Showing 298 items

matching machine design

-

Australian Gliding Museum

Australian Gliding MuseumMachine - Glider - Sailplane, 1937

The Golden Eagle is an original design by Geoff Richardson. Geoff commenced gliding in the early days of the sport circa 1933 in Melbourne, flying at Coode Island and Mt Frazer. In 1934, he began construction of a secondary type glider but scrapped it upon realizing that a better design was needed. He conducted further research and came up with a sailplane of similar size and general arrangement to the Grunau Baby but with a “Gull” wing using a Gottingen 535 wing section (the same as for the Grunau Baby). Geoff did all the technical calculations himself and even made up and tested a Casein glue for the construction. Geoff competed construction of his new sailplane (which he called the “Golden Eagle”) in 1937 and it was test flown at Laverton at the western edge of Melbourne in September 1937. On the same day, at Laverton, the Gliding Club of Victoria flew its new Grunau Baby 2 sailplane which it had imported as a finished machine from Edmund Schneider in Germany. The Golden Eagle was found to fly well, having a similar performance to the Grunau Baby. In the 1950s, the Golden Eagle was modified by rebuilding the front of the fuselage to enclose the cockpit with a Perspex canopy. A landing wheel was incorporated behind the skid. Spoilers were added to the wings and a trim tab to the elevators. The Golden Eagle has been flown with the VMFG (Victorian Motorless Flight Group) for most of its long life. When donated to the Australian Gliding Museum in 2016 by Alan Patching it was probably the oldest, continuously airworthy glider in the world. Having regard to the historical significance of the Golden Eagle, the Museum has decided to not to fly it anymore to avoid risk of loss or damage. The exhibit is of great significance for Australian gliding history – the Golden Eagle is a flyable 1930s aircraft in excellent condition that was designed and built by an Australian gliding pioneer. Single seat wood and fabric sailplane finished with white wings, tailplane and rudder and yellow fuselage Registration letters “FC” on fuselage nose port side, Australian flag, Vintage Gliders Australia and VMFG decals on rudder, “Golden Eagle” lettering in red on each side of the fuselage below the canopy, Aboriginal flag decal on port side of fuselage below the canopy. australian gliding, glider, sailplane, golden eagle, richardson, patching, vmfg, victorian motorless flight group -

Australian Gliding Museum

Australian Gliding MuseumMachine - Glider - Sailplane, 1974

The Pilatus B4 is an all metal intermediate sailplane meeting Standard Class rules that was designed in 1966 by Ingo Herbst, Manfred Küppers and Rudolf Reinke. It did not immediately go into production. In 1972 Pilatus Aircraft of Switzerland acquired a licence to build the aircraft and began production. The PCII and PCIIA versions were semi-aerobatic. The PC11AF released in 1975 was rated as fully aerobatic. By 1980, when Pilatus sold the rights to manufacture of the aircraft to Nippi Aircraft of Japan, 322 of the Pilatus B4 had been produced. Nippi Aircraft built a further 13 and also one two seat version. The Pilatus B4 proved popular in Australia with 26 appearing on the Australian register. The Museum’s example is a basic semi-aerobatic type (Serial Number 092) that was built in 1974. It is registered as VH-GID on 8 July 1974 by H.G. Sutton of Mandura, Western Australia and flown out of the Narrogin Gliding Club in Western Australia until September 1986 when it was sold to the Albury – Corowa Gliding Club, New South Wales. In 1999 it was acquired by Michael Green and moved to Townsville, Queensland. The aircraft changed ownership again in 2004 and fell out of use for nearly 4 years. By then it had recorded 4377 hours in the air from 4304 flights. It returned to service briefly in January 2008 (5 flights totalling about 5 hours). It was donated to the Museum by David Millward of the Geelong Gliding Club, Victoria, on 10 April 2017. The aircraft is representative of a popular imported 1970s intermediate single seat sailplane design of aluminium alloy construction.Single seat sailplane of metal alloy constructionWhite colour scheme with yellow fuselage underside highlighted by blue stripe – “Pilatus B4” in black lettering on starboard side of cockpit – black anti-glare paint on the fuselage nose – Registration “GID” on the underside of port wing.australian gliding, glider, sailplane, pilatus b4, sutton, narrogin, albury, corowa, green, townsville, millward, geelong -

Australian Gliding Museum

Australian Gliding MuseumMachine - Glider - Sailplane

The Schreder HP 14V is an all metal single seat sailplane designed by Richard Schreder in America. The design is an evolution of Schreder’s metal sailplane designs that date from the late 1950s. Schreder won the United States National Soaring Championship in 1966 in the prototype HP 14. He marketed the glider in kit form in the 1960s and 1970s and allowed Slingsby in the UK to further develop the design for production. Schreder HP14 V, registered as VH-GGB, was built in South Australia by Harry Bache of the Waikerie Gliding Club in the 1970s. Martin Simons, an authority on vintage sailplanes (including Slingsby types), refers to this airframe as “built entirely from scratch”. After Bache, this Schreder HP14V passed on to E.G. Moore and N.L. Lovell at Ararat in Western Victoria, then Graeme Rickert of the Canberra Gliding Club and finally, to Greg O’Sullivan of the Geelong Gliding Club. The glider was first flown on 20 December 1975. It appears to have been flown regularly over its life to 2015 and the cumulative use being 1386 hours flown from 702 launches. The log book does not disclose details of flights except as aggregates of flights and times. Details of notable flights by Bache and Moore et al are not available. However, reports from Rickert and O’Sullivan indicate that a good number of cross-country flights of 300km or longer were achieved in this aircraft. A well-engineered metal sailplane from the 1970s with good soaring performance which was designed for amateur construction. All metal single seat glider sailplane with a distinctive V-tail, finished in a white and blue colour schemeRegistration letters 'GGB' on sides of fuselageaustralian gliding, glider, sailplane, schreder, slingsby, bache, waikerie gliding club, moore, lovell, rickert, o’sullivan, canberra gliding club, geelong gliding club. -

Newcomb Secondary College Archives

Newcomb Secondary College ArchivesCostume - Rock Eisteddfod 1994 "The Sword in the Stone" - Black Knight Tabard, 1994

Costume designed for the NSC Rock Eisteddfod 1994. Character was Black Knight in the production of "The Sword in the Stone", based on the legend of King Arthur. Costume worn by Year 11 student Rowan Klingberg. Rowan Klingberg went on to be a teacher of PE and Mathematics at Newcomb Secondary College.Black satin tabard sewn by machine, overlocked at edges, biased binding at neckline in black. 'Sword pocket' zigzag stitched to front of item. Side ties half way down, front and back, overlocked along all edges. White eagle logo on front.Name tag - Rowannewcomb secondary college, costume, knight costume, rock eisteddfod -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Ephemera - MAGGIE BARBER COLLECTION: CIRCULAR CANE FAN, 1920-30's

Object. Circular in shape and 22 cms in diameter. The fan has a bamboo handle 26.5 cms long. Long strands of woven cane have been machine stitched into a circular shape, with the outside round in green dyed cane. (twenty rows of woven can make up the fan). A Floral design, 15 cm long is painted on one side of the fan-leaves, petals and centre of flower in green, red, yellow. Markings as above.costume accessories, female, circular cane fan -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - MAGGIE BARBER COLLECTION: FINE LINEN PETTICOAT- LACE TRIMMED

Clothing. Extremely fine linen petticoat, rounded neckline with a blue satin ribbon insertion, threaded through a lace insertion. This ribbon is now badly aged and shedding and splitting. A plackett at the centre back conceals six tiny 9mm covered buttons, and machine (?) stitched button holes. The neckline is outlined with three bands of cotton lace - the first band is 4.5 cm wide, and has a 'shamrock' leaf design. The middle band is 1.5 cm wide, and has a 'twisted' design, which holds the blue ribbon insertion. The outer row is 2.5 cm wide and has a scalloped edging.costume, female, lace trimmed fine linen petticoat -

Monbulk RSL Sub Branch

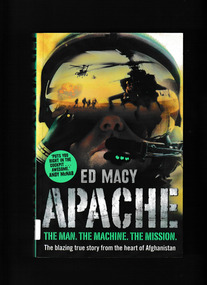

Monbulk RSL Sub BranchBook, HarperPress, Apache : the man, the machine, the mission, 2008

Apache' is the first book to come from the cockpit of the most sophisticated fighting helicopter the world has ever known. Designed in the mid 1980s to take on the Soviets, these machines have proven themselves as the perfect tool for combat in Afghanistan. Ed Macy's account of the incredibly hard Apache selection process, tougher than that of the SAS, combined with his description of the sheer difficulty of flying one of these helicopters provides a fascinating insight into the relationship between man and machine fighting in the toughest conditions imaginable.Index, ill, maps, p.374.non-fictionApache' is the first book to come from the cockpit of the most sophisticated fighting helicopter the world has ever known. Designed in the mid 1980s to take on the Soviets, these machines have proven themselves as the perfect tool for combat in Afghanistan. Ed Macy's account of the incredibly hard Apache selection process, tougher than that of the SAS, combined with his description of the sheer difficulty of flying one of these helicopters provides a fascinating insight into the relationship between man and machine fighting in the toughest conditions imaginable.afghan war 2001-2021 - military operations - britain, afghan war 2001-2021 - personal narratives - britain -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Textile - LINEN AND LACE TRAY CLOTH/HAND TOWEL, Mid 1900's - 2000's

Rectangular shaped tray cloth/hand towel, edged in 1.25 cm wide cotton lace edging - edging is a braid type, commercially made edging. One end has a 10 cm band of machine - made cotton lace, in a floral design. Lace has been attached to the linen fabric in a zig - zag machine stitch. Cream in colour.manchester, table linen, tray cloth/hand towel -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Textile - SIDE TABLE CLOTH, Mid 1900's - 2000's

Cream linen fabric, rectangular in shape. One log edge is finished with a 16 cm wide band of lace. This lace has been.machine made, and attached to the linen with a zig-zag machine stitch. The woven pattern in the lace is geometric in style. The other three sides are edged with 1.5 cm wide, woven lace in a scalloped design. Long-edge lace is 15.5 cms wide.manchester, table linen, side-table cloth -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - WHITE LINEN LACE TRIMMED CAMISOLE

Wide neckline, rounded at the back, and a deep V shaped front. Short sleeves, edged with a one cm band of scalloped edge lace. This edging also trims the back neckline. Front neckline is trimmed with six cm deep scalloped edge, broiderie anglaise, featuring an embroidered floral design, and cutwork. A casing at the waistline, one cm wide, appears to contain elastic, which is now perished. Machine stitched side seams, which are slightly to the back, rather than at the sides.costume, female, white linen lace trimmed camisole -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - FINE COTTON AND LACE ROUND NECK CAMISOLE.- A BEAUTIFUL GARMENT, Late 1800's - early 1900'

Deep round neck, front and back. Sleeveless. Armholes edged wit a two cm band of lace, featuring a diamond shaped geometric design. Lace is spoke stitched to the garment, and has a scalloped edge finish. Two bands of the lace edge - one 2.5cm wide, and one three cm wide. Where they are stitched together, a drawstring of stranded cotton enables the neckline to be gathered in. The lace is spoke-stitched to the fabric, and inserts in circular loops (2) and oval inserts (3) decorate the back across the bustling. One circular shape and two oval shapes decorate the back across the shoulders. Fine, machine stitched, french seams at side seams. Right side seam has a nine cm opening in the seam to the hemline, with a metal hook and hand stitched loop to fasten.costume, female, cotton and lace round neck camisole -

Dutch Australian Heritage Centre Victoria

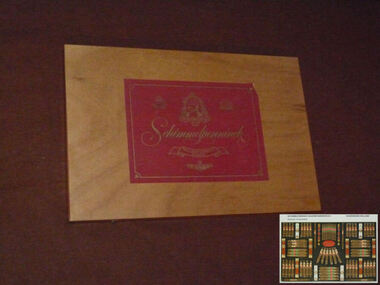

Dutch Australian Heritage Centre VictoriaCigar Box

The Schimmelpenninck factory stood in Wageningen until it finally closed in 2000. The Schimmelpenninck brand started in 1924 when two brothers and an uncle merged their cigar factories into one company. It was called after Rutger Jan Schimmelpenninck, raadspensionaris (kind of a prime minister) of the Batavian Republic in 1805-1806. The tobacco industry has a long history in this town; in the 17th century one fifth of all arable land around the town was used for tobacco. Originally used in pipes and as snuff, the popularity of cigars in the 19th century led to a large expansion of the Dutch tobacco industry. The Schimmelpenninck factory was at its largest just before World war II, 700 employees produced 32 million cigars. Wageningen was heavily damaged during operation Market Garden in 1944, the whole population was evacuated and most of the machines of the Schimmelpenninck factory were stolen or destroyed. After the war, consumption of cigars was much reduced and the firm slowly merged with others. Eventually they became part of Rothmans.This box and the brand name Schimmelpenninck represent several periods of Dutch history between the time of the Republic and the post WWII years. Cigar smoking was very popular in the Netherlands pre-war but less so in the second half of the 20th century partly due to a growing awareness of tobacco's carciogenic properties.Large flat wooden box designed to hold 78 cigars. The lid is attached with brass hinges and two brass clasps enable it to be closed. A large red label with silver script and illustrations is attached to both the outside and the inside of the lid.Schimmelpenninck. Hollands Finest Cigars -

Moorabbin Air Museum

Moorabbin Air MuseumDrawing (item) - CAC Tool Standards Machine Capacity Book No. 2

Aircraft Factory Tool Design Dept. -

B-24 Liberator Memorial Restoration Australia Inc

B-24 Liberator Memorial Restoration Australia IncAircraft, B-24 Liberator, Consolidated Aircraft Corporation, c. 1940

This particular aircraft was modified with a search radar in the lower fuselage to help locate and track targets and was then redesignated as a B-24R model. The RAAF took A72-176 on charge in late 1944 and this saw it issued to 7 OTU (Operational Training Unit) based at Tocumwal, south west NSW. The training saw bomber crews learn how to fly the bomber, operate as a team and work with fighters. Towards the end of the war there were up to 50 aircraft located at Tocumwal along with 5000 personnel. A72-176 was noted as flown on training missions by various aircrew.This aircraft is one of the only remaining B-24 bombers in the southern hemisphere and 1 of only 8 remaining B-24 airframes still existing in the world, out of the nearly 19,000 which were originally built. The restoration honours the contribution of one of the RAAF’s main bombers of the WWII era. This restored Liberator aircraft was assembled from parts salvaged from B-24M models, manufactured during the 1940s in the USA. Made from aluminium, the plane is 68 feet long, with a wingspan of 110 feet, and is metallic silver with a distinctive blue and white target design on each side. The aircraft is powered by four wing-mounted engines, and is fitted with 10 heavy machine guns.Registration number on side of fuselage at rear of plane: 'A72-176' Inscription on side of fuselage at front of plane: 'ROYAL AUSTRALIAN AIR FORCE / US ARMY B24-10 CO / AIR FORCES SERIAL NUMBER 44-41956' aircraft, liberator, bomber, wwii -

Jewish Museum of Australia

Jewish Museum of AustraliaKathryn Tilley, Afikoman pouches, by Kathryn Tilley, 2007

Artist's statement: I chose to make these afikoman pouches even though they may not be familiar to or used by all Jewish families. In these little pouches, a small piece of matzah would be placed in the pouch and then hidden in the house for the children to find during the Passover meal. On finding it, a gift is given. The story of Passover and Judaism in general have been kept alive over the centuries. I wanted to honour the passing down of the Torah through the generations, and, in particular, the role of children in its transmission. I have used the Australian desert as a metaphor for the great wilderness crossed by the People of Israel. A recent trip to Broken Hill and beyond inspired me to work with the subtle colours and textures of that landscape and I have incorporated into the work found objects, stones and beads collected there. (2007, New Under the Sun: Australian Contemporary Design in Jewish Ceremony III)machine embroidered -

Puffing Billy Railway

Puffing Billy RailwayNew Record Saw Bench, circa 1930's

Saw Bench - New Record Saw Bench Timber framed with steel wheels, belt driven saw blade powered by a Rosbery internal combustion engine. The Rosebery Engine No C28437 R.P.M 800 H.P. 6 Manufactured By Westinghouse Rosebery Pty.Ltd. Sydney Rosebery Engine Works Ltd began as the engine and pump manufacturing division of Buzacott & Company, and in 1923 became an incorporated company. In 1935, Westinghouse gave Rosebery Engine Works the right to manufacture and sell nearly all Westinghouse products. The name of the company then changed to Westinghouse Rosebery Ltd From the late nineteenth century, petrol engines gradually supplanted steam engines for running a wide range of machines, and in turn petrol engines were largely supplanted by electric motors. The Champion was a successful small petrol engine made by the large Sydney company, Westinghouse Rosebery, based on the American-designed Fuller and Johnson engine. With hopper cooling and a fuel tank between the skids, and weighing only 240 pounds (109 kg), it was easy to mount on wheeled transport, making the Champion a self-contained mobile source of power. Engines of this type were used in rural areas for driving chaff cutters, small saw benches, pumps and orchard sprayers. These engines were also commonly used in both rural and urban areas for powering concrete mixers. Both Westinghouse Rosebery in NSW and Toowoomba Foundry in Queensland made these engines in large quantities, beginning in the 1920s when tariff protection made local manufacturing viable. The production of small petrol engines continued in Australia until the 1970s, when reduced tariff protection led to increased competition from cheaper imported engines. Historic - Industrial Timber working - belt driven saw blade powered by a Rosbery internal combustion engine. Timber framed with steel wheels, belt driven saw blade powered by a Rosbery internal combustion engine. The Rosebery Engine No c28437 R.P.M 800 H.P. 6 Manufactured By Westinghouse Rosebery Pty.ltd. Sydneysaw bench, puffing billy, new record, internal combustioin, westinghouse rosebery pty.ltd., rosebery pty, internal combustion engine. -

Puffing Billy Railway

Puffing Billy RailwayLister Auto Truck

The Lister Auto-Truck was a small monowheel tractor built for moving light loads around factories, railway yards and similar sites. They were built by R A Lister and Company of Dursley, Gloucestershire, well known for their range of small stationary engines The Auto-Truck was one of several monowheel tractors to appear in the 1920s and '30s, with the availability of small, reliable petrol engines, as developed for motorcycles and the stationary engines for which Lister were already known. These were tricycle vehicles, with the single leading wheel used for both drive and steering. Their simple construction carried most of the mechanism on this wheel as a single unit, the chassis with the trailing wheels being little more than a trailer for balance. Simplicity was a key feature. The engines were single-cylinder and air-cooled. Ignition was by magneto, rather than requiring a battery and electrical system. One of these designs was produced in the 1920s by George Grist of the Auto Mower Co., Norton St Philip, Somerset. The engine was a JAP 600 cc four-stroke air-cooled sidevalve, a typical small engine of the time. The Auto Mower Co. were Lister agents and when Lister heard of this 'Auto-Truck' they bought one for use in their own factory. It was used to carry heavy engine castings from the foundry to the machine shop. Lister customers saw them and there was such interest in wanting to buy them that Lister negotiated with Auto Mower to build them under licence. Although Lister were already well known for their small petrol stationary engines, these were heavy cast-iron engines with water hopper cooling and unsuitable for vehicle use. Lister remained with the JAP engine for the Auto-Truck. The Auto-Truck was designed for use in factories or other places with smooth surfaces of concrete or tarmac. This allowed the use of small solid-tyred wheels with only simple suspension, making the vehicle simple, cheap and lightweight. They had little ability on soft surfaces though and could even topple over if driven carelessly across slopes. Their design was a compromise between the top-heavy nature of the tall engine grouping above its wheel and a well thought-out chassis for stability. The bearing between them was a large diameter ring roller bearing, mounted at the lowest part of the chassis. This gave rigidity and stability, even after long wear. A ring of rolled channel girder was attached to the engine group and rollers on the chassis carried the load upon this. On early Auto-Trucks this bearing is set very low, in line with the chassis members, and is covered by thin steel plates. The front panel of the engine cover is distinctive with large ventilation holes and a Lister signature cut through it. Strangely this panel is made of thick cast iron, providing substantial weight high on the engine and only adding to its top heaviness. To improve visibility of moving vehicles in noisy factories, this panel was often painted white, the rest of the vehicle being Lister's usual brunswick green. The driver was seated on a Brooks bicycle saddle, which in recognition of the lack of vehicle suspension, was carried on the end of a cantilevered bar that acted as a leaf spring. A wide handlebar on the engine group was used for steering. A squeeze bar the width of this handlebar engaged the clutch. Controls included a hand throttle, a gear lever with two forward and one reverse gears, and a large handbrake lever. The engine unit rotated freely for a full 360° rotation. When used in reverse, the Auto-Truck could either be driven from the saddle, looking backwards over the driver's shoulder; or they could dismount, swivel the engine unit around and control it as a pedestrian-controlled truck from behind. Under the engine cover were two equal diameter tanks, a fuel tank for petrol and a shorter oil tank. Engine and chain-drive lubrication used a total-loss oil system, controlled by a small pump and needle valve. Info Ref: Lister Auto-Truck - Wikipedia https://en.wikipedia.org/wiki/Lister_Auto-TruckHistoric - Industrial monowheel tractor for moving light loads around factories, railway yards and similar sites.The Lister Auto-Truck - small monowheel tractor Made of steel with three wheels. Powered by a J.A.P single cylinder petrol motor which is Hand Cranked to start.Lister puffing billy, lister, lister auto truck, monowheel tractor -

Puffing Billy Railway

Puffing Billy RailwayPhoenix Foundry Plate

Phoenix Foundry Plate - replica Made about 2010 cast off original from locomotive Y112 The Phoenix Foundry (1857-1906) fabricated iron and brass products - including engines and pumping gear for the mining industry, locomotives, steam rollers, water pipes, water gauges and diverse small items. Throughout its operation the business was located at premises on Armstrong Street, Ballarat . Background In 1852, at the age of thirty-three and after a year of operating his own engineering business at Williamstown, Lancashire-born blacksmith and engineer George Threlfall (1819-1897) arrived on the Sebastopol gold plain and immediately undertook blacksmith work repairing picks and tools for the miners. Little did he know that this fledgling business would be the genesis of the most iconic business of nineteenth-century Ballarat. At approximately thirty-nine years of age, English mechanical engineer Richard Carter (c1814-1883) came to Australia on board the Arrogant - arriving in Melbourne on 19 April 1853. He soon travelled to the Ballarat goldfields. Born in the year 1830 in Belfast (Ireland), mechanical engineer William Henry Shaw (1830-1896) arrived in Australia in October 1853. He worked briefly with George Threlfall at Sebastopol, then moved to Geelong to manage the small foundry of Frederick Moore. Twenty-four year old English-born iron moulder Robert Holden (c1831-?) left his home in Belfast (Ireland) in late 1854 and travelled from Liverpool to Melbourne on board the James Baines - arriving in February 1855. Afterwards he joined his brother-in-law William Henry Shaw in Ballarat. History Foundation to Incorporation In March 1857 George Threlfall joined in business with Richard Carter, William Henry Shaw and Robert Holden. They relocated Threlfall's successful engineering enterprise from Sebastopol to new premises in Armstrong Street, Ballarat. This business was then known variously as the Phoenix Iron Works Company, Phoenix Foundry or Messrs Carter and Co. By 15 April 1857 they were advertising that they were open for business as engineers, millwrights, boiler makers, smiths, iron founders and brass founders. In January 1858 George Threlfall left the partnership. Incorporation to 1889 1890 to Closing locomotive Y112 Builder: Phoenix Foundry, Ballarat Builder’s Number & Year: 238 of 1889 Designer: Kitson & Co Wheel Arrangement: 0-6-0 No. in class: 31 Entered Service: 24 July 1889 Taken off Register: 11 May 1961 The origins of the Victorian Railways Y-class lay with the decision by Kitson & Co, Leeds to place a 0-6-0 freight locomotive on display at the Centennial International Exhibition, Melbourne in 1888, together with a 2-4-2T suburban passenger locomotive. This marketing initiative proved successful as the Victorian Railways were clearly impressed with these machines, with both purchased after the exhibition and becoming the patterns for new standard locomotive types. Thirty examples of the 0-6-0 heavy freight design were ordered from the Phoenix Foundry, Ballarat, becoming the Y-class for main line heavy freight duties, while the 2-4-2T design became the E-class for Melbourne suburban passenger duties (represented by preserved locomotive E 236). The Y-class prove successful in service and accrued high mileages. They were inevitably superseded by more modern and powerful steam locomotives and a number cascaded into shunting and yard pilot duties, often with the addition of shunters steps along both locomotive and tender. Y 112 was one of the last in service when withdrawn in 1961. Fortunately it was saved for preservation and plinthed in central Ballarat, ostensibly in commemoration of Phoenix Foundry. I understand it is owned by the Sovereign Hill Museums Association. During the 1980’s, Y 112 was leased to Steamrail Victoria and restored to operation at an industrial site in Ballarat. Y 112 features an attractive lined apple green livery and has performed various rail tours around Victoria since restoration. It is normally based at the Steamrail depot in Ballarat East. Y 112 is the only 19th century design in operational condition in Victoria and as such is one of the oldest working steam locomotive in Victoria . Historic - Phoenix Foundry Plate - replica Made about 2010 cast off original from locomotive Y112Phoenix Foundry Plate Oval shaped plate with an image of a phoenix centered at the top with lettering surrounding it.Phoenix Foundry No 238 Ballarat Company Limited 1889.puffing billy, phoenix foundry, ballarat, locomotive y112, phoenix foundry plate - replica -

Puffing Billy Railway

Puffing Billy RailwayPlatform Scales, Avery

Averys Ltd was the holding company for the 32 operating companies in the Avery Group. The Group's main activity was the design, manufacture, sale and servicing of a wide range of weighing machines, physical testing machines and fluid measuring equipment. The company's history can be traced back to 1730, with the manufacturing by hand of steelyards and beam scales in a small workshop in Birmingham. When legislation was introduced at the turn of the century requiring the stamping of all weighing machines used for trade Avery branches were set up in some 100 towns in the United Kingdom. This was the beginning of the sales and service organisation that expanded to cover not only every important town in the United Kingdom but was also established in many overseas countries. Historic - Railway Platform Scales Avery Platform Scales - Iron and glassavery scales, puffing billy, platform scales, scales -

Puffing Billy Railway

Puffing Billy Railway1920's Station Cash Box Tin - Hobbs & Co London, 1920's

1920's Station Cash Box Tin Made by Hobbs & Co London Lever Machine Made Alfred Charles Hobbs (October 7, 1812 – November 6, 1891) was an American locksmith and inventor. Hobbs went to London as a representative of the New York company of Day & Newell, which was exhibiting at the Great Exhibition of 1851. Hobbs had brought with him his boss's (Robert Newell) Parautoptic lock, designed to compete with, and surpass, the locks available at the time in Britain. He was the first one to pick Bramah's lock and the Chubb detector lock at the Great Exhibition of 1851 and forced the lock manufacturers to improve their designs. The lock controversy continues a subject of great interest at the Crystal Palace, and, indeed, is now become of general importance. We believed before the Exhibition opened that we had the best locks in the world, and among us Bramah and Chubb were reckoned quite as impregnable as Gibraltar— more so, indeed, for the key to the Mediterranean was taken by us, but none among us could penetrate into the locks and shoot the bolts of these masters. The mechanical spirit, however, is never at rest, and if it is lulled into a false state of listlessness in one branch of industry, and in one part of the world, elsewhere it springs up suddenly to admonish and reproach us with our supineness. Our descendents on the other side of the water are every now and then administering to the mother country a wholesome filial lesson upon this very text, and recently they have been "rubbing us up" with a severity which perhaps we merited for sneering at their shortcomings in the Exhibition. In 1854 he was awarded a Telford Medal by the Institution of Civil Engineers for his paper 'On the Principles and Construction of Locks'. Sign on a strong room door. Hobbs became one of the founders of the lock making firm of Hobbs Hart & Co. Ltd. The company started in 1851 and was formally registered as Hobbs and Co. in 1852. But by 1855 it had become Hobbs, Ashley and Company. The name then changed to Hobbs, Ashley and Fortescue, with an address at 97 Cheapside in London. Then for the next ninety years the address was 76 Cheapside in London. In 1860 Hobbs returned to America and lived in Bridgeport, Connecticut, and went on to hold a dozen patents for firearm ammunition manufacturing. In 1880 he listed himself as a "Superintendent Of Cartridge Factory" Info from https://en.wikipedia.org/wiki/Alfred_Charles_HobbsHistoric - Railways - Station Cash Box Tin 1920's Station Cash Box Tin - Hobbs & Co London Metal Tin - painted Black, Gold and Red with Brass Lock and HandleHobbs & Co London Lever Machine Made1920's station cash box tin, puffing billy -

Tatura Irrigation & Wartime Camps Museum

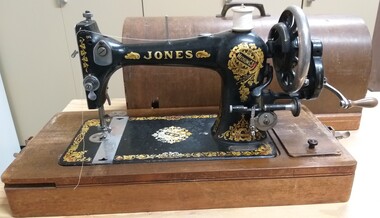

Tatura Irrigation & Wartime Camps MuseumDomestic object - Sewing Machine, Jones Sewing Machine

This Jones sewing machine was one of the few sewing machines that accompanied the Germans who were deported from Palestine in 1941 to Australia where they were interned at Tatura. The machine was owned by Nelly Wied (nee Glenk). See notes in Item receipt form.Lid is plywood constructed with domed top. Brown handle on top and a clip each end to fasten to machine base. Machine is on a wooden base with clips on each end to fasten to lid. Right hand side of machine has a rectangular hole with wooden lid and brown wooden knob. To keep accessories in. Machine is made from metal, painted black and has fancy gold patterns on front right, "Jones" in gold and gold design around the metal base. It has a silver turning wheelJONESjones sewing machine, palestine germans, german templers, palestine internees, templer internees, nelly wied, nelly glenk, helmut glenk, tatura internment camps -

Anglesea and District Historical Society

Anglesea and District Historical SocietyPocket Phonograph, Palliard Cie (St Croix), Circa 1926

This mikiphone has an approximate manufacture date of circa 1926. It is stamped in the interior with the maker’s mark of Palliard Cie (St Croix), who partnered with the patent owners, Nicolas and Etienne Vadasz for the large scale production of the mikiphones. A Mikiphone – or Pocket Phonograph is one of the earliest versions of a portable music player. The Mikiphone was small enough to fit into a pocket for portability, and once unpacked had the ability to play 10” records. Power was supplied to the unit by a small hand crank, and sound was amplified by a small resonator. It is estimated that 100,000 to 180,000 of the units were made between 1924 and 1927. Luxury editions were also available with either a gold or silver casing. Le Corbusier is quoted as saying he could ‘see in the Mikiphone the essence of Esprit Nouveau’. The pocket gramophone is significant for historical and social reasons. It is primarily an enabler of leisure activities due to its portability and size. The design of the object is also significant as it showcases design advancements in the early part of the 20th century. The Swiss made "Mikiphone", the smallest talking machine ever placed on the market folded up to the size of a large pocket watch or small cheese case. Production stopped in 1927. A total of 180,000 were made. A few were made in a luxury version with gold or silver case for a "Pretentious clientele".Inside on dial: Mikiphone / Pocket Phonograph / Swiss made / System Vadasz. Outside: Pocket Phonograph / Mikiphone / System Vadosz / Patented in all countries.pocket phonograph, mikiphone, gramophone, pocket, music player, swiss made, switzerland -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object - Realia, New National Treadle Sewing Machine

... Gold leaf floral design on machine and flat greyhound... Clothing Manufacture Gold leaf floral design on machine and flat ...Treadle home Sewing machine - pre-electric. Rusted partsBlack "pre-electric treadle sewing machine with "fly wheel" "New national"Gold leaf floral design on machine and flat greyhound trademark inside floral circle, fastened to wooden lid of tableclothing manufacture -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object, Sewing Machine Treadle

... Gold leaf floral design on machine. Shield of gold leaf... missing parts rusted gold leaf Gold leaf floral design on machine ...Treadle home sewwing machine. pre-electric - rusted missing parts rusted gold leafBlack pre-elctric Treadle sewing machine with silver coloured rim on fly wheel.Gold leaf floral design on machine. Shield of gold leaf. fastened to wooden table -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object, Singer Sewing machine Treadle type

Home Sewing machineBlack - Floral Design - crackled. Wooden curved top case. Case with handle metal turned wood - keyhole. key on black wool no box for tools and parts. Empty bobbin in slot. Foot Pedal'Singer" Trade mark Stamp " The Singer Maine co" fastened to the machine "Y8089019" "Simarco 193017" -

National Wool Museum

National Wool MuseumTextile - Quilt, Judith Oke et al, Isolation Quilt, 2020-2021

In 2020 during the period of lockdown due to COVID the National Wool Museum asked their volunteers to make and donate blocks made from a variety of materials found in their homes, for an ISO quilt. The NWM reached out to the patchwork and quilter community to find a local quilter to sew the donated blocks together. The quilt is sewn together and quilted by Judith Oke, 2020-2021. Judith is a local patchwork and quilter and a member of Geelong Patchwork & Quilters Guild. Through the process she was inspired by the tradition of wagga quilts, where bits and pieces are stitched together, sometimes lined with whatever the sewer found available, such as clothing and sacking, to provide warmth. In construction of the finished quilt the challenge was combining 10 inch blocks made from a variety of materials, with uneven sizing. The aim was to combine these very different blocks into a harmonious whole. To this end a light and dark pattern was planned, with the blocks to be sewn onto a blanket. The choice to layer the blocks over each other, rather than sew an even seam was aimed at emphasizing the make do nature of these ISO blocks. Due to the weight of the blanket a decision was made to sew the blocks onto a base before the whole was stitched onto the blanket. The blanket was sourced from NWM donations. The rich, red of the blanket provides a bright, warm background for the colourful squares. Some of the light weight blocks were backed with iron-on interfacing to strengthen them for sewing. The edges of two of the woven squares were blanket stitched with knitting wool. The 10 inch donated blocks/squares were machine sewn to a cotton sheet base, with liberal use of blanket stitching, as the blanket was too heavy to sew the blocks directly onto the blanket. The base with squares was then machine sewn onto the red blanket backing.Various multi coloured and designed patchwork squares sewn onto a red woollen blanket. isolation, covid, quilt, wool -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

"Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.Book, front cover: "Modern Developments in the Australia Woollen Industry" c.1923; Yarra Falls Spinning Co. Pty Ltd and Australian Knitting Mills Limited.weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, logo merino: sheep in australian art and design - exhibition (29/07/2000 - 04/02/2001), weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

National Wool MuseumQuilt, Ladies samples coverlet

UnknownLadies samples coverlet. Machine stitched. Backed with a patchwork of mattress damask offcuts in a simple slat design.quilting history, patchwork history, running stitch group, running stitch collection, quilting - history, patchwork - history -

National Wool Museum

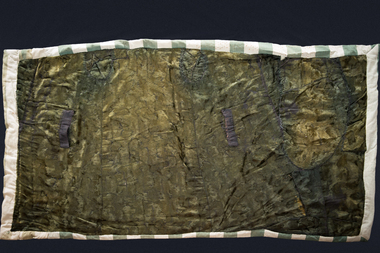

National Wool MuseumQuilt, Travelling rug

Part of the Wagga collection. Maker unknown, c. early 1940s. Possibly from South Australia. This 'travelling rug' was found in an opportunity shop in Campbell's Creek near Castlemaine in Victoria. Unfortunately, nothing is known about the maker but it could be surmised that the quilt had many uses. It is heavy and designed for warmth, lined with a woollen blanket and hessian. Its size suggests usage in an open buggy or car when travelling or as a picnic rug along the way. The sturdy canvas backing is of the type commonly used for awnings, chair coverings or tent cloth. The quality of the green velvet made it ideal for further use as a quilt after the original use as an overcoat or smoking jacket for either a man or a woman. Apart from the original machine stitched seams in the garment, it is sewn together by hand using herringbone stitch. It is not known if this quilt was designed to be used with a cover. However, the arrangement of pieces in the garment to create a shape with straight edges may suggest that this may have been a consideration.Travelling rug made of wool, cotton and green velvet.No. 27 "Travelling rug" Maker Unknown Running Stitch Collection...quilting history, handicrafts, running stitch group, blankets, running stitch collection, highlights of the national wool museum: from waggas to the wool quilt prize - exhibition (22/09/2001 - 02/12/2001), quilting - history