Showing 3384 items

matching tooth-puller

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Corkscrew

The design of the corkscrew may have been derived from the gun worm, which was a device from at least the early 1630s, used by men to remove unspent charges from a musket's barrel in a similar fashion. The corkscrew is possibly an English invention, due to the tradition of beer and cider, and the 'Treatise on Cider' by John Worlidge in 1676 describes "binning of tightly corked cider bottles on their sides", although the earliest reference to a corkscrew is, "steel worm used for the drawing of Corks out of Bottles" from 1681. In 1795, the first corkscrew patent was granted to the Reverend Samuel Henshall, in England. The clergyman affixed a simple disc, now known as the Henshall Button, between the worm and the shank. The disc prevents the worm from going too deep into the cork, forces the cork to turn with the turning of the crosspiece, and thus breaks the adhesion between the cork and the neck of the bottle. The disc is designed and manufactured slightly concave on the underside, which compresses the top of the cork and helps keep it from breaking apart. In its traditional form, a corkscrew is simply a steel screw attached to a perpendicular handle, made of wood or some other material. The user grips the handle and screws the metal point into the cork, until the helix is firmly embedded, then a vertical pull on the corkscrew extracts the cork from the bottle. The handle of the corkscrew allows for a commanding grip to ease removal of the cork. https://en.wikipedia.org/wiki/CorkscrewThis object is significant as an example of an item in common use since the late 17th century.Metal corkscrew with wooden handle that is partly broken. Has metal steel spike to create a starting point for the use of the corkscrew. Very rusty. None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, corkscrew, beverages, kitchen equipment, bottle opener -

Royal District Nursing Service (now known as Bolton Clarke)

Royal District Nursing Service (now known as Bolton Clarke)Photograph - Digital image, c.1935

Each Ward in the Melbourne District Nursing Society After-Care Hospital, at 45 Victoria Parade, Collingwood, had a Sun Room which was well lit by its many windows. This digital image is taken in one of the Sun Rooms and shows the type of hospital beds, furniture and the uniforms worn by Sisters and nurses in the 1930s.Melbourne District Nursing society opened the After-Care Home, situated at 39 Victoria Parade Collingwood in 1926 following a public appeal for funds. The name changed from 'Home' to 'Hospital' in 1934. The After-Care Home was originally established to provide nurse-managed convalescent care to poor and underprivileged people who could not look after themselves at home due to illness or on release from hospital. Opening in 1926, at a cost of £27,000, the home included maternity, children’s and adult wards as well as accommodation for Matron, twelve nurses and four domestic staff. In 1930 an ante-natal clinic was opened at the home. During 1934 the Women’s Welfare Clinic including, at the time, a very controversial Family Planning Clinic, the first of its kind in Australia, was opened to support women at risk following multiple and difficult pregnancies. Major extensions occurred in 1936. Each Ward in the After-Care Hospital at 45 Victoria Parade, Collingwood, had a Sun Room which was well lit by its many windows. Several donors gave money to furnish some of the Wards. Following Government intervention, the After-Care Hospital was separated from the Melbourne District Nursing Society in 1957. The District division of Melbourne District Nursing Society became the Melbourne District Nursing Service and moved to 452 St Kilda Road; later, in 1966, with Royal patronage this became Royal District Nursing Service (RDNS). The After-care hospital continued to operate at the same address in Collingwood until 1985 when it became the Melbourne Geriatric Centre. This digital Image shows six men patients and nursing staff in a Sun Room in the Melbourne District Nursing Society After-Care Hospital. In the left foreground is a low bedside cupboard, beside it is a man with short dark hair lying in an iron framed hospital bed with a white cover pulled up to his shoulders. A Sister, who is looking at the camera, is wearing a grey uniform with a white collar, and a white veil over her short dark hair; she is standing behind, and at the head of the bed with her right hand holding the vertical bar of the bed frame. Behind her is an open door and then a nurse wearing a long white apron over her grey long sleeved uniform; she has a white cap over her shoulder length dark hair and is looking at the camera. Both of her hands are resting on an empty cane chair. Next along is a man with a bandage wrapped around his head and over his left eye. He is wearing dark clothing and is sitting on a padded cane chair, as are the rest of the men in the room. To the rear, in front of four long windows, are another two men, one on the left has short white hair and is wearing light clothing, and to his right is a man with short dark hair and is wearing a dark dressing gown over light colour pyjamas. On his right is a large vase of flowers on a tall white stand. On the right hand side of the photograph are another two men with short dark hair and wearing dressing gowns; part of a wall with windows can be seen behind them.mdns, after- care hospital, melbourne district nursing society, rdns, royal district nursing service -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BASIL MILLER COLLECTION: BENDIGO SAYS GOOD-BYE TO THE TRAMS, c1972

13 April 1972. Bendigo Says Good-bye to the Trams. A1 sheet - double sided. Tramway history 1890 - 1972, 2 copies. At the stroke of 5 pm from Eaglehawk Town Hall clock 82 years of history will end as the last tram makes its sentimental journey to the city, while at the Bendigo Cemetery - the Quarry Hill line terminus - another tram will be leaving for its last resting place. Other articles include: Four Eras, of trams. The Trammies, covering Ballarat, Geelong in the form of a poem. 1927 and all that, by Basil Miller, remembering his 45 years of service with the trams. How it all started, The twin communities of Sandhurst and Eaglehawk were relatively early in considering the possibility of operating street tramways within their boundaries. Cabs, Battery Cars, Construction, Strikes, Bendigo 1890 to 1972 - Tramways. Man and his Mates, continued from previous page, Explosion, Touchy Task, A Quickey, Horrors. Electric in 1903, There was excitement galore in the City during April, 1903 - and the Advertiser recorded the progress of the new-fangled electric machine. One man's Memories, Tough times, humour, tragedy and comradeship - they all came flooding back as former Bendigo tramway-man Tom Griffiths recently turned the clock back. Keb Sir Keb Sir? 'Keg sir? Tram off the line,' was the call of the cabbies when a train pulled in at the Bendigo railway station. Altered Shopping Trend, With advent of the electric tram in Bendigo came change in shopping habits.bendigo trams -

Mission to Seafarers Victoria

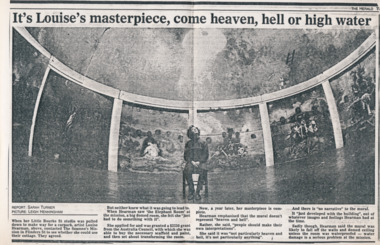

Mission to Seafarers VictoriaArticle - Clipping, photocopy, Sarah Turner, It’s Louise’s masterpiece, come heaven, hell or high water, 1988

Louise Hearman used the Norla Dome and painted a mural painted which had taken her around a year to complete. The exhibition called Elephant Room was shown from June 1988. The work was vandalised in 1989 and subsequently demolished.Louise Hearman is a Melbourne born artist and Archibald Prize winner. Hearman first came to public notice in 1987/88 when she spent a year painting the mural in the Norla Dome. The premises of the Mission also served as her studio at that time.Black and white copy of a newspaper article, printed on A3 paper.It’s Louise’s masterpiece, come heaven, hell or high water Report: SARAH TURNER PICTURE: LEIGH HENNINGHAM When her Little Bourke St studio was pulled down to make way for a carpark, artist Louise Hearman, above, contacted The Seamen’s Mission in Flinders St to see whether she could use their cottage. They agree. But neither knew what it was going to lead to. When Hearman saw ‘the Elephant Room’ at the mission, a big domed room, she felt she “just had to do something with it”. She applied for and was granted a $3250 grant from the Australia Council, with which she was able to buy the necessary scaffold and paint, and then set about transforming the room. Now, a year later, her masterpiece is complete. Hearman emphasised the the mural doesn’t represent “heaven and hell”. Rather, she said, “people should make their own interpretations”. She said it was “not particularly heaven and hell, it’s not particularly anything”. And there is “no narrative” to the mural. It “just developed with the building”, out of whatever images and feeling Hearman had at the time. Sadly though, Hearman said the mural was likely to fall off the walls and domed ceiling unless the room was waterproofed - water damage is a serious problem at the mission. louise hearman, norla dome, exhibitions, 1988, elephant room, flinders street, melbourne, leigh henningham, cultural events -

The Beechworth Burke Museum

The Beechworth Burke MuseumPostcard, George Symons, c.1990

The photograph printed on this postcard comes from the collection of the Mitchell Library in Sydney. It is sepia in tone and depicts seven men standing and sitting around a mine shaft in the Beechworth region. The photograph has been dated to approximately 1872. This period in history post-dates the Victorian gold rushes which occurred 1852-1853 in Ballarat, Bendigo and Beechworth. During this period, in the 1870s, the surface alluvial gold had been discovered and removed from location. Therefore, in order to reach the deeper and less accessible alluvial gold, diggers began to dig shafts into the earth. These shafts sunk below the ground level by 20 to 30 feet and required timber structures around the entrance and winches to bring the paydirt to the top. The top of this wooden structure is visible behind the man standing in the upper right of the image. This type of mining was highly dangerous as mines often caved in which injured the minors and often resulted in death. Thus, following this period, in the early 1900s, miners opted instead for hydrolic slucing which cut away the earth without the devastating consequences of a mine cave in. This particular group of miners appear to have been unable to afford a horse (then worth around 50 pounds) which were generally used at mines like this to help pull buckets attached to ropes up and down the mine. Instead, this group brought the buckets up and down by windlass. The windlass was a wooden structure mounted over the mining shaft and fitted with a hand-cranked winch which enabled the bucket attached to the rope to be brought up and down.Gold was first discovered in Beechworth in Spring and Reid's Creek in the summer of 1852-1853. At its popularity, this region had approximately 8000 people on the gold fields searching for gold on the banks of these creeks. These periods did not require the use of heavy machinery or the digging of deep mining shafts like the one depicted in this image. Therefore, this image has important connotations for the technologies associated with mining during the approximated 1870s when gold was harder to access. This is a later period in gold history which does not fit into the "gold rush" period. Instead, it occurred after the surface gold had disappeared and therefore, is essential for researchers who are investigating the mining techniques and structures used to reach the alluvial gold which was located deeper under ground in the 1870s. This period predates the use of big heavy machinery used to mine in the 1900s which include dredges. Images such as this one can also impart essential information as to the wardrobe and fashion of men during this period. It also imparts knowledge about the landscape of Beechworth which is useful for people researching the environment and impact of gold mining in the north-east region of Victoria. In addition, since this image is a postcard reproduction of an early Australian image which may date to approximately 1990 it can impart knowledge as to the interests of people during this time period when there may have been an increase into Australian history.A sepia tone facsimile of an early Australian photograph (circa 1872) printed as a postcard.Obverse: BEECHWORTH / Victoria, Australia / Reverse: GM 2 3275 / CORRESPONDENCE / AUSTRALIAN / YESTERYEAR / CARDS / ADDRESS / Published by George Symons (057) 65 3240 / THE MINEHEAD C. 1872 / The easily gleaned gold of the early fields did / not last very long. In order to reach less / accessible alluvial gold diggers began sinking shafts as much as twenty to thirty feet down / and the mines required timbering and winches / to bring the paydirt to the top. / This syndicate has been unable to afford the / luxury of a horse (about 50 pounds) and so everything / must go up and down by windlass and rawhide / bucket. / Photo: Mitchell Library, Sydney / A sepia tone facsimile of / an early Australian photographmining album, gold mine, beechworth, burke museum, mine shaft, postcard, australian yesteryear cards, george symons, the minehead, gold fields, alluvial gold, early australia, c.1872, 1872, gold diggers, north east victoria -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph - Photograph: Workers at Tarnagulla Flour Mill, c. 1873-1920, probably around 1900

Williams Family Collection. A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. Thomas Comrie was the proprietor and was responsible for the Mill being built. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years.Monochrome photograph depicting workers at Tarnagulla Flour Mill, some loading or unloading a horse-drawn cart. An original photograph, mounted on card. Handwritten on back: 'L.Williams Tarnagulla' and 'Leo Fitzgerald' and full recipe for a red currant dessert.tarnagulla -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - CREAM EMBROIDERED SILK AND LACE GIRLS DRESS, Late 1800's

Beautiful soft cream silk dress, with a random silk embroidered three petal flower over the fabric. Round neckline with overlaid square yoke of embroidered lace on a net background. Two 7cm wide bands of the lace are gathered over the shoulder armhole edge. These frills, and the scalloped edges of the front and back lace yoke are trimmed with 4 cm long decorative silk tassels.(one missing). Long sleeves, tapered in at the wrist are trimmed at the wrist with a 4.5cm wide band of lace, part of which is threadedwith two rows ofsoft pink silk ribbon insertion. Soft pink silk, folded into three 2.5cm tucks-overall width 6cm trim the high waistline, with a 7cm diameter rosette at the left front, and a bow(?), and tails, trimming the back waistline. This is severely damaged. Four metal hook and loops fasten the back lace collar, and nine metal hooks and eyes fasten the bodice. Bodice and sleeves are fully lined. Bodice is boned with thirteen 12-4 cm long ''bones''. Skirt is in two tiers; Top is 38cm deep, and made from the plain embroidered silk. A 5cm deep band of lace, with scalloped edges then joins the 36 cm deep ;lower panel of beautifully embroidery and pulled threadwork. Hem is faced, and finished or hemmed with french knots. Dress , which is hand stitched is fully lined with cotton. The lower 36 cm deep tier of the underskirt is trimmed with three .5cm tucks, and two 8cm bands of cutwork lace in a floral and geometric pattern. An oval shaped pocket is sewn into the front of the ''petticoat'' lining. This pocket contained some plant material, included in attached bag.costume, children's, cream embroidered silk and lace dress -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - HILDA HILL COLLECTION: BLACK AND WHITE PHOTOS

Hilda Hill Collection. A Combination of Sepia & Black & White Photos Taken Between 1920 & 1921 Total 8. The First shows the flow of the Kyneton Weir in September 1920 and the surrounding countryside. Black and white photo of a man sitting on a window ledge in a white shirt jodhpurs and long boots, foreground is a garden with a number of plants, window has internal Venetian blind. Photo of family members relaxing at their Kilmuir property, three ladies all in white with large sun hats standing in a garden with large trees in the background. A group of five men and three ladies standing on a tennis court, one man holding a tennis racquet, two of the ladies wear white tennis apparel of the day at 'Kilmuir' December 19th 1920. Photo showing two ladies and a child in the foreground against a background of a large tree and house further back, there are more houses to the right of the tree and a dead tree. Photo of man sitting in cane chair and boy sitting on step, in front of house that is in the background, window has a round column on the left side, titled below as 'Vin' Durvol September 1920. Three ladies and one man, the ladies are dressed in white and the man in black coat and white shirt, all have their hands behind their backs 'Kilmuir' 1920. Seven young girls standing on the front stepson the house 'Kilmuir' , one girl is dressed in dark clothing all the rest are in full white, to the left is a sun blind pulled right down, ornate fretwork along verandah below guttering, to the right of girls is a window with lace curtains, garden in front foreground, December 19th 1920.Hilda Hill Personal Collectionaustralia, history, images 1920-1921 -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesAlbum - Black and white prints and negatives, Photograph Collection, 1940-1950

Collection of 39 photographs. Some photographs with handwritten annotations in what looks like the handwriting of J.L. Provan. Mostly at Burnley, some at Moorabbin. (1) "Opium Poppy 1942 Burnley. Publicity Branch Department of Agriculture." Negative in envelope marked, "Prints 1 of No. 398 Department of Agriculture 'McP.' " (2) Grape vine and cabbages. (3) Rows of seedlings in the Orchard. (4) Orange tree? unpruned. (5) Flowers. (6) "Double and single rows of French Beans." (7) "Sage & marjoram." (8) Hydrangeas. (9)Sprinkler on newly planted cabbages. (10a)"Lettuce Iceberg 1/1/43." Seeds on soil surface. (10b) "Lettuce Iceberg 1/1/43." Seedlings emerging. (11)? planted in terracotta pipes. (12) Rows of seedlings in the Orchard. (13) "A student sowing Parsnip seed in a drill row. School of Horticulture Burnley Gardens." (14) Student distributing fertilizer? (15) Similar. (16) Similar. (17a) Flowers. (17b) Flowers. (18)"Beetroot Crimson Globe." (19) A seed drill. (20)Canna. (21a) Vegetable rows. (21b) ? (22) Student hoeing. (23) Student hoeing. (24) Similar. (26) "Cabbage Burbees Allhead 2/2/43," seedlings. (27) Water, manure, etc. (28) "Celery beds Ray Marriott Moorabbin April 2nd 1943." (29-37) Also at Moorabbin probably: (29) Vegetables. (30) Onions. (31) Vegetables. (32) Planting seedlings. (33) Vegetables. (34) Celery, carrots, turnips on display. (35) Carrots growing and just pulled up. (36) Peas. (37) Ploughing with horse. (38) Student spraying vegetables at Burnley. (39) House?j.l. provan, burnley, moorabbin, opium poppy, grape vine, cabbages, seedlings, orchards, orange trees, flowers, french beans, sage, marjoram, hydrangea, sprinkler, lettuce iceberg, seeds, students sowing, parsnips, school of horticulture burnley gardens, beetroot, hoeing, water, manure, celery, vegetables beds, ray marriott, onions, carrots, turnips, peas, ploughing, horse, spraying -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - ANDREW - MONSANT COLLECTION: LADIES DRESS - BODICE AND SKIRT, 1909

BHS CollectionWaist length dark green cotton bodice. Fabric has alternating stripes of pulled thread pattern and wider stripes of small dot pattern. Front opening with deep V to waist with lined lace insert extending from throat to waist. LHS of bodice fastened to lace insert with five press studs. Stand up collar of lined black lace (%cm) fastened with two hook and eyes. The bodice is made from five pieces. The two front sections have three knife pleats facing out and falling from the shoulder. The pleats are stitched down for twenty cms from the shoulders. On either side of the front opening is decorative embroidered black lace that extends across the shoulders to the back of the collar. There are two side panels from under the arm. The back section has three box pleats falling from the collars and tapering to the waist. The hem of the bodice is fastened with black cotton tape. Leg of mutton sleeves are trimmed with black embroidered brais at elbow and wrist. Lower sleeves have pintucks from elbow to wrist. The sleeves are lined with black cotton fabric. The back of the bodice is lined with black cotton fabric almost to the hem. A three cm piece of white and blue cotton tape is attached across the lower back with cotton ties at either end. The underarm panels are lined with brown cotton fabric and green satin inserted sections. The front has a separate lining with front opening and shaped with darts. Fastened with six buttons and buttonholes. Two shoulder pads on each side- one white piece under the shoulder and a green satin piece under the gathered section of each sleeve. Dark green full length skirt. Cotton fabric with alternating stripes of pulled thread pattern and wider stripe of small dot pattern. Skirt is made of three sections. Centre front panel widens slightly to hemline. Side panels continue around to join at centre back. Darts at both hips to shape sides. Panels widen to hemline. Inverted pleats at either side of back opening create fullness. Back opening(30cm) has insert of black satin joined to LHS of opening to enlarge the opening. Insert attached to waist band with two press studs. Two other press studs attach skirt to RHS of insert. Brown cotton waistband hand stitched to skirt. Ties attached to waistband at back opening- one cotton tape, one satin ribbon. Front centre panel has a piece of black satin stitched as lining from eighteen cm below waist (57cm deep). Stitched across and attached to side seams. Lower edge trimmed with black lace. Second piece of satin lining stitched to centre seam and stitched around the hip to partway across back.(Looks like a nylon petticoat cut in two pieces and stitched inside skirt as a lining). Hemline has fifteen cm piece of cotton lining attached and lower edge of hem has fringed cotton binding attached.. Side seams of front panel have decorative trim of embroidered braid extending seventy-six cms from waist. Braid then turned ninety degrees and continued in a horizontal zig zag line around to centre back seam (both sides) twenty cms above hem. Hand and machine stitched.costume, female, ladies dress- bodice. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTin Tea Pyramids Blend, early 1900's

This early 1900's tin which contained loose leaf blended tea was imported into Australia by those tea merchants who wanted to provide the Australian tea drinkers with quality tea. It could well be early Lipton distributors to both city and rural clients and consumers. This was in a period when most rural families were heavy tea drinkers. It was well before the introduction of coffee as a drink (especially instant) for the early morning, after meals and general "drink any time" pick me up beverage.This relatively large tea tin marks a period in time when loose leaf tea was in great demand and large quantities were not only used by families but also restaurants, workers mess halls and remote large rural families. The ability to obtain a quick tea supply in semi remote rural areas such as the Kiewa Valley was not possible due to the factors of all weather road access and the economics of traders going out of their way. Stocking up with important beverages, such as tea, was a "one of those things" that early rural communities had to endure with. Bulk storage tins such as this item were not only a requirement but also offered storage for other household items. This usefulness was not overlooked by the "canny" rural family.This large metal tin container was specifically manufactured for the kitchens requiring a bulk storage "bin" type of loose leaf tea content. When emptied, it could also be used as a general kitchen storage container for other bulk consumables.On the front side and in the background, there are three sketches of Egyptian pyramids(increasing in size from left to right). At the forefront there is a camel "train" loaded with supplies and handlers, making their way over the sandy desert going towards a large sign(in a freehand script) "PYRAMIDS BLEND". The left side "Specially Selected" and underneath "PURE TEAS" below this and within a circle is the figure of a Geisha clad of Asian appearance (with a fan in a raised hand with boxes(of varying sizes) around her. All these are in (off white design and wording on a green background. On the back in green print on off white background "PYRAMIDS BLEND" and underneath "OF SPECIALLY SELECTED PURE TEAS". On either side are columns of similar print. To the left "THESE UNRIVALLED BLENDS ARE GUARANTEED TO CONTAIN ONLY PURE TEAS".To the right "SPECIALLY SELECTED FROM THE CHOICE GROWTHS OF CHINA INDIAN & CEYLON". Below both columns is "for delicacy & fragrance of flavor, combined with great strength, and are confidently recommended to the public as the best values in teas obtainable" On the last side is a sketch of an " Indian encircled, holding a staph with palm trees in the background and four tea containers on his left, with "PYRAMID BLEND" as a subject heading. There are two Oxen pulling a two wheeled cart with a load of six large boxes. On lid and barely readable "FIVE POUNDS NET"loose leaf tea containers, food storage tins, kitchen tidies -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, John Manners, 1792-1822

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: We know little of John Manners other than his firm was acquired by Alexander Mathieson & Sons in 1822, Mathieson were one of the leading makers of hand tools in Scotland at this time. 1792 was deemed by Mathieson & Sons to be that of its foundation and it was in all likelihood the year in which John Manners had also set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, it is presumed having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker, from 1822 we hear nothing regards what happened to John Manners.A vintage tool made by a known maker John Manners the item is a significant wood working tool from the late 18th century that today is quite rare. As this maker sold his business to Alexander Mathieson another collectable tool maker in the early 19th century. This item would be sought after by wood working tool collectors and it gives us a snapshot of how cabinet makers went about creating furniture during this time period. Wood Moulding plane Side Bead - Single Box type Stamped Manners (Maker) (also inside stamped GN, & W, M. Nicol also F W. probably owners of item over the years.)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bottle, c. 1850's - 1900's

This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in 1850's - 1900's. Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020. The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s-1900s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. Bottle, solid colour brown glass,concave base, tapering slightly wider towards shoulder then inwards towards neck; ring of glass just below opening. Base is blown glass; pontil mark on base. Label "c.1850's STUBBY ALE", "ENGLISH HAND MADE, CORK & WIRE SEAL", "PONTIL MARK ON BASE $6" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, handmade beer bottle, handmade late 19th century bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bottle, c. 1850's - 1900's

This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in 1850's - 1900's. Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020 The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s-1900s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. Bottle, opaque brown glass, concave base, tapering slightly wider towards shoulder then inwards towards neck; ring of glass just below opening. Base is blown glass; pontil mark on base. "STUBBY 1850-1900 SMALL SIZE", ENGLISH 3 PIECE MOULD, HAND MADE TOP", "PAPER LABEL, CORK & WIRE SEAL $6flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, handmade beer bottle, handmade late 19th century bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Sculling Oar, Mid to late 19th century

An oar is an implement used for water-borne propulsion. Oars have a flat blade at one end. Rowers grasp the oar at the other end. The difference between oars and paddles is that oars are used exclusively for rowing. In rowing the oar is connected to the vessel by means of a pivot point for the oar, either an oarlock, or a hole. The oar is placed in the pivot point with a short portion inside the vessel, and a much larger portion outside. The rower pulls on the short end of the oar, while the long end is in the water. By contrast, paddles, are held in both hands by the paddler, and are not attached to the vessel. Rowers generally face the stern of the vessel, reach towards the stern, and insert the blade of their oar in the water. As they lean back, towards the vessel's bow, the blade of their oars pivots in the oarlock, and the end in the water moves towards the stern, providing forward thrust. There also is another way of propelling a small craft it's called a sculling oar which is attached to the transom and used to propel a small vessels rather than using two oars as previously described. It is believed the subject item is just such an oar given it’s long blade associated with a sculling oar. For thousands of years vessels were powered either by sails, or by the mechanical work of rowers, or by paddlers. Some ancient vessels were propelled by both oars and sail, depending on the speed and direction of the wind. Wooden oars, with canoe-shaped pottery, dating from 5000–4500 BC have been discovered in a Hemudu culture site at Yuyao, Zhejiang, in modern China. The history of man using wooden oars to propel a boat has a considerable record in marine archaeology going back many centuries. The item is significant for marine archaeology as it gives a snapshot into how a small row boat was powered using a wooden sculling oar. A method of propelling a small boat still used today an example is the gondoliers in Venice using a sculling oar in a circular motion to propel his craft. Single sculling oar with long flat blade, two copper bands, on blade with rowlock fittingNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, boat oar, sculling oar, row boat -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood smoothing plane coffin pattern, 18th to early 19th century

Being smaller than other bench planes, the coffin-shaped smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more manoeuvrable. A vintage tool made by an unknown 18th or early 19th-century woodworking tool maker. This item would have been made for individuals or cabinet makers that worked in wood and needed a tool that could produce a flat smooth finish to timber. These tools were used before routers and spindle moulders came into use in the late 19th and early 20th centuries before this time producing either a decorative moulding or a smooth finish to furniture timber, door trims etc had to be accomplished using hand planing tools and in particular one of these types of planes. Traditionally wood planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding or had a flat blade used for achieving a flat and smooth finish to timber. The blade or iron was likewise formed to the intended moulding profile or for smoothing and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers' shop might have many, perhaps hundreds, of moulding and flat-bladed planes for a full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. These vintage planes are well sought after by collectors of antique tools due to their rarity. A significant tool from the 18th to early 19th century by an unknown maker that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves handmade show the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber furniture item. Smoothing Plane Coffin type. Stamped GM inside "W" indicating sizeflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing Wood Plane Coffin Pattern, 18th to Early 19th Centuries

Being smaller than other bench planes, the coffin shaped smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more manoeuvrable. A vintage tool made by an unknown 18th or early 19th century woodworking tool maker. This item would have been made for individuals or cabinet makers that worked in wood and needed a tool that could produce a flat smooth finish to timber. These tools were used before routers and spindle moulders came into use in the late 19th and early 20th centuries before this time to produce either a decorative moulding or a smooth finish to furniture timber, door trims etc had to be accomplished using hand planing tools and in particular one of these types of planes. Traditionally wood planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding or had a flat blade use for achieving a flat and smooth finish to timber. The blade, or iron was likewise formed to the intended moulding profile or for smoothing and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding and flat bladed planes for a full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. These vintage planes are well sought after by collectors of antique tools due to their rarity. A significant tool from the 18th to early 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber furniture item. Wood smoothing plane known as a coffin plane due to it's shape, wood insert screwed on front of base. Stamped "MILLER". Inscribed "X" (probably the size)flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cabinet makers tools, woodworking tools, wood plane, smoothing plane, timber finishing, furniture manufacture -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVehicle - Spring Cart, Late 19th to early 20th centuries

A spring cart is a two-wheeled, one-horse cart, often with the driver standing up to drive it, and otherwise seated on a simple seat. Carts like this one had springs to make the ride smoother. It is a lighter version of a farm dray and is sometimes called a spring dray. Spring carts were often used on farms for carrying loads. In the towns, some businesses used a spring cart for deliveries of bread, milk and other goods. The carts would be used for travel and for families going on outings and picnics. Visitors to Flagstaff Hill Maritime Village from 1986 to 1992 would enjoy watching a Clydesdale horse named Duke as he worked around the village with his driver Pat McGowan. He would be hitched to a wagon or to this lightweight spring cart or sometimes he would pull the wagon with the cart attached as a trailer. The cart was used for maintenance, carting loads of timber or stone around the site or from town to Flagstaff Hill. Sometimes Duke and the cart would take visitors for cart rides around the Village. Pat McGowan was known for his restoration of horse-drawn vehicles including this spring cart. He already had 40 years of horse handling experience when he began looking after Duke, feeding and harnessing him and driving the horse and cart around the Village. Pat’s dog ‘Yabbie’ would often join them. In August 1992 Duke had to be put down. Warrnambool Veterinary Clinic and other fund-raisers began well-supported appeals and the beloved horse was replaced by a Clydesdale also named Duke (the second), who began work in late October 1992. He, like his predecessor, had a quiet temperament and was comfortable in the traffic. The spring card is an example of vehicles used on farms, for business delivery and for domestic transport in the late-19th and early-20th century. This cart is of note for being associated with the Clydesdale horse Duke which pulled the cart around Flagstaff Hills in the 1980s and 1990s, representing transport of that period.Spring cart; two-wheeled cart with shallow box tray and plank seat bolted across the front. Wheels have metal rims and fourteen (14) wooden spokes. A plank is bolted from side to side. A decorative metal step is on the cart's left and has acorn cut-out shapes in the plate. Both wheels have a brake block that is operated by a lever on the cart's right. The cart has eight-leaf suspension from front to back. The box tray is painted blue and has decorative pale yellow detail. Each shaft pole has has a handle fitting on it. (Horse equipment with the cart is a leather covered, straw filled collar.) flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, springcart, spring cart, jingle, horse-drawn cart, one horse cart, two-wheeled cart, dray, spring dray, wagon, transportation, travel, cart, duke, clydesdale, pat mcgowan, delivery cart, yabbie, cartwright, horse-drawn vehicle, transport, horse cart -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Miss Congue's Costumier Shop, Bay Street, Port Melbourne, c. 1900

This laser print is a copy of a photo which has been in the Congues/McKenzie family collection since early this century. Mrs Marie Vernon of Doncaster showed the photo to her cousin, Elva Mason, also of Doncaster but formerly of 35 Cruikshank Street. Elva had the copy done and passed it on to Barbara Gardiner. Mrs Vernon was unable to give us much information but could tell us that her mother, Mrs Mary Jane Congues (known as Ruby) was a tailoress who started her apprecticeship at age 13 and later established the shop which was next to Earl's hardware shop. We think that she was born in the 1880s. The Congues family lived at 36 Cruikshank Street, and their landlord in later years was Mr Sullivan, who supplied horse and drays for rubbish collection for the Council. Simon McKenzie was the loca policeman who patrolled up and down Bay Street and became interested in Ruby. She later visited a fortune teller who told her she would marry a man with numbers on his hat. They married and lived in Brunswick East, Carrum Downs and later Calligee (near Traralgon). LIfe was tough but Mrs Vernon remembers that her talented mother was able to teransform garments and hats so that her daughters always felt that they had a new dress for each special occasion. Mrs Vernon also remembers when a member of the famly needed dental care, they wee put on the train to stay with Grandma at Port Melbourne, who took them to Frost the Dentist (on the corner of Graham and Bay Strees), who pulled teeth for one shilling each. Miss Gongues is the lady in skirt and blouse on the right; other people unknown.Laserprint of four women in entrance to Miss Congue's Costumier shop in Bay Streetbusiness and traders - tailors and clothing, mary jane (ruby) congues, mary jane (ruby) mckenzie, simon mckenzie, mr sullivan, frost the dentist -

Chiltern Athenaeum Trust

Chiltern Athenaeum TrustDomestic object - Child's food pusher, J. Biggin & Co, Unknown

This children's eating utensil is believed to belong to the household of Chiltern writer and historian, W.C. Busse. The level of tarnish and the mark 'EPNS' may indicate it is electroplated. The blade also contains the maker's mark 'APEX', which was used by John Biggin & Co, Sheffield, United Kingdom. Pushers such as these were a common utensil in Victorian and early twentieth-century households. They were used to help children too young to use knives learn to eat politely at the table - the blunt blade was used to push food onto the fork. Pushers could also be used to pull food from a serving platter onto an individual plate. Wilfred Clarence Busse was born in Chiltern in 1898. He went to school at Wesley College in Melbourne, studied law at the University of Melbourne and became a barrister. Additionally, after spending time on a Victorian station in his early twenties, he wrote two historical novels about bush life. His first novel was 'The Blue Beyond: a Romance of the Early Days in South Eastern Australia', written in 1928 and published in 1930. Busse's second novel was titled 'The Golden Plague: A Romance of the Early Fifties'. The judges of the Henry Lawson Society's T.E. Rofe competition to advance Australian literature unanimously awarded it the Gold Medal in 1931 for the best historical novel of 1930. Newspaper articles about the award mention the writer's meticulous documentary and oral history research regarding life on the Gold Fields in the 1850s. It became a best-seller. Busse also wrote a series of articles about local history for "The Federal Standard" newspaper in Chiltern. He was a member of the Chiltern Athenaeum. He died in 1960.This child's eating utensil is significant for the detail it conveys of ordinary domestic life in the household of a significant Victorian writer with special reference to Chiltern and the surrounding region. It may also be significant in understanding the customs and practices of English-speaking nations in the early Twentieth Century. The object is a metal food pusher, a child's eating utensil with a blunt lozenge at right angles to the handle. The metal is tarnished, indicating that it may be silver or silverplated. APEX EPNS AI w.c. busse, wilfred clarence busse, chiltern, indigo shire, north-east victoria, gold fields, gold mining, gold rush, table manners, etiquette, children, childhood, john biggin & co, sheffield, golden plague, blue beyond, historical fiction, 1930s, 1850s, t.e. rofe, henry lawson society, electroplate, tableware, cutlery -

Tarnagulla History Archive

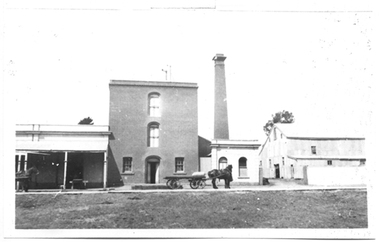

Tarnagulla History ArchivePhotograph of Flour Mill, Tarnagulla, Flour Mill, Tarnagulla, circa 1920

Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. Thomas Comrie was the proprietor and was responsible for the Mill being built. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. This is a poor copy of an older original. Copy probably made by Murray Comrie in the late 1960s. Monochrome photograph of the Flour Mill in Tarnagulla, around 1920.tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Tarnagulla History Archive

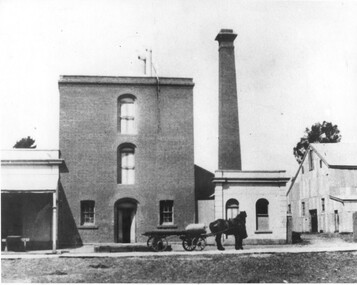

Tarnagulla History ArchivePhotograph of Flour Mill, Tarnagulla, Flour Mill, Tarnagulla, circa 1920 (original image)

Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. Thomas Comrie was the proprietor and was responsible for the Mill being built. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. This is a poor copy of an older original. Copy probably made by Murray Comrie in the late 1960s. Monochrome photograph of the Flour Mill in Tarnagulla, around 1920. Cropped version of 2019.0047.tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Phillip Island and District Historical Society Inc.

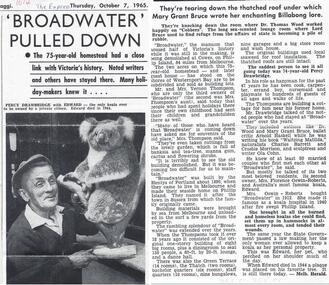

Phillip Island and District Historical Society Inc.Documents, Powlett Express, 1940 - 1960's

A collection of articles all relating to Phillip Islanders.A collection of Press Cuttings relating to people, buildings, wildlife and history of Phillip Island. 358-01: Item relating to the Broadwater homestead being pulled down after 75 years. Mrs Oswin Roberts bought Broadwater in 1912 and made it a famous koala hospital in 1940 after fire swept Phillip Island. Mrs Roberts was given permission to keep a koala as a pet - called Edward who died in 1944. He now resides in the museum. 358-02: A letter to the Powlett Express dated 8/11/1940, from Mr Clarrie Taberner correcting an article that stated it was roughly 65 years since the first settler arrived. Mr Taberner pointed out the his mother-in-law was living on the island over 83 years ago. 358-03: An article (1942) about a table made for the Phillip Island and Westernport Historical Society from the limb of a cypress tree planted by the late J. D. McHaffie about 100 years ago. 358-04: An article in the Powlett Express about the proposed shift of the Speke Figurehead from the Cowes State School. The Figurehead now resides in the museum. 358-05: An article in the Powlett Express - July 6, 1961 - about the funeral of the late Mr Percy Herbert McFee of Rhyll. He died at 79 in the Warley Bush Nursing Hospital. Article tells of part of his life on Phillip Island. 358-06: An article in the Powlett Express - May 5, 1960 - telling about Mr Stan McFee who was at the 90th Anniversary of the Cowes church of England where he had been attending for 65 years. 358-07: An article in the Powlett Express - August 26th 1949 - telling about the life in a year of the "Mutton Birds of our Bass Strait". (Shearwaters) stan mcfee, percy mcfee, mrs oswin roberts, edward the koala, mutton birds, shearwaters, broadwater, st philip's church of england, speke figurehead, margaret rixon -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . J Moseley. maker and R Knight & J Heath also stamped stamped (Owners)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . Stamped HB on one end and 8 on otherflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Wood Moulding Plane J Moseley & Son maker also stamped (Previous Owners) HIT & E Dunstan, RA Dixon with an N inside a W flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century