Showing 4196 items

matching reg

-

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - GERTRUDE PERRY COLLECTION: PHOTOGRAPH OF GERTRUDE PERRY, 1953

Photograph. Photograph of Gertrude Perry. Three photographs of Gertrude Perry in costumes. 1st, 2nd & 3rd acts Lead Role 'The Merry Widow'. Folding wooden frame painted cream.Reg V Brock Bendigoperson, individual, personal portrait, gertrude perry collection, gertrude perry -

Ballarat RSL Sub-Branch Inc.

Ballarat RSL Sub-Branch Inc.Machete & Scabbard

Reg No = 103RE, Scabbard No = 105R4weapons, ballarat rsl, ballarat -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Haeusler Collection Tea Measure, Stokes & Sons

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s. This object is a scoop for measuring tea leaves, also known as a tea caddy spoon. It was manufactured in Melbourne, Australia by Stokes & Sons. Stokes & Sons was established in 1856 by Thomas William Stokes, a die-sinker from Birmingham, England. It was likely manufactured in the early twentieth-century. This item has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It contributes to our understanding of domestic and family life in early twentieth century Wodonga, as well as providing interpretative capacity for themes including local history, social history, and women’s history.A small metal tea caddy, or tea measure, with an engraved clock face on the scoop showing the time as 4 o'clock. On the reverse of the scoop a makers mark lists place of manufacture as Australia, and lists a registration number. "MADE IN AUSTRALIA REG NO 15733"tea, teaware, tea caddy, kitchenware, social history -

Bendigo Historical Society Inc.

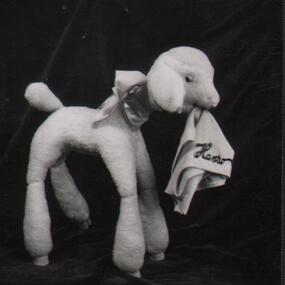

Bendigo Historical Society Inc.Photograph - HANRO COLLECTION: A COLLECTION OF PHOTOGRAPHS OF DECORATIONS FOR HANRO WINDOW DISPLAY

See Item 11000.189A Collection of Photographs of decorations for Hanro Window Display: All black and white photo's. Photo A) A soft toy of a lamb with a bow around its neck and in the mouth is a garment with Hanro embroider on it. On the back is the number 2056 hand written in blue ink. Photo B) has two cane suitcases with handles one smaller than the other. Both have flowers woven through the cane. A petticoat with lace and two thin straps at the top is laid through the larger suitcase and a sign *Hanro* sits on the bench. On the back is 2100 hand written in blue ink and in pencil VV11. Photo C) Is of a Cane French Horn with a bunch of flowers in the horn part. A Hanro sign is attached to the middle of the Horn and a petticoat with a lace bodice and hem and two thin straps is draped through the bottom of the French Horn. Some glue on the back and 2114 in biro, 14 in pencil. Photo D) Is a mock cloths line in front of a dark background with three petticoats. The first has a lace top and hem with two straps pegged to the line, the second is hung upside down with two pegs. It has a lace top with a V neck. The third has a lace V neck top and at the hem line. The garment is pegged to the line by the straps. There are two pots with flowers hanging from the line. Photo E) A vase made of cane with flowers and a Hanro sign attached. Two petticoats either side are laid on the bench both with a lace bodice. There are two Hanro signs on the table. On the back in blue ink hand written is *Dek. Nt.2094 Photo F*. There are three cane baskets with flowers and Hanro signs at the top of each hung on a wall and two cane baskets with flowers on the table. One petticoat is hung up on the wall through the baskets. The petticoat has a lace border at the bodice, The other is laid on the table, has a V neck and lace border. A Hanro sign is in front of the petticoat. On the back printed in blue ink is *Dek. Nr. 2098* Photo G) Is three bunches of flowers to have Hanro sign attached. On the back is *Dek. 2077. Photo H) Is three groups of several crystal balls strung together with pine needles at the top and the sign Hanro at the top of each. On the back hand printed in blue ink is *Dek.2124* The photos were together in a piece of paper which has writing in green ink *Decorations for clients window display*.Reg. V. Brock Studiosphotograph, hanro. reg. v. brock. -

Linton and District Historical Society Inc

Linton and District Historical Society IncPhotograph, Richards and Co Paris Panel 23 Sturt St, Ballarat, Will Jennings

Sepia photograph of a well-dressed young man wearing suit, fob watch, with flower in buttonhole, standing leaning with left hand on arm of a chair, right hand on hip."Will Jennings father of Reg Jennings".will jennings -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - BASIL MILLER COLLECTION: TRAMWAY PORTRAIT

BHS CollectionA tram conductor in tramway uniform, '9' badge on hat. Mounted in brown card folder. Possibly Basil Miller but not named on portrait.Reg V. Brock, Bendigoperson, individual, basil miller -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePrinting Press, C. 1934

This small Adana letterpress was based on a larger press. It was intended for printing stationery such as business cards, visitor’s cards, shop price cards and notepaper headers, Used for letterpress printing, and advertised as “Virtually indestructible”. Used for hobby printing, schools, and similar uses. When donated to Flagstaff Hill the chase still had letter type in it, which was printed out "THE SHADOWS / apahc / the aauage / shaboogie ". Currently, the machine is used by the Flagstaff Hill "Examiner" office to make business cards for use by some of the Volunteers in the Village. HISTORY Donald Aspinall, born in London in 1899, suffered shell shock while serving in World War 1. During his recovery, while still a teenager, he worked his hobby, the design of a small flatbed printing press, then advertised it in The Model Engineer’ in 1918 and received an overwhelming response of orders. In 1922 Aspinall founded the Adana Agency, in Twickenham. His had great success in his sales of flatbed, self-inking wooden presses to hobby printing enthusiasts. Over the years Adana made a variety of machines; flatbed, lever, treadle and powered presses Adana cast its own type in 1925 and has a number of patents for press parts. In the 1980’s the company wound down, and was purchased by Caslon, who still service and supply part for the Adana machines. Printing press; hand operated small letterpress machine made by Adana. Tiny platen style. Model Five-Three (5 inch x 3 inch). Cast metal base and lever handle with rounded end, both painted dark red, rounded red metal lever handle. C. 1934 Marks on foot of stand " REG. NO. / ISIL 46 & S00575 / PATENTS PENDING" and "REG. TRADE MARK / ADANA"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, adana letterpress, adana model three-five, mini letterpress, printing machine, donald aspinall -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Business Plate, Robinsons Motor Pty Ltd, Early 20th century

This plate was probably shortened to fit an office or factory door. Alexander Robinson (1862-1932) established a coachbuilding business in Fairy Street Warrnambool in 1880. In 1883 he joined with Fred Morse to set up the coachbuilding business of Robinson and Morse. This firm was noted for its production of fine Abbott buggies. Later Morse established his own business in Warrnambool and Robinson’s business continued at Fairy Street and converted to motor car building in the early 1900s. Alexander Robinson was Mayor of Warrnambool from 1907 to 1909. In the early 1930s Robinson’s Motors was replaced by Callaghan Motors. This business traded on the Fairy Street site until 2018 but now operates from Raglan Parade. The grandfather of one of the donors of this item, Tom Smith, worked at Robinsons Motor Pty Ltd in the early 20th century. This plate is of great interest as it came from the motor car business of Robinson’s Motor Pty Ltd. The Robinson businesses (coach building & motor car building) existed in Warrnambool for over 50 years. This is a brass business plate with three small holes at each corner. The lettering etched on the plate is gold and black but the black may have been put on to the lettering at a later stage as only some of the gold lettering is still visible. The plate has been cut off on one side and part of the lettering is missing.‘Reg. Office’ ‘Robinsons Motor Pro..’ robinson & morse, history of warrnambool, robinson’s motor pty ltd, alex robinson, warrnambool -

Bendigo Military Museum

Bendigo Military MuseumFootwear - BOOTS, AB, Post 1950

Boots unworn, pair black leather with synthetic soles & black laces.In relief on soled: “Sherpa / Reg No 215448”costume - male - footwear, uniforms - army, passchendaele barracks trust -

Bendigo Military Museum

Bendigo Military MuseumEquipment - BOOTS & GAITERS

.1) & .2) Boots, pair of black leather boots with soles & heels screwed onto uppers. .3) Gaiters .4) GaitersOn soles in relief: SHERPA / REG 215448uniforms-army, costume-male footwear -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkKitchen boiler, Copper Kitchen boiler, Approx 1900

Joseph Fowler (1888-1972), businessman and municipal councillor, was born on 28 February 1888 at Bagworth, Leicestershire, England, one of thirteen children of John Fowler, groom, and his wife Mary, née Ash. With his brother Sydney, in the early 1900s Joseph worked in a fruit-preserving business run by an uncle at Maidstone, Kent, and continued with the firm after 1908 when it was relocated at Reading. At St Andrew's parish church, Leicester, on 7 September 1910 he married a nurse, Elizabeth Harris (d.1965); they emigrated in 1913 and settled at Camberwell, Melbourne. Encouraged by his commercial experience, and by the variety and quality of fruit in Australia, Fowler set up a fruit-bottling business in the rear of his small house in Burke Road. Trading as J. Fowler & Co., by 1915 the company had begun producing home-bottling kits which contained a sterilizer, bottles, lids, rings and a thermometer. To acquire the capital to establish a factory, Fowler travelled the district, selling his kits door-to-door from the back of a cart. In 1920 he bought a shop at the corner of Power Street and Burwood Road, Hawthorn, and registered his business as a private company. During the Depression his kits became a household name. In 1934 Fowlers Vacola Manufacturing Co. Ltd was registered as a public company. Housewives, nationwide, were urged to bottle their own fruits and jams by 'Mrs B Thrifty', the dainty cartoon character who graced the firm's advertisements. Numerous recipes and instruction books, such as From Orchard to Bottle the Fowlers Way, advertised the necessary preserving equipment, extending to jelly bags and juice extractors. Australian-made glass and imported steel and rubber were used in the production of Fowlers Vacola Bottling Outfits. Determined to put something back into the community which had supported him so well, in 1933-60 Fowler represented Yarra Ward on the Hawthorn City Council (mayor 1938-39 and 1945-46). He served as vice-president of Swinburne Technical College (1942) and of the Hawthorn branch of the Australian Defence League (1943); he was also a Rotarian, and a warden and vestryman of St John's Anglican Church, Camberwell. Changed demands in World War II encouraged Fowlers Vacola to diversify their product. Canned goods were manufactured for allied troops in the South Pacific. In 1953 new buildings and plant, including a giant pressure-cooker, were installed to increase productivity: from that time Fowlers Vacola sold canned and bottled food throughout Australia and abroad. By 1960 the factory occupied more than 122,000 sq. ft (11,330 m²) and further expansion was to occur when the firm moved to Nunawading. Fowler retired in 1961, but remained chairman of directors; his son Ronald succeeded him as managing director. Variously described as a generous, jovial man with a sense of humour, and as a strict and astute manager whose company was his life, Fowler was renowned for his straight business dealings and his 'no-nonsense' attitude. Survived by his son and daughter, he died on 24 April 1972 at Camberwell and was cremated. His estate was sworn for probate at $204,424. On Ronald Fowler's death in 1978, the company was bought out by the Sydney firm, Hooper Baillie Industries Ltd; it in turn sold to Sabco Ltd of South Australia; in 1994, when Sabco went into receivership, Australian Resource Recovery Technologies re-established Fowlers Vacola Australia Pty Ltd's headquarters in Melbourne. Copper boiling pot for home preserves, handles, lid and removable thermometer, also acc ompany instruction booklet. "Fowlers Method of Bottling Fruits and Vegetables"Fowler's "Vacola" Reg. No. 68081 Sterilizer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Johnson Bros

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.A white earthenware side plate with a gadroon edge. Has water marks and chips on front.‘Johnson Bros England Reg No 15587’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, johnson bros, ceramics, tableware -

Clunes Museum

Clunes MuseumContainer - BOTTLE

PHENYLE WAS USED AS A DOMESTIC DISFECTANTCLEAR GLASS PHENYLE BOTTLE - DIAMOND SHAPEDPOISONOUS REG NO. 2140 NOT TO BE TAKEN PHENYLElocal history, domestic item, containers, domestic items -

Mont De Lancey

Mont De LanceyTrousers, Can't Tear-Em

Dark grey men's trousers with 4 buttons at the front (fly)Sanforized Reg. Td. Shrunk Fabrictrousers -

Clunes Museum

Clunes MuseumLeisure object - PIPE - SMOKING

Black curved stem, metal join, brown bowlMarking on join - "Capt Kettle Reg. No. illegible" Marking on bowl - "Capt Kettle Reg No. 317747 Made in France"-smoking paraphernalia, pipe -

Ringwood and District Historical Society

Ringwood and District Historical SocietyClothing - shoe, Baby's Shoe Ringwood c1927

Belonged to June Jones (nee Webber) one of her first shoes.Coffee coloured baby's shoe with ribbon ties. Lace ruffle around front and double stitching top to sole.Made by Fautleys Reg no. 34599 Size 0 -

Stawell Historical Society Inc

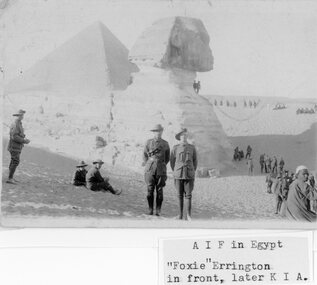

Stawell Historical Society IncPhotograph - A.I.F, Soldier "Foxie" Errington closer to the front in Cairo Egypt & was later killed in action

Two Soldiers in Uniform in front of the Sphinx Cairo Egypt. Fox Errington in Front later Killed in Action.CARTE POSTALE: FROM FOXIE TO REG CHAPMANstawell ww1 -

Melbourne Tram Museum

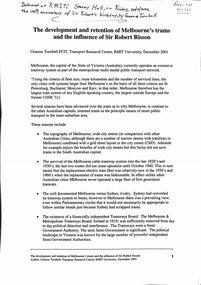

Melbourne Tram MuseumDocument - Report, Graeme Turnbull, "The development and retention of Melbourne's trams and the influence of Sir Robert Risson", Apr. 2001

Copy of a lecture by Graeme Turnbull presented 2001 titled "The development and retention of Melbourne's trams and the influence of Sir Robert Risson" Consists of 22 A4 pages, with Bibliography. Looks at the history of the Melbourne's trams, why they have been retained, the MMTB, its formation, Chairmen, Overseas influences and reports, Bourke St buses, Bourke St, the PCC car, Robert Risson, Hector Bell, Reg Ansett, the Union, design of trams, accidents, trolley poles, uniforms, Risson's personality and his strong support for trams in Melbourne. See Reg Item 6061On top in ink "Delivered at RMIT Storey Hall on Friday 20/4/2001, the 100th anniversary of Sir Robert's birthday by Graeme Turnbull" and "Received 7/12/01"trams, tramways, mmtb, chairman, pcc, buses, accidents, trolley poles, uniforms, public transport -

Ballan Shire Historical Society

Ballan Shire Historical SocietyBook - Book. St John's Anglican Church, Ballan, St. John's Anglican Church Ballan. Index to Register of Baptisms 1849 -1991, 1991

The book is a collection of index cards transcribed from the Register of Baptisms from 1849 to 1991 at the St. John's Anglican Church in Ballan. These cards were then photocopied ten to a page and assembled and bound into this book. The book contains Volume 1 A -K and Volume 2 L -Z and the wording on the Title Page "This is a copy of the transcription, which was completed by Roy Huggins and a team of volunteers at Ballan. Acknowledgment is given to The Rector without whose permission the project could not have been completed. March 1991."The book is significant in that it contains a complete register of Baptisms conducted at the Church from 1849 to 1991 in alphabetical order. This is of significance to family researchers and makes a search of the records much easier.An A4 size book which is a collection of loose pages stapled, with cardboard covers and a brown tape spine binding. About 250 pages of transcribed, photocopied index cards. Book No.105.Pencil markings - Book No.105. Reg No. VBSH 01098ballan, baptism records, anglican church, st johns anglican church -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Coin, Queen Elizabeth 11 Silver Jubilee

This is a British coin to the value of 25 newpence. It is a commemorative coin to celebrate the 25th anniversary of Queen Elizabeth's ascension to the throne of England.This coin has no local provenance but is of interest as a British commemorative coin of 1977.Circular silver coin with a reeded edge The obverse depicts a raised profile figure of Queen Elizabeth 11 mounted side saddle on a horse and text. (It is reminiscent of the Queen at the Trooping of the Colour.) The reverse features a crown , an eagle with outstretched wings on a dais, decorative leaves and berries. QUEEN ELIZABETH. 11 DG REG FD . 1977queen elizabeth 11 -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Seal, Portland Borough, c. 1855

Item from the Borough of Portland (1855-?)Iron seal with rectangular base oval insignia centred in cross-bar designFront: Borough of/Reg/No/Portland (in reverse) circular sealborough of portland, 1800s, seal, administration -

Sir Reginald Ansett Transport Museum

Sir Reginald Ansett Transport MuseumHeadwear - Hat, Bowler, 1972-1977

Ansett Airlines of Australia 1972-1977Complements the collection of air flight crew attire.Orange bowler hat, with black stripe on band and around crown, lined in cream material. This hat comes with the round Ansett Delta - golden A shape on black enamel - insignia attached in front. Made by NIVEK HEADWARE. Reg. Melb. Donor: EDDY hostess, flight attendant, uniform, orange, 1972-1977, bowler, nivek headwear, stewardess, ansett, delta -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Equipment - Equipment, Army, Field Torch

Olive green plastic with coloured filters stored in handle. The torch is modified in that the front red plastic filter has a star shape cut out of it for night identification.MX 9914.0 Bright star, Trade mark reg.torch -

Clunes Museum

Clunes MuseumTool - HAME HOOK

1 x pair - Hook on bolt, hook on link, hollow shaft, ring on ling, length of chain on link"DOWNEE" REG ALL STEEL MADE IN SYDNEY 28agricultural tool, farm tool -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumBook, The Tatura Secret Radio, 1997

Army Intelligence knew there was a secret radio operating in Tatura No.1 Camp. The inmates were getting the war news direct from Germany. They had to have a strong shortwave receiver, but where was it?White soft cover book with an entrance made with barb wire. The front cover depicts a man with headphones on. A map of Victoria and short history of the book on the back cover. B/W photos, with a map of Tatura No 1 camp.Reg. No. 1870.1 signed "With Best Wishes Laura Nilsen"the tatura secret radio, nilsen h, nilsen l, glover i, camp 1, tatura, ww2 camp 1, books, history, local -

Cobram Historical Society Inc

Cobram Historical Society IncEgg beater

Green depression Uranium egg mixer beater Crown Crystal Glass. Circa 1930Crown crystal glass Sydney Made in England REG -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - LYDIA CHANCELLOR COLLECTION : CUP SAUCER & PLATE

Grindley trio of cup saucer & plate, brightly coloured floral design with black bands, a note included reads this cup, saucer and plate belonged to Lydia Chancellor ''Taraxville'' Golden Square Vic.W.H.Grindley & Co Ltd Ivory England Reg No 714550domestic equipment, table setting, cups, lydia chancellor collection, collection -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Photograph, Blackburn Methodist Cricket Club

Black and white photograph of Blackburn Methodist Cricket Club in formal pose. Front row 2nd from left is Ron Booth, Harry Wellman (Shoe Shop Blackburn), Frank Hocken, Max Tippett (boy), not known, Gordon Toogood, Harry Sinclair (father was Postmaster), Reg Brain (fruit shop Blackburn).|Back row 5th from left Morris Wellman.blackburn methodist cricket club, booth, ron, wellman, harry, hocken, tippett, max, toogood, gordon, sinclair, brain, reg, morris -

Ballarat Tramway Museum

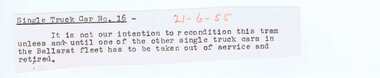

Ballarat Tramway MuseumDocument - Tramcar Record - SEC No. 16, Wal Jack, 1950's

Tramcar record for SEC Ballarat No. 16, builder, system location, short history and work in Ballarat. Loose on the same folder was a typed sheet of paper dated 21-6-55, noting the SEC proposal for this tram, not intended to recondition it. See btm5526i1.jpg See Reg Item 5614 for a photo of the 21E truck after the body was sold and disposed of.Yields information about the history of individual tramcars in Ballarat.Handwritten note on foolscap lined sheet outlining the history of Ballarat Tramcar No. 16, who built for, date to Ballarat, painting and other changes to the tramcar as compiled by Wal Jack. Part of a series on each SEC Ballarat operated tramcar, except for the ESCo trams. Contained within Reg Item 5507 - Foolscap binder with green covers, black binding edge and metal clips. trams, tramways, ballarat, tramcars, tramcars of ballarat, tram 16