Showing 6430 items

matching geelong wool museum

-

National Wool Museum

National Wool MuseumTool - Drench Gun, 1940-1950

... National Wool Museum 26 Moorabool Street Geelong geelong ...NJ Phillips was the first Australian company to invent a drench gun that overcame the problem of drench going the 'wrong way' down the throat and onto a sheep’s lungs. This was the drench gun that they developed. It had an ingenious double action on the handpiece. The first squeeze projected a long nozzle that went right down the oesophagus before delivering the dose of drench automatically once this was in place. It also had a readily adjusted dose lever seen at left which minimised overdosing. This company dominated the market for many yearsSilver metal with black finishing drench gun. Minimal curvature tips on gun protrude from the body. Features a thin squeezable trigger to the rear of the body. The main bulk, which the trigger is squeezed towards, has badge which reads “Manufactured and designed by N.J. Phillips Pty Ltd, Sydney” in circular design. On top of this body is a large silver chamber in which both tips meet. This chamber is for the liquid to be transferred from the tube and into the tip of the drench gun for delivery onto the ewe’s tongue. The small section of tubing still attached has a yellow/orange appearance from remanence of drench which would have been this colour.Right circular lettering: MANUFACTURED/ & DESIGNED BY/ N.J.PHILLIPS PTY. LTD./ SYDNEY . AUSTRALIA/sheep drenching, veterinary instruments -

National Wool Museum

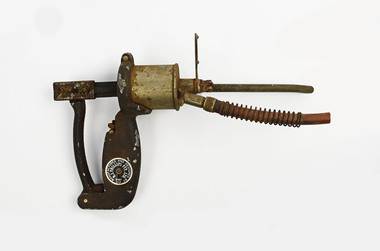

National Wool MuseumTool - Drench Gun, 1940-1950

... National Wool Museum 26 Moorabool Street Geelong geelong ...There are several different designs of drench guns within the NWM Collection that show the change in their development over time. This drench gun has a large diameter curvature suggesting this gun was typically used for dosing ewes as opposed to lambs. The attached spring-loaded hose is the only example in our collection how this mechanism works. The hose will be screwed into the liquid which is used to drench the sheep. This liquid is typically located on the back of the operator who will wear a large container in a backpack. This gun also has a adjustable dosing mechanism located on the right side of the gun.Silver metal with black finishing drench gun. Large curvature tip on gun protrudes from the body which feature a thin squeezable trigger to the front of the body. The main bulk, which the trigger is squeezed towards, has badge which reads “Manufactured and designed by N.J. Phillips Pty Ltd, Sydney”. Behind this body is silver cylinder featuring attachment point for the tubing which would have carried the liquid drench into the gun. The attached tubing has a yellow/orange appearance from remanence of drench which would have been this colour.Left rotated lettering: MANUFACTURED/ & DESIGNED BY/ N.J.PHILLIPS PTY. LTD./ SYDNEY . AUSTRALIA/sheep drenching, veterinary instruments -

National Wool Museum

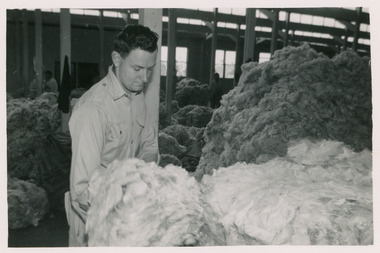

National Wool MuseumPhotograph - Denny Lecelles Photographs, c1950

... National Wool Museum 26 Moorabool Street Geelong geelong ...Father of the donor, Mervyn Graham, worked for Denny Lascelles for many years as a wool classer in Geelong and later as a representative in Hamilton. The Denny Lascelles Wool Warehouse was the first building in Victorian planned to facilitate storage, inspection and marketing of wool in one operation, and upon completion was the second largest store in the colony. CJ Denny's was largely responsible for establishment and development of the wool marketing industry in Geelong and is a figure of significance in the history of settlement in Geelong.Black and white photos showcase different rooms of the Denny Lascelles building and the process of classing the wool within the store, from classing the wool to packaging and transportation.8080.7 - On wool press - Made by Johns & Waygood LTD. Melbourne Australia 8080.10 - On truck - Blackiston & Co PTY. LTD. Road transporters. Geelong & Melb.denny lascelles, geelong, wool, wool class, transportation -

National Wool Museum

National Wool MuseumPhotograph - Royal Melbourne Show, c1950

... National Wool Museum 26 Moorabool Street Geelong geelong ...Father of the donor, Mervyn Graham, worked for Denny Lascelles for many years as a wool classer in Geelong and later as a representative in Hamilton.Black and white photos showing Denny Lascelles employees in front of their stand and the Melbourne Show. The last photo is of four employees in front the Dennys office building.8081.1 - Sign on wool - JL/RBW Rainbow 8081.2 - Sign on wool - Banocre Durham Ox 8081.3 - Sign on wool - Wattle Back/G Guildford 8081.4 - On building - Dennys Lascelles Limited Wool . Stock . Landwool, denny lascelles, royal melbourne show, sheep, geelong -

National Wool Museum

National Wool MuseumFunctional object - Needles, W.H. Head & Son, c1895

... National Wool Museum 26 Moorabool Street Geelong geelong ...Needles are over 100 years old. The donor obtained them from Mrs Patricia Wrench, a granddaughter of Lord Brassey, Governor of Victoria between 1985 – 1900. The needles were manufactured by W.H. Head & Son, a Trimming Manufacture and Wholesale Haberdashers company established in London.A purple leather case containing 39 steel knitting needles of varying widths.Above clip of case, gold lettering - W.H. Head & Son, Sloane st, London, S.W. Inside case, gold lettering - 10 11 12 13 14 15 16 17 18 19 20england, needles, patricia wrench, lord brassey, knitting -

National Wool Museum

National Wool MuseumPlaque - Donald & Sons Plaque, Donald & Sons Ltd, Unknown

... National Wool Museum 26 Moorabool Street Geelong geelong ...Donald & Sons Ltd is a manufacturer and importer of wool presses and other machinery. Located in Masterton, NZ, they transported wool presses around the world. This plaque would have been attached to one of their machines.Gold colored organisational plaque with embossed lettering on the front, containing the organisation description.Donald & Sons Ltd Patentees, manufacturers and machinery importers. Masterton N.Z.wool press, new zealand, donald & sons -

National Wool Museum

National Wool MuseumTextile - Onkaparinga Blanket, Waffle Collection, Unknown

... National Wool Museum 26 Moorabool Street Geelong geelong ...Onkaparinga started in South Australia in 1869. Migrating from Germany, two brothers, Heinrich and Edward Kramm, both weavers, purchased and brought with them some machinery and established themselves in Hahndorf in a mud hut. Their original plant consisted of one carding machine, one spinning mule of 30 spools and 2 hand looms. The spinning mule was horse driven, the others all hand operated. The wool was washed by hand and dried in the sun then teased by hand. Now 145 years later the brand name Onkaparinga, is known all over the world, the products reflect the experience, passion and ingenuity of over a century's tradition in providing luxurious home wares. Donated to the National Wool Museum by Joyce GrayLight orange waffle weave woolen blanket, with nylon trimming. Product tag included with plastic case. On product tag - The better way to sleep. Onkaparinga onkaparinga, blanket, wool, kramm -

National Wool Museum

National Wool MuseumTool - Drench Gun, 1940-1950

... National Wool Museum 26 Moorabool Street Geelong geelong ...There are several different designs of drench guns within the NWM Collection that show the change in their development over time. On the left side of this gun white paint indicates the adjustable dose lever. It is a sliding scale from 10 to 0 cubic centimetres of liquid (now typical measure in millilitres). It also has a small and straight tip suggesting this gun was typically used for dosing Lambs as opposed to ewes. The manual adjuster helped to minimise cases of overdosing which can be fatal for livestock while the additional curvature helped to ensure the liquid reached the desired location within the sheep’s mouth. This desired location is on the left rear of the sheep’s tongue (from the sheep’s point of view) as this is where the oesophagus is located. The main risks are that drench may be delivered into the lungs via the trachea or “windpipe”, which can also prove fatal. The opening to the trachea which leads to the lungs is in the middle of the back of the throat. Another risk is the throat can also be damaged due to rough handling.Silver metal with black finishing drench gun. Straight tip on gun protrudes from the body which feature a thin squeezable trigger to the front of the body. The main bulk, which the trigger is squeezed towards has silver cylinder on top of the handle where tubing carrying the liquid drench into the gun attaches. The small section of tubing still attached has a yellow/orange appearance from remanence of drench which would have been this colour.sheep drenching, veterinary instruments -

National Wool Museum

National Wool MuseumModel Ship, David Lumsden, SS Edina, 2018-2019

... National Wool Museum 26 Moorabool Street Geelong geelong ...The Edina was one of the longest serving steam vessels anywhere in the world. Built on the Clyde by Barclay, Curle & Co. she was an iron hull single screw steamer of 322 tons with three masts. In 1855 Edina was requisitioned by the Admiralty from her owners the Leith, Hull & Hamburg Steam Packet Co. to carry stores and horses to the Black Sea during the Crimean War. After return to her owners Edina traded around the UK and Mediterranean before being purchased and used as a blockade runner during the American Civil War carrying cotton from the Confederate states in 1861. Edina arrived in Melbourne under sail in March 1863 and was purchased by Stephen Henty for use from ports in western Victoria and later carried gold prospectors across the Tasman to New Zealand. After a refit in 1870 she was used in the coastal trade along the Queensland coast for Howard Smith until returning to Victoria and the Melbourne-Geelong trade as a cargo-passenger vessel. The Edina had two narrow escapes from destruction in 1898 and 1899 when she collided with other steamers, both being sunk. A further refit in 1917 altered her appearance with a new mast, funnel, bridge and promenade deck. By 1924 Edina had made over 12,000 Melbourne-Geelong passages and carried over one million people on the service. A further collision in July 1931 which sank the tug Hovell forced Edina onto a mudbank on Port Phillip Bay. She was taken out of service in 1938 but was later renamed Dinah and used as a lighter until 1958 when she was broken up and her remains used as land-fill.Model of a Coastal Trader & Passenger Ship with hull painted red and black. Red flag and black flag with S attached to flag pole. On forward of ship - Edinageelong, transport, ship model, water transport -

National Wool Museum

National Wool MuseumDecorative object - Model Ship, David Lumsden, Lightning, 2020

... National Wool Museum 26 Moorabool Street Geelong geelong ...In the early nineteenth century larger Australian wool producers sent all their wool by sailing ship to London, where colonial auctions were held in November, January, February and March. Wool bales were carried from the farm on drays or wagons pulled by bullocks, horses or camels to port warehouses. In these times, wool transport could take anything from a week to six months. Ships, such as the Lightning, were then loaded and raced each other to get to London ahead of their rivals. The wooden ship 'Lightning' was destroyed by fire while loading wool at Geelong 31 Oct. 1869. Scuttled in Corio Bay and the remains later blown up. Reputed to be one of the fastest sailing ships. Famous in the Australian passenger trade.Model of a clipper ship with hull painted brown and black. Red Ensign flag attached to flag pole.On label - Lightning Black Ball Line 1854-55geelong, transport, model ship, lightning, wool transport -

National Wool Museum

National Wool MuseumClothing - Dress, 1979

... National Wool Museum 26 Moorabool Street Geelong geelong ...This dress was created by Jean Inglis for a competition of garments hosted by the Geelong Handweavers and Spinners Guild at a ski weekend in 1979. It was entered in the ‘evening wear’ category of hand spun and knitted garments. The Warp was commercially brought 2/24 wool. The Weft was hand spun black Corriedale wool. This wool was brought at a sale in Geelong and was hand dyed and spun by Jean. The patter is a ‘Ripple’ variation of a ‘Crackle’ weave completed on Jean’s own Dobby Loom (pictured). Long black dress stretching from the feet, reaching up to a hood at the neckline and down to the hands in the sleeve. The dress is black with a glossy silver pattern in the form of a band around the hood, hands and feet of the garment. In these bands is a wavy pattern of silver and black lines. There are multiple thick and thin lines of both the silver and black colours mirroring each other as the pattern stretches around the garment. wool, weaving, hand spun, corriedale -

National Wool Museum

National Wool MuseumClothing - Suit, 1987

... National Wool Museum 26 Moorabool Street Geelong geelong ...Hand spun, hand dyed, hand woven and hand sewn suit which won best garment in the 1987 Geelong show. Size 12 in a design by Chanel. It was spun with variegated natural greys on a Sheridan horizontal spinning wheel. It was then dyed pink using natural dyes. The jacket had commercially brought warp and hand spun weft in twill on a 24” loom. All spinning, dyeing and weaving was by Jean Inglis of Geelong. The suit was sewn by Caroline Mogic of Geelong, with iron on interfacing, commercially brought trim. It was worn only once in the parade at the Geelong show. The pink suit jacket has four pockets with gold buttons on front, size 12. The jacket has a checker-plate pattern in which the predominate pink is always present and is accompanied in areas which have grey or white showing through the pink. This checker plate pattern continues down the sleeves of the jacket. The edge of the jacket has a lighter pink trim. A pink skirt accompanies the suit jacket. It has horizontal lines with pink as the predominate colour and areas of grey and white showing through in sections. geelong show, hand spun, hand dyed, hand woven, hand sewn, channel -

National Wool Museum

National Wool MuseumClothing - Dress, 1993

... National Wool Museum 26 Moorabool Street Geelong geelong ...This dress was made for the Melbourne Show in 1993 and won 3rd prize. It was designed by Jean Inglis who was inspired by the Blue Triangle Butterfly (Scientific name: Graphium sarpedon choredon). The Warp was 2/24 commercially brought black wool with a “tie down” thread of black polyester and Weft of the same 2/24 wool 2 ply. Jean utilised a twill technique devised by Theo Morgan in creating the dress. The dress was handwoven by Jean Inglis with the help of Ruth Rondell with some of the pattern and final sewing. Black dress stretching from below the knees, reaching up to the neckline and down to the hands in the sleeve. The dress has three butterflies attached to the front approximately 50mm in diameter going from right knee to left hip in a nonvisible diagonal line. Lower half of dress has ten thin blue & green lines of varying lengths, reaching a max height of the hip. The neck of dress has four frills of blue and green colour. The longest two frills are in the centre pointing diagonally outwards towards the hands. The second layer of frills is shorter and further around the neckline towards the shoulders. The dress is completed with a cape of blue and green colour with a thick black seam separating each segment of colour. The cape sits on the shoulders and droops to a height of the hips. At the rear, the cape reaches the height of the rump. The cape has two draw strings for tying to the shoulders. wool, butterflies, melbourne show, butterfly -

National Wool Museum

National Wool MuseumFunctional object - Floorboards, 1994

... National Wool Museum 26 Moorabool Street Geelong geelong ...Two short sections of flooring cut for distribution during Deakin Universities ‘Open Day’ in December 1994. This was during the conversion of Dalgety Wool Store to Deakin University’s Woolstore Campus. These small pieces of timber are part of Geelong’s history and were salvaged from the Dalgety Woolstores during the renovations. Hundred of meters of ironbark, red gum, pine and other timbers, some more than a century old, were reclaimed from the site and have been recycled as furniture and featured building materials for the woolstore campus. The old brick stores, located on a formerly neglected section of the Corio Bay shoreline, now house the administration and chancellery, architecture and building schools, information technology services, the student union, a cafeteria and, as the focal facility, a Great Hall seating 1500 people and acoustically tuned for symphony orchestras. The refit was developed from the existing grid of substantial timber columns and beams extending over 52,000 square metres. This framework was filled with lightweight panels to enclose workplaces and removed in some parts to establish courtyards, atriums and streets. The brick facades were redefined with new doors and double-glazed windows in proportion to original fenestration. Bright colours and industrial finishes identify the new insertions.Square sections of redgum lumber cut into floorboards. The sides of the lumber have a grove cut on one side and a matching section to fit within this groove on the other side. This has been done to ensure the floorboards have a tight and consistent fit with one another. The bottom of the lumber also has an additional grove running through the middle of the redgum. On top, one of the sections of lumber has three nail holes, which travel all the way through to the bottom of the wood.deakin university, dalgety wool store, red gum -

National Wool Museum

National Wool MuseumTool - Metal Files, c. 1920

... National Wool Museum 26 Moorabool Street Geelong geelong ...Selection of metal files used for cutting wool bale stencils with an accompanying box. Not all files belong to this box as some are too long to fit within. Used in Denny’s Lascelles Bow Truss building by Maurice Dalton who was the foreman of the building for 34 years. Files are ‘Cup Brand’ – ‘Best refined steel files’ and were manufactured by the no longer trading Moss & Gamble Brothers LTD at the Franklin works in Sheffield, England.12 steel files of varying length, thickness and shape. The longest and thickets are in a flat half circle with some files being fully flat, others complete cylinders, one is a complete square and others are in the shape of a triangle. Cardboard box is brown with black inscription on lid of box.stencils, denny’s lascelles bow truss building -

National Wool Museum

National Wool MuseumArtwork, other - Paper Taxidermy, Mary-Jane Walker, Plains Wanderer, 2020

... National Wool Museum 26 Moorabool Street Geelong geelong ...The world’s most ecologically distinct bird lives in the native grasslands of Victoria - but only just. The plains-wanderer is a small bird that was once widespread across the grasslands of south-eastern Australia. Today there are fewer than 1000 mature birds in the wild. The plains-wanderer is under threat due to habitat loss caused by overgrazing, cropping and suburban sprawl. Unlike most other birds, female wanderers are larger and more colourful and the males take care of the chicks. They are only about 15cm tall and weigh between 40-80g for the male and 55-90g for the female. Their intricate plumage mirrors the colours of their grassland home so they blend in perfectly with their surroundings. The plains-wanderer’s origins date back to when Australia was part of the Gondwana supercontinent over 60 million years ago. They are so biologically distinct that their extinction would result in the loss of a branch of the tree of life. A fussy grass dweller, they like neither too much nor too little grass. That is where sheep grazing can help. After years of low numbers in Victoria, plains-wanderer populations have been increasing in Terrick Terrick National Park in north west Victoria, as sheep grazing maintains the grass in the park at a suitable level. With the right management, this ecologically important bird species is continuing to survive in the native grasslands of Victoria. Managing these habitats for the plains-wanderer can also support the conservation of many other threatened plant and animal species. Object: Nest of plains-wanderers by Mary-Jane Walker, 2020. Outer made from upcycled paper, internal structure steel. Nest of plains-wanderers by Mary-Jane Walker, 2020. Outer made from up cycled paper, internal structure steel. native grasslands, plains-wanderer, terrick terrick national park -

National Wool Museum

National Wool MuseumTool - Numnuts Prototypes, Numnuts

... National Wool Museum 26 Moorabool Street Geelong geelong ...Worldwide, more than 100 million lambs are castrated, and their tails are docked each year. Numnuts is a technological innovation to improve animal welfare. It combines traditions with innovation. In the mid-1990s it was scientifically shown that the immense pain felt during castration and tail docking could be significantly reduced with the use of anaesthetic. For the next 15 years, the industry said the cost the welfare devices and development were too high. But todays ethical consumer has demanded that sheep have no more pain. Initiated in Glasgow in 2009, Numnuts took nearly a decade to develop. Here you can see five stages of development, from an early prototype to the Numnuts device farmers use today. Each phase of development took years of on-farm trails to achieve the final product. Today there is even NumOcaine, an approved local anaesthetic used by Numnuts. Using the simple elastrator ring and adding an anaesthetic injector, Numnuts delivers pain relief during tail docking and castration. In the world’s first rubber ring applicator with a pain relief delivery mechanism. Through innovation and consumer pressure the wool industry is going through a moment of rapid change.Four prototype numnuts tools made from white plastic and stainless steel, each in varying stages of production. FInalised version made with black, orange and clear plastics.8097.2 - Mk4 8097.3 - Numnuts Tool V7; 20 10 0 8097.4 - On label - Numnuts NumOcaine 100ml 65 proceeduressheep, tools, castration, innovation, docking -

National Wool Museum

National Wool MuseumTool - Numnuts, Numnuts, 2020

... National Wool Museum 26 Moorabool Street Geelong geelong ...Worldwide, more than 100 million lambs are castrated, and their tails are docked each year. Numnuts is a technological innovation to improve animal welfare. It combines traditions with innovation. In the mid-1990s it was scientifically shown that the immense pain felt during castration and tail docking could be significantly reduced with the use of anaesthetic. For the next 15 years, the industry said the cost the welfare devices and development were too high. But todays ethical consumer has demanded that sheep have no more pain. Initiated in Glasgow in 2009, Numnuts took nearly a decade to develop. Here you can see five stages of development, from an early prototype to the Numnuts device farmers use today. Each phase of development took years of on-farm trails to achieve the final product. Today there is even NumOcaine, an approved local anaesthetic used by Numnuts. Using the simple elastrator ring and adding an anaesthetic injector, Numnuts delivers pain relief during tail docking and castration. In the world’s first rubber ring applicator with a pain relief delivery mechanism. Through innovation and consumer pressure the wool industry is going through a moment of rapid change.8098.1 - Numnuts tool made with stainless steel and black, orange and grey plastic. 8098.2 - Glass bottle with orange and grey plastic nozzle containing water for injection. 8098.3 - Yellow plastic case containing 12 stainless steel needles 8098.4 - 10 green plastic elastrator rings 8098.5 - Product cardboard box with the product image on the front8097.2 - on label - For animal treatment only WATER FOR INJECTION 100mL 8097.3 - On case - numnuts 12x Veterinary Hypodermic Needles On needdles - 18G 8097.5 - Numnuts targeted pain relief for tail docking and castrationnumnuts, tools, sheep, castration, docking -

National Wool Museum

National Wool MuseumTool - Water Pump, c.1960

... National Wool Museum 26 Moorabool Street Geelong geelong ...A windmill may be considered one of the most iconic sights of Australian Farming life. A pump like this rest at the heart of all such windmills, turning wind energy into water for farmers both here in Australia and worldwide alike. The water windmills access is referred to as an aquifer, an underground layer of water trapped in rocks but accessible with use of water wells and windmills. Australia is home to an underground aquifer known as the Great Artesian Basin. It is the largest and deepest aquifer in the world. Stretching over 1,700,000 square kilometres, the Basin underlies nearly a quarter of the continent including most of Queensland, the south- east corner of the Northern Territory, the north-east part of South Australia and the northern part of New South Wales. The basin is 3,000 metres deep in places and is estimated to contain 64,900 cubic kilometres of groundwater. To try and give this number context, a megalitre is a million litres. The Great Artesian Basin contains 65,000 million megalitres of water. This would be enough to cover all the land on the planet in almost half a metre of water.Lift style piston pump typical of an Australian farm connected to a multi-bladed windmill. Bronze cylindrical construction coming up from removable wood base. Rotating lever is above outlet pipe which would send water to the storage tank.windmill, australian farming, great artesian basin, aquifer -

National Wool Museum

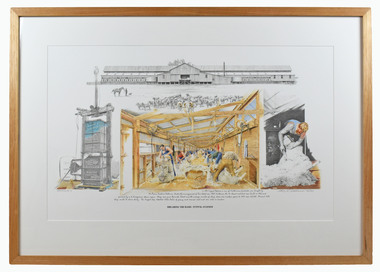

National Wool MuseumPrint, Chris McClelland, Shearing the Rams – Tuppal Station, 210

... National Wool Museum 26 Moorabool Street Geelong geelong ...Chris was invited to be artist in resident for the historic re-enactment of “Shearing the Rams” at the North Tuppal Station woolshed held on the 4th and 5th June 2010. The celebration attracted record crowds to witness the shearing of the station rams by 72 blade shearers. Over a single weekend in 2010, thousands of people queued for hours to see a piece of Australian history recreated at North Tuppal Station near Tocumwal, NSW. In 1900, Francis Faulkner invested a staggering £4000 to extend his shearing shed on Tuppal Station, making it the biggest in the country. Over the next decade more than three million sheep trod its pine boards and were shorn in its 72 stands. After years of drought and the Great Depression, the property fell into disrepair and the station was split up. When North Tuppal Station was sold to the Atkinson family in 1928, just five of the 72 stands were in operation. In 2010, Sport Shear Australia approached the Atkinson family about holding an event in the historic shearing shed to raise money for a team of Australian shearers to go to the world shearing title in Wales. An army of volunteers restored the T-shaped shed and yards and organised a weekend of events. Over two days, 6,000 sheep were shorn and all 72 stands of the restored North Tuppal shed were brought back to life. A total of 117 shearers shared the boards with 90 wool handlers who skirted 19 fleeces every minute. For a period on each day of this historic weekend, the machines were then silenced, and 72 shearers picked up their old blade shears to recreate past shearing methods. “When they fired up and got the blades out there was deathly silence on the board - you could hear a pin drop because normal shearing you have all the machines and it is quite noisy. Here you could just hear the click, like in the song Click Go the Shears Boys. People had tears in their eyes. It was quite an emotional thing to see that and very proud to be here.” George Falkiner, grandson of Francis FalkinerColoured framed print of shearing scene in the Tuppal station, Ferrrier’s wool press on the left-hand side and station on the top. Print in framed in a light-coloured wooden frame with white coloured matte.Under artwork - In 1891 Tuppal Station, a sum of 176,000 acres threshold, was bought by Mr Fiane Sadlies Falkines, Under the management of his eldest son F.B.S. Falkines, the 72 stand woolshed was build in 1900 and powered by a 16 horsepower steam engine. Sheep were pure Boonoke blood and the average numbers of sheep shorn over nineteen years to 1909 was 152,780. Around 7200 sheep could be shorn daily. The largest clip totalled 3326 baled of greasy and scoured wool and was sold in London. Bottom right corner - Chris McClelland 181/720 Shearing The Rams – Tuppal Station -

National Wool Museum

National Wool MuseumPhotograph, Andrew Chapman, Shearing time at Cooninbil Station, 2006

... National Wool Museum 26 Moorabool Street Geelong geelong ...Shearing time at Cooninbil Station, NSW, 2006. The Ferrier Wool Press sits among penned sheep in an old woolshed. Invented and made in Geelong, the Ferrier wool press could be found in woolsheds all over Australia and around the world.A Green large wool press reaches towards the ceiling in the centre of the image. Rays of bright orange sunlight extend around the green wool press. Surrounding the wool press are numerous sheep. The sheep are penned within a large multileveled wooden woolshed.shearing, ferrier wool press, cooninbil station -

National Wool Museum

National Wool MuseumTextile - Quilt, India Flint, Red Blanket Wagga, 2008

... National Wool Museum 26 Moorabool Street Geelong geelong ...Created for and entered in the 2008 ‘Expressions: The Wool Quilt Prize’- “The quilts connect us to our past and to our future, by interpreting Australian themes and telling our stories.”- Judy Hooworth, Quilter and Judge of the Prize. Donated to the National Wool Museum after the conclusion of the exhibition.Eucalyptus dyed woolen blanket base with salvaged fabrics hand sewn to create a patchwork effect. The eucalyptus dye has been used to create different tones of brown and red throughout the design with further dyeing used to create leaf imprints on the fabrics. A running stitch has been used to quilt the wagga, the stitching is imperfect, in places tied on the surface of the wagga.On reverse: INDIA FLINT RED BLANKET WAGGAexpressions: the wool quilt prize, quilt, india flint, wagga -

National Wool Museum

National Wool MuseumClothing - 1984 Los Angeles Olympics Men's Opening Ceremony Shirt, c. 1984

... National Wool Museum 26 Moorabool Street Geelong geelong ...On the 1984 Los Angeles Olympic Uniforms donator Doug wrote- During the 1980s the Australian wool industry was at its most prosperous times with record numbers of sheep producing wool receiving ever increasing values due to the success of the Reserve Price Scheme, and the overall guidance of the Australian Wool Corporation (AWC). As a humble technician, my role was a low profile newly created position of “Controller, Technical Marketing” where wool was to be marketed on its technical properties, as distinct from the “Product Marketing Group” which exploited trhe traditional high profile approach of marketing wool;s superior fashion attributes. The Woolmark was the tool central to this approach. When the forthcoming Los Angeles Olympic Games was announced, the Product Marketing Group seized upon the chance to show the world that we could make top fashion garments and display them on our elite athletes on the world stage. A concept was launched using a contemporary top designer, Adel Weiss, with the most exclusive fabrics and knits available, and all with a lot of hype. This launch failed dismally for the following reasons- - The designer did a wonderful job presenting an excellent fashion range on perfect skinny models. The AOC however wanted a uniform which had an obvious Australian appearance when fitted to elite, and frequently muscular, athletes. - The fabrics chosen did not reflect the performance required by travelling athletes, there was no recognition of the need for ‘easy care.’ - There was no recognition given to the problem of measuring, manufacturing and distribution of a range of articles when the selected athlete could be domiciled anywhere in Australia. - There was no appreciation of such historical facts as Fletcher Jones, who had been unofficial suppliers dating back to the 1954 Olympics in Melbourne, and the Fletcher Jones board member, who was also an AWC board member, and was not in favour of the change. The project passed from Product Marketing to Public Relations, a big spending off-shoot of the AWC Chairman David Asimus, and due to the day to day operations of the project was passed to me and PR took care of the financial matters. The first task was to meet with the AOC and find out exactly their requirements. This lead to the production of a design and manufacturing brief, cointaining exact time lines for each event required to ensure an appropriate uniform on every athlete chosen to represent his/her country on the date given for the Opening Ceremony in Los Angeles. Working backwards the timeline becomes- 1. Noted the exact date of the Opening Ceremony. 2. Estimated the date for distributing completed garments to each athlete. 3. Estimated the time span available for measuring each athlete and commence making each component of the ensemble to the individual measurements of each athlete. 4. Decided the date for making the final choice of uniform design concept. 5. Decided the date for distribution of the design brief to selected designers. These five steps were spread out over a two year period. The Commonwealth Games occur midway between each Olympic Games, work on the Olympic uniform commences the week after the Commonwealth Games closing ceremony and MUST be ready by the prescribed day two years hence. The project also had to remain cognisant of trade politics existing within the span of the task, as well as the temperament of designers in general. It is no overstatement to say that in the past every designer in Australia believed they could, and should, be chosen to design the Australian Uniform. The final choice of designer almost always faced criticism from the fashion press and any designer who had been overlooked. However, with the contenders receiving an exacting brief the numbers of serious contenders greatly reduced. The Los Angeles Olympic Uniforms. A further reason for the AWC bid failure to design the LA uniform was that the AOC had already chosen Prue Acton to design it. This was based on her proven performance during previous games as she had a talent for creating good taste Australiana. Her design concepts also considered the effect when they were viewed on a single athlete as well as the impact when viewed on a 400 strong team coming on to the arena. A blazer trouser/skirt uniform in bright gold was chosen for the formal uniform. It was my task to select a pure wool faille fabric from Foster Valley weaving mill and have sufficient woven and ready within the prescribed timeline. The trouser/skirt fabric selected was a 60/40 wool polyester plain weave fabric from Macquarie Worsted. This fabric had a small effect thread of linen that was most attractive when dyed to match some eucalyptus bark Prue had brought back from central Australia. For the Opening Ceremony uniform, Prue designed a series of native fauna, a kookaburra for the men’s shirt and a pleated skirt with a rural scene of kangaroos, hills and plants. This presented an insurmountable printing challenge to the local printing industry as it had an unacceptably large repeat size and the number required (50) was also commercially unacceptable. The solution was a DIY mock up at RMIT and the employment of four student designers. The fabric selected for this garment was a light weight 19 micron, pure wool with a very high twist yarn in alternating S and Z twist, warp and weft. This fabric proved to be the solution to a very difficult problem, finding a wool product which is universally acceptable when worn next to the sin by young athletes competing in the heat of a Los Angeles summer. Modifications to this fabric were developed to exploit its success when facing the same problem in future games. Garment Making- The most exacting garment in the ensemble is the tailored blazer, plus the related trouser/skirt. Unfortunately tailoring athletes that come in various shapes and sizes such as; - Weight lifters develop an enormous chest, arms and neck size. A shirt made to a neck size of 52 would produce a shirt with cuffs extending well beyond the wearer’s hands. - Basketball players are up to 7 feet tall and garments relying ona chest measurement grading would produce a shirt with cuffs extending only to elbow length. - Swimmers develop enormous shoulders and slim hips, cyclists by contrast develop thighs I liken to tree trunks and a uniform featuring tight trousers must be avoided at all cost. Suffice to say many ensembles require specialist ‘one off’ treatment for many athletes. Meanwhile there is a comfortable in between group who can accept regular sizes so you can cater for these by having back up stock with plenty of built in contingencies. Athletes may be domiciled anywhere in Australia, this creates a fundamental problem of taking their measurements. The Fletcher Jones organisation was key to answering this problem due to their presence in every capital city, as well as many provincial towns around Australia. Each athlete on being selected for the Olympic Team was simultaneously requested to visit their nearest Fletcher Jones shop. The standardised measurement data collected was shared with the other manufacturers, e.g. Pelaco Shirts, Holeproof Socks and Knitwear, Maddison Belts, and even Hush Puppy Shoes. As the time for the Games approached the AOC made arrangements for combining meeting of all. Selected available athletes at the Australian Institute of Sport, Canberra, where, among other things, they were fitted and supplied with their uniform. The method evolved as follows.Men’s cream coloured button up, collared shirt. Images of a kookaburra have been printed onto the shirt, a single kookaburra on the left breast and a pair of kookaburras on the reverse of the shirt. The kookaburras are printed in a brown tone to complement the cream colour of the fabric.On tag - FMaustralian wool corporation, 1984 los angeles olympics, olympic uniforms, men's uniforms, sport, athletes -

National Wool Museum

National Wool MuseumCeremonial object - 1988 Seoul Olympics Closing Ceremony Paper Lantern, c. 1988

... National Wool Museum 26 Moorabool Street Geelong geelong ...This paper lantern was used by Australian athletes in the ‘Lantern Dance’, the last program of the closing ceremony, the lantern is called “Ch’ong sa ch’orong” and is traditionally used during weddings and festivals.When closed the lantern appears as a large, red spiral bound book with detailed inscriptions describing the way to correctly use the lantern in the ceremony. This description appears in several languages as well as a drawn depiction. When opened latticed crepe paper forms a cylinder. The two thirds of the paper is dyed dyed blue and the last third is dyed red. A small battery pack is used to light the lantern.GAMES OF THE XXIVTH OLYMPIAD SEOUL 1988 o The last program of the Closing Ceremony is called “Lantern Dance”. When all the performers enter the stadium holding lanterns, turn the paper board inside out and press the ends so that they snap shut. This will then allow the lanterns to light up. Hold the lantern by the handle at the centre and gently rock it above your head as shown in the picture. o Listen to the announcements via the ear-phones and follow the signals from the guides for further instructions. o* This lantern is called “Ch’ong sa ch’orong” and was traditionally used during weddings and festivals. This inscription is repeated several times in various languages on the cover of the lantern.1988 seoul olympic games, closing ceremony, lantern dance -

National Wool Museum

National Wool MuseumClothing - 1988 Seoul Olympics women's scarf, c. 1988

... National Wool Museum 26 Moorabool Street Geelong geelong ...The conduct of the LA games changed many factors in a short space of time. The Americans made their Games a huge financial success, whereas other countries, e.g. Canada, was left with a huge debt. The key to this was SPONSORSHIP which soon replaced the old Australian way of fundraising with pub raffles. It also began to change the atmosphere where the AWC had previously been valued for their generous donation. There was a move by commercial specialist uniform marketing organisations paying sponsorship money to publicise the fact that they were clothing high profile athletes. Old loyalties remained but became tested more and more as time progressed. For example, each uniform was expected to include an Akubra hat, why? Because it always had. For the same reason the uniforms also had Driza-Bone Coats. The day before the Seoul Opening Ceremony it rained in Seoul, so at the Opening Ceremony the Australian Team emerged in their Driza-Bones, made from cotton, not a wool fibre in sight, and the wool growers were footing the bill for over a million dollars. Thoroughly embarrassed, I resolved to avoid this situation next time by having all uniform fabrics pre-treated with Scotchguard prior to garment making.The scarf is brightly coloured in blue, green, yellow, purple and red on a plain cream base fabric. The lines of colour run on an angle across the fabric as jagged, irregular lines with small motifs of Australia, the Southern Cross stars, fish, triangles and a wave pattern, placed throughout. The centre of the scarf is dominated by a depiction of Australia presented in yellow. Within Australia are eucalyptus leaf shapes as well as mountainous shapes and the wave shape that is featured elsewhere on the scarf. The left hand short hem of the scarf has a differing pattern with larger lines running on the opposite angle to the rest of the scarf. Within the larger lines the same motifs are again printed. -

National Wool Museum

National Wool MuseumMedallion, CENTENAIRE DU DELAINAGE MAZAMET, 1951

... National Wool Museum 26 Moorabool Street Geelong geelong ...This medallion was struck to celebrate the 100th anniversary of fellmongering in Mazamet in 1951. Fellmongering - In French, ‘delainage” means, literally, ‘de-wooling'. It is the industrial process of separating wool from sheepskins. In the 19th century, the southern French town of Mazamet became the world centre of délainage and played an important part in the Australian wool industry. At one time Mazamet was reputed to be the 15th richest town in Europe, and it was said that the town’s branch of the Banque Nationale de Paris (French banking firm) was the second largest in France. At its height, Mazamet had 48 fellmongeries and imported more than 100,000 tonnes of sheepskins a year from the southern hemisphere, mostly from Australia and Argentina. It also supported numerous associated industries such as tanneries, spinning mills and clothing manufacturers. In the 1980s Mazamet’s fellmongering industry fell into decline under pressure from environmental concerns and cheap imports. The town’s last two fellmongeries closed in 2004. The town continues to have a strong relation to Australia, with street names such as, Rue de Australie, Adelaide, Brisbane, Melbourne and Sydney in recognition of a connection to the two distant lands. Today, half a century since wool importation largely ended, there remains a link to the past. Elite quality leather and woollen clothing companies such as Hermes and Chanel still source much of their stock in Mazamet. This medallion was presented to William Haughton and Co. who were one of Australia’s largest wool-buying companies of the first half of the 20th century. Wm Haughton had a major presence in Geelong and its “SKINS WOOL HIDES TALLOW etc.” signs were prominent on railways stations throughout the Western District and beyond. Haughtons had branches in all Australian capital cities, New Zealand, London and Bradford. Its agents in Mazamet were Maison Louis Maffre, an enterprise founded by M. Louis Maffre, mayor of Mazamet from 1912 to 1919. This medallion was donated to the National Wool Museum by the family of Sir Robert Southey AO CMG, former managing director of Wm Haughton & Co.Bronze medallion contained within purple case. On one side of the medallion, a mill worker is seen scraping the wool off the treated sheepskin. On the reverse the inception can be read.Wording: CRESCAM ET LUCEBO // CENTENAIRE / DU DELAINAGE / MAZAMET // 1851-1951. Smooth edge stamped with a cornucopia and the inscription BRONZEmazamet, fellmongering, délainage -

National Wool Museum

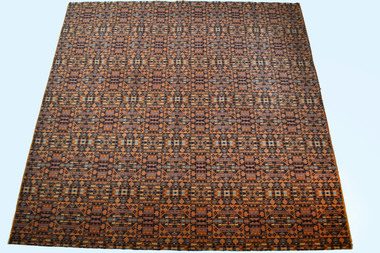

National Wool MuseumRug, Tascot Templeton Carpet (TTC), c.1990

... National Wool Museum 26 Moorabool Street Geelong geelong ...This rug was woven in the mid-1990s at the Tascot Templeton Carpet (TTC) mills in Devonport, Tasmania. It was an in-house design. The rug was woven as a one-off design exercise and was given a Golden Thread Award by the Australian Wool Corporation. The design never went into standard stock production and was never released for public sale. This rug has been woven with 100% wool on a 1 metre wide loom. The loom was purchased by TTC from United Carpet Mills of Preston and the rug was woven to demonstrate the capabilities of these looms. This rug is an example of Wilton weaving. Wilton differs from Axminster in that it is usually Loop Pile and 100% wool whereas Axminster is Plush (cut) pile and normally 80/20 wool nylon blend. TTC manufactured primarily high-quality narrow and broad loom, Axminster and Wilton carpets for the domestic and commercial market. They operated from the early 1960s until their closure in 2011. This rug was also on display in the Tascot Templeton head offices before being donated to the National Wool Museum in 2021 by Roger Warn. 3 x 3-meter carpet rug woven in 1-meter wide sections. The pattern repeats 3 times both in the width and the length. Starting from the bottom left corner, a square can be seen within a larger circular shape. These circular shapes connect end on end across the width and length of the rug. 5 Circles make up the length of the rug while 6 circles make up the width. Numerous small shapes encompass the entirety of the rug. These small shapes work together to form many interconnected repeating forms that draw your eye in a new direction every time you look at the rug. The predominant colour of the rug is a purple background with blue, cream and orange colours making up the foreground colours.carpet rugs, woollen rugs, tascot templeton carpets, axminster carpet loom -

National Wool Museum

National Wool MuseumPicker

... National Wool Museum 26 Moorabool Street Geelong geelong ...Wool picking machine designed to separate locks of wool before it is carded and spun. The picker opens the wool’s locks which makes it easier to send the fleece through a carding machine. It does this by teasing the fibres (which can also be done by hand just by pulling the lock structure apart), but a picker does this in bulk and much quicker than what can be done by hand. It is possible to spin fibres directly after the picking stage; however, it is usually more desirable to card and blend them with other fibres. Typically, at a textile mill, a picking machine can separate enough lengths of fibre for a full day’s work after just a single hour. It will also help to remove any vegetation matter or other any unwanted elements that may be present in the wool. The quality of the casting on this machine suggest that it was made locally, either in Australia or New Zealand. Mike Leggett, the donor of the machine, acquired it from New Zealand where the seller said it had been used by his father to pick wool to make hand stuffed horse saddles. Mike attempted to used it a couple of times to pick alpaca hair, but the speed of the attached motor caused damage to the fibres. The motor is thought to be an added attachment, sometime around the 1960s judging by its age, while the machine itself is thought to be dated around the 1920s. The machine works by inserting wool through the rollers. Initially there was a conveyor belt feeder system which was powered by the handle on the side. This conveyor belt has been removed however, most likely due to age and deterioration. Wool is now fed through the initial teeth and is met by a spiked rotating drum which works to separate the fibres. The separated fibres would then complete a loop of the drum before being dispatched somewhere below, around where the motor presently sits, at a rapid rate of speed. Typically this wool will be collected in a closet or large catchment area, as can be seen from the 8:47 minute marker in the linked video (link - https://www.youtube.com/watch?v=kMjx-t3tH3A). It is not apparent how the wool is collected with this machine. Red and green machine with four green legs currently attached to a wooden pallet with wheels for easy movement. The green legs lead up to a red central circular barrel from which many attachments are present. Also present on the wooden pallet is a small black motor which is attached by a rubber belt to the central drum inside the red barrel. The belt spins the wooden drum via a dark red circular plate attached to the side of the drum. On the other side of the red barrel, a green handle extends for turning the picker’s conveyor belt feeder system. Two green walls extend forward from the central red barrel, guarding either side of where the conveyor belt would have been. At the start of these walls is a wooden cylinder, which the conveyor belt would have wrapped around, followed by two interlocking gears which rotate and accept the fed wool. The red roof extends over the central cylinder from here, securing the wool inside and protecting hands from the heavily spiked internal wooden cylinder which rotates and separates (picks) the wool. Extending over the top of this red roof is a green handle which reaches to the back of the machine (not pictured). Here it accepts a weight to ensure pressure is always present for the initial feeder interlocked gear teeth. There are two large gear cogs on the rubber belt side of the machine and 3 small gear cogs on the handle side of the machine, all coloured green. A green handle is also present at the rear of the machine, below the location from which the weight is hanging. A power cable extends from the motor and there are two adjustable metal rods on the top of the machine, the purpose of these rods is presently unknown. Black texter. On top of drum. Wording: HG3707 Wording. Imprint: BRACEWIND BLYN On motor. Wording AEIwool picking, textile manufacturing, wool processing -

National Wool Museum

National Wool MuseumCarpet Samples, Godfrey Hirst and CO. Pty Ltd, c.1990

... National Wool Museum 26 Moorabool Street Geelong geelong ...Carpet samples created by Godfrey Hirst, a carpet mill whose history spans back to 1865 when the Victorian Woollen and Cloth Manufacturing Company began operations in Geelong and was purchased in the 1890s by the man Godfrey Hirst. Godfrey Hirst’s entrepreneurial skills and knowledge of the industry led to the great success which saw the company expand in multiple forms over the next century and a half. Today, thousands of metres of carpet are produced by Godfrey Hirst every day, and their flooring can be found in millions of homes. These 6 carpet samples date from the early 1990s and each have a unique colour pattern and design.Each carpet sample is made with a pile fibre that is 100% wool. The primary backing of the carpet is a woven polypropylene with a secondary backing a woven jute. Carpet 8102.1's colour name is Slate. It has a dark grey background with a red and blue diagonal stripe. The pattern repeats in a 10cm x 11.5cm block. Carpet 8102.2’s colour name is Terracotta. It is a mostly block pink colour with no repeating pattern. It has occasional flicks of grey. Carpet 8102.3’s colour name is Arctic Night. It has white, light blue and grey colours repeating one after another in a diagonal line. Carpet 8102.4’s colour name is Ivory. It has a brown background with a cream colour diamond. The pattern repeats in a 15cm x 15cm block. Carpet 8102.5’s colour name is Glenwood. It has a thin darker green and lighter green horizontal stripe spanning its entire width. These stripes repeat the height of the carpet. Carpet 8105.6’s colour name is also Ivory. It has a brown background with a cream colour leaf pattern. The pattern repeats in a 92cm x 92cm block.Wording on rear: Numerous. See Media.godfrey hirst, carpet, textile manufacture -

National Wool Museum

National Wool MuseumUndervest, c.1960

... National Wool Museum 26 Moorabool Street Geelong geelong ...These wool undervests were purchased by Edith Bender for her husband Edwin, prior to 1963. Edwin would catch a ‘Red Rattler’ train along the North Shore line to go to work in Pitt Street., Sydney. Edith was concerned Edwin would catch a cold in the unheated train or in his unheated office, so she brought these woollen undervests for him to wear to work. Edwin would wear the undervests under a woollen suit and with a woollen overcoat. Edwin passed away in 1963, at which point Edith stored the undervests away. They were passed to Edith’s daughter when Edith passed away in 1980. They were then passed to Tanya Davis on the death of her mother. Tanya donated the undervests to the National Wool Museum in 2021.2x cream wool undervests. Henley style with short sleeves and three buttons at the front. Labels from the maker ‘Braemar’ have been stitched to the neckline of both vests. An additional label is stitched under the first button on the front of both undervests. Label stitched to neck of vest: BRAEMAR / MADE IN SCOTLAND / OPTIMUS / PURE WOOL / TREATED TO RESIST / SHRINKAGE / QUALITY / B. OPTIMUS Label stitched to front buttons of vest: MADE IN SCOTLAND / FOR FARMER’S / SYDNEY Attached swing tag: BRAEMAR / The WASHING of WOOLLENS / PREPARE a bath of good bar or flake soap, thoroughly dissolved in water not hotter than the hands can bear. Squeeze the garments through the hands several times in the bath. Don’t rub them on a board. Rinse in warm water until soap is thoroughly removed. Wringing should be done in the hands. Stretch well to width and length and dry at once, preferably in the open air Stretch again in the hands when dry. Attached swing tag. Reverse: IMPORTANT POINTS / Do not use soda or washing powders. / This garment must not be subbed on a board, or subjected to mechanical friction.red rattler, wool clothing