined high-pitched ceilings. The house also descends to a wine cellar. Curiously the roof is of corrugated iron on the south and slate on the north, to save costs. Small-paned windows and three French doors open onto the front lawn, which extends to Jelbart Court.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, eltham, arthur street, jelbart barn, jelbart home, kinloch gardens -

Melbourne Tram Museum

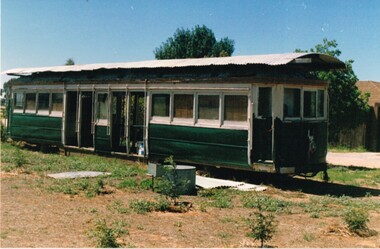

Melbourne Tram MuseumPhotograph - Set of 4 Colour Print/s, Norm Cross, 1/01/1994 12:00:00 AM

Set of four colour prints of an Ex Victorian Railways bogie tram body at Sloan NSW. Photo by Norm Cross, printed on AGFA paper. Photo dated 1/1/1994. Advised by Tony Smith - 29/3/2017 "The tram in question is VR 39. It was one of the last 4 trams disposed of from Elwood depot in 1959 after the system closed. They were purchased complete by Upton's machinery dealers of Corowa. The other cars were 29, 33 & 37. He then stripped them and sold the bodies. When we obtained VR 41 in 1977 we immediately went searching for other bodies that might yield parts to help in rebuilding 41. We located 37 on the outskirts of Wangaratta and it yielded many body items including a complete drivers bulkhead that was used to replace the one in VR 41 that had been cut out with an axle by the previous owner. You may also recall that we obtained 3 complete broad gauge 77e trucks from Upton's (they had cut up the other 5 bogies years previous). These 77E trucks are now under the Christchurch Brill tram with the 3rd as a spare as we were able to obtain standard gauge 77e's when we acquired L 105 for dismantling."Each photo has written in ink on the rear "Body of VR tram # @ Sloan NSW 1 Jan 1994, photo by Norm Cross".trams, tramways, vr trams, sale of trams, scrapped trams, tram 39 -

Federation University Historical Collection

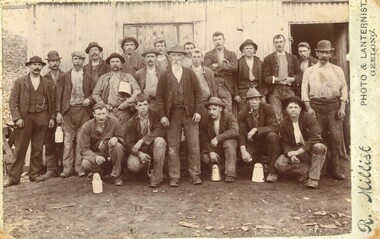

Federation University Historical CollectionPhotograph, R. Millist, Hanlon Consols Mine Rokewood, 1901

The photo depicts one shift of mine hands at Hanlon Consols Mine Rokewod in 1901. ist on the left is George Edgar Yung. George was born in Ararat the son of Yohann Godlip and Christina (b Weller)Yung. They lived at Happy Valley near Linton. and Piggoreet. Yohann was a miner and died in the All Nations Mine collapse at Derwnt Jack's in 1877. Interesting to note in the following information that the Hanlon Consol mamager, William Maughan was also the manager of the Try Again Mine in Piggoreet. He was also on the six man school committee of Piggoreet Common School No. 726. (Is this why George Yung ended up working in Rokewood because of a previous connection at Piggoreet? George married Clara Emma Smith from Happy Valley and worked in a mine at Allendale. They later moved to Yendon) About the Hanlon gold mining company near Rokewood. 1901 - Information Bendigo Prospecting Club, 21/08/2020. Information provided once again by Peter McCarthy. Christopher Hanlon had put down a line of bores south of the Rokewood main street, looking for a continuation of the Break O’Day lead which had been worked for two or three miles with highly payable results, though in a primitive manner. Ground was being paddocked 30 feet deep and made to pay. The bores suggested the sinking would be about 70 feet and a shaft site was selected at the back of Stanbrook’s Hotel. The Hanlon Gold Mining Company was formed in March 1895 and the shaft was bottomed at 68 feet, getting just over an ounce of gold from the shaft bottom. By January 1896, the poppet heads were up, and steam plant was nearly ready. The mine produced 846 oz by September, which was not as good as expected, but they installed a second puddling machine. The mine was profitable for the next three years, with periods of prospecting and the need to install steam pumps in 1897. A second shaft was sunk in 1899, which bottomed at 86 feet on good wash and was sunk on to 109 feet. 1743 oz of gold had been produced in six months to September 1899, but the No1 shaft was let on tribute as the No2 workings were opened and machinery installed the following year. The No1 shaft tributors broke even in 1900 and in 1901 the shaft was shut down, with the No1 shaft machinery sold late in 1902. By September 1901, the mine had produced gold worth £66,124 and the No2 shaft main drive was in 346 feet, with gold being found mainly in crevices in the hard floor. Mining continued, but once the No2 shaft workings met up with the old No1 shaft workings at the end of 1902 there was not much wash remaining. The mine was let on tribute in June 1903 and a drive was put in to test deeper ground. The company was wound up in February 1904 and the plant sold. From what they discovered, the manager concluded that the mine sat at the edge of an ancient coastline and the gold was in a beach deposit. The total gold production from the mine was worth £73,294. J Lee Archer JP, shareholder, was the manager of the Bank of Victoria in Ballarat. Born in Tasmania, he came to Victoria with his parents and first came to Ballarat in 1855 as a junior clerk with the bank. He died in 1902 aged 64. Alexander J. Peacock was a legal manager and a share broker. In 1897 Peacock, born in Creswick, had been elected as one of the Victorian delegates to the Constitutional Convention which wrote the Australian Constitution. He later became a politician, state treasurer and three times state premier of Victoria and was knighted KCGM. He died in 1933 aged 72. William Maughan, director, was an English miner who came to Victoria in the 1850s and became a mine manager, managing the Try Again at Piggoreet, Ryan’s Freehold and the Madam Berry, among others. He died in Williamstown in 1915 aged 85. Sepia photographRhs front of photo: R. Millist Phto & Lanternist Geelong Verso (upside down): ONE SHIFT OF MINE HANDS HANLON CONSOLS MINE ROKEWOOD 1901 Grandfather Yung 1st on left rokewood, hanlon consols mine, shift of mine workers 1901, gold mines, george edgar godlip yung, william maughan -

Eltham District Historical Society Inc

Eltham District Historical Society IncFilm - Video (VHS), Jenni Mitchell, Demolition of the Shire of Eltham Offices, 1996

Poor video quality (noise and interference), incomplete and unedited raw footage. A video documenting the demolition of the Shire of Eltham offices at 895 Main Road Eltham under the direction of the Commissioners appointed for the new Shire of Nillumbik and some of the communities activities surrounding the event. The building was demolished exactly 25 years after the southern wing housing Engineering and Planning on the upper level and the Eltham Library on the ground level was opened in celebration of the Shire of Eltham's centenary. Video has lots of distortion and noise, and sections of clips dubbed over. Immediate initial footage of Jenni Mitchell talking about asbestos claims in the Shire Offices (Sigmund Jorgensen standing behind her) advising Council did a review of the building several years previously and had been cleared of health problems. Cuts to group of people standing outside front door of offices but possibly voice dub over not related ? Then the date 27 Jul 1996 on a scene flashes on screen immediately followed by an edited clip intro of title and credits with classical music track. It then opens with Jenni Mitchell driving to the Shire Offices on Saturday 27 July 1996 at 11.00am. Footage of Main Road past Pitt Street, Alistair Knox Park then entering Shire Office driveway which is fenced off and contractor signs hanging up. Scenes at rear of building showing some internal demolition has commenced. View of the Administration wing. More clips of road driving, Alistair Knox Park, Eltham Library and visitor car park for Shire Offices. Cuts to a group of people standing in access to visitor carpark with new Eltham Library in background, one being immediate former Shire of Eltham President, John Graves. Scenes of people looking through chain link fence and security guard checking front door. John Graves being filmed that someone informed him the Shire was offering the building to the Community Health Centre for $2.3 million and that if they had been offered a price of $1.1 for what it apparently was sold for they would have snapped it up. View of truck loaded with brick rubble literally struggling to ascend the hill of Library Place to exit into Main Road. Cuts to a scene looking at Eltham War memorial Hall through the Memorial Gate, then the Shillinglaw trees and large banner sign ‘Delta Demolitions’ hanging on office façade. Views of front door, old library and bluestone wall. Scene (31 Jul 1996) filmed at night of several white crosses with “RIP Community” and “RIP Democracy”. Scene (1 August 1996) again driving along Main Road towards the Shire Offices then scenes of the offices showing substantially more demolition to exterior, groups of people standing on footpath outside watching, Delta heavy demolition machines, woman holding sign “Democracy where have you gone …”, the odd person in full protection gear and breathing apparatus hand carrying materials out to place on rubbish pile in front of people standing on footpath watching (with no protection) and then stamping on it to break it creating dust, security person in hard hat (no other protection) wandering around, many groups standing around watching, news film crew, person standing on roadside edge holding signs facing traffic stating “Pirate Planning” and “ Grant us your ears” also sign on back of parked car “Elthams High Jacks”, another sign “Community Democracy”, views of crosses in Main Road median strip “RIP Community”, groups of people on footpaths and reporters conducting interviews, footage of unknown person standing with Jenni Mitchell and Sigmund Jorgensen advising people have the right to protest, Jenni Mitchell urging people to ask questions of local MP and Council and Sigmund Jorgensen referring to the three historic Shillinglaw trees with demolition machinery operating in background, Jenni Mitchell and others installing more crosses in median strip; demolition machines operating inside and outside the building, more views of onlookers including Sigmund Jorgensen then Police approaching on footpath, workers and machinery continuing to operate, views of the old library being demolished, the former Community Services department, security personnel. Scene (2 August 1996) more heavy demolition machinery in operation smashing building up, people standing around southern wing watching, view overlooking Eltham Library of train pulling in to Eltham station. Scene (7 August 1996) more heavy demolition and people wandering around with only hard hat protection, no dust protection, comments from one operator dumping a bin of material stating “wait till there’s a Hungry Jack’s here, you’ll be laughing, fuel, videos, hamburgers. You’ll be up with the rest of the world soon, you’ll have electricity and everything here, ha ha ha ha”, more heavy machinery demolition and breaking up of materials, view of Hitachi train going by and Administration wing, view inside the front door opening of the staircase leading to upper level, person walking around operating heavy machinery with a hose spraying rubble (no protective gear other than hard hat interspersed with edit cuts of meeting of Commissioners and independent observers on panel as well as members of the community in public gallery. Nillumbik Shire CEO Barry Rochford addressing the meeting., Chief Commissioner Don Cordell directly addressing Jenni Mitchell with respect to permission to take photographs, Barry Rochford continues to address the question asked of Council about the valuation of the former Shire of Eltham Office building/site, public gallery calling out asking why was building demolished, what was the urgency. Scene (14 August 1996) views of southern wing, previous single demolition operator again mocking people filming, operators working in and around building, Shillinglaw trees and largely demolished front, heavy demolition equipment at work, piles of building rubble, hose spraying water over rubble, large trucks arriving for rubble removal and loading of truck. Scene (21 August) more of the same, building virtually down, Shillinglaw trees standing tall and alone, water spraying on rubble and wattle in bloom. Cuts to Council meeting with public onlookers. Barry Rochford walks out, Wayne Phillips addresses meeting explaining one or two people shouting, members of the community challenging Council (Commissioners) about why due process appear to have been subverted. Former Shire President Robert Marshall in public audience, cuts back to Shire office carpark entrance site and sign hung on fence in front of library “Think Again!” and people standing around observing awaiting a protest demonstration erecting a large sign on stilts stating “Shell No!”, people singing a revised version of God Save the Queen (God Save Us All), Sigmund Jorgensen in attendance, Jenni Mitchell, Sigmund Jorgenson and others address the protest crowd, followed by people mingling, music being played then people standing around the cleared site circumference all with arms linked (video very broken up with noise) then chants “Save the Gateway” and “No Shell for Eltham” and more music and singing “Put up a parking lot”. The crowd then proceeds to walk along the footpath of Main Road. Scene (15 Sep 1996) meeting at Montsalvat in Great Hall addressed by Sigmund Jorgensen discussing a recently published list of the Commissioner’s to senior Council Officers of banned Nillumbik people, others encouraging people to view proposed plans for the site and lodge objections. Specific issues regarding asbestos claims are also addressed. Harry Gilham addresses the meeting on the subject of the Eltham War Memorial and Memorial Gardens and how Council believe a roundabout in the vicinity is of greater importance. Views of various artworks on display (for auction) and music performance in the Barn Gallery. Meeting addressed by Sigmund Jorgensen discussing an appeal against Council granting a permit to Dallas Howgate to develop the site and that the Minister has called the matter in to be decided by the governing council. This is followed by an auction of paintings. 0.05 - Jenni Mitchel, Sigmund Jorgensen and Peter Doughtery in background. 0.18 - Jock Kyme in front of building – David Essex, Marg Johnson on his left-hand side. 5.34 - John Graves – ex Shire of Eltham Councillor and President. 9.02 - Unknown person being interviewed. 9.30 - Jenni Mitchell, unknown person, Mark Burns, community activist. 10.04 - Sigmund Jorgenson, Jenni Mitchell. 12.04 - Police members 21.33 - Nillumbik Council offices 7 August 1996 Barry Rochford CEO, Vin Heffernan Commissioner, Don Cordell Chief Commissioner, Kevin Abbott Commissioner, unknown person. 28.00 - Barry Rochford CEO 28.05 - Kahn Frankie - in commissioner’s seat after commissioners and council staff have vacated the council chamber. 28.26 - Wayne Phillips, State Liberal member for Eltham, addressing community in response to questions. 28.36 - Mark Burns, community activist addressing gallery. 28.48 - Ken Hines, ex Shire of Eltham Councillor and President. 29.34 - Ken Hines, ex Shire of Eltham Councillor and President standing, Robert Marshall, ex Shire of Eltham Councillor and President seated in front. 29.41 - Karen Gerhards, community activist. 30.06 - Marg Johnson with loud hailer, next to Jock Kyme, community activist. 31.32 - Marg Johnson with possibly Frank Burgoyne?, Sigmund Jorgensen, Jock Kyme. 35.35 - Harry Gilham at meeting at Montsalvat on 15 September 1996. 35.43 - Sigmund Jorgenson at lectern. 36.42 - Marg Jennings. 37.47 - Mark McDonald, Jim Connor, ex Shire of Eltham Councillor in background. 36.28 - John Cohen, ex Shire of Eltham Councillor and President. 38.56 - Ken Hines, ex Shire of Eltham Councillor and President. 41.11 - Harry Gilham, president of the Eltham District Historical Society. 43.55 - Sigmund Jorgensen in Long Gallery at Montsalvat, at start of the art auction to raise funds for community action. 45.50 - Unknown person conducting art auction. VHS Video cassette (poor quality) Converted to MP4 file format 45:01, 535MBvideo recording, 895 main road, alistair knox park, artworks, auction, barn gallery, barry rochford, community health centre, dallas howgate, delta demolitions, demolition, don cordell, eltham, eltham library, eltham shire office, eltham war memorial, eltham war memorial gate, eltham war memorial hall, great hall, harry gilham, jenni mitchell, john graves, library place, main road, memorial gardens, mervyn hannan, montsalvat, pitt street, protest, robert marshall, roundabout, shell oil, shillinglaw trees, sigmund jorgensen, sign, wayne phillips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1922

In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Sewing machine, treadle operated, "Branded Premier" 5-7-9-2-0-0-" Serial Number Y6243048 (denotes 1922 year of manufacture) flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand operated, dressmaking, textile machinery, portable, premier sewing machine, premier, singer treadle sewing machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1907 -1920 (see note section this document for further information regards model identification)

In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Singer sewing machine treadle type wooden stand with six drawers plus instruction manual Lotus decoration to machinewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing-machine, clothes repair, singer sewing machine -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, Jelbart Barn, 93 Arthur Street, Eltham, 11 November 2006

Situated at the top of the hill in Arthur Street, the former Jelbart residence and barn were part of a major change that transformed Eltham's character in the late 1960s. Built from the mid 1940s through mid 1950s when Eltham was a rural community, the Jelbrat residence and barn are all that remain of a family property of some 250 acres (100 ha). With growing population pressures, in the late 1960s, owners Ron and Yvonne Jelbart decided to subdivide their property creating the Woodridge Estate in the early 1970s, a major factor towards the transformation of Eltham to the suburb it is today. The Jelbarts had moved to Eltham in the early 1940s when they purchased a poultry farm in New Street, now Lavendar Park Road. (The local Black Friday bushire of January 13, 1939 had started at C.A. (Clarrie) Hurst’s Eltham Poultry Farm and Hatchery in New Street.) Jelbart was primarily a businessman importing office machinery but desired farm beef and dairy cattle so the couple purchased the virgin bushland at what was then at the end of a dirt road, Arthur Street. With post war shortages of most building materials, they followed the example of the Eltham Artists' Colony (later called Montsalvat) and built thier home from mud-bricks and recyclked materials. The barn was first to be completed in 1945 which they made their home whilst building the main residence. It took eight years to complete the two buildings. Both the main residence and the barn are now separate homes, and along with the remaining property being sub-divided further in 1998 are now part of the Kinloch Gardens Estate at 93 Arthur Street. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p139This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, eltham, arthur street, jelbart barn, jelbart home, kinloch gardens -

Federation University Historical Collection

Federation University Historical CollectionDocument, Indenture Between Robert M. Serjeant, Joseph Flude and the Trustees of the Ballarat School of Mines regarding Letters of Patents for the Benefit of the Ballarat School of Mines, 1877, 04/03/1875

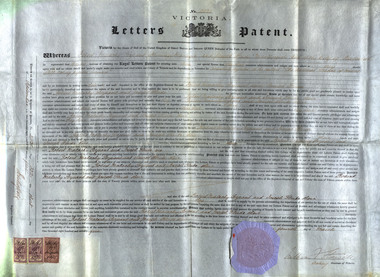

R.M. Serjeant was listed as a mining manager and Joseph Flude as a metallurgist. In 1875 they were both living in Ballarat. The patent number is A.D.1875, 4th March. No 2031. According to the patent the hearth of the furnace is in the form of a cone revolving horizontally. The feed is supplied to the apex of the cone by an archimedian screw. The crown of the furnace comprises a double covering or roof with an intermediate chamber for receiving heated air. The inner covering is pierced to admit of the heated air being brought into contact with the pyrites on the face of the revolving hearth. The discharge of the roasted substance is affected by means of a scraper at the base of the cone. It was claimed that this was a new mode of introducing heated air, and the exclusion of flame during the operation of roasting pyrites. The self-acting charge and discharge of the furnace and the peculiar construction of the hot air chambers, and the use of perforated bricks through which the supply of air is affected were also new. (http://patentsvictoria.net/002031.html) From the Goulburn Herald, 14 September 1878 "A feature connected with the school of mines is the yet unfinished pyrites works. The extraction of the gold from pyrites and the utilization for commercial purposes of other substances connected with pyrites are peculiarly important to Ballarat, because were a simple and inexpensive method devised there are millions and millions of tons of quartz that would then be made remunerative. With this thought in their minds two scientific gentlemen invented the school of mines self-acting rotatory furnace. This, for lack of funds, has not been completed as yet, but the amount in hand for the purpose is daily increasing, and it will eventually be an accomplished fact. It is in contemplation also to erect machinery shops in connection with the school, and it is purposed to con struct a steam-engine to do at once the work of the pyrites treatment and the ma chine room. A model shaft and mine too are being prepared for on the reserve, so that practical mining of the most thorough character may be taught on the ground.'Large indenture on red bordered vellum. The indenture was regarding a patent for the benefit of the Ballarat School of Mines. Letters Patent for an Invention for Roasting Pyrites to be called 'the Ballarat School of Mines self-Acting Pyrites Furnace" to Robery Malachy Serjeant and Joseph Flude. The large document is on a vellum type paper complete with stamps and seal. The document is signed by Acting-Governor William Stawell. Inscriptions and Markings Written on verso: "Date of Patent 4th March 1875 No 2031 Letters Patent for An invention for roasting pyrities to be called "The Ballarat School of Mines Self-acting Pyrities Furnace" to Robert Malachy Serjeant and Joseph Flude Melbourne, Victoriaballarat school of mines, serjeant, r.m. serjeant, robert m. serjeant, flude, joseph flude, patent, barry, redmond barry, rogers, judge rogers, bland, rivett henry bland, john airy, warrington rogers, establishment, indenture, legal, cuthbert, ballarat school of mines trustees, william stawell, john warrington rogers -

Federation University Historical Collection

Federation University Historical CollectionDocument, Letters Patent for an Invention for Roasting Pyrites, 1875, 1875

R.M. Serjeant was listed as a mining manager and Joseph Flude as a metallurgist. In 1875 they were both living in Ballarat. The patent number is A.D.1875, 4th March. No 2031. According to the patent the hearth of the furnace is in the form of a cone revolving horizontally. The feed is supplied to the apex of the cone by an archimedian screw. The crown of the furnace comprises a double covering or roof with an intermediate chamber for receiving heated air. The inner covering is pierced to admit of the heated air being brought into contact with the pyrites on the face of the revolving hearth. The discharge of the roasted substance is affected by means of a scraper at the base of the cone. It was claimed that this was a new mode of introducing heated air, and the exclusion of flame during the operation of roasting pyrites. The self-acting charge and discharge of the furnace and the peculiar construction of the hot air chambers, and the use of perforated bricks through which the supply of air is affected were also new. (http://patentsvictoria.net/002031.html) From the Goulburn Herald, 14 September 1878 "A feature connected with the school of mines is the yet unfinished pyrites works. The extraction of the gold from pyrites and the utilization for commercial purposes of other substances connected with pyrites are peculiarly important to Ballarat, because were a simple and inexpensive method devised there are millions and millions of tons of quartz that would then be made remunerative. With this thought in their minds two scientific gentlemen invented the school of mines self-acting rotatory furnace. This, for lack of funds, has not been completed as yet, but the amount in hand for the purpose is daily increasing, and it will eventually be an accomplished fact. It is in contemplation also to erect machinery shops in connection with the school, and it is purposed to con struct a steam-engine to do at once the work of the pyrites treatment and the ma chine room. A model shaft and mine too are being prepared for on the reserve, so that practical mining of the most thorough character may be taught on the ground.'Letters Patent for an Invention for Roasting Pyrites to be called 'the Ballarat School of Mines Self-Acting Pyrites Furnace' to Robert Malachy Serjeant and Joseph Flude. The large document is on a vellum type paper complete with stamps and seal. The document is signed by Acting-Governor William Stawell.Written on verso: "Date of Patent 4th March 1875 No 2031 Letters Patent for An invention for roasting pyrities to be called "The Ballarat School of Mines Self-acting Pyrities Furnace" to Robert Malachy Serjeant and Joseph Flude Melbourne, Victoriaballarat school of mines, serjeant, r.m. serjeant, robert m. serjeant, flude, joseph flude, richard gibbs, stawell, william stawell, pyrities furnace, philately, statute stamp, seal (victoria), ballarat school of mines self-acting pyrities furnace, ballarat school of mines self-acting pyrites furnace -

Wodonga & District Historical Society Inc

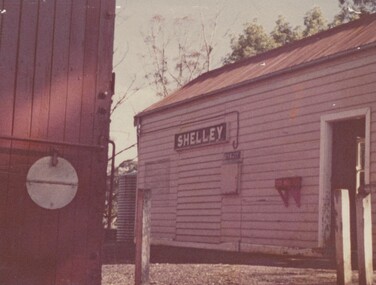

Wodonga & District Historical Society IncPhotograph - Fred Rochow Railways Collection - Shunting at Shelley Station, 1961

The Fred Rochow Railways Collection incorporates photos related to the operation of the Wodonga Railway Station including different types of trains and railways staff C. 1930 – 1990. It was donated to the Wodonga Historical Society by Fred Rochow, a railwayman who spent many years based in Wodonga. He joined the Victorian Railways on 17th June l947 and retired in 1988. For some time, he was a member of the Australian Federated Union of Locomotive Enginemen and served a term as a member of the Trades Hall Council. He had an extensive knowledge of the struggles that took place to achieve better conditions for railway workers. Fred worked for many years as a fireman and then worked his way up the ranks to driver, experiencing many changes from the days of steam locomotives through to diesel trains, locomotives and even the modern XPT train. He worked throughout Victoria at different stages of his career, with his final working years focused on the northeast of Victoria and the Albury to Melbourne line. After his retirement, Fred continued to share his love of steam miniature trains with the community. Shelley Railway Station - Shelley was once Victoria's highest railway station, located 781 metres above sea level. The Shelley Railway Station was opened in 1916 and closed in 1979. The railway was used early in its life to transport farmer’s livestock from the Upper Murray to Wodonga. From the 1950s the railway was used heavily to transport equipment and machinery from Wodonga to the Upper Murray to help build the Snowy Mountains Hydro Electric Scheme. The Snowy Hydro Scheme was completed in 1974 and after several years of low level use, the railway was closed. Some remnants of the Shelley Station passenger platform can still be seen today, along with some information boards. The Shelley Railway Station now forms part of the High Country Rail Trail.This collection has local and statewide significance as it captures images of trains, locomotives and personnel who operated the railway services in Wodonga and throughout Northeast Victoria. The railways played a critical role in opening up Victoria and connecting Australia for trade, business, social communication and transport.Left to Right: Fireman Bert Cadman, Driver Wally Riley, Guard Hugh Fraser. Locomotive S300 - the ‘Matthew Flinders’ The S class diesel locomotives were built by Clyde Engineering in 1957 for the Victorian Railways. Designed as premier express passenger diesels, they assumed the ‘S class’ title from a fleet of steam locomotives. They were also given names of famous Australians. The S300 took the name ‘Matthew Flinders’. In 1962, S300 was converted from the Victorian broad gauge of 5’3” to the New South Wales gauge of 4’8.5”, in order to operate the new Southern Aurora between Sydney & Melbourne. As the locomotive grew older it was removed from these duties and was sold to Chicago Freight Car Leasing Australia (CFCLA) in 2004. It is now owned by a private owner and is on loan to the Canberra Railway Museum.railways wodonga, fred rochow, wodonga railwaymen, s class locomotive -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Fred Rochow Railways Collection - Shelley Station

The Fred Rochow Railways Collection incorporates photos related to the operation of the Wodonga Railway Station including different types of trains and railways staff C. 1930 – 1990. It was donated to the Wodonga Historical Society by Fred Rochow, a railwayman who spent many years based in Wodonga. He joined the Victorian Railways on 17th June l947 and retired in 1988. For some time, he was a member of the Australian Federated Union of Locomotive Enginemen and served a term as a member of the Trades Hall Council. He had an extensive knowledge of the struggles that took place to achieve better conditions for railway workers. Fred worked for many years as a fireman and then worked his way up the ranks to driver, experiencing many changes from the days of steam locomotives through to diesel trains, locomotives and even the modern XPT train. He worked throughout Victoria at different stages of his career, with his final working years focused on the northeast of Victoria and the Albury to Melbourne line. After his retirement, Fred continued to share his love of steam miniature trains with the community. Shelley Railway Station - Shelley was once Victoria's highest railway station, located 781 metres above sea level. The Shelley Railway Station was opened in 1916 and closed in 1979. The railway was used early in its life to transport farmer’s livestock from the Upper Murray to Wodonga. From the 1950s the railway was used heavily to transport equipment and machinery from Wodonga to the Upper Murray to help build the Snowy Mountains Hydro Electric Scheme. The Snowy Hydro Scheme was completed in 1974 and after several years of low level use, the railway was closed. Some remnants of the Shelley Station passenger platform can still be seen today, along with some information boards. The Shelley Railway Station now forms part of the High Country Rail Trail.This collection has local and statewide significance as it captures images of trains, locomotives and personnel who operated the railway services in Wodonga and throughout Northeast Victoria. The railways played a critical role in opening up Victoria and connecting Australia for trade, business, social communication and transport.Shelley Railway Station. This image shows the tank where the hand brakes were lifted. They were applied again at the "up" side of Koetong for about another 10 miles then lifted near Bullioh.railways wodonga, fred rochow, shelley station, high country rail trail -

Bendigo Historical Society Inc.

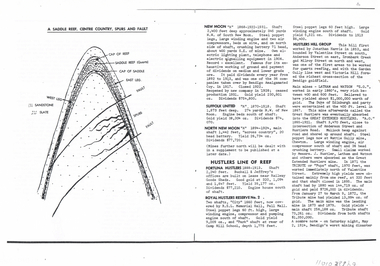

Bendigo Historical Society Inc.Document - LONG GULLY HISTORY GROUP COLLECTION: HUSTLERS LINE OF REEF

Page mentioning mines on the Hustlers Line of Reef. The are: Fortuna Hustlers, Royal Hustlers Reserve No 2 - City and Park Shafts, Great Hustlers, Latham, Watson, Great Extended Hustlers, Tribute or Pups Shaft, Bendigo's Worst Mining Disaster May 2 1914, Hustlers Reef (Old Hustlers) and Hustlers Reef No 1, Lansell's Comet Lightening Hill Line, The Old Comet (Cooper's Claim), United Hustlers and Redan, K K Shaft, North or New Hustlers (once known as Agnew Hustlers), Derby Line - Johnson's No 3, Paddy's Gully Line, Lansell's 'Sandhurst' (Needle), Needle Loops, Cleopatra Needle top, British American, Collman and Tacchi and South Virginia. Also mentioned is Total Gold Yield, Main Shafts on Field, Price of Gold (Old Currency) and Saddle Reefs and Spurs. Also mentioned are New Moon, Suffolk United, South New Moon and North New Moon. There is a diagram of a Saddle Reef, Centre Country, Spurs and Fault. Depth of shaft, machinery, location, dividends and yields are also mentioned. Price of Gold (Old Currency): 1851-1930, Price varied from Approx. £3/17/6 to £4 per ounce. 1938, from £6/19/10 to £7/8/10 per ounce. 1946/47/48 £10/15/3 per ounce, May 1, 1954 £15/12/6 per ounce.bendigo, history, long gully history group, the long gully history group - hustlers line of reef, fortuna hustlers, buckell & jeffrey's, railway goods sheds, rsl memorial hall, camp hill school, royal hustlers reserve no 2 - city and park shafts, jonathan harris, latham and watson, great hustlers, great extended hustlers, wattle gully mine, messrs j hustler latham and watson, tribute or pups shaft, bendigo's worst mining disaster, hustlers reef (old hustlers) and hustlers reef no 1, lansell's comet, the old comet (cooper's claim, united hustlers and redan, k k shaft, north or new hustlers (once known as agnew hustlers), derby line - johnson's no 3, pa ddy's gully line, lansell's 'sandhurst' (needle), needle loops, cleopatra needle top, british american, collman and tacchi, south virginia, saddle reefs and spurs, new moon, suffolk united, south new moon, north new moon -

Ballarat Tramway Museum

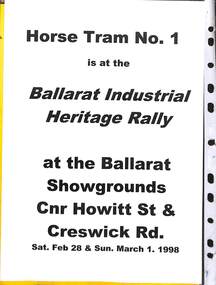

Ballarat Tramway MuseumMemorabilia - Event Materials, BEMPS, "Ballarat's Industrial Heritage Rally - Feb. 1998", 28/06/1998 12:00:00 AM

The following items are associated with the display of Horse Tram No. 1 at the Ballarat Engine and Machinery Preservation Society Rally at the Ballarat Showgrounds on Feb. 28 and Mar. 1, 1998. 807.1 - A4 sheet of paper, printed by BTM on 27/2/1998, advising the horse tram was on display at the showgrounds - used at the depot. 807.2 - A4 sheets of card, printed by BTM on 27/2/1998, advising people to take care when climbing the stairs, and please do not enter signs on reverse, tours on the hours and where queries could be made. Printed by laser printer on yellow card and contained within a plastic display folder. 807.3 - Three copies of the Rally brochure or flier, advertising the Rally at the Showgrounds. Printed mid 1997, on orange paper, phone numbers etc. 807.4 - A4 exhibit sheet for use on the Horse tram at the exhibition. Overprinted by BTM on 28/2/1998. 807.5 - Souvenir Programme - 28 pages plus heavy card covers, 32 pages in all, with index on page 3, list of exhibitors, Ballarat Foundries and Metal Manufacturers listings, Agricultural manufacturers, photographs, advertisements, with colour cover. 807.6 - cast brass rally badge - with organisers name cast on an oval shaped plaque with the words "Ballarat Industrial Heritage Rally" cast under and two figures, a farmer and an miner on either side. Has been stamped No. 64.trams, tramways, souvenir programmes, industrial heritage rally, ballarat manufacturers, ballarat showgrounds -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesBooklet, Michele Adler, Studies in Horticulture

Royalties from the sale of booklets donated to the Friends of Burnley GardensPlants in Print price labels on some of them. Display Copy Not for Sale on some of them.studies in horticulture, horticulture, t.a.f.e., rod mcmillan, michele adler, plant recognition, workplace requirements, industry requirements, workplace communication, peter esdale, workplace maintenance, peter sheppard, teamwork, soil characteristics, lanscape drawing, graphics, ken wallace, scott watson, ron barrow, operate tractors, operate machinery, ken james, work environment, john stanley, promotional program, oh & s procedures -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVice, 1800s

A wheelwright’s spoke vice was used to hold the wheel hub firmly while the spokes were hammered into the wheel hub, then the spokes would be joined to the wooden wheel felloe before finally the metal flat tyre, or later the rubber tyre, would be attached to the felloe. A wheelwright’s spoke vice would have been very necessary for blacksmiths circa 1800s-1920s as it would have been used in the manufacture and repair of carts, wagons, coaches and other horse-drawn vehicles. This wheelwright’s spoke vice was once used by Harry Goodall of H. Goodall & Sons Pty. Ltd. corner of McKinnon and High Streets, Terang. Victoria. Henry Goodall & Sons Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The wheelwright’s spoke vice is significant as it demonstrates how blacksmiths or wheelwrights could make new metal rims for wagon wheels for carts, wagons, stage coaches and carriages over a 135 years ago. The machine is a part of our social history as it demonstrates part of the process of making wagon wheels, which played an important part in aiding the continuation of daily transport needs that people had at the time, such as farming, personal transport and commercial activities. The tool is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. Vice; wheelwright’s wheel spoke vice. Manufactured in 1800s. This was once belonged to Harry Goodall & Sons, blacksmith's of Terang. Victoria.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, machinery, wagon wheel, steel rim wheels, henry goodall (1870-1936), terang, wheelwright tool, blacksmith trade, blacksmithing equipment and supplies, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, wheel hub, wheel spoke, wheel felloe, wheel tyre, wheel tire -

Puffing Billy Railway

Puffing Billy RailwayFunctional object - Billabong Ram Pump Size #5, Unknown

Pump - Billabong Ram Pump Size #5 Based on available historical data, the Australian-made Billabong Hydraulic Ram is one of the oldest rams produced anywhere in the world The Billabong Hydraulic Ram was first introduced into Australia in 1855 by John Danks and Son Limited, John Danks & Son Pty Ltd began as a plumbing business in 1859, established by brothers John and Samuel. It occupied a prominent site in Bourke Street, Melbourne, for 100 years. The business quickly grew to include factories in Melbourne and Sydney which manufactured and supplied a variety of plumbing and engineering products such as brassware, pumps, windmills and bells. The company was registered in Victoria on 25 January 1889 to continue the hardware manufacturing and supply business founded by brothers John and Samuel Danks in 1859. The head office was based in Bourke Street, Melbourne while another branch was established in Sydney in the 1880s. The company had factories in Melbourne and Sydney. The John Danks and Son Limited catalogue published in 1890, listing Billabong Hydraulic Rams as one of its major machinery products. The catalogue also provides reference to the company’s ram experience and manufacture, beginning by stating that in 1890 they already had 35 years of experience with Billabong Hydraulic Rams. The Hydraulic Ram has stood the test of time and it remains one of the few really practical and efficient uses of natural energy today. It operates without almost any cost, will last indefinitely and, with only two moving parts, is simplicity itself. It requires minimum maintenance and minimum replacement of parts. It is not uncommon to find rams working continuously for many years without any attention. • The Rams do not require electricity, fuel or steam to operate. • They possess simplicity of construction and operation – only 2 moving parts. • Powered only by running water. • Require very minimal or almost no maintenance. • Heavy duty cast Iron base and Dome. This Pump recovered from the Clematis Creek in the Mid 1970's Used to pump water from the creek to the Paradise (Clematis) Hotel. Historic - Farm Equipment - Used to pump water from the creek to the Paradise (Clematis) Hotel.Cast Iron Bronze valveBillabong 5billabong, puffing billy, ram pump -

Puffing Billy Railway

Puffing Billy RailwaySteam Engine - Tangye single cylinder vertical, Circa 1920

Used by the Malvern city council until 1969 to drive a rock crushing plant. While large horizontal steam engines predominated in major factories, small vertical steam engines like this were the workhorses of industries that had modest power requirements. This reliable little engine, made by leading UK manufacturer Tangye Bros of Birmingham Steam engines had the advantage that any fuel could be used to fire their boilers, but they were less convenient and efficient than internal combustion engines, required operators with higher skill levels, and had lower power to weight ratios. Tangye Limited was founded in 1857 in Birmingham by businessman Richard Tangye (1833-1906) and his mechanic brothers James and Joseph; brothers Edward and George joined them later. Richard was born near Redruth in Cornwall and educated at the Friends School at Sidcot, Somerset, where he became a pupil-teacher. From there he moved to Birmingham to work as a clerk for an engineering firm. In 1856 he started a hardware factor and commission agent business in Birmingham whose customers were mainly Cornish mine-owners in the Redruth district. From 1858 Tangyes concentrated on the manufacture of machinery and secured the sole right to manufacture Weston's differential pulley block (object 2003/45/1). They established their Cornwall Works in the Birmingham suburb of Smethwick in 1864 and soon developed a huge range of products. It was stated that 'there are perhaps no other works in the kingdom so largely employed upon so great a variety of specialities as the Cornwall Works of Messrs Tangye Bros.' The Tangyes attracted creative people to work for them. They wrote: 'We are in a position to offer unusual facilities to Inventors for carrying out their patents.' Info about Tangye Bros of Birmingham from Powerhouse Museum https://ma.as/207954 Donated by Malvern City Council in 1969 Of Interest : The Vertical and Horizontal Tangye engines on display are of the design that won a Gold Medallion at the Paris Industrial Exhibition of 1878.Historic - Industrial Steam Engine Equipmentsingle cylinder vertical Steam Engine made of Cast Iron, (Painted)Tangye Birmingham Builder's number 2462tangye, vertical steam engine, steam engine, puffing billy, stone crushing, george and george, malvern -

Vision Australia

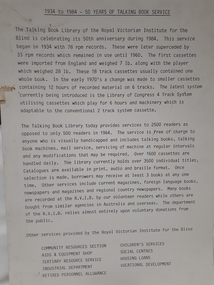

Vision AustraliaDocument - Image, 1934 - 1954 - 50 Years of Talking Book Service, 1984

The Talking Book Library of the Royal Victorian Institute for the Blind is celebrating its 50th anniversary during 1984. This service began in 1934 with 78 rpm records. These were later superceded by 33rpm records which remained in use until 1960. The first cassettes were imported from England and weighed 7 lb. along with the player which weighed 28 lb. These 18 track cassettes usually contained one whole book. In the early 1970's a change was made to smaller cassettes containing 12 hours of recorded material on 6 tracks. The latest system currently being introduced is the Library of Congress 4 Track System utilising cassettes which play for 6 hours and machinery which is adaptable to the conventional 2 track system cassette. The Talking Book Library today provides services to 2500 readers as opposed to only 500 in 1964. The service is free of charge to anyone who is visually handicapped and includes talking books, talking book machines, mail service, servicing of machines at regular intervals and any modifications that may be required. Over 1600 cassettes are handled daily. The library currently holds over 3500 individual titles. Catalogues are available in print, audio and braille format. Once selection is made, borrowers may receive at least 3 books at any one time. Other services include current magazines, foreign language books, newspapers and magazines and regional country newspapers. Many books are recorded at the R.V.I.B. by our volunteer readers while others are bought from similar agencies in Australia and overseas. The department of the R.V.I.B. relies almost entirely on voluntary donations from the public. Other services provided by the Royal Victorian Institute for the Blind Community Resources Section, Aids & Equipment Shop, Tertiary Resource Service, Industrial Department, Retired Personnel Allowance, Children's Services, Social Services, Housing Loans, Vocational Development1 digital image of typewritten pageroyal victorian institute for the blind, talking books -

Ringwood and District Historical Society

Ringwood and District Historical SocietyDocument, Packet: Ringwood Coolstore Cuttings, Historical Notes, Equipment Sale, Rule Book. 1911-1959

Miscellaneous documents relating to the Ringwood Coolstore and Horticultural Society.Packet includes: . 3793(f): Hand written notes on the development of Ringwood Cool Stores in the early 1900's. . 3793(h): Typed document titled 'Fruit Cool Storage Symposium' dated 1963, produced by the Department of Agricultue and the Orchardists and Fruit Cool Stores Association. . 3793(g): Hand written minutes and general notes of the Ringwood Horticultural Society meetings and Shows, from 1899 to 1902. . 3793(e): Small booklet- 'Rules of The Ringwood Co-operative Cool Stores Society Limited, 1934.' . 3793(b),(c),(d): Typed documents: 1. How to lay out a packing shed. 2. Notice of the Forty-third Ordinary General Meeting of The Ringwood Co-operative Cool Stores Society Limited held in the Ringwood Town Hall on 31st March, 1959. 3. Notice of Important Auction Sale of 'Cool Stores Machinery and Plant Buildings for Removal' on December 2nd, 1959. . 3793(a): 2 Newspaper articles by J. K. McCaskill, J.P. on the Early History of Parish of Ringwood and Official Opening of the Ringwood Cool Stores in 1911. (Mail 3/12/1950 and 10/12/1959). -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Personal Papers, Melbourne & Metropolitan Tramways Board (MMTB), 9 Acts of the Victorian Parliament that involved the MMTB and other tramways, 1930's

Book - dark green card stippled cover, bound with 9 Acts of the Victorian Parliament that involved the MMTB and other tramways. Acts have been sewn into the book with glued end papers. Contains the following Acts: 1. - Act 2920 - Purchase of Goods and Machinery of Materials for Works undertaken or on behalf of certain local authorities - 22/10/1917 - bound all the Trusts and other authorities to purchase items made in the Commonwealth over 250 pounds unless certified by the Minister. 2 - Act 2995 - Melbourne and Metropolitan Tramways Act 1918 - set up the MMTB - 7/1/1919 3 - Act 3074 - Act to amend the above Act - 28/9/1920 4 - Act 3023 - ditto - 16/12/1919 5 - Act 3243 - construction by the MMTB of an electric tramway from Melbourne to West Brunswick - 21/12/1922. 6 - Act 3247 - relating to the works and undertakings of The North Melbourne Electric Tramways and Lighting Company Limited in the Municipal District of the City of Melbourne and the City of Essendon - 21/12/1922 7 - Act 3308 - Act to amend the MMTB Act - 18/12/1923 8 - Act 3367 - ditto - 15/12/1924 9 - Act 3583 - authorise the construction by the MMTB of an Electric Tramway in Racecourse Road, Melbourne - 21/8/1928 Unknown who made the book - made for an MMTB officer. Binds the original Act's printed by the various Government Printers at the time. See also Reg Item 2121 for other Acts associated with the MMTB.Inside front cover on first page in ink "Mr. J. Cass" and in other locations as well.trams, tramways, tramways, acts of parliament, mmtb, nmetl, west coburg, construction, racecourse rd -

Federation University Historical Collection

Federation University Historical CollectionLetter, Ballarat School of Mines, 1908, 1908

October inwards correspondence for the Ballarat School of Mines. * School of Mines and Industries, Bendigo (certification of Mine Managers) * Telegram - examination papers * Commonwealth telegram - Ballarat School of Mines battery availability for crushing ten tons. * Letterhead from the Roneo Co., Melbourne * J. Donald of Wallace St, Toorak * Letterhead from York Chambers, 49 Queen Street, Melbourne - signed J. Kaufmann * Letterhead from Cochran & Co - re Cocnran boilers * Letterhead of Thames School of Mines, New Zealand * Letter re James Chambers missing school from his father James Chambers Snr of Talbot * Education Department Circular * letter signed by F.W. Calaby * F.W. Silberberg & Co re crucibles * Letterhead of New Black Horse Mining Company - signed E. Howell * Australasian Institute of Mining Engineers, 57-59 Swanston Street, Melbourne - signed D.L. Stirling * Letterhead of John F. Paterson * Letterhead of the Welcome Stranger Dredging Company, Dunolly - W.J. Parker manager * Letterhead of Nevett and Nevett Barristers and Solicitors, Lydiard Street, Ballaarat * John Barker, H. Barbour * Telegram re Brearley Lyndhurst * Letterhead of the Commonwealth Minerals Co - John F. Paterson, Legal Manager * Query re courses at the Ballarat School of Mines - A. O'Mara * Stone to be crushed, Egerton from J.H. Davidson * Letterhead from 'Terascoa' Port Kembla signed by W.S. Macartney * Letter from Thomas Williams * Letterhead from Australian Institute of Mining Engineers regarding excursion to Toongabbie and Walhalla - Signed D.L. Stirling * Assay from George Brearley of Lyndhurst via Scottsdale * Letterhead of Berry United Deep Leads Limited, Ulina * Embossed leather classes for coachwork from S. Mee of Clunes * The Lord Nelson North Gold Mning Company No Liability signed by Edward H. Shackell * Correspondence from May Consolidated Gold Mining Company, Transvaal signed by Jason Hawthorne * Letterhead of the Northern Assurance Company, 448 Collins St, Melbourne * Letter fom James Lidgett of "Braelands" Myrniong * Gordon sides asking for a reference * Letterhead of Fraser & Chalmers Ltd, Manufacturersw of mining machinery, steam engines, boilers and machinery for systematic milling, smelting and concentration of ores, signed by W.R. Caithness * Letterhead of the Board of Examiners for Engine-Drivers, signed by R. Birrell * Letter concerning outstanding amount due to theBallarat East School of Design, signed by Edward Reid, Manager * Letterhead of the Ballarat Public Library concerning an outstanding amount in the School of Design Account. * Letterhead of the A. Gallenkamp and Co. regarding their new catalogue * Letterhead from the Creswick Advertiser, Albert Street, Creswick * Handwritten letter from John Brittain inviting Ballarat School of Mines students to join him at the telescope weather permitting * Letterhead of Victorian Railways, signed by E.B. Jones * Letterhead of the Ballarat East Town Clerk's Office * Letterhead of Elliott, Maclean and Co. Handwritten letter re Dressmaking from J.H. Wrightrand, south africa, kalgoorlie, school of mines and industries, bendigo, certification of mine managers, bendigo school of mines, telegram, ballarat school of mines battery, roneo co., melbourne, j. donald, york chambers, cochran & co, thames school of mines, new zealand, james chamberseducation department circular, f.w. calaby, * f.w. silberberg & co, crucibles, new black horse mining company, e. howell, * australasian institute of mining engineers, john f. paterson, welcome stranger dredging company, dunolly, w.j. parker, nevett and nevett, john barker, h. barbour, brearley lyndhurst, commonwealth minerals co, a. o'mara, j.h. davidson, 'terascoa' port kembla, w.s. macartney, thomas williams, australasian institute of mining engineers, excursion, toongabbie, walhalla, d.l. stirling, george brearley, lyndhurst via scottsdale, berry united deep leads limited, ulina, embossed leather classes for coachwork, s. mee, clunes, the lord nelson north gold mning company no liability, edward h. shackell, may consolidated gold mining company, transvaal, jason hawthorne, northern assurance company, james lidgett, "braelands" myrniong, gordon sides, fraser & chalmers ltd, mining machinery, w.r. caithness, examiners, ballarat east school of design, edward reid, ballarat public library, school of design, a. gallenkamp and co., creswick advertiser, john brittain, telescope, victorian railways, e.b. jones, ballarat east town clerk's office, elliott, maclean and co., dressmaking, j.h. wright, ausimm, berry united, school of mines and industries bendigo, lyndhurst tasmania, may consolidated gold co germiston transvaal, transvaal, germiston, roneo, thames school of mines, schools of mines, welcome stranger dredging co, cowley copper development syndicate ltd, department of mines, maryborough school, pharmacy board of victoria, tongalla survey camp, ballarat fine art gallery association, central microscopical -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionDocument - Military Submission, John Ferres, Government Printer, Defences of the Colony, 1864

1864 group of 4 submissions bound in to one document. Heavy paper sewn together with twine, black print on white.portland battery, military, major scratchley, commodore wiseman, governor, john ferres -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, T & F Johnson, boilermakers, late 19th century