Showing 331 items

matching tool maker

-

Flagstaff Hill Maritime Museum and Village

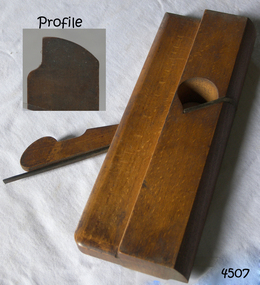

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . J Moseley. maker and R Knight & J Heath also stamped stamped (Owners)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

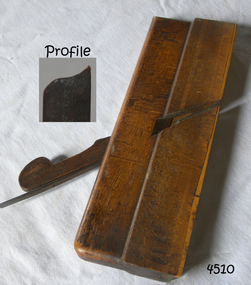

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, Unknown

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. The maker of this plane is unknown but probably made in London early to mid 18th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world with no makers marks however moulding planes from this era are well sought after by collectors of vintage tools.A vintage tool made by an unknown maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the early to mid 18th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item.Wood Moulding Plane Rabbet typeMarked J Heath on end, (no makers mark)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, ames -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, 1844-1860

... ) stamped at one end (maker unknown) Moulding Plane Tool Wood ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. This item is unmarked so the maker is unknown, these types of decorative moulding planes of all sizes and designs are for sale around the world and these tools are well sought after by collectors of vintage tools.A vintage tool made by an un known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the early to mid 18th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item.Moulding Plane J Heath (owner) stamped at one end (maker unknown)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, 1844-1860

... ) stamped at one end (maker unknown) Moulding Plane Tool Wood ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. This item is unmarked so the maker is unknown, these types of decorative moulding planes of all sizes and designs are for sale around the world and these tools are well sought after by collectors of vintage tools.A vintage tool made by an un known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the early to mid 18th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item.Moulding Plane J Heath (owner) stamped at one end (maker unknown)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Smoothing Plane, Heinrich Boker, Mid 19th to late 19th Century

... Tool Cabinet Makers Tool Blade marked Henry Boker Smoothing ...A smoothing plane is typically used after the work piece has been flattened and trued by the other bench planes, such as the jack, fore, and joiner planes. Smoothing planes can also be used to remove marks left by woodworking machinery. When used effectively alongside other bench planes, the smoothing plane should only need a handful of passes removing shavings as fine as 0.002 inches (0.051 mm) or less. The work piece is then ready to be finished, or can be further refined with a card scraper or sandpaper. The smoothing plane is usually held with both hands, and used in a similar manner to the other bench planes. Though designed for smoothing, a smoothing plane can be used as an 'all-round' bench tool and for rougher work depending on how it is set up. Being smaller than other bench planes, the smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more manoeuvrable. It has also been claimed that the coffin design exposes more end grain, enabling the plane to better adjust to changes in humidity. Henry Boker Maker: Heinrich "Henry" Böker of Reimschied-Solingen, Germany and his family was making tools in the 17th century. In 1829 Hermann and Robert Böker added sabres to the company's offerings, in 1837 they emigrated to New York City and established a firm to import German cutlery. H. Boker sabres would be eventually supplied to some American soldiers during the Civil War. Heinrich Boker in 1869 , a relative of Hermann and Robert, established a cutlery firm in Solingen, a centre of industry and cutting tool manufacturing in Germany. The company became a leader in the manufacture of razors, scissors and eating utensils. As early as 1900 the majority of tools produced by Boker were distributed in the U.S. market by the New York branch of the family, and pocket knives became the company's most important product line. During WWII the Solingen factory was destroyed and all the equipment and inventory was lost. After the war the factory was rebuilt and the company resumed operations, but in the early '60s the company was sold to the scissors manufacturer Wiss & Sons, and in the early 70s Wiss sold out to Cooper Industries. At some point Heinrich Boker adopted the Americanised version of his name, Henry Boker and was used as a brand name for the company's products. A vintage smoothing plane of the coffin pattern made by Henry Boker the item is a rare and significant example of vintage woodworking tools used in the manufacture of wooden items.Smoothing Plane Coffin design. Blade marked Henry Bokerflagstaff hill, warrnambool, maritime-museum, shipwreck-coast, smoothing plane, heinrich boker, carpenters tool, cabinet makers tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing Plane, Mid to Late 19th Century

A smoothing plane is typically used after the work piece has been flattened and trued by the other bench planes, such as the jack, fore, and joiner planes. Smoothing planes can also be used to remove marks left by woodworking machinery. When used effectively alongside other bench planes, the smoothing plane should only need a handful of passes removing shavings as fine as 0.002 inches (0.051 mm) or less. The work piece is then ready to be finished, or can be further refined with a card scraper or sandpaper. The smoothing plane is usually held with both hands, and used in a similar manner to the other bench planes. Though designed for smoothing, a smoothing plane can be used as an 'all-round' bench tool and for rougher work depending on how it is set up. Being smaller than other bench planes, the smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more maneuverable. It has also been claimed that the coffin design exposes more end grain, enabling the plane to better adjust to changes in humidity. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a smooth finish to timber. The tool was used when timber items needed to have a smooth finish these types of planes were used in conjunction with profiled planes that provided a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Smoothing Plane coffin design Maker J Moseley & Son London & 2 1/4"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, 1770-1809

The story of Christopher Gabriel born on April 2, 1746, in Falmouth England is a tale of a poor boy who made good. Shortly before he turned thirteen years of age in 1759 he was apprenticed to a local master carpenter, recorded as a Mr Barnicot the master trained his apprentice well as we can assume by Christopher's later successes. The apprenticeship ended in 1766 after seven years when Christopher reached twenty. Then in 1768, he relocated to London walking the two hundred miles from Falmouth carrying his possessions in a sack. He no sooner arrived in London when he met Alice Trowell who became his wife in March 1769. They set up house on Albermarie Street Clerkenwell and by the first of 1770, Gabriel had begun his business of plane making. It has been speculated that Gabriel took over the shop of John Cogdell aided with an investment from his in-laws of 131 pounds. He went on to prosper as a plane-maker and lumber merchant over the next forty years. His business did well and in 1774 Gabriel moved to a house in Golden Lane, London and 1779 moved again to a home in Ould Street London. By now Gabriel was making a name for himself and his business at this time was located at 32 Banner Street Golden Lane, the following year he purchased another home in Banner Street and 1793 purchased the house next door. At the time of his death in 1808, he owned twenty-seven houses and commercial building. Christopher Gabriel s descendants became quite prominent in England and his grandson, Sir Thomas Gabriel became the Sheriff of London and Middlesex in 1859 and the Lord Mayor of London 1866 and 1867. Gabriel was an extremely prolific plane-maker with a lot of examples made in the 18th century can still be found today. He made good quality tools and was an innovator of several new plane designs. A vintage tool made by a well-known plane-maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could give a decorative finish to timber. These planes came in various shapes and sizes to achieve a finish to timber surfaces and came in many sizes. A significant Christopher Gabriel plane from the mid to late 18th century that after 200 years can still be used today. Planes made by Gabriel are eagerly sought after by collectors. The tool gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting edged hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items. Moulding multi patterned plane has a "5" long bladeStamped Maker C Gabriel (owner JB).flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, side rabbet plane, gabriel m hobling -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Wood Moulding Plane J Moseley & Son maker also stamped (Previous Owners) HIT & E Dunstan, RA Dixon with an N inside a W flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Edward Preston & Sons, Early 20th century

... leading makers of hand tools and in many ways a British... of England's leading makers of hand tools and in many ways a British ...By the end of the nineteenth century, the firm of Edward Preston & Sons was founded in 1825, becoming one of England's leading makers of hand tools and in many ways a British counterpart to America's "Stanley" for its wide range of quality utilitarian tools at affordable prices. Edward Preston Sr. (1798–1883) was first listed as a plane-maker at 77 Lichfield Street in the Birmingham Directory of 1833, but later listings and advertisements assert that the business was started in 1825. Preston is likewise recorded as a plane-maker living with his family in Lichfield Street in the 1841 census, at which time his younger son Edward was 6 years old. Around 1850, his son Edward left school to join his father's business and is recorded in the 1851 census as a plane-maker at his father's address. He appears to have been quite a talented and resourceful young man, as he had later been able to start up his own "wood and brass spirit level manufacturing business at 97½ Lichfield Street by 1864. By 1866, Edward Jnr had added planes, routers, joiners, coach, gun, cabinet, and carpenters tools to his line, and the following year he moved his shop from his father's address and relocated to 26 Newton Street, before moving again to much larger premises at 22–24 Whittall Street. This location became known as the Whittall Works and later was the office and factory of Edward Preston & Sons, Ltd. In 1889 Edward Preston Jnr and his three sons were brought into the firm and the name was changed to Edward Preston & Sons, becoming Edward Preston & Sons Ltd on incorporation in 1898. Part of the firm's output was a healthy line of malleable and gun-metal planes and patent adjustable iron smoothers, shoulder planes, bull-nose, and block planes - a range that was expanded in later years. The 1901 catalog shows several styles of planes that were unique to the Preston brand, along with the usual styles which had already been set by other makers. The death of Edward Preston Jnr was reported in the Lichfield Mercury of 26 September 1913. "Mr. Preston was decided of an innovative turn of mind," the newspaper wrote, "as many of the machines in use at his works, as well as of the tools produced were the invention of himself and his three sons, who now manage the business." The report noted that at the time of his death, the business was carried on at Whittall Works, Cheston Street, Aston, Birmingham. Falling on hard times, the firm of Edward Preston & Sons was sold to the Birmingham firm of John Rabone & Sons in 1932, and shortly thereafter manufacturing rights to some of the Preston range of planes were sold to the Sheffield firm of C. & J. Hampton, who would later merge with the Record Tool Company. Some of the Preston planes were directly added to the Record line by the Hampton firm, while others were modified or discontinued altogether. Generally, all Preston wooden planes are stamped on the front of the plane, the shape, size, and character type of the stamp indicating the age of the plane. On some metal planes, all the parts were stamped with a number or symbol during manufacture. This number was used to re-assemble the parts following a batch process. Not all Preston tools are trade-marked clearly. Early shoulder, rebate, chariot planes, and chamfer rebates commonly appear without trademarks but may have assembly numbers. The "E P" trade-mark was already in use by 1882. The trade-mark "Preston" also appears on some later tools that were manufactured in Sheffield, England. These are generally smoothing planes and appear modern and very similar in construction to other modern manufacturers' planes.The item gives a snapshot of one of England's premier tool manufacturing companies at a time when significant industrial changes were occurring in manufacturing and business structures in the World that were beginning to affect social changes.Ogee wood moulding plane Maker E Preston & Sons No 5 (Owner A T Nipe) also has A's stamped on ends and the No 7flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Side Bead Single Box moulding plane J Moseley & Sons maker also stamped Healy 188 High Street Poplar Surrey (retailers) marked (owners A Bowen & J W Gower with a symbol "M"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Side Bead Single Box moulding plane J Moseley & Sons maker also stamped Healy 188 High Street Poplar Surrey (retailers) marked (owners A Bowen & J W Gower Size 9/16"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood smoothing plane, G Davis, 1821-1876

A smoothing plane used for making a flat and smooth finish to timber items predominantly used in furniture or cabinet work or other wooden objects. Traditionally, planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile or a flat and smooth finish with the blade secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of smoothing and moulding planes for the full range of work to be performed. For example large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about George Davis is he and his successors made planes in Birmingham, England, from about 1821 to 1876. There are many of his tools including smoothing and decorative moulding planes of all sizes and designs for sale around the world and that his wood working planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals who worked in wood and needed a tool that could produce a smooth finish to timber. These types of planes came in various shapes and sizes to achieve the required finish. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Smoothing plane known as a coffin plane due to it's shapeStamped GM inside W (owner) maker possibly G Davisflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane, moulding, single bead reeding plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing wood Plane, Mid to Late 19th Century

A smoothing plane is a wood plane used for making a smooth surface to wood surfaces traditionally, these planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape or size required. The blade, or iron was likewise formed to the intended flat or level profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding and smoothing planes for the full range of work to be performed. Large crown mouldings or smoothing plane surfaces required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by an unknown maker, that was made commercially for firms and individuals who worked in wood and needed a tool that could produce a flat or level finish to timber. These types of planes came in various shapes and sizes to achieve the required finish to timber surfaces used in cabinet making. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools only. Smoothing Plane Coffin typeMaker J Moseley & Son London and 2¼" also has OS stamped on side (probably an owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePen Nibs, 1920's

The two cards of nibs are retail display cards of the dip pen nibs that William Mitchell Calligraphy produced, dating back to around the 1920’s, which was the time of the Great Exhibition in the UK. At that time dip pens with steel nibs were the main writing instruments. British Pens Ltd. had recently formed as a company and its subsidiaries included the the company William Mitchell, which is why British Pens Ltd. is named on the cards as well. One card (1) has the Round Hand nib, which is widely used today for calligraphy scripts. The other card (2) has the Script nib that has round upturned points for monocline or unshaded lettering that is also used for calligraphy. The nibs also have a detachable reservoir. The pen nibs are shaped to fit into a slot in the base of a wooden or Bakelite pen holder. The hole at the front of the nib is for collecting ink from a well, which is then stored in a reservoir at the back of the nib. The nibsare stamped with their nib size and Pedigree (what type of nib it is) and maker’s details. William Mitchell Calligraphy still makes these nibs today with a slightly difference finish. (ref: Sales and Marketing Director of William Mitchell Calligraphy in 2016). HISTORY of the Ink Pen Quills and ink were common writing tools until the early 19th century when the pen trade began mass producing steel nibs and pens. The steel nibs each have a hole in the middle that acts like a well for the ink. When the nib is dipped into the ink well the writer needs to ensure that it is dipped to only just past that well. India Ink was one of the most popular inks used with the nib pens, notable for its satin-like smooth flow. This ink is composed of a particularly fine carbon mixed with water; it can also be obtained as a dry stick that is then crushed and mixed with water as required. The Jewellery Quarter of Birmingham had the largest concentration of independent jewellers in Europe. Birmingham became the centre of the world’s pen trade for many years -, during the 1800’s over 100 factories, employing 1000s of skilled workers, manufactured the ‘Birmingham Pen’. ABOUT WILLIAM MITCHELL CALLIGRAPHY LTD.* (*The following text is quoted from the William Mitchell Calligraphy website) British based William Mitchell Calligraphy has been designing and manufacturing exceptional pens for almost 200 years. The William Mitchell heritage in making pen nibs began whilst working with his brother John Mitchell in the early 1820s. William Mitchell established his own business in 1825 to become one of the leading nib manufacturers and famous for lettering pens. Almost 100 years later William Mitchell merged with Hinks, Wells & Co, another pen manufacturer, to form British Pens, employing around 1000 people in the Bearwood Road area of Birmingham. During the early 1960s British Pens acquired the pen business of other pen manufacturers Perry & Co and John Mitchell, once again reuniting the two brothers. Joseph Gillott, who were famous for their artist drawing and mapping nibs, amalgamated with British pens in 1969. William Mitchell and Joseph Gillott established in Birmingham during the early part of the nineteenth century and [their products] are still proudly made here. British Pens were subsequently purchased by its current owner Byron Head, the owner of William Mitchell (Sinkers) in 1982, and was subsequently renamed William Mitchell (calligraphy) Ltd. Established in 1827 Joseph Gillott was one of the pioneers of mass steel pen nib manufacturing. The company was particularly strong in the American market, prompting Elihu Burrit, the American consul, to write “In ten thousand school houses across the American continent between two oceans, a million children are as familiarly acquainted with Joseph Gillott as with Noah Webster” (The compiler of the famous American dictionary). The company consequently received visits from many notable Americans, including president Ulysses S Grant. The early 19th century invention and mass production of pen nibs such these in our collection had a large impact on education and literacy because the nibs could be produced in great numbers and affordable prices.Pen nibs; 2 cards of steel dip pen nibs from the 1920’s. The steel nibs are attached to cards by 2 rows of entwined cotton cord. Reverse sides of cards have some hand written marks. Manufacturer; William Mitchell, Birmingham, England. Card issued by British Pens Ltd. Nibs have shaped ends, a hole in the centre with a well on the underside, and the tops are shaped approximately quarter circle. Inscriptions are pressed into each nib. The script pens have detachable reservoirs made of a metal different to the nib. (Card 1) Round Hand Pens, 11 nibs remain from card of 12. Printed on card “Round Hand Pens for Beautiful Writing, Twelve degrees of point, Square points. William Mitchell, Birmingham, England. This card is issued by British Pens Ltd. MADE IN ENGLAND” Also printed on top left of card is a pen drawing of a person writing at a desk, background of decorative 3-paned window in brick wall. (Card 2) Script Pens; 11 nibs remain from card of 12. “Script pens fitted with detachable reservoir. William Mitchell, Birmingham, England. This card is issued by British Pens Ltd. MADE IN ENGLAND” Also printed on top right of card is a pen drawing of a person writing at a desk, background of decorative 3-paned window in brick wall. On Card 1, - each nib is stamped with its size, and “Wm MITCHELLS / PEDIGREE / ROUND HAND / ENGLAND” - hand written on front bottom of card in ball point pen “Lettering 5 times size of nib” - hand drawn on back of card in red and blue ball point pen are scribbled lines On Card 2 - each nib is stamped with its size, and “WILLIAM / MITCHELLS / SCRIPT PEN / ENGLAND” - a black circle corresponding to the nib is printed on the card above each nib. - hand written on back of card in black felt tip pen are numerals - hand drawn on back, 4 parallel lines in red ball point pen with the numbers “10” between 2 of the lines flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, great ocean road, william mitchell calligraphy ltd, british pens ltd., pen nib, writing implement, dip pen, round hand nib, script nib, birmingham manufacturer, communication in writing, mass produced pen nibs -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Sander, c. 1930-1955

This burgundy coloured, portable electric belt sander is stored in its own heavy duty cardboard box. It was made in England and, according to the label on the lid of the box, it is a Portrix Sander-Polisher, all-electric, portable, sands wood metal and polishes. Its uses include decorating, carpentry and polishing. It has a complete with electric unit with flex. The price of 75/- (75 shillings) is printed on the label of the box. The model and the brand of the sander have been removed from the manufacturer’s information embossed on the side of the sander. The sander is part of a collection of objects used by Jim Williams, maker of fine ship models from about 1930-1955. Most of the components for the models, as well as many of the tools, were handmade by Jim Williams. Jim’s family has donated the ship model “Sovereign of the Seas” and many tools, accessories and documents used in the making of this and other ship models have been donated to Flagstaff Hill Maritime Village. Please see our record 3732 of the mode Sovereign of the Seas for further details of the ship and the maker.This vintage Portrix sander-polisher represents tools used for the hobby and skill of ship model making that has been carried as a leisure activity out for generations. Ship model making was also a pastime for sailing crew, who often made a model of the ship in which they were sailing. This sander was used by local Warrnambool man, Jim Williams, who was employed at Cramond and Dickson clothing store, and then at Fletcher Jones menswear for 27 years. It was used in making components for the model of the historic ship, the Sovereign of the Seas. The Sovereign of the Seas was a historic 17th century English war ship with important maritime heritage.Belt sander, electric. Portable power tool, Portrix model Sander–Polisher, burgundy coloured body with swivelling, black electric cable, 250V 1 / 4 amp. For sanding wood and metal, and for polishing. (Stored in original box.) Made in England. Part of a collection of tools and accessories used by Mr. Jim Williams to build ship model of the “Sovereign of the Sea” and other models. c. 1930-1955. Moulded into body “ - - - SANDER –POLISHER / 1 / 4 amp. PRODUCT OF - - - MANUFACTURING CO. LTD. 50 CYCLES / MADE IN ENGLAND PAT. PEND. 200/250 volts A.C.” (the Brand and Manufacturer’s name have been removed)flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, portrix sander-polisher, portrix power tool, portrix belt sander, woodworking equipment, ship modelling equipment, jim williams, james bernard williams, ship model, hobby, ship model tool, sovereign of the seas, english war ship -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Wooden Tap, H. Gage, Melbourne, n.d

Displayed in History HouseWooden tap. Two parts joined in centre.Front: H. Gage/Maker/Melbourne Back: 2 -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Iron stamp, n.d

Saddler's tool. J H Jones Saddler and Harness maker. Percy Street, PortlandIron stamp, octagonal shaped handle, oval head with 'J.H. JONES, SADDLER, PORTLAND'j h jones, saddler, percy street, stamp -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Brace and Bit hand drill, 20thC

Before drills and braces, T-shaped augers were used to poke holes into wood, while smaller gimlets were used to start them. Auger handles were usually made of a piece of hardwood that was sanded, rounded, or even contoured to give the user a firm grip. Bits on spoon augers essentially carved a hole in the piece of wood, and had to be periodically removed to clear the chips. Spiral-bit augers were precursors to modern drills, whose bits cleared the hole of chips as the user drilled. A significant advance on the auger was the brace, which was originally designed with a single, permanently fixed bit at its end. Eventually, though, braces were designed with sophisticated chucks to accommodate replacement bits, as well as bits of different sizes and for various purposes. Chucks were patented as vigorously as the braces themselves The braces themselves also evolved for particular trades, from furniture makers to surgeons. The operator holds the ‘head’ in one hand, positions the drill in the wood , applies pressure and rotates the ‘centre piece’ to cause the drill to pierce the wood. A steel revolving hand tool for boring and screw-driving with wood handles * pioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, screws -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Churn, small domestic butter, c1880

... , carpenters and tool makers c1900. As pioneers and early settlers had ...A butter churn is a device used to convert cream into butter. This is done through a mechanical process, via a crank used to manually turn a rotating device inside the barrel shaped churn. The agitation of the cream, caused by the mechanical motion of the device, disrupts the milk fat. The membranes that surround the fats are broken down, subsequently forming clumps known as butter grains. These butter grains, during the process of churning, fuse with each other and form larger fat globules. Air bubbles are introduced into these fat globules via the continued mechanical action of the churn. The butter grains become more dense as fat globules attach to them while the air is forced out of the mixture. This process creates a liquid known as buttermilk. With constant churning, the fat globules eventually form solid butter and separate from the buttermilk. The buttermilk is then drained off and the butter is squeezed to eliminate excess liquid and to form it into a solid mass. Then rinsing could be done simply by washing in water, followed by draining, salting and working or "kneading" the butter with a pair of wooden butter pats, or with bare hands. This is a paddle churn, a barrel that contains a paddle, which is operated by a handle. The paddle churned the butter inside the container when the handle was turned. Early settlers had to be self sufficient, growing their own vegetables, making tools and clothing and usually had a house cow to produce their milk supplyThis domestic butter churn is an example of the skill of the pioneer craftsman, carpenters and tool makers c1900. As pioneers and early settlers had to be self sufficient they usually kept a dairy cow or 'house cow' to provide milk for drinking and for butter and cheese to made by the family.A small wooden, domestic butter churn with a lid and a crank that manually rotated the paddle inside. E. CHERRY / MAKER / GISBORNE / VICTORIA / Apioneers, early settlers, market gardeners, moorabbin, brighton, cheltenham, dairy products. dairy farmers, milk, butter, dairies -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWoodworking Tool - Jack Plane

Very Old. Until the end of the 19th century the bodies of jack planes were predominantly wooden, typically made out of beech (wood). Wooden planes were largely superseded by iron-bodied planes.Used by carpenters and cabinet makers in the Kiewa Valley from the late 1800s and the early 1900s.A Jack Plane is a general purpose woodworking bench plane, used for dressing timber down to size in preparation for truing and/or edge jointing. It is usually the first plane used on rough stock, but for rougher work it can be preceded by the scrub plane. German Pattern Jack Plane. The smallest - 1.5 inches. Ref. Page 21 - Tools for all Trades Catalogue 1930s?"The Burgham Tools Company / Solingen Germany"woodworking tool, jack plane, plane -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWoodworking Tool - Wooden Spokeshave

A spokeshave was made with a wooden (usually beech wood) body and metal cutting blade. With industrialisation metal bodies displaced wood in mass-produced tools. The name 'spokeshave' reflects the early use of the tool by wheelwrights.Used by carpenters and/or cabinet makers and/or wheelwrights in the Kiewa Valley in the 1800s and 1900s. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. It is a shaping and smoothing tool eg. curves and rounding and used after cutting with chisels or saws. Ref. Pg 28 Tools for all Trades Cataloguewoodworking tool, spokeshave tool -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWoodworking Tool - Shaping Planes - Set of 5

Very old. Beech is the best wood for moulding planes since the early 1700s when other woods were passed over in preference for the straight-grained non-problematic beech wood. The blades are made of steel.Used by carpenters and / or cabinet makers in the Kiewa Valley.Shaping wooden (possibly beech or maple wood) planes bundled up. Each makes a different shape eg. nose, tail, concave. Ref. Pages 20 and 21 Tools For All Trades Catalogue.wooden planes, woodworking, shaping plane -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWoodworking Tool - Marking Guage

Very old. Made of wood possibly beech wood.Used by carpenters and/or cabinet makers living in the Kiewa Valley.Wooden scribe - marking tool. A marking gauge is a measuring tool used in woodworking projects. It is ideal for marking out lines or scribing on various surfaces before sawing, chiseling, or cutting. Most models have a radius bottom edge ideal for sliding along the wood being marked, making it an easy tool to use.woodworkers tool, marking guage, wooden scribe -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTools - Vice and Clamp

Very old vice. The clamp is 50 to 60 years old when they were made by Technical School students in metal work class.Used by carpenters, woodworkers, furniture makers, welders, construction and metal workers in the Kiewa ValleyMathieson's Hand Vice, the smallest at 3 inches. Ref. Page 74 Tools for all Trades Catalogue. Small steel vice consisting of two parallel jaws for holding a workpiece. One jaw is fixed and the other movable by a screw. The clamp is used for holding a workpiece during hand operations eg. filing, hammering or sawing. Small steel clamp is a versatile tool that serves to temporarily hold work securely in place by screwing each jaw together.vice/vise tool, clamp tool, hand tools -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPlane Wood, 1890 -1900

... as blades for wood working tools they were also sword makers (used ...J.E. Bleckmann were German Blade makers, registry shows Bleckmann (1899, No. 37190):J.E.Bleckmann, Solingen, registry class 9b). As well as blades for wood working tools they were also sword makers (used in American Civil War), Bayonet makers 1871-1918 and also pocket cutlery (pocket knives) as per advertisement 1907.This wood plane holds historical importance as carpentry tools such as this would have been used in the construction of local homes, outbuildings, furniture. It represents an era before power tools. Investigation is ongoing as to ownership and specific use in the area. Hand made wooden hand plane with metal blade. Carpentry tool from 19th century1/38 / 34 mm stamped into wood on front edge of plane. Metal Blade inscribed "J.E. BLECKMANN/ WARRANTED / CAST STEEL / SOLINGEN/GERMANY"tool, blade makers, hand plane, woodworking. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900s

This item wasused before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength. This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) within the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools was and still is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron, hand operated Auger has a short barrel shaped cylinder at one end (known as the "Eye") and at the other end a Helical screw blade (screws the cutting edge into wooden material, thereby creating a hole 3/4 inch diameter in the wood) . The barrel section at the top permits a metal or wooden leverage plank to be inserted. The main rod has a 180mm long cutting/screw blade running from the bottom up towards the "eye" end. From the end of the screw blade to the handle is 380mm and cylindrical, but this changes at 550mm from the "eye" end to a 14mm x 10mm rectangular shape shaft.This shaft end is welded to the "Eye".On the shaft below the "eye" is stamped " MATHESON GLASGOW" on the front side and a spade (cards) symbol on the back.auger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0471 for another 1/8th inch hole.A number 5 stamped on the flat sideauger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0470 for another 1/8th inch hole.auger, hand drill, fencing, tool, rural trades, brace & bit -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Tools, Name Stamp, Late 19th century/early 20th century