Showing 2637 items matching "saw-tooth"

-

Warrnambool RSL Sub Branch

Warrnambool RSL Sub BranchHand Saw, Unknown

These saws were very portable and were carried in a small leather case with was attached to a belt a soldier would were while in the field it also had to small wooded rolled shaped handles to attach to the saw when in use.A Long flexible hand saw Nilhand saw, portable, flexible, -

Flagstaff Hill Maritime Museum and Village

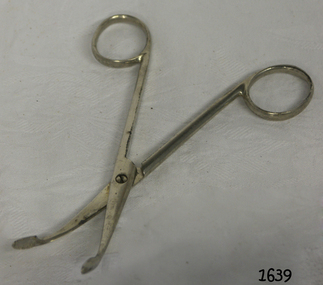

Flagstaff Hill Maritime Museum and VillageForceps

Screw hinge plated forceps, saw tooth grip. Made by G Turton & Son Sheffield. Made for Elliott Bros Sydney. Stamped "2" at hinge.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumBow Saw, 1940's

Made by internees at Camp 3, Tatura and used there as carpentry toolLarge handmade bow-saw with turned wooden handles either end of wooden frame next to metal toothed blade. Metal rod at top of framebow saw, hoefer family, camp 3, tatura, ww2 camp 3, trades, carpentry -

National Wool Museum

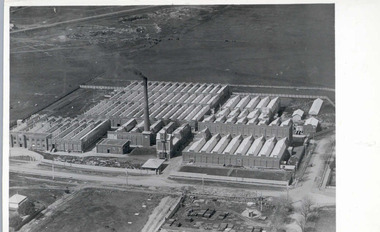

National Wool MuseumPhotograph - Valley Worsted Mill, 1923

Photographic postcard depicting the newly constructed Valley Worsted Mill, c.1923.Photographic postcard, black and white. Depicts an aerial view of the newly constructed textile mill. A chimney stack and many saw toothed roofs can be seen.POST CARD / CORRESPONDENCE ADDRESS ONLY / KODAK / AUSTRALtextile mills, valley worsted mill foster valley mill pty ltd, aerial photography, factory, wool, industrial building -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Tooth, Probably 19th century

The toothed whales (also called odontocetes, systematic name Odontoceti) are a parvorder of cetaceans that includes dolphins, porpoises, and all other whales possessing teeth, such as the beaked whales and sperm whales. Seventy-three species of toothed whales are described. They are one of two living groups of cetaceans, the other being the baleen whales (Mysticeti), which have baleen instead of teeth. The two groups are thought to have diverged around 34 million years ago (mya). Toothed whales range in size from the 4.5 ft (1.4 m) and 120 lb (54 kg) vaquita to the 20 m (66 ft) and 55 t (61-short-ton) sperm whale. Several species of odontocetes exhibit sexual dimorphism, in that there are size or other morphological differences between females and males. They have streamlined bodies and two limbs that are modified into flippers. Some can travel at up to 20 knots. Odontocetes have conical teeth designed for catching fish or squid. They have well-developed hearing, that is well adapted for both air and water, so much so that some can survive even if they are blind. Some species are well adapted for diving to great depths. Almost all have a layer of fat, or blubber, under the skin to keep warm in the cold water, with the exception of river dolphins. Toothed whales consist of some of the most widespread mammals, but some, as with the vaquita, are restricted to certain areas. Odontocetes feed largely on fish and squid, but a few, like the killer whale, feed on mammals, such as pinnipeds. Males typically mate with multiple females every year, but females only mate every two to three years, making them polygynous. Calves are typically born in the spring and summer, and females bear the responsibility for raising them, but more sociable species rely on the family group to care for calves. Many species, mainly dolphins, are highly sociable, with some pods reaching over a thousand individuals. Once hunted for their products, cetaceans are now protected by international law. Some species are attributed with high levels of intelligence. At the 2012 meeting of the American Association for the Advancement of Science, support was reiterated for a cetacean bill of rights, listing cetaceans as nonhuman persons. Besides whaling and drive hunting, they also face threats from bycatch and marine pollution. The baiji, for example, is considered functionally extinct by the IUCN, with the last sighting in 2004, due to heavy pollution to the Yangtze River. Whales occasionally feature in literature and film, as in the great white sperm whale of Herman Melville's Moby-Dick. Small odontocetes, mainly dolphins, are kept in captivity and trained to perform tricks. Whale watching has become a form of tourism around the world. Reference: https://en.wikipedia.org/wiki/Toothed_whaleWhale teeth were much prized for use in scrimshaw work.Whale tooth. Significant staining and yellowing. Broken at base, and missing the root.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale tooth, whaling, whaling industry, whales -

Rutherglen Historical Society

Rutherglen Historical SocietyArmstrong saw, 1920 (Approximate)

Information about this saw came from Lyle Ruddell, Toora, Victoria, Aug 1986Large saw used for splitting bullock carcass in abattoirs. Known as an Armstrong Saw. Riveted wooden handle each end. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Coping saw, c1900

A coping saw is a type of hand saw used to cut intricate external shapes and interior cutouts in woodworking or carpentry. It is widely used to cut mouldings to create coped rather than miter joints. It is occasionally used to create fretwork though it is not able to match a fretsaw in intricacy of cut, particularly in thin materials. Coping saw blades are always thicker and much coarser cutting than typical fretsaw blades. A coping saw consists of a thin, hardened steel blade, stretched between the ends of a square, c-shaped, springy-iron frame to which a handle is attached. The blade is easily removed from the frame so that the blade can be passed through a drilled hole in the middle of a piece of wood. The frame is then re-attached to the blade and the cut starts from the middle of the piece. Long cuts perpendicular to the edge of the material are possible but the shallow depth of the frame rather limits how far from the edge one may cut. The much deeper frame of the fretsaw is more useful for cutting well away from the edge but conversely cannot manage the thicker materials commonly cut by the coping saws. The coping saw blade is installed with the teeth pointing towards the handle. Unlike a hacksaw, which has the teeth pointed away from the handle, the coping saw cuts on the pull stroke. The coping saw blade is removable by partially unscrewing the handle. The blade is prevented from rotating by means of the short, steady bar provided where the blade is attached. Loosening the handle also allows the blade to be rotated relative to the frame as desired. Carefully aligning the finger steady bars at the top and bottom of the blade ensures that the thin blade is straight and not twisted along its length. Re-tightening the handle tensions the blade and locks it at the desired angle relative to the frame. The short steady bar nearest the handle is held securely between finger and thumb while the handle is tightened to ensure the blade remains at the desired angle. Unlike the fretsaw the coping saw blade has holding pins which lock securely into the angled slots of the rotatable blade holders. Gentle curves are achieved by slowly turning the whole frame by means of the handle while continuing to cut steadily. A coping saw with wooden handle but no bladetools, saws, steel , clamps, metalwork, woodwork, carpentry, early settlers, pioneers, market gardeners, moorabbin, bentleigh, cheltenham, fretsaw, coping saw, bowsaw, blacksmiths, -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionWright Reciprocating Saw

Continuous cutting chain was patented in 1905 by Samuel Bens of San Francisco, while the first portable chainsaw was developed and patented in 1918 by Canadian millwright James Shand. But the main advancements of modern petrol chainsaws occurred in Europe in the 1920s and 30s where Andreas Stihl is often hailed as the "father of the chainsaw" After the second world war lighter materials, metal alloys and improved engine designs revolutionised the logging and timber industry. This Wright Reciprocating Saw was made in Sheboygan, Wisconsin, between 1960 and 1962. Its a Rare GS-5020A model. It has a 7.06 cu. in. (115.7 cc), two-stroke motor, which weighed 25 lbs. (11.3 kg) complete. The blade doesn't stop reciprocating when the saw is running because it's attached directly to the crankshaft. There is no clutch system.Reciprocating Saw.forests commission victoria (fcv), forest harvesting, hand tools -

The Beechworth Burke Museum

The Beechworth Burke MuseumAccessory - Chatelaine, C. 1890

The exact creation date of this chatelaine is unknown, however the hallmarks and engravings on some of the attached objects indicate that this chatelaine was made in the late 1890s. The shark tooth and the liberty bell attached to the chatelaine suggest that the item once belonged to an Australian who had connections to America. The compact, scent bottle lid, and feminine design of the other objects suggest that this wasowned by a woman. The name on the plate indicates that this object may have belonged to someone with the surname Heine. The hallmarks on the scent bottle lid and the compact indicate that they were made in Birmingham, England in the late 1890s, and that the compact was made by H. Matthews. Chatelaines where used by both men and women, usually fastened to a belt or pocket, and small household objects were attached to the main body of the chatelaine by chains. They were only worn by the heads of the household as a display of position and power.The social history objects held in the Burke Museum's collection help to tell the stories of Beechworth's past by showing the social, cultural, and economic aspects of the town's history.A decorative silver belt hook with small household object attached by chains to a suspended name plate. There are 8 chains and 7 objects; a vesta case, scent bottle lid, compact, shark tooth, bell, button hook handle, container.HEINE/ [plate] CHERRY./ from/ LEO/ May 12th 1899/ [inscription on vesta case] L??S/ Anchor symbol/ x symbol/ lion symbol/ [Hallmark on scent bottle lid] R/ HM/ Anchor symbol/ Lion symbol/ m symbol/ [Hallmark on back of the compact] SYDNEY/ [inscription on shark tooth] Proclaim liberty throughout all the land unto all inhabitants thereof/ By order of the Assembly of the Province of Pensylvania for the State House in Philada/ [inscription on bell] A01176/ burke museum, silverware, social history, heine -

Mont De Lancey

Mont De LanceyTool - Saw set, Early 20th century

A tool to set the teeth of saws used in the early 20th centuryA metal guide used to set the teeth of a circular or crosscut saw when sharpening - i.e. to angle the teeth so that the saw bites into the wood.. It was used in the early 20th century.handsaws, woodworking saws, log saws, woodcutter saws -

Orbost & District Historical Society

Orbost & District Historical Societysaw, late 19th -early 20th century

A tenon saw is a hand tool designed to cut joints and to cut in a miterbox. They are often called "backsaws".A tenon saw. Wooden handled with a rectangular steel bladetools woodwork saw-tenon-backsaw timber -

8th/13th Victorian Mounted Rifles Regimental Collection

8th/13th Victorian Mounted Rifles Regimental CollectionPhotograph

The M113 LRV was introduced to 8/13 VMR in 1971 when the regiment transitioned from tank to recon role.The 8th/13th Victorian Mounted Rifles was raised as a regiment of the Royal Australian Armoured Corps on 1 May 1948 with Headquarters in Melbourne and squadrons in Sale, Benalla/Wangaratta and Albury. In 1955 Regimental Headquarters moved to Wangaratta and a second squadron was located at Albury. The Sale squadron transferred to 4th/19th Prince of Wales’s Light Horse. In 1977 8/13 VMR Regiment was reduced to an independent squadron A Squadron 8th/13th Victorian Mounted Rifles and in 1991 was linked with 4th/19th Prince of Wales’s Light Horse forming the VMR Squadron of that regiment.Black and white photograph of M113 Light Reconnaissance Vehicle ( LRV ) topping a saw tooth obstacle during training at 8/13 Victorian Mounted Rifles Annual Camp, Puckapunyal 1971. -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Tool - Wood Saw, H. Disston & Sins, Late 19th century

This saw could have been used in industry or in a home situation. It was made by the H. Disston & Sons of U.S.A. This company was established in 1850 by Henry Disston and by the 20th century it was the largest maker of hand saws in the world. The hand saws used today differ little from this early model. This saw is retained as a good example of a hand tool that is over 100 years old. This hand saw has a triangular-shaped metal blade with a serrated edge on the straight side of the blade The handle is wooden with five metal screws. There is a metal plaque containing the name and emblem of the manufacturer. The saw is a little rusty and stained.‘H. Disston & Sons Philada’ ‘T.E.G.’ household tools, history of warrnambool, wood saw -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw, Prior to 1950

An unusual carpenters hand saw for cutting wood with a curved blade A mass produced tool made for domestic use no history or manufacturing provenance currently available.Hand saws are significant as various designs have been in use since biblical times the subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Saw metal with wooden handle curved bladeNoneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, saw -

Puffing Billy Railway

Puffing Billy RailwayRail Saw, Hand Operated

Hand Operated Rail Saw Out on the track in the old days, it was sometimes required to cut a piece of railway track. Before the use of generators and oxy cutting, the only way to do this was with a hand saw. This is the machine operated by two people, that would cut a piece of rail in half. And when the rail was cut, it was usually required to join it to another rail which required putting in 4 to 6 holes in the rail with a Hand Operated drill. Historic - Railways Permanent Way and Works - track equipment - Hand Operated Rail Saw Hand Operated Rail Saw made of cast metalpuffing billy, hand operated rail saw -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw gauge, Henry Disston, 1890-1920

Disston Saw Works of Philadelphia was one of the better known and highly regarded manufacturers of handsaws in the United States. During the Machine Age, the company was known as Henry Disston & Sons, Inc. a supplier of industrial saw blades. History: The story of handsaws in the United States mirrors the technical and development of steel in Sheffield, England, which was the center of handsaw production during the 18th century and through most of the 19th century. England's political and economic lock-on steel making in the colonies held American saw makers at bay until well after the Revolutionary War. American steel producers were unable to compete until the US government introduced import tariffs to level the playing field in 1861. Henry Disston: Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He had emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world, the Keystone Saw Works. Some five years later, Disston built a furnace—perhaps the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons began to set the standards for American saw makers, both in terms of producing high-quality saws and files in 1865 through his development of innovative manufacturing techniques. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets. It took over 25 years to move the entire facility to Tacony. Henry Disston was renowned for having one of the first industries that exhibited environmental responsibility, as well as a paternalistic view towards his employees. For example, he had thousands of homes built in Tacony for his workmen. Funds to purchase these homes were made available through a building and loan association set up by the Disston firm. His caring influence on the community was evident in everyday life. To meet employees' cultural needs, a hall and a library were built with Henry Disston agreeing to pay a fixed sum towards its maintenance. The Tacony Music Hall was erected in 1885, also with the assistance of Disston money. Henry Disston had fallen ill by 1877 and never truly recovered; he suffered a stroke and died the next year. This came only one and a half years after seeing his products receive the highest honors at the great Philadelphia Centennial Exposition of 1876. His vision of a working-class community and the completion of the transfer of his enormous saw plant was carried out by his wife and his sons. The company, by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's armor-plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A tool used to set and sharpen cross cut saws used to fell trees for building construction made by a well known American maker whos firm pioneered the making of saws and their related items including files.combination cross cut saw raker and gauge/jointerDisston USA in the castingflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Tilting Saw Bench, W F & John Barnes, 1874 to 1880

he subject item is a pedal-powered rip saw with a tilting table made in the USA by W.F. & John Barnes Co. of Rockford, Illinois, between 1874 and 1890. The saw's blade moves rapidly in a circular motion and is driven by a pedal that spins a heavy flywheel with a leather belt attached to a gear drive that in turn drives the circular saw blade. The operator holds a wood workpiece on the table and moves it forward so the blade cuts it to the desired width and length. Company History: WF & John Barnes Co. was established in 1869, by making a formal partnership between William F. Barnes and John Barnes in 1872, and then incorporating in 1884. This company was an early manufacturer of pedal-powered equipment. By 1881 they were also making powered machinery such as lathes and pedestal drills. Many companies were making lightweight foot-powered equipment, but Barnes and the Seneca Falls Co. were the only ones to also make professional-grade workshop machines. From the beginning of their existence, they focused on pedal-powered machinery and specialised in making scroll saws. By 1937 the company focus had completely shifted to automotive assembly machinery, and custom-built machinery, machine tools, electrical, hydraulic, and mechanical controls and systems, including nuclear hardware. their production of foot-powered machinery had ceased. In the intervening years, they have got out of manufacturing completely. After a series of ownership changes, their equipment parts and stock were purchased in 1998 by LeBlond Ltd. of Amelia, Ohio. An item that although incomplete gives a snapshot into the manufacture and use of early woodworking machinery before the introduction of electricity or electric motors to power machines.A Treadle powered tilting table saw benchWF & J Barnes, Rockford Ill USA flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bench Saw Vice, Henry Disston & Sons, 1910 -1925

The subject item is a saw blade sharpening clamp that attaches to a bench allowing the operator to sharpen the teeth on a saw with a file while keeping the saw blade in an upright position. Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world the ”Keystone Saw Works” on the Delaware River. Some five years later, Disston built a furnace possibly the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons set the standards for American saw makers, both in terms of producing high-quality saws and developing innovative manufacturing techniques. Disston also started making files in 1865. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets, Disston sought to establish his business away from this cramped area. It took over 25 years to move the entire facility to Tacony. This Philadelphia neighborhood seems to have been the only company town in the United States established within an existing city. At its peak of operations, Disston Saw Works employed 8,000 people and the factory covered 300 acres. The company, known as Henry Disston and Sons, Inc by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's Armour plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A significant American company that pioneered the making of high-quality steel and saws along with other tools and accessories. The subject item is significant as it was made at a time when the company was in its hay day. Adjustable Ball & Socket Saw Sharpening vice, cast iron, with clamp to attach to a workbench. Made by Henry Disston & Co. No 1 painted greyflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, saw clamp, henry disston & sons, saw sharpening, tool accessories, wood saws -

Puffing Billy Railway

Puffing Billy RailwaySaw Bench - Flat Belt Driven, 1930s

Early Industrial Timber working Flat Belt driven saw bench Historic - Early Industrial Timber working Flat Belt driven saw bench Wood framed with a sliding table and a steel shaft with a pulley on one end and a saw blade on the othersaw bench, puffing billy, flat belt driven -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Tool - Carpenter's hand saw, H. Disston & Sons, Late 19th century

This saw was made by H. Disston and Sons, a Philadelphia, U.S.A. company founded in 1850 by Henry Disston. It became the largest saw maker in the world in the 20th century. This saw could have been used for industrial or for household purposes. The hand saw used today features the same basic pattern as this one. This saw has no known local provenance but is retained as an example of a hand saw that is over 100 years old. This saw has a triangular-shaped metal blade with a serrated edge on the straight side. The blade has details of the manufacturer imprinted into the metal but this is mostly indecipherable. The wooden handle has four wooden screws and a fern pattern etched into one side. It also has a metal plaque with the name and emblem of the maker. The saw has some staining.‘H. Disston & Sons Philada’household tools, history of warrnambool, wood saw -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw, 1930-1955's

This tenon saw was used in the planning and making of components for the ship model Sovereign of the Seas. It is part of a collection of objects used by Jim Williams, maker of fine ship models from about 1930-1955. Most of the components for the models, as well as many of the tools, were handmade by Jim Williams. Jim’s family has donated the ship model “Sovereign of the Seas” and many tools, accessories and documents used in the making of this and other ship models have been donated to Flagstaff Hill Maritime Village. Ship model of HMS Sovereign of the Seas, scale model of 17th Century English war ship, was handmade and carved from plans, enclosed in airtight glass case. All components of that model, including even the smallest pulleys, were hand crafted using tools designed and made by Jim. Outstanding details include functional rigging and moving cannons. Please see our record 3732 of the mode Sovereign of the Seas for further details of the ship and the maker. This saw is connected with the hobby and skill of ship model making that has been crafted as a leisure activity for many generations. The hobby is often chosen by serving and retired mariners who appreciate the connection with maritime history. This saw was used by local Warrnambool man, Jim Williams, who was employed at Cramond and Dickson clothing store, and then at Fletcher Jones menswear for 27 years. It was used in making components for the model of the historic ship, the Sovereign of the Seas. The Sovereign of the Seas was a historic 17th century English war ship with important maritime heritage. Tenon aw. Hand saw with small-toothed metal blade set into a slotted brass back, attached to a round brass fitting in the light coloured, turned wooden handle. Top on handle is marked with two concentric rings scored into the wood. On top of blade is maker’s name Dennan & Robinson. This tenon saw is part of a collection of tools and accessories once used by Jim Williams, maker of a series of ship models 1930-1955 including “HMS Sovereign of the Seas”. "Dennan & Robinson"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jim williams, james bernard williams, ship model hobby, ship model tools, ship model making equipment, ship model making accessories, saw, wood cutting tool, tenon saw, carpenter's saw, dennan and robinson, sovereign of the sea, ship model, hobby, ship model tool -

Halls Gap & Grampians Historical Society

Halls Gap & Grampians Historical SocietyPhotograph

A temporary saw-mill in the central Grampians.Photo shows a clearing containing a saw mill. There is a saw with traction engine to the right ands a bullock wagon containing a large log to the left. There is a man to the right working with the engine, four men among the wood in the centre and two men near the wagon on the left. A large wood stump is prominent in the foreground. timber industries, logging, sawmilling -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Treadle Scroll Saw, Hobbies Ltd, Manufactured by Hobbies in England from 1928- 1965

Since 1895, Hobbies Ltd have been supplying model makers and enthusiasts throughout the world with a wide range of quality model kits, accessories, tools, components and handbooks. The Hobbies Company began life in Dereham, Norfolk in 1881 with a London Office opened later (1922) at 65 New Oxford Street, WC1. In 1895 Hobbies began supplying model makers with their products and in 1897 were incorporated into a Public company. In 1922 at a British Industries Fair the company had a stand advertising their products as "The All-British Firm with a World reputation". Fretwork Outfits. Fretwork Machines. Carpentry Outfits. Strip work Outfits. Also manufactures of Fretwork Tools and Benches, Wood, Circular Saws, Lathes, Picture Framing Outfits, Tools, etc. In 1947 the company had expanded and was still making tools and materials for the amateur craftsman in wood. They had acquired a reputation as manufacturers of quality Fretwork Outfits, Tools, Treadle Machines, Model Maker's Tool Kits. The company also publishers of ‘Hobbies Weekly magazine’ and also sold plans for fretwork, model making and wooden toys. In 1961 they were still manufacturers and retailers of craft tools and materials, timber merchants, light engineers and Government contractors with around 500 employees. A vintage tool made for hobbyists and distributed throughout the world by a British company that is still in existence today. The item is significant as it catalogues the manufactures history at a specific time in the company's development.Foot operated treadle Fret saw called "GEM" subject item is a short saw , the stand in the background is the base for a Delta Q3 model scroll saw. Gem inscription cast into the cast iron frameworkflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, saw, treadle saw, fret saw, pedal saw, the gem, tool, hobbies ltd, treadle, foot operated -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bow Saw, 1850 to 1900

The Bow Saw is considered by many to be the most satisfactory saw for cutting shapes since the narrow blade negotiates curves easily, and is held in tension. Both the handle and knob (at the other end of the blade) can be turned so that a cut can be made more or less parallel to the required cut. Obviously the blade must be free of twist when in use. It is available with blade lengths of 25 to 40 cm (10 to 16 in). Generally both hands grips the one handle, hence the bulbous shape with narrow neck, but when thick wood has to be sawn it is helpful to have a person at each side, both sides of the wood having been marked. In this way it is much easier to keep the cut square to the sides of the timber. The rivets holding the blade to the handle can be withdrawn so that the saw can be used for an internal cut, the blade being threaded through a hole drilled through the timber.A vintage bow saw used in cabinet work by a cabinet maker in the mid to later part of the 19th century probably made in England.Bow saw wooden frame and handles. Twine attached to upper section of frame.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bow saw, carpenders tools, cabinet makers tools, wood working, wood saw -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSaw

Bow saw. Joiners Bow saw or Turning saw.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionPlain peg-tooth one-person crosscut saw

Used in the 1930s in the Forests Commission's Erica Forest District by a rigger for cutting the top off spar trees to be used in high-lead logging. The advent of crawler tractors after the Second World War brought about the end of high-lead logging. The saw was adopted in the 1940s by the-then Assistant Forester of Erica (James McKinty) for cutting firewood for domestic purposes; this use continued until about 1987. One-person cross cut saw with riveted handleforests commission victoria (fcv), hand tools -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncPlane

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.plane, wood, toothing -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Tooth Extractor, Late 19th - early 20th century

Toothaches have been with us since the evolution of teeth and extracting teeth. I wonder what poor Homo erectus did when suffering with a toothache. He probably just suffered and probably became very bad tempered. Ancient Dentistry Significant tooth decay did not appear until hunter-gatherer societies became agrarian. The change in diet included a large increase in carbohydrates which then led to tooth decay. Early man was primitive but he was also pretty smart. Some time around 8000 years ago someone in the area that is now Pakistan was using a drill to remove tooth decay. Examination of Neolithic skulls have revealed the handiwork of at least one very early dentist. A Sumerian text in about 5000 B.C. taught that the cause of tooth decay was tooth worms. Proposed cures for toothache were numerous. Early Egyptians wore amulets. An Egyptian named Hesy-Re, is known as the first dentist. Praise for his dentistry is inscribed on his tomb. Unfortunately it doesn’t delineate what he did to earn the praise. Pliny, the Elder, recommended finding a frog at midnight and asking it to take away the pain. The doctor to Emperor Claudius around 50 A.D. had his toothache patients inhale smoke produced by scattering certain seeds on burning charcoal and then rinsing the mouth with hot water. This was to expel the tooth worms. On the more practical side Aristotle and Hippocrates both wrote about the treatment of tooth decay. A primitive forceps was used for extracting teeth. Some dentists at that time were able to weave wire in the teeth to stabilize loose teeth. Medieval Torture From about 500 A.D. to 1100 A.D. monks were well educated and well trained and did some of the surgical procedures of the time. Barbers handled the rest of the operations, especially blood letting and tooth extractions. In 1163 the Pope put a stop to all surgeries by monks and the field was left open to the barbers. Barbers were, after all, very skilled with knives and razors. In fact, the barber pole, red and white spiraling stripes, is a symbol of the blood letting; red for blood. white for bandages. In the 1300s a Barbers’ Guild was established which divided the barbers into two groups: those with the skills and training to do procedures and those who were relegated to blood letting and tooth extractions. Pliers from a blacksmith’s foundry were the only device available. Barbers would often go to fairs and advertise painless tooth pulling. A shill in the audience would come on the stage, feigning severe toothache. The barber would pretend to extract tooth, pulling out a bloody molar he had palmed earlier. The supposed sufferer would jump for joy. The barbers set up near the bands at the fairs so that the music would drown out the screams of their patients. If the tooth was loose enough, the barber would tie a string around the tooth and yank hard to extract the tooth. This was a much less painful and dangerous procedure than the pliers. The pliers often fractured other teeth and sometimes the jaw. The procedure was far from sterile and infection was a common problem and some people bled to death. The Renaissance and the Rise of Tooth Decay In the 1400s refined sugar was introduced into Europe but only reached the tables of the wealthy. While their betters were munching on sweets, the poorer folk suffered fewer toothaches. Queen Elizabeth I was known for her blackened teeth. George Washington had a tooth extraction every year after age 22. He supposedly had a set of wooden false teeth but his dentures were actually ivory. The earliest instrument designed for tooth extraction was the dental pelican, which was shaped something like a pelican’s beak. The pelican was replaced in the 1700s by the dental key, which was fitted down over the affected tooth and was better able to grip the tooth. Both still often caused more damage than relief. The Development of Modern Dentistry Modern dental equipment began to be introduced in the 1800s about the time when dentistry became a profession and dental schools began to open. Ether was used starting in 1846 to anesthetize the pain and local anesthetics were introduced in the early 1900s. Modern dentists no longer have to seat their patients on the floor and have helpers to hold them down. Dentistry is as close to painless as possible now. There is no excuse to suffer the agony of a toothache these days. And extracting teeth is no longer dangerous. https://arizonadentalspecialists.com/the-surprising-history-of-extracting-teeth/ This tooth extractor was donated to Flagstaff Hill Maritime Village by the family of Doctor William Roy Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” that includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. ABOUT THE “W.R.ANGUS COLLECTION” Doctor William Roy Angus M.B., B.S., Adel., 1923, F.R.C.S. Edin.,1928 (also known as Dr Roy Angus) was born in Murrumbeena, Victoria in 1901 and lived until 1970. He qualified as a doctor in 1923 at University of Adelaide, was Resident Medical Officer at the Royal Adelaide Hospital in 1924 and for a period was house surgeon to Sir (then Mr.) Henry Simpson Newland. Dr Angus was briefly an Assistant to Dr Riddell of Kapunda, then commenced private practice at Curramulka, Yorke Peninsula, SA, where he was physician, surgeon and chemist. In 1926, he was appointed as new Medical Assistant to Dr Thomas Francis Ryan (T.F. Ryan, or Tom), in Nhill, Victoria, where his experiences included radiology and pharmacy. In 1927 he was Acting House Surgeon in Dr Tom Ryan’s absence. Dr Angus had become engaged to Gladys Forsyth and they decided he would take time to further his studies overseas in the UK in 1927. He studied at London University College Hospital and at Edinburgh Royal Infirmary and in 1928, was awarded FRCS (Fellow from the Royal College of Surgeons), Edinburgh. He worked his passage back to Australia as a Ship’s Surgeon on the on the Australian Commonwealth Line’s T.S.S. Largs Bay. Dr Angus married Gladys in 1929, in Ballarat. (They went on to have one son (Graham 1932, born in SA) and two daughters (Helen (died 12/07/1996) and Berenice (Berry), both born at Mira, Nhill ) Dr Angus was a ‘flying doctor’ for the A.I.M. (Australian Inland Ministry) Aerial Medical Service in 1928 . The organisation began in South Australia through the Presbyterian Church in that year, with its first station being in the remote town of Oodnadatta, where Dr Angus was stationed. He was locum tenens there on North-South Railway at 21 Mile Camp. He took up this ‘flying doctor’ position in response to a call from Dr John Flynn; the organisation was later known as the Flying Doctor Service, then the Royal Flying Doctor Service. A lot of his work during this time involved dental surgery also. Between 1928-1932 he was surgeon at the Curramulka Hospital, Yorke Peninsula, South Australia. In 1933 Dr Angus returned to Nhill where he’d previously worked as Medical Assistant and purchased a share of the Nelson Street practice and Mira hospital from Dr Les Middleton one of the Middleton Brothers, the current owners of what was once Dr Tom Ryan’s practice. Dr L Middleton was House Surgeon to the Nhill Hospital 1926-1933, when he resigned. [Dr Tom Ryan’s practice had originally belonged to his older brother Dr Edward Ryan, who came to Nhill in 1885. Dr Edward saw patients at his rooms, firstly in Victoria Street and in 1886 in Nelson Street, until 1901. The Nelson Street practice also had a 2 bed ward, called Mira Private Hospital ). Dr Edward Ryan was House Surgeon at the Nhill Hospital 1884-1902 . He also had occasions where he successfully performed veterinary surgery for the local farmers too. Dr Tom Ryan then purchased the practice from his brother in 1901. Both Dr Edward and Dr Tom Ryan work as surgeons included eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. He too was House Surgeon at the Nhill Hospital 1902-1926. Dr Tom Ryan had one of the only two pieces of radiology equipment in Victoria during his practicing years – The Royal Melbourne Hospital had the other one. Over the years Dr Tom Ryan gradually set up what was effectively a training school for country general-practitioner-surgeons. Each patient was carefully examined, including using the X-ray machine, and any surgery was discussed and planned with Dr Ryan’s assistants several days in advance. Dr Angus gained experience in using the X-ray machine there during his time as assistant to Dr Ryan. Dr Tom Ryan moved from Nhill in 1926. He became a Fellow of the Royal Australasian College of Surgeons in 1927, soon after its formation, a rare accolade for a doctor outside any of the major cities. He remained a bachelor and died suddenly on 7th Dec 1955, aged 91, at his home in Ararat. Scholarships and prizes are still awarded to medical students in the honour of Dr T.F. Ryan and his father, Dr Michael Ryan, and brother, John Patrick Ryan. ] When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. His practitioner’s plate from his Nhill surgery states “HOURS Daily, except Tuesdays, Fridays and Saturday afternoons, 9-10am, 2-4pm, 7-8pm. Sundays by appointment”. This plate is now mounted on the doorway to the Port Medical Office at Flagstaff Hill Maritime Village, Warrnambool. Dr Edward Ryan and Dr Tom Ryan had an extensive collection of historical medical equipment and materials spanning 1884-1926 and when Dr Angus took up practice in their old premises he obtained this collection, a large part of which is now on display at the Port Medical Office at Flagstaff Hill Maritime Village in Warrnambool. During his time in Nhill Dr Angus was involved in the merging of the Mira Hospital and Nhill Public Hospital into one public hospital and the property titles passed on to Nhill Hospital in 1939. In 1939 Dr Angus and his family moved to Warrnambool where he purchased “Birchwood,” the 1852 home and medical practice of Dr John Hunter Henderson, at 214 Koroit Street. (This property was sold in1965 to the State Government and is now the site of the Warrnambool Police Station. ). The Angus family was able to afford gardeners, cooks and maids; their home was a popular place for visiting dignitaries to stay whilst visiting Warrnambool. Dr Angus had his own silk worm farm at home in a Mulberry tree. His young daughter used his centrifuge for spinning the silk. Dr Angus was appointed on a part-time basis as Port Medical Officer (Health Officer) in Warrnambool and held this position until the 1940’s when the government no longer required the service of a Port Medical Officer in Warrnambool; he was thus Warrnambool’s last serving Port Medical Officer. (The duties of a Port Medical Officer were outlined by the Colonial Secretary on 21st June, 1839 under the terms of the Quarantine Act. Masters of immigrant ships arriving in port reported incidents of diseases, illness and death and the Port Medical Officer made a decision on whether the ship required Quarantine and for how long, in this way preventing contagious illness from spreading from new immigrants to the residents already in the colony.) Dr Angus was a member of the Australian Medical Association, for 35 years and surgeon at the Warrnambool Base Hospital 1939-1942, He served as a Surgeon Captain during WWII1942-45, in Ballarat, Victoria, and in Bonegilla, N.S.W., completing his service just before the end of the war due to suffering from a heart attack. During his convalescence he carved an intricate and ‘most artistic’ chess set from the material that dentures were made from. He then studied ophthalmology at the Royal Melbourne Eye and Ear Hospital and created cosmetically superior artificial eyes by pioneering using the intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering in artificial eye improvements. He was Honorary Consultant Ophthalmologist to Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. He represented the Victorian South-West subdivision of the Australian Medical Association as its secretary between 1949 and 1956 and as chairman from 1956 to 1958. In 1968 Dr Angus was elected member of Spain’s Barraquer Institute of Barcelona after his research work in Intrasclearal cartilage grafting, becoming one of the few Australian ophthalmologists to receive this honour, and in the following year presented his final paper on Living Intrasclearal Cartilage Implants at the Inaugural Meeting of the Australian College of Ophthalmologists in Melbourne In his personal life Dr Angus was a Presbyterian and treated Sunday as a Sabbath, a day of rest. He would visit 3 or 4 country patients on a Sunday, taking his children along ‘for the ride’ and to visit with him. Sunday evenings he would play the pianola and sing Scottish songs to his family. One of Dr Angus’ patients was Margaret MacKenzie, author of a book on local shipwrecks that she’d seen as an eye witness from the late 1880’s in Peterborough, Victoria. In the early 1950’s Dr Angus, painted a picture of a shipwreck for the cover jacket of Margaret’s book, Shipwrecks and More Shipwrecks. She was blind in later life and her daughter wrote the actual book for her. Dr Angus and his wife Gladys were very involved in Warrnambool’s society with a strong interest in civic affairs. Their interests included organisations such as Red Cross, Rostrum, Warrnambool and District Historical Society (founding members), Wine and Food Society, Steering Committee for Tertiary Education in Warrnambool, Local National Trust, Good Neighbour Council, Housing Commission Advisory Board, United Services Institute, Legion of Ex-Servicemen, Olympic Pool Committee, Food for Britain Organisation, Warrnambool Hospital, Anti-Cancer Council, Boys’ Club, Charitable Council, National Fitness Council and Air Raid Precautions Group. He was also a member of the Steam Preservation Society and derived much pleasure from a steam traction engine on his farm. He had an interest in people and the community He and his wife Gladys were both involved in the creation of Flagstaff Hill, including the layout of the gardens. After his death (28th March 1970) his family requested his practitioner’s plate, medical instruments and some personal belongings be displayed in the Port Medical Office surgery at Flagstaff Hill Maritime Village, and be called the “W. R. Angus Collection”. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The collection of medical instruments and other equipment is culturally significant, being an historical example of medicine from late 19th to mid-20th century. Dr Angus assisted Dr Tom Ryan, a pioneer in the use of X-rays and in ocular surgery. Tooth extractor, dental surgical instrument. Metal with cross hatched pattern on handle. Stamped with maker's mark on hinge. Other stamps inside handles. Part of the W.R. Angus Collection.Stamped on hinge 'CASH & SONS ENGLAND'. Inside handles are 'C', 'P' and '27'.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dr w r angus, dr ryan, surgical instrument, t.s.s. largs bay, warrnambool base hospital, nhill base hospital, mira hospital, flying doctor, dental surgical instrument, tooth extractor -

Orbost & District Historical Society

Orbost & District Historical Societyfret saw frame, early 20th century

This fretsaw frame , with a blade, would have been used for intricate cutting work having tight curves. a fretsaw is capable of much tighter radii and more delicate work. than other saws because it has much shallower blades, which are usually extra-fine,This is an example of a woodworking tool used in the first half of the 20th century.A fret saw with very high frame. It has a plain, simple wooden handle.woodwork saw-fret -

Bendigo Military Museum

Bendigo Military MuseumSouvenir - SHARK TOOTH, 1900-2000

Item relates to Gilbert Turner MM, No 1410 45th Batt AIF. Refer Cat No 1038 for his service details.Shark tooth with serrated edges natural history specimens - icthyology, sharks, teeth