Showing 1036 items

matching drill.

-

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesSlide - Glass slide, 1891-1905

Sale Agricultural and Horticultural Society '52. -Sale A.H.S. Fighting the Aphis Blight,-' and, '-Sale A.H.S. Drilling in Oats.-' 2 images on 1 slide.52. -Sale A.H.S. Fighting the Aphis Blight/Sale A.H.S. Drilling in Oatsschool gardens, australia, sale, agricultural and horticultural society -

Williamstown High School

Williamstown High School1957 Orchestra Drill Hall

Black and white photograph of Miss Boardman with the Williamstown High School orchestra in the Drill Hall.On front of the photograph: Miss A.B. Boardman, Head Mistress, and school orchestra in Drill Hall 1957.williamstown high school, music, 1957, miss boardman, orchestra, drill hall -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedes Drill, 1900 to 1930s

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples have no makers names.A vintage drilling tool that has been nickel plated with brass fitting and easier to sterilise. The item therefore could have been used in the medical profession as a bone drill during surgery. Weighted Archimedes drill all metal construction, nickel plated with brass handles centrifugal typeNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill, drill, tool, drilling tool -

El Dorado Museum Association Inc.

El Dorado Museum Association Inc.Photograph - Digital Image

Drilling tests.mining, gold, gold mining, tin, tin mining, churn drill, drilling, machinery, el dorado, eldorado -

Orbost & District Historical Society

Orbost & District Historical Societyhand drill

The invention of a hand drill is credited to Arthur James Arnot and William Blanch Brain of Melbourne, Australia who patented the electric drill in 1889. In 1895, the first portable handheld drill was created by brothers Wilhem & Carl Fein of Stuttgart, Germany. Hand-powered devices have been used for millennia. However, during the last quarter of the 19th century a radically improved generation of tools appeared. These tools took advantage of modern mass production machinery and processes (like interchangeable parts) and an increased availability in superior material (metal instead of wood). One of the outcomes included an array of new drilling machines. These human-powered tools were a vast improvement over earlier tools.This item is an example of a commonly used domestic tool - pre power tools.A Stanley hand drill with two wooden handles. The red wheel is painted metal. On red wheel - STANLEY ENGLANDwoodwork tool hand-drill -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Blacknose Quarry, 05/11/1952

Port of Portland Authority ArchivesFront: 'WLL BORING AT BLACKNOSE QUARRY 5.11.52 PERCUSSION DRILLING BY CONTRACT ' - printed on bottom frame Back: Purple PHT stamp '13/1' - top left inkport of portland archives, blacknose quarry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Chain Drill Attachment, Millers Falls Co, 1900-1931

An auxiliary tool for use with a breast drill or bit brace, when extra power is needed, or where pressure cannot be easily applied. The drill is automatically fed into the work by an adjustable friction feed which is automatically regulated by the resistance the drill encounters. These were made to fit on breast drills, and used for drilling metal, particularly round sections like a pipe. The chain is run around the object being drilled and gradually tightens as the hole is drilled, maintaining pressure while being a bit easier on the operator. Millers Falls Co. is a tool manufacturing company originally based in Millers Falls, Massachusetts, USA. It was established in Greenfield, Massachusetts in 1868 as Gunn & Amidon by Levi J. Gunn and Charles H. Amidon. Gunn and Amidon, along with a third partner, Henry L. Pratt built a factory in the north of Greenfield. After the Greenfield factory burned down, the company was reorganized as the Millers Falls Manufacturing Co. It merged with Backus Vise Co. in 1872 to form Millers Falls Co. In 1931 Millers Falls tools purchased the majority of the shares of Goodell-Pratt tools and merged with that manufacturer in 1932. In 1962 the company was acquired by Ingersoll Rand. In 1982, Ingersoll Rand sold the Millers Falls business to the newly created Millers Falls Tool Co. The company was head quartered in Alpha, New Jersey. Since 2002 the company trademark has belonged to Hangzhou Great Star Industrial, of Hangzhou, China. The item is associated with a tool manufacturing company established in the mid-19th century that pioneered the development of many types of tools used in many differing trades. The company grew to become a major supplier of tools around the world and today its tools that were produced during the mid-19th and early 20th centuries are now collectable items. Drill attachment with chain No 717 from 1925 catalogue 1/2 socket hole Millers Falls, Massachusettsflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, chain drill, mast drill, millers falls, drilling attachment, drilling tools -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Electric Drill, c1960

Heavy duty SHER dual speed electric drill with a 3/8 inch chuck, chuck key, electric lead and plug.SHER POWERMATIC Duel Speed Drill|220-250 Volts - Made in Australia 1.75 Amps. ( & other information)trades, carpentry, mechanics, tools -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyAuger

Augers are used to drill holes. Sizes vary as does the surface that they can drill into. Electric and cordless (battery operated) drills are more commonly used now.Small wood auger used to drill small holes in timber. It has a wooden cylindrical handle attached at right angles to a steel auger half of which is straight before twisting to a point.auger. woodwork. drill. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Drill Brace, 1800s

The subject item is an early Victorian Scotch Brace with a 10-inch sweep. They were also known as a six penny or "gentleman's" brace and were designed to accept tapered square shank bits, early designs have a thumb screw to help secure the bit. Later designs had a catch to secure drilling bits. This type of brace was used in wagon making for boring & drilling holes into the wood for a variety of purposes, including driving screws. The subject item is unmarked but could have been made in Glasgow Scotland by John Fray in the 1800s A significant early example of a drill brace made in the UK during the 1800s demonstrates the evolution of this type of tool from this time that today is a rare and collectable example of woodworking tools.Drill Brace metal with socket and thumbscrew, varnished wooden head and handleNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, brace, carpenders wheel brace, cabinet makers tools, drilling tool, wagon makers drill -

Kiewa Valley Historical Society

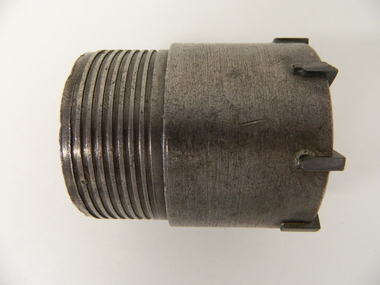

Kiewa Valley Historical SocietyDrill Bit Diamond, circa mid to late 1900's

This hollow core bit has hard cutting inserts for drilling into rock. It was used to drill and recover 50mm diameter (most common size) rock cores. The rock cores were assessed by geologists and engineers to provide information for design of structures such as tunnels, dams and underground power stations (eg. McKay Creek Power Station, West Kiewa Power Station). This type of bit was also used where damage to the surrounding rock had to be minimised. The Diamond Drill Bit,used in the early 1900's, when it was primarily used as a method of sampling rock for ore deposits and oil exploration resulting in a "coring" of rock. The use of "coring" to obtained samples for the SEC Kiewa Hydro Electricity Scheme(1920's onward) was to analyse the core to obtain temperature and rainfall patterns shown by the levels of layered solidified soil(rock). This diamond drill would have been used in the early 1900's to provide a sub strata map of temperature and water patterns (over an long period of time). This was a pre requisite to any decisions about the viability of the region to provide the water needed for a successful hydro electricity scheme.This diamond drill for core sampling was at the forefront of the analysis whether to construct a hydro electrical facility in the Kiewa Valley and the adjoining alpine region. The rock core samples produced were assessed by geologists and structural engineers. It was only after extensive core drilling covering the region that solid scientific evidence could be provided to start the "SEC Vic Hydro Electricity Scheme" within its current boundaries.This "diamond" drill bit has eight "teeth" at its cutting edge. The drill creates an 55mm hole in extremely hard rock material to obtain 50mm core samples.. Three quarters down the shank it has thread screw channels to attach the bit to the drill pipe. The coring pipe attaches via screwing it onto this bit. Core samples are the main objective of this tool.alternate energy supplies, alpine feasibility studies temperature, rainfall, sec, kiewa hydro electric scheme, electricity -

Stawell Historical Society Inc

Stawell Historical Society IncRealia, Set of Woodworkers or Carpenters Tools of W E Coward

W E Coward builder came to Stawell around 1919 and had a workshop in Campbell Street Stawell. Tools kept by his son Frank Coward. Donated by grandsons Ron and Jeff Coward of Stawell. Ten Moulding Planes, Wooden Mallet, Woodworking Drills, Three rounded Chisels, Counter sink Auger, Scouring Tool, Spoke Shave, Sawblade Tooth setting tool, simple Caliper, Wooden Plane, Hand Drill, Moulding Plane with Offsets, Two Handled routing tool, Two flat Blade Screwdrivers Wood working tools including set of Moulding Planes, mullet drills etcSome tools have makers stamps on them -

8th/13th Victorian Mounted Rifles Regimental Collection

8th/13th Victorian Mounted Rifles Regimental CollectionPhotograph

The Benalla Drill Hall was an original8/13 VMR depot. It was closed for a period in the 1970s then reopened in early 1980s.Colour photograph of 14 soldiers of A Squadron 8/13 Victorian Mounted Rifles at Benalla Drill Hall c. 1983" Aslt Troop Benalla Depot, Back: Tpr Petering, Lynch, Butler, ( two unknown, Centre: Tpr. Dudley ( unknown), Grant, ( Unknown ). Front: Lt. Carrington, Pte Tucknott ( Unknown ), Pte. Hilton ( Unknown ). -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Bit, Circa 1950

This is the cutting bit on the end of a drilling rod. It would have been used to drill holes into rock for placing explosives, for installing steel rock anchors, etc. In hard rock the bits need to be replaced regularly. Compressed air is blown through the holes near the tip of the bit to blow rock fragments out of the drill hole. The main drilling unit would have been powered by compressed air (Pneumatic). Rotary Air Blast Drilling. This drill bit was used by workers in the SEC Vic. Kiewa Hydro Electricity Scheme. This type of bit although strong needed replacing frequently when the rock composition (type of rock) was extremely compact. The configuration of the tip bit (four star like pattern) was to provide the "teeth" to tear into the rock. This bit was manufactured in 1949 however drilling for rock cores, in the Kiewa Valley and the Victorian Alps, was carried out from the late 1920's.This particular drill bit would have been used by construction workers to drill holes into rock for either explosives or for installing steel anchor points into the rock. The use of compressed air was not only for waste extraction but also for running the main drilling unit.This four star rotary air balst (RAB) drill bit has a central "blow" hole (compressed air outlet to remove the ground rock particles through four extraction holes). There are four raised cutting/grinding lugs which allows the air compression hole(incoming) to always have a clear unblock opening. Extracted ground material is "blown" out from the drill head via the larger hole created by the steel bit.Stamped on the bottom outside shank "FAGERSTA SECO SWEDEN" and below this "102 7041 01 05 049".sec vic kiewa hydro scheme, alternate energy supplies, drilling into rocks in alpine regions -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, 1920s-1950s

This drill once belonged to Goodall and Sons, who were blacksmiths in Terang. The smith was called upon to do a variety of work. In the early 1900s he was often the nearest person to be able to perform an engineer’s services for many miles around. The Dawn Ball-bearing Post Drill no. 611 is described in McPherson’s Catalogue as a “drilling machine with adjustable automatic feed, with improved Dawn coupler and ball-bearing thrust’. The heavy design of the flywheel enables it to maintain momentum” and is “fitted with pulleys for belt drive if desired” The hand crank drives an automatic feed to work off a cam-follow system opposite a large wheel. Made by Dawn Manufacturing Co. Australia 1920-1950. DAWN MANUFACTURING CO. Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. In 1959 the company was taken over by G.N. Raymond Group, then in 1973 the Siddons Ramset Limited acquired Dawn. In December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. In November 1998 Dawn became 100 per cent Australian owned. HENRY GOODALL & SONS Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The drill is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the 1920s-1950s.Dawn Ball-bearing Post Drill no. 611, made by Dawn of Melbourne, model no 611. Hand operated drill press. Self-feeding blacksmiths’ drill-press. This drill once belonged to Harry Goodall & Sons, blacksmiths of Terang. Dated 1920s-1950s. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. "Dawn", "Melbourne"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall, terang 1900s, warrnambool district 1900s, post drill, blacksmith’s drill, dawn post drill, dawn ball-bearing post drill no. 611, blacksmiths, dawn of melbourne -

Orbost & District Historical Society

Orbost & District Historical Societywheel, Late 19th century - early 20th century

This feed wheel is part of the drill press catalogued as No. 2030.A cast iron wheel ( a feed wheel) with three spokes (one has been broken off). It has a screw nut for fastening to the shaft of a workshop drill (cat. no. 2030).BUFFALO FORGE Co. BUFFALO N.Y.drill machinery engineering cast iron -

Bendigo Military Museum

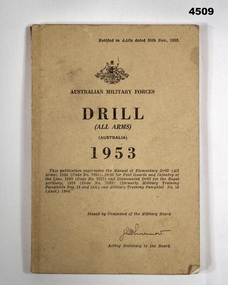

Bendigo Military MuseumManual - MILITARY DRILL ALL ARMS, Command of the Military Board, C.1953

The contents cover 16 differant types of drill from the basics to military Funerals.Manual, Australian Military Forces Drill, all Arms 1953, light Kahki colour cardboard covers, 134 pages, all images and print in black., books military, drill 1953 -

Stawell Historical Society Inc

Stawell Historical Society IncArchive - Ledger Book, Old Ledger Book, 1800's estimated

Dimond DrillLedger Green cover, Leather Binding. A Leather Corner, top and Botttom. Listed are Provisions & Suppliers 1873 - 1874- 1875 Inside Cover Green and red marble Effect. Dimond Drill 1883 wages. Roses gap Glenorchy 1954 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Port Fairy Historical Society Museum and Archives

Port Fairy Historical Society Museum and ArchivesPhotograph

Drill Hall, Bank Street, Port Fairy. This two-storied building was constructed in 1874 as livery stables and was later used for the garrison from c.1885. The structure is symmetrically arranged about a large arched opening and features include the plinth, quions and the parapet. Reconditioned c.2000 when the interior was renovated for functionsBlack and white photograph of the drill hall a two storied rendered building with double doors opening into the streetdefence, hall, drill hall, bank street -

8th/13th Victorian Mounted Rifles Regimental Collection

8th/13th Victorian Mounted Rifles Regimental CollectionUniform - Crewman c.1948

Khaki drill was standard working uniform for tank crewmen of 8/13 Victorian Mounted Rifles. Khaki drill was replaced by black tanksuit in 1959. The 8th/13th Victorian Mounted Rifles was raised as a regiment of the Royal Australian Armoured Corps on 1 May 1948 with Headquarters in Melbourne and squadrons in Sale, Benalla/Wangaratta and Albury. In 1955 Regimental Headquarters moved to Wangaratta and a second squadron was located at Albury. The Sale squadron transferred to 4th/19th Prince of Wales’s Light Horse. In 1977 8/13 VMR Regiment was reduced to an independent squadron A Squadron 8th/13th Victorian Mounted Rifles and in 1991 was linked with 4th/19th Prince of Wales’s Light Horse forming the VMR Squadron of that regiment.Mannequin dressed in khaki drill jacket and trousers with basic web equipment and pistol pouch, black beret with silver rising sun badge. uniform, tank, military, vmr, cmf -

Glenelg Shire Council Cultural Collection

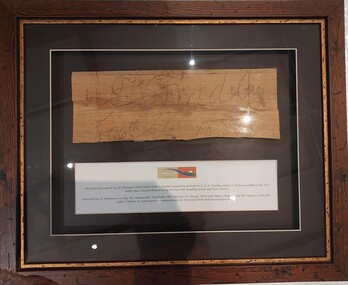

Glenelg Shire Council Cultural CollectionArtwork, other - Framed timber from Portland Drill Hall, 1888

Dark timber frame with a glass front. Inside is a piece of timber taken from the Portland Drill Hall. Underneath the mounted timber is a label with the Glenelg Shire logo on it.Label: Identification Mark by the Portland Drill Hall (orderly room) carpentry contractor G. & A. Findlay. Dated 16 February 1888 Piece of timber in pencil script: G. & A Findlay/ 16 Feb / 1888portland drill hall, portland, findlay, portland builder, portland businesses, 1800s -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Article, Blackburn Level Crossing

Blackburn Road level Crossing was closed for 2 weeks.Blackburn Road level Crossing was closed for 2 weeks for the rail line to be lowered under Blackburn Road. More than 1,000 piles will be drilled to reinforce the rail corridor which is due to be completed 2017.Blackburn Road level Crossing was closed for 2 weeks. level crossing removal authority, blackburn road, blackburn railway crossing, blackburn railway station -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - AUSTIN COLLECTION: Quartz vein, Central Deborah Gold Mine, Possibly 1990's

Black and white photograph. Underground miner, wearing hard hat and light, inspecting a quartz vein on the wall of a drive at the William's United Gold Mine, Eaglehawk. On back of photo: ' Ian Clark, 8" drill hole'and drill holegold mining, central deborah gold mine, underground, quartz vein, williams united gold mine, eaglehawk -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Pamphlet, Stanley-Titan Pty Ltd, 1960s?

Hand tool catalogue.Hand tool catalogue: wood chisels, auger bits, eyed augers, machine bits, masonry drills, linoleum or leather knives, handsaws, plane irons, woos screw pilot bits and flat power bits.Hand tool catalogue.stanley-titan pty ltd, woodworking tools -

Cobram Historical Society Inc

Cobram Historical Society IncDrill bitDrill bit

Drill bit with changable drill tip -

Emerald Museum & Nobelius Heritage Park

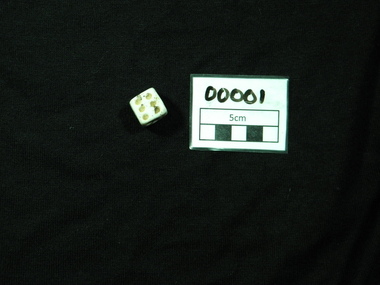

Emerald Museum & Nobelius Heritage ParkDice

Miners not having much to interest them would make their own entertainment . If they did not have what they needed they made it.This Die was found at the diggings and donated to the museum.This item is significent because this is local quartz and handmade on the diggings.White quartz die drilled holes to indicate numbersgold, mining, 1850s, emerald, diggings, sassafras creek -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Portland Harbour Trust staff, n.d

Port of Portland Authority ArchivesBack: "Drill for Tug Crew"port of portland archives, portland harbour trust, drill, tug crew -

Lorne Historical Society

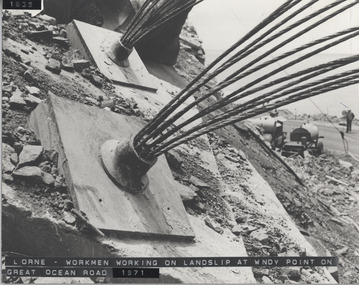

Lorne Historical SocietyPhotograph, Great Ocean Road. Windy point land slip

1971. This was some of the machinery used in stabilsing the Great Ocean Road between the St George's River and the Sheok River. Holes were drilled in the rock and large cables inserted and concrete forced in around themGreat Ocean Road. This was some of the machinery used in stabilizing the G.O.R. at Windy Point, between the St George River and the Sheoak River. Holes were drilled in the rock and large cables inserted and concrete fixed around them. This took place in late 1971great ocean road. g.o.r. landslip. windy point. 1971 -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Post Drill Set

Used by donor's father, John Palmer, on his parents dairy farm at Mupunga East and later on his own dairy farm at Allansford. From 1966 until 1992 used in Mitcham and Blackburn.A post mounted drill stand with a gearing arrangement driven by a handle. The depth of drill is adjusted by a large red wheel which raises or lowers the drill. There are other adjusting devices on the drill.Buffalo Forge Co, Buffalo N.Y. No 151 (on both sides of main casting)trades, tools, metalworking