Showing 340 items matching "appliances "

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMix Master

The Kiewa Hydro Electric Scheme (KHES) produced electricity for the people living in the Kiewa Valley and beyond to many parts of Victoria. The people and their families working on the scheme were encouraged by their employer the State Electricity Commission of Victoria to purchase and use electrical appliances. The mix master was popular for mixing food for baking and for making juice drinks. Ron White owned this 1950s vintage Sunbeam model 9 mixer with stand, milk glass bowls and complete juicer. Ron was a senior member of staff during the construction and operation of the KHES.This mix master was owned by Ron White who was appointed Area Operations Engineer Kiewa in June 1956. Ron was later appointed General Superintendent and then in 1974 to principal Hydro Engineer of the recently titled Hydro Division.White electrical food mixer with six parts. 1. Motor upright - white, on black stand horizontal. Black dial at back with speeds numbered and type of mix eg. mash. Front switch on/off. Black electric cord attached. Long black handle on one side. 2 Two beaters, silver 3. Bowls, white one small and one large. The small one has a spout. 4. Squeezer, white - fits on top for juicing. Parts as with orange juicer and with funnel at the front for juice to flow into a bowl.'Sunbeam' (in red) / 'Mix Master' in (black) on gold oblong 'emblem' sunbeam mix master; kitchen appliance; cooking; ron white; kiewa hydro electric scheme; food preparation -

Warrnambool and District Historical Society Inc.

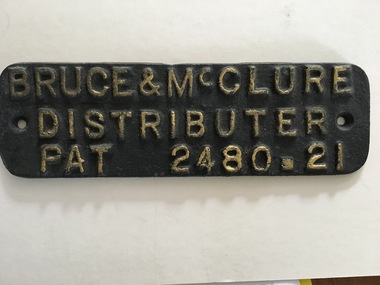

Warrnambool and District Historical Society Inc.Brass Plate, Bruce & McClure Distributer, C early 20th century

Bruce & McClure were manufacturers of windmills and agricultural machinery including motor engines , pumps, tanks,and appliances for supplying and conserving water.Also included was brass,iron and steel foundry works. They won 11 first prizes at the Grand national Show of 1907 and in 1914 designed and manufactured a new water boring machine which could also be used for oil and gold exploration They operated from Lava Street well into the 1940's as well as from the geelong area. This plaque is possibly from one of their machines.A tangible link to one of Warrnambool's manufacturing businesses which was innovative and an essential part of the beginnings of machine use in farms and industry in the district. Cast iron plaque with moulded text which is coloured in gold. rectangular with rounded corners. Back is painted grey.Bruce & McClure Distributer Pat 2480.21warrnambool, bruce & mcclure, bruce & mcclure machinery -

Melbourne Tram Museum

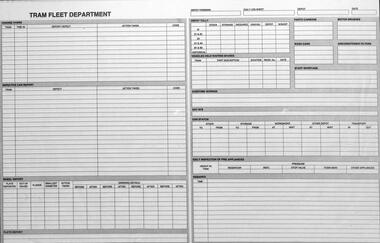

Melbourne Tram MuseumDocument - Forms, Public Transport Corporation (PTC), "Tram Fleet Department" - Daily Log Book, c1990's

Has space for entries of date, depot, change over details, defective cars, flats, brake shoe, leading hand inspections, day in cars, number of cars, transport of vehicles, staff shortages, overtime worked, wheels inspected and remarks, depot tally by class, pantographs, motor brushes overtime works, car status, daily inspection of fire appliances and general remarks. See Reg Item 3611 for an earlier version. Includes B1 and B2 class trams. Sampled from a large book of forms.Demonstrates tramcar maintenance forms.Form, titled - "Tram Fleet Department" - Daily Log Book comprising original sheet and copy sheet (carbon paper not required - NCR)trams, tramways, forms, tramcars, tramcar maintenance, ptc -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionWork on paper - Vertical file, Armitstead family

The Armitstead family's first woodyard in Surrey Hills was located in Croydon Road but later they moved to 153-157 Union Road, Surrey Hills. The business delivered timber and briquettes for heating to homes in the local area but also blocks of ice in the days before refrigerators were a usual household appliance. The timber was unloaded from railway trucks at a siding at Surrey Hills station; some came from the Armitstead's property of 130 acres of timbered land near Killara. They also sold mallee roots and briquettes.A vertical file containing the following documents: 1. Land Victoria map of Surrey Hills including Union Road from Bedford Street to Montrose Street, showing location of woodyard (undated) (1 A3 page). 2. Possibly ‘Sun’ article ‘When Surrey Hills ran short of wood’, Michael Sefton (undated) (1 page). 3. Plaque for the red mechanism of the weighbridge at Centre, by convenor, Surrey Hills Heritage Group, 12.11.2002 (1 page). 4. Pooley and Sons weighbridge, notes by Dennis Armstrong, in email to Sue Barnett, 4.4.2013 (2 pages). 5. Laminated diagram and notes by Ken Hall re weighbridge from Armitstead’s woodyard, and photocopy, undated (3 pages). 6. ‘Armitstead’s woodyard’ 153-7 Union Road (now Neighbourhood Centre), typed Progress Leader article, 13.1.1982 (2 pages). pooley and sons weighbridge, armitstead family, woodyard, armitstead's woodyard, union road -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - ALBERT RICHARDSON COLLECTION: THE VICTORIA HILL, HISTORICAL CONNECTIONS

One page handwritten document titled Victoria Hill, it's historical connections. Extract from document: Gold first found in 1853 by two colored men, one named Weymouth or 'Dido'. Sold out to Theodore Ballerstedt senior, who in Deember 1853 was known as the 'Father of the Hill'. In the first six years, this Hill produced more than $1,200,000 worth of gold and this in a period when crushing with crude appliances cost $13 a ton instead of $0.50c to 80 cents per ton, and unskilled men were receiving $2.00 per day instead of 75 cents a day for practical miners some years later.bendigo, mining, victoria hill -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Farm Equipment, Horse Collar medium 20thC, 20thC

A horse collar is a part of a horse harness that is used to distribute the load around a horse's neck and shoulders when pulling a wagon or plough. The collar often supports and pads a pair of curved metal or wooden pieces, called hames, to which the traces of the harness are attached. The collar allows the horse to use its full strength when pulling, essentially enabling the animal to push forward with its hindquarters into the collar. It is a padded appliance that conforms well to the shape of the horse's body and is constructed so that at all points of contact with the body of the horse it avoids the air passage.The early settlers in Moorabbin Shire depended on the draught horse to pull the equipment need to plough the fields, grade the roads, pull their wagons of produce and small carts for transport as they developed the land after the Henry Dendy Special Survey 1841Horse Collar, 20thC mediumearly settlers, pioneers, draught horse, ploughs, farm equipment, saddles, leatherwork, blacksmiths, cheltenham, sandringham, city of moorabbin, county of bourke, moorabbin roads board, parish of moorabbin, shire of moorabbin, henry dendy's special survey 1841, were j.b.; bent thomas, o'shannassy john, king richard, charman stephen, highett william, ormond francis, maynard dennis, market gardeners, horse drawn wagons, plateway, vegetables, poultry farms, dairy farms, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Farm Equipment, Horse Collar large, 20thC

A horse collar is a part of a horse harness that is used to distribute the load around a horse's neck and shoulders when pulling a wagon or plough. The collar often supports and pads a pair of curved metal or wooden pieces, called hames, to which the traces of the harness are attached. The collar allows the horse to use its full strength when pulling, essentially enabling the animal to push forward with its hindquarters into the collar. It is a padded appliance that conforms well to the shape of the horse's body and is constructed so that at all points of contact with the body of the horse it avoids the air passage.The early settlers in Moorabbin Shire depended on the draught horse to pull the equipment need to plough the fields, grade the roads, pull their wagons of produce and small carts for transport as they developed the land after the Henry Dendy Special Survey 1841Horse Collar large 20thCearly settlers, pioneers, draught horse, ploughs, farm equipment, saddles, leatherwork, blacksmiths, cheltenham, sandringham, city of moorabbin, county of bourke, moorabbin roads board, parish of moorabbin, shire of moorabbin, henry dendy's special survey 1841, were j.b.; bent thomas, o'shannassy john, king richard, charman stephen, highett william, ormond francis, maynard dennis, market gardeners, horse drawn wagons, plateway, vegetables, poultry farms, dairy farms, -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Foot Warmer, Hecla Electrics Pty Ltd, c. 1920

From Museum Victoria: Made in about 1927 by Hecla Electrics Pty Ltd and sold under the model name 'Foot Warma'. The foot warmer was made from the late 1920s until the 1950s and did not change substantially in design during this time. The Hecla brand name and logo was registered in 1918 by Clarence Marriott. It was inspired by the recent eruption of Iceland's volcano Mt Heckla. Clarence and his father James were metal workers who had made Australia's first carbon filament electric radiators in 1899, and also built an early steam car. As electricity use exploded in the 1920s and 1930s, 'Hecla' became a household name in Melbourne. They made a wide range of appliances for the home, and supplied commercial appliances to cafés, hospitals and offices. In 1927, the company shifted from small premises in the city to a bigger, electric-powered factory in South Yarra. Hecla had no retail stores of its own - instead it sold products through wholesalers and retailers, including the State Electricity Commission (SEC). The company promoted its goods through advertisements in home magazines and displays in shop windows, home shows and the 1935 All-Electricity Exhibition. A popular advertising slogan in the 1930s was 'Hecla household helps make happy healthy housewives!'. Hecla ceased manufacturing in Melbourne in the 1980s.Documentation of how people lived and is an example of early domestic electrical appliances. From Museum Victoria: Hecla Electrics Pty Ltd were a significant Melbourne manufacturing company, who became a household name in the 1920s making small electric appliances such as heaters and kettles. They also made a variety of other electrical appliances for domestic, commercial and military use. The company manufactured electric appliances in Melbourne from about 1922 until the 1980s, although Clarence Marriott, who formed the company, had begun making radiators with his father James in 1899. The company had a reputation for quality products. The company also played an important role within the Australian domestic and commercial appliance industry, both as a leading innovator and through its role in training skilled staff, many of whom went on to work for competitors such as Kambrook, Electrolux and Sunbeam. This electric coffee percolator represents the typical small domestic appliance that the Hecla company was famous for. Along with other items in the Hecla Collection, it highlights the diversity of electric appliances that the company made. This object also highlights the legacy of high quality design and metal construction work that Clarence and James established for the company, stemming from their early work as talented art metal workers. It also represents the first major period of the take-up of electricity use in the home. This take-up began in the 1920s and 1930s with the use of small appliances, and by the 1950s electricity had become commonplace in the home, and large appliances such as refrigerators and stoves became standard.Square metal object. The top surface is heavy cast iron and patterned with floral motifs. In the centre is a circle with the words ' Hecla Foot Warma' inside. Under the top is a black metal base with two feet at either end which extend the length of the base. The back foot is higher than the front foot. There is a circular disk from which extends the electrical cord. The cord is brown and white checks. At the end of the cord is a plug on which is printed 250V AMP S.2 EARTH 5. The plug is brown and made from Bakelite. On the base is a rectangular label which has words printed - HECLA Australia.Top: HECLA/-FOOT-/WARMA Base: Volts / 230/250 / WATTS / 80 / HECLA / Australia / CAT. NO. F26domestic, city of portland, glenelg shire council, electrical, foot warmer, heating, hecla, manufacture -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

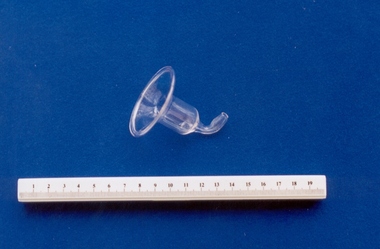

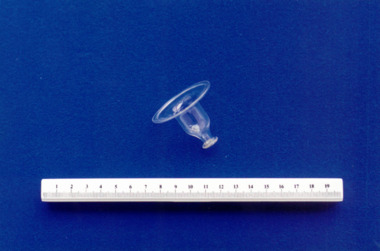

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Glass nipple shield associated with midwife Mary Howlett, c. 1866 - 1920

A rubber teat would be attached to the top of this nipple shield for breast feeding. From 1801 onwards, nipple shields were available in a variety of materials, such as pewter, horn, bone, ivory, wood, glass and silver. They varied in shape from a bell to a flatter, cap shaped appliance. With the application of the nipple shield, the baby was able to take milk from the breast without giving added trauma to the nipples. In the ante partum period the nipple shield could be worn to assist in drawing out flat nipples; or, as it was known during this period, for the formation of "new nipples". (Fildes, Valerie. 'Breasts, Bottles & Babies - A History of Infant Feeding', 1986) Mary Howlett (1840-1922) began practising as a country midwife in 1866 in the western district of Victoria. She qualified as a 'ladies monthly nurse' in 1887 and continued to practise as a nurse and midwife until 1920. She began her six months training at the Melbourne Lying-In Hospital. She was known by many as 'Auntie', and her career spanned more than 50 years. Mrs Howlett's midwifery box and contents were given to Dr Frank Forster, and he donated them to the museum collection in 1993. Glass nipple shield. Shape resembles that of a bell.infant feeding, midwifery -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Glass nipple shield associated with midwife Mary Howlett, c. 1866 - 1920

A rubber teat would be attached to the top of this nipple shield for breast feeding. From 1801 onwards, nipple shields were available in a variety of materials, such as pewter, horn, bone, ivory, wood, glass and silver. They varied in shape from a bell to a flatter, cap shaped appliance. With the application of the nipple shield, the baby was able to take milk from the breast without giving added trauma to the nipples. In the ante partum period the nipple shield could be worn to assist in drawing out flat nipples; or, as it was known during this period, in the formation of "new nipples". (Fildes, Valerie. 'Breasts, Bottles & Babies - A History of Infant Feeding', 1986) Mary Howlett (1840-1922) began practising as a country midwife in 1866 in the western district of Victoria. She qualified as a 'ladies monthly nurse' in 1887 and continued to practise as a nurse and midwife until 1920. She began her six months training at the Melbourne Lying-In Hospital. She was known by many as 'Auntie', and her career spanned more than 50 years. Mrs Howlett's midwifery box and contents were given to Dr Frank Forster, and he donated them to the museum collection in 1993.Glass nipple shield. Shape resembles that of a bell.midwifery, infant feeding -

Melbourne Tram Museum

Melbourne Tram MuseumSlide - Set of 3, Keith Caldwell, 11/3/1960

Set of 3 Agfa Colour slide, cardboard mount, by Keith Caldwell of 11 March 1960 of trams at St Kilda Junction. .1 - L 106 arriving at the junction from Wellington St. Tram has the destination of City, route 4. Signals for the trams can been seen on a pole on the left hand side of the photo. .2 - SW6 - as for .1 .3 - W3 668 ditto, from Fitzroy St, showing Moreland, route 15. Has an advert for 3AW. In the background in all photos are adverts for Speedie electrical appliances, Fosters Lager, Stonefell wines, Gilbeys Gin, Penfolds, Stockdale's Bread, Hamburger Max Snack bar, Ardath, Brooks Books.All hand stamped "11 Mar '60"; .1 "L" in ink and .3 "W3" in ink written on.trams, tramways, st kilda junction, signal box, l class, w3 class, tram 106, tram 926, tram 668, sw6 class, wellington st, mmtb, route 4, route 64, route 15 -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - NEW RED WHITE & BLUE MINE - NEW RED WHITE & NEW CHUM RAILWAY MINE MANAGER'S REPORT 17/2/03

Handwritten extracts and typed copies of same, from the New Chum Railway Mine Manager's Report 17/2/03. Mine Manager W Hicks. Extracts: Machinery. New Boiler is giving every satisfaction. While bailing water after the Xmas holidays, one of the ropes broke with a full tank of water. The tank being fitted with safety appliances, acted. Therefore no damage was done to the shaft. The old ropes were taken off and replaced by two new ones of 2,500 feet each, with a breaking strain of 34 tons. Mine 7 machinery are all in good working order. 1925 - Portion of Cath. Reef battery sold to Big Blue. Albert Richardson Collectiondocument, gold, new red white & blue mine, new red white & blue mine, new red white & blue mine manager's report 17/2/03, w hicks, cath reef battery -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron Hand Kerosene, mid to late 1900s

The 1950's saw a revolution in small appliances for use in the average household. This hand held self heating(kerosene) iron was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing a separate fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns (domestic electric steam irons were invented in 1938). This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation.In the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing remained for an extended period covering the 1960s to 1970s. Kerosene products, such as this kerosene iron was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This Coleman kerosene iron has a solid steel chrome plated(press) base with a painted (blue) wooden handle. The handle is stud fastened onto an oblong shaped rolled steel handle frame and screwed (two screws) onto the base plate. Both the heating plate and the top securing plate are shaped similar to a river boat. The main housing enclosing the heating element is enamel coated(blue in colour) steel and has a half hole for lighting the kerosene at the rear end. Behind the handle and protruding upwards is a stainless steel fully enclosed container (bowl shaped) for the main supply of kerosene to the burner or generator(enclosed within the main body of the iron. The bowl has an air valve and inlet for pressurised air intake (hand pump) On the bottom rear of the fuel bowl there is a screw regulated fuel pump. The fuel heated base plate provides the heat for this advertised "self heating iron(instant lighting). See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench; and KVHS 0347D Fuel can.Stamped on the base plate of the handle, front region "COLEMAN LAMP & STOVE CO." below this "WICHITA KAN" below this"TORONTO CAN". In the middle of the handle base and in larger print "COLEMAN Instant-Lite" At the rear location in large print "MODEL 4" in smaller print below "MADE IN U.S.A." below this "PAT#1718473"household appliances, alternative non electrical ironing appliances, domestic appliances, kerosene appliances -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Food vitamiser, Semak, c1950

Semak is an Australian company, manufacturing Australian-Made equipment for the Foodservice Industry. It was established in 1948. The most famous Semak appliance is the 'Vitamizer'. Designed in 1948 it quickly became the standard for blending. An updated version was relaunched in 2012. The Semak vitamiser was advertised as a wonder machine which every housewife should have.Advertising claimed that the Semak could whip cream, grind coffee, blend jam, makes soups and sauces, makes cakes, sandwich spreads, ice-cream, special diets, puree fruit drinks, supper snacks, mayonnaise and dessert. It sold for £21. Demonstrations were conducted in electrical stores across the nation. A recipe book and full instructions for operation was included.This item is representative of a popular Australian-made kitchen appliance used across the country. A food vitamiser in 2 sections. Top section is detachable for cleaning. Has electrical cord attached.Surrounding power control: Semak Vitamiser Under base: CAT No. S2/ 230 - 25 V / 240W / 40 - 60kitchen appliances, food vitamisers, semak industries -

Federation University Historical Collection

Federation University Historical CollectionBooklet - Reports, John Ferres, Government Printer, Safety Mining Cages. Report of the Board of Enquiry on Safety Cages 1878-9; together with proceedings of the Board and Appendices, 1879

From the Argus, Friday 18 July 1879:- SAFETY MINING CAGES. The report of the board on safety mining cages was laid on the table of the Legislative Assembly fortnight The board, which has tested the following inventions Nances, Williams patent, Jackson and Middleton's patent Sesmours patent, Allans patent, and Hassan a patent, reports as follows - 1. That the preponderance of evidence given by miners and others qualified to form an opinion is strongly in favour of the adop-tion of a safety cage for general use in the mines of this colony, provided that a reliable invention can be brought forward, and its practical utility satisfactorily determined 2. That in view of the rapid increase of cage accidents, and supported by the evidence before them, the board are of opinion that some special provision should be made to check such a prolific source of danger as is shown to exist in the working of the shaft and machinery employed for winding purposes. 3. That this check could be imposed by means of such a regulation as that at present contained in the statute, i e -" Every cage used in a mine shall be fitted with special and suitable appliances to prevent its sudden fall down a shaft and also to prevent its coming into contact with the poppet heads." The board, however, consider that mine proprietors should be permitted to exercise their own discretion in the selection of safety cages, but safety hooks and balance catches must be used in connexion with every case 4. That the board have witnessed trials of all the inventions brought under their notice, and from the result of their observations the members are of opinion that the adoption of these safety appliances will afford additional security to the large section of the community engaged in mining operations.48 foolscap pages report stitched together. safety cages, safety mining cages, george collins levey, mining, mitchell and osborne's patent safety catches for mining cages, mining cages, seymour's patent safety cage, pryor's safety cage, white's safety cage, mining accidents, dyke's freehold gmc creswick, angelo mining co castlemaine, britannia qmc ballarat, alexander kennedy smith, george r. fincham, henry roberts williams, robert clark, r. richardson, allan's patent balalrat, hassan's patent daylesford, david white, charles stewart, w.h. grainger, h.b. nicholas, t. hassan, r. allan, a.k. smith, james thomson, william collard smith, j.h. seymour, john s. delbridge, william buttle, james davidson, j.p. carolin, r. clark, thomas eyre, george marshall, g. thureau, william bottoms, robert carr, j.c. march, john keam, david park, j.a. lewis, lester's hotel, ballarat, robert allan, nancarrow saftey cage, robert malachi serjeant, robert henderson, g.f. smith, r.w. newman, william benson, f. bennett, john sharp, thomas couchman, john a. wallace, john small, william h. grainger, james cowling, tools -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCan Fuel Measuring, circa 1950

The 1950's saw a revolution in small appliances for use in the average household. The hand held self heating(kerosene) iron for which this filling can was provided ,was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing an external fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns. This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation and the ability to service them from this filling can was an essential part.n the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing appliances remained for an extended period covering the 1960s to 1970s. Kerosene products, such as the kerosene self heating (KVHS 0347A) iron and this kerosene filling item, was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This specially spout fitted can was provided with the Coleman self heating kerosene iron (see KVHS 0347A). On one side of the half enclosed top of the can there is a small spout(for poring the appropriate liquid into the egg shaped fount container) at the rear end of the hand iron. The can is made from tin. See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench.On one side of the can in black print on yellow background is "FUEL MEASURING CAN" underneath is "For Coleman Instant-Lite Iron" underneath are four numbered paragraphs detailing the use of this can. Below this is the name and places of manufacture. On the other side of the can is printed "BE SURE" with filling and maintenance instructionskerosene can, ironing, domestic appliances, household appliances -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - TILLEY Paraffin Pressure Iron, Tilley Lamp Company, 1950s to 1970s

Irons such as this were very popular prior to the widespread introduction of electricity in Australia. It was manufactured by the Tilley Lamp Company Ltd. In 1818 John and William Henry Tilley established W. H. Tilley, in Stoke Newington, London, England. During WW1 they started to use paraffin as a lamp fuel in pressurised containers. A production plant was established at Hendon, just north of London, and the first commercial lamps were produced after World War 1. During the 1920s the company diversified into domestic lamps. This expanded to other appliances such as heaters and eventually to irons. The use of paraffin or kerosene as a fuel was a much cleaner form of heat, especially when compared to older flat irons which used coal.This item is significant because it is representative of domestic appliances used in the Wodonga District prior to the introduction of electricity throughout the area.Cream coloured iron with a black Bakelite handle which attaches to the fuel tank. It has a steel sole plate. The heat of the iron is provided by a paraffin burner.On Metal plate: Model D.N. 250 Made in England British Pat. 524719 Australian Pat. 114305 On Knob at rear: ON/OFF TILLEYdomestic appliances, tilley paraffin iron, tilley lamp company ltd. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTongs Blacksmith, circa mid to late 1900's

These long handled "Blacksmith" tongs were used in the late 1800's to mid 1900's by a blacksmith(or others) within the Kiewa Valley. During these times blacksmiths would regularly visit "remote" rural properties and work on any "hard to manufacture" items. A few properties had either stockmen,farm hands, or owners able to do "minor" blacksmith work. The ability to undertake blacksmith functions was sometimes "by necessity" handled by a local "jack of all trades" person. During this period however demand for rural based blacksmiths was very high. The rural store, however was usually very small and many "off" the shelf rural appliances and apparatus available in the larger rural towns were not available to the semi remote rural areas.This long handled shaped nipper tongs is very significant to the Kiewa Valley because it represents one of the essential mores relating to isolated rural regions as was the Kiewa Valley at this period in time (1800's to mid 1900's). This "ingrained " more was the ability to achieve anything that was required to maintain a living standard or survival in a remote grazing, mining and farming region. The remoteness was due to the small population, poor transport routes and flood prone roads winding through the lower lying flat plains of the Kiewa Valley. Any blacksmith work whilst grazing Cattle on the Bogong High Plains or any part of the Kiewa Valley, had to be done in situ. The part of the "culture" of this regions was that of "self help" either from within the family or from a friendly neighbour.Long handled blacksmith's tongs. The handles are rusted and painted orange. The nippers have one central fixing and are flat edged.tools, blacksmith, horses, trades -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTongs Blacksmith, circa early 1900s

These long handled "V" shaped tongs were used late 1800's to mid 1900's by a blacksmith within the Kiewa Valley. During these times blacksmiths would regularly visit "remote" rural properties and work on any "hard to manufacture" items. A few properties had either stockmen,farm hands, or owners able to do "minor" blacksmith work. The ability to undertake blacksmith functions was sometimes "by necessity" handled by a local "jack of all trades" person. During this period however demand for rural based blacksmiths was very high. The rural store, however was usually very small and many "off" the shelf rural appliances and apparatus available in the larger rural towns were not available to the semi remote rural areas.This long handled "V" shaped nipper tongs is very significant to the Kiewa Valley because it represents one of the essential mores relating to isolated rural regions as was the Kiewa Valley at this period in time. This "ingrained " more was the ability to achieve anything that was required to maintain a living standard or survival in a remote grazing, mining and farming region. The remoteness was due to the small population, poor transport routes and flood prone roads and lower flat plains of the Kiewa Valley. Any blacksmith work whilst grazing Cattle on the Bogong Plains had to be done in situ.Long handled tongs with "V" shaped ends on the nippers (used by blacksmiths)I.T.O.C.tools, blacksmith, horses, wrought iron tools -

Ballarat Fire Brigade

Ballarat Fire BrigadeTrophy

Trophy was won at the Geelong Fire Brigade Jubilee in 1904. This would have been a demonstartion to celebrate the 50th Anniversary of the Geelong brigade which formed in 1854 Silver shield mounted on a wooden backing board. Trophy was won by Ballarat Fire Brigade at the Geelong Fire Brigade Jubilee in 1904. Trophy was donated by Llyods of London and presented by E. Steane Price esq. Trophy has a Lion at the top centre, angels on both the left and right sides. In the centre there is a depection of 2 large multi storey buildings. The building in the front of the picture has a carraige ladder raised up against it with 2 firemen climbing the ladder. There are 2 additional firemen either side of the ladder and an additional fireman in front of standing in front of with another standing on top of what appears to be either a mannual pump or possibly the ladders appliance. There are various other branches, leaves etc. that make up the remainder of the decorations on the sheild. Item is very similar to item 018GEELONG FIRE BRIGADES JUBILEE / 1904 / PRESENTED / BY / E.STEANE PRICE Esq. LLYODS LONDON1904, geelong fire brigade, geelong fire brigade jubilee, elkington and co, e steane price esq, llyods london -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Electric Toaster, Hecla Electrics Pty Ltd, c1940s

Hecla produced a wide range of appliances for domestic use, beginning with heaters and later branching out to a wider range of kitchen appliances Hecla was established by Clarence William Marriott, a young Melbourne metal worker. He began manufacturing Australia's first carbon filament electric radiators in 1899. He originally worked for his father James Marriott who commenced business in Melbourne as an art metal worker in 1872 and was, in 1907, appointed as the official art metal worker to the Victorian Government producing items including the ornate iron gates and gas lamp standards outside Melbourne's Parliament House. With the invention of nickel chromium wire after 1900, C.W. Marriott began making more efficient heating elements using this new material in 1916. After being influenced by the eruption of Mount Hekla in Iceland, on 19 December 1918, Clarence registered the brand name "HECLA" with an erupting volcano as its logo. The company Hecla Electrics Pty Ltd was officially registered in 1922. In 1928 the company adopted the advertising slogan, 'By Hecla, it's Good'. The Hecla range rapidly expanded to include electric heaters and radiators, electric foot warmers, electric kettles, ceramic & metal electric jugs, immersion hot water elements, electric fans, electric coffee percolators, electric toasters, electric grillers and stoves, electric irons and electric frypans, clocks and curling wands. Electric blankets were introduced shortly after WWII.In 1930, a controlling interest in Hecla Electrics Pty Ltd was acquired by General Electric Corporation. Clarence William Marriott died in June 1967 in Melbourne, Victoria.This item is representative of a common domestic appliance used throughout Australia. It was manufactured by a pioneering Australian company.A small chrome steel toaster manufactured by Hecla Australia. It has a door on either side which flips down to insert or remove a slice of bread on each side, Each door has two black Bakelite knobs. The electric element is placed down the centre of the cavity. A detachable electric cord is included.240 Volts, 600 Watts. Cat. No. T4 Submitted to Electrical Approval Board Ref Application A1/AD01 SECV 240 Volt 600 Watt MANFED. IN AUSTRALIA SOLID BRASSelectrical appliances, hecla corporation australia, clarence william marriott, domestic appliances -

Anglesea and District Historical Society

Anglesea and District Historical SocietyCassette Recorder, GAC, Not known

Six key portable cassette recorder/player with rotary volume control. It can be operated directly from batteries or AC power (cord included). Also has Automatic Recording Level Control Circuitry (ALC), thus no need to adjust volume while recording. In original box with instructions and power cord. (Purchased at Waltons for 29.99).Auto Stop / GAC - logo Top: Condenser mic Rec / Play / Rewind / FF / Eject Left side: Ear O / Remote Mike 00 / Volume Bottom markings: Model No. SW-201 AC: 240V 50HZ 6W DC: 6V (UM - 2x4) Made in Hong Kong Warning: To prevent fire or electrical shock hazard, do not expose this appliance to rain or moisture, do not remove cover, no user serviceable parts inside, refer servicing to qualified service personnel. cassette recorder, gac -

Flagstaff Hill Maritime Museum and Village

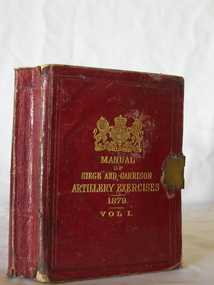

Flagstaff Hill Maritime Museum and VillageBook - Instruction Manual, British War Office, Manual of Siege and Garrison Artillery Exercises Vol 1, ca 24-06-1882

This little book has been designed to fit into a small space such as a pocket, backpack or trunk. The brass book lock helps keep the pages and covers together, preserving them from being bent, torn or damaged in handling.The book includes four of ten parts of the Manual, published for use in training the garrison troops, including the placement and firing of cannon. The four parts included in this Volume I are: - Part 1 - Gunnery Part 2 - Ammunition Part 3 - Siege Artillery Part 4 - Garrison Gun Drills The remaining six of then parts are: - Part 5 - Material and Appliances Part 6 - Elementary Instruction Part 7 - Machines Part 8 - Mounting and Dismounting Ordnance Part 9 - Sleighs Part 10 - Sheers and DerricksThe book is significant to both British and Australian history, being issued for the training of the garrison defense of both countries in the late 10th Century. It is also significant for its connection with other historical military items within the Collection at Flagstaff Hill Maritime Museum and Village.Manual of Siege and Garrison Artillery Exercises Vol 1 [Parts I, II, III, IV] Publisher Her Majestys Stationery Office Date 1879, Corrected June 24th 1882 Small, red, hard-cover book with embossed gold letters and British Coat of Arms on the front. The book has a brass closure or locking clip across the text block. There are diagrams and a foldout table within the text. flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, training manual, book, british garrison, garrison artillery, siege exercises, british government training book, technical book, pocket book, manual of siege and garrison artillery exercises vol 1, garrison exercises, military training, defense training, british artillery, royal artillery, gunnery, gun drill, brass book lock, british war office, locking clip, reference book -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, 'Smoothwell' electric flat iron c1935, c1935

c1881 Henry W Seely, of New Jersey, USA, designed and patented an electric sad iron for pressing and smoothing material. He continued to modify and improve his designs, with his partner Richard Dyer, and other electrical appliance firms, e.g Hotpoint, began producing these flat irons that could provide continuous heat by connecting via an electrical flex to a light socket and hence without the need for hot fires, ash, or burning hot handles. Women with access to an electricity supply were delighted and their ironing chore became much less arduous No heat was felt at all from the iron as it is all concentrated on the bottom surface. By the early 20th century enthusiasm was building for the new electric smoothing irons: clean, powerful, adjustable, and labour-saving. This c1935 Premier System 'Smoothwell' flat iron was used by a resident of City of Moorabbin and is an example of the progress made from the sad irons used by the pioneers that are displayed beside it.A "Premier Smoothwell" electric flat iron with switched control lead and original box, c 1935 On plate of handle attached to Iron ' HARRODS Ltd. / LONDON On attached plate at rear of iron ' The "SMOOTHWELL" / "Premier System" /......... Plate on cord Plug " PREMIER/ FLAT IRON CONNECTOR/ THIS SIDE OUTWARDS/ (2 columns) 1) FOR 100-125 VOLTS/ USE THREE TERMINALS/ THUS ..... 2) FOR 200 - 240 VOLTS/ USE TWO RIGHT/ HAND TERMINALS/ ONLY/ THUS......seely henry w., sad irons, electric flat irons, dyer richard, edison thomas, hotpoint pty ltd., premier electric company birmingham england, pioneers, early settlers, moorabbin, bentleigh, cheltenham, laundry, sewing, craftwork, table ware, irons -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Patent Applications - Trolley Pole safety appliance, Percy Ireland, 1920

Percy Markham Ireland (1893-1976), a tramway rolling stock engineer with the MMTB and a Military engineer applied in 1920 for a patent for a "Trolley Pole safety appliance for electric trams and the like". He was successful in gaining a patent in a number of countries including the UK, France, Germany, Canada, the USA, and New Zealand. The associated documents show the differences in making patent applications in various countries. From research undertaken by the Museum it appears that while his patent applications were successful, his invention was never actually implemented on tramcars in Melbourne". Collected by Noelle Jones as research for an article in the March 2023 issue of the Museum's magazine Bellcord, giving details of Mr Ireland's tramway and military career. He retired as the MMTB Rolling Stock Engineer in 1958 after 44 years of service.Yields information about patents applied for by Percy Ireland in different countries.Set of digital patent documents for Australia, USA, UK, France, Germany and Canada. tramways, patents, trolley poles, percy ireland, safety devices -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - bale hook small, c1900

A hook as a hand tool is used for securing and moving loads. It consists of a round wooden handle with a strong metal hook projecting at a right angle from the centre of the handle. The appliance is held in a closed fist with the hook projecting between two fingers. This type of hook is used in many different industries, and has many different names. It may be called a box hook, cargo hook, loading hook, or a docker's hook, and a baling hook, bale hook, or hay hook in the agricultural industry. Other variants exist, such as in forestry, for moving logs, and a type with a long shaft, used by city workers to remove manhole covers. A hay hook is slightly different in design in that the shaft is typically longer. It is used on farms to secure and move bales of hay, which are otherwise awkward to pick up manually. A small bale hook with a wooden handle and 2 curved steel hooks pioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, graziers, wool bales, hay bales, -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Foot Bellows, Fletcher Russell & Co. Ltd, c1895

FLETCHER RUSSELL & CO. LTD/ WARRINGTON MANCHESTER & LONDON Thomas Fletcher (1840-1903) had established a gas appliance manufactory in Thynne Street, Warrington by the 1880s. By 1895 the company had become Fletcher Russell and Co Gas Engineers, his firm having merged with Alexander and William Russell of Pendleton Iron Works. In 1950, the firm merged into Radiation Ltd which was later acquired by 'TI New World. In the early 1880s Thomas Fletcher was a registered dentist who went on to found a dental apparatus manufacturing business. He later diversified into producing equipment for blacksmiths, foundries, forging and other sectors. The company had grown to 900 employees in 1914. These foot-operated bellows were for pumping gas to keep the patient relaxed while the dentist worked on their teeth. They were later modified for a variety of uses where a continual flow of air was needed.These bellows are representative of a range of devices developed in the late 19th Century to assist in manufacturing. They were donated to our collection by a Wodonga resident.A set of foot bellows made from timber, metal and leather. The bellows were activated by pressing up and down on the metal step-shaped lever at the front. The air outlet on one side would have a hose attached to it to direct the air current to wherever it was needed. The bellows are made from leather. The manufacturers mark is attached to the top within a metal circle.On top of Bellows in a circle: "FLETCHER RUSSELL & CO./ WARRINGTON/ MANCHESTER / LONDON"foot bellows, fletcher russell & co. ltd. -

Melbourne Tram Museum

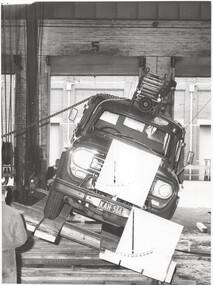

Melbourne Tram MuseumPhotograph - Set of 8 - testing roll over of fire trucks, Melbourne & Metropolitan Tramways Board (MMTB), c1969 - 1970

Photographs of fire trucks being tested for the roll over characteristics at Preston Workshops. .1 - .3 - Metropolitan Fire Brigade Board (Melbourne - MFBB) appliance or fire truck or pumper, being tested at Preston Workshops. Based on the number plate in .1 - c1969 - 1970 see https://en.wikipedia.org/wiki/Vehicle_registration_plates_of_Victoria (accessed 22/4/2020) The facility appears to be long enough to test a bus, but appears to be one that was stored and then brought out for use - see photo 8. .4 to .6 are of testing a UK truck on a more dedicated facility. .7 - workers, some ex MFB workshops possibly, winching rope .8 - the testing frame or lift panel with crane ropes attached and W6 tram No. 986 in the background. A copy of the Newsletter of the Fire Services Museum of Vic. 9/2021 featured some of these photos. Item stored in box 192 with the photographs.Demonstrates the testing of the roll over angles of a fire truck.Series of eight black and white photographs trams, tramways, preston workshops, mfbb, testing, tram 986 -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - GROUP OF ADULTS - THEATRICAL GROUP, 1920 - 1930?

Black and white group of eight adults in a line. Men (four) wear dinner suits (white ties and tails) and are holding monkey masks to resemble the :Monkey Brand: appliance cleaning product they are advertising or using in a theatrical performance. The four women wear black, knee length dresses and are dressed as maids, with white 1/2 length aprons and white caps. They have the 'Monkey Brand' advertisement pinned onto their aprons and are holding another cardboard ad. (the same one) suspended from a block. Four clean saucepans on floor at men's feet. Inscriptions: in image - the same advertisement seen eight times - Monkey Brand Won’t Wash Clothes. On board: front - Kalma 57 & 59, Pall Mall, Bendigo. Back - (hand written, J Dean, Joe Borrell, John Borrell, F Donaldson. Second line of names on back - A Hurst, Kathleen Dixon. In lower LH corner, brand indentation (photographer?)/Kalma, 57 & 59 Pall Mall, Bendigoperson, group, theatrical group?, see also 2001.334.01