Showing 226 items

matching castings

-

Port Fairy Historic Lifeboat Station

Port Fairy Historic Lifeboat Stationbag, oil bag, early 20th Century

Item acquired from Lakes Entrance boat builder/owner who sold it to the PFHLS in 2008. Oil bags were part of the lifeboat equipment. Only one other example known is at the Port Albert Maritime Museum The oil bag was used to put oil on the sea's surface, to inhibit spray, wave burst and fear for survivors transferring from the shipwreck to the lifeboat. This was essential, as the lifeboat would never come close to the wreck, to avoid the risk of being damaged itself. The item is rare, and a vital part of the lifeboat's rescue equipment. The technique probably generated the phrase "pour oil on troubled waters" textile (flax) bag, shaped like a tennis racquet cover, with a brass tube attached to bag. The tube has a series of very small circular holes (in lines) arranged along the length of the tube. These were to allow the light oil contained within the bag to be sucked from the bag by a venturi action. The bag has a light line attached to it to secure to the lifeboat when in use (by casting the bag into the sea).. no markingsno markingsoil bag -

Tennis Australia

Tennis AustraliaRacquet, Circa 1924

A 'Birmal' model tennis racquet manufactured by Birmingham Aluminium Casting (1903) Co. Ltd. Has open throat and handle wrapped with string whipping and leather. Metal indented butt cap. Metal strings with some double stringing in a grid pattern. Manufacturer name embossed on one edge of shaft. Model name and words: 'ALL METAL' embossed on other edge of shaft. Materials: Metal, String, Leathertennis -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern was possibly made for casting a part for Craftman Marine, makers of engines for boats and other machines. It is part of a set that is stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block with a corner cut diagonally. A five-sided shape has been carved into the centre, with one side curved inwards and slightly shallower than the other sides. The cut-out area is painted black. Three holes are drilled in the cut-out side to align the pattern with another piece of work. A wooden slat is fixed across the diagonal side. The back of the pattern has a handwritten inscription, possibly by two writers. The pattern is part of a set of foundry patterns from Briggs Brass Foundry and is connected to Craftman Marine.In black handwriting: "1 # H AL" Handwritten in a different hand: "CRAFTMAN MARINE" Written the the first hand: BRIGGS" (or "BRICK")flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912, craftman marine, craftsman marine -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph, St Ausgustine's Catholic Church, Creswick, 2020, 24/10/2024

This church was opened on 15th, September 1872, and was constructed over two years at a cost of 4500 pounds. The bluestone was sourced from Dean. The St Augustine statue is by Mattei Brothers. Mattei Brothers and Co. were modellers and figurine manufacturers at 126-132 Greeves Street, Fitzroy. Ferdinando Mattei, Amedeo Mattei and Amato Mattei were skilled in plaster casting, they migrated from Gromignana to Australia in the early 1920s and in 1926 opened their business.Photographs of the bluestone Catholic church at Creswick, Victoria. The photograph was taken while churches were closed due to the Covid 19 pandemic.creswick, bluestone, catholic church, d. foley -

Bayside Gallery - Bayside City Council Art & Heritage Collection

Bayside Gallery - Bayside City Council Art & Heritage CollectionMonument - Memorial, Irwin and Stevenson, Brighton War Memorial, 1927

On 23 July 1922, Brighton City Council adopted the recommendation from a sub-committee that the site for a war memorial be at Green Point, Brighton Beach. Brighton Council invited designs, limited to returned soldier architects and 18 designs were received. The first prize of £30 was awarded to the architecture firm Irwin and Stevenson and the designs were exhibited at the Brighton Town Hall in 1925. The bronze casting, using lost wax technique, was executed by sculptor Mr. Paul Montford, to the design of the architect and the central assemblage was believed to be the largest bronze casting in relief carried out in Australia at the time. The Brighton War Memorial was unveiled by His Excellency the Governor, the Right Honourable Arthur Herbert Tennyson Baron Somers, K.C.M.G., D.S.O., M.C., on Sunday 24th April 1927 in the presence of 4,000 people. The memorial was originally constructed to commemorate those from the City of Brighton who served in World War One but has since been augmented to commemorate those from the municipality of Bayside who have made the ultimate sacrifice during official periods of hostility.War memorial consisting of a sandstone cenotaph, granite base and sandstone terrace situated at Green Point, Brighton. The cenotaph is a truncated obelisk with classical decoration in stone and bronze. The cenotaph bears the Rising Sun badge in bronze relief near its top with bronze lettering running down the cenotaph reading "ERECTED IN HONOUR OF THOSE WHO FOUGHT IN THE GREAT WAR 1914 – 1919". A bronze relief assemblage of crossed weapons, a wreath, the lamp of valour and the Latin phrase "DUCIT AMOR PATRIA" (love of country leads me) sit above the base which is carved with the word "SERVICE". The terrace walls have bronze relief medallions with images of the head of an airman on the left and an infantryman on the right. The back of the cenotaph bears a torch in bronze relief near its top. On the sandstone wall behind the cenotaph are three large bronze plaques that lists the names of those from the City of Bayside who have served in the various conflicts in which Australia has been involved. At the back of the sandstone wall is carved lettering reading "HISTORY GAVE THEM A COMMON FAME. POSTERITY A COMMON MONUMENT" with 1914 carved on the left and 1919 on the right.brighton war memorial, memorial, cenotaph, green point, war memorial, brighton, service, paul montford, irwin and stevenson, rising sun, wreath, weapons, lamp of valour, great war, world war one, honour roll, honour board, roll of honour, ducit amor patriae, brighton beach, city of brighton, leighton major francis irwin, roy kenneth stevenson -

Tennis Australia

Tennis AustraliaRacquet, Circa 1924

A 'Birmal' model tennis racquet manufactuerd by Birmingham Aluminium Casting (1903) Co. Ltd. Has open throat and wood handle wrapped with leather, and with leather end wrap. String whipping seals leather onto handle at bottom of shaft. Metal strings. Manufacturer name embossed on one edge of shaft. Model name and words: 'ALL METAL' embossed on other edge of shaft. Materials: Metal, Leather, String, Woodtennis -

Melbourne Tram Museum

Melbourne Tram MuseumFunctional object - Conductors (Signal) Bell - N&C pattern

Bell used by the conductor or passengers to signal to the driver - stop, proceed or an emergency stop. N&C - Demonstrates a conductors communication or signal bell made for use on tramcars.Brass Conductor Communication Bell, or signal bell, consisting of cast frame, bell, striker, bell pull part, sheet metal domed section that is secured to the underside of the bell with one nut to secure the bell to the frame and two rivets securing for the bell pull part. Has at both ends, six screw holes that were used to secure the bell to the roof. Note the difference in the casting detail between the two ends of the bell.trams, tramways, conductors, bells, mmtb -

Ballarat Tramway Museum

Ballarat Tramway MuseumAdministrative record, State Electricity Commission of Victoria (SECV), "Some notes pertaining to tramway conference, Ballarat", 4/1954

Set of notes prepared before the 1954 conference by the Ballarat office. Notes actions on the 1952 and 1953 conferences, rail profile survey, bitumen paving, painting of tram, blinds, removal of sun blinds, lights fitted to trams, brake blocks - hardness and allowable wear, side bearing clearances, castings, track and depot workshop hours, costs, trolley wheels, lubrication products used, alterations to Maximum traction tramcars, and failure of pony wheel axles.Yields information and demonstrates SECV meeting notes prepared prior to a joint meeting.Four foolscap sheets - carbon copy.secv, ballarat, trams, tramways, minutes, sec, tramcar equipment, maintenance, trackwork, trolley wheels, motors, maximum traction, employees -

Ballarat Tramway Museum

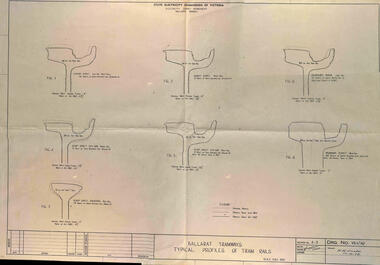

Ballarat Tramway MuseumDocument - Report and drawing, State Electricity Commission of Victoria (SECV), "Ballarat Tramways - Tracks", October 1962

Document or report dated October 1962, outlining the history of the Ballarat Tramways tram tracks, rail replacement, extensions, type of construction, present condition, eg Sebastopol, notes on photos which are not included within the report, including point castings and crossings, issues and recommending that the track is rehabilitated. Refers to a drawing with 7 rail cross sections, titled "Ballarat Tramways typical prfiels of tram rails" - see image 2, for VB4/40. See item 9936 for a similar drawing for Bendigo Tramways.Yields information about the condition of the Ballarat Tramways track in Oct. 1962Document - memo - typed carbon copy on 3 foolscap sheets and dyeline printed drawing.tramways, trackwork, ballarat, reports, track materials, stringer tram tracks, tram track construction, drawings, rails, profiles -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, Hadfield's, "Points, Crossings and Special Track Work for Tramways & Railways, c1910

160 page book with heavy covers, with title "Points, Crossings and Special Track Work for Tramways & Railways / Hadfield's Steel Foundry Co. Ltd., Sheffield England" giving details with many photographs of the company and their work in producing cast steel points and castings for Railways and Tramways. Shows many photos of the layout of complex junctions in their Sheffield works at East Hecla. Has many fine detailed engravings. Images added 24-12-2016"Ballarat Tramway Preservation Society Catalogue No. 4" on page 1.trams, tramways, trackwork, hadfield's, special work, cast steel -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Rubber Stamp, Andrew Cook, "Ballarat Tramways Official Opening, 1st Feb. 1975", Jan. 1975

Rubber stamp and wood stamp holder for use on official opening day for trams operated by the BTPS. Rubber casting with words "Ballarat Tramway Official Re-opening 1st February 1975". Red wood stamp hold and black wood handle with black direction pin. Second one added 17/09/2009 along with SEC stamps at the same time - btm352i1. See Reg item 4776 and 6430 for sample tickets stampedtrams, tramways, btps, reopening, ballarat tourist tramway, opening, tickets -

Ballarat Tramway Museum

Ballarat Tramway MuseumNewspaper, The Courier Ballarat, No headline - but depot Tram Lines ripped up, 13/02/1973 12:00:00 AM

Yields information about the demolition or removal of the track in Wendouree Parade and how it was done.Newspaper clipping from The Courier, 13/2/1973- photo of tram lines being ripped up in Wendouree Parade at what would appear to be the site of Depot Loop, though possibly at the junction for the SEC depot. Has a point casting in the foreground and the church on the corner of Forest St. in the background. Has arm of excavator and a worker crossing the ripped up track as well. On top has a caption small note about the work and reference to Lydiard St. works.date in pencil of "13/2/73" in top right hand corner of cutting.trams, tramways, wendouree parade, track removal, sec depot, depot loop -

Puffing Billy Railway

Puffing Billy Railway216 NQR - Open Medium Truck, 15/ 1/1914

The NQRs were the standard Medium open goods wagon. Generally the sides and ends were removable thus providing a totally flat truck. Three long drop-down doors formed the sides thus allowing easy loading and unloading. 218 of these goods vehicles were built between 1898 and 1914 ? numbered 1 - 218. Originally, these wagons carried the code letter R as they were built with sides and ends. They later had the R removed. Unlike the Broad Gauge, VR's 2 ft 6 in (762 mm) narrow gauge network never had four-wheeled wagons (aside from a handful of trolleys). Because of this, a single design of open wagon emerged and this was the only type of wagon ever used on these lines. This was the NQR class, a wagon with the same length and loading capacity as a Broad Gauge four-wheeled open wagon to make transferring freight between the gauges easier. The wagons, numbered 1 through 218, were built between 1898 and 1914. The wagons used the same underframe as most other non-locomotives on the VR Narrow Gauge. Letters and numbers were originally painted only on the end bulkheads and doors, both of which could be removed as traffic dictated, and this made wagon identification difficult until the decals were transferred to the underframes of each wagon In the 1910s some NQRs were provided with removable wood and steel frameworks with canvas roof canopies and side curtains, and internal seating to supplement the rest of the passenger stock during busy holiday periods. Puffing Billy has re-created these for emergency capacity. Five more NQRs, numbered 219-223, were built between 1990 and 1992 initially for passenger use so were fitted with the removable frames Vehicle Length 25 feet 2 inches ( 7671 mm) Coupled Length 27 feet 4 inches (8330 mm) Width 6 feet 3 inches (1905 mm) Weight 5 tons Capacity 11 tons Built 1898 - 1915 (1992) Number Built 218 (223) In use 14 To be restored 6 216 NQR - Open Medium Truck 15/ 1/1914 NWS Built new VR Service History *NQR 216.VA - 15/ 1/1914 NWS Built new - / /1926 - To NQ 216.VA - Puffing Billy Service History or Notes April 2016 - Trial fitting of brake rigging May 2016 - Riveting of the draw gear castings in progress July 2016 - Riveting of the draw gear castings in progress. Truss rods threaded ready for fitting Aug 2016 - Rivetting of the draw gear castings in progress. Draw gear and couplers being evaluated. Sept 2016 - Riveting of the draw gear castings in progress. Draw gear and couplers being overhauled. Oct 2016 - Riveting of the draw gear castings completed, brake piping installed. Nov 2016 - Floor installed, under framing welding completed, fitting of side doors, hand brake fitted Dec 2016 - Car Workshop - Side panels fitted, end panels to be fitted Jan 2017 - Couplers fitted, brake rodding connected, transferred to Emerald for bogie work and sign writing. Feb 2017 - At Emerald - Tyres machined, braking system being prepared Historic - Victorian Railways - Narrow Gauge Rolling Stock - NQR Open Medium Truck216 NQR - Open Medium Truck made of Steel and metal216 NQRpuffing billy railway, pbr, rolling stock , 216 nqr - open medium truck, victorian railways, nqr - open medium truck -

Ballarat Tramway Museum

Ballarat Tramway MuseumAdministrative Record - Meeting Minutes, State Electricity Commission of Victoria (SECV), "Tramway Maintenance Minutes of 3rd Annual Conference March 30 and April 13, 1953", 1953

Document titled "Tramway Maintenance Minutes of 3rd Annual Conference March 30 and April 13, 1953" in the Bendigo and the Geelong offices. See item 9192 for Notes and Agenda for this meeting. Topics covered - cleaning of trams, tracks, track surface repairs, sleepers, car renovation, painting, flooring, notes on a Ballarat Field inspection, disinfecting blinds, electrical systems, truck maintenance, castings, maintenance costs, trolley wheels, employees duties and a summary of actions. Each item where relevant looks back at the actions from the previous conference. Has a list of attendees.Yields information and demonstrates SEC Meeting minutes about discussions between the three Provincial operators about tramcars and operations.Minutes - 50 duplicated foolscap sheets pinned with a folding clip in top left hand corner.trams, tramways, minutes, sec, geelong, ballarat, bendigo, tramcar equipment, maintenance, trackwork, overhead, painting, trolley wheels, motors, one man trams, employees -

Ballarat Fire Brigade

Ballarat Fire BrigadeTrophy, prior to May 1888

Large silver shield with highly detailed casting & hand engraving of a scene from the garden of eden. Shield is approximatley 630mm W x 850mm H surrounded by a 70mm wide mauve velvet material band. A gold curved rectangular plate withthe donor and winner name is set into the band. Shield was presented to the brigade in Sydney in May 1888 for first prize in the hose & ladder event as part of the centenial demonstration. Trophy was donated by the Australian Mutual Fire Insurance Society and presented by Walter Church, Manager.Centennial Demonstration / Sydney May 1888 / Hose & Ladder / First Prize Won By / W.Trahar, P.Cockburn / W.Smith, R.Young / W.Perkins, R.Johnstone / A.Reynolds, J.Coward / Captn W.Trotman, Apparatus Off W.Dark. (on gold plaque) Presented by the / Australian Mutual Fire / Insurance Society / Walter Church, Manager / Won bysydney, centennial-demonstration, sydney-may-1888, may-1888, hose-and-ladder, first-prize, w-trahar, w-smith, w-perkins, a-reynolds, p-cockburn, r-young, r-johnstone, j-coward, captain-w-trotman, apparatus-officer-w-dark, australian-mutual-fire-insurance-society, walter-church -

Federation University Historical Collection

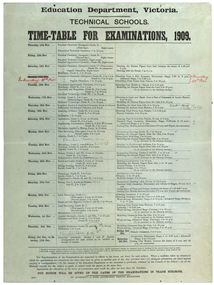

Federation University Historical Collectionposter, J. Kemp, Education Department Victoria Technical School Timetable for Examinations, 1910, 1910

Large printed timetable for Technical School examinations in 1901. Subjects included Chemistry, Geology, Asssaying, Hydraulics, Agriculture, Engineering , Mine Surveying, Algebra, Mineralogy, petrology, Botany, Trigonometry, Euclid, Land Surveying, Steam and gas Engines, Applied Mechanics, Drawing, painting, engineering drawing, building construction, architecture, drapery, modelled design, casting clay models, composition of form and colour, Lettering, Wood Carving, historic ornament, Wood Carving. .1) Trade Subjects .2) Other subjects, including artexaminations, technical schools, trades, art, technical art school, timetable, clay modelling, ceramics -

Federation University Art Collection

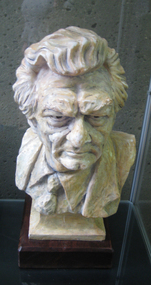

Federation University Art CollectionArtwork - Marquette, Malcolm Fraser by Peter Nicholson

John Malcolm Fraser AC, CH, GCL (21 May 1930 – 20 March 2015) was the 22nd Prime Minister of Australia and the Leader of the Liberal Party from 1975 to 1983. Fraser's bust was originally created by Victor Greenhalgh. However, Greenhalgh and others were critical of the final casting. Following Greenhalgh's death in 1983, Peter Nicholson was asked to create a new bust for Fraser, which was completed after the bust of Fraser's successor Hawke had been installed. This item is part of the Federation University Art Collection. The Art Collection features over 1000 works and was listed as a 'Ballarat Treasure' in 2007. A plaster marquette of Prime Minister Malcolm Fraser produced for the bronze bust in the Ballarat Botanical Gardens' Prime Ministers Avenue.art, artwork, prime minister, prime minister's avenue, malcolm fraser -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlaque - Nameplate, Circa 1886

The brass letter “A” is from the starboard bow of the FALLS OF HALLADALE, a 2085-ton iron-hulled and four-masted sailing ship that was wrecked near Peterborough on 14 November 1908. Two companion pieces, the letters “S” and “D”, are also in the Flagstaff Hill Maritime Village collection of shipwreck artefacts (as registered numbers 748 and 6596). The ship’s name originally appeared in these impressively large brass letters across the stern and both port and starboard bows of the vessel. The FALLS OF HALLADALE was built in 1886 by Russell & Co at their Greenock shipyards on the River Clyde. She was the seventh of nine similar cargo carriers produced for the owners of the Falls Line, Wright, Breakenridge & Co of Glasgow. All nine ships were named after waterfalls in Scotland. First was the FALLS OF CLYDE in 1878, then the FALLS OF BRUAR in 1879 (lost in 1887), the FALLS OF DEE in 1882 (sunk in 1917), the FALLS OF AFTON in 1882, the FALLS OF FOYERS in 1883 (disappeared in 1898), the FALLS OF EARN in 1884 (wrecked in 1892), the FALLS OF HALLADALE in 1886 (wrecked in 1908), the FALLS OF GARRY in 1886 (wrecked in 1911), and the last of the fleet, the FALLS OF ETTRICK (lost in 1906). The FALLS OF CLYDE is still afloat as an exhibit at the Hawaii Maritime Center in Honolulu. Russell & Co delivered the owners full-bottomed, economical ships of 1800 to 2000 tons, practically designed to minimise loss of speed while increasing seaworthiness and carrying capacity. The sturdily constructed FALLS OF HALLADALE had iron masts and wire rigging, allowing her to maintain full sail even in gale conditions, and square “warehouse-type” bilges to accommodate maximum bulk cargo on her long-haul voyages. This class of ship remained commercially competitive into the twentieth century despite the advantages of coal-fired steamships. When the 22 years old FALLS OF HALLADALE finally foundered on Victoria’s Shipwreck Coast in 1908, the Melbourne Court of Marine Inquiry held it was entirely due to Captain D.W. Thomson’s navigational error, rather than any technical failure of the Clyde-built ship. The shipwreck of the FALLS OF HALLADALE is of state significance — Victorian Heritage Register No. S255. The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).A brass letter “A”, from the shipwreck FALLS OF HALLADALE, raised along the central axis to form three dimensional effect, in unrestored and fair condition. Of dull grey-green metal, bent and with irregularly worn edges, it has been subjected to amateur cleaning on the front face, with some remaining greenish copper oxidation and surface pitting. The rear face is uncleaned with a layer of sedimentary concretion, orange-red staining from the iron hull, and green copper oxidisation. Three sediment-filled bolt collars on the rear face are part of the original casting.warrnambool, shipwreck coast, flagstaff hill, shipwrecked coast, flagstaff hill maritime village, flagstaff hill maritime museum, shipwreck artefact, maritime museum, great ocean road, brass lettering, falls of halladale, 1908 shipwreck, russell & co., ship's nameplate, letter, letter a -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Stove, 1960 - 1983

The Mont Eltham Pot Belly Stove History The Mont Eltham Pot Belly Stoves were first manufactured in the 1960s at the Burrowes family business The Lyn Iron Foundry in Coburg Victoria by Barry and his father Charles Thomas Burrowes. The manufacture of The Mont Eltham Pot Belly continued in Victoria as The Mont Eltham Stove Co. by Barry and Glenda Burrowes in Montmorency and later in Thomastown. The castings were produced by leading Melbourne foundries, Cox & Rosetti , and Anderson & Ritchie. They were also made in Ballarat by The Harding Bros Foundry, and in Shepparton by The Furphy Foundry. The Mount Eltham pot belly stoves were manufactured until the late 1980s. Stove; cast iron pot belly stove. Very large cylinder shape with square base, grate shelf around centre, on 4 legs. Inscription on door. "Swagman" model. Made by Mont Eltham Stoves, Victoria. "Mont Eltham Stoves Vic Swagman Aust"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, domestic heating, domestic heating, stove, pot belly stove, wood fired stove, old world stove, the mont eltham stove co., the lyn iron foundry, barry and glenda burrowes -

Puffing Billy Railway

Puffing Billy RailwayNKS 9, Victorian Railways 2'6" gauge trolly

NKS Type Gangers Trolly - Victorian Railways 2'6" gauge trolley - a KS series Section Car oftern called the Kasey Jones The narrow gauge version of the broad gauge KS series cars. They were classed NKS with two stroke motors. These cars were built by the Spotswood Workshops, with castings coming from the Newport Workshops. KS is lighter car capable of carrying 4 men or sevenhundredweight Trolly 9 was built for the State Electricity Commission of Victoria for use on their metre gauge railway of Yallourn. It was sold to a preservation group at Walhalla and regauged to 2 foot 6 inch. It came to the Puffing Billy Railway in the early 1980s.Historic - Victorian Railways Narrow Gauge - Track Patrol Vehicle used by the State Electricity Commission of Victoria for use on their 900mm gauge railway of Yallourn. And then at Walhalla Railway where it was regauged to 2 foot 6 inchMotorised small rectangular trolly made of wood and wrought iron - currently stored dismantled Engine Type: 1 Cyl. reversible Fuel: 2 stroke Transmission: Belt driveNKS 9puffing billy, puffing billy museum, trolley, narrow gauge, 2'6" gauge, victorian railways, state electricity commission of victoria - yallourn., trolly -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; pair of U-shaped carved blocks, unpainted. The blocks have opposing metal pins and holes to hold them together. One block has a disc shape carved into the base. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; hexagonal wooden shape painted orange. The thick carved wooden shape is in halves forming a hole when locked together with the dowel pegs and opposing drilled holes. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; round wooden shape with a wide concave centre and a round flat handle in the middle, painted dark brown. The underside has a large wooden disc added to the centre. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; an unpainted, rectangular wooden frame with a top and sides, similar to a small rectangular stool. A solid half-cylinder shape was added under the horizontal 'seat' with another smaller half-cylinder attached to it, end-to-end. A string is tied between two metal loops attached to the back. There are two X marks stamped into the back. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.Stamped: "X" "X"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

NMIT (Northern Melbourne Institute of TAFE)

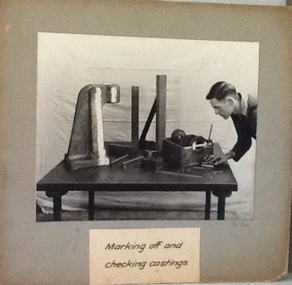

NMIT (Northern Melbourne Institute of TAFE)Photographs - Collingwood Technical School, Allan Studios, Mounted photographs of Trade School CTS, circa 1940, Early 1940s

Collingwood Technical School trained apprentices in many trades. These photographs depict some of the machines and machine parts built in class. Captions : 1. Marking off and checking castings 2. Examples of other machine parts, etc., being made in Youth Employment classes in engineering machine shop. 3. Cutting the traversing screw for a 5 ¼ inch lathe. 4. Grinding lathe spindle. 5. Cutting helical flutes in a shell end mill. 6. Arbor Press. Another valuable machine produced by Youth Employment and senior technical evening students. 7. Milling angular slides of lathe saddle. 8. 5 ¼ inch lathe product of Collingwood Technical School. These are high quality professional photographs taken circa 1940. 8 black and white photographs mounted on brown card. Photographs depict various aspects of lathe work.Each photograph has a hand written caption on the front. Also handwritten in black pen "Allan Studios".collingwood technical school, cts, apprentices, students, lathes, machinery, machine parts, nmit, -

Ballarat Tramway Museum

Ballarat Tramway MuseumAdministrative Record - Meeting Minutes, State Electricity Commission of Victoria (SECV), "Tramway Maintenance Minutes of Conference - April 26 and 27 1951", 1951

Document titled "Tramway Maintenance Minutes of Conference - April 26 and 27 1951", attended by SEC Head Office Officers, representatives from Bendigo and Geelong. Opening note on page 2 - that the discussions should be based on the SEC operating the tramways indefinitely. Topics covered - tyres and wheel centres, truck maintenance, suspension bearings, bearing metal (white metal), motor armatures, carbon brushes, air receivers, overhead equipment, tracks, car renovation - painting, gold lining, roof, floor treatment and covering, trolley wheels, purchase requisitions, spare parts, supplies, brake shoes, timber, castings, tramway drawings, patterns and a summary of action. Has a list of attendees.Yields information and demonstrates SEC Meeting minutes about discussions between the three Provincial operators about tramcars and operations.Minutes - 26 duplicated foolscap sheets pinned (was stapled poorly) in the left hand corner.trams, tramways, minutes, sec, geelong, ballarat, bendigo, tramcar equipment, maintenance, trackwork, overhead, painting, trolley wheels, brakes, motors -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Foundry Patterns set, Briggs Brass Foundry, Early 20th century

The wooden crate contains a set of patterns or moulds that were once used at Briggs’ Brass Foundry for making sand moulds. The traditional method of sand casting is over 2000 years old. It is part of a crafted process used to make brass and copper alloy goods suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-corrosive and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry display was one of the early ‘working craft’ shops at Flagstaff Hill. It included a historic Cornish chimney that was set up as a working model, telling the story of heat from furnaces to smelt metal, which would then be poured into the sand moulds. This chimney is made from specially curved bricks and is about two-thirds of its full height when originally located at the Grassmere Cheese factory. HISTORY of BRIGGS BRASS FOUNDRY: - The family business was founded in 1912 by Herbert Harrison Briggs (1963-1931) with his son George Edward Briggs, trading as Briggs & Son Foundry at 70 Wellington Street, Collingwood. Younger son Cyril Falkiner McKinnon Briggs joined the foundry in 1922, and it was renamed H H Briggs & Sons Foundry. Both sons ran the firm after Herbert’s death in 1931, making products mainly for marine purposes. They became Bell Founders in 1936 and were known for their specialty of high-quality ship bells. They produced miniature varieties of these and other decorative items such as small propellers. The firm became known as Briggs Marine Foundry. The great-granddaughter of Herbert Briggs inherited the Briggs Brass Bell, similar to the one at Flagstaff Hill. Cyril became the sole family member of the firm in 1965. The Briggs Marine was an exhibitor at the 1965 Boat Show, where he advertised as “non-ferrous founders” and “Bell Specialists”. The foundry relocated to Chesterville Rd, Moorabbin. Cyril passed away in 1967. It is thought that either Cyril or his business partner Frank Lee donated the objects from the Briggs’ Foundry around the time when the business moved to Moorabbin. However, Flagstaff Hill hadn’t been thought about until 1972. The donated items were registered in the Collection in 1986 but they could have been in storage from an earlier date. In October of that same year, Briggs Marine restored Schomberg Bell, a shipwreck artefact from the collection at Flagstaff Hill. Peter Oram, who had worked for the previous owners of Briggs Marine as a fitter and turner, took over the firm in 2014, reviving some of the old casts for current use. The business is now located at Seaford in Victoria and is part of Alliance Casting & Engineering Solutions (Alliance Casting Pty Ltd). In 2016 the original Collingwood Foundry building was repurposed as a thriving business hub named The Foundry. The crate and its patterns are significant for their association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. The patterns are associated with the long-running firm, Briggs Brass Foundry, that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine is also associated with the Schomberg Bell in Flagstaff Hill, restoring the bell to is former state to show an example of the bell from a luxury mid-19th century vessel. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. Wooden rectangular crate with removable wooden lid. Inside is a set of wooden patterns of various shapes and sizes for making sand moulds in a metal foundry. The crate is made from thick wooden planks nailed together. The extended wooden struts on the long sides form a frame to hold the wooden lid. A pair of metal handles are at each short end of the crate, fixed with strong metal bolds. Between each pair of handles is an inscription stamped into the wood. The underside of the crate has red paint splashes. There are insect holes in the wood but no sign of current infestation. Stamped: "H.33 / II" (H may be N or a square B)flagstaff hill maritime museum and village, great ocean road, shipwreck coast, pattern, mould, foundry, brass foundry, metal foundry, crate, box, wooden container, briggs, traditional method, trade, sand cast, cast, brass alloy, copper alloy, marine equipment, marine tools, marine fittings, briggs' bronze, copper tin zinc lead, non-corrosive, briggs family, brassware, metalware, foundering, metalwork, maritime, casting, cornish chimney, curved bricks, grassmere cheese factory, 1912, herbert harrison briggs, h h briggs, george edward briggs, briggs & son foundry, collingwood, cyril falkiner mckinnon briggs, cyril briggs, h h briggs & sons foundry, bell founders, schomberg bell, alliance casting & engineering solutions, collingwood foundry, ship chandlers, marine products, flagstaff hill, warrnambool, maritime museum, maritime village, briggs & son brass foundry, briggs marine, moorabbin -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1920s

In 1902, William E Sessions and other family members purchased a controlling interest in the E.N. Welch Company, a clock manufacturer located in Forestville, Connecticut. Sessions' father owned a foundry located in the town of Bristol, Connecticut that produced cases for E.N Welch Co. On January 9, 1903, the company was reorganized and registered as The “Sessions Clock Company”. Within a few years the Sessions Clock Company was producing clock movements, cases, dials, artwork and castings for their line of mechanical clocks. Between 1903 and 1933 Sessions produced 52 models of mechanical clocks, ranging from Advertisers, large and small clocks with logos of various businesses, to wall, or regulator clocks, and shelf or mantel clocks, designed for the home. Many of the Session clocks from this period are prized by collectors. In 1930, the company expanded to produce electric clocks and timers for radios, while continuing to produce traditional brass mechanical movements. Beginning at the end of World War II Sessions W Model (electric) was widely used by various casting companies for their clocks. The dial of the W Model read Movement by Sessions. In the early 1950s Sessions begin to produce timers for television. In 1956, Sessions was absorbed by a company interested mainly in their timing devices. In 1959, William K. Sessions, grandson of William E. Sessions left the Sessions Clock Company and formed the New England Clock Company. In 1960, one of the Sessions Clock buildings was sold to the Bristol Instrument Gears Company. Kept as the Sessions Company, the new owners ran the operation until 1969 when changes in the market forced the Sessions Company into liquidation. In 1970, the remaining buildings were sold to Dabko Industries, a machine parts manufacturer.The item marks a time when clock production in America was at it’s peak producing clocks for sale in many countries, they were keenly priced, mass produced and available to all. The company had a relatively short life span life regards clock manufacture later diversifying into electric timer mechanisms. Yet it was perhaps inevitable with the advent of electricity along with stiff competition from other clock manufactures that would ultimately herald the end in 1935 of the Sessions company's ability to continue manufacturing mechanical clocks. Clock mantle type face set in a painted black case designed to represent a Greek building with gold decorative pillars. Free standing with decorative feet. No markings or inscriptions on clock case or mechanism flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sessions, mantel clock, clock, clock industries -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; thick square mostly unopainted wooden block with a solid half-cylinder added to the top, which has rounded shoulders. A disc is added to the front, aligned with the curve at the top. The top curve has orange paint and the dial is pink. Three holes are drilled in the back, in a triangular configuration. It is similar in shape to a mantle clock or an early-style radio. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912