Showing 2556 items

matching road works

-

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photographs, Richard Vincent, Washed Away Bridge at Garibaldi, c1933

Newspaper clipping documents deputations to the Minister of Public Works for grants to be made available for repairs to bridges and roads damaged by heavy flooding in 1933, in particular, the replacement of a stone and concrete bridge over the Leigh River at Garibaldi in the Buninyong Shire. The concrete slabs were still in the water in the 1960s/70s or even later. Three black and white photographs showing flood damage to the bridge over the Leigh River at Garibaldi, plus a photocopy of a newspaper clipping from The Argus December 1933 describing the extent of the flood damage. .1) shows blue stone buttress and collapsed bridge/road. .2) mirror image of above .3) unknown man waling an a girder of the Garibaldi bridge .4) photocopy of newspaper clipping about flood damage from The Argus December 1933Damage by Floods: Bridges washed away (The Argus December 1933)leigh river, garibaldi, buninyong shire, richard vincent, garibaldi bridge -

Federation University Historical Collection

Federation University Historical CollectionLetter - Correspondence, Letter on Bendigo United Pyrites Company Letterhead, 1898, 1898

"The United Pyrites Company's Works are situated about three quarters of a mile from Spargo Brothers, and are on the northern side of the Marong road, in Pinch-gut Gully. Two processes are followed at these works, viz., the amalgamating process and the treatment by means of chlorine gas. The latter is called the Newbery-Vautin system, and the mode pursued is that laid down by Mr. Cosmo Newbery and Mr Vautin, whose names have been given to the process. Mr. Edwards manages these works. Three reverbatory furnaces are used to roast the pyrites, which is weighed in the truck before being put into the furnaces. At this weighbridge a sample of each lot is kept, and if the yield is not equal to expectation, the works are carefully gone over to see where the fault occurs. Care is taken at the furnace to regulate the heat, otherwise the pyrites might slag instead of roasting evenly right through. An immense revolving furnace (made of boiler iron) was used at these works. It was found to be suitable for treating blanket sand, but was not a success for roasting coarse pyrites. The process of amalgamating by means of Chilian mills is the same in these works as at the Western Works, but the United Works are on a larger scale, and eleven mills are utilised. It is the chlorine gas process which is most interesting here. The gas is made from sulphuric acid, black oxide of manganese, and common salt, and the gas is introduced into huge vats, where it works its way through a filter of pieces of quartz and then through the bed of roasted pyrites lying above. The action of the gas transforms the gold into chloride of gold. This is easily dissolved in water, and in that form is drawn off into huge delf jars, where the use of sulphate of iron precipitates the gold to the bottom. A small battery—eight head of stamps in two boxes—is in use here to crush small consignments of stone sent for trial. Test crushings come from all the Australasian colonies, and even from India. The jars used are manufactured at Epsom, and some of the salt used is also of home manufacture, from the Salt Lakes on the Northern plains. Mr. Edwards took us over a new building in course of erection, and in which the chlorine gas is to be generated in the midst of the pyrites— a still further advancement in the new process. There is some very good machinery in this new building, and the tailings from the ordinary pyrites works will also be treated by this chlorine gas system, which has been found to work well at Mount Morgan, in Queensland. The purest of gold is obtained by this process, the gold passing in solution into a charcoal filter, from which it emerges in the shape of metallic gold. We saw some nice cakes of retorted gold at the works. One of 26oz. was from some New Zealand pyrites (2½ tons), and assayed over 23 carats. There were also cakes of Avoca gold, of silver, and of the tremulous amalgam." (The Argus, 4 February 1887)Two handwritten letters to the Ballarat School of Mines on Bendigo United Pyrites Company Letterhead.bendigo united pyrites company, pyrites, ballarat school of mines, j.j. deeble, joel deeble, joel james deeble, a.m. dean, fred j. martell, martell, s.h. cowan, letterhead -

Federation University Historical Collection

Federation University Historical CollectionLetter - Correspondence, Margaret Malone, Letter regarding gold assay from Mount Egerton Mine, 10/02/2014

Margaret Malone was associated with a kaolin mine at Mount Egerton. WOMAN WHO MANAGES A MINE Works With A Vision (By a Special Corespondent) BALLARAT, August 22.—Like a Heroine in a Bret Harte story of the Soaring: Forties Miss Margaret Malone, the only woman mine manager in Australia, has lived most of her life in an atmosphere where hope springs eternal in the gold-seeking breast. Forty years ago her father gave up farming to seek the elusive mineral near Ballarat. "One day my mother went for a walk along the Gordon-Egerton road and picked up a pebble with a few specks of gold in it," she told an interviewer yesterday, recounting the early history of the nine she now runs at Egerton. "Dad said, There must be more where that came from,' and hopefully sank a shaft. Our hopes were dashed, however, when he found only white clay. No one realised then the value of the disappointing looking white stuff which was all that Dad could find from every shaft he sank. At last be gave up the search, and the kaolin remained untouched." Later an Englishman from a pottery town in the old country urged Mr. Malone to try and sell his clay, and he sent some to the Bendigo potteries, but nothing came of it, and it was left to Miss Malone, after her father's death, to start on her unusual career by finding purchasers in Sydney and Melbourne for her clay, and herself working the mine. Strenuous Work "Mine managing is strenuous work in more ways than one," she admitted. "I have, to go down my mine daily, ad sometimes have to descend perpendicular ladders for about 150 ft. to reach areas being worked. I have to be my own manager, she explained, "because it is necessary to teach the men I employ the methods of grading clays." A New Cure She is convinced that a number of uses for kaolin, apart from pottery, soap and drugs, are yet to be discovered. "One of my employees has already found a new use for it," she said, "although scarcely one to be generally recommended, perhaps. By chewing a small piece of the clay he firmly believes that he "cured himself of heart burn." "All That Glistens" There is more in Miss Malone's mining than meets the eye, however. The actual working of the field and the substantial profit she makes on it do not fill her days. Always before her - dangles the compelling vision that caused her father, in his day, to give up farming to seek for gold. "All the time I am getting my clay dug," she confessed, "1 am watching for the colour of gold. One of these days I may strike it." WOMAN WHO MANAGES A MINE Works With A Vision (By a Special Corespondent) BALLARAT, August 22.—Like a Heroine in a Bret Harte story of the Soaring: Forties Miss Margaret Malone, the only woman mine manager in Australia, has lived most of her life in an atmosphere where hope springs eternal in the gold-seeking breast. Forty years ago her father gave up farming to seek the elusive mineral near Ballarat. "One day my mother went for a walk along the Gordon-Egerton road and picked up a pebble with a few specks of gold in it," she told an interviewer yesterday, recounting the early history of the nine she now runs at Egerton. "Dad said, There must be more where that came from,' and hopefully sank a shaft. Our hopes were dashed, however, when he found only white clay. No one realised then the value of the disappointing looking white stuff which was all that Dad could find from every shaft he sank. At last be gave up the search, and the kaolin remained untouched." Later an Englishman from a pottery town in the old country urged Mr. Malone to try and sell his clay, and he sent some to the Bendigo potteries, but nothing came of it, and it was left to Miss Malone, after her father's death, to start on her unusual career by finding purchasers in Sydney and Melbourne for her clay, and herself working the mine. Strenuous Work "Mine managing is strenuous work in more ways than one," she admitted. "I have, to go down my mine daily, ad sometimes have to descend perpendicular ladders for about 150 ft. to reach areas being worked. I have to be my own manager, she explained, "because it is necessary to teach the men I employ the methods of grading clays." A New Cure She is convinced that a number of uses for kaolin, apart from pottery, soap and drugs, are yet to be discovered. "One of my employees has already found a new use for it," she said, "although scarcely one to be generally recommended, perhaps. By chewing a small piece of the clay he firmly believes that he "cured himself of heart burn." "All That Glistens" There is more in Miss Malone's mining than meets the eye, however. The actual working of the field and the substantial profit she makes on it do not fill her days. Always before her - dangles the compelling vision that caused her father, in his day, to give up farming to seek for gold. "All the time I am getting my clay dug," she confessed, "1 am watching for the colour of gold. One of these days I may strike it." (WOMAN WHO MANAGES A MINE Works With A Vision (By a Special Corespondent) BALLARAT, August 22.—Like a Heroine in a Bret Harte story of the Soaring: Forties Miss Margaret Malone, the only woman mine manager in Australia, has lived most of her life in an atmosphere where hope springs eternal in the gold-seeking breast. Forty years ago her father gave up farming to seek the elusive mineral near Ballarat. "One day my mother went for a walk along the Gordon-Egerton road and picked up a pebble with a few specks of gold in it," she told an interviewer yesterday, recounting the early history of the nine she now runs at Egerton. "Dad said, There must be more where that came from,' and hopefully sank a shaft. Our hopes were dashed, however, when he found only white clay. No one realised then the value of the disappointing looking white stuff which was all that Dad could find from every shaft he sank. At last be gave up the search, and the kaolin remained untouched." Later an Englishman from a pottery town in the old country urged Mr. Malone to try and sell his clay, and he sent some to the Bendigo potteries, but nothing came of it, and it was left to Miss Malone, after her father's death, to start on her unusual career by finding purchasers in Sydney and Melbourne for her clay, and herself working the mine. Strenuous Work "Mine managing is strenuous work in more ways than one," she admitted. "I have, to go down my mine daily, ad sometimes have to descend perpendicular ladders for about 150 ft. to reach areas being worked. I have to be my own manager, she explained, "because it is necessary to teach the men I employ the methods of grading clays." A New Cure She is convinced that a number of uses for kaolin, apart from pottery, soap and drugs, are yet to be discovered. "One of my employees has already found a new use for it," she said, "although scarcely one to be generally recommended, perhaps. By chewing a small piece of the clay he firmly believes that he "cured himself of heart burn." "All That Glistens" There is more in Miss Malone's mining than meets the eye, however. The actual working of the field and the substantial profit she makes on it do not fill her days. Always before her - dangles the compelling vision that caused her father, in his day, to give up farming to seek for gold. "All the time I am getting my clay dug," she confessed, "1 am watching for the colour of gold. One of these days I may strike it." (Adelaide Observer, 31 August 1929.)Hand written letter from Margaret Malone of the Mount Egerton Mine.Mount Egerton Mine February 10/14 The Manager Mining Dept Dear Sir, Last Monday week, I left with Mr Martell, a parcel of stone to be treated, requesting that cost of treatment, be deducted from some and balance of gold be forwarded me to above address. I was informed, this would occupy about a day or so, but not having received any communication so far, I shall be glad to hear from you are same. Yours faithfully Margaret Malonemargaret malone, female mine manager, kaolin, mount egerton, women -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePrint - Vessel - Sailing Ship, A.V. Gregory, ca. 1899-1922

This photograph is a print from an original painting by the Australian marine artist A V Gregory (1867-1957), also known as Arthur Victor Gregory. Gregory lived and worked in South Melbourne. He took over the Gregory Studio owned by his father, George Frederick Gregory, painting actively between 1899 and 1932. He usually signed his works as ‘A V Gregory’. Some of his original works have been sold for thousands of dollars. The four-masted iron barque 'Rowena' was built in 1883 by Barclay, Curle & Co. of Glasgow as the 'Cluny Castle', and renamed about 1890 as 'Rowena' by owners Rowena Ship Co.. After consequent owners, the ship was converted to a hulk in 1922 at Port Adelaide. The detailed image of the vessel depicted in this print shows one of the many sail and steam vessels painted by the renowned Victorian marine artist A V Gregory, whose original works are highly valued today by marine collectors.Photograph of a print, black and white, mounted onto card. It depicts the four-masted iron barque ship 'Rowena', originally named 'Cluny Castle'. The original painting was by marine artist A V Gregory.Painted on bow "ROWENA"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, photograph, photograph of rowena, gregory, cluny castle, a v gregory, rowena, iron baque, rowena ship co., barclay, curle & co, glasgow -

Flagstaff Hill Maritime Museum and Village

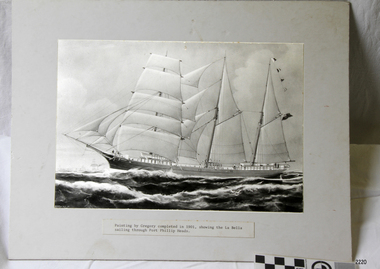

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessel - Sailing Ship, A.V. Gregory, 1901

This photograph is a copy of an original painting by the Australian marine artist A V Gregory (1867-1957), also known as Arthur Victor Gregory. Gregory lived and worked in South Melbourne. He took over the Gregory Studio owned by his father, George Frederick Gregory, painting actively between 1899 and 1932. He usually signed his works as ‘A V Gregory’. Some of his original works have been sold for thousands of dollars. The barque "La Bella" was built in 1893 in Norway. On 31st October she commenced her maiden voyage. After six voyages, the vessel was offered for sale in Hamburg. After much negotiation, she was sold on December 1900 for £3,600 to Mr D C Turnbull and sailed back to New Zealand. The "La Bella" was primarily used on the Australian-New Zealand run, her cargo being timber, coal and produce. In October 1904, she ran aground at Owhira bay, New Zealand. The vessel was subsequently refloated. In November 1904, the "La Bella" attempted to enter Warrnambool Harbour without a pilot aboard. The vessel struck Annabella reef and many members of the crew perished. The "La Bella" captain was later charged and found guilty of negligence. In 1905 he was charged and tried for manslaughter. He died of a heart attack later that year and is buried in an unmarked grave at Melbourne General Cemetery.The detailed image of the vessel depicted in this photograph shows one of the many sail and steam vessels painted by the renowned Victorian marine artist A V Gregory, whose original works are highly valued today by marine collectors.Photograph of a painting of the three-masted sailing ship "La Bella" sailing through Port Phillip Heads. The original painting is by marine artist A V Gregory. A label is pasted below the photograph. The artist's signature is visible.Signed "GREGORY-01" Painted on the ship's bow "LA BELLA" Typed label "Painted by Gregory completed in 1901, showing the La Bella sailing through Port Phillip Heads'.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, la bella, d c turnbull, warrnambool harbour, lady bay -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessels - Sail and Steam, A.V. Gregory, Australian Rivals - Past and Present, 1899-1932

These photographs are copies of original paintings by the Australian marine artist A V Gregory (1867-1957), also known as Arthur Victor Gregory. Gregory lived and worked in South Melbourne. He took over the Gregory Studio owned by his father, George Frederick Gregory, painting actively between 1899 and 1932. He usually signed his works as ‘A V Gregory’. Some of his original works have been sold for thousands of dollars. These mounted photographs, by A.V. Gregory, show both steam and sailing ships sailing in the Tea Race from China to London in 1872. The information included with the photographs has the following text: “Tea Clippers “ Well done Cutty Sark, by Bobbie Burns The CUTTY SARK and THERMOPYLAE. The start of the 1872 Tea Race from China to London. The “Cutty Sark” first away, followed closely by the “Thermopylae”, finally parting after several days’ company. On this race the “Cutty Sark” lost her rudder in the Indian Ocean, putting her hopelessly out of the race, and enabling the “Thermopylae” to pass her and reach London on 11th October, 115 days out, the “Cutty Sark” limping home seven days later. The credit of the race was given to the “Cutty Sark” by the shipping world. Copies of the pictures may be had from A.V. Gregory, 326 Albert Road, South Melbourne."The detailed images of the vessels depicted in this photographs shows some of the many sail and steam vessels painted by the renowned Victorian marine artist A V Gregory, whose original works are highly valued today by marine collectors. The pictures and document are significant for their association with the Tea Clippers, famous for racing across the world to arrive in Australia with the fastest time.Photographs of paintings of sail and steamships, three photographs mounted together side by side, titled "Australian Rivals - Past and Present". The centre shows the sailing ships Thermopylae and Cutty Sark. It is flanked on each side by a photograph of a steamship. The document with the photographs gives the history of the famous Tea Race from China to London in 1872.Title: "Australian Rivals - Past and Present". Handwritten on Left photograph "A.V. GREGORY - SS KATOOMBA" Handwritten on Centre photograph; "THERMOPLAE - A.V. GREGORY - CUTTY SARK - FIRST AWAY" Handwritten on Right photograph; "CANBERRA - A/V/ GREGORY" Handwritten on accompanying card is the story of the Tea Clippers.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, ss katoomba, thermopylae, cutty sark, tea race, tea race china to london 1872, canberra, tea clippers, a v gregory -

Flagstaff Hill Maritime Museum and Village

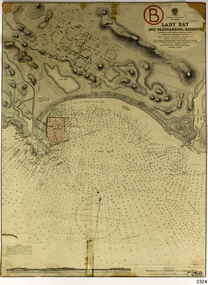

Flagstaff Hill Maritime Museum and VillageDocument - Navigation Chart, Admiralty Office, Lady Bay and Warrnambool Harbour, 1893

This navigation cart of Lady Bay and Warrnambool Harbour was originally surveyed in 1870 but this version includes the update for magnetic variation in 1893. Since the printing of the chart several annotations have been added. These include an additional stamp dated 15-8-1910, a handwritten comment across the top of the page dated August 1910, and another handwritten comment regarding the ‘Proposed Extension of Dock’ dated 19-2-1925, plus connected drawings, notes and figures. The 1925 proposal on this chart may have been a reaction to the Royal Commission of 1923, when the damaged stonework on the seaward side of the Warrnambool Breakwater, caused by the action of the sea, was the subject of enquiry. A conference between the Public Works, Water Commission and the Harbour Trust concluded that it would less costly to make repairs to prevent further damage rather than replaced the damage portion of the wall. A contract was raised in late 1924 to deposit rubble on the damaged side of the breakwater to minimise the Southern Ocean’s destructive action and work had started by August 1925. The Breakwater construction had begun in 1874 and was completed in 1890. The Victorian Government had commissioned Sir John Coode, a British harbour engineer, to present a plan to complete the Warrnambool Breakwater but his original plan was too expensive. He prepared a revised plan for a shorter structure. The construction proved to be too short to protect adequately from the weather and didn't allow enough depth for larger vessels to come into port. The decreasing trade was further affected by siltation in the bay due to the breakwater, and the completion of the railway line. The situation of the harbour became a real problem by 1910 and required continuous dredging. In 1914 the Breakwater was extended but proved to be a failure because the work began to subside and by 1920 about two thirds of the harbour was silted up. Alterations made in the 1920's increased the silting problem and by the 1940's the harbour was no longer used. More alterations were made in the 1950's and 1960's. This chart is significant for its strong connection to the maritime history of Warrnambool Harbour and Lady Bay and the Warrnambool Breakwater. The Warrnambool Breakwater is registered as a place of significance on the Victorian Heritage Database (VHR H2024). The Warrnambool Breakwater is one of the most important late 19th century maritime engineering projects in Victoria and significant in the development of Victorian coastal shipping. It is also significant for its connection with British harbour engineer, Sir John Coode. The chart is a historical record of structures existing in 1893; the Warrnambool Jetties, Warrnambool Breakwater in Lady Bay, the leading lights (lighthouses), streets, roads, bridges and many buildings. It also shows the lay of the land and seabed. Navigation Chart: Lady Bay and Warrnambool Harbour, Australia - South Coast - Victoria. Surveyed by Nav. Lieut. H.J. Stanley, R.N., 1870. Updated for Magnetic Variation, 1893. The rectangular chart is printed on heavy cream paper. Stamps are shaped rectangular, oval and round. Around the Breakwater and Jetty area are handwritten notes, dotted and joined lines, numbers and signatures, and shading of red and green. The chart shows the surrounds of Warrnambool Harbour, Lady Bay, the Breakwater and Jetty, roads, bridges and the streets in Warrnambool. It has sounding details, and angles of line from the leading lights.Stamp, rectangular, including "AUG 1910" Stamp, double oval " - - - -CHART" Stamp, hand drawn, red circle, with "B" inside Hand written note "22-8-1910 - - - - - of surveying C. Ca - - - request of 15-8-10 [initials] " Notes and lines in red pen, including a grid of sounding numbers: "1300" "1050" "1200" "Possible Extension of Dock" "19-2-25" "Dock Dredged to 20 Ft" Notes and lines in blue pen "Extension of Dock to accommodate vessels drawing 20 Feet" and "Light not visible south of this line" Red dots (4) with yellow highlight at both leading lights, breakwater and jettyflagstaff hill, warrnambool, flagstaff hill maritime museum & village, maritime museum, maritime village, shipwreck coast, map, chart, navigation chart, plan, lady bay, warrnambool harbour, port of warrnambool, breakwater, jetty, pier, dock extension, proposed extension, vhr h2024, 1870, 1893, 1910, 1925, warrnambool town late 1800s, warrnambool streets late 1800s royal commission, 1923, public works, water commission, harbour trust, victorian harbours, sir jon coode -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Hurricane Lantern, Nier Feuerhand, Between 1915-1920

... Warrnambool great-ocean-road The Feuerhand lantern works were ...The Feuerhand lantern works were established in Beierfeld in the Saxon Ore Mountains. Called Erzgebirge in German or Krušné hory in Czech, is a mountain range in the south of Saxony in Germany known for its craftwork. Lantern production began in the area by Hermann Nier who ran a plumber's workshop around the 1870s and made lanterns, amongst other things. In the town of Beierfeld, also well-known for its metalworking were the brothers Hermann and Ernst Nier who founded a modern production centre for hurricane lanterns manufacture in 1893. Five years after the foundation, the company Frankonia (Albert Frank metalware) bought up the production site and the brothers Nier became production managers. Owing to differences with Frankonia, Hermann Nier finally started its hurricane lantern factory "Hermann Nier Feuerhandwerk" in 1902. In the same year, he applied for a patent for the manufacturing of lanterns using the stamping and folding techniques with tinning by hot-dipping and without hand-soldering. In 1914 the trademark "Feuerhand" was registered for all products as a utility model of the German Reich in German: "Deutsches Reichs-Gebrauchsmuster" (DRGM) and in 1920 the round Feuerhand emblem was added to the brand. Finally, in 1926 the patents, as well as the trademark "Firehand", were also registered in the USA. The manufacture of the well-known small hurricane lanterns the “Baby Series” complete with fireproof borosilicate glass from the Firma Schott firm from Jena started in 1933. Between 1918 and 1938 Nier Feuerhand became the biggest producer of hurricane lanterns in the world. Production continued until 1990.A significant item that demonstrates from its fabrication a manufacturing process that was far in advance of its time and that influenced the production of lanterns from many other manufactures around the world. These types of lanterns made by Feuerhand around the early 20th century are now sought after by collectors.Monarch style Lantern painted black. Made in Germany has Freuerhand, manufactures logo on filler cap and top of lamp centre postflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, hurricane lantern, kerosene lamp, feuerhand lantern works, albert frank metalware, hermann and ernst nier -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Serving Plate, Edward Challinor, Circa1862-1891

The pottery was at Fenton, Stoke on Trent, Staffordshire UK and was established in 1825, by C J & GM Mason, they were succeeded by Mr. Samuel Boyle from whom the works passed into the hands of E & C Challinor, formally E Challinor & Co. Of Sandyford and Tunstall. The partners in Sandyford and Tunstall works are recorded as Edward Challinor Jnr and Charles Challinor Jnr and is presumably they are the sons of the partners of the Fenton pottery business. They produced china of white granite, printed sponged common earthenware for the American, Australian, and other foreign and colonial markets. The main goods produced were tea, coffee, breakfast, dinner, and toilet ceramic sets as well as other earthenware goods. Their pottery marks were the Staffordshire rope knot with or without E & C Challinor or just E C. An early piece of earthenware pottery made in England for the Australian colonial market around the mid to late 19th century.Serving plate white body, smooth rim, and blue oriental designRope knot motif printed on back in blue with letters EC warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, earthenware, ceramic, willow pattern, serving plate, e & c challinor, potteries -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Gravy Boat & Plate, Burleigh Pottery, 1930

Burleigh Pottery (also known as Burgess & Leigh) is the name of a pottery manufacturer in Middleport, Stoke-on-Trent. The business specialises in traditionally shaped and patterned domestic earthenware of high quality. The business was established in 1851 at the Central Pottery in Burslem as Hulme and Booth. The pottery was taken over in 1862 by William Leigh and Frederick Rathbone Burgess, and traded from that date as Burgess & Leigh. The trademark "Burleigh", used from the 1930s, is a combination of the two names. Burgess and Leigh moved to different works, first in 1868 to the Hill Pottery in Burslem and then in 1889 to the present factory at Middleport, that at the time was regarded as a model pottery. Its scale and linear organisation was in contrast to other potteries constricted sites and haphazard layout of their working spaces. In 1887 Davenport Pottery was acquired by Burleigh primarily for its moulds. These historic moulds are still used today in the production of Burleigh ware. Leigh and Burgess died in 1889 and 1895 respectively, and were succeeded by their sons, Edmund Leigh and Richard Burgess. On Richard's death in 1912, the business passed entirely into the ownership of the Leigh family. In 1919 it became a private limited company, Burgess & Leigh Ltd. The years between the wars are often regarded as the company's "golden age", with a number of extremely talented designers and artists such as Harold Bennett, Charles Wilkes and Ernest Bailey. Perhaps the best known was Charlotte Rhead, who worked between 1926 and 1931, noted particularly for her work in tubelining. By 1939, the factory was employing over 500 people. The business took great pains, from as early as 1897, to build up a thriving export network, concentrating primarily on the Empire later becoming the Commonwealth and American markets, focusing later on Europe. After a run of financial difficulty, the company was sold in 1999 to the Dorling family, Rosemary and William Dorling, and traded as Burgess Dorling & Leigh. In 2010 it was acquired by Denby Holdings Ltd, the parent company of the Denby Pottery. A significant company producing pottery over many generations and exporting their products all over the world. Its designs are still in use today demonstrating the longevity and significance of the Burleigh Ware trade mark.Gravy Boat & plate-willow pattern Burleigh Ware "WILLOW" within a floral decoration & Made in England flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, willow pattern -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Ironing board, 1910-1930

Ironing is the use of a machine, usually a heated tool (an iron), to remove wrinkles from fabric. The heating is around 180–220 °Celsius, depending on the fabric type. Ironing works by loosening the bonds between the long-chain polymer molecules in the fibres of the material. While the molecules are hot, the fibres are straightened by the weight of the iron, and they hold their new shape as they cool. Some fabrics, such as cotton, require the addition of water to loosen the intermolecular bonds. Many modern fabrics developed in or after the mid-twentieth century require little or no ironing. Permanent press clothing was developed to reduce the ironing necessary by combining Wrinkle resistant polymers with cotton. The first known use of the iron for removing wrinkles in clothes is known to have occurred in China, and the electric iron was invented in 1882, by Henry W. Seeley. Seeley patented his "electric flat iron" on June 6, 1882 (U.S. Patent no. 259,054). On 15 February 1858 W. Vandenburg and J. Harvey patented an ironing table that facilitated pressing sleeves and pants legs. A truly portable folding ironing board was first patented in Canada in 1875 by John B. Porter. The invention also included a removable press board used for sleeves. In 1892 Sarah Boone obtained a patent in the United States for improvements to the ironing board, allowing for better quality ironing of shirt sleeves.A domestic item with an interesting history of development, significant as it shows the progress and the evolution of a domestic item designed to make housework more efficient.Wooden Ironing board with press board for sleeves, board is folding.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, flagstaff-hill-maritime-village, domestic item, ironing board, ironing, clothes, wrinkles in clothes, henry w. seeley, w. vandenburg and j. harvey -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Boiling Copper, Newberry & Walker, Boiling Tub, Circa1900

Francis John Newberry founded the Victoria Foundry and Enameling Works in 1890 with a workmate from the Humbles iron foundry in Lupton Street Geelong where he worked. Newberry & Walker Foundry & Enameling Works was built adjoining a cottage that was to be the home of the Newberry family during the ensuing years. Although Walker soon relocated to New Zealand, the Newberry and Walker foundry had become a local success. The foundry produced numerous cast iron products such as washing copper frames, and friezes, balustrades and verandah columns. Verandah posts are to be found in declining numbers, but the Newberry and Walker mark can sometimes be seen on the few which remain. A certain number of iron culvert posts were also made; some of them were still in place on the road to Cressy as late as 1961. Perhaps half the iron friezes on Geelong West verandahs came from the local firm’s foundry. A significant item made in Geelong giving a snapshot into the early beginnings of Victoria's industrial manufacturing of products that helped to replace previously imported items from England or America.Copper boiling tub, cast iron frame copper bowl inside of 14 gallon capacity Newberry & Walkerflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, copper, cast iron, newberry & walker, washing copper frame, laundry, dairy, butchering -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Razor and case, E.M. Dickinson, 1895-1930

E M Dickinson was a cutlery company in Sheffield that made all types of cutlery knives of all types and patterns, razors domestic electroplated cutlery etc. Edwin Murray Dickinson started recruiting workers for his new cutlery firm at 11 Cambridge Street Sheffield England in 1870. The original premises consisting of warehouse, offices, cutlers shops fitted with the latest steam-powered equipment however this premises was offered for let in November 1887, and new premises were secured at 51 Division Street and were occupied by Dickinson's in early 1888. By October 1890 Dickinson was advertising the Division Street premises to let and moved the company into other new works (still called Murray Works) at 122 Rockingham Street. On 12th October 1901, Dickinson gave notice that the firm was to be converted to a limited company and by March 1908 the Rockingham Street works had been advertised for sale. In 1909 the deeds for other new premises at 203 Arundel Street Sheffield were deposited to secure a £3,000 loan from the Sheffield Banking Company. Then on Christmas Eve 1926 several hundred pounds worth of damage was caused by a fire at the Arundel Street works. The founder, Edwin Dickinson died on 21st October 1930 aged 81 at his home at 449 Crookesmoor Road and on the 23rd May 1939 the firm went into voluntary liquidation.An item made by a company that made many different types and patterns of cutlery for domestic use and export.Straight razor with black celluloid handle and it’s boxBlade has marking, INVICTA" with decorative engraved design, on the other side engraved "E M DICKINSON SHEFFIELD ENGLAND"flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, razor, e m dickinson ltd, e m dickinson ltd sheffield england., cut throat razor, cutlery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Standard avoirdupois weights, Avery Ltd, 1950s

A weight made in England by W&T Avery a British manufacturer of weights and weighing machines. The company was founded in the early 18th century and took the name W & T Avery in 1818. The undocumented origin of the company goes back to 1730 when James Ford established the business in the town of Digbeth. On Joseph Balden, the then company’s owner’s death in 1813 William and Thomas Avery took over his scale making business and in 1818 renamed it W & T Avery. The business rapidly expanded and in 1885 they owned three factories: the Atlas Works in West Bromwich, the Mill Lane Works in Birmingham and the Moat Lane Works in Digbeth. In 1891 the business became a limited company with a board of directors and in 1894 the shares were quoted on the London Stock Exchange. In 1895 the company bought the legendary Soho Foundry in Smethwick, a former steam engine factory owned by James Watt & Co. In 1897 the move was complete and the steam engine business was gradually converted to pure manufacture of weighing machines. The turn of the century was marked by managing director William Hipkins who was determined to broadening the renown of the Avery brand and transforming the business into specialist manufacture of weighing machines. By 1914 the company occupied an area of 32,000m² and had some 3000 employees. In the inter-war period, the growth continued with the addition of specialized shops for cast parts, enamel paints and weighbridge assembly and the product range diversified into counting machines, testing machines, automatic packing machines and petrol pumps. During the second world war, the company also produced various types of heavy guns. At that time the site underwent severe damage from parachute mines and incendiary bombs. Then from 1931 to 1973, the company occupied the 18th-century Middlesex Sessions House in Clerkenwell as its headquarters. Changes in weighing machine technology after World War II led to the closure of the foundry, the introduction of electronic weighing with the simultaneous gradual disappearance of purely mechanical devices. The continued expansion was partly achieved through a series of acquisitions of other companies. After almost a century of national and international expansion, the company was taken over by GEC in 1979. Keith Hodgkinson, managing director at the time, completed the turn-around from mechanical to electronic weighing with a complete overhaul of the product range of retail sales of industrial platform scales. In 1993 GEC took over the Dutch-based company Berkel and the Avery-Berkel name was introduced. In 2000 the business was in turn acquired by the US-American company Weigh-Tronix, who already owned Salter, and is today operating as Avery Weigh-Tronix. An item used used by grocers and merchants to weigh store bought goods around the 1950s. This item gives an insight into social history of the time.Weights, metal, silver electroplated, 1 x 2lb, 2 x 4lb, 1 x 7lb. (4) all government stamped, made by Avery Ltd.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, weight, imperial weight, imperial standard weights and measures, imperial standard weight -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Weight Avoirdupois, Avery Ltd, 1940-1950s

A weight made in England by W&T Avery a British manufacturer of weights and weighing machines. The company was founded in the early 18th century and took the name W & T Avery in 1818. The undocumented origin of the company goes back to 1730 when James Ford established the business in the town of Digbeth. On Joseph Balden, the then company’s owner’s death in 1813 William and Thomas Avery took over his scale making business and in 1818 renamed it W & T Avery. The business rapidly expanded and in 1885 they owned three factories: the Atlas Works in West Bromwich, the Mill Lane Works in Birmingham and the Moat Lane Works in Digbeth. In 1891 the business became a limited company with a board of directors and in 1894 the shares were quoted on the London Stock Exchange. In 1895 the company bought the legendary Soho Foundry in Smethwick, a former steam engine factory owned by James Watt & Co. In 1897 the move was complete and the steam engine business was gradually converted to pure manufacture of weighing machines. The turn of the century was marked by managing director William Hipkins who was determined to broadening the renown of the Avery brand and transforming the business into specialist manufacture of weighing machines. By 1914 the company occupied an area of 32,000m² and had some 3000 employees. In the inter-war period, the growth continued with the addition of specialized shops for cast parts, enamel paints and weighbridge assembly and the product range diversified into counting machines, testing machines, automatic packing machines and petrol pumps. During the second world war, the company also produced various types of heavy guns. At that time the site underwent severe damage from parachute mines and incendiary bombs. Then from 1931 to 1973, the company occupied the 18th-century Middlesex Sessions House in Clerkenwell as its headquarters. Changes in weighing machine technology after World War II led to the closure of the foundry, the introduction of electronic weighing with the simultaneous gradual disappearance of purely mechanical devices. The continued expansion was partly achieved through a series of acquisitions of other companies. After almost a century of national and international expansion, the company was taken over by GEC in 1979. Keith Hodgkinson, managing director at the time, completed the turn-around from mechanical to electronic weighing with a complete overhaul of the product range of retail sales of industrial platform scales. In 1993 GEC took over the Dutch-based company Berkel and the Avery-Berkel name was introduced. In 2000 the business was in turn acquired by the US-American company Weigh-Tronix, who already owned Salter, and is today operating as Avery Weigh-Tronix. An item used used by grocers and merchants to weigh store bought goods around the 1950s. This item gives an insight into social history of the time.Weight, brass, Stamped F27, 2lb.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, weight, brass weight -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Auger, Stanley Rule & Level Co, 1922-1935

... Warrnambool great-ocean-road The Stanley Works was founded ...The Stanley Works was founded by Frederick Trent Stanley in 1843, originally a bolt and door hardware manufacturing company located in New Britain, Connecticut, USA. The Stanley Rule and Level Company was founded in 1857 by Henry Stanley in New Britain, Connecticut. In 1920, this company was independent from Trent Stanley's works but they merged with the separate but related Stanley Works, that was founded by Henry Stanley's cousin Frederick Trent Stanley, and continued operating as its hand tools division. At this time after the merger the “Sweetheart” Trademark was adopted for tools made between 1922 to 1935 with augers manufactured during this time having the “AA” trademark and this is when the Stanley company we know today came into being. Around 1937, Stanley acquired the British J. A. Chapman company, a British manufacturer of carpentry tools and other items (including bayonets during World War I) formerly located in Sheffield, from Norman Neill. This helped Stanley to enter the British market.A early tool manufactured by an emerging company that today produces tools for sale in just about every country in the world. The subject items trademark shows the item was produced between 1922-1935 at a time when the company had just merged and was transitioning into Stanley Tools Ltd.Nose bit auger. Similar to shell bit except the nose turned inwards to form a cutting lip. Stamped on shank "AA" trade mark (Stanley Tools)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Auger, Thomas R Ellin, First half of the 20th century

Footprint Tools is a hand tool manufacturer based in Sheffield, England. In 2014 most of their hand tools were still made in Sheffield at the Footprint factory. Footprint Tools can trace its manufacturing history as far back as the 1760s when Alfrid Ridge & Sons was established as a manufacturer of woodworking tools. Ridge was bought by the current owning family in 1932. The Footprint brand originates from 1875 when Thomas R Ellin, a member of a cutlery manufacturing family, started a tool manufacturing business under the brand "Footprint". This subsequently became known as Thomas R Ellin (Footprint Works). This company was bought by the current owning family in 1948 and began to manufacture a range of tools under the Footprint, Domino, Climax, John Bull, and Clinker brands. During World War 2 the divisions of the business were engaged in manufacturing hand tools for British and Commonwealth forces. After the war Footprint continued to grow, manufacture, and expand its range of hand tools for the professional tradesman. In 2008 Footprint moved to a larger factory and invested in new forging equipment, but this process was interrupted by a global recession, and Footprint was unable to generate enough business to cover the cost of the upgrades. In early 2009 the company was forced to liquidate and lay off its staff to pay creditors. The Jewitt family retained the brand and intellectual property, and later that year revived the company under the name Footprint Sheffield and began producing a smaller range of products at first. With the same family of owner-managers, now run by the fourth generation, in 2015 Footprint continues to manufacture most of their products in Sheffield, England, and exports worldwide.This item gives us a look into the history of the beginnings of an early company that made tools in Sheffield England and is still producing tools today.Ring Auger, Double Twist with Lead Screw, bit 1" with round shaft Imprinted 'footprint' trademarkflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bench Saw Vice, Henry Disston & Sons, 1910 -1925

The subject item is a saw blade sharpening clamp that attaches to a bench allowing the operator to sharpen the teeth on a saw with a file while keeping the saw blade in an upright position. Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world the ”Keystone Saw Works” on the Delaware River. Some five years later, Disston built a furnace possibly the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons set the standards for American saw makers, both in terms of producing high-quality saws and developing innovative manufacturing techniques. Disston also started making files in 1865. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets, Disston sought to establish his business away from this cramped area. It took over 25 years to move the entire facility to Tacony. This Philadelphia neighborhood seems to have been the only company town in the United States established within an existing city. At its peak of operations, Disston Saw Works employed 8,000 people and the factory covered 300 acres. The company, known as Henry Disston and Sons, Inc by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's Armour plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A significant American company that pioneered the making of high-quality steel and saws along with other tools and accessories. The subject item is significant as it was made at a time when the company was in its hay day. Adjustable Ball & Socket Saw Sharpening vice, cast iron, with clamp to attach to a workbench. Made by Henry Disston & Co. No 1 painted greyflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, saw clamp, henry disston & sons, saw sharpening, tool accessories, wood saws -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Letter Scale, Philip Jakob, Maul, 1930s

Jakob Maul (1866-1953) founded a metal works factory in 1912 at Zell in Odenwald not far from Frankfurt. He was born the son of a winegrower from the Rheinhessen region of Germany that lies on the left bank of the river Rhine. At the age of 45, he started a metal works factory to produce various types of scales but during the second world war the factory was bombed and production ended. Production for the manufacture of scales resumed in 1948. In 1953 at his death Jakobs son Fritz Scharmann an engineer who had been working with his father since 1923 took over the management of the Maul companies. In 1970 the production responsibilities for Philip J Maul was taken over by Porti Office Equipment who was based in Hamburg. The company has undergone several integrations with subsidiary companies. Today the company has diversified into different areas one of which is manufacturing solar scales. An original postal scale made in Germany before the Second World War and regarded today as a collector's item. It is significant as it is a snapshot into the past and how everyday vintage items were used and interacted within society in the 1930s.Antique German Jacob Maul "Concav" brass postal or letter scale, quadrant type, with pendulum, measuring up to 9ozs. The scale has a level-adjusting screw.The balance is marked "CONCAV" and graduated in imperial ounces to 9 ozflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, scale, quadrant scale, postal weight, 9 oz, philip jakob, maul, scale manufacturer, german industry, weighing instrument, inclination scale -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Chemical Storage Jug, Wilhelm & Marie Wischer, 1895-1920

Wilhelm and Marie Wischer were the founding couple of the successful Wischer phosphate and chemical works at Yarraville, Melbourne. They had emigrated from Magdeburg in Germany in the late 19th century and had undertaken the journey to Australia over three months. During this voyage, several passengers had died and a number of babies had been born. The travellers had endured storms, injuries, broken equipment, and numerous other privations. The couple had lived in the suburb of Hawthorn and their family history is documented in a book by John Wischer. The link is in references this document from "Kainos Books" and makes for fascinating reading as it reveals an account of life in Melbourne during the late 19th and early 20th century. The book also gives an account of the Wischer phosphate mining activities on Ocean Island in 1904, Wischer & Co. eventually merged with Mt. Lyell Chemical works.An item giving a snapshot of early industrial life in Melbourne during the late 19th century with also an interesting story of early migration to Australia. The item also makes us aware of the privations early migrants had in trying to establish a life in a new country and how the Wischer family overcame these challenges to establish a very successful business.Jug, clay large with handle glazed screw on stopper. Sulphur Acid Wischer Chemical Company Yarraville printed on side, also a number 5 on the screw lidflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDish

The maker’s initials on the back of the patter, “A.F. & S.” are one of the marks of Alfred Fenton & Sons (& Co) of Brook Street Works (renamed Century Street in 1950’s), Hanley, Staffordshire, Stoke-on-Trent in the United Kingdom. The partners were Alfred Fenton, James Tunstall Fenton, Arthur Fenton and John Fenton. Other initials used are “A F & Co.” The company operated from 1887 to 1901. According to the London Gazette of January 10, 1899, the Earthenware Manufacturers “Alfred Fenton & Sons“ also had a location in Australia at the corner of Elizabeth Street and 314-316 Bourke Street Melbourne Victoria, and Bond Street, Sydney, and in New Zealand at Manse Street, Dunedin. The maker’s mark also includes the word ‘PRAHRAN’, which is an inner suburb of Melbourne. “Prahran” may have been the name of this particular pattern or even the location chosen in preference to the location ‘Melbourne’. The Melbourne address was purchased from a long established drapery business, Wright and Neil, between 1911-1914 by Sidney Myer. Myer constructed his 1914 building in on this site in Bourke Street. This platter is an example of late 19th or early 20th century dinnerware.Dish; white ceramic rectangular platter with picture in brown ink depicting vegetation (including bamboo and blossoms), flower pot, plates and two oriental persons. Made by Alfred Fenton and Sons 1887-1901.Stamped on back, "PRAHRAN / A.F. & S." surrounded by a buckled belt. Number "14" printed in the clay. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, dish, food perparation, dinnerware, catering, a.f. & s., a fenton and son potters of hanley uk, bourke street melbourne, prahran dinnerwear -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Cherry and Sons, 1890-1920

The subject item is a good example of a large, hand-operated Bentwood box butter churn used to make up to 14 pounds of butter. It was made in Gisborne, Victoria, by the famous manufacturer, E. Cherry, and is known as an Improved Patent No.2 model probably dating from the late 1800s. The Cherry works specialised in making all types of butter churns and equipment for both domestic use on farms and small butter factories during the late nineteenth and early to mid. twentieth centuries. Milk was "separated" to retrieve the cream which was then beaten to make butter. E Cherry began making various models of Cherry butter churns in 1858, Edward Cherry migrated from Herefordshire England to Australia in 1855 with his wife Ann Appleby, nee Davis, and established a joinery workshop at Gisborne, Victoria. He began by making butter churns in his spare time and his product soon became popular allowing him to establish a viable business. A factory was established in 1875 and he started to make churns of all sizes including up to industrial scale. He exported his products to many countries around the world, Edward Cherry died in 1909 and the business was then run by his son George until he died in 1917. E Cherry's other son Thomas (1861-1945) was also involved in the firm maintaining an interest for several years. He had been born in Gisborne and became a senior house medical surgeon at the Melbourne Hospital in 1890. He continued his studies at Kings College London, eventually becoming a renowned bacteriologist and agricultural scientist. A significant giving an snapshot into how early industrial manufacturing became established in Australia.Rectangular manual butter churn, footed wooden box containing an X-shaped wooden interior rack, which is joined to an exterior metal hand crank with turned wood handle, through a hole in the box. Beneath the hand crank is a hole from the interior lined with metal. The lid has a carry handle affixed to the lid on two cross pieces attached to the lid by brass screws.Label in block transfer Manufactured by Cherry & Sons Pty Ltd Gisborne, Victoria Size "00"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, butter churn, cherry and sons, wooden butter churn -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Crucible, The Patent Plumbago Crucible Company, circa 1878

... Battersea Works, Church Road, London SW1, England ...This crucible was raised from the wreck of the LOCH ARD. It is one of six similar relics, in a range of sizes, now in the Flagstaff Hill collection. All bear markings to indicate their manufacture by the Morgan brothers of Battersea, trading as the Patent Plumbago Crucible Co. A crucible is a container used for purifying and melting metals so that they can be cast in a mould to a predetermined shape and use. They must withstand extremely high temperatures, and abrupt cooling, and shed their contents with minimal adherence. The addition of graphite to the traditional firing clays greatly enhanced the durability of industrial crucibles in mid-Victorian Britain, a significant technological advance at a time of great activity in foundries and expansion of demand for refined metals. The Morgans first noticed the advantages of graphite crucibles at the Great Exhibition held in London in 1851. Initially, they contracted to be sole selling agents for the American-made products of Joseph Dixon and Co. from New Jersey, but in 1856 they obtained that firm’s manufacturing rights and began producing their own graphite crucibles from the South London site. The Morgans imported crystalline graphite in 4-5 cwt casks from the British colony of Ceylon (now Sri Lanka) and mixed it with conventional English (Stourbridge) clays to be fired in kilns. Their products were purchased by the Royal Mints in London and India, and exported to official mints in France and Germany. They were successful exhibitors of their crucibles and furnaces at the London Exhibition held in 1861 (Class 1, Mining, quarrying, metallurgy and mineral products, Exhibit 265, Patent Plumbago Crucible Co). The range of sizes represented by the six crucibles retrieved from the LOCH ARD, suggests they may have been part of a sample shipment intended for similar promotion in the Australian colonies ― at Melbourne’s International Exhibition to be held in 1880. The summary of the LOCH ARD cargo manifest, by Don Charlwood in ‘Wrecks and Reputations’, does not mention any crucibles, implying that they were not a large consignment of uniform items. A newspaper account of an 1864 tour of the Morgan brothers’ ‘Black Potteries’ at Battersea indicates: “All the pots were numbered according to their contents, each number standing for one kilogram, or a little over two pounds; a No. 2 crucible contains two kilogrammes; a No. 3, three kilogrammes, and so on.” These numbers are obscured by marine sediment on three of the crucibles in the Flagstaff Hill collection, but those legible on the remaining three are 5, 6, and 8. None of the six is of the same size from a visual appraisal. A brief history of the Loch Ard (1873-1878): - The sailing ship Loch Ard was one of the famous Loch Line of ships that sailed the long voyage from England to Australia. Barclay, Curdle and Co. built the three-masted iron vessel in Glasgow in 1873. It had sailed three trips to Australia and one trip to Calcutta before its fateful voyage. Loch Ard left England on March 2, 1878, under the command of recently married, 29-year-old Captain Gibbs. It was bound for Melbourne with a crew of 37, plus 17 passengers. The general cargo reflected the affluence of Melbourne at the time. Onboard were straw hats, umbrellas, perfumes, clay pipes, pianos, clocks, confectionery, linen and candles, and a heavier load of railway irons, cement, lead and copper. Other cargo included items intended for display in the Melbourne International Exhibition of 1880. The Loch Ard had been sailing for three months and was close to its destination on June 1, 1878. Captain Gibbs had expected to see land at about 3 am but the Loch Ard ran into a fog that greatly reduced visibility and there was no sign of land or the Cape Otway lighthouse. The fog lifted at 4 am and the sheer cliffs of Victoria's west coast were much closer to them than Captain Gibbs expected. He tried to manage the vessel but failed and the ship struck a reef at the base of Mutton Bird Island, near Port Campbell. The top deck loosened from the hull, and the masts and rigging crashed down, knocking passengers and crew overboard. The lifeboat was launched by Tom Pearce but crashed into the side of Loch Ard and capsized. He clung onto its overturned hull and sheltered under it. He drifted out to sea and the tide brought him back to what is now called Loch Ard Gorge. He swam to shore and found a cave for shelter. A passenger, Eva Carmichael, had raced onto the deck to find out what was happening and was confronted by towering cliffs above the ship. She was soon swept off the ship by a huge wave. Eva saw Tom Pearce on a small rocky beach and yelled to attract his attention. He swam out and dragged her to the shelter of the cave. He revived her with a bottle of brandy from a case that had washed up on the beach. Tom scaled a cliff in search of help and followed some horse hoof prints. He came from two men from Glenample Station, three and a half miles away. He told the men of the tragedy and then returned to the gorge while the two men rode back to the station to get help. They reached Loch Ard Gorge and took the two shipwreck survivors to Glenample Station to recover. Eva stayed at the station for six weeks before returning to Ireland by steamship. In Melbourne, Tom Pearce received a hero's welcome and was presented with a medal and some money. Of the 54 crew members and passengers on board, only two survived: the apprentice, Tom Pearce and the young woman passenger, Eva Carmichael, who lost her family in the tragedy. The shipwreck of the LOCH ARD is of State significance ― Victorian Heritage Register S417. Flagstaff Hill’s collection of artefacts from LOCH ARD is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. It is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417). The collection is significant because of the relationship between the objects, as together they have a high potential to interpret the story of the LOCH ARD. The LOCH ARD collection is archaeologically significant as the remains of a large international passenger and cargo ship. The LOCH ARD collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the LOCH ARD, which was one of the worst and best-known shipwrecks in Victoria’s history.A Morgan’s Patent graphite crucible No.8 (i.e. 8kgs capacity), one of a set. It was recovered from the wreck of the LOCH ARD. It is in its original grey colouring with minimal sediment accretion on the top rim. It rises in a slight curve from a flat circular base to a wider rim with a pouring lip. Maker’s marks on the side of the container clearly identify the manufacturer. The maker's details are stamped into the base around and within a circle. A white sticker is attached. Made by the Patent Plumbago Crucible Company at the Battersea Works in London. Number “8”. Letters “MORGAN’S PATENT”. Details on the base "MORGAN'S PATENT" "THE PATENT PLUMBAGO CRUCIBLE COMPANY" Symbol [8] above "BATTERSEA WORKS LONDON" Handwritten on a white sticker in black pen "LA/89"flagstaff hill, warrnambool, maritime museum, shipwreck coast, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, graphite crucible, plumbago crucible, morgans crucible company, flagstaff hill maritime museum and village, fluxing pots, crucible, morgan’s patent, morgan brothers, patent plumbago crucible co, battersea works, london, port campbell -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Crucible, The Patent Plumbago Crucible Company, circa 1878