Showing 271 items matching "cutting tool"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Compass Saw, Mid to late 20th Century

A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone.The subject item is believed to date from around the mid to late 20th century and is regarded as a modern item. The maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture. Compass saw with wooden handle broken and metal blade. Small teeth.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood cutting, wood saw, cross cut saw, cabinet makers tools, wood working tools, tool, compass saw -

Federation University Historical Collection

Federation University Historical CollectionTool, Handshears

Hand shears needed to be very sharp and often had a leather strap or ‘driver’ which passed over the hand. Others had sheepskin bound around the grip. Blades had to be regularly sharpened on a grinding stone. Most hand shears were made in Sheffield, England, with various models produced offering wide or narrow blades, sharp or rounded points, and various grips and bows. The technique of Australian hand shearing gradually developed from the 1830s using the old English method of cutting the flank with hand shears in a series of circular cuts from the sheep’s neck to the tail. In the early 1930s the Ballarat School of Mines introduced a wide-ranging Wool Classing Course as jobs were in extremely short supply during the Great Depression. Metal handshears used for shearing sheep.ballarat school of mines, shearing, woolclassing, sheep -

Federation University Historical Collection

Federation University Historical CollectionTool, British Oxygen Company Ltd, Oxy-cutting and Welding Blow Pipes, c 1904

In 1903 the oxyacetylene welding process was developed. Around the same time, new cryogenic air separation processes, based on work undertaken by Carl von Linde and others, replaced the barium oxide process. This paved the way for larger scale and more efficient production. British Oxygen Company, [1905 to 1969] was formally BRIN'S Oxygen Company Ltd from 1886 to 1905. In 1969 it became BOC. These Blowpipes were used at the Ballarat School of Mine c1916 Interesting article = 1917. https://trove.nla.gov.au/newspaper/article/1629321Boxed Universal Blow Pipe, presented under a perspex top. Pipes mounted by metal bar and hooks to polished wooden board. Display case is 69.0cm x 12.0cm x 25.0cmBoth pipes have metal plates indicating information of maker.blowpipes, ocyacetylene, ballarat school of mines, welding, cutting, commonwealth industrial gases, boc, brin's oxygen company, british oxygen company -

Federation University Historical Collection

Federation University Historical CollectionHacksaw Frame

A hacksaw is a fine-tooth saw with a blade held under tension by a frame. It is used for cutting materials such as metal or plastics. Hand-held hacksaws consist of a metal arch with a handle, usually a pistol grip, and pins for attaching a narrow disposable blade. A screw or other mechanism is used to put the thin blade under tension. The blade can be mounted with the teeth facing toward or away from the handle, resulting in cutting action on either the push or pull stroke. On the push stroke, the arch flexes slightly, decreasing the tension on the blade.Steel frame for blade. adjustment lever in handle.Dimpled feature on curved sectionhacksaw, tool, ballarat school of mines, trade, cutting, metal, plastics -

Federation University Historical Collection

Federation University Historical CollectionBook - Book -Scrap Book, Ballarat School of Mines: Scrap Book of newspaper cuttings, Book 29, November 1986 to February 1987, 1986-1987

Collection of newspaper articles related to Ballarat School Of Mines.They cover activities and advertisements for staff. The papers concerned are The Courier, Ballarat, The Australian, The Age over the period of 20 November 1986 to 14 February 1987.Book with blue cover, front, spiral bound.courses available, tertiary orientation program, t o p, teaching positions advertised, smb programs, fashion of the future, clare schreenan, lisa willison, mary anne rowe, smb staff join protest, wool classing exams, smb secretarial program, women graduate with trades skills, linda bland, julie baulch, tracey coleman student, royal horticultural society of victoria, garden tools for field officers, helen mclennan course teacher, writing for pleasure, book launch "wednesday's words"june griffiths, nan gale, averil macklin, smb applied science grant, atomic absorption spectrophotometer, julie baulch encourages women to break with tradition, family centre space in tippett building, mellissa bone win photographic award, smb computer world's best, sue dennis, school's in for adults, smb vocational programs, university of the third age, ken flecknoe managing director courier retires -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scythe, 1930-1960

... as opposed to using a machine. A hand tool used for the cutting ...A Scythe was one of the most important of all agricultural hand tools, consisting of a curved blade fitted at an angle to a long, curved handle and used for cutting grain. In modern scythes the handle has a projecting peg that is grasped by one hand, facilitating control of the swinging motion by which grass and grain are cut. The exact origin of the scythe is unknown, but it was little used in the ancient world. It came into wide use only with agricultural developments of the Carolingian era (8th century AD) in Europe, when the harvesting and storing of hay became important to support livestock through winters. Scythes can still be found in use today by hobby farmers and permaculturists. ( producing food, by using ways that do not deplete the earth's natural resources) to cut grass in a more eco-friendly way as opposed to using a machine.A hand tool used for the cutting of crops and grain, modern versions are still being produced today in Europe. The subject item gives us a snapshot into agricultural practices in times past.Scythe with long wood Snath (curved handle) with 1 hand holding piece & curved blade. Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Auger, Stanley Rule & Level Co, 1922-1935

... a cutting lip. Tool Auger Stanley Rule & Level Co. ...The Stanley Works was founded by Frederick Trent Stanley in 1843, originally a bolt and door hardware manufacturing company located in New Britain, Connecticut, USA. The Stanley Rule and Level Company was founded in 1857 by Henry Stanley in New Britain, Connecticut. In 1920, this company was independent from Trent Stanley's works but they merged with the separate but related Stanley Works, that was founded by Henry Stanley's cousin Frederick Trent Stanley, and continued operating as its hand tools division. At this time after the merger the “Sweetheart” Trademark was adopted for tools made between 1922 to 1935 with augers manufactured during this time having the “AA” trademark and this is when the Stanley company we know today came into being. Around 1937, Stanley acquired the British J. A. Chapman company, a British manufacturer of carpentry tools and other items (including bayonets during World War I) formerly located in Sheffield, from Norman Neill. This helped Stanley to enter the British market.A early tool manufactured by an emerging company that today produces tools for sale in just about every country in the world. The subject items trademark shows the item was produced between 1922-1935 at a time when the company had just merged and was transitioning into Stanley Tools Ltd.Nose bit auger. Similar to shell bit except the nose turned inwards to form a cutting lip. Stamped on shank "AA" trade mark (Stanley Tools)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bread Board

In the high tech, fast paced society that we live in, it’s easy to take some things for granted. Case in point: the wood cutting board on which you’ll probably be preparing the evening’s dinner. Have you ever taken the time to think about the history of the cutting board? Where did it come from, and what did ancient civilizations use to cut their meats, fruits and vegetables? Wood throughout the ages Since the dawn of time, wood has been one of the most available materials used by mankind to build tools and lodgings, so it’s not really surprising to know that wood has been used in the preparation of food since the prehistoric ages. Of course, back then, cavemen probably used an unpolished slab of tree trunk to cut the kill of the day on and they probably didn’t think twice about saving it once the meal was over. Chances are they probably threw it in the fire with the rest of the wood needed to kindle it. Advances in technology Throughout the centuries, mankind evolved and started creating machines from steam, electricity and metal. When the circular saw was invented, nicer, cleaner slabs of wood were cut and used as cutting boards. Since soft wood was the most available type of wood at the time, it was the material of choice for to be used for cutting boards. Boards were made smaller since the slab of wood could now be cut to any desired size. Since they were made smaller, they were also used to eat off of and some people referred to them as trenchers. Trenchers were originally pieces of stale hard bread that were used as substitute plates. Wood trenchers quickly became the replacements of the eatable dinnerware. The butcher block: the cutting board’s larger cousin In the industrial ages, many industries rapidly developed, and the butchery industry followed this trend as well. Before the invention of the cutting board, butchers used tree rounds to carve their meat on. The rounds were often too soft and they rapidly became unsanitary. Hard maple wood butcher blocks were the preferred choice of the industry. They were made to be extremely thick and durable, so durable in fact, that a butcher could use the same block for almost his entire career. Cutting boards around the world As cutting boards began to be more and more used in kitchens around North America, the rest of the world crafted such boards from different materials. The East used thick bamboo as their material of choice. Despite its frail appearance, bamboo is quite strong and made durable cutting boards and butcher blocks. Europe used maple in the crafting of their cutting boards while Persia used flat pieces of polished wood in their kitchens. The world then saw cutting boards that were being made from other materials like plastic and they came in all shapes and sizes, but they always served the same purpose, to provide a household with a safe, clean surface on which to prepare meals for their friends and family members. https://www.woodcuttingboards.com/news/quick-history-of-the-cutting-board-47.aspxThe bread board is an example of kitchen equipment used during Victorian times and similar to those used today.Bread board wooden round with carved inner circle and carving an outer rim in old English lettering "Bread"None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, chopping board, cooking, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedes Drill, 1900 to 1930s

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples have no makers names.A vintage drilling tool that has been nickel plated with brass fitting and easier to sterilise. The item therefore could have been used in the medical profession as a bone drill during surgery. Weighted Archimedes drill all metal construction, nickel plated with brass handles centrifugal typeNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill, drill, tool, drilling tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Plane, Late 19th to early 20th century

... of cutting-edged hand tools. Tools that were themselves handmade show ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers' shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will named his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard's estate when he died in 1856. From John's will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool-making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield.A vintage tool made by a well-known company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could remove large amounts of timber. These jack or dressing planes came in various shapes and sizes to achieve a flat and even finish to timber surfaces and came in many sizes. A significant tool from the mid to late 19th century that is still in use today with early models sought after by collectors. It gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting-edged hand tools. Tools that were themselves handmade show the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items.Jack Plane metal body with rose wood filler.Mosley & Sons London No 2flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, john moseley & son, jack plane, woodworking tool, carpenders tools, cabinet makers tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedean drill, Mid to late 1800s

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples such as the subject item have no makers names.A vintage drilling tool that gives a snapshot into how holes were drilled by hand into small or delicate objects during the Victorian era. Tools from this time are today regarded as collectable items eagerly sought by collectors of antique tools.Archimedean drill with wooden grip and butterfly nut on chuck.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill, drill, fretwork tools, wood working tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedean drill, Late 19th Century

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples have no makers names.A vintage drilling tool, the item therefore could have been used in various industries or professions where precise drilling is required. Archimedean drill with Rosewood hand, brass grip and fittings Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Awl, Mid to late 20th century

An Awl is used to make indentations in wood or other materials in order to ease the insertion of a nail or screw. The blade is placed across the fibers of the wood, cutting them when pressure is applied. The Awl is then twisted through 90 degrees which displaces the fibers creating a hole. This then gives a start to the nail or screw being inserted into the work piece. There is a difference between an Awl and a Bradawl, the Awl is a small hand-held tool with a sharpened point and a Bradawl is similar but is flattened at its tip to produce a sharp chisel edge.An everyday tool used in carpentry, the subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as believed to have been produced during the 20th century.Awl with wooden handle with brass ferrule & steel pointed shaftStamped on handle J McArthur (owner)flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, awl, j mcarthur, carpenders tools, woodworking tools, nail starter -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Saw, Mid to late 20th century

... sawmill from the third century AD used for cutting stone ...A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone. The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, as the maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture around the mid to late 20th century.Wood hand saw with wooden handle attached to saw by 4 rivets. No blade markings Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, handsaw, wood saw, carpenders tools, cabinet makers tools, wood cutting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Mathieson and Son, 1860 to 1910

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces. The name spokeshave dates back to at least the 16th century, though the early history of the tool is not well documented. The name spokeshave reflects the early use of the tool by wheel wrights. The first spokeshaves were made of wood usually beech with steel blades, before being largely superseded by the development of metal-bodied spokeshaves in the latter half of the 19th century, though many woodworkers still use wooden spokeshaves. Due to their widespread use and versatility vintage wooden spokeshaves remain commonly available and relatively low in price. Spokeshaves consist of a blade or iron secured to the body or stock of the tool, which has two handles – one for each hand. The bottom surface of the tool is called the sole. The blade can be removed for sharpening, and adjusted to vary the depth of the cut. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached, as with a draw knife. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. There are a wide variety of different types of spokeshave, suited to different trades and applications. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tin men's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm.A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used to shape various items mainly in use by wheel wrights. A significant vintage item from the mid to late 19th century that today is quite sought after by collectors. It gives us a snapshot of how trade people predominately worked materials such as wood by hand and with tools that were themselves hand made shows the craftsman's art of the time. Spokeshave with blade 4 inches wide.Mathieson and Son Glasgow. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spokeshave, mathieson and son, carpentry tools, wheel wright tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Mallet, Prior to 1950

Wooden mallets are usually used in carpentry or by a cooper to knock wooden pieces together, or to drive barrel bungs, dowels or chisels. A wooden mallet will not deform the striking end of a metal tool, as most metal hammers would. It is also used to reduce the force driving the cutting edge of a chisel, giving better control. Hardwood mallets are also used by a cooper to knock bungs or other wooden parts of a barrel in place.A significant tool a carpenter or cooper would use to knock wooden staves or furniture parts in place without damaging the soft surface of the timber being used. Item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Mallet large with wooden handle attached to wooden head with 2 metal ferrules at top and bottom of head Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, wooden mallet, barrel bung, carpenters tool, hammer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, 1770-1809

... of cutting edged hand tools. Tools that were themselves hand made ...The story of Christopher Gabriel born on April 2, 1746, in Falmouth England is a tale of a poor boy who made good. Shortly before he turned thirteen years of age in 1759 he was apprenticed to a local master carpenter, recorded as a Mr Barnicot the master trained his apprentice well as we can assume by Christopher's later successes. The apprenticeship ended in 1766 after seven years when Christopher reached twenty. Then in 1768, he relocated to London walking the two hundred miles from Falmouth carrying his possessions in a sack. He no sooner arrived in London when he met Alice Trowell who became his wife in March 1769. They set up house on Albermarie Street Clerkenwell and by the first of 1770, Gabriel had begun his business of plane making. It has been speculated that Gabriel took over the shop of John Cogdell aided with an investment from his in-laws of 131 pounds. He went on to prosper as a plane-maker and lumber merchant over the next forty years. His business did well and in 1774 Gabriel moved to a house in Golden Lane, London and 1779 moved again to a home in Ould Street London. By now Gabriel was making a name for himself and his business at this time was located at 32 Banner Street Golden Lane, the following year he purchased another home in Banner Street and 1793 purchased the house next door. At the time of his death in 1808, he owned twenty-seven houses and commercial building. Christopher Gabriel s descendants became quite prominent in England and his grandson, Sir Thomas Gabriel became the Sheriff of London and Middlesex in 1859 and the Lord Mayor of London 1866 and 1867. Gabriel was an extremely prolific plane-maker with a lot of examples made in the 18th century can still be found today. He made good quality tools and was an innovator of several new plane designs. A vintage tool made by a well-known plane-maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could give a decorative finish to timber. These planes came in various shapes and sizes to achieve a finish to timber surfaces and came in many sizes. A significant Christopher Gabriel plane from the mid to late 18th century that after 200 years can still be used today. Planes made by Gabriel are eagerly sought after by collectors. The tool gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting edged hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items. Side Rabbet Plane Stamped Maker Gabriel (owner M Hobling).flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, side rabbet plane, gabriel m hobling -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Broad axe, mid-to-late 20th century

A broad axe is used for the initial cutting and shaping of a log to prepare it for the piece to be made. The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings. You can see Laurie’s inscription on the tool called a ‘bevel’. Laurie worked for Ports and Harbours, Melbourne, for over 50 years, beginning in the early 1960s. He and a fellow shipwright inscribed their names on a wheelhouse they built in 1965; the inscription was discovered many decades later during a repair of the plumbing. Many decades later Laurie worked on the Yarra moving barges up and down the river and was fondly given the title ‘Riverboat Man’ His interest in maritime history led him to volunteer with the Maritime Trust of Australia’s project to restore and preserve the historic WWII 1942 Corvette, the minesweeper HMAS Castlemaine, which is a sister ship to the HMAS Warrnambool J202. Laurie Dilks donated two handmade displays of some of his tools in the late 1970s to early-1980s. The varnished timber boards displayed the tools below together with brass plaques. During the upgrade of the Great Circle Gallery Laurie’s tools were transferred to the new display you see there today. He also donated tools to Queenscliffe Maritime Museum and Clunes Museum.The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright at Ports and Harbours in Melbourne in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings.Broad axe; a wooden handle with a round metal wedge-shaped head, reinforced with a metal plate on at the back of the handle. There is a hole in the handle about halfway along its length. It once belonged to shipwright Laurie Dinks.flagstaff hill, maritime museum, maritime village, warrnambool, shipwreck coast, great ocean road, shipwright, carpenter, shipbuilding, ship repairs, hand tool, equipment, caulking, ship maintenance, cooper, shipwright’s tools, shipwrights’ tools, tools, maritime trade, broad axe, caulking iron, laurie dilks, l dilks, port and harbours melbourne -

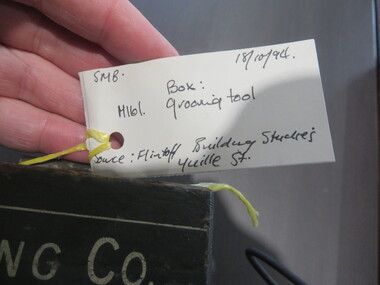

Federation University Historical Collection

Federation University Historical CollectionTool - Electrical Instrument, Electric Belt Sander, c1960s

Used in Building Studies at Ballarat School of Mines. The sander used to sand rough timber smooth, remove old finish from wood, put a bevel on a door, reduce the thickness of timber, dress up a poor saw cut. Also used for back cutting miter cuts for neater joints and for polishing and cutting.Stainless steel with rollers and sanding plate. Hand held. Continuous loop of sandpaper would be mounted.Maker's Plate: MILLER FALL TOOLS CATALOG 830 3 INCH BELT SANDER MODEM "C" USE 3" X 21" BELT 230/250 VOLTS 3 AMPS 25-60 CYCLES MADE IN USA PATENT 2,991,595 MILLER FALLS COMPANY, GREEFIELDS, MASS. TO CHANGE BELT PULL LEVER DIRECTION OF BELT ballarat school of mines, building studies, david flintoff, timber, smooth, miter cuts, polishing, buffing, thinning -

Federation University Historical Collection

Federation University Historical CollectionTool - Object - Tool, Wooden moulding Plane

Wooden moulding plane build in the Grecian ogee style with bevel; it features a single cutting iron with a scalloped profile held in place by a wooden wedge.'A Mathieson and Sons, Glasgow' stamped on one end and '9/6' at the other end.plane, moulding plane, mathieson & sons, wooden plane, grecian ogee style, glasgow -

Federation University Historical Collection

Federation University Historical CollectionTool, Sargent & Co, Sargent Plane

Planes similar to this came with several additional parts. They were designed for use in dadoing, rabbeting, tonguing and grooving, beading,slitting and sash cutting. It could also be used as a filleister and with special cutters, as a Reeding Plane. Sargent & Co. were in operation from 1887 to 1964.Plane with wooden handle (mahogany) and fence plate. Adjustment points for various uses."SMB" on handle. "SARGENT" on metal near handle.plane, dadoing, rabbeting, tongue and groove, beading, slitting, sash cutting, sargent, united states of america -

Federation University Historical Collection

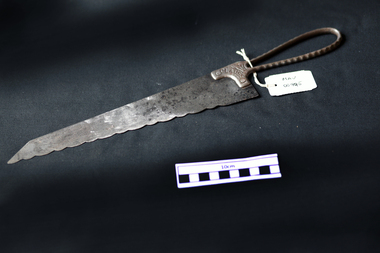

Federation University Historical CollectionTimber Instrument, Teco Grooving Tool

This item was last used at the Ballarat School Of Mines, Flintoff Building Studies Centre, Youille Street, Ballarat. Instructors at the above centre used them. Two pages photocopied from a text book dealing with timber trusses (100-101) are filed for reference.A steel disc equipped with four cutting blades bolted to disc periphery. Disc mounted on a plain shaft, top end can be inserted into a chuck, bottom end enters a pilot hole. Purpose - to produce a circular deep groove in structural timber. Stored in a green wooden box.Stamped on disc top and bottom faces "TECO 418" On front of box, ' "TECO " GROOVING TOOL' On lid of box, "TIMBER ENGINEERING Co - SYDNEY - N S W " Brass hook for closing lid.ballarat school of mines, flintoff building studies, cutting blades, disc, chuck, plain shaft, circular deep grooves -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, Bread Knife 'Clauss', c1900

Clauss Cutlery’s long and vivid history started in early 1880’s when John Clauss and his younger brother Henrie established Elyria Shear Works in Elyria, Ohio. At one time the company was the largest manufacturer of scissors and shears in the world and was acquired by Acme United Corporation in 2004. John and Henrie Clauss, of German origin, started Elyria Shear Works from a one-room building in Elyria, Ohio Together with five employees, they began manufacturing scissors, shears, straight razors and serrated kitchen knives In August 1887, the Company moved to Fremont, Ohio to be near an accessible, abundant supply of natural gas which had recently been discovered. 1889, disaster struck as the plant was completely destroyed by fire, In 4 months Clauss built a new plant and was back in full operation and changed the company’s name to Clauss Shear Company. 1919 Clauss Shear merged with Henkel Company, to become Henkel-Clauss Company. Henkel Company was founded in 1906 to manufacture manicure and pedicure files, knives, shears and razors. After World War II, Clauss was unable to compete with European firms producing household scissors and shifted its focus to industrial scissors. In 1967 Clauss was taken over by Alco Standard Corporation who integrated Clauss into its existing structure to manufacture tools for industrial niche markets. Clauss made surgical scissors for eye operations, heavy duty metal cutting shears, poultry shears for gutting chickens and specialty items such as anti-acid, anti-magnetic tweezers for the electronics industry. Clauss had approximately 100 employees and produced about $18 million in annual revenues in the late 1980s, but profits continued to decline. In 2004, Acme United Corporation acquired the Clauss inventory, trademarks and brand names from Alco Industries for approximately $500,000A large Bread Knife with scalloped / serrated edge and looped handle Front : CLAUSS Back : FREEMONT / OHIOcutlery, knives, clauss shear company, ohio, freemont, market gardeners, early settlers, moorabbin, cheltenham, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, stainless steel pen-knife, 20thC

A penknife, or pen knife, is a small folding knife. It was originally used to describe a knife used for cutting or sharpening a quill to make a dip pen nib. Originally, penknives were used for thinning and pointing quills to prepare them for use as writing instruments and, later, for repairing or re-pointing the quills. They did not necessarily have folding blades, but resembled a scalpel or wood knife by having a short, fixed blade at the end of a long handle. Today a penknife can have single or multiple blades, and with additional tools incorporated into the design. The most famous example of a multi-function penknife is the Swiss Army knife A folding pen-knife with 2 stainless steel bladeson long blade end; STAINLESS / MADE IN / SHEFFIELDpen-knife, scouts, cheltenham, moorabbin, bentleigh, tools, early settlers -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Equipment - Dairy Equipment, cheese cutter

This cheese cutter was made and used by an early settler family in Moorabbin Shire c 1900Early settler families in Moorabbin Shire were self sufficient making their own tools , kitchen equipment, and clothing while they established market gardens, dairy farms , poultry farms, orchards and flower nurseries. Each family had a 'house cow ' to provide dairy products of milk, cheese, cream and butter.A wooden frame with wire cross pattern for cutting cheesecheese cutter, equipment, box cottage, dairy -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, metal scythe, c1880

A scythe is an agricultural hand tool for mowing grass or reaping crops. It was largely replaced by horse-drawn and then tractor machinery. A scythe consists of a wooden shaft and a long, curved blade is mounted at the lower end, perpendicular. Scythes always have the blade projecting from the left side when in use. Mowing is done by holding the handle , with the arms straight, the blade parallel to the ground and very close to it, and the body twisted to the right. The body is then twisted steadily to the left, moving the scythe blade along its length in a long arc from right to left, ending in front of the mower, thus depositing the cut grass to the left. Mowing proceeds with a steady rhythm, stopping at frequent intervals to sharpen the blade. The correct technique has a slicing action on the grass, cutting a narrow strip with each stroke Mowing grass is easier when it is damp, and so hay-making traditionally began at dawn and often stopped early, the heat of the day being spent raking and carting the hay cut on previous daysEarly settlers and market gardeners used these scythes as they established their farms in Moorabbin Shire c1880A large metal scythe with a wooden handle x 2early settlers, pioneers, market gardeners, moorabbin, bentleigh, brighton, cheltenham, tools, blacksmiths -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, marker wooden gauge, c1900

A marking gauge, also known as a scratch gauge, is used in woodworking and metal working to mark out lines for cutting or other operations. The purpose of the gauge is to scribe a line parallel to a reference edge or surface. It is used in joinery and sheet metal operations.The gauge consists of a beam, a headstock, and a scribing or marking implement, typically a pin, knife, pen or wheel. The headstock slides along the beam, and is locked in place by various means: a locking screw, cam lever, or a wedge. The marking implement is fixed to one end of the beam.Early settlers in Moorabbin Shire had to be self reliant and made their own clothes and tools as they established homes and farms for their familiesc1900 A hand made wooden marker gaugeearly settlers, pioneers, market gardeners, moorabbin, bentleigh, brighton, cheltenham, tools -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, hand made wood plane, c1880

A hand plane is a tool for shaping wood Hand planes are generally the combination of a cutting edge, such as a sharpened metal plate, attached to a firm body, that when moved over a wood surface, take up relatively uniform shavings, by nature of the body riding on the 'high spots' in the wood, and also by providing a relatively constant angle to the cutting edge, render the planed surface very smooth. A cutter which extends below the bottom surface, or sole, of the plane slices off shavings of wood. A large, flat sole on a plane guides the cutter to remove only the highest parts of an imperfect surface, until, after several passes, the surface is flat and smooth.The family of Mr Lamb were early settlers in Moorabbin Shire and had to be self reliant and made their own clothes and tools as they established homes and farms for their families.c1880 A hand made wood planeearly settlers, pioneers, market gardeners, moorabbin, bentleigh, brighton, cheltenham, tools -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel hacksaw 'Marples', 20thC

A hacksaw is a fine-toothed saw, originally and principally for cutting metal. They can also cut various other materials, such as plastic and wood; for example, plumbers and electricians often cut plastic pipe and plastic conduit with them. On hacksaws, as with most frame saws, the blade can be mounted with the teeth facing toward or away from the handle, resulting in cutting action on either the push or pull stroke. In normal use, cutting vertically downwards with work held in a bench vice, hacksaw blades should be set to be facing forwards. Joseph Marples & Son Pty Ltd Traditional Craftsmans Hand Tools made in Sheffield. The finest quality hand made tools, backed by over 170 years of manufacturing heritage. .In the 1840’s Joseph Marples was one of several ‘Marples’ (most of which were related) in Sheffield manufacturing joiners tools, such as brass inlaid rosewood & ebony braces, boxwood spokeshaves, beech planes, gauges and squares. The business has remained within the family to this date, and has been based in Sheffield since those early days. Although modern technology has been used in some instances, many of the traditions of manufacturing fine hand tools has remained the same using selected materials and hand finishing, indeed the same threads are used in the gauges as were used over 100 years ago. A steel hacksaw. 'Marples' with bladeMARPLEStools, woodwork, metalwork, carpentry, pioneers, market gardeners, early settlers, moorabbin, cheltenham, bentleigh, ormond, joseph marples & son pty ltd, sheffield , england,