Showing 359 items

matching processing company

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Cooper’s Hollowing /Jigger Knife, William Greaves & Sons, 1823 -1850

... during the first half of the 19th century. This company undertook ...William Greaves was once a prolific company that highly prospered in the 19th century during the boom of the tool and cutlery trades in Sheffield England as steel became more commercially available. William Greaves's works were situated at the Sheaf Works in the heart of Sheffield, at Maltravers Street, opening in 1823 and was known to be the largest business in this area at this time. The Sheaf Works made a range of tools and saws including cutlery, penknives and razors and also even made its steel in-house. The factory used its perfect position for water power being built on the edge of the Sheffield canal and also used the railway line nearby giving them the perfect opportunities for transporting its goods. The factory itself was also a revolution because it attempted to bring together as many cutlery manufacturing processes as possible together in one place, something that had not been attempted before. The money to build these huge works came from Greaves' trade with America, where they sent razors, table cutlery and sturdy Bowie knives. This allowed the Greaves’ to build the factory and expand their production, which made them even more money. This made William Greaves very rich indeed, and it was reported that when he died in 1830 he left each of his five surviving daughters £30,000 each, an astronomical sum at the time. In today’s money that is approximately £2.3 million. The firm finally dissolved in 1850, but Sheaf Works continued to be used by many cutlery manufacturers until the 1980s. With most of the buildings still standing today.A significant item made by a successful cutlery manufacturer in England during the first half of the 19th century. This company undertook many new processes to streamline cutlery production and introduced innervations regards working with steel that are still in use today. This item is now regarded as a collector's item given the company ceased trading in 1850. jigger/hollowing knife with internal bevel, Electro Boracic Steel. Stamped 3.1/2″ William Greaves, Sheaf Works, Sheffield flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cooper's jigger, howeling knife, wm greaves & sons -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Screen, Thomas Hope, 1905-1913

The fire screen was part of the original furnishings of the Lighthouse Keeper's Quarters in Merri Street, Warrnambool. It was made by Lighthouse Keeper, Thomas Hope. Thomas served two terms as an assistant lighthouse keeper in Warrnambool. His first term was from 1905 to 1907. He later returned from 1910 to 1913, when he was appointed as Keeper five months after the untimely death of his predecessor Peter Quinn. Woodworking was one of Thomas Hope’s hobbies, and the three-panel fire screen he made as a lighthouse keeper is now in the Flagstaff collection and is displayed in the Lighthouse Keeper’s Cottage. Thomas Hope 1857 - 1928 Thomas James Hope was born in Camden, Surrey, England in 1857. His father, also called Thomas, was reputed to be a member of the Royal Family, and Thomas Hope Junior his illegitimate son. Thomas was subsequently brought up on the estate of the Earl of Hopetoun in Somerset and it was thought that Thomas was the Earl’s grandson. Against the wishes of those in charge of Thomas, he joined the navy at an early age, seeing much of the world until he settled in New Zealand at the age of twenty-four. After some years in New Zealand, he came to Australia to live. One of the jobs Thomas Hope had prior to becoming an assistant lighthouse keeper in 1896 was as a cook in the Lunatic Asylum at Sunbury, Victoria. He served as an assistant keeper at Shortlands Bluff, Gabo Island, Split Point and Warrnambool, retiring in 1918. He bought a house in Nicholson St, Warrnambool and died in March 1928. He is buried in the Warrnambool cemetery. Thomas Hope is recorded in family history as being of short stature and, not surprisingly given his alleged aristocratic connections, possessed a beautiful speaking voice. He and his wife Elizabeth nee Waters, whom he married in New Zealand, had six children (Thomas, killed in World War One), Ellen (Nell), Nora (who was married at the Warrnambool lighthouse keepers cottage), William (who died in Warrnambool), Marion and Alan. Joseph Hoover (Dec 29, 1830, to Aug 7, 1913) Joseph Hoover, the printer of the pictures on the screen, was born in Baltimore, of Swiss-German heritage. He was trained as an architectural woodturner. In 1856 Hoover moved to Philadelphia and began producing elaborate wooden frames in his wood-turning and framing business. By 1865 Hoover had started to produce popular prints for publishers and artists, which included noted Philadelphia artist James F. Queen. In the 1880s Hoover set up a complete plant specialising in chromatography, the process of producing colour prints from lithographic plates. The coloured prints he produced were affordable to business and private customers. In 1893 his son Henry L., a trained lithographer, joined the company as overseer and it was called J. Hoover & Son. It became one of the largest in America by the turn of the century. Hoover won a medal for Excellence for his Chromolithographs of James Queen’s works. In 1904 Joseph’s other son, Joseph W, joined the business as a partner and the company was called Jos. Hoover & Sons. Hoover died of a heart attack in 1913. He was survived by his wife and six children: two sons who were also his business partners, and four daughters. The firm continued in production until around 1985. Hoover’s prints included scenes, still life and landscapes of America and other locations. They were sold in America and overseas to countries including Canada, Germany, Mexico and England. The three-panelled screen in the Lighthouse Keeper’s Cottage was made by the Assistant Lighthouse Keeper, Thomas Hope during one of his two terms at the Lighthouse Keepers' Quarters. It is the only object in the collection known to be connected to Hope. The Lighthouse Keeper's Cottage is part of the Lady Bay Lighthouse Complex, which is listed on the Victorian Heritage Register for being of historical, scientific (technological) and architectural significance to the State of Victoria.Fire screen comprising three black wood framed panels hinged together. Each panel contains a glass-encased print depicting a rural landscape. Ornate stencil cut wood edging and quilt-inspired parquetry sits above each panel. The central panel is taller than those either side. Screen is lined in black-painted cardboard.Printed at the base of each of the three prints “COPYRIGHT 1896 BY J. HOOVER & SON, PHILAD’’A.”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, firescreen, thomas hope junior, ellen (nell) hope, nora hope, william hope, marion hope, alan hope, jos. hoover & sons of philadelphia, lighthouse keeper, assistant lighthouse keeper, carved screen, merri street, lighthouse keeper's cottage, lighthouse residence, lighthouse, wood carving, lighthouse complex, lady bay lighthouse, fire screen -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDocument - Certificate of Competency, Marine Department, Commonwealth Council for Trade, 1883-1894

Fifteen year old Albert Edward Gill was born in Poplar, Middlesex, in 1868. He volunteered in May 1883 as an Apprentice Ordinary Seaman with the Merchant Services under the London shipping company James P. Corry & Co., owner of the Star Line. The shipping company by this time had a fleet of both clipper and steam cargo ships that sailed as far away as Australia and New Zealand. Gill’s apprenticeship was a four year unpaid term, with only his food, drink, lodgings, washing and medical needs provided for him. The contract had many conditions but it was a wonderful opportunity for a young man. His father James Gill signed the papers as his guarantor. In December 1887 Gill completed his apprenticeship and qualified as an Able Seaman. He served for another seven years with James P. Corry & Co. and earned his Certificate of Competency as a Master in the Merchant Service in April 1894, having passed the Ordinary Examination. (The transcription of Gill's two certificates is provided further down this page.) JAMES P. CORRY & CO. - The Belfast Company was formed in 1826 by Robert Corry, and imported timber from Canada to Ireland. In 1859 the company expanded to import timber from Calcutta, and relocated its offices to London. In the 1880s the company had a fleet of 13 tall clipper ships and included ports in Australia and New Zealand in its destinations. It continued to expand trade even further and by 1908 the Star Line had seven cargo steamers trading with the East and Far East (the ships were named Star of Australia, Star of Japan, Star of England, Star of New Zealand, Star of Ireland, Star of Scotland and Star of Victoria). In 1912 the Star Line ships added an emigrant service to Australia. TRANSCRIPTION OF CERTIFICATES - = = = = = = = = = = = = “Ordinary Apprentice’s Indenture” Transcribed:- (Printed form with printed logo of the Marine Department, Commonwealth Council for Trade. Sanctioned by the Board of Trade, May 1855. ) Registered at the Port of London, Sixteenth of May, 1883, and signed for the Registrar General. Stamped in blue ink “REGISTERED IN LONDON, MAY 16 1883” “RECORD OF THE REGISTER GENERAL OF SEAMEN” “This Indenture, made the SIXTEENTH day of MAY 1883 between ALBERT EDWARD GILL aged FIFTEEN years, a native of POPLAR, in the county of MIDDLESEX of the first part JAMES P. CORRY & CO. OF 9 & 11 FENCHURCH AVENUE in the CITY of LONDON of the second part, and JAMES GILL, of POPLAR, in the county of MIDDLESEX, of the third part, WITNESSETH, That the said ALBERT EDWARD GILL hereby voluntarily binds himself Apprentice unto the said JAMES P. CORRY & CO., his Executers, Administrators and Assigns, for the term of FOUR years from the date hereof; And the said Apprentice hereby covenants that, during such time, the said Apprentice will faithfully serve his said Master, his Executors, Administrators and Assigns, and obey his and their lawful commands, and keep his and their secrets, and will, when required, give to him and them true accounts of his or their goods and money which may be committed to the charge, or come into the hands, of the said Apprentice; and will, in case the said Apprentice enters Her Majesty’s Service during the said term, duly account for and pay, or cause to be paid, to his said Master, his Executors, Administrators, or Assigns, all such Wages, Prize Money and other Monies as may become payable to the said Apprentice for such service; and that the said Apprentice will not, during the said term, do any damage to his said Master, his Executors, Administrators, or Assigns, nor will he consent to such damage being done by others, but will, if possible, prevent the same, and give warning thereof; and will not embezzle or waste the Goods of his Master, his Executors, Administrators, or Assigns, nor give or lend the same to others without his or their licence; nor absent himself from his or their service without leave; nor frequent Taverns or Alehouses, unless upon his or their business, nor play at Unlawful Games : IN CONSIDERATION WHEREOF, the said Master hereby covenants with the said Apprentice, that during the said term he the said Master, his Executors, Administrators, and Assigns, will and shall use all proper means to teach the said Apprentice or cause him to be taught the business of a Seaman, and provide the said Apprentice with sufficient Meat, Drink, Lodgings, Washing, Medicine, and Medical and Surgical Assistance, NO WAGES, the said Apprentice providing for himself all sea-bedding, wearing apparel, and necessaries (except such as are herein-before specially agreed to be provided by the said Master): AND IT IS HEREBY AGREED, that if, at any time during the said term, the said Master, his Executors, Administrators or Assigns, provide any necessary apparel, or sea-bedding for the said Apprentice, he and they may deduct any sums properly expended thereon by him or them from the sums so agreed to be paid to the said Apprentice as aforesaid: And for the performance of the Agreements herein contained, each of them, the said A.E.GILL and JAMES P CORRY & Co., doth hereby bind himself, his Heirs, Executors, and Administrators, unto the said JAMES P. CORRY & CO., his Executors and Administrators, unto the other of them, his Executors and Administrators, in the penal sum of THIRTY pounds; and for the performance of the covenants on the part of the said Apprentice herein contained, the said JAMES GILL as surety, doth hereby bind himself, his Heirs, Executors, and Administrators unto the said JAMES P. CORRY & Co., his Executors and Administrators, the penal sum of THIRTY pounds; Provided, that notwithstanding the penal stipulations herein contained any Justice or Justices of the Pease may exercise such jurisdiction in respect of the said Apprentice as he or they might have exercised if no such stipulations had been therein contained. In witness whereof, the said parties have hereunto set their hands and seals, the day and year above written. Signed, sealed, and delivered, in the presence of - - Weston, 9 & 11 Fenchurch Avenue Signed, James P. Corry (Master) Signed, Albert Edward Gill (Apprentice) James Gill (Surety) NOTE – This Indenture must be executed in duplicate, both copies must be taken to the Registrar General of Seamen; or if in the Outports to the Shipping Master; one copy will then be retained and recorded, and the other returned to the Master with the necessary endorsement. = = = = = = = = = = = = Reverse of the Indenture, Transcribed:- “This is to certify that the herein mentioned Alfred Edward Gill has served the full term of the Indenture in our employ during which time he has conducted himself satisfactorily. According to the Captain’s report he has been strictly sober during the last – years [? from his failure?] Signed: James P. Corry & Co., Owner, Star Line 9 Fenchurch Avenue St, 13 Dec. ‘87 = = = = = = = = = = = = Certificate of Competency, Transcribed:- (Board of Trade logo and printed text of the certificate, with hand written details filled in) By the Lords of the Committee of Privy, Council for Trade Certificate of Competency as MASTER to Albert Edward Gill Whereas it has been reported to us that you have been found duly qualified to fulfil the duties of MASTER in the Merchant Service, we do hereby, in performance of the Merchant Shipping Act, 1854, grant you this Certificat6e of Competency. By Order of the Board of Trade, this 19th day of APRIL, 1894 Signed INGRAM B WALKER (one of the Assistant Secretaries of the Board of Trade) Countersigned -, Regulator General. Registered at the Office of the Regulator General of Shipping and Seamen. = = = = = = = = = = = = Reverse of Certificate of Competency, Transcribed:- No. of Certificate - 020886 Address of Owner - SUNNY LAWN, WALLWOOD ROAD, LEYTONSTONE Date and Place of Birth – 1868, POPLAR Signature – A E GILL. This Certificate is given upon an Ordinary Examination passed at LONDON on the 17th day of APRIL 1894 Every person who makes, or procures to be made, or assists in making any false Representation for the Purpose of obtain for himself or for any other Person a Certificate either of Competence or Service, or who forges, assists in forgery, or procures to be forged, or fraudulently alters, assists in fraudulently altering, or procures to be fraudulently altered, any such Certificate or any Official Copy of any such Certificate, or who frequently makes use of any such Certificate, or copy of any such Certificate, which is forged, altered, cancelled, suspended, or to which he is not justly entitled or who fraudulently lends his Certificate to, or allows the same to be used by any other person, shall for each offence be deemed guilty of a Misdemeanour, and my be summarily punished by imprisonment with or without hard labour for a period not exceeding Six Months or by a penalty not exceeding 100 pounds, and any Master or Mate who fails to deliver up a Certificate which has been cancelled or suspended is liable to a penalty not exceeding 50 pounds. N.B. – Any person other than the Owner thereof becoming possessed of the Certificate is required to transmit it forthwith to the Register General of Shipping and Seamen, Custom House, London, E.C. Issued at the Port of LONDON on the 20th day of APRIL 1894. Signed J I-, - Supt. = = = = = = = = = = = = These certificates are significant as a record of the process required to qualify as a ship’s Master, which was required by the vast number of merchant ships that crossed the world to Australia with cargo and passengers, all contributing to the early settlement and development of Australia as a Colony and a Nation. The certificates are also significant for their association with James P. Corry & Col. owner of the Star Line shipping company that provided trade and passengers to Australia in the late 19th and early 20th centuries. Set of two documents from the Board of Trade, printed on cloth and wax paper, each relating to achieving the standard of Master Seaman, and belonging to Albert Edward Gill. They are dated 1883 to 1894. The forms have been stamped, signed, dated, details completed and sealed with three red wax seals. The certificate number has been stamped onto the document is such as was as to deter forgery. The forms relate to Albert Edward Gill and James P. Corry & Co, Star Line Merchant Services and show his registered number as a Master Seaman. 245.1 – Front: Ordinary Apprentice’s Indenture, printed certificate, with spaces completed and signed by hand, and sealed with three red wax seals. Signed and dated 16 May 1883 Reverse: Handwritten statement, signed and dated 13 Dec 1887. 245.2 – Front: Certificate of Competency, Master in the Merchant Service, printed and completed by hand, registered at the Office of the Regulator General of Shipping and Seamen, dated 19 April 1894. Reverse: Certificate, Ordinary Examination Passed, printed and completed by hand, dated 17 April 1894Signatures and other handwritten details. Stamped with security lines, Registration Number "020886"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, albert edward gill, certificate of compentency, apprentice's indenture, education, employment, 1880's, ordinery examination, able seaman, master seaman, james p. corry & co., star line, timber merchant, emigrant ships -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlaque - Nameplate, Circa 1886

The Falls of Halladale was an iron-hulled, four-masted barque, used as a bulk carrier of general cargo. She left New York in August 1908 bound for Melbourne and Sydney. In her hold was general cargo consisting of roofing tiles, barb wire, stoves, oil, and benzene as well as many other manufactured items. After three months at sea and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland on the 15th of November, 1908. The captain and 29 crew members survived, but her cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson's navigational error, not too technical failure of the Clyde-built ship. The Falls of Halladale was built in1886 by Russell & Co., at Greenock shipyards on the River Clyde, Scotland for Wright, Breakenridge & Co of Glasgow. She was one of several designs of Falls Line of ships named after waterfalls in Scotland. The company had been founded between 1870- 1873 as a partnership between Joseph Russell, Anderson Rodger, and William Todd Lithgow. During the period 1882-92 Russell & Co. standardised designs, which sped up their building process so much that they were able to build 271 ships during that time. The Falls of Halladale had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the 'windjammers' that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new raised catwalk-type decking allowed the crew to move above the deck in stormy conditions. The Falls of Halladale shipwreck is listed on the Victorian Heritage (No. S255). She was one of the last ships to sail the Trade Routes from Europe and the Americas. Also of significance is that the vessel was one of the first ships to have fore and aft lifting bridges as a significant safety feature still in use on modern vessels today. The subject model is an example of an International Cargo Ship used during the 19th and early 20th centuries to transport goods around the world and representing aspects of Victoria’s shipping industry. Nameplate, large brass letter “S” part of the nameplate, recovered from the starboard bow of the wreck of 'Falls of Halladale'. The letter is raised along central axis to form three dimensional effect, and restored to burnished bronze colour.warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime village, flagstaff hill maritime museum, shipwreck artefact, great ocean road, brass lettering, falls of halladale, 1908 shipwreck, ship nameplate, letter s, letter, nameplate -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Chair, Harnisch & Co, 1876-1918

The design of this pair (RN 758 & 759) is based on Thonet’s No. 18 chair, which was originally produced in 1876 by Thonet, and is still one of the best-selling designs for café and restaurant owners. It is elegant, sophisticated and durable. The label notes the design as “AUS MASSIV GEBOGENEM HOLZE vorm” which translates to “solid curved sandals shape”, a good description for the back of the chair. The chairs have marks, paper labels and symbols on them that show that the maker was Harnisch & Co., Neuschler (also called Banská Bystrica) Furniture Factory in Neuschol (Beszterczebanya), Hungary, privileged makers for the Imperial and Royal Austrian-Hungarian Empire 1867 – 1918. Bentwood chairs are made by a process of wetting wood in water, bending it into curved shapes, then allowing it to dry so that the shape becomes permanent. This process originated by Michael Thonet, who had been given the right to bend wood into desired curves by the Austrian Courts in 1842. In 1856 he was granted a 13 year patent to manufacture chairs and table legs of bent wood treated by steam or boiling water. In 1859 his company Gebruder Thonet produced his original design. Thonet’s early designs also featured hand carved or laminated wooden seats. His Model No. 14 produced in the 1850’s, was his most popular design. After Michael’s death in 1871 the family went on designing and producing chairs. The No. 18 chair was produced in 1876, one of a group of chars with back inserts consisting of curves and loops of bentwood. These bentwood chairs are believed to be associated with the either the original Warrnambool Town Hall or the Toc H Group in Warrnambool. The Warrnambool Town Hall played a significant role in the both the local government and the social events of local and district areas. It was a place for Council meetings, community events and entertainment, theatrical and musical.Chair, bentwood, 'French Bistro Chair' with a floral pattern carved in seat. Backrest has inverted U shape inside that extends to the seat. Supports on either side of backrest's base join to back of seat. Legs have a wooded bracing ring. Marks are embossed into rim under seat. Paper label, cream with black print, on rim; Right side of label has the symbol of Heraldic Shield. Text on label. Made by NEUSOHLER FABRIK FUR MOBEL, AUS MASSIV GEBOGENEM HOLZE, vorm. HARNISCH & Co, NEUSOHL (BESZTERCaZEBANYA) UNGARN ' Hand written under seat "T H" in black paint, "T H " in white chalk.Marks; pressed into rim under seat is "3", and "Crown [over] (N)", Paper label, cream with black print, on rim; Left side has Mark “N inside circle under crown”. Right side has symbol of Heraldic Shield. Text on label “Trade – K.u.K.- Mark / NEUSOHLER FABRIK FUR MOBEL/ AUS MASSIV GEBOGENEM HOLZE, vorm. HARNISCH&Co / NEUSOHL (BESZTERCaZEBANYA) UNGARN ' Hand written under seat "T H" in black paint, "T H " in white chalk. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bentwood chair, café chair, restaurant chair, thonet design chair, neusohler fabrik fur nobel, k.u.k. approved manufacturer, hungry, harnisch & co, k.u.k., public hall chair, toc h -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Chair, Harnisch & Co, 1876-1918

The design of this pair (RN 758 & 759) is based on Thonet’s No. 18 chair, which was originally produced in 1876 by Thonet, and is still one of the best-selling designs for café and restaurant owners. It is elegant, sophisticated and durable. The label notes the design as “AUS MASSIV GEBOGENEM HOLZE vorm” which translates to “solid curved sandals shape”, a good description for the back of the chair. The chairs have marks, paper labels and symbols on them that show that the maker was Harnisch & Co., Neuschler (also called Banská Bystrica) Furniture Factory in Neuschol (Beszterczebanya), Hungary, privileged makers for the Imperial and Royal Austrian-Hungarian Empire 1867 – 1918. Bentwood chairs are made by a process of wetting wood in water, bending it into curved shapes, then allowing it to dry so that the shape becomes permanent. This process originated by Michael Thonet, who had been given the right to bend wood into desired curves by the Austrian Courts in 1842. In 1856 he was granted a 13 year patent to manufacture chairs and table legs of bent wood treated by steam or boiling water. In 1859 his company Gebruder Thonet produced his original design. Thonet’s early designs also featured hand carved or laminated wooden seats. His Model No. 14 produced in the 1850’s, was his most popular design. After Michael’s death in 1871 the family went on designing and producing chairs. The No. 18 chair was produced in 1876, one of a group of chars with back inserts consisting of curves and loops of bentwood. The popularity of the Bentwood chair, even now, is due to its versatility and timeless quality. Its style, whether varnished or painted, suits any room in the house. The lightweight chairs are also popular for café and restaurant seating, as well as for public gatherings. They can be easily moved around and grouped in a variety of ways to suit any occasion.Chair, bentwood, 'French Bistro Chair' with pattern carved in seat. Backrest has inverted U shape inside that extends to the seat. Supports on eitherside of backrest's base join to back of seat. Legs have a wooded bracing ring. Marks; pressed into rim under seat. Paper label, cream with black print, on rim. Right side of label has symbol of Heraldic Shield. Text on label. Made by Harnisch & Co.Marks; pressed into rim under seat is "3" and "4", and "Crown [over] N", Paper label, cream with black print, on rim; Left side has Mark “N inside circle under crown”. Right side has symbol of Heraldic Shield. Text on label “Trade – K.u.K.- Mark / NEUSOHLER FABRIK FUR MOBEL/ AUS MASSIV GEBOGENEM HOLZE, vorm. HARNISCH & Co / NEUSOHL (BESZTERCaZEBANYA) UNGARN ' Hand written under seat "T H" in black paint, "T H " in white chalk. flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, bentwood chair, café chair, restaurant chair, meeting hall chair, thonet design chair, harnisch & co, k.u.k., neusohler fabrik fur nobel, approved manufacturer, neusohl (besztercazebanya) ungarn -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGlue Pot, T & C Clark, Late 19th Century

T. & C. Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enameled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councillor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enameled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enameled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enameled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading.An item that was made by a British foundry that was a pioneer and innervated many new processes in the manufacture of enamel ware, producing many items for every day use.Glue pot with inner pot, metal, corroded, both pots have handles."T & C CLARK & Co Ltd, ENGLAND, 55279 RD" and "FIRST QUALITY No. 4/0"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, t& c clarke, cast iron, foundry, sanitary ware, ironware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Guillotine, c. 1880's

This guillotine is a hand operated machine specifically designed to cut through multiple sheets of paper or card. It has a very heavy and sharp single blade knife mounted between vertical guides or runners. The main users of a machine like this is in by the printing and publication binding industry. Book binding companies use a guillotine to evenly trim the pages of a book after it has been bound. The way the guillotine is used is - paper or card is stacked squarely on the flat table and pushed firmly against the back guide - the handle below the table at the front of the machine is wound around, which brings the back guide forward, pushing the paper stack forward and positioning the centre of the stack below the vertical frame - the upper wheel is wound around, which brings the clamp and firmly in position on top of the paper, to hold it very firmly - the large wheel on the side of the machine is turned around to lower the long sharp blade down onto the pages and cut them through. The sharp edge of the blade is protected somewhat from becoming blunt; a block of wood sits in the table under the stack of paper An early model of a guillotine was patented in 1837 by Thirault, who built a model with a fixed blade. Guillotines similar in principal to this one were patented by Guillaume Massiquot in 1844 and 1852. Over the years many improvements have been made and operation has moved from man power to electricity. Oscar Friedheim Ltd. was the importer and wholesaler of a large range of machinery and equipment for the printing and bookbinding industry. He sold most of his equipment under his own name. On this guillotine or paper cutter he refers to the origin of the guillotine’s manufacture only as “German Manufacrure”. A reference book “Commercial Bookbinding: a description of the processes and the various machines used" by Geo. Stephen, 1910, recommends Oscar Friedheim, amongst others, for the supply of “reliable cutting machines for hand or power”. It also recommends Oscar Friedheim’s for a wide range of other printing machinery and processes. OSCAR FRIEDHEIM LIMITED, LONDON Oscar Friedheim Ltd. was established in 1884 and operated from Ludgate in London. The company was an importer and wholesale supplier in the 1880’s, offering machinery and equipment for the printing and packaging industry for the UK and Ireland. The company became incorporated in 1913. An advertisement of 1913 includes a telegraphic code plus two telephone numbers for Oscar Friedheim Ltd and invites readers to call at the Ludgate, London, showrooms to see the machines working. The company later became Friedheim International Ltd. The book titled “Friedheim, A Century of Service 1884-1984 by Roy Brewer, celebrates Oscar Friedheim’s achievements. Friedheim International currently operates from Hemel Hempstead, on the northern outskirts of London UK. It promotes itself as “… the leading supplier of finishing, converting and packaging machinery to the printing, graphic arts, and highly varied packaging industries in the UK and Ireland. The company’s policy is simple – “employ the best people, work with the best equipment manufacturers in the world, and treat our customers as partners!” The company still sells guillotines. The guillotine is significant for its ability to represent aspects of the printing trade in Warrnambool and in a typical port town circa 1850 to 1910. It represents communication methods and processes used in the time before electrically powered equipment became common in industry.Guillotine (or paper cutter), hand operated. Metal framework with vertical guides, stand and metal mechanical parts including wheels and gears. Table with back guide; handle below front of table winds to move the back guide. A wheel at top of machine winds to adjust pressure of the clamp on the work on the table below it. The cutting blade fits between vertical guides; a timber insert in the table below the blade helps minimise the loss of sharpness of the blade. A handle on the side of the machine turns a large spoked wheel, which rotates a large gear, causing the blade to move up and down. Makers details are on a small oval plaque with embossed maker’s details is screwed onto main body. Maker is O Friedheim, London, and the machine is of German manufacture, circa late 1880’s.Maker’s plaque inscribed "O. FRIEDHEIM / London / German Manufacture"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, printing machinery, printer’s guillotine, paper guillotine, paper cutter machine, oscar friedheim ltd london, friedheim international ltd, bookbinding industry, printing industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Balance Spring Scale, Peck, Stow & Wilcox, 1890-1910

Peck, Stow & Wilcox was founded in 1870 by the merger of three different industrial tool manufacturers specializing in tin-processing equipment. Their factory complex was at 217 Centre Street in Southington, Connecticut. The company grew rapidly, and was by 1890 producing a diversified array of tools. It was also the town's largest employer. The plant was substantially enlarged in 1912, which is the period when most of the buildings surviving in 1989 were built. By that time, the complex was operated by Ideal Forging. That company went bankrupt in 2003, and the plant was acquired by real estate developers not long afterwards. Demolition of the premises took place in 2015, after hazardous materials were removed from the site.A large American company that exported it’s goods all over the world and was a major producer of balance scales. The company no longer in existence and its products are now regarded as collectors items. The subject item in the Flagstaff Hill collection is significant as the pocket spring balance scale is one of the earliest produced.Spring Balance Scale Weighs 0 to 25LBS.Stamped PS&W. Has a five pointed star stamped on front.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spring balance scales, peck stow & wilcox, pocket balance scale, weighing scales -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCraft - Ship Model, Falls of Halladale, 1886-1910

The Falls of Halladale was an iron-hulled, four-masted barque, used as a bulk carrier of general cargo. She left New York in August 1908 bound for Melbourne and Sydney. In her hold was general cargo consisting of roofing tiles, barb wire, stoves, oil, and benzene as well as many other manufactured items. After three months at sea and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland on the 15th of November, 1908. The captain and 29 crew members survived, but her cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson's navigational error, not too technical failure of the Clyde-built ship. The Falls of Halladale was built in1886 by Russell & Co., at Greenock shipyards on the River Clyde, Scotland for Wright, Breakenridge & Co of Glasgow. She was one of several designs of Falls Line of ships named after waterfalls in Scotland. The company had been founded between 1870- 1873 as a partnership between Joseph Russell, Anderson Rodger, and William Todd Lithgow. During the period 1882-92 Russell & Co. standardised designs, which sped up their building process so much that they were able to build 271 ships during that time. The Falls of Halladale had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the 'windjammers' that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck in stormy conditions. The Falls of Halladale shipwreck is listed on the Victorian Heritage (No. S255). She was one of the last ships to sail the Trade Routes from Europe and the Americas. Also of significance is that the vessel was one of the first ships to have fore and aft lifting bridges as a significant safety feature still in use on modern vessels today. The subject model is an example of an International Cargo Ship used during the 19th and early 20th centuries to transport goods around the world and representing aspects of Victoria’s shipping industry. Ship mode,l Falls of Halladale, four masted ship diorama. Glass case with wood frame. Paper on back of case with inscription "Frank Davey etc" Case frame has title "Falls of Halladale" and date on base of wood frame is" 1908". It was a four-masted iron-hulled barque.On top of case frame "FALLS OF HALLADALE" and on base of case frame "1908". Paper on back of case has inscription "Frank Davey " (See note section this document for details on Frank Davey)flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, shipwreck peterborough vic, ship model, fall of halladale ship, trade winds, barque, trade vessel, wright, breakenridge & co, ricer clyde -

Flagstaff Hill Maritime Museum and Village

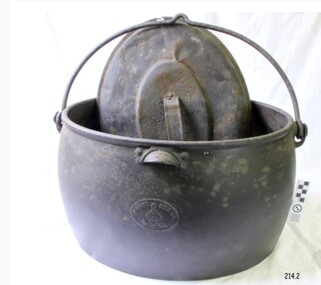

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooking pot and lid, T & C Clark, 1880-1910

T & C Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enamelled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councilor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enamelled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enamelled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enamelled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading.The item is significant as it was used as a domestic kitchen or camp fire item used to cook food safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. T C Clark innervates the first manufacturing process of cast iron cook ware to have enamel lining in his products to alleviate the possibility of lead or arsenic contamination of food.Oval cast iron boiler or cooking pot, with lid, pot is oval shaped lid is dented and handle buckled.Inscription on base "Clark & Co Patent", "Best Quality", "9 Gallons" and a Trade Mark of a "C" inside two triangles to side of potflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, cooking pot, stew pot, food, kitchen utensil, shakespeare foundry, tc clark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tin, Fred Walker Cresco Foods, 1910

Fred Walker 1884 – 1935 was an Australian businessman and founder of Fred Walker & Co. first in Hong Kong, then in Melbourne as the Fred Walker Company. He also set up Kraft Walker Cheese Co. in partnership with American businessman James L. Kraft in 1926, to market Kraft's patented method of processing cheese in Australia. Fred Walker & Co. is best known for creating Vegemite, a yeast extract-based food spread and Australian cultural icon. Kraft Walker Cheese Co. Is best known for manufacturing a cheese known as Red Coon around 1931, which later became known as Coon cheese. He founded the Fred Walker Company at 54 William Street and later moving to Flinders Street in 1911. This company specialised in canned foods, especially dairy products, exporting them to Asia. It manufactured Red Feather canned foods including butter and cheese from around 1910. He also went on to created Cresco Food Co. for his younger brother, which was the first factory to manufacture "flaked food" or dehydrated food products in Australia.A significant item that catalogues the start of dehydrated food production and sale in Australia was initiated by an Australian businessman and well-known entrepreneur. The history of Fred Walker gives insight into how many food brands in Australia now that we take for granted had his involvement in their early beginnings. Large cylindrical tin with push on lid, painted label on the sides in maroon, black gold and dark fawn colours with text.Palm Flaked Rice manufactured by the Cresco Co. Limited Melbourne Australiaflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, container, food container, kitchen ware, flaked rice, cresco, palm flaked rice, tin, fred walker, dehydrated food -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, Late 19th century or early 20th century

Glass manufacturing has evolved over thousands of years. Glass making has been traced back to 3500 BC in Mesopotamia. The earliest known glass objects were beads, perhaps made by accident while working with metal. In the late Bronze Age, several civilizations discovered how to make vessels and glass bottles by wrapping threads of melted glass around cores of sand or clay. Later, moulds were used to form dishes and table wares. Around the 1st century BC, glassblowing was discovered. This made glass containers less expensive than pottery. Mould-blown glass, the process of blowing a piece of molten glass into a wooden or metal mould, was invented during the 1st century AD. This technique was faster with more consistent results. It paved the way for mass production. It wasn’t until the late 1800s that the production process to become more efficient. In 1887, a company in England created a semi-automatic process that could produce up to 200 bottles an hour. This process has been refined to the point where modern machines can yield more than 600 containers per minute. Blown vs. Manufactured Glass Bottles Nowadays, glass bottles, jars, and cups are usually manufactured on a bigger scale than is found in individual glassblowing studios. If we still depended on hand-blown glass for all of our glass containers, we would see some major differences in the process of creating bottles and jars. First, there's the time. Hand blowing glass takes a significant amount of time, even for one simple container. In contrast, hundreds of jars per minute can be made using modern technology. This leads to the second advantage: price. Because of the automated and streamlined process, the price for manufactured containers is much lower than that of hand-blown glass. Third, manufactured bottles will be much more consistently uniform than bottles blown by hand. Automated glass manufacturing produces nearly identical batches of jars. Glass blowing is awesome for unique, beautiful pieces of art. But for lots of lower priced and uniformly shaped containers, automatic manufacturing is the preferred method to create glass bottles and jars. https://www.containerandpackaging.com/resources/glass-bottles-brief-history The invention and development of glass for domestic items including bottles, has been nothing short of revolutionary. The use of glass bottles, that could be easily washed, led to improved hygiene, and mass manufacturing of drinks of all types, including milk, cordial and alcoholic beverages.Green Glass Bottle Possibly a ginger beer bottle.Concave indentation at the base. Also on base are two raised lumps. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, glass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Paper, circa 1908

This roll or reel of paper was part of a consignment carried as cargo of the Falls of Halladale. The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29 The Falls of Halladale was a four-masted sailing ship built-in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. The lines flag was of red, blue and white vertical stripes. The Falls of Halladale had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck stormy conditions. This idea is still used today on the most modern tankers and cargo vessels and has proved to be an important step forward in the safety of men at sea. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles (roof slates), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the night of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on the south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. The roll of paper is an example of cargo brought to Australia in the early 20th century. It is also significant for its association with the Falls of Halladale shipwreck, which is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Roll of paper. Paper was part of a large consignment of paper listed as part of the cargo manifesto. It was recovered from the wreck of the ship Falls of Halladale. A section of the paper has been cut away after it was recovered.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, falls of halladale, shipwreck peterborough, 1908 shipwreck, great clipper ships, russell & co., paper, reel, roll, paper reel, paper roll, cargo, consignment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Paper, circa 1908

These sheets of paper were from a roll or reel of paper that was part of a consignment carried as cargo of the Falls of Halladale. The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four-masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29 The Falls of Halladale was a four-masted sailing ship built-in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. The lines flag was of red, blue and white vertical stripes. The Falls of Halladale had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck stormy conditions. This idea is still used today on the most modern tankers and cargo vessels and has proved to be an important step forward in the safety of men at sea. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles (roof slates), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the night of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on the south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. The roll of paper from which the sheets were cut is an example of cargo brought to Australia in the early 20th century. It is also significant for its association with the Falls of Halladale shipwreck, which is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Wad of paper sheets that was cut from a roll of paper. Three sides of the sheets are straight and the other side is rough due to exposure to sea water for many years. The roll was part of a large consignment of paper listed on the cargo manifesto of the wreck of the ship Falls of Halladale. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, falls of halladale, shipwreck peterborough, 1908 shipwreck, great clipper ships, russell & co., paper, paper reel, paper roll, cargo, consignment, paper sheets, wad of paper -

Flagstaff Hill Maritime Museum and Village

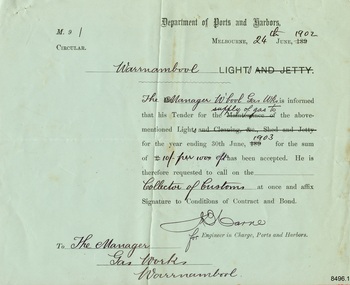

Flagstaff Hill Maritime Museum and VillageDocument - Ports and Harbours, Ports and Harbours, Tender for Warrnambool Light, 24-06-1902

The document confirms that the Tender for the supply of gas to the Warrnambool Light, also known as the Lighthouse, by the Warrnambool Gas Works was successful. The Tender was issued by the Engineer in Charge, Ports and Harbours, Melbourne, for a the period ending 30th June 1903, at the offered rate of 10/- (ten shillings) per 100.0 c/f (cubic feet). The Manager of the Warrnambool Gas Works expected to follow this acceptance with a visit to the Collector of Customs to sign the Conditions of Contract and Bond. The light of Warrnambool's Lady Bay Lighthouse was originally powered by oil. Later it was converted to gas, followed by electricity, then solar power, and finally to battery power. The Warrnambool Gas Company operated the gas works from the 1870's to the late 1920's.This document connects Warrnambool's Lady Bay Lighthouse to the Warrnambool Gas Works during the first decade of the 20th century. It documents to process of a Government department requesting Tenders for the supply of goods to operate a service, the the formal documentation required at that time.Pale green rectangular paper with template text printed in black and completed in black ink script. Letterhead of the Department of Ports and Harbours, Melbourne, and addressed to the Gas Works, Warrnambool, dated 24th June 1902, for the supply of gas to the Warrnambool Light until 30th June 1903 at the cost of Ten Shillings per 100 cubic feet."24th [June] 1902" Warrnambool [Light]" "Manager W'bool Gas Wks" "supply of gas to" "1903" "10/- per 100.0 c/f" "Collector of Customs" " The Manager / Gas Works / Warrnambool" [Signature] "for" [Engineer in Charge, Ports and Harbours]flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, department of ports and harbours, ports and harbours, ports and harbours melbourne, warrnambool light, warrnambool lighthouse, warrnambool gas works, w'bool gas works, gas works, gas supply, early 1900s, early 20th century, shillings, cubic feet, collector of customs, customs, warrnambool customs, engineer in charge, lady bay lighthouse, warrnambool gas company -

Flagstaff Hill Maritime Museum and Village

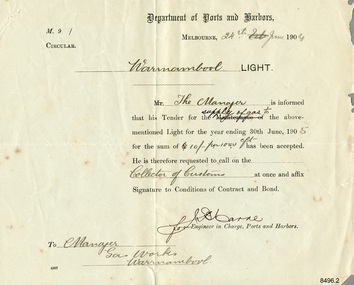

Flagstaff Hill Maritime Museum and VillageDocument - Ports and Harbours, Ports and Harbours, Tender for Warrnambool Light, 24-06-1904

The document confirms that the Tender for the supply of gas to the Warrnambool Light, also known as the Lighthouse, by the Warrnambool Gas Works was successful. The Tender was issued by the Engineer in Charge, Ports and Harbours, Melbourne, for a the period ending 30th June 1905, at the offered rate of 10/- (ten shillings) per 100.0 c/f (cubic feet). The Manager of the Warrnambool Gas Works expected to follow this acceptance with a visit to the Collector of Customs to sign the Conditions of Contract and Bond. The light of Warrnambool's Lady Bay Lighthouse was originally powered by oil. Later it was converted to gas, followed by electricity, then solar power, and finally to battery power. The Warrnambool Gas Company operated the gas works from the 1870's to the late 1920's.This document connects Warrnambool's Lady Bay Lighthouse to the Warrnambool Gas Works during the first decade of the 20th century. It documents to process of a Government department requesting Tenders for the supply of goods to operate a service, the the formal documentation required at that time.Pale cream rectangular paper with template text printed in black and completed in black ink script. Letterhead of the Department of Ports and Harbours, Melbourne, and addressed to the Gas Works, Warrnambool, dated 24th June 1904, for the supply of gas to the Warrnambool Light until 30th June 1905 at the cost of Ten Shillings per 100 cubic feet."24th [June] 1904" Warrnambool [Light]" "Manager W'bool Gas Wks" "supply of gas to" "1905" "10/- per 100.0 c/f" "Collector of Customs" " The Manager / Gas Works / Warrnambool" [Signature] "for" [Engineer in Charge, Ports and Harbours]flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, department of ports and harbours, ports and harbours, ports and harbours melbourne, warrnambool light, warrnambool lighthouse, warrnambool gas works, w'bool gas works, gas works, gas supply, early 1900s, early 20th century, shillings, cubic feet, collector of customs, customs, warrnambool customs, engineer in charge, lady bay lighthouse, warrnambool gas company -

Flagstaff Hill Maritime Museum and Village

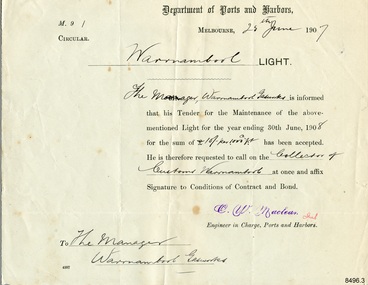

Flagstaff Hill Maritime Museum and VillageDocument - Ports and Harbours, Ports and Harbours, Tender for Warrnambool Light, 24-06-1907

The document confirms that the Tender for the supply of maintenance to the Warrnambool Light, also known as the Lighthouse, by the Warrnambool Gasworks was successful. The Tender was issued by the Engineer in Charge, C. Maclean, Ports and Harbours, Melbourne, for a the period ending 30th June 1908, at the offered rate of 10/- (ten shillings) per 100.0 c/f (cubic feet). The Manager of the Warrnambool Gasworks expected to follow this acceptance with a visit to the Collector of Customs to sign the Conditions of Contract and Bond. The light of Warrnambool's Lady Bay Lighthouse was originally powered by oil. Later it was converted to gas, followed by electricity, then solar power, and finally to battery power. The Warrnambool Gas Company operated the gas works from the 1870's to the late 1920's.This document connects Warrnambool's Lady Bay Lighthouse to the Warrnambool Gas Works during the first decade of the 20th century. It documents to process of a Government department requesting Tenders for the supply of goods to operate a service, the the formal documentation required at that time.Pale cream rectangular paper with template text printed in black and completed in black ink script. Letterhead of the Department of Ports and Harbours, Melbourne, and addressed to the Gas Works, Warrnambool, dated 25th June 1907, for the supply of maintenance to the Warrnambool Light until 30th June 1908 at the cost of Ten Shillings per 100 cubic feet. A purple stamped signature is also added and initialled in red pen."25th [June] 1907" Warrnambool [Light]" "Manager W'bool Gasworks" "supply of gas to" "1908" "10/- per 100.0 c/f" "Collector of Customs" " The Manager / Warrnambool Gasworks" [Signature] "for" [Engineer in Charge, Ports and Harbours] Stamped " C. -. Maclean"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, department of ports and harbours, ports and harbours, ports and harbours melbourne, warrnambool light, warrnambool lighthouse, warrnambool gas works, w'bool gas works, gas works, gas supply, early 1900s, early 20th century, shillings, cubic feet, collector of customs, customs, warrnambool customs, engineer in charge, lady bay lighthouse, warrnambool gas company, gasworks, warrnambool gasworks, maintenance, c. - maclean -

Glen Eira Historical Society

Glen Eira Historical SocietyLetter - Rosstown Railway