Showing 226 items matching " sealing"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBottle Corker, late 1800's to early 1900's

This hand held, wooden bottle corker would have been used by soft drink or wine producers to insert corks into their bottles to seal the drink inside. It seems it may have had a metal tip on the end of the plunger, as do other similar bottle corkers, because this plunger has a compressed end and a ring shape impressed into the wood a little way up from the tip. How to use the bottle corker … - soak a long, bullet shaped cork in water to soften it - place the bottle corker over the bottle’s neck - insert the cork through the side opening and place onto the metal funnel - push the plunger down onto the cork, forcing it into the tapered, which will squeeze the cork to size as it enters the bottle. Use a mallet or hammer if necessary The design of this bottle corker is very similar to “"Redlich's Apparatus for Corking Bottles", which was invented and patented by Henry Redlich of Chicago, USA, in 1862, US patent #35,325. H. Redlich’s gave the following instructions for the use of the bottle corker: “DIRECTIONS: SOAK THE CORK, DROP INTO THE OPENING AND TAP THE PLUNGER WITH A MALLET OR HAMMER.” This hand held, wooden bottle corker would have been used by soft drink or wine producers to insert corks into their bottles to seal the drink inside. It seems it may have had a metal tip on the end of the plunger, as do other similar bottle corkers, because this plunger has a compressed end and a ring shape impressed into the wood a little way up from the tip. How to use the bottle corker … - soak a long, bullet shaped cork in water to soften it - place the bottle corker over the bottle’s neck - insert the cork through the side opening and place onto the metal funnel - push the plunger down onto the cork, forcing it into the tapered, which will squeeze the cork to size as it enters the bottle. Use a mallet or hammer if necessary The design of this bottle corker is very similar to “"Redlich's Apparatus for Corking Bottles", which was invented and patented by Henry Redlich of Chicago, USA, in 1862, US patent #35,325. H. Redlich’s gave the following instructions for the use of the bottle corker: “DIRECTIONS: SOAK THE CORK, DROP INTO THE OPENING AND TAP THE PLUNGER WITH A MALLET OR HAMMER.” Bottle corker, a hand operated wooden corking device for sealing bottles. Bottle corker has two parts comprising a wooden plunger rod with knob handle, and wooden cylinder containing a metal tube that is flared to a funnel shape on the top. The cylinder has a hole the diameter of the rod at both ends and an oval insertion slot in one side. The tip of the plunger rod is slightly compressed and it has an indented line around the circumference as though it has had something attached to it. Manufactured in the late 1899s to early 1900s in Melbourne.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cork -

Phillip Island and District Historical Society Inc.

Phillip Island and District Historical Society Inc.Photograph, Summerland Estate advertising and early Sealers settlement photos

Photos from brochure called "Ideal Summerland on the Nobbies, Phillip Island." Phillip Island Holiday Developments, c. 1927, promoting a new subdivision. Sealing photos are 'Habitation de Pecheurs de Phoques au Port Western' and 'Vue prise au Port Western dans la crique des Mangliers' by Louis Auguste de Sainson. They are plates from the Atlas Historique of J S C Dumont D"Urville's Astrolabe voyage of 1826. Habitation photo is believed to be the first view of Victoria.HistoricalA DVD containing digital images of the 4 photos. Also 4 large, high quality, glossy coloured photos.summerland estate, sealers, early phillip island settlers, explorers phillip island, dvd -

Falls Creek Historical Society

Falls Creek Historical SocietyDocument - Circular - To Lessees and Licensees

Bob (Herman) Hymans (a former member of the Royal Netherlands Navy) was born in Bloemendaal, Holland on 30th September 1922. During World War II he fought against the Japanese in the Dutch East Indies (now Indonesia) and was imprisoned in Changi and on the Burma Railway. After gaining qualifications as a Ski Instructor, Bob arrived in Falls Creek in July 1950. Working as an Instructor and Supervisor at Bogong Lodge, Bob decided his future was in accommodation. He was successful in negotiating an indenture for land from the State Electricity Commission (SEC). It took Bob two years to build his Grand Coeur Chalet but, tragically, it was burned down in August 1961. Bob also built the first Chairlift in Australia. This was a single chairlift and the structure was built from wooden electricity poles. He was constantly full of new ideas and proposals for the village. Bob Hymans died on 7th July 2007. This Collection of documents and letters tells the story of Bob's endeavours to develop Falls Creek into the ski village it is today.This item is significant because it documents actions taken by the Falls Creek Tourist Area Management Committee in their role overseeing the Tourist Area.A circular from the Management Committee summarising the 1970 season and plans for future development. This included further plans for slope improvements and medical services in Fall Creek Reference is also made to the need for positive public relations. Developments planned for the ski tows were outlined. Prices for lifts and tows for the 1971 season were included. Information for a clean up and oversnow transport were mentioned. Extension of the Village and internal improvements also necessitated sealing of roads. The predicted cost for this was $200,000. A full list of Committee Members finished off the circular.falls creek tourist area management committee, falls creek administration, bob hymans -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle - Ginger Beer, early to late 1900's

This glass ginger beer bottle was manufactured and used early to late 1900's, until the time that cheaper containers were invented(plastic bottles). This bottle was so constructed to be easily moved within the ginger beer processing plants from the brewing vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1990s the bottle slowly became phased out of production however boutique suppliers still preferred thick glass to contain any explosive action. Two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. were the main suppliers for the Victorian State. In the period when this bottle was manufactured and used the major ginger beer brewing plants for the whole of Victoria were located in Melbourne because this was where its greatest consumer base was there and most rural areas were supplied by domestic sources (mother brewing ginger beer for the children). The Kiewa Valley and its region was one rural area which until road invrastructure was enhance covered the ginger beer thirst by local family production. As the population expanded considerably in the late 1940's (SECV Hydro Scheme) with a greater demand for "soft" drinks" being established supplies from larger towns and cities were call for. Each bottle was "branded" during manufacturing to show the contents were from a reputable supplier (H Taylor) and where it originated from. These bottles were recyled by the manufacturer as a way to cut production costs. This method of recycling the bottles back to the specific manufacturer has (except for South Australia)been overtaken by a no cost recycling collection by councils (funded by their communities). This method by passes the user cost principle as the bottles are processed as non generic. The uneconomical "on cost" which was replaced by the "throw away" less costly plastic containers however did not provide the keen domestic brewer of the "beer" with a reusable bottle. This heavy gauged glass ginger beer bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the filling production line. The method of pouring ginger beer into the bottle has been part of the "production line". This bottle has a one and a half pint capacity and is made from "light green" coloured glass(a protection against light penetration). This thick glass bottle, to contain ginger beer, required its thickness because of the extensive handling (man and machine) before final consumption. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck. Ginger beer was a "soft drink" of great demand. On the middle portion of this bottle is a large elongated circle within it and following the spherical line is "H. TAYLOR" ans a star separates this from "MELBOURNE" rounding out the bottom curviture. Within these words are the large initials "T H" . The "T" superimposed onto the "H". On the base and covering the whole bottom is the letter "T". At the opposite side to the manufacturers logo is "THIS BOTTLE CANNOT BE SOLD OR USED BY ANY OTHER PERSON & IS NOT COMPLETE WITHOUT STOPPER" glass bottle, non alcoholic drink, taylor ginger beer bottle, reuseable bottles -

Tennis Australia

Tennis AustraliaRacquet, Circa 1952

A Wright & Ditson 'Mercer Beasley Signature Model' tennis racquet. Lower head painted white, throat painted black. Leather and braiding reinforcements around shoulders and around base of throat. Racquet model name, manufacturer name and words 'FIBRE/SEALED/THROAT' printed across throat on obverse and reverse. Manufacturer trademark printed on shaft on reverse and obverse. Handle spiral-wrapped with leather grip, with plastic tape sealing top of grip. Leather end wrap. White butt cloth featuring manufacturer initials. Materials: Wood, Metal, Lacquer, Glue, Ink, Leather, Nylon, String, Plastic, Painttennis -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Ginger Beer, circa mid to late 1900's

This glass ginger beer bottle was manufactured and used early to late 1900's, until the time that cheaper containers were invented(plastic bottles). This bottle was so constructed to be easily moved within the ginger beer processing plants from the brewing vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1990s the bottle slowly became phased out of production however boutique suppliers still preferred thick glass to contain any explosive action. Two major glass bottle works companies, e.g. Australian Glass Manufacturers and the Melbourne Glass Bottle Works Co. were the main suppliers for the Victorian State.In the period when this bottle was manufactured and used the major ginger beer brewing plants for the whole of Victoria were located in Melbourne because this was where its greatest consumer base was there and most rural areas were supplied by domestic sources (mother brewing ginger beer for the children). The Kiewa Valley and its region was one rural area which until road invrastructure was enhance covered the ginger beer thirst by local family production. As the population expanded considerably in the late 1940's (SECV Hydro Scheme) with a greater demand for "soft" drinks" being established supplies from larger towns and cities were call for. Each bottle was "branded" during manufacturing to show the contents were from a reputable supplier (PHIBBS Bros) and where it originated from. These bottles were recycled by the manufacturer as a way to cut production costs. This method of recycling the bottles back to the specific manufacturer has (except for South Australia)been overtaken by a no cost recycling collection by councils (funded by their communities). This method by passes the user cost principle as the bottles are processed as non generic. The uneconomical "on cost" which was replaced by the "throw away" less costly plastic containers however did not provide the keen domestic brewer of the "beer" with a reusable bottle.This heavy gauged glass bottle (Ginger Beer) has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the production line. The method of pouring ginger beer into the bottle has been part of the "production line" process of automation. This bottle has a capacity to hold 250ml of ginger beer and is made from "clear" glass. The marority of ginger beer bottles produced in this time frame where made with a "green" tint in them.This tinting helped reduce the sunlight effecting the contentsAround the bottom side of the bottle and blown into the glass is "THIS BOTTLE IS THE PROPERTY OF PHIBBS BROS, ALBURY" above this, in "running script" and sloping up from left to right is "Phibbs Bros" and underneath parallel to it "ALBURY". On the base of the bottle is molded a big "L 289" underneath this "M" and below this "AGM".ginger beer bottle, soft drink bottles, cordial bottles -

Orbost & District Historical Society

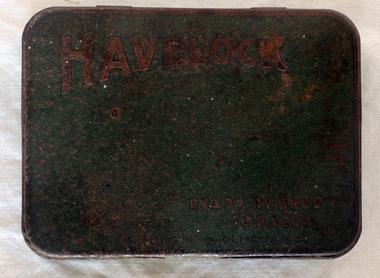

Orbost & District Historical Societytin, Mid to late 1900s

The British Australasian Tobacco Co. was based in Melbourne and Sydney. The parent company was founded in England, circa 1902. This item "HAVELOCK" is one of many ready rubbed tobacco tins produced by the British Australasian Tobacco Company.The ready rubbed tobacco held within the tin was mainly used by those smokers who rolled their own cigarettes. These smokers would have mainly used their palm and formed a cup then placing their choice of the amount of tobacco to be rolled. This would then be placed on the fine cigarette paper and rolled and sealed (using saliva in the mouth) into the required shape. There were mechanical "roll your own" gadgets on the market but most rural users, especially males used their palms. (Ref Victorian Collections)Roll your own cigarettes were popularly used in rural areas, especially when "tailor made" cigarettes were more expensive. Tobacco consumption in Australia is decreasing and fewer smokers are "rolling their own" cigarettes.A dark green rectangular shaped metal Havelock tobacco tin with a weave pattern. It is made from tin plated thin rolled steel. The lid is attached by two hinges.Lid - top left in gold coloured letters "HAVELOCK". bottom -"READY RUBBED TOBACCO" "2oz NET WEIGHT WHEN PACKED". Rim - "THE BRITISH AUSTRALASIAN TOBACCO CO. PTY. LTD." Inside lid -black print on gold background - "Every tin of genuine HAVELOCK Ready Rubbed Tobacco has the mane Havelock printed on the paper lining, and also on the band or wrapping sealing the tin. On the hinge side of the lid is "HAVELOCK READY RUBBED"tobacco cigarettes tin -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Document - Thomas Coffey Letters of Administration 1898, 1899

Tait collection: item 17 of 62 These are the Letters of Administration for Thomas Coffey who died intestate in February 1898. He was formerly a settler from Corowa, New South Wales and latterly from Warrnambool and Colac. His real estate valued at £20 and his personal estate valued at £746 was granted to his widow, Margaret Coffey of Kirkstall. Thomas Coffey died in Colac at the age of 64 but no other information on him has been found.This document is of minor interest, being the Letters of Administration following the death of Thomas Coffey. He may have lived in Warrnambool for some time in the latter part of the 19th century. The document has been in the possession of Ernest Chambers, a lawyer with offices in Warrnambool, Port Fairy and Koroit at the end of the 19th century and the beginning of the 20th century. The document has then been stored in the Kepler Street offices of successive law firms until it was located in the premises previously occupied by the firm of Mackay Taylor.This 1898-1899 document consists of three pages of parchment paper tied together with thin green cord and cropped at the top and bottom left hand corners of the document. There are two seals attached, one with red sealing wax from the Supreme Court of New South Wales and the other attached with green ribbon from the Supreme Court of the Colony of Victoria. The document material is handwritten in black ink. There are six stamps – three from New South Wales, one from Geelong and two are indecipherable. The document also has a blue stamp duty label attached (New South Wales, one per cent stamp duty). The document is in fair condition with one page with the writing fading and difficult to read. letters of administration, thomas coffey, tait collection -

Bendigo Historical Society Inc.

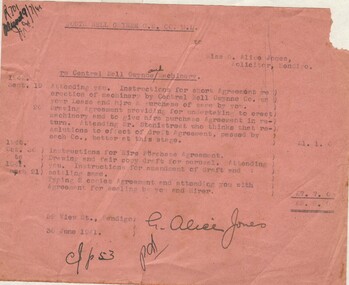

Bendigo Historical Society Inc.Document - MISS G ALICE JONES COLLECTION: ACCOUNT

Pink paper, South Nell Gwynne G.M. Co. N.L. to Miss G. Alice Jones re Central Nell Gwynne and Machinery dated Sep. 19 and 20 1940, Oct 30, 1940, to March 21, 1940, and 30 June 1941. Account is for instructions for short Agreement re erection of machinery by Central Nell Gwynne Co. on your lease and hire & purchase of same by you. Cost £1. 1. 0. Also, instructions drawing of Hire Purchase Agreement and amendment of draft and settling same and typing 2 copies and attending with Agreement for sealing by you and Hirer. Cost £7.7.0, Total £8.8.0. Pd. Written at the end. R701 Delivered 9/7/41 written in the top left corner.the miss g.alice jones collection - account, south nell gwynne g.m. n.l., central nell gwynne co., mr stanistreet -

Orbost & District Historical Society

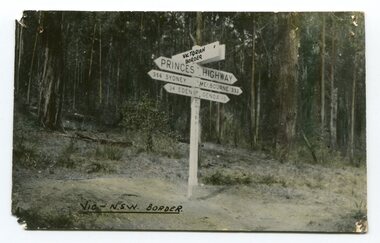

Orbost & District Historical Societyblack and white photograph, first half 20th century

Prior to the sealing of the Princes Highway west of Orbost, the road surface was anything but good, even by C1917 when cars started to use the road. From Orbost the old road via Marlo to Sydenham was abandoned for the new location which traversed more rugged country via Cabbage Tree, Bell Bird and Club Terrace to Cann River, and the reason for this diversion was on account of settlements being established at Murrungowar and Club Terrace, at which latter place there was a temporary rush to obtain gold. This road was constructed by the Public Works department and a maximum grade of 1 in 19 was adopted, and as speed was not to be catered for the grade followed in and out round the spurs and gullies, resulting in a maze of turns and twists which required a good deal of skill on the part of the horse driver to negotiate." - Bairnsdale Advertiser, Friday, May 2, 1947. (More information from Newsletter February 2010)This is a pictorial record of an early road distance sign on a major highway through East Gippsland. The distances are indicated in miles, a measurement standard no longer in use.A black / white photograph postcard of the signpost at the Victorian - New South Wales border. It shows distances to Sydney and Eden on one arrow and distances to Melbourne and Genoa on another. on front - Vic - NSW Borderprinces-highway-east-gippsland road-transport road-sign -

Orbost & District Historical Society

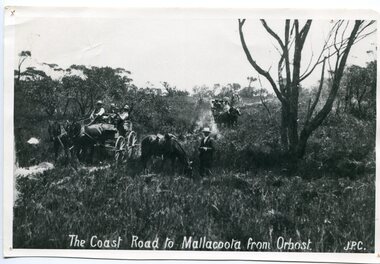

Orbost & District Historical Societyblack and white photograph, late 19th century - early 20th century

Prior to the sealing of the Princes Highway west of Orbost, the road surface was anything but good, even by C1917 when cars started to use the road. From Orbost the old road via Marlo to Sydenham was abandoned for the new location which traversed more rugged country via Cabbage Tree, Bell Bird and Club Terrace to Cann River, and the reason for this diversion was on account of settlements being established at Murrungowar and Club Terrace, at which latter place there was a temporary rush to obtain gold. This road was constructed by the Public Works department and a maximum grade of 1 in 19 was adopted, and as speed was not to be catered for the grade followed in and out round the spurs and gullies, resulting in a maze of turns and twists which required a good deal of skill on the part of the horse driver to negotiate." - Bairnsdale Advertiser, Friday, May 2, 1947. (More information from Newsletter February 2010)n the late 1800's early 1900's transporting goods by road was difficult and at times impossible because roads as thoroughfares did not exist.The means of travelling along the roads in the 1800's was by bullock wagon, horse pulled dray, pack horse or simply by foot. This road is still in use in East Gippsland as a part of many four-wheel-drive touring routes.A large black / white photograph of two horse - drawn wagons on a narrow sandy bush track. It is surrounded by scrub. There is one man standing beside a horse not harnessed to a wagon.on front - "The Coast Road to Mallacoota from Orbost JPC" -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPlan - Plans and photographs, Burnley Low Energy Greenhouse, c. 2008

Laminated plans for greenhouse (1) Burnley Low Energy Greenhouse, (2) Solar Boosted Heat Pump - Greenhouse Bench Heating System. C photographs pasted on cardboard and labelled (3) Loading 20 mm gravel into Rock pile. (4) Reinforcement at Bottom Gravel level. (5) Sealing the Top of the Rock pile. (6) Top of Rock pile Before A-Frame Construction. (7) Corner Detail of Portal Frame. (8) Glazing Frames for Solar Panels. (9) Structure Partially Clad, with Solar Panel Supports at Rear. (10) Back of Solar Panels in Place. Laminated C photographs pasted on cardboard and labelled. (11) Burnley Low Energy Greenhouse. (12) Greenhouse Covering Materials Burnley. Pamphlet (13) Burnley College Institute of Land and Food Resources (slightly damaged)burnley, greenhouse, solar energy, construction, pamphlet -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPlan - Colour prints, Burnley Low Energy Greenhouse, c. 2008

Laminated plans for greenhouse (1) Burnley Low Energy Greenhouse, (2) Solar Boosted Heat Pump-Greenhouse Bench heating System. Photographs pasted on cardboard and labelled (3) Loading 20mm gravel into Rockpile. (4) Reinforcement at Bottom Gravel level. (5) Sealing the Top of the Rockpile. (6) Top of Rock pile Before A-Frame Construction. (7) Corner Detail of Portal Frame. (8) Glazing Frames for Solar Panels. (9) Structure Partially Clad, with Solar Panel Supports at Rear. (10) Back of Solar Panels in Place. Laminated photographs pated on cardboard and labelled. (11) Burnley Low Energy Greenhouse. (12) Greenhouse Covering Materials Burnley. Panphlet (13) Burnley College Institute of Land and Food Resources (slightly damaged)greenhouse, burnley, low energy greenhouse, solar boosted heat pump, greenhouses, bench heating system, rockpile -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTin Tobacco, Mid to late 1900s

The British Australasian Tobacco Co. (based in Melbourne and Sydney. The parent company was founded in England, circa 1902). This item "HAVELOCK" is one of many ready rubbed tobacco tins produced by the British Australasian Tobacco Company.The ready rubbed tobacco held within the tin was mainly used by those smokers who rolled their own cigarettes. These smokers would have mainly used their palm and formed a cup then placing their choice of the amount of tobacco to be rolled. This would then be placed on the fine cigarette paper and rolled and sealed (using saliva in the mouth) into the required shape. There were mechanical "roll you own" gadgets on the market but most rural users, especially males used their palms. The quantity of tobacco used to make up the cigarette was up to the individual user. The thinner that the cigarette was rolled the longer and more economical did the supply last. The by -products of this method were nicotine stained fingers and hands. "Chain" smokers were easily identified and could therefore be discriminated against obtaining smoke sensitive employment. The two world wars (1914-18 and1939-45) produced a significant rise in the consumption of cigarette use by men and the eventual overflow to women. Cigarette smoking before the 1900s was seen as rough and uncouth (socially frowned upon), however after the introduction of overseas films (U.K. and U.S.A.) and film stars presenting smoking as socially acceptable, the rise of smoking cigarettes, especially roll you own (American western movies) in rural areas was an accepted way of life. Things however started to change in the mid 1900s when medical evidence pointed to the health problems of regular smokers. Governments were now implementing non smoking education material. Restrictions on where and when smoking was permitted and acceptable started to creep into all areas of society whether city or rural. This was the era that highlighted the use of roll your own cigarettes, especially when the costs of "tailor made" cigarettes were taxed at an increasing amount. Roll your own cigarettes also provided an avenue for the consumption of illicit drug use.The significance of this ready rubbed tobacco tin to this rural region is, stems from how much influence that the Western novels and overseas films (portraying rural lifestyles) played in shaping the rural social and working mores of the Kiewa Valley. The post war depression (financially) resulted in more smokers turning away from expensive machine (tailor) made cigarettes to the roll your own, using ready rubbed tobacco. This tobacco tin relays a long ago era, when personal contact, and not something that has been written down by some "unknown", was valued as the true appraisal of a member of the community. This was especially relevant in a small regional area such as the Kiewa Valley. Although social networking was not as fast then as the internet provides now, appearances, manners, fashion and etiquette with first impressions high on the order of evaluating someone in the community. Pointer such as the brand of tobacco smoked was part of the rural assessment method. Up until the demise of the Australian Tobacco Industry, circa 2004, the Kiewa Valley and surrounding district was part of a vibrant producer of tobacco leaves. The remnants of this industry still remain today but the drying sheds (for tobacco leaves) are now used to store hay for the valley's dairy and beef cattle industries.This tobacco tin is constructed from tin plated thin rolled steel. The lid is attached by two pressed and formed (from the main frame) hinges using the nip and tuck construction method.The lid and outside frame have had a green "weave" pattern anodised to the metal.On the outside of the lid and at the top left is stamped, in gold coloured letters "HAVELOCK". The bottom of the lid is stamped (in smaller script) "READY RUBBED TOBACCO" and below this in smaller lettering "2oz NET WEIGHT WHEN PACKED". On the rim of the lid is "THE BRITISH AUSTRALASIAN TOBACCO CO. PTY. LTD." Inside of the lid and stamped in black print on a gold anodised lid is "Every tin of genuine HAVELOCK Ready Rubbed Tobacco has the mane Havelock printed on the paper lining, and also on the band or wrapping sealing the tin. On the hinge side of the lid is "HAVELOCK READY RUBBED"roll your own, cigarette tins, smoking accessories, personal effects, tobacco containers -

Orbost & District Historical Society

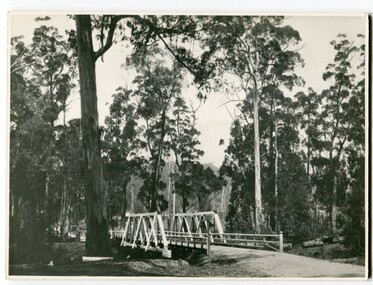

Orbost & District Historical Societyblack and white photograph, 1918

Tonghi Creek is 66km north - west of Orbost. Prior to the sealing of the Princes Highway west of Orbost, the road surface was anything but good, even by C1917 when cars started to use the road. From Orbost the old road via Marlo to Sydenham was abandoned for the new location which traversed more rugged country via Cabbage Tree, Bell Bird and Club Terrace to Cann River, and the reason for this diversion was on account of settlements being established at Murrungowar and Club Terrace, at which latter place there was a temporary rush to obtain gold. This road was constructed by the Public Works department and a maximum grade of 1 in 19 was adopted, and as speed was not to be catered for the grade followed in and out round the spurs and gullies, resulting in a maze of turns and twists which required a good deal of skill on the part of the horse driver to negotiate." - Bairnsdale Advertiser, Friday, May 2, 1947. (More information from Newsletter February 2010)This item is a pictorial record of roads in the early 20th century in East Gippsland.A large black / white photograph of a bridge over a small creek, surrounded by bush. The photograph is mounted on a thick cream coloured card.on back - "Bridge at Tonghi Creek 1918"tonghi-creek-bridge country-roads-east-gippsland -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Terminus Hotel footpath inlay

During the depression of the early 1930s, men on the dole carried out work for the Wodonga Shire Council. One of the projects during the term of councillor Mick Martin, as shire president, was to seal the footpaths in central Wodonga. Local business people supplied the cement. The police department refused to fund the cement for its section of High Street, north of the railway line, which included the police station and the courthouse. The then licensee of the Terminus Hotel offered to provide the cement for sealing the footpath in front of the police station and courthouse. This offer was made on the condition that tiles bearing the words Terminus Hotel be inserted into the footpath pointing toward the hotel.The police objected but the hotel licensee, Tex Bailey, won the day. As a result, his hotel’s tiled name was inserted into the footpath in front of the police station. Cr Mick Martin’s son, Des, wrote to the council in 1967 asking that the sign be preserved and it was moved to the Terminus Hotel and placed in the footpath there.The Terminus Hotel was one of the earliest hotels in Wodonga with clear links to the establishment of the railway line. It was an important business and meeting place for social gatherings.The name, Terminus Hotel worked into the brickwork of the footpath when they were surfaced by sustenance workers during the 1930s Depression. "TERMINUS HOTEL"hotels wodonga, businesses wodonga, terminus hotel wodonga -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWeapon - Harpoon, Early to mid 19th Century

A harpoon is a long spear-like instrument used in fishing, whaling, sealing and other marine hunting to catch large fish or marine mammals such as whales. It accomplishes this task by impaling the target animal and securing it with barb or toggling claws, allowing the fishermen to use a rope or chain attached to the projectile to catch the animal. The earliest known harpoons, have been recorded as having been made and used 90,000 years ago. In the early whaling industry the two flue harpoon was the primary weapon used around the world. This two fluke harpoon tended to penetrate no deeper than the soft outer layer of a whales blubber. Thus it was often possible for the whale to escape by struggling or swimming away forcefully enough to pull the shallowly embedded barbs out backwards. This flaw was corrected in the early nineteenth century with the creation of the one fluke harpoon. By removing one of the flukes, the head of the harpoon was narrowed, making it easier for it to penetrate deep enough to hold fast. In the Arctic, the indigenous people used the more advanced toggling harpoon design and by the mid-19th century, the toggling harpoon was adapted by Lewis Temple, using iron. The Temple toggle was widely used, and quickly came to dominate the whaling industry around the world.A hand forged harpoon demonstrating the blacksmiths art for fashioning an item used during the early 19th century in the significant industry of whaling. Used during a time when the world depended on the natural resources derived from whales, oil for lighting, lubrication, margarine, candles, soaps and cosmetics as well as the use of the whales bones for various other items such as corsets, umbrellas,fertiliser and animal feed. The item is significant as it was probably made between 1820-1850 after which a single fluke and toggle harpoon began to be use extensively in the whaling industry. Also coming in to general use was a black powder gun to fire the harpoon rather than the early type that had to be manually thrown by a mariner from a row boat of which the subject item is an example.Hand forged double fluke steel whaling harpoon with an arrowhead tip atop a square shank that tapers to a narrow round shaft with a split metal cone to accommodate a wooden harpoon pole.Noneharpoon, whaling, whaling harpoon, fishing industry, whales, flukes, lewis temple, marine technology, flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, early 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them.Around the bottom side of the bottle and blown into the glass "ONE PINT" and on the opposite side "MILK". Below these markings is "This BOTTLE BELONGS TO MILK BOTTLES RECOVERY LTD" below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION. On the base of the bottle is molded a big "M". An identification mark of "90" over "9" is beneath the "M". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles, milk, dairy, farms, kiewa valley -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid 1800's (1834 Victorian dairy industry was founded) to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the large volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36"This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against sunlight penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it 6/33 and next to this "ONE PINT" and under this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, circa mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head was manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle which contained milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "3"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/36" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "15" glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded), until the time that cheaper containers were invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle, to contain milk, required its thickness because of the extensive handling (man and machine) before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle is a circle within it "6/35" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "20"milk, dairy, glass bottle -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a half pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them and this tint was to protect the contents from sun damage. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the top half of this bottle is "MILK" and opposite "HALF PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base is "2 M" underneath this "8/11" and underneath is "ISM -169"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, Circa mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This particular one has "7/14".This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one Imperial pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them. Around the bottom side of the bottle and blown into the glass "ONE IMPERIAL PINT". Below these markings and stenciled is "KIEWA" (in freehand style and underlined) underneath is "PASTEURISED FULL CREAM MILK" underneath this ,in freehand stiyle is "USE" next to this in block style "KIEWA BUTTER, CREAM, AND ICE CREAM MIX" to the left of this ,and barely readable is stenciled "THIS BOTTLE ALWAYS REMAINS/ THE PROPERTY OF/ NORTH EASTERN DAIRY Co. Ltd". On the base of the bottle is molded a big "2". with a smaller "m". An identification mark of "7" over "14" is within a circled boundary. Below this is moulded "RM - 15". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking iron, Mid-to-late 20th century

Caulking is the use of cork or other substances to seal the seams and joints of the vessel to make them watertight. Caulking lasts for quite some time but eventually dries out and needs to be replaced. A hammer is often used with a caulking iron to drive it along the seams. The caulking iron’s blade is tapered to be narrower at the tip to make it easier to remove it from the joint. The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings. You can see Laurie’s inscription on the tool called a ‘bevel’. Laurie worked for Ports and Harbours, Melbourne, for over 50 years, beginning in the early 1960s. He and a fellow shipwright inscribed their names on a wheelhouse they built in 1965; the inscription was discovered many decades later during a repair of the plumbing. Many decades later Laurie worked on the Yarra moving barges up and down the river and was fondly given the title ‘Riverboat Man’ His interest in maritime history led him to volunteer with the Maritime Trust of Australia’s project to restore and preserve the historic WWII 1942 Corvette, the minesweeper HMAS Castlemaine, which is a sister ship to the HMAS Warrnambool J202. Laurie Dilks donated two handmade displays of some of his tools in the late 1970s to early-1980s. The varnished timber boards displayed the tools below together with brass plaques. During the upgrade of the Great Circle Gallery Laurie’s tools were transferred to the new display you see there today. He also donated tools to Queenscliffe Maritime Museum and Clunes Museum.The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright at Ports and Harbours in Melbourne in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings.Caulking iron, or broad chisel, wooden handle with reinforcing on the ends, metal shaft that tapers down from the handle to the end of the blade. It has an inscription. It once belonged to shipwright Laurie Dinks.Stamped into metal " - - WARD /(image of crossed swords) WEFT / WARRANTED"flagstaff hill, warrnambool, great ocean road, shipwreck coast, maritime museum, maritime village, shipwright, carpenter, shipbuilding, ship repairs, hand tool, equipment, ship maintenance, cooper, tool, marine technology, caulking iron, jerry iron, broad chisel, caulking, sealing, laurie dilks, l dilks, port and harbours melbourne -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBox, cardboard, 1892 - present in Australia

TROVE : Bendigo Advertiser (Vic. : 1855 - 1918), Saturday 7 September 1901, page 2 BONNINGTON'S IRISH MOSS. Bonnington's Carrageen Irish Moss was first introduced into New Zealand 35 years ago, and it spread gradually until the sales now extend through the whole colony, and has been in constant demand ever since. Through the genuine merits of the widely known and popular remedy for coughs, colds, etc., and encouraged by this success in New Zealand, the proprietor (Mr. Geo. Bonnington) chemist of that colony, was induced to place his celebrated preparation on the Australian market. With that object in view, some eight or ten years ago, a factory for manufacturing purposes was established (under the style of Bonnington and Co.) at 179 Harris-street, Sydney. Since then, its sales have spread far and wide, and the proprietors are pleased to notify the public generally that Bonnington's Carrageen Irish Moss can now be obtained in all the states of Australia. Every year it is becoming more known, and when once tried is always appreciated by the people. Hundreds of testimonials have been received by the proprietors from all parts, testifying to the wonderful curative properties in allaying irritating coughs, bronchitis, colds, and affections of the vocal organs. For the cure of croup, whooping cough, etc., it has proved marvellously successful and is especially prized by mothers for their children, as it never fails to give relief and effect a speedy cure. Containing nothing injurious, there is not the least danger in giving it to children. If they are troubled at night with a hacking cough or any chest affection, one dose will relieve and ensure a good night's rest. The unparalleled which has attended the sale of Bonnington's Carrageen Irish Moss has led to many worthless imitations, and the public when purchasing are cautioned to be sure and ask for Bonnington's. TROVE : Gippsland Times (Vic. : 1861 - 1954), Thursday 1 October 1908, page 3 BONNINGTON'S IRISH MOSS Can be had from any chemist or store. It is the universal remedy for Influenza, Coughs and Colds. A safe and pleasant medicine for children as well as adults. Brown cardboard box with dark blue printed text on side and pink label with black text on top. Contains seven (7) unopened and one (1) opened tall grey boxes with printed white red and black labels. Each grey box containing a cork stoppered rectangular amber glass bottle, with a red, black and white printed label. Each bottle filled with a dark liquid.Outer square cardboard box in dark blue printed text within a decorative border : ' ONE DOZEN BONNINGTON'S Irish Moss for CUGHS, COLDS, INFLUENZA etc'. Pink label sealing paper on top of outer brown cardboard box with black printed text : 'BONNINGTON'S IRISH MOSS PRICES:- No.1 size 36/6 doz. No. 2 size 56/- doz. Retail Price :- Small size 3/6 Large size 6/3. IN QUANTITY Individual packaging boxes containing bottles : Paper labels on each bottle : Embossed on side of bottles in recessed cartouche ' BONNINGTON'S IRISH MOSS COUGHS & COLDS'. Embossed on base of bottles AGM logo and 'IS 804' (4 inverted) over '6'. croup, carrageen, coughs, influenza -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Colour, Jarrod Watt, A thousand protestors surround Hong Kong's main police headquarters on Arsenal Street in Wan Chai on June 26th 2019, 21/06/2019

Carrie Lam, Hong Kong’s chief executive, had plenty of political support in the territory’s pro-Beijing legislature to pass a bill that would allow extraditions to mainland China. The legislators were set to begin discussing the bill in early June, and intended to vote on it just weeks later. A series of protests took place, and after a June 16 protest saw the largest turnout yet, Ms. Lam made a major concession: She postponed the bill, at least temporarily. It was an undeniable victory for the protesters — but it did little to quell the unrest. Since the bill could later be reintroduced, protesters felt they remained in danger. The police tactics to break up the demonstrations on June 12, including the use of more than 150 tear gas canisters to push protesters far away from the government office, created a new set of demands from the protesters. Now, instead of just calling for the withdrawal of the bill and Ms. Lam’s resignation, they said they wouldn’t be content unless there was an independent investigation of officers’ conduct. They also wanted the release of protesters arrested on June 12, and for the government to rescind its description of the demonstrations as a “riot,” a designation that carries legal significance. None of that has happened. Many analysts say Ms. Lam is unlikely to step down, nor would Beijing accept her resignation if she offered it. She has more wiggle room on the other demands, but has not indicated any willingness to budge. The Hong Kong Protests are a leaderless, digital movement.There is no single leader or group deciding on or steering the strategy, tactics and goals of the movement. Instead, protesters have used forums and messaging apps to decide next steps. Anyone can suggest a course of action, and others then vote on whether they support it. The most popular ideas rise to the top, and then people rally to make them happen. At its best, this structure has empowered many people to participate and have their voices heard. Protesters say it keeps them all safe by not allowing the government to target specific leaders. Their success in halting the extradition bill, which was shelved by the territory’s chief executive, speaks to the movement’s power. Despite the lack of a clear leader, protesters have shown extensive coordination at the demonstrations, having planned the specifics online beforehand. Supply stations are set up to distribute water, snacks, gloves, umbrellas and shields made of cardboard. Volunteer first aid workers wear brightly colored vests. People form assembly lines to pass supplies across long distances, with protesters communicating what they need through a series of predetermined hand signals. Anyone walking in dangerous areas without a helmet or a mask is quickly offered one. No individual can speak on behalf of the protesters, which makes negotiations difficult, if not impossible. (https://www.nytimes.com/2019/07/02/world/asia/hong-kong-protest-explained.html, accessed 07/07/2019) Hong Kong’s amended extradition law would allow the extradition of suspects to mainland China for the first time. Supporters say the amendments are key to ensuring the city does not become a criminal refuge, but critics worry Beijing will use the law to extradite political opponents and others to China where their legal protections cannot be guaranteed. The government claims the push to change the law, which would also apply to Taiwan and Macau, stems from the killing last year of a Hong Kong woman while she was in Taiwan with her boyfriend. Authorities in Taiwan suspect the woman’s boyfriend, who remains in Hong Kong, but cannot try him because no extradition agreement is in place. Under the amended law, those accused of offences punishable by seven years or more in prison could be extradited. The new legislation would give Hong Kong’s leader, known as the chief executive, authority to approve extradition requests, after review by the courts. Hong Kong’s legislature, the legislative council, would not have any oversight over the extradition process. Many Hong Kongers fear the proposed extradition law will be used by authorities to target political enemies. They worry the new legislation spells the end of the “one country, two systems” policy, eroding the civil rights enjoyed by Hong Kong residents since the handover of sovereignty from the UK to China in 1997. Many attending the protests on Sunday said they could not trust China as it had often used non-political crimes to target government critics, and said they also feared Hong Kong officials would not be able to reject Beijing’s requests. Legal professionals have also expressed concern over the rights of those sent across the border to be tried. The conviction rate in Chinese courts is as high as 99%. Arbitrary detentions, torture and denial of legal representation of one’s choosing are also common. Many in the protests on Sunday 09 June 2019 said they felt overwhelmed by a sense of helplessness in the face of mainland China’s increasing political, economic and cultural influence in Hong Kong. Hong Kong’s top political leader is not elected by ordinary voters but by a 1,200-strong election committee accountable to Beijing. Half of its legislature are chosen through indirect electoral systems that favour pro-Beijing figures. Many Hong Kongers also cited the jailing of leaders and activists from the 2014 Occupy Central movement– a 79-day mass civil disobedience movement – as well as the disqualification of young localist lawmakers as signs of the erosion of civil freedoms. Resentment towards China has been intensified by soaring property prices – with increasing numbers of mainland Chinese buying properties in the city – as well as the government’s “patriotic education” drive, and the large numbers of mainland tourists who flock to Hong Kong. Many Hong Kongers are also concerned about China’s growing control over the city’s news media, as they increasingly self-censor and follow Beijing’s tacit orders. https://www.theguardian.com/world/2019/jun/10/what-are-the-hong-kong-protests-about-explainerMore than a thousand protestors surround Hong Kong's main police headquarters on Arsenal Street in Wan Chai on June 26th following a peaceful rally at Edinburgh Place in Central. Doors to the complex were barricaded by protestors, who left after a six hour siege in protest at police violence at a prtest held earlier on 12 June 2019. Protesters ended a six-hour siege of Hong Kong’s police headquarters – their second in a week over the now-suspended extradition bill – early on Thursday morning. More than 1,000 were involved at the height of the protest, which began after 10pm on Wednesday. Around 100 were left at the end and dispersed without a fight when officers with riot shields emerged from the building in Wan Chai at 4am on Thursday. After a peaceful rally attended by thousands earlier at Edinburgh Place in the Central business district, hundreds descended on Arsenal Street, blocking the junction with Lockhart Road to all traffic and sealing the entrances to the police base. (https://www.scmp.com/news/hong-kong/politics/article/3016238/hong-kong-police-under-siege-again-protesters-surround )carrie lam, hong kong protests, extraditions, protest, protestors -

Tarnagulla History Archive

Tarnagulla History ArchiveCodd Bottle - Whittaker & Sons, Lemonade, Dunolly

David Gordon Collection. A Codd-neck bottle is a type of bottle used for carbonated drinks. Hiram Codd, an English engineer invented a successful process that he patented as “Codd’s patented globe stopper bottle” in 1872. This type of bottle has a closing design in which a glass marble is held against a rubber seal, which sits within a recess in the lip. The Codd-neck bottle was designed and manufactured with thick glass to withstand internal pressure, and a chamber to enclose a marble and a rubber washer in the neck. The bottles are filled upside down, and pressure of the gas in the bottle forced the marble against the washer, sealing in the carbonation. The bottle is pinched into a special shape to provide a chamber into which the marble is pushed to open the bottle. This prevents the marble from blocking the neck as the drink is poured. The bottles were regularly produced for many decades, but gradually declined in usage. Since children smashed the bottles to retrieve the marbles, vintage bottles are relatively scarce and have become collector items, particularly in the UK. William Whittaker's son Joseph Whittaker operated a cordial factory at Tarnagulla for many years. It was located at the southern end of Commercial Road, and was the last business premises on the eastern side of the road. Joseph Whittaker was a leading citizen at Tarnagulla for many years, and was a leading supporter of sporting activities including cricket and rifle clubs, as well as a strong patron of the fire brigade. He was known by some as Ginger Beer Joe. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This turn-moulded glass bottle is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. There is a portion of cork in the bottle’s mouth and dry remnants in the bottle’s base. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker