Showing 220 items

matching plant and machinery

-

Puffing Billy Railway

Puffing Billy RailwaySteam Engine - Tangye single cylinder vertical, Circa 1920

Used by the Malvern city council until 1969 to drive a rock crushing plant. While large horizontal steam engines predominated in major factories, small vertical steam engines like this were the workhorses of industries that had modest power requirements. This reliable little engine, made by leading UK manufacturer Tangye Bros of Birmingham Steam engines had the advantage that any fuel could be used to fire their boilers, but they were less convenient and efficient than internal combustion engines, required operators with higher skill levels, and had lower power to weight ratios. Tangye Limited was founded in 1857 in Birmingham by businessman Richard Tangye (1833-1906) and his mechanic brothers James and Joseph; brothers Edward and George joined them later. Richard was born near Redruth in Cornwall and educated at the Friends School at Sidcot, Somerset, where he became a pupil-teacher. From there he moved to Birmingham to work as a clerk for an engineering firm. In 1856 he started a hardware factor and commission agent business in Birmingham whose customers were mainly Cornish mine-owners in the Redruth district. From 1858 Tangyes concentrated on the manufacture of machinery and secured the sole right to manufacture Weston's differential pulley block (object 2003/45/1). They established their Cornwall Works in the Birmingham suburb of Smethwick in 1864 and soon developed a huge range of products. It was stated that 'there are perhaps no other works in the kingdom so largely employed upon so great a variety of specialities as the Cornwall Works of Messrs Tangye Bros.' The Tangyes attracted creative people to work for them. They wrote: 'We are in a position to offer unusual facilities to Inventors for carrying out their patents.' Info about Tangye Bros of Birmingham from Powerhouse Museum https://ma.as/207954 Donated by Malvern City Council in 1969 Of Interest : The Vertical and Horizontal Tangye engines on display are of the design that won a Gold Medallion at the Paris Industrial Exhibition of 1878.Historic - Industrial Steam Engine Equipmentsingle cylinder vertical Steam Engine made of Cast Iron, (Painted)Tangye Birmingham Builder's number 2462tangye, vertical steam engine, steam engine, puffing billy, stone crushing, george and george, malvern -

Eltham District Historical Society Inc

Eltham District Historical Society IncFilm - Video (VHS), Phil Burke et al, Shire of Eltham Grants Commsission Submission (Series 69, Item 7), 1993

Shire of Eltham Archives: Series 69, Item 7 Opens with aerial views of the Shire, 85% of the shire covered by the Green wedge principal. Discusses the obligations required of the Shire to maintain the Green Wedge. The Shire covers over 27,000 hectares with a population in excess of 45,000 residents, more than 70% living in the southern 10% of the Shire in suburbs of Eltham, Montmorency, Lower Plenty and Research. 85% of the Shire in the more sparsely populated northern area which is covered by the Green Wedge. Council is committed to providing a parity of services to all residents such as garbage collection and maintenance of roads. Views of rubbish collection trucks in Montmorency. It is emphasised that the cost of these services in highly populated areas is relatively low whereas in the sparsely populated Green Wedge areas, considerable. There are hundreds of kilometres of roads throughout the Shire, many unmade and maintenance is high to check overhanging trees and erosion especially on the steep hills is expensive and disproportionate to servicing the population in the dense urban areas. Shows views of hilly gravel roads and graders at work maintaining them. Shows scenes of assessing planning applications in these rural areas which takes significantly more time as well as other services provided such as Meals on Wheels, building permits, Ranger services. Provision of recreational facilities in hilly areas requires the acquisition of expensive river flats (views of cricket ground surrounded by hills) and where not possible, costly earthmoving required. Also, views highlighting extensive tracks of natural habitat home to significant bird, animal and plant life. Shire emphasises its commitment highlighted by the Eltham Copper Butterfly which the Shire maintains small pockets of bushland to ensure its survival at significant expense (views of Pauline Toner Copper Butterfly Reserve.) Short interview with Pat Vaughan, Environmental Officer for the Shire discussing the Eltham Copper Butterfly who also mentions many other species in the Shire of high significance from bats to mammals to plants as well as the importance of the Green Wedge to Melbourne – the lungs of Melbourne - and ensuring the protection of very important habitat which requires a great deal of planning and management to look after. Views of Wingrove Park to emphasise this maintenance by machinery in some areas is too damaging and introduced species, etc must be removed by hand. Balancing the services and facilities expected by the community with the needs of the environment requires careful planning demands requires careful planning and the principals of the Green Wedge require constant attention in the face of growing need for housing. Director of Planning & Environment, Richard Allen advises there are approximately 1,300 planning permits and development applications each year ranging from simple subdivision, boundary realignments to further complicated non-urban developments for agricultural pursuits and the level of expertise required from architectural and engineering to land degradation, flora and fauna. Video finishes with aerial views and parklands, streetscapes and rural areas. VHS Video cassette Converted to MP4 file format 00:07:39; 89MBshire of eltham, video recording, shire of eltham archives, eltham shire council, eltham, building permits, cricket ground, development applications, eltham copper butterfly, garbage collection, graders, green wedge, lower plenty, meals on wheels, montmorency, pat vaughan, pauline toner reserve, planning applications, planning permits, ranger services, recreational facilities, research, richard allen, roads, rural areas, wingrove park, victoria grants commission -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPhotograph - Black and white and colour slides, colour negative, Miscellaneous Horticulture, 1947-1985

57 slides and 1 negative. (1) "1947 Rolling the surface," in front of the newly constructed Administration Building. (2) "5-5-60 Same tree 7 months later-New Growth." (3) Men standing around a large horticultural machine. (4) "Lawns Housing Com" Aug "66?" (5) "Flemington Racecourse." (6) "Mustard-Cover Crop. 1960." (7) Tree climbing. (8) "Grafting-scions. BHC." (11) "Mildura-Soil Probe Oct 67." (12) Virus tested stock trees & layout Flemings Apr 70." (13) "Best's Winery Mar 75." (15, 16) Best's single student and group. (17) "Ploughing-Diagram to show incomplete cover of trash? Farm Practices." (18) "Spraying Hand Equipment for Insect Control in and around Buildings USA Yearbook 1952." (19) "Pasture Harrows." (20) "Mould Board Plough-Tractor." (21) "Disc Harrows-Offset-Tractor." (22) Tyne Cultivator-for Tractor." (23) See B91.258." (24) Burnley College libary. (25) "Irrigation-Delver Tatura 12/59." (26) "Tatura 12/59 Delver Ferguson T." (27) "Wilson's Prom? date." (28) "Wilson's Promontary Nov 1960 lunch." (29) "W. Prom." (30) Camp 1957 Wilson's Promontary." (31)" Longeronong Field Day 1964 Machinery Combination (Small)." (32, 33) "Longeronong Field Day 1964 Machinery Cultivating." (34-36) Photographs of plants in book. (35) Alnus? (37) "Meterosideros excelsa." (38) "Rhipsalidopsis rosea." (39) "Protea neriifolia." (40) Banksias-Species." Insects: (41) "Lacewing larva." (42) "Mites Aug 75." (43) "Yellow Mite, Red Spider (Arachnida)." (44) "Jassid-Life Cycle 9/51." (45) "Grape Fruit Crop (Florida) Destroyed by Fruit Fly. Animals without backbones." (46) "Jassid-Vegetable 9/51." (47) "Field Day 57 (Fruit Fly-Enlarged)." (48) "Field Day 57 (Fruit Fly-Stages)." (49) Insect Life Cycle. (50) "Comatibility (sic) Chart." for Insecticides & Fungicides. (51) "Insecticides-Toxicity." (52) "Life Cycle of the Leather Jacket." (53) "Grasshopper-Head Dissected Mouth Parts." (54) "Types of Antennae." (55) "Spider Mites USA Yearbook 1952." (56) "Cultivator." (57) "Organic Phosphates." (58) Negative Isopogon anemonifolius.administration building, lawns, flemington racecourse, mustard-cover crop, tree climbing, grafting, mildura, soil probe, pests, machinery, excursions, tatura, library, wilsons promontory, plants, alnus, zygocactus, schlumbergia, feijoa, acca sellowiana, protea neriifolia, banksia, isopogon anemonifolius -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionDocument - Military Submission, John Ferres, Government Printer, Defences of the Colony, 1864

1864 group of 4 submissions bound in to one document. Heavy paper sewn together with twine, black print on white.portland battery, military, major scratchley, commodore wiseman, governor, john ferres -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ship's Wheel, John Hastie et al, Early 20th Century

John Hastie Engineer and millwright John Hastie opened small manufacturing works in Greenock in 1845 and 1853 patented the first self-holding steering gear. The firm became known as John, Hastie and Co. Ltd. in 1898 after taking on limited liability status and their main works were at Kilblain Street, Greenock, where they specialised in ships' steering gear. The company also occupied works at Rue End Street, Greenock. Plans of this unit depict a stockyard to the east, with areas for welding; fitting and assembly; flame, cutting and fabrication; and a machine bay. The company was dissolved in 1991. Brown Brothers Brown Bros Rosebank Ironworks made the steering gears for many large ship's, including The Titanic. Andrew Betts Brown the founder was born in 1741 and closely associated with many improvements in marine engineering. He was educated in his native city and served his apprenticeship as an engineer in the locomotive works of the North British Railway Company at St. Margaret's. During his apprenticeship, he attended the evening classes at Watt College. subsequently going to Manchester to study chemistry. He went to London around 1863 and took over an old brewery, which he converted into an engineering works. During his time there he invented an overhead travelling crane, which was used on the construction of Blackfriars Bridge London. He went on to develop plant which used steam and hydraulic power for discharging ships as a result the company was contracted to install this equipment in Hamburg Docks. By around 1870 he continued to construct machinery in London but realised that conditions were more favourable in Edinburgh. He acquired land at Rosebank adjoining the North British Railway Company's line to Granton, and the necessary infrastructure was completed allowing him to finish the Hamburg contract. The works at Rosebank were eventually extended and added to until they became one of the largest engineering works in the East of Scotland. Mr Brown was a member of numerous engineering institutions, the best known at the time being the Institution of Naval Architects. He was also a Fellow of the Royal Society of Edinburgh, a member of the Institute of Mechanical Engineers and of the Institution of Marine Engineers he died in 1906 at the age of 67.An item made by two marine innovators of marine auxiliary machinery, equipment and itemsShip's wheel, brass, attached to brass pillar. The base has six holes in it for securing it in place. Top of the ship's wheel pillar has a brass, adjustable arrow pointer that is positioned over a dial etched into the flat brass surface. The dial reads " PORT STABD". Lines and degrees are marked, with '0' in centre and every 5 degrees, from 0-35, in both Port and Starboard sidesInscription to wheel hub "Brown Brothers & Co. Ltd, Rosebank Ironworks, Edinburgh"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, john hastie, john hastie, andrew betts brown, ships wheel, ship steering gear, marine equipment, instrument, navigation -

Puffing Billy Railway

Puffing Billy RailwayGreenbat Battery Loco, Greenwood & Batley ltd

Greenbat Battery Loco Built by Greenwood & Batley Ltd Builders No. 420363/2 This Greenbat Battery Loco has been loaned to the Museum by the Walhalla Goldfields Railway, who had acquired it in 2013 along with a large quantity of narrow gauge trollies and light rail from Orica’s now closed munitions factory in Melbourne’s western suburbs. The trolley on display was one of two in use from the 1970s. Orica - Deer Park Munitions factory Orica Deer Park in Melbourne’s west has been used since circa 1875 for various forms of manufacturing and storage of chemicals. Although the site is bounded by Ballarat Road, Station Street, Tilburn Road and the Western Ring Road, the current entry point for industrial operations is situated at Gate 6 off Tilburn Road. Operations include: • a specialty chemicals facility producing products for mining services operations • quarry services • other chemical manufacture activities. The Deer Park factory complex is of historical significance as the location of the first plant for the manufacture of high explosives in Australia and has been, for its entire history, the most important, if not only, commercial manufacturer of high explosives in Australia. It commenced operation under the importer Jones Scott and Co, and then the Australian Lithofracteur Company (Krebs Patent), a rival to Nobel's dynamite patent. The factory was producing nitro-glycerine based explosives in Australia only a couple of years after Nobel's Ardeer factory began operating in Scotland. The explosives factories complex is of historical significance for the association with the Australian Lithofracteur Company, Australian Explosives and Chemicals, the Nobel company and later ICIANZ, which grew to become one of the largest explosives, chemical and plastics manufacturers in Australia. It was the pioneer of the industry and retained its dominance through monopolistic practices, taking over most of its competitors in the Australasian region. Substantial parts of the pre-Second World War layout of the site remain which, with a number of significant buildings dating back to the 1920s and '30s, indicate past and present processes of manufacturing, the necessary safety measures required and the integrated nature of the explosives and chemical industry. The narrow gauge tramway, which ran through the explosives section, was a rare survivor of nineteenth century materials-handling methods into the 21st Century. Greenwood & Batley were a large engineering manufacturer with a wide range of products, including armaments, electrical engineering, and printing and milling machinery. They also produced a range of battery-electric railway locomotives under the brand name Greenbat. The works was in Armley, Leeds, UK. Greenbat was the trade name for the railway locomotives built by Greenwood & Batley. The company specialised in electric locomotives, particularly battery-powered types for use in mines and other hazardous environments. Historic - Industrial Narrow Gauge Railway - Battery Locomotive - Orica - Deer Park Munitions factory - Deep park, Victoria, Australia Battery Locomotive - made of iron puffing billy, greenbat battery loco, battery locomotive, industrial narrow gauge railway, orica - deer park munitions factory -

Bendigo Historical Society Inc.

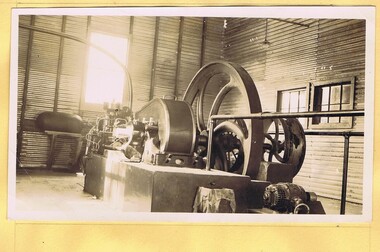

Bendigo Historical Society Inc.Photograph - MINING IN BENDIGO COLLECTION: MINING PHOTOGRAPHS

BHS CollectionFolded paper with copies of photos of mines and various mining buildings. On the front is a view from New Chum Hill, looking south in 1890's. Pictured is the Lazarus Crushing Plant and boiler house, Lansell's '222'. Amd the new Chum Mines in the background. On the inside at the top is the New Chum Railway, Golden Square. Pictured is the mine and its buildings, two chimneys, two large wood stacks and other mines in the background. On the left, a man is standing on the side of the railway line beside the mine. The next picture is the United Hustlers and Redan Mine, west of Comet Hill State School, Sandhurst Road. It shows the mine and its buildings, chimney, ore bins, mullock heap and tramway. The middle picture is the Central Deborah, Violet Street, near Bendigo Creek, Golden Square. It shows the poppet legs, buildings and some machinery behind the large building. The large building has eight ventilators in the roof. The buildings are made of corrugated iron. The bottom left picture is the Deborah Mine, Quarry Hill. The picture shows the poppet legs on the hilltop, the buildings beside it, a square chimney behind the poppet legs and some vegetation and a peppercorn tree in the foreground. The far building also has ventilators in the roof. The picture on the right is underground at 1000 feet level in the Deborah Mine. Pictured are three men with a rock drill. On the back, at the top is a picture of a First Motion Winding Engine at Deborah - later at Central Deborah. The picture shows the engine and driver. The middle picture is the South New Moon Mine, Eaglehawk - leading mine in State in 1903. The picture shows the poppet legs, buildings, chimney and a high tramway. In the foreground is a dam. The bottom picture is Victoria Hill looking south to New Chum Hill. In the foreground is Lansell's '180' Mine and Ballerstedt's Open Cut and in the background are the 'New Chum and Victoria', 'Old Chum' and the 'North Old Chum'.photo, mining in bendigo, mining photographs, lazarus crushing plant, lansell's 222, new chum mines, new chum railway, united hustlers and redan mine, comet hill state school, central deborah, deborah mine, first motion winding engine, south new moon mine, lansell's 180, ballerstedt's open cut, new chum and victoria, old chum, north old chum, square chimney -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pump, circa 1930's - 1940's

This pump is an Ajax Type L2 Series A model, made and sold by McPherson’s Pty Ltd of Melbourne circa 1930’s to 1940’s, is a mechanical, hand operated, constant flow pressure pump. It would have been used to pump fluids from one area to another, for example from a dam to a tank or used as a bilge pump on a small vessel, mounted on the vessel’s bulkhead, floor or deck. This type of hand pump is sometimes called a ‘Reciprocating Suction Pump’. It has a mechanical pumping action of the lever moves the piston inside the pump up and down. The water is lifted from below the pump through the inlet pipe and into the pump’s cylinder. This action causes the lower valve to close and the piston’s valve opens and the pressure within the pump forces the water out of the pump through the exit pipe. The limitation of this type of pump is that it can only raise the water a maximum of about 7 metres from beneath the ground and yields 24-26 Litres per minute. This type of pump could be used for many purposes such as pumping water or fuel. McPherson’s 1940’s advertisement proclaims “For all jobs on the land – irrigation, spraying, tank, plumbing, fire-fighting – there’s a suitable “Ajax” pump. Send us the details of you pumping problem. Our Expert’s advice will help you choose the right pump – the one that will give you most years of PROFITABLE PUMPING.” (The Australasian (Melbourne) Sat. 26th October 1940.) McPherson’s Pty Ltd, the manufacturer, advertised a similar pump to this one in The Australasian (Melbourne) in 1936, calling it the Ajax Double Acting Hand Pump. In 1942 another advertisement advised that a representative for a fire-fighting equipment supplier was visiting the western district of Victoria. The company could now supply double-action two-spray Ajax pumps at lower prices than similar pumps the district had recently purchased from Adelaide. McPHERSON’S FOUNDER and COMPANY TIMELINE 1860 – Thomas McPherson, a Scottish immigrant (c. 1853 ), founded McPherson’s in Melbourne, supplying pig iron (lead ingots imported as ballast in ships) to local manufacturers. 1882 – Thomas McPherson established a warehouse in Collins St Melbourne and included tools, steam fittings and machinery in his wares. The business expanded to include steam saw mills and became known as Thomas McPherson and Sons (William Murray and Edward). 1888 – Thomas passed away and his sons inherited the business. In 1896 William Murray became the sole proprietor after his brother Edward’s death. 1900 – The firm expanded, establishing Acme Bolt Company to manufacture nuts and bolts. 1912 – McPhersons Pty Ltd established a machinery warehouse and showroom in 554-556 Collins St Melbourne. McPherson’s went on to establish branches in Sydney (1911), Adelaide (1921) and Perth (1930) 1917 - McPherson’s supplied ‘dog spikes’ for the transcontinental railway, running from Eastern to Western Australia. 1918 – A tool works set up in Kensington, Melbourne, manufacturing Macson lathes and made machine tools that previously had to be imported. 1924 – The Bolt Works was transferred to a new building in Melbourne. McPhersons began making pumps. 1929 – McPherson retired. His son (Sir) William Edward McPherson (known as ‘WE’), was born in Hawthorne, Melbourne, in 1898. After his education he began work in his father’s Melbourne hardware and machinery business He took over as governing director when his father retired. 1929-1932 – McPherson’s supplied thousands of tons of rivets from its Richmond (Melbourne) Bolt Works for the construction of the Sydney Harbour Bridge. 1936 – McPherson’s Pty Ltd is advertising Ajax Pumps in newspapers 1934 – McPhersons purchased the property adjoining the warehouse in Collins Street, and during 1935-1936 built a new office and showrooms on the site of 546-445 Collins St. 1939 - McPherson’s acquired the Tool Equipment Co. Pty. Ltd and Associated Machine Tools Australia Pty Ltd was formed to separate McPherson’s machine-tool manufacturing and merchandising interests. 1939 – Ajax Pump Works, a foundry and pump manufacturing plant, was established in Tottenham, Melbourne, and the Ajax Bolt and Rivet Co Pty Ltd began manufacturing in New Zealand. 1944 - McPherson’s became a public company, McPherson’s Ltd. 1948 - The Ajax Pump Foundry opened at Kyneton, Victoria and in the post war years it grew to became a large manufacturer. 1980’s – Ajax Pumps brochure lists the address as 6 Buckhurst St, South Melbourne, Vic 3205 with the Telephone number 03 669 3588 1988 - Ajax Pumps acquired the Forrers Company, which was established in 1921. Manufacturing in Ipswich, Queensland, specialising in submersible sewage pumps. 1991 – KSB Ajax was formed, bringing together the companies KSB and Ajax Pumps 1993 – Manufacturing was moved to state-of-the-art premises in Tottenham, Victoria 2001 - The Forrers facility was moved to Tottenham. 2007 - Company name KSB Ajax Pumps was changed to KSB Australia Pty Ltd. 2009 - KSB Australia opened a branch in Townsville, Queensland. 2011 - KSB Australia moved to its dedicated Water and Waste Water Competence Centre in Bundamba, Queensland. DISPLAY OF THIS AJAX PUMP This pump was installed at Flagstaff Hill Maritime Village as part of a working display in the village by the Friends of Flagstaff Hill, in acknowledgement of the dedicated involvement of one of its long serving members, Bob Crossman. The display was officially opened 31st March 2018 and incorporates a restored Furphy Tank and Water Pipe Stand. The pump is used to draw water from the lake, through the water stand pipe and into the reconditioned Furphy Tank. This Ajax pump made by McPherson’s Pty Ltd is significant for its association with McPherson’s, a prominent manufacturer of hardware in Victoria. McPherson’s is famous for supplying ‘dog-spikes’ for the transcontinental railway (eastern to western Australia, 1917) and rivets for the Sydney Harbour Bridge (1929-1932). The Ajax pump is also of significance because of its association with McPherson’s Governing Director (Sir) William McPherson, former premier and treasurer in Victoria 1928-1929. The former McPherson’s Pty Ltd building in Collins Street Melbourne is now on the Victorian Heritage Register VHR H0942 This pump is representative of mechanical pumps popular in the early to mid-1900’s and still used today. Hand operated pressure pump, double acting. Cast metal case, painted red, with steel hose attachments and long metal lever. Pump is bolted to wooden plank. Model of pump is AJAX, Type L2, Series A pump. Embossed on lower section of pump "L2 - 10", "L2 - -1", "AJAX" “(?) –2-1” Embossed on lower handle “3-7” “L – 4” Embossed on attached plate “FOR SPARE PARTS / TYPE L2 / SERIES A / PUMP ASSEMBLED BY T R” Manufactured by McPherson’s Pty Ltd of Melbourne circa 1930’s - 1940’s.flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ajax pump works tottenham melbourne, ajax pump factory kyneton, william edward mcpherson, thomas mcpherson of melbourne, mcpherson’s pty ltd melbourne, acme bolt company, tool equipment co. pty. ltd, associated machine tools australia pty ltd, ajax bolt and rivet co. pty ltd new zealand, forrers company ipswich queensland, ksb ajax pumps, ksb australia pty ltd, macson lathes, tool manufacturer early to mid- 20th century, ajax double acting hand pump, ajax type l2 series a pump, qisjax pumps, water pump 1940’s, fuel pump 1940’s, hand operated constant flow pressure pump, reciprocating suction pump, agricultural hand pump, plumber’s hand pump, portable hand pump -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, Jelbart home, 93 Arthur Street, Eltham, 11 November 2006

Situated at the top of the hill in Arthur Street, the former Jelbart residence and barn were part of a major change that transformed Eltham's character in the late 1960s. Built from the mid 1940s through mid 1950s when Eltham was a rural community, the Jelbrat residence and barn are all that remain of a family property of some 250 acres (100 ha). With growing population pressures, in the late 1960s, owners Ron and Yvonne Jelbart decided to subdivide their property creating the Woodridge Estate in the early 1970s, a major factor towards the transformation of Eltham to the suburb it is today. The Jelbarts had moved to Eltham in the early 1940s when they purchased a poultry farm in New Street, now Lavendar Park Road. (The local Black Friday bushire of January 13, 1939 had started at C.A. (Clarrie) Hurst’s Eltham Poultry Farm and Hatchery in New Street.) Jelbart was primarily a businessman importing office machinery but desired farm beef and dairy cattle so the couple purchased the virgin bushland at what was then at the end of a dirt road, Arthur Street. With post war shortages of most building materials, they followed the example of the Eltham Artists' Colony (later called Montsalvat) and built thier home from mud-bricks and recyclked materials. The barn was first to be completed in 1945 which they made their home whilst building the main residence. It took eight years to complete the two buildings. Both the main residence and the barn are now separate homes, and along with the remaining property being sub-divided further in 1998 are now part of the Kinloch Gardens Estate at 93 Arthur Street. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p139 Standing on a hilltop at Arthur Street, Eltham, the Jelbart residence and former barn were part of a major change that transformed Eltham’s character in the late 1960s. Built from the late 1940s to the mid 1950s when Eltham was a rural community, they are all that remain of what was once a family property of around 250 acres (100 ha). As population pressure increased in the late 1960s, owners Ron and Yvonne Jelbart, decided to subdivide their property. The break-up of this property into the Woodridge Estate in the early 1970s, was a major factor towards transforming Eltham into the suburb it is today.1 Although standing only a few minutes from Eltham’s busy hub and hundreds of houses in Woodridge, scarcely any urban sound disturbs the peace. Views from the two buildings are almost exclusively of trees and extend to Mt. Dandenong to the south-east, the Great Divide to the north, and Melbourne city to the south-west. The Jelbarts had lived in Eltham since the early 1940s when they bought a poultry farm in New Street, now Lavender Park Road. Although Jelbart was primarily a businessman importing office machinery, he was keen to farm dairy and beef cattle, so the couple bought rough bushland at what was then the end of Arthur Street. But a shortage of building materials following World War Two hampered their plans to build their new home, so they followed the example of the Eltham Artists’ Colony (later called Montsalvat) and used mud-bricks and recycled materials.2 With great determination the family and friends constructed their house. Massive timber frames and huge quantities of mud-bricks were made on site. The barn was built first in 1945, and two years later, while camping inside, the Jelbarts started building their house. It took eight years to construct the two buildings, even with the help of professional tradesmen. The buildings, with timber frames infilled with mud-brick and plastered, are reminiscent of the English Tudor style. The Jelbarts are of Cornish stock. Much of the timber framework came from demolished bridges or warehouses, and recycled slate was used for roofs and floors. Quality second-hand materials were readily available in the late 1940s and 1950s when there was much demolition in Melbourne and little respect for heritage. A former 19th century Toorak mansion Woorigoleen provided the magnificent stone fireplace, the timber panelling and the parquetry floor in the living room. The large stone gateposts at the entry of the property came from Melbourne University. Almost no mechanical equipment was used to build the 55 square house and the 25 square barn. Massive timber frames were erected using block and tackle pulleys and timbers were shaped, sawn and drilled by hand. Son and architect Ian, with his family, have lived in and extensively renovated both buildings since the early 1970s. Ian transformed the steep ridge of the property into a plateau, where the main house Kinloch stands, surrounded by terraces and lawns. The grounds retain many native plants, including massive yellow boxes – some nudging 80 years. Ian attached 70 metres of pergolas draped with wisteria, roses and grape vines, to three sides of the house. The beautiful garden is featured in the book Through the Rose Arbour by Rosemary Houseman. The two-storey barn – now a house – retains traces of its original use. The cow-shed with milking and feed-rooms, and the machinery-shed remain. The house, separated on the ground floor by a breeze-way, soars two storeys and includes a mezzanine. These are connected by spiral staircases, to timber-beamed and plaster-lined high-pitched ceilings. The house also descends to a wine cellar. Curiously the roof is of corrugated iron on the south and slate on the north, to save costs. Small-paned windows and three French doors open onto the front lawn, which extends to Jelbart Court.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, eltham, arthur street, jelbart barn, jelbart home, kinloch gardens -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1867-1870

Chauncey Jerome (1793–1868) was an American clock maker in the early to mid 19th century. He made a fortune selling his clocks, and his business grew quickly. Jerome was born in Canaan USA in 1793 son of a blacksmith and nail-maker. He began his career in Plymouth, making dials for long-case clocks where he learned all he could about clocks, particularly clock cases, and then went to New Jersey to make seven-foot cases for clocks mechanisms. In 1816 he went to work for Eli Terry making "Patent Shelf Clocks," learning how to make previously handmade cases using machinery. Deciding to go into business for himself, Jerome began to make cases, trading them to Terry for wooden movements. In 1822 Jerome moved his business to Bristol New Haven, opening a small shop with his brother Noble and began to produce a 30-hour and eight-day wooden clocks. By 1837 Jerome's company was selling more clocks than any of his competitors. A one-day wood-cased clock, which sold for six dollars had helped put the company on the map. A year later his company was selling that same clock for four dollars. The company also sold one line of clocks at a wholesale price of 75 cents and by 1841 the company was showing an annual profit of a whopping $35,000, primarily from the sale of its brass movements. In 1842 Jerome moved his clock-case manufacturing operation to St. John Street in New Haven. Three years later, following a fire that destroyed the Bristol plant, Jerome relocated the entire operation to Elm City factory. Enlarging the plant, the company soon became the largest industrial employer in the city, producing 150,000 clocks annually. In 1850 Jerome formed the Jerome Manufacturing Co. as a joint-stock company with Benedict & Burnham, brass manufacturers of Waterbury. In 1853 the company then became known as the New Haven Clock Co, producing 444,000 clocks and timepieces annually, then the largest clock maker in the world. Jerome's future should have been secure but in 1855 he bought out a failed Bridgeport clock company controlled by P.T. Barnum, which wiped him out financially, leaving the Jerome Manufacturing Co. bankrupt. Jerome never recovered from the loss. By his admission, he was a better inventor than a businessman. When Jerome went bankrupt in 1856 the New Haven Clock Company purchased the company. One of the primary benefits of Jerome purchasing New Haven in the first place was the good reputation of the Jerome brand and the network of companies that remained interested in selling its clocks. In England, Jerome & Co. Ltd. sold Jerome clocks for the New Haven company until 1904, when New Haven purchased the English firm outright. After his involvement with the New Haven Company in 1856, Jerome traveled from town to town, taking jobs where he could, often working for clock companies that had learned the business of clock making using Jerome's inventions. On returning to New Haven near the end of his life, he died, penniless, in 1868 at the age of 74. The company struggled on after Jerome's bankruptcy until after World War II, when the company endeavored to continue through disruptions caused by a takeover along with poor sales, finally having to fold its operations in 1960 a little more than 100 years after it had been founded. The item is significant as it is associated with Chauncey Jerome who had made a historic contribution to the clock making industry during the 19th century when he began to substitute brass mechanisms for wooden mechanisms in his clocks. This was said to be the greatest and most far-reaching contribution to the clock industry. Because of his discovery of stamping out clockwork gears rather than using castings, Jerome was producing the lowest-priced clocks in the world. That can only add to his significance as the major clock manufacture of the 19th century. Jerome may have made and lost, a fortune selling his clocks but was perhaps the most influential and creative person associated with the American clock business during the mid-19th century. Also, he had served his community as a legislator in 1834, a Presidential elector in 1852 and mayor of New Haven, Connecticut from 1854 to 1855.Eight day movement wall clock with Roman numerals, octagonal shaped rosewood veneered casing, hinged face with locking clip. Wound from front. Face has adjustment for Fast-to-Slow.Part paper label on back of case can just make out "Jerome" and "ight and One" probable meaning is "Eight and One Day" describing the movements operational time between winding the mechanism.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock maker, jerome & co, new haven, chauncey jerome, canaan -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1867-1870

Chauncey Jerome (1793–1868) was an American clock maker in the early to mid 19th century. He made a fortune selling his clocks, and his business grew quickly. Jerome was born in Canaan USA in 1793 son of a blacksmith and nail-maker. He began his career in Plymouth, making dials for long-case clocks where he learned all he could about clocks, particularly clock cases, and then went to New Jersey to make seven-foot cases for clocks mechanisms. In 1816 he went to work for Eli Terry making "Patent Shelf Clocks," learning how to make previously handmade cases using machinery. Deciding to go into business for himself, Jerome began to make cases, trading them to Terry for wooden movements. In 1822 Jerome moved his business to Bristol New Haven, opening a small shop with his brother Noble and began to produce a 30-hour and eight-day wooden clocks. By 1837 Jerome's company was selling more clocks than any of his competitors. A one-day wood-cased clock, which sold for six dollars had helped put the company on the map. A year later his company was selling that same clock for four dollars. The company also sold one line of clocks at a wholesale price of 75 cents and by 1841 the company was showing an annual profit of a whopping $35,000, primarily from the sale of its brass movements. In 1842 Jerome moved his clock-case manufacturing operation to St. John Street in New Haven. Three years later, following a fire that destroyed the Bristol plant, Jerome relocated the entire operation to Elm City factory. Enlarging the plant, the company soon became the largest industrial employer in the city, producing 150,000 clocks annually. In 1850 Jerome formed the Jerome Manufacturing Co. as a joint-stock company with Benedict & Burnham, brass manufacturers of Waterbury. In 1853 the company then became known as the New Haven Clock Co, producing 444,000 clocks and timepieces annually, then the largest clock maker in the world. Jerome's future should have been secure but in 1855 he bought out a failed Bridgeport clock company controlled by P.T. Barnum, which wiped him out financially, leaving the Jerome Manufacturing Co. bankrupt. Jerome never recovered from the loss. By his admission, he was a better inventor than a businessman. When Jerome went bankrupt in 1856 the New Haven Clock Company purchased the company. One of the primary benefits of Jerome purchasing New Haven in the first place was the good reputation of the Jerome brand and the network of companies that remained interested in selling its clocks. In England, Jerome & Co. Ltd. sold Jerome clocks for the New Haven company until 1904, when New Haven purchased the English firm outright. After his involvement with the New Haven Company in 1856, Jerome traveled from town to town, taking jobs where he could, often working for clock companies that had learned the business of clock making using Jerome's inventions. On returning to New Haven near the end of his life, he died, penniless, in 1868 at the age of 74. The company struggled on after Jerome's bankruptcy until after World War II, when the company endeavored to continue through disruptions caused by a takeover along with poor sales, finally having to fold its operations in 1960 a little more than 100 years after it had been founded. The item is significant as it is associated with Chauncey Jerome who had made a historic contribution to the clock making industry during the 19th century when he began to substitute brass mechanisms for wooden mechanisms in his clocks. This was said to be the greatest and most far-reaching contribution to the clock industry. Because of his discovery of stamping out clockwork gears rather than using castings, Jerome was producing the lowest-priced clocks in the world. That can only add to his significance as the major clock manufacture of the 19th century. Jerome may have made and lost, a fortune selling his clocks but was perhaps the most influential and creative person associated with the American clock business during the mid-19th century. Also, he had served his community as a legislator in 1834, a Presidential elector in 1852 and mayor of New Haven, Connecticut from 1854 to 1855.Clock, marine, in octagonal rosewood veneer case. Roman numerals to dial, has a seconds dial. 2 key-winding holes slow-to-Fast adjustment pin through dial. Small lever in lower edge of case activates a chime. "8 day, 8 inch, Lever Striking escarpment " Paper label on the back of the clock "Jerome & Co, New Haven, Conn" "Manufacturers of every variety of Office and Home Clocks and Time Pieces".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, jerome & co, new haven, clock maker, chauncey jerome -

Bendigo Historical Society Inc.

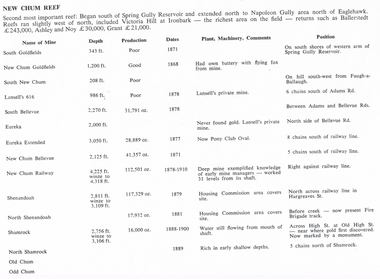

Bendigo Historical Society Inc.Document - LONG GULLY HISTORY GROUP COLLECTION: NEW CHUM REEF

Six pages titled New Chum Reef. No number on the first page, the others are 109 to 113. Mentions location of the reef and some of the rich mines. The mines are mentioned in a table with the Name of Mine; Depth; Production; Dates; Plant, Machinery, Comments and Position. Ballerstedt, Ashley and Noy, and Grant were three of the successful miners. Mines mentioned are: South Goldfields, New Chum Goldfields, South New Chum, Lansell's 616, South Bellevue, Eureka, Eureka Extended, New Chum Bellevue, New chum Railway, Shenandoah, North Shenandoah, Shamrock, Old Chum, Little Chum, Young Chum, Craven, Garibaldi, Ellesmere, South Old Chum, New Chum Consolidated, North Ellesmere, New Chum United, Lansell's 222, Lansell's Fortuna, Lazarus, West End, Pioneer, Old Chum, New Chum Victoria, North Old Chum, Lansell's Big 180, Sterry, Victoria Quartz, South Adventure, Great Central Victoria, Ballerstedt No 3, Adventure, Humbold, British and American, Midway, Victoria Consuls, Victoria absorbed by Ironbark, Hercules and Energetic, Victoria Pilot, North Hercules and Energetic, Great Extended Hercules, Pearl, Southern Victoria, Great Extended Victoria, Young Victoria, New Catherine Victoria, Weatern Victoria, New Victoria St Mungo, Surprise, Mystery, Duke of Edinburgh, New St Mungo, Duchess Tribute, South Devonshire, Duchess of Edinburgh, West United Devonshire, Albert, United Devonshire, Saxon and Celt, Hopewell, Prince of Wales, Phoenix, Unicorn, South St Mungo, Princess Alice, Lady Barkly, North Devonshire, Ranzeau, St Mungo, Dublin and Cornwall, Sadowa, Eastwood, Ellenborough, Belmont and Saxeby, Snobs Hill, York and Durham, La bElle, Old Williams United, Arcadia, Williams United, South Catherine, Central Catherine, Catherine United, Murchison, New Franklin, Catherine Extended, Pony Club Oval, Housing Commission, Mt Alvernia Hospital, Fortuna, Lunt, Army Survey Unit, Wybrandt, John Brown Factory, Canterbury, Hercules and Energetic and the North Red White and Blue.bendigo, history, long gully history group, the long gully history group - new chum reef, ballerstedt, ashley and noy, grant, south goldfields, new chum goldfields, south new chum, lansell's 616, south bellevue, eureka, eureka extended, new chum bellevue, new chum railway, shenandoah, north shenandoah, shamrock, old chum, little chum, young chum, craven, garibaldi, ellesmere, south old chum, new chum consolidated, north ellesmere, new chum united, lansell's 222, lansell's fortuna, lazarus, west end, pioneer, old chum, new chum victoria, north old chum, lansell's big 180, sterry, victoria quartz, south adventure, great central victoria, ballerstedt no 3, adventure, humbold, british and american, midway, victoria consuls, victoria absorbed by ironbark, hercules and energetic, victoria pilot, north hercules and energetic, great extended hercules, pearl, southern victoria, great extended victoria, young victoria, new catherine victoria, weatern victoria, new victoria st mungo, surprise, mystery, duke of edinburgh, new st mungo, duchess tribute, south devonshire, duchess of edinburgh, west united devonshire, albert, united devonshire, saxon and celt, hopewell, prince of wales, phoenix, unicorn, south st mungo, princess alice, lady barkly, north devonshire, ranzeau, st mungo, dublin and cornwall, sadowa, eastwood, ellenborough, belmont and saxeby, snobs hill, york and durham, la belle, old williams united, arcadia, williams united, south catherine, central catherine, catherine united, murchison, new franklin, catherine extended, pony club oval, housing commission, mt alvernia hospital, fortuna, lunt, army survey unit, wybrandt, john brown factory, canterbury, hercules and energetic, north red white and blue -

Ballarat Tramway Museum

Ballarat Tramway MuseumFilm - Video cassette tape and box, Chris Long, "Living Ballarat 1901 - 1941", 1990

Yields information through movie films of the 1960's of Ballarat trams operating in the streets of Ballarat and has a strong association with the maker - National Film and Sound Archives and Chris Long.Video cassette in a plastic case, titled "Living Ballarat - 1901 - 1941, National Film and Sound Archive (1990)". See Reg item 4519 for the DVD version. The DVD was made by Peter Winspur using this tape. Transferred to the Hard Drive 11/1/2010- AV Files - dB text/AV Files/Reg Item 4519/Video_TS (at 12/1/2010) Copyright provisions - National Film and Sound Archive - segments may not be used without their permission, viewing only. Synopsis: based on time - 0.00 - intro, 1901 film, Melbourne, first film in Ballarat, Royal visit to Ballarat, Boer War Monument, first feature length film in Ballarat. 2.50 - Bridge St and Sturt St scenes, filmed from a flat truck pushed by an electric tram, including No. 11 going to City Oval to Lydiard St. 5.00 - Sturt St Military parade, with trams in background and tram running alongside. 6.54 - scene of Alfred Hall and films. 7.32 - scene on Lake Wendouree and paddle steamer - Living Ballarat film - Pathe's Ballarat Gazette local film unit, football ground scene. a children's beauty competition, tree planting at Macarthur St state school, 1911 Ballarat Show, unveiling of the Boer War statue name plates, Lake Wendouree 1912. 13.22 - St Patricks David Pde with trams in the background. 14.24 - Ballarat Kennel club dog show. 15.50 - Royal visit in 1920, Arch of victory opening 17.48 - Day at Macarthur St state school and tree plantation 20.55 - Bakery Hill - Stones Corner with tram tracks, cars, little trams, Sturt St with a tram leaving Grenville St, ESCo 9 turning from Lydiard St to run down to Grenville St. 22.15 - Ballarat Show, Coliseum Hall, 1925, races, machinery shows, boxing troupe. 25.20 - Botanic Gardens Gates, Lake Wendouree area. 25.30 - Gem Picture travelling show - film 26.16 - Formal visit of English pressman to Ballarat, 1925, Botanic Gardens, Eureka Stockade, Avenue of Honor, Moorabool Reservoir. 29.15 - 1927 Fed Govt doco of Ballarat, Black Hill, 1927 Home to Ballarat Festival, Ballarat Commemorative song, Craigs Hotel, Ballarat Post Office, tram centre poles in Lydiard St, tram climbing Sturt St, Town Hall, tram at Lydiard St terminus coursing, 8, Sturt St, view of ESCo Sebastopol car leaving Grenville St, Selkirks Brickworks, the Welcome nugget, Peter Lalor statue, Eureka stockade, sewerage plant, modern housing, Sturt St west, water supply - golf club, the High School, the orphanage, fine homesteads around Ballarat, Lake Wendouree. 41.00 Opening of the Ballarat Aerodrome. 43.11 - Depression work and leading into radio broadcasting - 3BA open 1930, typewriters, radio transmission equipment, radio aerials, boys listening to crystal sets 47.50 - Bluebirds Children session tour to the Gardens, mentions the BTPS, trams 13, 3? and 14 carrying visitors arriving and getting off and picnic. 48.50 - expansion of 3BA transmitter capacity 51.30 - 1934 visit of the Duke of Gloucester - visit to the Lucas factory, views of the work floor and the factory history and then South St band competition at the Showgrounds. 55.10 - South St Music Festivals, Coliseum and fire. 56.25 - Ballarat Floral Festival March 1938 - Victorian Railways arch of welcome. 57.25 - segment in the shot of 12 and 19? in Sturt St 57.45 - colour segment of the festival, 58.39 - Grenville St tram shelter, Bridge St, Sturt St, arches, Main Road, Council Road Roller, Victoria St, Eureka Stockade Reserve, Botanic Gardens, setting up the flowers, wax papers. 1.01.48 - decorated tram, north side of Sturt St, details of the materials used, Crockers. 1.03.20 - Hospital Fund Raising Gala Day - March 1938, special trains arriving Ballarat Railway Station, fund raising procession, pageant at the Showgrounds, fly past. 1.07.35 - 1939 Summer, motor cycle races at Learmonth, City Oval fire brigade demonstrations, Ballarat (East) Fire Station decorated for the 1939 Floral Festival with tram in the background and No. 29, Floral Tram and others. 1.09.25 - July 1914 - Ballarat at War parade, troops. 1.10.10 - credits. Box has images of a tram and town hall on the front and details of the contents on the rear and who made it etc. See images for details. ballarat, 3ba, floral tram, royal visit, buildings, esco -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Codd neck bottle, E. Rowlands, 1921

The design of the bottle is called a Codd, sometimes referred to as a marble bottle or "Codd's patent bottle". During the mid-to-late 1800s, there were many inventions to keep the fizz in carbonated drinks such as ginger ale, soda water, and fruit drinks. Hiram Codd, an English engineer invented a successful process that he patented as "Codd's patented globe stopper bottle" in 1872. The Codd-neck bottle (commonly called Codd or marble bottle) is manufactured in two parts. The body of the bottle is cast in two sections. At the time of joining the sections, glass marble and rubber seal are inserted into the neck section. The lip is then applied to the top of the bottle. The Codd bottle is filled upside down as the pressure of the gas from the carbonated liquid holds the marble up and out of the way. When the bottle stands upright the gas pushes the marble up against the washer, creating a firm seal to keep the fizz inside. The bottle is opened by pushing the marble down firmly to allow some of the gas to escape. The marble drops down and is caught in a depression formed in the neck. When the bottle is tilted to pour or drink the liquid the marble rests in a dimple. Two Ballarat miners, Evan Rowland and Robert Lewis started manufacturing mineral and aerated waters, bitters, cordials, and liqueurs in 1854, in a tent on the shores of Lake Wendouree Ballarat. Another 13 firms at that time employed manual operations, whereas they introduced Taylor's No. 1 machine that speeded up the process and laid the foundation for their fortune. Evan Rowland was a pioneer in the aerated water trade in Australia. He was born on August 2, 1826, in North Wales. In 1852, during the gold rush, he emigrated to Melbourne, and in 1854 he went to Ballarat and formed a partnership with Robert Lewis, the firm being called ‘‘Rowlands & Lewis’’. Their next step was to secure a supply of pure water. Using mineral Waters that they found via a natural spring at Warrenheip, Victoria. From the outset, the beverages made from this water gained repute and were in great demand. Their business prospered so well that in 1858 they were able to build a factory at the corner of Sturt and Dawson Streets, Ballarat, and to fit with the most up-to-date machinery then in use. By 1870 their business had increased so much and demand had grown to such an extent that Mr. Rowlands erected another factory, covering over an acre of ground at the corner of Dana and Doveton Streets, costing £13,000. The factory was fitted with the most modern equipment of the time to manufacture cordials and aerated water. In 1873 Rowlands established an agency at 116 Collins St, Melbourne, because the demand for the products of the Melbourne factory became so large. The company expanded to Sydney opening a factory at the corner of Burns & Hay Streets Darling Harbour obtaining spring water to supply this plant from Katoomba in the Blue Mountains. The water was brought to Sydney by rail. In the meantime, the Melbourne concern had progressed so rapidly that in 1888 a magnificent factory embodying all the latest ideas and equipment was built in King Street Melbourne. Robert Lewis was a fellow Welshman born in 1816, and he arrived in Port Phillip in 1853 and became a partner in the early day with Evan Rowland but with lesser and shorter involvement in the firm, from which he retired in 1876. Robert Lewis was perhaps better known as Ballarat's first mayor and a Member of the Legislative Assembly. He was a strong supporter of local charities, president/treasurer of the Eisteddfod Committee, a major force in the development of the Ballarat Hospital, and he was the mayor of Ballarat five times, the first in 1863, (having been a counsellor as early as 1859) and for the last time in 1881. Lewis died in 1884 of a stroke in Ballarat. Rowlands continued in the firm and invented and patented an improved soda water bottle. The water used in Rowlands products was filtered four times but his attempts to use local corks failed on quality grounds. He was a stickler for quality, which was so good that many outside Victoria were prepared to pay the 'premium' imposed by inter-colonial customs duty payable at that time. By the 1890s, Rowlands had factories in Ballarat, Melbourne, Sydney, and Newcastle. He died in 1894 but his company continued until well after the Second World War when it was sold to Schweppes.An early manufacturing process producing the first mineral waters in Australia was invented and developed by an early Welsh migrant to Australia. The Evan Rowlands story gives an insight into the early development of manufacturing industries in Australia that allowed their workers and the towns they were situated in to prosper and develop into what they are today. Bottle; clear glass Codd neck bottle with small marble in top. Once contained soda water or soft drink. Manufactured in 1921 by E. Rowlands of Ballarat, Melbourne, Katoomba and Sydney. The bottle is 'recyclable' - the message on the base says that it remains the property of E. Rowlands Pty Ltd."E. ROWLANDS BALLARAT MELBOURNE KATOOMBA AND SYDNEY". Imprinted into bas "1921" "THIS BOTTLE REMAINS THE PROPERTY OF E. ROWLANDS PTY LTD"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bottle, codd bottle, hiram codd, glass marble bottle, e. rowlands bottle manufacturer, soda bottle australia, early recyclable bottle, codd's patent bottle, marble bottle -

Puffing Billy Railway

Puffing Billy RailwayV. R. Krupp 1888. IV. Rail, 1888

60lbs rail that was used throughout the Victorian rail network. In 1887 Gibbs, Bright and Co. had a contract with Victorian Railways for railway and canal construction and supply of Krupp Rails. Gibbs, Bright and Co were merchant bankers and shipping agents and merchants who where also Directors of the GWR ( Great Western Railway ) and the Ship The "Great Britain" in England Gibbs, Bright and Company had principally been involved in shipping and trading, mainly in the West Indies, but following the discovery of gold in Victoria they established an office in Melbourne and soon became one of the leading shipping agents and merchants in the Colony. They expanded into passenger shipping and soon established offices in Brisbane, Sydney, Newcastle, Adelaide and Perth as well as launching passenger services between England, Mauritius and New Zealand. Gibbs, Bright also held a number of financial agencies from British mortgage, finance and investment companies as well as representing several British insurance companies in Australia. In addition they conducted a growing import business as well as an export business that included livestock, dairy produce, wool and flour. Also the company played a substantial part in the development of Australia's mineral resources, starting with lead in 1895, and later venturing into tin, gold, copper, cement and super phosphates. In Australia, after WWI, many of the larger companies were managing their own import and export so Gibbs, Bright and Company tended to focus its Agency business on smaller companies while expanding their interest into other markets such as timber, wire netting, zinc, stevedoring, road transport, marine salvage, gold mining as well as mechanical, structural, electrical and marine engineering. The Company's shipping interests continued to grow as well and still formed a major part of its business. In 1948 the parent company in England took the major step from tradition when they changed the business from a partnership into a private limited company. The name was the same, Antony Gibbs and Sons Limited, and in practice the effect of the change was very little. Some of the firm's branches and departments had already become limited companies and the formation of a parent company simplified the structure. The Australian operation was in time changed to Gibbs Bright & Co Pty Ltd in 1963. In 1848 Alfred Krupp becomes the sole proprietor of the company which from 1850 experiences its first major growth surge. In 1849 his equally talented brother Hermann (1814 - 1879) takes over the hardware factory Metallwarenfabrik in Berndorf near Vienna, which Krupp had established together with Alexander Schöller six years earlier. The factory manufactures cutlery in a rolling process developed by the brothers. Krupp's main products are machinery and machine components made of high-quality cast steel, especially equipment for the railroads, most notably the seamless wheel tire, and from 1859 to an increased extent artillery. To secure raw materials and feedstock for his production, Krupp acquires ore deposits, coal mines and iron works. On Alfred Krupp's death in 1887 the company employs 20,200 people. His great business success is based on the quality of the products, systematic measures to secure sales, the use of new cost-effective steel-making techniques, good organization within the company, and the cultivation of a loyal and highly qualified workforce among other things through an extensive company welfare system. From 1878 August Thyssen starts to get involved in processing the products manufactured by Thyssen & Co., including the fabrication of pipes for gas lines. In 1882 he starts rolling sheet at Styrum, for which two years later he sets up a galvanizing shop. The foundation stone for Maschinenfabrik Thyssen & Co. is laid in 1883 with the purchase of a neighboring mechanical engineering company. In 1891 August Thyssen takes the first step toward creating a vertical company at the Gewerkschaft Deutscher Kaiser coal mine in [Duisburg-]Hamborn, which he expands to an integrated iron and steelmaking plant on the River Rhine. Just before the First World War he starts to expand his group internationally (Netherlands, UK, France, Russia, Mediterranean region, Argentina). info from The company thyssenkrupp - History https://www.thyssenkrupp.com/en/company/history/the-founding-families/alfred-krupp.htmlHistoric - Victorian Railways - Track Rail - made by Krupp in 1888Section of VR Krupp 1888 Rail mounted on a piece of varnished wood. Rail made of ironpuffing billy, krupp, rail, victorian railways -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Dioptric Apparatus, mid 19th century

Before the introduction of electricity, lighthouses had a clockwork mechanism that caused the lens to rotate with a light source inside that was either powered by Kerosene or Colza oil. The mechanism consisted of a large weight attached by a cable through the centre of the lighthouse to the top where the cable wrapped around a barrel, drum or wheels that controlled the speed of the lights rotation by a clockwork mechanism. The keeper would crank the clockwork mechanism, which would lift the weight ready for the next cycle similar to an old grandfather clock mechanism. Once the weight lifted to its apex at the bottom of the first landing, the keeper would let it fall, which would pull on the cable, which would, in turn, operate a series of gears activating the rotation of the Fresnel optical lens, which would then rotate to create the lighthouse’s unique light speed of rotation characteristic. Creating a specific characteristic required a way to regulate the speed of the rotation, and was important as sailors could identify a particular light by its speed and time between flashes. The weight had to fall at a certain rate to create the proper rotation speed of the lens and a regulator within the mechanism accomplished this. History: From 1851, Chance Brothers became a major lighthouse engineering company, producing optical components, machinery, and other equipment for lighthouses around the world. James Timmins Chance pioneered placing lighthouse lamps inside a cage surrounded by Fresnel lenses to increase the available light output these cages, are known as optics and they revolutionised lighthouse design. Another important innovation from Chance Brothers was the introduction of rotating optics, allowing adjacent lighthouses to be distinguished from each other by the number of times per revolution the light flashes. The noted English physicist and engineer, John Hopkins invented this system while employed at Chance Brothers. Chance Brothers and Company was a glass works and originally based in Spon Lane, Smethwick, West Midlands England. The company became a leading glass manufacturer and a pioneer of British glass making technology. The Chance family originated in Bromsgrove as farmers and craftsmen before setting up a business in Smethwick near Birmingham in 1824. They took advantage of the skilled workers, canals and many other industrial advances taking place in the West Midlands at the time. Robert Lucas Chance (1782–1865), known as 'Lucas', bought the British Crown Glass Company's works in Spon Lane in 1824. The company specialised in making crown window glass, the company ran into difficulty and its survival was guaranteed in 1832 by investment from Chance's brother, William (1788 – 1856). William owned an iron factoring business in Great Charles Street, Birmingham. After a previous partnership that Lucas had dissolved in 1836, Lucas and William Chance became partners in the business which was renamed, Chance Brothers and Company. Chance Brothers invented many innovative processes and became known as the greatest glass manufacturer in Britain. In 1848 under the supervision of Georges Bontemps, a French glass maker from Choosy-le-Roi, a new plant was set up to manufacture crown and flint glass for lighthouse optics, telescopes and cameras. Bontemps agreed to share his processes that up to then had been secret with the Chance Brothers and stayed in England to collaborate with them for six years. In 1900 a baronetcy was created for James Timmins Chance (1814–1902), a grandson of William Chance, who had started the family business in 1771 with his brother Robert. Roberts grandson, James became head of Chance Brothers until his retirement in 1889 when the company became a public company and its name changed to Chance Brothers & Co. Ltd. Additional information: Lighthouses are equipped with unique light characteristic or flashing pattern that sailors can use to identify specific lighthouses during the night. Lighthouses can achieve distinctive light characteristics in a few different ways. A lighthouse can flash, which is when brief periods of light interrupt longer moments of darkness. The light can occult, which is when brief periods of darkness interrupt longer moments of light. The light can be fixed, which is when the light never goes dark. A lighthouse can use a combination of flashing, oscillating, or being fixed in a variety of combinations and intervals to create individual light characteristics. It is a common misconception that a lighthouse's light source changes the intensity to create a light characteristic. The light source remains constant and the rotating Fresnel lens creates the various changes in appearance. Some Fresnel lenses have "bulls-eye" panels create beams of light that, when rotated between the light and the observer, make the light appear to flash. Conversely, some lenses have metal panels that, when rotated between the light and the observer, make the light appear to go dark. This Dioptric clockwork apparatus used to turn a lighthouse optical lens is very significant as it is integral to a lighthouses operation, we can also look at the social aspect of lighthouses as being traditionally rich with symbolism and conceptual meanings. Lighthouses illustrate social concepts such as danger, risk, adversity, challenge and vigilance but they also offers guidance, salvation and safety. The glowing lamp reminds sailors that security and home are well within reach, they also symbolize the way forward and help in navigating our way through rough waters not just on the oceans of the world but in our personal lives be it financial, personal, business or spiritual in nature. Nothing else speaks of safety and security in the face of adversity and challenge quite the way a lighthouse does. Revolving dioptric clockwork apparatus used to turn a Fresnel optical lighthouse lens. A cylindrical cast metal pillar and cabinet painted green with 3 glass doors enclosing the top section. Inside the pillar/cabinet is a large clockwork mechanism used to turn and regulate a lighthouse light by means of weights and a chain attached to same. One door has the name "Adams Mare" in metallic dots similar to "Braille" to the inside edge of door frame.shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, flagstaff hill, maritime-museum, shipwreck-coast, warrnambool, flagstaff-hill-maritime-village, revolving dioptric mechanism, dioptric mechanism for lighthouse, lighthouse clockwork timing mechanism, acetylene lighthouse light mechanism, 19th century lighthouse mechanism, kerosene light, fresnel lenses, colza oil, chance brothers -

Federation University Historical Collection

Federation University Historical CollectionPlan, Sulieman Pasha Co Plan Transverse Section

The Sulieman Pasha is possibly named after the most important Sultan of the Ottoman Empire, Suleiman One, or Suleiman the Magnificent, when the Ottoman Empire was at its peak. Or potentially a number of Ottoman governors, statesmen and military commanders with the same name after, however the spelling is slightly different to the mine name. No Turkish connection was found relating to the formation of the company, and remains unconfirmed. The mine operated from two shafts; No. 1 near the corner of Humffray and Mair streets, and also near where the Welcome Nugget (2217 ounces) was found years earlier; and the controversial No. 2 shaft several blocks south bordering the northern side of the main highway through Ballarat. The company produced 62 666 ounces of gold, the twelfth highest quartz reef gold production for any mine on the Ballarat goldfield. Some crushing figure examples are January-June 1881: 3674 tonnes 1085 ounces; January-June 1885: 2949 tonnes 1281 ounces; July-December 1885: 4459 tonnes 1119 ounces; January-June 1887: 1869 tonnes 730 ounces; July-December 1892: 1450 tonnes 771 ounces; July-December 1896: 4365 tonnes 1372 ounces. Like many mines in the area, gold grades were low. John Watson was noted as mine manager in the 1880s, and John Williams 1890s. The company was re-organised twice increasing the number of shares from 4000 to 24 000, and increasing the capital available. The Sulieman Pasha Company was formed in 1878. David Fitzpatrick was given the honour of turning the first sod of both the No.1 and later No. 2 shafts. The first dividend was given to shareholders in July 1881. The company obtained a prospecting vote (government grant) to start, and was very proud to be the first Victorian gold mining company to pay the funds back to the government. The event was marked by a lavish banquet laid out for ministers and government officials by the company. Leases were purchased to the south in 1885 to the Llanberris Mine boundary, after poor results began accumulating from the small No. 1 shaft. To take advantage of this new land the company planned to sink a second shaft. Initially this was to take place on government land, but the uproar from nearby residents caused the company to purchase land along the Main Road (now Western Highway), and the old Yarrowee Hotel which had occupied the site since the alluvial digger days of the 1850's was demolished. The area had since those days become heavily occupied with a number of shops, houses, a post office, church and two schools in the immediate area. The thought of an underground mine next door drew considerable opposition. The company (before the days of public relations departments) wrote 'most people would have thought that progress as vital as mining would be supported by tradesmen whose business rely on the mining industry. It seems when it comes to mining they are bereft of their senses, and considering the low ebb of mining in Ballarat East, the action of our opponents are unaccountable. (Sarcastically) There are certain engineering difficulties in moving the quartz reefs to a new location, but if we could to appease our opponents we would'. The company also wanted to take over 4 acres of the St Paul's school oval for machinery, but accused the St Paul's Church of wanting extortionate amounts of money upfront, and on a yearly basis for the privilege. It stated the church could not be opposed to mining when several years earlier it had formed its own company to mine the land, only for shareholders to lose their money. In 1886, the company approached the Minister for Mines, and attended heated public meetings on the matter. The local residents, shop owners, and church submitted a 60 person petition to the local council and government authorities. They stated the shaft contravened the mining statutes, which stating no mining could take place within 150 yards of a public building or church. A speech by a resident stated 'mining always comes with glorious pictures of the great benefits which would accrue all parties concerned if their request is granted, but if property is destroyed or depreciated in value, no-one then comes forward and compensates them'. The No. 2 shaft was approved including taking over part of the school oval. In 1888, workers at the company's No. 2 shaft went on strike to try and bring their wages in line with other mines in the district (the No. 1 shaft was operated by tributers). William Madden (26) was killed from a fall of earth underground the same year, while a year later his father John Madden (70) was similarly killed in the Madame Berry Mine elsewhere in the district. In 1897 as the amount of gold being found fell away, it came to light part of the deal to purchase the Yarrowee Hotel site was a 5% royalty on gold found. Shareholders could not understand why they were paying a royalty to the former owners of the property. The mine closed in 1898 due to a lack of gold. In 1902 a boy (age unknown) called Charles Lee was killed from a fractured skull while working to dismantle the Sulieman Pasha plant. The fuss over the No. 2 shaft had a sequel. On the company winding up, the land was purchased by J.S. Trethowan who built a house next to the shaft. In 1907, the shaft caved-in creating a sinkhole immediately at the back of the house. A Mr Chamberlain heard a deep rumbling sound at 5am, and looked out the window to see his fowl house and thirteen chickens disappear down an expanding hole. He then went back to bed, and called the police later in the day. The shaft was 1050 feet deep, and the hole at the surface that developed was 20 feet by 17 feet across, and 20 feet depth. In 1930 it is reported a syndicate had been formed to clean out the old shaft, and re-open the mine. It is assumed this was the No. 1 shaft but no more was found. (https://www.mindat.org/loc-304239.html, accessed 07/08/2019) A transverse section plan of the Sulieman Pasha Mine.sulieman pasha company, plan, mining, united black hill mine, victoria united mine, victoria street, britannia united mine, last chance mine, llanberris mine, ottoman empire, john watson, john williams, david fitzpatrick -

Federation University Historical Collection

Federation University Historical CollectionMagazine, Ballarat School of Mines Students' Magazine, 1898-1901, 1898-1901