Showing 2602 items matching " parts of buildings or structures"

-

Parks Victoria - Cape Nelson Lightstation

Parks Victoria - Cape Nelson LightstationEquipment - Rescue Harness

The ‘Resumatic’ brand, British made, lightweight device comprises a red pulley with attached length of white rope and harness. Information on the item indicates that it was the property of the Department of Transport, Australia. The Commonwealth Lighthouse Service was associated with the Department of Shipping and Transport in 1951 and the Navigational Aids Branch of the Department of Transport in 1972 so the harness may date to this period. The easily operated descent device was used for automatic, controlled descents from overhead structures, such as towers and other buildings and did not require a power source or tools. The user needed to make sure the unit is secured to an anchor point so that the cable could be dropped to the ground. As soon as it was secured the user could put on the support harness, step off the edge and travel down to safety. The device complements a number of other items of rescue equipment held in the wider Parks Victoria lightstation collection which attest to the dangers inherent in lightstation work and necessity for first aid kits, resuscitators, life buoys, life jackets and other devices such as harnesses and pulleys used for moving people. These include a bosun’s chair and harness with pulley, Royal Flying Doctor first aid cabinet, resuscitator kit and case, first aid kit, lifebuoy and cork fragments x 4 all in the Gabo Island collection; a rescue basket, resuscitation kit and case, and pulleys and ropes at Cape Otway; rescue stretcher made of bamboo at Wilsons Promontory; and a rescue anchor at Cape Schanck. The Cape Nelson rescue harness, although unique in the broader lightstation collection, is a relatively common device that is still manufactured more or less the same in England. It has second level contributory significance for offering insights into the various methods used in rescue operations by Victoria’s lightstations.Length of white rope attached to a harness and a red pully device.yes -

Melbourne Legacy

Melbourne LegacyDocument, Early History of the Shrine of Remembrance, c1928

After the first world war there was a decision made to create a memorial. Legatees were involved in the process at various times and capacities. In particular Legatee Kemsley was vocal in idea of a structure over a utilitarian memorial (such as a hospital or a park) - see letter at 01182. These notes include the resolution that passed at the Melbourne Town Hall at a public meeting: "That this meeting of citizens confirm the launching of an appeal by the Lord Mayor to establish a National War Memorial by means of a monument and that an executive committee with the Lord Mayor as Chairman with power to add and point sub-committees be formed to carry out the project." Also that 20 sites were selected for consideration in 1921. Although the St Kilda Road site was favoured early on, by 1926 there was pressure to change to a "provision of square" and Cenotaph at the intersection of Spring and Bourke Streets. Legacy Clubs voiced their opposition to this proposal by passing a resolution "That the Melbourne Legacy Club, representative of the returned soldiers in business in this city, whilst welcoming the Anzac Square Scheme as a city improvement, cannot support it as a War Memorial scheme and affirms its support for the Shrine of Remembrance in the Domain as the only War Memorial worthy of Victoria's unparalleled efforts in the Great War." The document was in an envelope with a letter dated 30 April 1971 (01182) that also outlines the efforts Legacy (especially L/- Kemsley) went through to promote the construction of the Shrine of Remembrance over a proposed square. The envelope says 'The Origin of the Shinre of Remembrance p/p Legatees Kemsley and Joynt'. And the initial 'JMBA'?. It was in a file with other documents concerning the Shrine and it's history.A record of the events that led to the construction of the Shrine of Remembrance as noted by a Legatee at the time. There was an effort to record historical events for the "Archive Committee" which collected this an other documents relating to the Shrine together in a file (see items 01181 - 01190)Five white foolscap pages of black type recording major events in the history of building the Shrine (covering the years from 1926 - 1928).memorial, shrine of remembrance -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Church, Clare Gervasoni, Daylesford Uniting Church, 18/10/2015

The Daylesford Uniting Church (formerly Wesleyan /Methodist Church) was built in 1865, replacing an earlier Wesleyan Chapel built in 1861 which is still on site and known as the Sunday School (2024). The foundaton stone for the newer, current church was laid on 12 June 1865, designed by Architects Crouch and Wilson the structure was built in early English Gothic style. The first service was held in the new church on 10 December 1865. It is of interest for its brick broach spire, diapered brick façade and spacious interior with aisles separated from the nave by slender columns. The church organ was installed and built in 1888 by William Anderson and boasts an impressive 724 pipes, many of which are decorated with Christian symbols. This organ is a rare example of Anderson’s work and is his only instrument in Western Victoria. It is classified by the National Trust of Australia (Victoria) as being of state significance. The organ was renpvated in 1979-80 by Leighton Turner. It has 2 manuals, 14 speaking stops, 3 couplers, tracker action, Gt: 8.8 divided.8.4.4.2-2/3.2. Sw: 8.8.4.2.8. Ped: 16. In the 1880s the decline in mining led to the congregation considering ways to reduce debt. Rent was received from pew hire as well as organ concerts and annual fairs. By the end of the 19th century the church had settled into a pattern of steady parish life. The 1950s and 1960s were really the glory days of the church with an active Sunday School, tennis clubs and vibrant social activity as well as many worshippers at Sunday services. The final service was held at the church on 21 April 2024.A redbrick church on stone foundation in Daylesforddaylesford uniting church, daylesford methodist church, daylesford, john mitchell uniting church, daylesford wesleyan church, crouch and wilson, daylesford uniting sunday school -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Church, Clare Gervasoni, Daylesford Uniting Church Baptisimal Font, 2023, 04/03/2023

The Daylesford Uniting Church (formerly Wesleyan /Methodist Church) was built in 1865, replacing an earlier Wesleyan Chapel built in 1861 which is still on site and known as the Sunday School (2024). The foundaton stone for the newer, current church was laid on 12 June 1865, designed by Architects Crouch and Wilson the structure was built in early English Gothic style. The first service was held in the new church on 10 December 1865. It is of interest for its brick broach spire, diapered brick façade and spacious interior with aisles separated from the nave by slender columns. The church organ was installed and built in 1888 by William Anderson and boasts an impressive 724 pipes, many of which are decorated with Christian symbols. This organ is a rare example of Anderson’s work and is his only instrument in Western Victoria. It is classified by the National Trust of Australia (Victoria) as being of state significance. The organ was renpvated in 1979-80 by Leighton Turner. It has 2 manuals, 14 speaking stops, 3 couplers, tracker action, Gt: 8.8 divided.8.4.4.2-2/3.2. Sw: 8.8.4.2.8. Ped: 16. In the 1880s the decline in mining led to the congregation considering ways to reduce debt. Rent was received from pew hire as well as organ concerts and annual fairs. By the end of the 19th century the church had settled into a pattern of steady parish life. The 1950s and 1960s were really the glory days of the church with an active Sunday School, tennis clubs and vibrant social activity as well as many worshippers at Sunday services. The final service was held at the church on 21 April 2024.A marble baptisimal font in Daylesford Uniting Church.In loving memory of my dear husband The late Rev. T. Pollard James 28.9.41daylesford uniting church, daylesford methodist church, daylesford, john mitchell uniting church, daylesford wesleyan church, daylesford uniting sunday school, baptisimal font, t. pollard james -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Church, Clare Gervasoni, Daylesford Uniting Church Interior, 2023, 04/03/2023

The Daylesford Uniting Church (formerly Wesleyan /Methodist Church) was built in 1865, replacing an earlier Wesleyan Chapel built in 1861 which is still on site and known as the Sunday School (2024). The foundaton stone for the newer, current church was laid on 12 June 1865, designed by Architects Crouch and Wilson the structure was built in early English Gothic style. The first service was held in the new church on 10 December 1865. It is of interest for its brick broach spire, diapered brick façade and spacious interior with aisles separated from the nave by slender columns. The church organ was installed and built in 1888 by William Anderson and boasts an impressive 724 pipes, many of which are decorated with Christian symbols. This organ is a rare example of Anderson’s work and is his only instrument in Western Victoria. It is classified by the National Trust of Australia (Victoria) as being of state significance. The organ was renpvated in 1979-80 by Leighton Turner. It has 2 manuals, 14 speaking stops, 3 couplers, tracker action, Gt: 8.8 divided.8.4.4.2-2/3.2. Sw: 8.8.4.2.8. Ped: 16. In the 1880s the decline in mining led to the congregation considering ways to reduce debt. Rent was received from pew hire as well as organ concerts and annual fairs. By the end of the 19th century the church had settled into a pattern of steady parish life. The 1950s and 1960s were really the glory days of the church with an active Sunday School, tennis clubs and vibrant social activity as well as many worshippers at Sunday services. The final service was held at the church on 21 April 2024.A redbrick church on stone foundation in Daylesforddaylesford uniting church, daylesford methodist church, daylesford, john mitchell uniting church, daylesford wesleyan church, crouch and wilson, daylesford uniting sunday school -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Church, Clare Gervasoni, Daylesford Uniting Church, 2023, 04/03/2023

The Daylesford Uniting Church (formerly Wesleyan /Methodist Church) was built in 1865, replacing an earlier Wesleyan Chapel built in 1861 which is still on site and known as the Sunday School (2024). The foundaton stone for the newer, current church was laid on 12 June 1865, designed by Architects Crouch and Wilson the structure was built in early English Gothic style. The first service was held in the new church on 10 December 1865. It is of interest for its brick broach spire, diapered brick façade and spacious interior with aisles separated from the nave by slender columns. The church organ was installed and built in 1888 by William Anderson and boasts an impressive 724 pipes, many of which are decorated with Christian symbols. This organ is a rare example of Anderson’s work and is his only instrument in Western Victoria. It is classified by the National Trust of Australia (Victoria) as being of state significance. The organ was renpvated in 1979-80 by Leighton Turner. It has 2 manuals, 14 speaking stops, 3 couplers, tracker action, Gt: 8.8 divided.8.4.4.2-2/3.2. Sw: 8.8.4.2.8. Ped: 16. In the 1880s the decline in mining led to the congregation considering ways to reduce debt. Rent was received from pew hire as well as organ concerts and annual fairs. By the end of the 19th century the church had settled into a pattern of steady parish life. The 1950s and 1960s were really the glory days of the church with an active Sunday School, tennis clubs and vibrant social activity as well as many worshippers at Sunday services. The final service was held at the church on 21 April 2024.A redbrick church on stone foundation in Daylesforddaylesford uniting church, daylesford methodist church, daylesford, john mitchell uniting church, daylesford wesleyan church, crouch and wilson, daylesford uniting sunday school -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Church, Clare Gervasoni, Former Daylesford Wesleyan Chapel, 2023, 04/03/2023

The Daylesford Uniting Church (formerly Wesleyan /Methodist Church) was built in 1865, replacing an earlier Wesleyan Chapel built in 1861 which is still on site and known as the Sunday School (2024). The foundaton stone for the newer, current church was laid on 12 June 1865, designed by Architects Crouch and Wilson the structure was built in early English Gothic style. The first service was held in the new church on 10 December 1865. It is of interest for its brick broach spire, diapered brick façade and spacious interior with aisles separated from the nave by slender columns. The church organ was installed and built in 1888 by William Anderson and boasts an impressive 724 pipes, many of which are decorated with Christian symbols. This organ is a rare example of Anderson’s work and is his only instrument in Western Victoria. It is classified by the National Trust of Australia (Victoria) as being of state significance. The organ was renpvated in 1979-80 by Leighton Turner. It has 2 manuals, 14 speaking stops, 3 couplers, tracker action, Gt: 8.8 divided.8.4.4.2-2/3.2. Sw: 8.8.4.2.8. Ped: 16. In the 1880s the decline in mining led to the congregation considering ways to reduce debt. Rent was received from pew hire as well as organ concerts and annual fairs. By the end of the 19th century the church had settled into a pattern of steady parish life. The 1950s and 1960s were really the glory days of the church with an active Sunday School, tennis clubs and vibrant social activity as well as many worshippers at Sunday services. The final service was held at the church on 21 April 2024.A stone church in Daylesford. Originally built at the Daylesford Wesleyan Chapel, it was later used as the Daylesford Uniting Church Sunday School. daylesford uniting church, daylesford methodist church, daylesford, john mitchell uniting church, daylesford wesleyan church, daylesford uniting sunday school -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Church, Clare Gervasoni, Daylesford Uniting Church John Mitchell Memorial Hall, 2023, 04/03/2023

The Daylesford Uniting Church (formerly Wesleyan /Methodist Church) was built in 1865, replacing an earlier Wesleyan Chapel built in 1861 which is still on site and known as the Sunday School (2024). The foundaton stone for the newer, current church was laid on 12 June 1865, designed by Architects Crouch and Wilson the structure was built in early English Gothic style. The first service was held in the new church on 10 December 1865. It is of interest for its brick broach spire, diapered brick façade and spacious interior with aisles separated from the nave by slender columns. The church organ was installed and built in 1888 by William Anderson and boasts an impressive 724 pipes, many of which are decorated with Christian symbols. This organ is a rare example of Anderson’s work and is his only instrument in Western Victoria. It is classified by the National Trust of Australia (Victoria) as being of state significance. The organ was renpvated in 1979-80 by Leighton Turner. It has 2 manuals, 14 speaking stops, 3 couplers, tracker action, Gt: 8.8 divided.8.4.4.2-2/3.2. Sw: 8.8.4.2.8. Ped: 16. In the 1880s the decline in mining led to the congregation considering ways to reduce debt. Rent was received from pew hire as well as organ concerts and annual fairs. By the end of the 19th century the church had settled into a pattern of steady parish life. The 1950s and 1960s were really the glory days of the church with an active Sunday School, tennis clubs and vibrant social activity as well as many worshippers at Sunday services. The final service was held at the church on 21 April 2024.A small hall in the grounds of Daylesford Uniting Church. John Mitchell was a teacher and superintendent from September 1861 to 1921. The hall was still in existence in August 2024.John Mitchell Memorial Hall 1931daylesford uniting church, daylesford methodist church, daylesford, john mitchell uniting church, daylesford wesleyan church, daylesford uniting sunday school, john mitchell -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDocument - Plan, Victorian Harbours Warrnambool, Victorian Harbours, Warrnambool, Plan to Accompany Sir John Coode's Report, 28-02-1879

This plan is of great significance to the local history of Warrnambool, in particular the Breakwater and its impact on Warrnambool's maritime and trade history. The plan shows the existing jetties at the Port of Warrnambool, plus the partially erected Breakwater and proposed works to the Breakwater by both the Borough of Warrnambool Surveyor and Sir John Coode. The plan was signed 28th February 1879 by Sir John Coode. The legend at the bottom left describes the existing works and the proposed works. The Warrnambool Breakwater Sir John Coode was a British harbour engineer. He was brought to Melbourne by the Melbourne Harbour Trust to advise on works to improve the Port of Melbourne. The Victorian Government commissioned him to present a plan to complete the Warrnambool Breakwater. His original plan was too expensive so he prepared a revised plan for a shorter structure. The work was completed in 1890. The construction proved to be too short to protect adequately from the weather and didn't allow enough depth for larger vessels to come into port. The decreasing trade was further affected by siltation in the bay due to the breakwater, and the completion of the railway line. The situation of the harbour became a real problem that, by 1910, required continuous dredging. In 1914 the Breakwater was extended but proved to be a failure because the work began to subside and by 1920 about two thirds of the harbour was silted up. Alterations made in the 1920's increased the silting problem and by the 1940's the harbour was no longer used. More alterations were made in the 1950's and 1960's. The Warrnambool Breakwater is registered as a place of significance on the Victorian Heritage Database. This plan of the proposed works for the existing Warrnambool Breakwater is of great significance to the local history of Warrnambool, in particular the Breakwater and its impact on Warrnambool's maritime and trade history. The Warrnambool Breakwater is registered as a place of significance on the Victorian Heritage Database (VHR H2024). It is historically significant to Victoria as one of the most important maritime engineering projects in Victoria in the late 19th century. The Warrnambool Breakwater is of historical significance as one of the most important maritime engineering projects in Victoria in the late nineteenth century. It is evidence of Victoria's nineteenth century investment in regional port infrastructure and the development of Victorian coastal shipping. It is of significance for its association with the English civil engineer Sir John Coode, the most distinguished harbour engineer of the nineteenth century, who was brought to Victoria to advise on works to improve the Port of Melbourne, but was retained by the Government to advise on improvements to the harbours at Portland, Geelong, Port Fairy, and Lakes Entrance, as well as Warrnambool. His projects for Melbourne, Lakes Entrance and Warrnambool were major engineering projects of the nineteenth century. The breakwater is historically significant as a reminder of Warrnambool's early maritime history as a Western District port, and as one of Victoria's major 'outer ports'. While the Warrnambool Breakwater is a demonstration of the engineering skills of the nineteenth century, it also demonstrates the limitations of knowledge relating to sedimentology at the time and the confidence apparent in a number of nineteenth century plans which assumed that natural forces could be overcome or contained by engineering.Plan of Warrnambool Harbour, Port of Warrnambool, dated 28 Feb 1879. Plan shows existing Breakwater and work proposed by both Warrnambool Borough Surveyor and Sir John Coode. Plan has gold coloured quarter-dowel rods top and bottom and a metal ring at the top. Stamped with title. Signed by Sir John Coode.Stamped "VICTORIAN HARBOURS / WARRNAMBOOL / PLAN / to accompany / SIR JOHN GOODE'S REPORT / DATED 28 FEB 1879" Signature "John Coode"flagstaff hill, warrnambool, maritime museum, shipwreck coast, great ocean road, sir john coode, borough of warrnambool surveyor, plan of warrnambool, victorian harbours, warrnambool harbour, warrnambool breakwater, port of warrnambool, vhd vhr h2024, flagstaff hill maritime museum & village, maritime village, map, chart, plan, lady bay, breakwater, jetty, pier, vhr h2024, proposed works, 1879 -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Photocopies, Alan Bradley, "The Ballaarat Tramway Company Limited - Half Yearly Reports", c1995

Set of A4 photocopies of 6 years of half yearly reports of The Ballaarat Tramway Company Limited (Horse Trams) from 3/1897 to 9/1902. All reports except the last one comprise a two sheet printed or typeset report giving notice of meeting, directors report, statement of assets and liabilities, share structure and profit and loss account. The last report 9/1902 is typed, and lists assets and credits only on the profit and loss account. Meetings were held at Craig's Hotel, Lydiard St. The Directors report from 9/1900 note the forthcoming sale of the company to the British Insulated Wire Company Limited and the problems of finalising the sale. Photocopies from the Public Records Office of Victoria, Company Reports, obtained by Alan Bradley c1995. .1 - 3/1897 .2 - 9/1897 .3 - 3/1898 .4 - 9/1898 .5 - 3/1899 .6 - 9/1899 .7 - 3/1900 .8 - 9/1900 .9 - 4/1901 .10 - 10/1901 .11 - 3/1902 .12 - 9/1902 All reports signed by the Company Secretary Edgar A. Akins, except the last one, Geo A Grace. The report notes that Mr. Akins had passed away. Geo. Grace was appointed as Secretary Pro-tem. Items separated by yellow coloured A4 sheets.trams, tramways, ballaarat tramway company, horse tram, esco, british insulated wire company, annual reports, directors reports -

Bendigo Historical Society Inc.

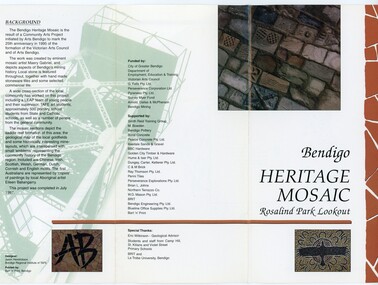

Bendigo Historical Society Inc.Pamphlet - MERLE HALL COLLECTION: ROSALIND PARK CREATIVE VILLAGE BENDIGO PROJECT PAMPHLET, 1995

Merle Hall Collection: Rosalind Park Creative Village Bendigo Project Pamphlet for Rosalind Park Lookout - two copies. One side of the pamphlet has a layout image of the five sections of the mosaic and the poppet head base. The sections are numbers 1 to 5 Section 1: A stylised representation of the main Bendigo Goldfield based on a geological plan (Publish in 1992). It shows the lines of reef, including the famous Hustlers, Garden Gully and New Chum. Section 2: A typical cross section of the Bendigo Goldfields Section 3: The mine layout shown in this design features part of the Garden Gully line of reef. Section 4: Shown here is the Iron Bark mine on the Sheepshead reef. It has an interesting pattern of drives, stopes and winzes. Section 5: In this section the artist uses gold as her inspiration. The larger mosaic shows quartz veins winding through the earth containing gold in its various forms. The smaller mosaic represents the atomic structure of gold. It shows the the nucleus, the six shells of the atom, their electrons and orbits. The other side of the pamphlet describes the background of the community arts project, the artist, and volunteer workers, also notes mentioning the Bendigo community history. It also lists the donors for funding and business's that supported the project, with special thanks to Eric Wilkinson - Geolpogical advoser, the students and staff from Camp Hill, St Killians and Violet Street primary schools. BRIT and La Trobe University, bendigo. -

Kew Historical Society Inc

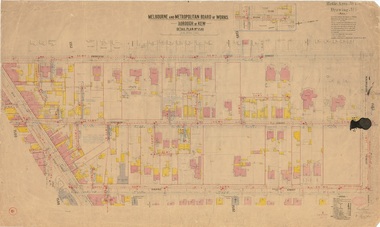

Kew Historical Society IncPlan, Melbourne & Metropolitan Board of Works : Borough of Kew : Detail Plan No.1581, 1904

The Melbourne and Metropolitan Board of Works (MMBW) plans were produced from the 1890s to the 1950s. They were crucial to the design and development of Melbourne's sewerage and drainage system. The plans, at a scale of 40 feet to 1 inch (1:480), provide a detailed historical record of Melbourne streetscapes and environmental features. Each plan covers one or two street blocks (roughly six streets), showing details of buildings, including garden layouts and ownership boundaries, and features such as laneways, drains, bridges, parks, municipal boundaries and other prominent landmarks as they existed at the time each plan was produced. (Source: State Library of Victoria)This plan forms part of a large group of MMBW plans and maps that was donated to the Society by the Mr Poulter, City Engineer of the City of Kew in 1989. Within this collection, thirty-five hand-coloured plans, backed with linen, are of statewide significance as they include annotations that provide details of construction materials used in buildings in the first decade of the 20th century as well as additional information about land ownership and usage. The copies in the Public Record Office Victoria and the State Library of Victoria are monochrome versions which do not denote building materials so that the maps in this collection are invaluable and unique tools for researchers and heritage consultants. A number of the plans are not held in the collection of the State Library of Victoria so they have the additional attribute of rarity.Original survey plan, issued by the MMBW to a contractor with responsibility for constructing sewers in the area identified on the plan within the Borough of Kew. The plan was at some stage hand-coloured, possibly by the contractor, but more likely by officers working in the Engineering Department of the Borough and later Town, then City of Kew. The hand-coloured sections of buildings on the plan were used to denote masonry or brick constructions (pink), weatherboard constructions (yellow), and public buildings (grey). The streets and built structures in this plan were surveyed in 1903 and released to contractors in 1904. In addition to the designation of building types by colour, the plan includes detailed descriptions of land use and ownership. While many buildings remain from this period, a number of the buildings represented have been demolished including the original Kew Town Hall, and the Congregational and Roman Catholic churches in Walpole Street. While the mansion ‘Illapa’ in Princess Street is still extant – now part of ‘Rylands’ – the neighbouring mansion ‘Elsmere’ was demolished some decades ago. Rivalling Illapa and Elsmere in size were two mansions in Walpole Street, one named on the plan as ‘Gnarlbine’. Over time, Kew Junction and the south side of High Street have been reconfigured and widened, so that the commercial buildings on the corner of Princess and High Street no longer exist. A surprising feature of this part of central Kew to the northwest of Kew Junction is the amount of vacant land. In a number of cases, this land is noted by the contractor as used for vegetable gardens.melbourne and metropolitan board of works, detail plans, maps - borough of kew, mmbw 1581, cartography -

Kew Historical Society Inc

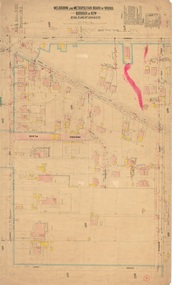

Kew Historical Society IncPlan, Melbourne and Metropolitan Board of Works, Melbourne & Metropolitan Board of Works : Borough of Kew : Detail Plan No.1294 & 1295, 1904

The Melbourne and Metropolitan Board of Works (MMBW) plans were produced from the 1890s to the 1950s. They were crucial to the design and development of Melbourne's sewerage and drainage system. The plans, at a scale of 40 feet to 1 inch (1:480), provide a detailed historical record of Melbourne streetscapes and environmental features. Each plan covers one or two street blocks (roughly six streets), showing details of buildings, including garden layouts and ownership boundaries, and features such as laneways, drains, bridges, parks, municipal boundaries and other prominent landmarks as they existed at the time each plan was produced. (Source: State Library of Victoria). This plan forms part of a large group of MMBW plans and maps that was donated to the Society by the Mr Poulter, City Engineer of the City of Kew in 1989. Within this collection, thirty-five hand-coloured plans, backed with linen, are of statewide significance as they include annotations that provide details of construction materials used in buildings in the first decade of the 20th century as well as additional information about land ownership and usage. The copies in the Public Record Office Victoria and the State Library of Victoria are monochrome versions which do not denote building materials so that the maps in this collection are invaluable and unique tools for researchers and heritage consultants. A number of the plans are not held in the collection of the State Library of Victoria so they have the additional attribute of rarity.Original survey plan, issued by the MMBW to a contractor with responsibility for constructing sewers in the area identified on the plan within the Borough of Kew. The plan was at some stage hand-coloured, possibly by the contractor, but more likely by officers working in the Engineering Department of the Borough and later Town, then City of Kew. The hand-coloured sections of buildings on the plan were used to denote masonry or brick constructions (pink), weatherboard constructions (yellow), and public buildings (grey).The streets and built structures in MMBW Detail Plan 1294 & 1295 were surveyed in 1903 and released to contractors in 1904. This plan is one of two in the collection where the lithographers amalgamated two separate plans. Both plans include sections of Studley Park. Dominating the south and west corners of Kew Junction are the Clifton and Kew Hotels. The Kew Hotel, owned by Patrick O’Shaughnessy was one of the oldest in Kew. MMBW plans were amended over time to take account of new subdivisions such as that which created Merrion Place. Of the four mansions shown in Studley Park Road, three remain – ‘Field Place’, the home of Frances Henty, ‘Leaghur’ and ‘Darley’. ‘Byram’ (later ‘Goathland’, then ‘Tara Hall’) was an architectural marvel. Designed in 1888 by E.G. Kilburn for the paper magnate George Ramsden, it was demolished in 1960. While an earlier sale of the southern section of Byram had created Tara Avenue in 1927, the demolition of the house in 1960 enabled the extension of Tara Avenue northward.melbourne and metropolitan board of works, detail plans, mmbw 1294, mmbw 1295, cartography -

Kew Historical Society Inc

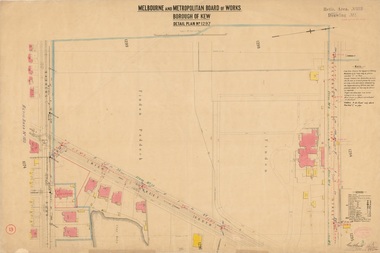

Kew Historical Society IncPlan, Melbourne & Metropolitan Board of Works : Borough of Kew : Detail Plan No.1297, 1904

The Melbourne and Metropolitan Board of Works (MMBW) plans were produced from the 1890s to the 1950s. They were crucial to the design and development of Melbourne's sewerage and drainage system. The plans, at a scale of 40 feet to 1 inch (1:480), provide a detailed historical record of Melbourne streetscapes and environmental features. Each plan covers one or two street blocks (roughly six streets), showing details of buildings, including garden layouts and ownership boundaries, and features such as laneways, drains, bridges, parks, municipal boundaries and other prominent landmarks as they existed at the time each plan was produced. (Source: State Library of Victoria)This plan forms part of a large group of MMBW plans and maps that was donated to the Society by the Mr Poulter, City Engineer of the City of Kew in 1989. Within this collection, thirty-five hand-coloured plans, backed with linen, are of statewide significance as they include annotations that provide details of construction materials used in buildings in the first decade of the 20th century as well as additional information about land ownership and usage. The copies in the Public Record Office Victoria and the State Library of Victoria are monochrome versions which do not denote building materials so that the maps in this collection are invaluable and unique tools for researchers and heritage consultants. A number of the plans are not held in the collection of the State Library of Victoria so they have the additional attribute of rarity.Original survey plan, issued by the MMBW to a sewage contractor with responsibility for constructing sewers in the area identified on the plan within the Borough of Kew. The plan was at some stage hand-coloured, possibly by the contractor, but more likely by officers working in the Engineering Department of the Borough and later Town, then City of Kew. The hand-coloured sections of buildings on the plan were used to denote masonry or brick constructions (pink), weatherboard constructions (yellow), and public buildings (grey). This plan of Kew encompasses the area bounded by Barkers Road, High Street and Stevenson Street. Because of the angle created by High Street, a number of houses on the northern side of High Street are shown. The area is dominated by one of the great original landholdings in Kew, described here as the ‘Findon Paddock’. ‘Findon’, the house from which the name of the paddock was taken fronts Stevenson Street and was clearly a rambling structure. The best-known occupant of Findon was Henry ‘Money Miller’ who bought the house in 1871. Miller was a member of Victoria’s first parliament and assisted in the framing of its constitution. Findon was to be subdivided as early as 1912, when the Findon Subdivision was advertised to be sold by auction. In the plan of the subdivision, the original house is not shown, so, presumably it had previously been demolished. Fincham & Son moved the organ, built by Henry Willis, which was installed in the house, first to ‘Whernside’ in Toorak, and later to the Box Hill Methodist Church.melbourne and metropolitan board of works, detail plans, mmbw 1297, cartography, kew (vic.) — municipal collection -

Royal District Nursing Service (now known as Bolton Clarke)

Royal District Nursing Service (now known as Bolton Clarke)Photograph - Photograph, black and white, Barry Sutton, 22.06.1977

Royal District Nursing Service (RDNS) Sisters worked from this, their rented Collingwood Centre at 98 Charles Street, Collingwood, which opened in 1977. The Sisters left each morning taking any sterilized equipment needed with them to carry out their nursing visits in a specific area (district), They returned at the end of the day to write up their patients nursing histories, clean and reset any equipment used ready for re-sterilization, and contact other medical and community personal as necessary. From its inception as Melbourne District Nursing Society (MDNS), in 1885, their Trained nurses (Nurses) worked in specific areas, 'districts'. The first Nurse worked east and west, between Victoria Parade and Flinders Street and, north and south, between Spencer Street and Spring Street. When a second Nurse was employed they divided this area at Elizabeth Street so each Nurse could attend to patients in the same area giving continuity of care. Gradually over the years, Melbourne District Nursing Service (MDNS), later known as Royal District Nursing Service (RDNS) from 1966 when they received Royal patronage, opened Centres throughout the Melbourne Metropolitan area and outer suburbs with Heidelberg Centre opening in 1971. Their Trained nurses (Sisters) left from these Centres each morning to carry out their nursing visits in a specific area (district), taking any sterilized equipment needed with them. They returned at the end of the day to write up their patients nursing histories, clean and reset any equipment used ready for sterilization, and contact other medical and community personal as necessary. Through its expansion quality of care was not lost, the RDNS nursing staff gave best practice care in many fields of nursing and to people of many cultures with their patients ranging in age from babes, children, adults to the elderly. Some of the care provided was – Post-Natal care, Diabetic Care, Wound Care, Giving of injections and medications, Catheterizations on children and adults, Stoma care, Dementia care, Palliative Care, General care, Rehabilitation, Spinal care, Cystic Fibrosis care, Haemo-Oncology care, Home Enteral Feeding care, and IV therapy at home. Assisting with rehabilitation with an aim towards independence remained at the forefront of the Sister’s minds. All care included giving advice and support to the patient and their Carers. Black and white photograph showing the front facade of the Royal District Nursing Service (RDNS), Collingwood Centre. It is a Victorian style, single story, light coloured painted concrete faced building built around the 1870s. To its left is the front wooden door with a small central glass section in the upper center, and a wire door in front of this. To its right is an Electricity Department meter attached to the wall, and under this a large "98" and to its right, and a little lower is an attached rectangular white sign, with black capital letters, saying "Royal District Nursing Service" and below this in smaller letters "Collingwood". To the right sits a long sash window with dark frame. At either end of the building white concrete face extensions, with embellishments, support a corrugated iron straight veranda roof, with wrought iron embellishment attached to its outer edge. This sits above the window and door and runs along the building protecting the small porch. Above this, along the building, is deep decoration, including a row of concrete balusters and above and central is a concave shell shaped structure. A short dark metal spiked fence runs along the edge of the narrow garden bed. In the foreground the footpath and part of a road can be seen. A small bare tree can be seen on the left hand side of the building and a small bush on the right hand side.Photographer stamp. Quote No. DO 66royal district nursing service, rdns, rdns centre -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone in two pieces. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070. Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined