Showing 194 items matching "turned wood"

-

Flagstaff Hill Maritime Museum and Village

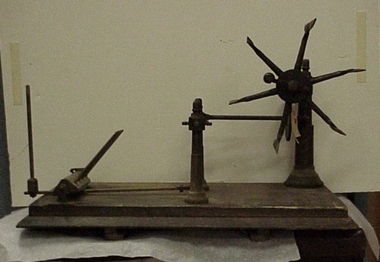

Flagstaff Hill Maritime Museum and VillageTool - Tilting Saw Bench, W F & John Barnes, 1874 to 1880

he subject item is a pedal-powered rip saw with a tilting table made in the USA by W.F. & John Barnes Co. of Rockford, Illinois, between 1874 and 1890. The saw's blade moves rapidly in a circular motion and is driven by a pedal that spins a heavy flywheel with a leather belt attached to a gear drive that in turn drives the circular saw blade. The operator holds a wood workpiece on the table and moves it forward so the blade cuts it to the desired width and length. Company History: WF & John Barnes Co. was established in 1869, by making a formal partnership between William F. Barnes and John Barnes in 1872, and then incorporating in 1884. This company was an early manufacturer of pedal-powered equipment. By 1881 they were also making powered machinery such as lathes and pedestal drills. Many companies were making lightweight foot-powered equipment, but Barnes and the Seneca Falls Co. were the only ones to also make professional-grade workshop machines. From the beginning of their existence, they focused on pedal-powered machinery and specialised in making scroll saws. By 1937 the company focus had completely shifted to automotive assembly machinery, and custom-built machinery, machine tools, electrical, hydraulic, and mechanical controls and systems, including nuclear hardware. their production of foot-powered machinery had ceased. In the intervening years, they have got out of manufacturing completely. After a series of ownership changes, their equipment parts and stock were purchased in 1998 by LeBlond Ltd. of Amelia, Ohio. An item that although incomplete gives a snapshot into the manufacture and use of early woodworking machinery before the introduction of electricity or electric motors to power machines.A Treadle powered tilting table saw benchWF & J Barnes, Rockford Ill USA flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Brace & Bit, John S Fray, 1883 - 1906

... or auger) to drill holes, usually in wood. The pressure is applied... the bit into the wood as the user turns the brace handle ...Context: A brace is a hand tool used with a bit (drill bit or auger) to drill holes, usually in wood. The pressure is applied to the top and the tool is rotated with a U-shaped grip. Bits used to come in a variety of types but today the more commonly used Ridgeway and Irwin pattern bits also rely on a snail point (called the snail), which is a tapered screw point shaped the same as a wood screw thread, which helps to pull the bit into the wood as the user turns the brace handle and applies pressure. The designs used today come from an original idea and pattern invented by John S Fray. Company History: John S. Fray (1833 ) immigrated to Bridgeport Connecticut USA from England in the 1850s and established a working relationship with Nelson Spofford, who held an 1858 patent for a bit brace (the tool could be augured in a continuous circular motion by hand). He established the John S. Fray Co. around the same time and immediately began producing the Spofford bit brace. Fray himself held at least two patents: one awarded in 1869 for a boring brace attachment, and another awarded in 1883 for a tool handle. By 1889, the firm was located at the industrial complex that sits between the former International Silver Company and the former Bridgeport Chain Company on Crescent Avenue and is identified on the Sanborn Insurance Atlas as a manufacturer of Spofford bit braces, hollow handle awl, and toolsets. The company was in competition with Peck Stow and Wilcox Co. of Southington, and in 1898 was enjoined from making a ratchet bit brace for which the latter company held a patent. By the 1920s, the factory had been purchased by the Stanley Company of New Britain and leased to the American Tube and Stamping Company, a manufacturer of brass, copper, seamless, and bicycle tubing, which also ran a rolling mill to the south on Stafford Avenue (now demolished). The Stanley Company bought both mills in 1926, perhaps as a strategic move to be located along the Bridgeport Harbour, through which much of the raw material used in its operations throughout the state came. By the 1950s, the Crescent Avenue operations had been moved to other sites in Connecticut, and Stanley again leased the building to a company called Cornwall and Patterson, a manufacturer of piano hardware. Today the building appears to be vacant. An early carpenters tool made by a well known early manufacturer from America who instigated many innovations to the making of tools. His early pattern for the improvement of a tool that could be used for the boring of holes in wood was a significant step forward. His design for a boring brace attachment and later a specific handle is still in use today and his original brace and bit is now sought after by collectors of antique tools. Spofford Carpenter's Bit Brace metal has bit attached. Wing nut holds bit in place but nut missing. holds bit in place. 285mm long x 160mm Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageChair

Chair wooden with missing round seat & plain legs. Has 6 turned back supports & decorative carving on back piece. Bracing ring under seat & on sides. Chair is reddish coloured woodflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, chair, wooden chair -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Object, Mulga wood bowl, c1950

Mulga, is an Acacia shrub or small tree native to arid outback areas of Australia. It is light, easy to carve and has strength and durability It is commonly used for turned objects or small decorative items. The wood is dark brown with yellow bands and polishes well. Traditional uses included spears, clubs and boomerangs. George Reed was a draftsman who lived in Bentleigh , City of Moorabbin in mid 20th CGeorge Reed was a draftsman who lived in Bentleigh , City of Moorabbin in mid 20th C and used this Mulga wood bowl in his officeA souvenir Mulga wood bowl with metal aeroplane on the lidearly settlers, market gardeners, wood carvers, souvenirs, mulga wood, acacia trees, boomerangs, vases, post world war 2 estates, bentleigh, mckinnon, highett, cheltenham,south australia, victoria,reed george, reed gladys, clark judy, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

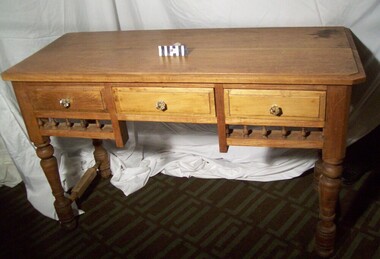

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Furniture - Table, small hardwood, circa1850

A small, hard-wood table with decorative spindles, three drawers, and turned legs is from the original pioneer cottage built on land that was part of the Dendy's Special Survey 1841 . Now 302 Jasper Road Ormond. The table is in fair condition, but not complete. It is thought that the original drawer handles most likely deteriorated or were broken over the years. An unknown person replaced the original handles with modern glass knobs, in the late 1970’s. This table was in the original pioneer cottage which is now Reconstructed Box Cottage Museum. An unknown pioneer built the Cottage circa 1850 and it was purchased by William Box in 1865. William and Elizabeth Box lived in the Cottage until 1914 when it was sold to August Reitman who resided there until 1950. In 1964 the Cottage was moved to the present site , Joyce Park, adjacent to 302 Jasper Road Ormond A small, hard-wood table with decorative spindles, three drawers, and turned legs is from the original pioneer cottage built on land that was part of the 1841 Dendy's Special Survey The table is in fair condition, but not complete. It is thought that the original drawer handles most likely deteriorated or were broken over the years. An unknown person replaced the original handles with modern glass knobs, in the late 1970’s. moorabbin, table, ormond, bentleigh, pioneer, dendy henry, box william, market gardener, reitman august, dendy special survey -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Furniture - Furniture, spindle-leg, wood table, 20thC

A small wooden occasional table with 4 turned legs with 4 rails running around the basefurniture, woodwork, craftsmen, moorabbin, bentleigh, melbourne, early settlers, market gardeners -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Furniture, Dressing table swing mirror c1900, c1900

This dressing table with swing mirror was used by the early settler families of Moorabbin Shire c1900. Accompanied by a wash stand , basin and water jug people cleansed, shaved and tidied their hair and themselves between their weekly bath. This Dressing table mirror was owned by a pioneer family of Moorabbin Shire c1900 c1900 Mahogany Toilet / Swing Dressing table mirror A shaped mirror, domed top with thick frame, turned side supports finished with small finials and a solid base on 4 round supportseraly settlers, pioneers, furniture , mirrors, dressing tables, mahogany wood, carpenters, cabinet makers, market gardeners, moorabbin shire, bentleigh, cheltenham -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Ship Log

The ship's log part, called a fish, is likely to be from a mechanical taffrail log system. It was recovered from the wreck site of the barque, the 1840-1852 Grange. There are no marks on the fish to identify its maker or model. It is part of the John Chance Collection. This ‘fish’ is part of an early to mid-1800s ship's log. It would likely have been part of a taffrail log connected to a rotor (also called propeller, spinner) by a strong line, and the other end connected by a line to a dial mounted on the taffrail, or stern rail, at the stern of the vessel. As the propeller rotated through the water it would spin the log, which in turn would cause a number to register on the dial, showing the current speed in knots; one knot equals one nautical mile per hour. TAFFRAIL LOGS A taffrail log is a nautical instrument used for measuring the speed of a vessel, providing vital navigational information to be calculated, such as location and direction. A log has been used to measure the speed of a vessel since the 1500s. A simple piece of wood was tied to a long line and thrown into sea at the back of the vessel. The rope was knotted all along at equal distances apart. On a given signal the log line was pulled back into the vessels, the knots counted until the log came up, then the figures were calculated by a navigator In 1802 the first successful mechanical log available for general use was invented by Edward Massey. It had a rotor 'V' section connected to a recording mechanism. The water’s movement rotated the rotor, which intern sent the movement to the recorder. There are examples of this invention available to see in some of the maritime museums. Thomas Walker, nephew of Edward Massey, improved on Massey’s design, and Walker and his son took out a patent on the A1 Harpoon Log. In 1861. Both Massey and Walker continued to improve the designs of the taffrail log. New designs were still being introduced, even up to the 1950s. THE GRANGE, 1840-1858- The wooden barque ’Grange’ was a three-masted ship built in Scotland in 1840 for international and coastal trade. On March 22, 1858, the Grange set sail from Melbourne under Captain A. Alexander, carrying a cargo of ballast. The barque had left the Heads of Phillip Bay and was heading west along the Victorian coast towards Cape Otway. The ship struck Little Haley’s Reef at Apollo Bay due to a navigational error and was stuck on the rocks. The crew left the ship carrying whatever they could onto the beach. Eventually, the remains of the hull, sails and fittings were salvaged before the wreck of the Grange broke up about a month later. About 110 years later, in 1968, the wreck of the Grange was found by divers from the Underwater Explorers Club of Victoria. They were amazed to find a unique, six to nine pound carronade (type of small cannon) and a cannonball on the site. There have been no other similar carronades recorded. In that same year the anchor of the Grange was recovered by diver John Chance and Mal Brown. The ship’s log is significant historically as an example of hardware used when building wooden ships in the early to mid-19th century. The ship’s log is historically significant as an example of the work and trade of blacksmith. The ship’s log also has significant as it was recovered by John Chance, a diver from the wreck of the Grange in the 1968. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. The ship’s log is historically significant for its association with the 1840s wooden barque, the Grange. The Grange is an historical example of a Scottish built vessel used for international and coastal trader of both cargo and passengers in the mid-19th century. The Grange is an example of an early ship, designed with a wooden hull. It is significant as a ship still available to divers along the south coast of Victoria, for research and education purposes. The Grange is an example of a mid-19th century vessel that carried a weapon of defence onboard. Ship log fitting, called a fish; part of a brass navigational instrument, likely to be from a taffrail log. The metal is a tan colour and has rough surface with a sheen, and discolouration in places. Its basic shape is a hollow cylinder with ends tapering to a smaller size. In the centre there are opposing openings cut out, showing a rough texture inside. One end on the cylinder is closed with a ring and shank installed, fixed by an embedded screw through the end of the cylinder. There are no inscriptions.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, west coast trader, apollo bay, mid-19th century shipwreck, the grange, scottish barque, little henty reef, captain a alexander, underwater explorers club of victoria, vhr 5297, coastal trader, wooden shipwreck, john chance, wooden ship, taffrail log, marine instrument, marine technology, navigation, nautical instrument, mechanical log, nautical navigation, navigation equipment, scientific instrument, ship log, ship log register, ship speed, taff rail log, patent log, towed log, taffrail log fish, edward massey, thomas walker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Chair, 1900-1914

Bentwood furniture is a type of furniture made by bending wooden rods into the required shape after they have been heated with steam. Mundus bentwood chairs are among the most successful examples of early mass-produced furniture. The inventor of manufacturing chairs using this method was Gebrüder Thonet. The subject item was made at Josef Jaworek small factory that produced bentwood chairs and was the only Polish member associated with the Mundus furniture company of Vienna. This company was founded in 1907 and Mundus went on to merge with J & J Kohn in August of 1914. Mundus furniture was a significant manufacturing company, active in several places in the Austro Hungarian Empire, at the end of the 19th century and early 20th century. Factories seem to have existed in multiple locations including Poland. Their products carry diverse labels, such as "Budapest", "Borlova", "Czechoslovakia", etc, some of the furniture was co-signed with "Jacob and Josef Kohn". Mundus also merged with Gebrüder Thonet in 1922 the inventor of the bentwood chair.The subject item is believed to be associated with the original Warrnambool Town Hall and would have been part of the buildings furnishings. The town Hall played a significant role in both local government and social events of local and district areas. It was not only a place for Council meetings but community events and social events. The item is significant as it is an early example of mass-produced manufactured furniture from a company in Austria that pioneered this type of furniture around the turn of the late 19th and early 20th centuries. This item is now regarded as a collector's piece giving it additional significance and interest.Bentwood chair (3 of 4), painted black, inner back is curled loop. Seat is plain wood (replacing original). Splayed legs with bracing ring. Marks; Stamped into wood under seat, a small paper label and a label, cream with dark print. Paper label on rim under seat says the chair is made in Austria.Marks; Stamped into wood under seat is "49" and a small paper label with "49". Makers label, cream with dark print; on either side are 2 coins, top left coin has bust of a man, top right has an emblem with 1885 under it. Text of label "MOBEL-FABRIKEN / von / JOSEF JAWOREK / Teschen, osterr, Schlesien" flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, bentwood chair, café chair, restaurant chair, josef jaworek, austrian chairs, furniture, gebrüder thonet -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Australian Gliding Museum

Australian Gliding MuseumMachine - Glider – Sailplane, 1940

The “Coogee” is an intermediate single seat sailplane designed and built by Tom Proctor in 1940. Only one was built. It was first flown at Stuart Hill near Bendigo Victoria in January 1941 and was maintained in flying condition until 1967. The aircraft was flown extensively by the Victorian Motorless Flight Group (now the Melbourne Gliding Club) and Geelong Gliding Club and several subsequent owners. This exhibit is a "one off" Australian designed and built glider similar in some respects to the Hutter H17. Its usage is relevant to the history of gliding in Victoria in the post war years. Also the aircraft provides an insight into gliding technology in Australia in the 1940s. Wood and fabric single seat glider sailplane with strutted wings and strutted tailplane – features metal framed perspex canopy, central fuselage skid and wheel, small tail skid, instruments include airspeed, turn and bank indicator; variometer and altimeter. Metal parts include struts and fairing covering wing joint. All surfaces are pink doped – awaiting painting.australian gliding, glider, sailplane, coogee, tom proctor, victorian motorless flight group, geelong gliding club -

Bay Steamers Maritime Museum

Bay Steamers Maritime MuseumShip's Wheel

This is one of two ship's wheels that are associated with the steam tug Wattle. This wooden wheel replaced the original steel wheel which was much larger and proved unwieldly.Wooden Ship's wheel with eight spoke handles and a central brass reinforcing plate. The wheel is constructed of mid brown timber. The outer wheel is constructed of short timber lengths inbetween the eight turned spokes. A central circular brass plate is rivetted in the middle to hold the wooden components together.wood, ships wheel, wattle, steering gear, steam tug, bay steamers maritime museum -

Wannon Water

Wannon WaterGavel, Brian Rowe, 1995

The gavel was presented by Russell Worland (Acting Secretary Glenelg Region Water Authority) to the inaugural chairman of the Glenelg Region Water Authority 1995, Sandra Hempel. Glenelg Region Water Authority amalgamated the previous authorities of Glenelg-Wannon Water Board, Hamilton Water Board, Shire of Dundas and Shire of Mount Rouse Water and Sewerage Authorities and was constituted on 1 July 1994. Glenelg Region Water Authority was then amalgamated with South West Water and Portland Coast Water to form Wannon Water on 1 July 2005.Presented to the first chairman of the newly constituted Glenelg Region Water Authority, a predecessor authority to Wannon WaterWooden turned gavel and a base carved from Konongwootong blackwood, a brass plaque with an inscription. The underneath of the base has an inscription detailing the craftsperson and origin of the wood.Top of the gavel base : "The gavel : symbol of the/ Chairman's authority/ presented to the inaugural Chairman/ Sandra Hempel /17/8/1995/ Glenelg Region Water Authority" Underneath of the gavel base : "Handcrafted by Bryan Rowe/ from Koonongwootong blackwood/ Hamilton August 1995"gavels -

Wangaratta Historical Society

Wangaratta Historical SocietyWooden Fruit Bowl, Red Gum Bowl

This wood is made from Red River Gum tree wood, these trees live for between 500 to 1,000 years of age. The wood in this bowl has been carbon dated in the USA to be 4,500 years old.This bowl is significant because of the age of the wood it is made from. 000016 Wooden Fruit Bowl The timber this fruit bowl was made from was a red gum tree taken from the Ovens river at Tarrawingee (12 km from Wangaratta)where it had been submerged for years. It was made on a lathe by Ken Hill. The bowl warped and cracked shortly after being turned. A piece of the wood was taken to the USA by a visitor where it was carbon dated to be 4500 years old Measurements: Diameter: 22cm Height: 6cm Colour: Dark red brown Photographed beside a piece of natural red gum Tarrawingee is 12 Km North East of Wangaratta on the Great Alpine Road Significance: 4500 year old red gum wood is rare in this area. red river gum wooden bowl wangaratta historical society -

Clunes Museum

Clunes MuseumFunctional object - YOKE

... WOODEN YOKE, DARK WOOD, CARVED AND TURNED AT EACH END ... YOKE MINING TOOLS WOODEN YOKE, DARK WOOD, CARVED AND TURNED ...WOODEN YOKE, DARK WOOD, CARVED AND TURNED AT EACH END chinese yoke, mining tools -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumWooden Handle

... material was selected from the fire wood. tatura trades tools ...Made & used by internees at camp 3, tatura material was selected from the fire wood.Turned wooden handle with metal rim & rink & hole( for inserting blade/metal tool) Handle is shaped near to the metal ring/rim, slightly darker wood section at bottomtatura, trades, tools -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumAbacus, Between 1939-1945

Camp 3 was one of the Tatura Group of civilian & prisoner of war internment camps during World War 2. Camp 3 was a civilian 'family' camp. The abacus was made by a German internee, for his son in the camp. It was made from scrap materials found in and around the camp & the beads & other wooden parts of the abacus were turned on a lathe also constructed by the internees. Wood & metal abacus with wooden base, sides & beads (100), & metal rails. Wood painted red & black. camp 3, tatura, internment camps, civilian internees -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumToy - Spinning top, 1940'sq

Made by internee and used by children at Camp 3Wooden hand turned spinning top. Convex shape on the top. 6 ridges around the centre. Painted red and yellowspinning top, wood, wied l, camp 3, tatura, ww2, toys, general -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumWood Plane, 140's

Handmade by internee at Camp 3Wood plane, camp coins used as washers. One imprinted "Internment Camp". The handle turned on a pedal lathe, also made in Camp. All from materials found in camp surroundsOn coins - "One penny Internment Camp"plane, wood, hoffmann k, hoffmann e, camp 3, tatura, ww2 camp 3, handcrafts, woodwork, trades, tools -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumFunctional object - Button, Wooden Buttons, 1940's

Made by internees at Camp 3, Tatura. These buttons had to be removed each time the garment was washed.Pair of small polished/turned wooden shank buttons. Grain of wood distinctivebutton, wood, dostser, frank r, baumert m, camp 3, tatura, ww2 camp 3, costume, accessory, clothes -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumAccessory - Buttons, Large Wooden Buttons, 140's

Made by internees at Camp 3, Tatura. (These buttons had to be removed each time the garment was washed)4 round turned wooden shank buttonsbuttons, wood, baumert m, beilharz, doster, frank r, camp 3, tatura, ww2 camp 3, costume, accessory, clothes -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumPlate - wood, c. 1943

Given to the donor's parents while in Camp 3ATurned wooden flat plate with slight lip on side, Lightly decorated, polished.tatura, camp 3a, craft work -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumWooden Handle, 1941-1947

... , material was selected from fire wood. tatura trades tools Turned ...Made & used by internees at camp 3, tatura, material was selected from fire wood.Turned wooden handle with metal ring/ rim & hole ( for inserting in a metal tool) Handle nearest metal ring is shaped, lower on handle are two sets of finely grroved rings.tatura, trades, tools -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumWood Plane, 1940

... Wood Plane with turned & shaped wooden handle, metal pieces... there as a handtool for carpentry tatura trades tools Wood Plane with turned ...Made by internee Camp 3 Tatura, used there as a handtool for carpentryWood Plane with turned & shaped wooden handle, metal pieces forming cutting/shaping blades.tatura, trades, tools -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumDomestic object - Egg Cup, c1940

made and used in camp 3 Tatura during WW2Fawn coloured, hand turned wooden egg cup exterior varnishedegg cup, wood, camp 3, tatura, glenk, handcrafts, woodcarving, domestic, items, food, drink, consumption -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumBowl, 1940's

Made by internee in Camp 3, TaturaHand turned wooden bowl. Varying shapes of wood grains incorporating a small circular base.bowl, frank b, wood, camp 3, tatura, ww2 camp 3, hancrafts, woodwork -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumPlane - Wooden, 1940's

Made by internee at Camp 3 Tatura. Used there as a wood working handtoolHandmade varnished, polished wooden plane with curved, turned handle. Metal washers support centre metal barHaeringplane, wood, haering, m, camp 3, tatura, ww2 camp 3, trades, tools -

Uniting Church Archives - Synod of Victoria

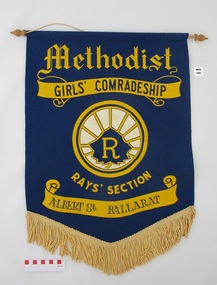

Uniting Church Archives - Synod of VictoriaBanner

... and gold fringing. Rays emblem in centre. On wood hanger... in centre. On wood hanger with turned ends. Banner ...Blue felt banner with yellow and white screen printing and gold fringing. Rays emblem in centre. On wood hanger with turned ends."METHODIST GIRLS' COMRADESHIP RAYS' SECTION ALBERT ST. BALLARAT"methodist girls' comradship rays section, methodist church albert street ballarat -

National Wool Museum

National Wool MuseumMachine - Wrap Reel

Wrap reel manufactured at Valley Worsted Mill and possibly used in the laboratory. "Wrap reels were used to check the yarn count in a spinning mill. A set length of yarn was wound off several test bobbins and weighed, if the weight was not the correct amount expected the spinning machines draft could be re calculated and the machine draft wheel ( cog ) changed to achieve the required count". - Greg AldridgeA small hand operated wrap reel. The reel is on a wooden base, the winding mechanism is metal and turned by a wooden handle. There is a metal plaque on the base inscribed MAKERS VWM. A wood and metal yarn feeder has broken off its mount.MAKERS/ VWMtextile machinery textile production weaving, valley worsted mill valley worsted mill, warping machinery, textile machinery, textile production, weaving, wrap reel, skein winder