Showing 1460 items matching "bowl"

-

Bendigo Military Museum

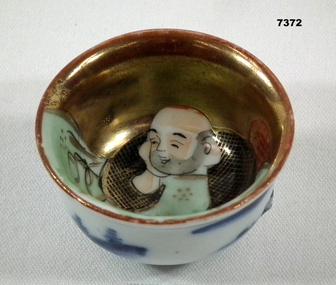

Bendigo Military MuseumCeramic - CEREMONIAL BOWL

Small bowl, possibly a finger bowl used for ceremonies. Item in collection of "Richard William McGILVERY" RAAF. Refer Cat No. 7287P for his service details, photos and awards.Small bowl, outside white with blue images of Japanese country side. Inside picture of Asian man sitting on a chair looking at a green cloth covering half of the inside. Other half gold background.Japanese symbol on bottom.bowl, souvenir, richard william mcgilvery -

Flagstaff Hill Maritime Museum and Village

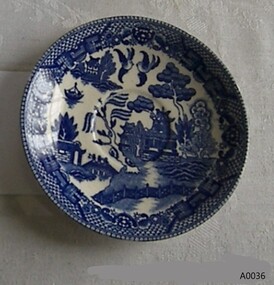

Flagstaff Hill Maritime Museum and VillageCeramic - Bowl, Broadhurst Staffordshire Ironstone Pottery, 1950s - 1960s

Broadhurst China was established in 1862 the firm was based at the Crown Pottery, Longton, Staffordshire until 1870 where James Broadhurst made a range of gold and silver lusterwares. In 1870 the firm moved to the Portland Pottery at Fenton, Staffordshire and continued to produce good quality earthenware. In 1897 "& Sons" was added to the company name and "Ltd" from C.1922. The full name, James Broadhurst & Sons Ltd. appears from 1957. In 1984 James Broadhurst & Sons Ltd became Churchill Tableware Ltd.Items made around 1950s or slightly later that are now collectors items made by one of the founders of ironstone pottery in England.Small ironstone willow pattern bowlThe back is stamped "WILLOW BROADHURST STAFFORDSHIRE IRONSTONE Made in England Detergent and Dishwasher Proof" Mass produce, Ceramic, Potteryironstone pottery, staffordshire pottery, flagstaff hill museum, crockery, dinner set, willow pattern -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Early 20th Century

Enamel cookware became very popular because people wanted a way of coating iron to stop metallic tastes or rust getting into food: something acid-resistant and easy to clean without laborious scouring, something more durable than the tin linings used inside copper. Enamelware dates back to 1760 in GermanyThis object is significant as an example of an item in common use in the 19th and early 20th centuries.Large light blue enamel bowl.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, enamel, kitchenware, washing -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Ringwood Bowls Club- Ladies Section , Club Champion for 2003/2004 Gordana Baric putting down the first bowl of the season

Coloured photograph"Attached to photograph" On 31st August, 2004 the VLBA ladies open day was held with Sue Hudson rolling the new yellow jack on the synthetic green. Sue was runner-up in the Ladies Club Championships. The Club Champion for 2003/2004 was Gordana Baric shown putting down the first bowl of the season. Gordana represented Australia at the Commonwealth Games in 2002. -

Flagstaff Hill Maritime Museum and Village

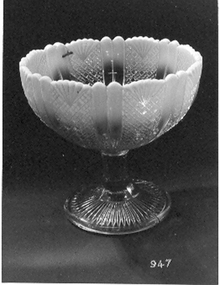

Flagstaff Hill Maritime Museum and VillageBowl

Glass bowl oval shaped with patterned bottom.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Uniting Church Archives - Synod of Victoria

Uniting Church Archives - Synod of VictoriaBowl

Spherical silver engraved bowl with 2 handles.Front: Presented to The Union Memorial Church by Mrs T Ingram Back: Jubliee October 1904 -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Domestic object - Baby's Plate, Child's feeding dish

Heavy, flat-sided baby’s feeding bowl, the design of which encourages the child to feed himself. A good example of a common household item.Round cream ceramic bowl with flat lip and straight sides which is straight on the inside and indented on the outside. “BABY’S PLATE “ written in brown on rim. Transfer of three young girls with one astride a black and white dog, in garden setting. Gold on rim.Baby’s plate.bowl, ceramic -

Orbost & District Historical Society

Orbost & District Historical Societybowl

Owned by Alexander Cameron who arrived in Australia in 1853. Alexander Cameron ("Big Alex") was an early settler on the Snowy River flats. he worked the paddle steamer Cheviot for a while, having a wharf and sheds on the Snowy River in 1900. Later moved to Cann River. The Bowling Club was founded in 1929, by a group of farmers and businessmen. They set about providing a sporting icon for the town. Six rinks were constructed on the current site using horse drawn scoops and drags. The "Back to Orbost” 1937 book, describes the greens as "a bit rough for the first two seasons but now compare favourably with most country greens". Funds for the construction were raised by the issue of debentures at £5 each, and subscriptions were £1/1s/0d ($2.10). (info. Margaret Smith)Alec Cameron was a prominent early Orbost settler. The Orbost Bowling Club was established in 1929.Wooden lawn bowl with wooden circles on top and bottom. Top- I Bottom - J.R.22recreation sport lawn-bowls cameron-alexander -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBowl

Small glass bowl. Has a chip out of bottom.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Bowl

Round cream bowl with green, yellow and black designdomestic items, crockery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBowl

Bowl ceramic with decorative floral design around rim in green and gold. Bowl area is white. "Verona 5 ways England" stamped on back. Has several chips.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Nillumbik Shire Council

Nillumbik Shire CouncilCeramic (bowl): Alexandra COPELAND, Alexandra Copeland, Vanity, 1/9/1994

This bowl is part of a series completed in 1994 on the subject of the sin of 'Vanity' / A smug looking woman flirts coquettishly with a manservant who helps her to put on her shoes / The people depicted on the bowl are dressed in 18th century costumes / The court of Marie Antoinette of France is evoked / The blue and white drawing is in the style of 18th century woodblock prints and was drawn freehand / The bowl is signed and dated on the base / The technique is traditional tin glaze (majolica, maiolica or delft) / Coloured oxides were painted onto a clear glaze which had been opacified with tin oxide, and then fired at 900 degrees / The bowl was exhibited at Christine Abrahams Gallery, Melbourne in 1994 / A bowl from the 'Vanity' series is held in the Collection of the Queen Victoria Museum and Art Gallery in Launceston, Tasmania. Copeland's parents are John and Betty Hipwell, one of the founding members of Potters Cottage (an influential ceramic collective that grew out of Nillumbik) / Copeland grew up surrounded by this artform. Reg Preston (another founding member of Potter's Cottage) introduced her to the Majolica technique which has influenced her ceramic work to this day / This bowl is characteristic of Copeland's speciality and mastery of the Majolica technique. This bowl is hand painted with an image of a couple flirting (man-left side and woman-centre) in 18th century French dress / Decorative circle and polka dot pattern along the rim and underside of the bowl / The bowl is predominantly painted in cobalt blue and orange colour using the Majolica (maiolica or delft) technique; a traditional tinglaze method of application. Coloured oxides are painted onto a clear glaze which has been opacified with tin oxide / The bowl is then fired at 900 degrees.Underside has in colbalt blue artist signature and date / 'A. Copeland . 1.9.1994'.copeland, earthenware, majolica, potters cottage, vanity, bowl, eighteen century, french, marie antoinette -

Mont De Lancey

Mont De LanceyBowl

Pink fluted bowl with raised gold pattern interior. (Milk glass) -

Mont De Lancey

Mont De LanceyBowl, Burlington Ware

Used by Edna Andrews for storing dripping.Oval cream china bowl with orange and gold flowers and a green rim.Burlington Ware Made in Englandbowls -

Bright & District Historical Society operating the Bright Museum

Bright & District Historical Society operating the Bright MuseumPipe clay

White clay long bowl of pipe. The bowl has a thick wall. Shaft broken off at the base of the bowl. Has a rest bar at the base of the bowl."CORK" inscribed on the outer surface of the bowl, above the shaft.pipe, goldfields, tobacco, leisure, smoking, recreation, gios -

Orbost & District Historical Society

Orbost & District Historical Societybowl, Mid 20th century

Carnival glass is an inexpensive pressed glass, made as both functional and ornamental objects. Most carnival glass was made between 1907 and 1925, with production tapering off by the end 1931 during the great depression. the name "carnival glass" came about because when the demand for the glass tapered off it was often given away as prizes at carnivals.Large amber coloured glass bowl. It has four short legs moulded to the base. It is very ornate and solid. On the base is a pattern of fruit and flowers. The rim is fluted and the bowl is oval shaped. It is carnival glass. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBowl

Bowl white enamel small with blue rim around top-in good conditionflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Mont De Lancey

Mont De LanceyBowl

Purchased by Mr. & Mrs. H.N. Lord in 1966"Vancouver Ware" ruby bowl with pewter rose design fused onto glassbowls -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumDomestic object - Bowl

Medium sized patterned green glass bowl with two handles. Transparent glass. -

Mont De Lancey

Mont De LanceyBowl

Red lacquer Japanese stud bowl with lid & 2 cotton wing backed collars.bowls, collars, wing collars, neckwear -

Kyneton Fire Brigade

Kyneton Fire BrigadeMemorabilia - Bowl

Fire Brigade Trophy - no inscriptionPart of Kyneton Fire Brigade trophy collectionBlue glass bowl on silver stand with silver surround and handles. Silver base with decorationkyneton fire brigade, country fire authority, fire brigade demonstrations -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic - Ceramics, Ceramic Sugar bowl by Wartook Pottery, c1990

Graham WOOD Wartook Pottery was set up in the early 70s by Graham Wood, and was sucessful for nearly 25 years. It then moved to Halls Gap (The Grampians, Victoria), and the name was changed to Jimmy's Creek Pottery in 1998. The pottery conitnued under that name until 2003. when cheap imports hurt the business. Hand thrown ceramic bowl with 'Gum Leaf' design and the word 'sugar'. According to decorator Wendy McGuiness all decoration was made and applied by hand - an extremely time consuming activity. Texture to the body of each piece was created by using a piece of coral. Tenmoku glaze was applied to the top of the pieces, with iron oxide to the main body. This was the first of the Wartook range that sold commercially from around 1987 all over Australia. At the height of production Wartook Pottery had 5 employees, including a new wheel potter (who was adept at creating the pieces as Graham had done before). Additional ranges were still hand thrown, but with a floral wreath (slip cast) applied to the top of each pot, as well as a range that used decals for decoration. australian landscape pottery, les macleman, ceramics, landscape, graham wood -

Greensborough Historical Society

Greensborough Historical SocietyPipe, ASPA, Timber pipe, 1970s

Timber pipe stem.From a collection held in Greensborough.Wooden pipe with hexagonal bowl, two-tone. "ASPA Supreme" stamped on bowl.pipes, smoking pipes -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBowl

According to Lloyd's Shipping Register 1837-1839, the CHILDREN was built in 1825 at Liverpool and operated by owners Gordon & Co, of London. London registered number 123/1837. James Henty then bought her in 1837 as a three-masted barque of 254 tons, with a hull of “part pitch pine, felt sheathed” and “coppered 1837”. Launceston registered number 6/1837. In 1838 the CHILDREN, under her master Captain H. Browne, completed a successful round trip from Launceston to London (carrying wool and whale oil loaded in Portland), returning in late November of that year (carrying a general cargo including the house bricks). On the 11th January 1839, the CHILDREN sailed from Launceston for Adelaide, with 24 passengers, 14 crew, and an awkward mixed cargo, including 1500 sheep, 8 bullocks, 7 horses, and farming implements, and six whaleboats with associated whaling gear. One account states that when the CHILDREN “put out from port she was light and badly ballasted”. The vessel immediately encountered four days of hurricane force storms, eventually clearing on the early morning of the 14th to “west force 10”, but too late to take accurate measurements of the sun or stars to establish their position relative to the coast. The CHILDREN collided with a limestone stack at the entrance of Childers Cove, and the seas smashed her into pieces within half an hour. All the cargo and 16 lives were lost (including 8 children). The Henty’s contributed £150 towards a fund for the 22 survivors at a memorial service held in Launceston later that year. It was a major financial setback for the Henty’s, but one from which they recovered. In a submission to the Governor of New South Wales dated 24 March 1840, the Henty’s summarised their work over the previous six years of settlement: “Six stations have been occupied, one at Portland Bay…three at the open country about 60 miles inland called ‘Merino Downs’…They have erected two houses at Portland Bay and two others at Merino Downs”. The shipwreck of the CHILDREN is of State significance ― Victorian Heritage Register S116Part of terracotta bowl from the wreck of the Children, 2 segments have been glued together.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, children -

Flagstaff Hill Maritime Museum and Village

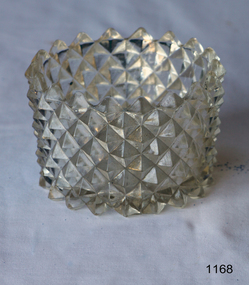

Flagstaff Hill Maritime Museum and VillageBowl

Bowl glass diamond pattern in relief covering entire outside, creating jagged top rim.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Shallow Vegetable Serving bowl, Johnson Brothers England, 1913 - 1942

Johnson Bros. was founded by two brothers named Alfred and Frederick who purchased a pottery factory in Hanley, England, in 1883. They were grandsons of a renowned English potter, Alfred Meakin. They were later joined in the business by their brothers Henry and Robert. Their business grew rapidly, as they were one of the world's largest pottery factories by the turn of the 20th century. By 1970, Johnson Bros. obtained the Royal Charter to become the official provider of china for Her Majesty Queen Elizabeth II. More than 1,300 patterns have been created throughout Johnson Brothers' history. Due to their growing success, manufacturing plants were established overseas including the establishment of a tableware factory, Johnson Brothers Australia in 1957 in Croydon, Victoria operated through a company known as Sovereign Pottery Ltd. Due to rising competition, Johnson Brothers became part of the Wedgewood Group in 1968. In 2015, following the acquisition of Wedgewood by Finnish company Fiskars, the Johnson Brothers branding was discontinued. The trademark on this bowl was used by Johnson Brothers between 1913 and 1942. An item which reflects the changing market for tableware that was reasonably priced and serviceable. Their innovation of the pottery line called semi-porcelain changed the industry. This development allowed potteries to produce fashionable pottery items that were affordable to all social classes of the time. Their use became widespread in Australia, especially following their establishment of a tableware factory in Melbourne, Victoria. A shallow white bowl with gold trim, probably used for serving vegetables at the table. The underside of the bowl bears the mark of Johnson Bros England. The mark is composed of a green crown above the words "Johnson Bros England" also in green.On under side of bowl, beneath a green crown "Johnson Bros/England"johnson brothers ceramics, domestic utensils, kitchenware -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkDomestic object - Sugar bowl

This tea set was presented to Harold Leggett by the Emerald Mechanics Institute for his services as secretary to the committee 1926 - 1938This tea set is significant because the recipient was a well-known local man in the early part of the twentieth century and the Mechanics Institute was an important Emerald institution Silver Plate "Challenge" Sugar BowlUnder the bowl - "CHALLENGE EPNS A1"emerald mechanics institute, leggett, tea set -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Bowl

Blue glass bowl on stand in graduations of blue cut glass. Has been damaged see condition report.glass technology, glassware -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Bowl, c1805

Belonged to donor's grandmother, Mrs. Esther Gledhill. Esther came from a pioneer family and was married to Robert Gledhill who was a sleeper cutter for the railways.'Carnival Ware' glass bowl with three fluted edges standing on three legs. Leaf and berry pattern inside.glass technology, carnival