Showing 3800 items matching " american."

-

Flagstaff Hill Maritime Museum and Village

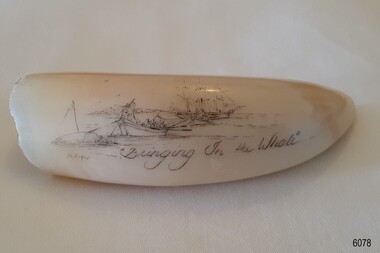

Flagstaff Hill Maritime Museum and VillageCraft - Scrimshaw, Bringing in the Whale

When scrimshaw is mentioned, most people think of carving on sperm whale teeth only. But scrimshaw also includes engravings on skeletal whale bone–such as the jaw bone, called pan bone and ivory from other marine mammals such as walrus. Although scrimshaw is widely associated with nautical themes and designs of the 19th century whaling industry, vintage scrimshaw was also produced as tribal art in many cultures. Today, scrimshaw is recognized as a unique medium in which present-day artists have developed their own modern themes. Scrimshaw reproductions may take several forms. There are - New carvings on genuine ivory or bone with the deliberate intent to create an "antique” - New carvings on genuine ivory or bone sold as signed and dated contemporary art - Clearly marked synthetic museum reproductions and mass marketed - Unmarked synthetic replicas This scrimshaw work is done on a sperm whale's tooth. It is one of two pieces by artist Gary Tonkin in Flagstaff Hill’s collection. Sperm whales can live for 60 or even 70 years, so the tooth could be quite old. It came from the whaling station in Albany, Western Australia, which ceased processing whales in 1978 and is now a whaling museum. The two works were commissioned by Flagstaff Hill in the 1980s. Tonkin could spend from a few days to a few months in intensive work on each piece of scrimshaw. He is a world-renowned Master Scrimshander and a Fellow of the Australian Society of Marine Artists (FASMA), and lives in Albany, Western Australia. Gary Tonkin, FASMA – Tonkin was born in 1949 in Portland, Victoria, and grew up there with a history of whaling and related industries. He moved to Albany in southwest WA in 1971 and worked as an Export Meat inspector for the Federal Government. This small town also had a historical connection to whaling. The Cheynes Beach Whaling Station was still operating, and there were even three whaling ‘chaser’ vessels at the old jetty. In 1975, his employment now permanent, Tonkin bought an old cottage near the bay, purchased some whales’ teeth, and began learning the sailors’ art of scrimshaw, combining this with his artistic skills and knowledge of history. His job gave him access to buy as many whale teeth as he could afford, straight from the whaling station. Tonkin gained further marine knowledge as he sailed on the schooner ‘Esperance’ from Fremantle to Mauritius in 1988. He watched the sailors at work and experienced the rough and stormy sea conditions first-hand. Tonkin later visited whaling museums, galleries and libraries in England and America to gather reference materials and information on all aspects of whaling and scrimshaw. In 1993 he was Commissioned to engrave six large whale teeth, from the Albany whaling station, for the USA Gallery at the Australian National Maritime Museum in Sydney. This work is now in the museum’s permanent collection. From that time, Tonkin began working full-time as a Scrimshander. Tonkin’s work is now in galleries and museums in America and Australia, as well as in private collections. He is the founder of the Albany Maritime Heritage Association and was the inaugural President. In the 1990s he actively and successfully campaigned for the preservation of the Cheynes Beach Whaling Station in Albany, which is now Whale World, an open-air whaling museum. His continuing work as a Scrimshander contributes to the preservation of the art of scrimshaw and the history of whaling. This scrimshaw represents the ancient craft of scrimshaw, associated with mariners in the whaling trade in the early 19th century. The work is also Nationally significant for being created by world-renowned Scrimshander, Gary Tonkin, from Albany, Western Australia. Scrimshaw; whale tooth carved with an image of two whaleboats hauling a dead whale back to the mother ship. Inscribed Title and signature of artist Gary Tonkin.Inscribed "Bringing in the whale". Signature "G Tonkin"flagstaff hill maritime museum and village, warrnambool, great ocean road, shipwreck coast, maritime museum, flagstaff hill, perth, whaling, whales, australia, scrimshaw, scrimshander, gary tonkin, g tonkin, bone, tooth, craft, albany, western australia, cheynes beach whaling station, whale world, portland, engraving, maritime art, sperm whale's tooth, albany whaling station, albany whaling museum -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCraft - Ship Model, Arethusa, 1894

Original Ships History: Aréthuse was a French frigate, launched in 1757 during the Seven Years War between England and France. She was captured by the Royal Navy in 1759 and became the fifth-rate HMS Arethusa. She remained in Royal Navy service for twenty years until she was wrecked after being badly damaged in battle. The ship was constructed at Le Havre for privateer warfare as ”Pélerine” and soon after her launch, she was purchased by King Louis XV (1710-1774) and commissioned as Aréthuse on 21 January 1758. In June, under captain Vauquelin, she sailed through the British blockade of Louisbourg helping to defend the site before departing, again forcing the blockade. On 18 May 1759, she was in transit from Rochefort to Brest, under the command of Louis-Philippe de Rigaud, Marquis of Vaudreuil, when she was intercepted near Audierne Bay (Baie d'Audierne) by three Royal Navy ships the Thames, Venus and Chatham. She attempted to escape but after two hours, lost her topmasts and was overtaken by her pursuers. Thames and Venus engaged her with heavy fire, causing 60 casualties before the vessel surrendered. She entered service with the Royal Navy for the rest of the war, and was in service in British home waters and became responsible for the capture of several French privateer cutters. In 1777, a Scotsman James Aitken, widely known as John the Painter, was hanged from her mizzenmast for burning the Rope House at Portsmouth Royal Dockyard on 7 December 1776, to aid the struggle of American independence. The mast was struck from the ship and re-erected at the dockyard entrance so as many people as possible could watch the execution. On 17 June 1778, she fought a famous duel against the French 36-gun frigate, Belle Poule. Belle Poule was on a reconnaissance mission, along with the 26-gun Licorne, the corvette Hirondelle and the smaller Coureur when she encountered a large British squadron that included Arethusa at a point 37 km south of The Lizard. Admiral Keppel, commanding the British fleet ordered that the French ships be pursued. The captain of Belle Poule refused the order to sail back to the British fleet. The British fired a warning shot across his ship's bow, to which he responded with a full broadside. This action began a furious, two-hour battle between the two ships that resulted in the deaths of the French second captain and 30 of the crew. However, Arethusa was crippled by the loss of a mast and withdrew, allowing Belle Poule to escape. This battle was the first between British and French naval forces during the American Revolutionary War and took place around three weeks before France had made a formal declaration of war. The battle was widely celebrated in France as a victory, even inspiring a hair-style in court circles that included a model of Belle Poule. It was also viewed as a victory in Britain and became the subject of a traditional Sea shanty, The Saucy Arethusa. On 18 March 1779, under captain Charles Holmes Everitt, Arethusa engaged the French Aigrette, under Lieutenant Mortemart, sustaining considerable damage in the fight. Arethusa was wrecked the next day off Ushant, It was the fame of this Arethusa which induced the Royal Navy, during the following two centuries, to bestow the name on a further seven consecutive individual ships and two consecutive classes of cruisers. (See Provenance Sec this document for information on the makers of this model). Model ship of the 3 masted frigate the “Arethusa”, model is painted black and white with varnished deck and masts. A British flag is flown at the stern. The ship is displayed in a glass case with timber frame and 4 legged stand.Label at bottom of glass case, printed in black script on a gold strip “Model of the “Arethusa" "A famous frigate, taken from the French by the British, on the 18th of May 1759 and lost on the French coast in 1779. – Made and presented by G. Lance & P. Diggins, October 1894” flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, arethusa ship model, george lance, peter diggins, len asling, warrnambool art gallery, warrnambool exhibition, message in a bottle -

Victorian Interpretive Projects Inc.

Victorian Interpretive Projects Inc.Photograph - digital, LJ Gervasoni, Murtoa Stick Shed 00031, 13/08/2011

From the Victorian Heritage Register statement of significance H0791 The Marmalake/Murtoa Grain Store, originally the No.1 Murtoa Shed, is located within the Murtoa Grain Terminal, adjacent to the grain elevator tower and railway line. The shed is 280m long, 60m wide and 19m high at the ridge with a capacity of 3.4 million bushels. The hipped corrugated iron roof of the shed is supported on approximately 600 unmilled hardwood poles set in a concrete slab floor and braced with iron tie rods. These poles are the reason for use of the term "stick shed". With its vast gabled interior and the long rows of poles the space has been likened to the nave of a cathedral. An elevator at one end took wheat from railway trucks to ridge level where it was distributed by conveyor along the length of the shed, creating a huge single mound of grain. Braced internal timber bulkheads on either side took the lateral thrust of the wheat, and conveyors at ground level outside the bulkheads took wheat back to the elevator for transport elsewhere. Wheat had been handled in jute bags from the start of the Victorian wheat industry in the mid nineteenth century. Bulk storage had been developed in North America from the early 1900s. NSW began building substantial concrete silos from 1920-21. In Western Australia, farmers' co-operatives, who had to supply their own bulk storage from 1934-5, pioneered the use of low-cost horizontal sheds of timber and corrugated iron for bulk storage. Following its establishment in 1935 the Victorian Grain Elevators Board (GEB) planned a network of 160 concrete silos in country locations, connected by rail to the shipping terminal at Geelong. By the outbreak of the Second World War there was a worldwide glut of wheat, and Australia soon had a massive surplus which it was unable to export. Only 48 silos had been established under the Victorian Silo Scheme so far, and wartime material and labour restrictions prevented progress with this scheme. The storage deficit had become an emergency by 1941 as Britain obtained its imports from North America, rather than over the lengthy and difficult shipping route from Australia. In 1941 the GEB, under chairman and general manager Harold Glowrey, proposed large temporary versions of the horizontal bulk storage sheds already in use in Western Australia. The proposal was approved by the Victorian Wheat and Woolgrowers Association, who considered the use of shed storages as a longer term proposition. After initial resistance from the Australian Wheat Board, some of whose members represented wheat bagging interests, the Commonwealth and Victorian governments agreed to split the costs, and Murtoa was chosen as a suitable site for the first emergency storage. The main contractor, Green Bros, commenced work on the No.1 Murtoa Shed in September 1941, deliveries of bulk wheat began in January 1942, and the store was full by June of the same year. In the following years the Council for Scientific and Industrial Research (later CSIRO) conducted valuable research and experiment on the impacts and control of insect pests at the Murtoa No.1 shed. With these discoveries, and the development of more effective pesticides, use of the No.1 shed and the larger No.2 shed, erected in 1942/43, continued for many years. The No.2 shed was demolished in 1975. By the 1990s, pest resistance to pesticides and requirements for both pest free and insecticide free grain rendered open storage of this type unviable. The No. 1 store was also becoming increasingly expensive to maintain, and its use was phased out from 1989.Image of the Marmalake/Murtoa Grain Store which is of historical, architectural, scientific (technical) and social significance to the State of VictoriaDigital colour image of the interior of the Marmaduke . Murtoa grain storage facility better known as the Stick Shed. The shed was constructed in World War Two to store grain. The supporting columns are trees.marmalake, murtoa grain store, wheat store, stick shed, murtoa -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Platform Scales

Large platform scales such as these ones made by W. & T. Avery were used for weighing goods for trading and passengers' luggage. They would be used in places such as railway stations, shipping ports, customs offices and ticketing offices. Often fees would be charged to customers according to the weight of their goods and luggage. Items would be placed onto the large horizontal platform then weights would be added to the weighing bar until the bar leveled to being horizontal. The weights would be added together and the total of the weights would be used for the final figure. These scales were made in Birmingham, England, by the British company, W and T Avery. The company had its origins in the early 1700s but only became known as W and T Avery when the brothers William and Thomas Avery inherited the scale-making business from a relative, Joseph Balden, on his death in 1813. By 1885 they had three factories and In 1895, the company acquired James Watt & Co and two years later had moved to the 25-acre Soho Foundry site in Smethwick, Birmingham where James Watt had manufactured steam engines. When the last Avery family member died in 1918, the company employed over 3,000 people and had businesses all over the world. Following the highly successful introduction of the first digital retail scale in 1971, the company was taken over by the GEC Group in 1979. The business was subsequently acquired by the American company, Weigh-Tronix, in 2000 which had already acquired a competitor, Salter. The Avery name continues today in the company known as Avery Weigh-Tronix.An item that was used at the turn of the century as train platform scales or for weighing agricultural products. Made by a company that pioneered weighing equipment with offices all over the world. With many examples of this scale in museums throughout the world. Platform scales with wheels. Large cast iron, scales painted black, weight capacity to 7 CWT (hundred weight). Weight beam has markers "0. 5. 10. 15. 20. 25". Platform scale loose weight type with relieving handle; cast iron construction, fluted columns with integral weight stand, the two wheels are fitted to base at front of platform; there is a graduated steelyard 0-14bs with pear-shaped poise. Weight carrier is missing.Pressed into cast iron arm on scale, one side "W. & T. AVERY", opposite side "BIRMINGHAM", and into the platform "TO WEIGH 7 CWT, W. & T. AVERY, MAKERS, LONDON & BIRMINGHAM" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, measuring scales, weighing scales, weighing instrument, fees for goods, fees for luggage, ticket office -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Suitcase, 1920-1950

The suitcase didn't catch on until the end of the 19th century, it was quite literally as a case for suits. A typical suitcase came equipped with an inner sleeve for storing shirts, and sometimes a little hat box on the side. But even in the early 20th century, the "dress-suit case" was only one of countless styles of container travellers could buy, from steamer trunks to club bags. By the late 19th century a significant point was reached in the history of transportation, it was the beginning of mass tourism, rather than travel for travels sake made use of by the wealthy in society. Travel wasn't just for the wealthy any more but everyone. Suitcases began as an afterthought in the luggage and leather goods business, but they soon became the very symbol of travel. An 1897 wholesale price list included the words "suitcase" only twice in a 20-page list of luggage types. In America a 1907 T. Eaton & Co. Catalogue, trunks took up a full page while suitcases share a page with club bags and valises. In a 1911 a United Company catalogue, now displayed around 40 per cent of the advertisements were for suitcases. Early suitcases were lighter and more portable than trunks, but they were still bulky by today's standards. Leather, canvas, wicker or thick rubbery cloth was stretched over a rigid wood or steel frame. Corners were rounded out using brass or leather caps and some had wooden rails running around the case. Until steamship travel declined during the mid-20th century, many of these types of the case were advertised as waterproof with some lightweight models marketed specifically to women. The item gives us a snap-shot as to how people undertook travelling during a time when undertaking a journey for pleasure at the end of the 19th century was mainly only for the wealthy. This time saw the beginnings of change from the wealthy in society being able to travel, to the onset of mass tourism. Along with this change in societal norms saw many innervations to the design of luggage as it became a fashionable item.Suitcase wooden with four wood reinforcing ribs, 2 leather straps with buckles & leather handles each end. Has inner shelf.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, suitcase, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Chair, 1855-1900

Heywood & Wakefield Furniture Co: The Heywood-Wakefield Company is an American furniture manufacturer established in 1897 that went on to become a major presence in the US. Its older products are considered collectibles and have been featured on television antique programs. The Heywood brothers established themselves in 1826, as furniture makers and the Wakefield Company began in 1855 as a separate company. Both firms produced wicker and rattan furniture, and as these products became increasingly popular towards the end of the century, they became serious rivals. In 1897 the companies merged as Heywood Brothers & Wakefield Company (this name was changed to Heywood-Wakefield Company in 1921), purchasing Washburn-Heywood Chair Company in 1916, Oregon Chair Company in 1920, and Lloyd Manufacturing Company in 1921. While its wooden furniture plant in Gardner, Massachusetts closed in 1979, a branch in Menominee, Michigan continued to manufacture metal outdoor seats, auditorium seats, and school furniture. The Heywood-Wakefield Company Complex in Gardner was added to the National Historic Register in 1983. The South Beach Furniture Company acquired the rights to the name in 1994 and reproduces its wooden furniture. Both founding companies produced wicker and rattan furniture in the late 19th century. The wicker styles drew on the Aesthetic Movement and Japanese influences simpler designs arose in the wake of the Arts and Crafts Movement. The merged entity stayed abreast of wicker furniture trends by hiring designers such as Paul Frankl and Donald Deskey during the 1920s. Its furniture was exhibited at the 1933 Century of Progress exhibition and the 1964 New York World's Fair. During the 1930s and 1940s, Heywood-Wakefield began producing furniture using sleek designs based on French Art Deco.The chair has social significance at a local level, because it illustrates the level of material support the Warrnambool community gave to Flagstaff Hill when the village and Museum was established. The wicker nursing chair is a fine example of late 19th century light weight domestic furniture that today are very collectible items and quite rare and valuable.Nurse wicker chair, wood, cane and rattan with round rushed seat. The one left arm being that to support the infant during feeding. 1870s-1890s. Believed to have been made by Heywood Brothers & Wakefield Company, USA. flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, great ocean road, 19th century furniture, rolled serpentine wicker work, cane armchair, classic wicker furniture, victorian style furniture, domestic furniture late 19th century, heywood-wakefield company, feeding chair, nursing chair, mother's chair, nursery furniture -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bottle, c. 1850's - 1900's

This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in 1850's - 1900's. Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020. The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s-1900s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. Bottle, solid colour brown glass,concave base, tapering slightly wider towards shoulder then inwards towards neck; ring of glass just below opening. Base is blown glass; pontil mark on base. Label "c.1850's STUBBY ALE", "ENGLISH HAND MADE, CORK & WIRE SEAL", "PONTIL MARK ON BASE $6" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, handmade beer bottle, handmade late 19th century bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bottle, c. 1850's - 1900's

This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in 1850's - 1900's. Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020 The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s-1900s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. Bottle, opaque brown glass, concave base, tapering slightly wider towards shoulder then inwards towards neck; ring of glass just below opening. Base is blown glass; pontil mark on base. "STUBBY 1850-1900 SMALL SIZE", ENGLISH 3 PIECE MOULD, HAND MADE TOP", "PAPER LABEL, CORK & WIRE SEAL $6flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, handmade beer bottle, handmade late 19th century bottle -

Eltham District Historical Society Inc

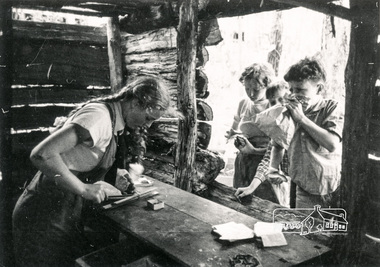

Eltham District Historical Society IncPhotograph, David Potts (Latrobe University), Koornong School collection, c.1940-c.1945

Photos include: Log building which the students constructed and used as a co-operative shop, Primary Class, Science class outside their classroom, Government meeting held in the outdoor theatre, Janet and Lawrence Nield. "Koornung School, Warrandyte was established by Clive and Janet Blake Nield in 1939, after they had visited progressive schools in Europe and America. They believed children should be given freedom to grow while learning to accept responsibility; that school should be a miniature democracy and education not a preparation for life but experience of life itself. A government of children and all staff (whatever their jobs in the school) met regularly, made the rules and dealt out punishment for breaking them. The few rules set down by staff related to health and safety, for instance, no pupils were allowed to go into the river without supervision. The school could not have been started at a worse time. Food rationing and coupons, petrol shortages and men at war limiting teaching staff made difficulties. It was an expensive school to run. Financial difficulties became more serious and eventually the school had to close in 1946. Efforts by the children and a Board of Management of notable people failed to save it. Janet Nield (M.A., Dip Ed.) was an inspired teacher of history. She was one of the few women at Melbourne University at that time to gain a Masters degree in history. The Nields left Melbourne to live in Sydney, Clive to work at Sydney University in lecturing in Education and particularly interested in Colombo Plan students. Janet devoted herself to children as a Lay Analyst. She was awarded the title of Training Analyst by a meeting of international psychoanalysts in Europe. - Pat Scott (Mrs Wynne Scott), a former member of staff at Koornung School Collection of five black and white photographs a, letter and descriptive material relating to Koornong School, Warrandyte showing various teachers and students and Connie and Alec Smith's studio.schools, koornong, warrandyte, danila vassilieff, lorna carter, adrian rawlins, teachers, janet nield, clive nield -

Cheese World Museum

Cheese World MuseumCentrifuge, electric

This Babcock tester was used in the laboratory at the Kraft cheese factory, Allansford. When it was superseded it was passed to one of the users of the machine, Les O'Callaghan, president of the Warrnambool & District Historical Society who placed it in the historical society collection. In 2009 when the historical society premises were upgraded there was insufficient room to store the tester so it was donated to Cheese World Museum. The machine was used to test the butterfat content of milk. Prior to dairy factories coming into existence farmers made butter individually on farms. There was no need for milk testing until farmers supplied factories for payment. Payment was based on a gallon of milk weighing 10lbs (pounds) and this led to richer milk, containing a high degree of butterfat for use in buttermaking, being paid at the same rate as lesser quality milk. In 1890 Stephen Moulton Babcock, an American professor at the University of Wisconsin-Madison, developed a method of determining the amount of butterfat in milk, thus providing a standardised and fairer system for payment. Babcock Test Process 1. 18 grams of milk (17.6ml) was put into a test tube 2. The same amount of sulphuric acid was added 3. A centrifuge at 50ºC was rotated at more than 900 revs per minute 4. The fat floating on top of the liquid in the test tube was measured The Babcock Test provided fairer compensation to farmers and also helped produce a consistent product for consumers. It also allowed for selective breeding when dairy herd testing evolved. ‘The Babcock Test is so simple that it can be used by any careful person, and it is inexpensive to operate. From the very beginning it was so complete in every detail that no change has had to be made in it.’ (Babcock Test http://www.en.wikipedia.org/wki/Babcock_test 31 March 2009) Round green metal container with opening lid. Inside houses a spinning rotor with 20 test tube holders around the outside in two circular rows.7173 BABCOCKTESTER 190allansford, dairy manufacturing, milk testing, babcock test, babcock, stephen moulton, butter, warrnambool cheese and butter factory company -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Floor Tile, circa 1878

This Minton floor tile is from the wreck of the Loch Ard and is currently on display in the Great Circle Gallery at Flagstaff Hill. The iron hulled clipper ship from the Loch Line was heading for Port Phillip from London, when it ran into the cliffs of Mutton Bird Island near Port Campbell. The Loch Ard was laden with a high value cargo including luxury goods intended for display at the Melbourne International Exhibition in 1880. One notable survivor from the ship’s freight manifest was the well packed Minton porcelain peacock, a two meter high ceramic masterpiece of vivid glazed colours. (This is also on display in the Great Circle Gallery). The almost total loss of life and property from the Loch Ard registered as a shocking tragedy for the Colony of Victoria, at a time when social confidence and economic optimism were otherwise high. Wealth generated from Gold and Wool was increasingly being spent on grandiose private residences and imposing public buildings. The demand for quality furnishings and fittings was therefore strong. Among the products consigned to burgeoning colonial markets by the Milton pottery at Stoke upon Trent, were their new range of colourfully patterned but very durable floor tiles ideal for the high-traffic spaces in the large civic buildings then being constructed in Australia and America. These new floor tiles were “encaustic”, meaning that their designs and colours were encased “within” the depth of the tile. Rather than their decorative patterns being glazed onto the surface of the tile, their inlaid designs were created during the manufacturing process, as “coloured slips” (or liquid clay) were poured into a deep pre-molded casting. When fired, the resulting tile was colours-fast and design-fast. The Minton floor tile is significant for its hard-wearing yet attractive design. The shipwreck of the Loch Ard is of significance for Victoria and is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulations of artefacts from this notable Victorian shipwreck of which the subject items are a small part. The collections of objects give us a snapshot of how we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. Through is associated with the worst and best-known shipwreck in Victoria's history. A square Minton floor tile with a dark brown, beige and white pattern. The tile has a piece broken off along one side and some chipping along the edges. This ‘encaustic’ floor tile was recovered from the shipwreck of the LOCH ARD. Branded "... MINTON&CO Patent ..."flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, minton floor tile, encaustic tile, melbourne international exhibition, floor tile -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Iron, Mrs Florence Potts, Late 19th to early 20th century

Sad irons of the 19th century were so named because of the weight 1.8Kg that was needed to press wrinkled clothes and sheets. They were made of solid metal, including the handle. When the iron was heated, this meant that the handle would also heat up. The user would have to use a thick cloth or a mitt of some sort before they could pick up the iron. Even so, burns and blisters, as well as strained, tired arms, were a normal part of the “ironing day.” Mrs Mary Florence Potts of Ottumwa, Iowa, brought a change to the world of ironing. At the age of 19, in 1870, she invented her first sad iron. It had a hollow metal body that could be filled with a non-conducting material such as plaster of Paris. In 1871, Mary invented the removable wood handle, so that it could be changed from the cool iron to one that was hot and ready to use. A final improvement was the shape: Mary made both ends pointed so its user could iron in either direction. All of these inventions were patented under her name, a rarity for the time. Mary, with the help of her husband, tried unsuccessfully to market her invention on her own. It wasn't until she sold the sales rights to the American Manufacturing Company that sales took off. Advertised as "Mrs Potts' sad iron," it became a sensation. The company manufactured the iron from about 1876 to 1951. Mrs Potts' sad iron became a household word and a standard for future inventors to have to surpass. This didn't happen until 1882 when Henry W. Seely patented the first electric iron. The item is significant not only as a usable domestic tool, but it was, at the time of its creation, a revolutionary labour-saving device. Mrs Potts invention remains associated with a housewife's answer to the domestic drudgery of ironing.Iron,"Mrs Potts" pattern iron. Semi-circular or 'D' shaped wood handle and wood knob.Mrs Pottsflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, iron, clothes iron, flat iron, laundry, sad iron, mrs potts -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Floor Tile, circa 1878

This Minton floor tile is from the wreck of the Loch Ard. The iron-hulled clipper ship from the Loch Line was heading for Port Phillip from London, when it ran into the cliffs of Mutton Bird Island near Port Campbell. The Loch Ard was laden with high-value cargo including luxury goods intended for display at the Melbourne International Exhibition in 1880. One notable survivor from the ship’s freight manifest was the well-packed Minton porcelain peacock, a two-meter high ceramic masterpiece of vivid glazed colours. (This is also on display in the Great Circle Gallery). The almost total loss of life and property from the Loch Ard registered as a shocking tragedy for the Colony of Victoria, at a time when social confidence and economic optimism were otherwise high. The wealth generated from Gold and Wool was increasingly being spent on grandiose private residences and imposing public buildings. The demand for quality furnishings and fittings was therefore strong. Among the products consigned to burgeoning colonial markets by the Milton Pottery at Stoke upon Trent, were their new range of colourfully patterned but very durable floor tiles ideal for the high-traffic spaces in the large civic buildings then being constructed in Australia and America. These floor tiles were “encaustic”, meaning that their designs and colours were encased “within” the depth of the tile. Rather than their decorative patterns being glazed onto the surface of the tile, their inlaid designs were created during the manufacturing process, as “coloured slips” (or liquid clay) were poured into a deep pre-moulded casting. When fired, the resulting tile was colour-fast and design-fast. The Minton floor tile is significant for its hard-wearing yet attractive design. The shipwreck of the Loch Ard is of significance for Victoria and is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulations of artefacts from this notable Victorian shipwreck of which the subject items are a small part. The collections of objects give us a snapshot of how we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. Through is associated with the worst and best-known shipwreck in Victoria's history. A square Minton floor tile with a white background, and beige, dark blue, light blue and black geometric pattern as well as leaves in the design. The tile has corner broken off and some chipping along the edges. The reverse has five rows of five evenly spaced holes. The back of the tile has inscriptions. Made by Minton & Co. at Stoke upon Trent. This encaustic floor tile was recovered from the shipwreck of the LOCH ARD. Branded "... MINTON&CO / PATENT / STOKE UPON TRENT"flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, minton floor tile, encaustic tile, melbourne international exhibition, floor tile, minton tile, minton & co., stoke upon trent -

Glen Eira Historical Society

Glen Eira Historical SocietyAlbum - Album page, Normanby Road, Circa 1972

This photograph is part of the Caulfield Historical Album 1972. This album was created in approximately 1972 as part of a project by the Caulfield Historical Society to assist in identifying buildings worthy of preservation. The album is related to a Survey the Caulfield Historical Society developed in collaboration with the National Trust of Australia (Victoria) and Caulfield City Council to identify historic buildings within the City of Caulfield that warranted the protection of a National Trust Classification. Principal photographer thought to be Trevor Hart, member of Caulfield Historical Society. Most photographs were taken between 1966-1972 with a small number of photographs being older and from unknown sources. All photographs are black and white except where stated, with 386 photographs over 198 pages. From: Glen Eira Heritage Management Plan (1996) - Vol 2 by Andrew Ward and Associates The widening of Dandenong Road during the late 1980's has resulted in the destruction of the houses in the path of the roadworks and the construction of a high fence serving as a visual barrier between that thoroughfare and the remaining houses. Where comparatively large villas once stood on spacious allotments, only "Wisteria" survives at No. 135 Normanby Road. Adopting forms and timber enrichment characteristic of the American Queen Anne style, it has this in common with the largely reconstructed timber villa at no. 11 Normanby Avenue and to a lesser extent, 746 Inkerman Road. Normanby Road retains its comparatively opulent Edwardian character in a mature landscaped setting with spacious gardens and mature planes parallel with the railway reserve which, on account of the low lying ground in its vicinity has a high embankment commencing on the alignment of Malvern Grove and continuing to Caulfield Station. The earliest villas are Edwardian. Page 148 of Photograph Album with one landscape photograph of a house on Normanby Road (not Street).Handwritten: Normanby St [top right] / 148 [bottom right]trevor hart, verandah, porch, bull nosed verandah, tower house, tower, stone fence, normanby road, wisteria, american queen anne style, queen anne style, 1890's, mayfield grove, normanby street, timber houses, caulfield north, house names, edwardian, edwardian style, gardens -

Federation University Historical Collection

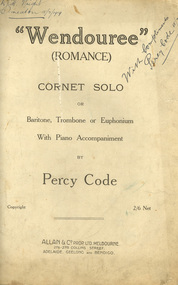

Federation University Historical CollectionBooklet - Sheet Music, Allan & Company Pty Ltd, "Wendouree", Romance by Percy Code, 1919

This music was used by Frank Wright who had been tutored by Percy Code. Frank Wright won the Australian Open Cornet Championship using this music, and won the gold medal for the highest mark in the British Colonies. Percy Code was born in Melbourne on 03 July 1888. He started learning the violin and piano at the age of eight. Three years later his father, Edward, started tutoring him on the cornet. His first competition was in October 1902 in Ballarat's South Street Competitions. Percy Code was Musical Director of Ballarat City Brass Band from 1913 until 1921. He was Frank Wright's teacher. Code apparently lived in a large house just west of where St Peter's church (Ballarat) now stands. Percy Code toured the world as principal cornet with the 'Besses o' th' Barn Band.' He returned to Australia in 1912. Frank Wright at one stage rode his pushbike from Smeaton to Ballarat for lessons. Leaving Australia for America in March 1921 Percy Code obtained an appointment as trumpet soloist for the 70 piece San Francisco Symphony Orchestra. He returned home two years later and became bandmaster to the Prahran City Band in 1925. From 1938, as part of Australia's Sesqui Centenary celebrations, Percy Code conducted the Sydney Symphony Orchestra for the ABC orchestral concerts in Sydney Town Hall. His career with the ABC came to an end in late 1951 due to poor health. Percy Code died on 17 October 1953. From 'Legend in Brass' with additions from Bob Pattie of the Ballarat Brass Band.11071.1 Four cream pages containing handwritten title page in front, two sheet music pages inside and blank back cover. 11071.2 Eight cream pages containing front page typed title with handwritten text at top, Six pages of sheet music cream pages, with parts for piano and cornet, with black printed notes. A photograph of the composer Mr Percy Code is glued into the first page at the top left hand corner. The back cover page has advertisements for four music albums from Allan & Co. Prop. Ltd..1) Front page handwritten in blue pen and pencil. Hand written notations in pencil for cornet throughout sheet music pages. Frank Wright Smeaton 15 July 1919 in top right hand corner; Champion Bb cornet solo South Street 1919 in top left hand corner. Under title on front page: Handwritten notes in pencil giving results of competition and judge's comments. 2) Frank H. Wright Smeaton 15/7/1919 handwritten in top left hand corner. "With Compliments Percy Code 15/7/1919 written diagonally in blue pen in at right hand top.cornet, frank wright, allan & co., allans music, ballarat, south street, percy code, code, wright, sheet music, "wendouree", (romance), wendouree, romance, wendouree -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Suitcase/Trunk

The suitcase didn't catch on until the end of the 19th century, it was quite literally as a case for suits. A typical suitcase came equipped with an inner sleeve for storing shirts, and sometimes a little hatbox on the side. But even in the early 20th century, the "dress-suit case" was only one of countless styles of container travellers could buy, from steamer trunks to club bags. By the late 19th century a significant point was reached in the history of transportation, it was the beginning of mass tourism, rather than travel for travels sake made use of by the wealthy in society. Travel wasn't just for the wealthy any more but everyone. Suitcases began as an afterthought in the luggage and leather goods business, but they soon became the very symbol of travel. An 1897 wholesale price list included the words "suitcase" only twice in a 20-page list of luggage types. In America a 1907 T. Eaton & Co. Catalogue, trunks took up a full page while suitcases share a page with club bags and valises. In a 1911 a United Company catalogue, now displayed around 40 per cent of the advertisements were for suitcases. Early suitcases were lighter and more portable than trunks, but they were still bulky by today's standards. Leather, canvas, wicker or thick rubbery cloth was stretched over a rigid wood or steel frame. Corners were rounded out using brass or leather caps and some had wooden rails running around the case. Until steamship travel declined during the mid-20th century, many of these types of the case were advertised as waterproof with some lightweight models marketed specifically to women. The item gives us a snap-shot as to how people undertook travelling during a time when undertaking a journey for pleasure at the end of the 19th century was mainly only for the wealthy. This time saw the beginnings of change from the wealthy in society being able to travel, to the onset of mass tourism. Along with this change in societal norms saw many innervation's to the design of luggage as it became a fashionable item.Suitcase/trunk with inner tray, brown canvas covered with 2 hinge clamps and a central Eagle lock, four wooden lateral buffer railed slats running around the case, leather handles each end. noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, suitcase -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Suitcase, 1930-1945

The suitcase didn't catch on until the end of the 19th century, it was quite literally as a case for suits. A typical suitcase came equipped with an inner sleeve for storing shirts, and sometimes a little hat box on the side. But even in the early 20th century, the "dress-suit case" was only one of countless styles of container travellers could buy, from steamer trunks to club bags. By the late 19th century a significant point was reached in the history of transportation, it was the beginning of mass tourism, rather than travel for travels sake made use of by the wealthy in society. Travel wasn't just for the wealthy any more but everyone. Suitcases began as an afterthought in the luggage and leather goods business, but they soon became the very symbol of travel. An 1897 wholesale price list included the words "suitcase" only twice in a 20-page list of luggage types. In America a 1907 T. Eaton & Co. Catalogue, trunks took up a full page while suitcases share a page with club bags and valises. In a 1911 a United Company catalogue, now displayed around 40 per cent of the advertisements were for suitcases. Early suitcases were lighter and more portable than trunks, but they were still bulky by today's standards. Leather, canvas, wicker or thick rubbery cloth was stretched over a rigid wood or steel frame. Corners were rounded out using brass or leather caps and some had wooden rails running around the case. Until steamship travel declined during the mid-20th century, many of these types of the case were advertised as waterproof with some lightweight models marketed specifically to women. The item gives us a snap-shot as to how people undertook travelling during a time when undertaking a journey for pleasure at the end of the 19th century was mainly only for the wealthy. This time saw the beginnings of change from the wealthy in society being able to travel, to the onset of mass tourism. Along with this change in societal norms saw many innervations to the design of luggage as it became a fashionable item.Suitcase, brown canvas with three wooden reinforcing lateral rails running around the case, leather handle each end (one broken), two locks.. Maker Pettigrew & Stephens Ltd Glasgow. "A.T.Cox 354/3 Riversdale Rd Campberwell, Vic Australia" and "W.ON" painted over on each endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, suitcase, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Steamer luggage Trunk, First quarter of the 20th century

Item used around the first quarter of the 20th century The suitcase didn't catch on until the end of the 19th century, it was quite literally as a case for suits. A typical suitcase came equipped with an inner sleeve for storing shirts, and sometimes a little hat box on the side. But even in the early 20th century, the "dress-suit case" was only one of countless styles of container travellers could buy, from steamer trunks to club bags. By the late 19th century a significant point was reached in the history of transportation, it was the beginning of mass tourism, rather than travel for travels sake made use of by the wealthy in society. Travel wasn't just for the wealthy any more but everyone. Suitcases began as an afterthought in the luggage and leather goods business, but they soon became the very symbol of travel. An 1897 wholesale price list included the words "suitcase" only twice in a 20-page list of luggage types. In America a 1907 T. Eaton & Co. Catalogue, trunks took up a full page while suitcases share a page with club bags and valises. In a 1911 a United Company catalogue, now displayed around 40 per cent of the advertisements were for suitcases. Early suitcases were lighter and more portable than trunks, but they were still bulky by today's standards. Leather, canvas, wicker or thick rubbery cloth was stretched over a rigid wood or steel frame. Corners were rounded out using brass or leather caps and some had wooden rails running around the case. Until steamship travel declined during the mid-20th century, many of these types of the case were advertised as waterproof with some lightweight models marketed specifically to women. The item gives us a snap-shot as to how people undertook travelling during a time when undertaking a journey for pleasure at the end of the 19th and early 20th century was mainly only for the wealthy. This time saw the beginnings of change from the wealthy in society being able to travel, to the onset of mass tourism. Along with this change in societal norms saw many innervation's to the design of luggage as it became a fashionable item.Suitcase/trunk leather reinforced at corners with wooden slats to strengthen the lid. Leather straps to close lid with metal lock in the middle of the lid. Closing strap missing.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Spoon, SSP Sheffield Silver Plate & Cutlery Co. Ltd, About 1913 to early-1930s

This electroplated silver teaspoon was made by the Sheffield Silver Plate & Cutlery Company Limited from about 1913 to early-1930s. It was recovered from an unknown shipwreck in the coastal waters of Victoria in the late 1960s to early 1970s. The shipwrecks in the area range from around the 1840s to the early-1930s. It is part of the John Chance Collection. Sheffield manufactures produced high quality silverware products. In the mid-1700s a cutler, Thomas Boulsover, invented a process to fuse copper between two sheets of silver, which could still be like solid silver then the edges were bound in silver. Items made this way are now referred to as Old Silver Plate. The modern method of electroplating has a much thinner layer of silver. The firm Sheffield Silver Plate and Cutlery Co. Ltd. was established in 1913 by Mappin & Webb to make spoons and forks using the American Wilzin process, which was a failure. In 1923 the company was incorporated then re-financed and reverted back to the older production method for electroplating. The maker’s stamp usually had the letters “S.S.P. & C. Co Ltd EPNS” and often included an octagon stamp with “SSP”. The firm had the registered trademarks of ‘SILCUTA’ and ‘SILTONA’ and has also used the name ‘Sheffield Nickel & Silver Plating Co. Ltd.’ The firm had manufacturing Works at Priestley Street, Sheffield from 1913 until the 1960s. They also had a London office in 1919 at Atlantic House, 40a Holborn Viaduct, London, E.C.1., then in 1921 at Union Bank Buildings, Charterhouse Street, E.C.1. The company was dissolved in 2000, the last office address being 23 Albemarle Street London, W1S 4AS. Although this spoon is not linked to a particular shipwreck, it is recognised as being historically significant as an example of cutlery, possibly from a passenger’s luggage or imported for use in Colonial Victoria in the 19th to early 20th century. The spoon is the only example in Flagstaff Hill’s collection that is connected to the manufacturer Sheffield Silver Plate and Cutlery Co. Ltd., historically significant also, as in 1939 the same manufacturer was a recognised supplier to the British Government. The spoon is also significant as it was recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value.Spoon; teaspoon, nickel plated silver, discoloured to brown. Old English design. Inscription on handle. Made by Sheffield Silver Plate & Cutlery Co Ltd., Sheffield. Spoon has dimpled surface, nicks and dents. Embossed logo within sunken elongated octagon [SSP] Embossed letters following logo, “S S P C & CO LTD EP/NS” flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, sheffield, cutlery, eating utensils, electroplate, silver plate, silverware, flatware, antique flatware, old english flatware pattern, spoon, teaspoon, silver flatware, dining, silver plated, epnns, sheffield silver plater & cutlery, ssp, ssp & c co ltd, 20th century silverware -

Australian Gliding Museum

Australian Gliding MuseumMachine - Glider – Sailplane, 1972

The Hall Cherokee II glider is an American design for amateur construction from plans. The designer was Stan Hall (1915-2009), a professional engineer, who gained extensive experience in the United States aviation industry during World War 2 including the programs for military gliders. He continued to work as an engineer for aircraft manufacturers and as a consultant to the industry after the war. He was active in gliding and, in particular, the home built sailplane movement. The Cherokee II was one of about 10 glider designs that he produced: it came out in 1956. It is understood that over 100 Cherokee gliders have been built. In Australia the number is possibly 10 or 11. The Hall Cherokee VH-GVO was built by R.D Meares of Caringbah, New South Wales. The glider was registered as VH-GVO on 11 October 1973 and given serial number “GFA-HB-82” by the Gliding Federation of Australia. The Logbook for VH-GVO appears to be a complete record of the flying history; in aggregate 210 hours 40 minutes in the air from 331 flights. The first test hop occurred on 29 July 1972 at Camden, New South Wales. VH-GVO was last flown on 22 July 1986. Many of the flights recorded are of one or two hours duration. The glider was last inspected and certified as airworthy and in a reasonable condition at the Hunter Valley Gliding Club in July 1986. Since that time, until transferred to the Australian Gliding Museum, the glider was in storage. Structural restoration work has been completed on the fuselage and one wing. However, inspection of the other wing revealed extensive damage to the ribs and spars and consequently a decision was taken to make it a static exhibit. The exhibit is an example of home built construction of a type that has proved popular amongst amateur glider builders.The Hall Cherokee (formerly registered as VH-GVO) is a single seat wooden home built glider. The glider is constructed from wood, plywood, fabric and metal fittings, all commercial grade except for main wing fittings, pulleys, cables and bolts. The fuselage is simple with four main longerons and bulkheads with diagonal bracing. The wing has two identical solid spars which form a geodetic structure, hence the leading edge is non-structural. Registration VH-GVO – serial number GFA-HB-82 australian gliding, glider, sailplane, hall, cherokee, meares, hunter valley gliding club -

St Kilda Historical Society

St Kilda Historical SocietyPhotograph, St Kilda Municipal Depot, Inkerman Street - images collection, 1979

Prior to its demolition in 1979, the St Kilda Municipal Depot occupied a 1.2 hectare site at 33 Inkerman Street St Kilda. The land was initially purchased by the Council in 1867 as a site for a permanent market, which ceased to operate in about 1882. In October 1923, the Council discontinued the practice of disposing garbage by burial in tips when it opened a garbage incinerator at the Depot. After thirty years this incinerator had become both obsolete and objectionable to health and was replaced in March 1953 by American-designed Monohearth Garbage Destructor Units. According to the Council, these Destructor Units were the only ones of their kind in Australia and they removed all the objectionable features of garbage disposal (particularly for the employees). They were expected to serve St. Kilda's requirements for the next 80-100 years. In 1957 the Council said that the Destructor Units had 'enabled substantial economies to be effected in the annual costs and have proved a very successful venture. The Council now destroys the garbage from the City of Brighton, which pays for the privilege, and it is anticipated that other Municipalities will also take advantage of ihe benefits of this modern and, in Australia.' See 'City of St Kilda 1857-1957 A Brief Outline of Progress and Development' [82] In 1994, as a result of the local government amalgamation process combining the former Cities of Port Melbourne, South Melbourne and St.Kilda, the new City of Port Phillip owned three municipal depots. The St. Kilda municipal depot site became surplus to requirements and, in 1996, the City of Port Phillip resolved to use the site for a community housing project under the City of Port Phillip Housing Program. Colour photographCouncil Yards before demolition 1979st kilda, st kilda municipal depot, inkerman street, council depot, destructor -

Puffing Billy Railway

Puffing Billy RailwayNew Record Saw Bench, circa 1930's

Saw Bench - New Record Saw Bench Timber framed with steel wheels, belt driven saw blade powered by a Rosbery internal combustion engine. The Rosebery Engine No C28437 R.P.M 800 H.P. 6 Manufactured By Westinghouse Rosebery Pty.Ltd. Sydney Rosebery Engine Works Ltd began as the engine and pump manufacturing division of Buzacott & Company, and in 1923 became an incorporated company. In 1935, Westinghouse gave Rosebery Engine Works the right to manufacture and sell nearly all Westinghouse products. The name of the company then changed to Westinghouse Rosebery Ltd From the late nineteenth century, petrol engines gradually supplanted steam engines for running a wide range of machines, and in turn petrol engines were largely supplanted by electric motors. The Champion was a successful small petrol engine made by the large Sydney company, Westinghouse Rosebery, based on the American-designed Fuller and Johnson engine. With hopper cooling and a fuel tank between the skids, and weighing only 240 pounds (109 kg), it was easy to mount on wheeled transport, making the Champion a self-contained mobile source of power. Engines of this type were used in rural areas for driving chaff cutters, small saw benches, pumps and orchard sprayers. These engines were also commonly used in both rural and urban areas for powering concrete mixers. Both Westinghouse Rosebery in NSW and Toowoomba Foundry in Queensland made these engines in large quantities, beginning in the 1920s when tariff protection made local manufacturing viable. The production of small petrol engines continued in Australia until the 1970s, when reduced tariff protection led to increased competition from cheaper imported engines. Historic - Industrial Timber working - belt driven saw blade powered by a Rosbery internal combustion engine. Timber framed with steel wheels, belt driven saw blade powered by a Rosbery internal combustion engine. The Rosebery Engine No c28437 R.P.M 800 H.P. 6 Manufactured By Westinghouse Rosebery Pty.ltd. Sydneysaw bench, puffing billy, new record, internal combustioin, westinghouse rosebery pty.ltd., rosebery pty, internal combustion engine. -

Nillumbik Shire Council

Nillumbik Shire CouncilReinis ZUSTERS (b.1918 Ukraine, arr.1950 Aus - d.1999 NSW Aus), Sunday Morning Montsalvat, 1979

Reinis Zusters OAM was born 15 October 1918 in Odessa, Ukraine, of Latvian parents. Zusters’ father died before he was two years old and he was raised in an orphanage from an early age. He had one sister. He studied Art at the Riga Technical College, Latvia, from 1935 to 1940. He married Aldija Kapteinis, and they had a daughter, Rudite (born 1942 in Riga). After World War II the Zusters family were refugees. They reached Western Australia in 1950, where they stayed for 6 months before moving to Canberra, ACT. In 1952, Zusters moved from Canberra to Pennant Hills in Sydney with his second wife, Arija Biks. Their daughter Laura was born in Sydney in 1956. In 1966, Zusters met his future third wife, Venita Salnajs. In 1969, Zusters bought a house in Greenwich, Sydney. He married Venita on September 17, 1976, and they moved to Wentworth Falls in the Blue Mountains. Zusters died on 8 October, 1999 at Wentworth Falls, and was cremated at Rookwood Crematorium, Sydney. His ashes are buried in the Latvian section of Rookwood Cemetery. Zusters studied at the Technical College of Riga (Latvia), and at East Sydney Technical College, Australia. He was influenced by his Latvian cultural heritage, and admired the artist Voldemars Tone (1892-1958). Shortly after arrival in Australia, Zusters became a draughtsman with the Department of Works and Housing in Canberra. Later he was appointed chief designer with the Australian-American architectural firm Austin-Anderson, at St. Leonards, Sydney. Zusters practised as a full-time professional artist from 1968. Zusters was a prolific painter, predominantly in oils. He produced many large landscapes, including triptychs of the Blue Mountains. His landscapes were mountain scenes prepared in the manner of Jackson Pollock and completed with washes and pale glazes of colour. His cityscapes featured a rich paint surface and sharp-edged thickness of paint applied with a palette knife, layer upon layer. He painted urban scenes of Sydney, inland Australian scenes, and several major portraits including Sir Winston Churchill’s gardener (purchased by Art Gallery of NSW). He made many small informal portrait-drawings of friends. His usual signature was “Zusters”. His work is represented in numerous public and private collections in Australia and abroad. He won numerous prestigious awards in Australia, Japan and USA and was honoured with the Order of Australia Medal in 1994. -

National Wool Museum

National Wool MuseumModel Ship, David Lumsden, SS Edina, 2018-2019

The Edina was one of the longest serving steam vessels anywhere in the world. Built on the Clyde by Barclay, Curle & Co. she was an iron hull single screw steamer of 322 tons with three masts. In 1855 Edina was requisitioned by the Admiralty from her owners the Leith, Hull & Hamburg Steam Packet Co. to carry stores and horses to the Black Sea during the Crimean War. After return to her owners Edina traded around the UK and Mediterranean before being purchased and used as a blockade runner during the American Civil War carrying cotton from the Confederate states in 1861. Edina arrived in Melbourne under sail in March 1863 and was purchased by Stephen Henty for use from ports in western Victoria and later carried gold prospectors across the Tasman to New Zealand. After a refit in 1870 she was used in the coastal trade along the Queensland coast for Howard Smith until returning to Victoria and the Melbourne-Geelong trade as a cargo-passenger vessel. The Edina had two narrow escapes from destruction in 1898 and 1899 when she collided with other steamers, both being sunk. A further refit in 1917 altered her appearance with a new mast, funnel, bridge and promenade deck. By 1924 Edina had made over 12,000 Melbourne-Geelong passages and carried over one million people on the service. A further collision in July 1931 which sank the tug Hovell forced Edina onto a mudbank on Port Phillip Bay. She was taken out of service in 1938 but was later renamed Dinah and used as a lighter until 1958 when she was broken up and her remains used as land-fill.Model of a Coastal Trader & Passenger Ship with hull painted red and black. Red flag and black flag with S attached to flag pole. On forward of ship - Edinageelong, transport, ship model, water transport -

Melbourne Legacy

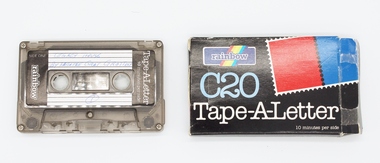

Melbourne LegacyAudio - Recording, tape, Legacy House, by Legatee Grat Grattan

The tape has not been played from the label it is Legatee Grat Grattan talking about Legacy House. Legatee Grattan was very important member of Legacy for many years. He was well placed to tell the story of the donation towards Dureau House as L/ Grattan was pivotal in it's story. BG Corporation of New York used 'Brown and Dureau' as agents in Melbourne for their spark plug manufacturing (for the American aircraft based in Australia during the war). A royalty of two shillings and sixpence was agreed. The entrepreneur President of BG Corporation was Richard Goldsmith. L/ Grat Grattan had a friend Mr Edwards who was managing director at Brown and Dureau and heard of the desire by Goldsmith to leave a permanent memorial to ex-servicemen in Australia (Children's Hospital was considered). Grat took Edwards to Market St and showed him the inadequacy of the building. It was agreed if Melbourne Legacy could come up with a purchased building in 10 days they would get the money needed. The property purchased was 'Storey Hall' in Swanston St (also called Hibernian Hall in other documents). After the war it turned out not to be suitable and a new building was required. Contents TBC 'Perhaps his most lasting monument is Melbourne Legacy House. Through his friendship with one of the principals of the firm, Brown and Dureau, Legacy was given a donation of 30,000 pounds in 1944. A condition of the donation was that Legacy had only eight days in which to buy a building. A building across the road from the Royal Melbourne Institute of Technology was bought for 18,000 pounds and the balance invested. The building was sold in the early '50s and the proceeds plus the invested money enabled Legacy to buy its headquarters, Dureau House, in Swanston Street in 1955."It may be confirmed when played but it is likely a significant recording of the history of the acquisition of Dureau House.Clear plastic cassette tape in a cardboard box.Cardboard box, rainbow, C20, Tape a letter. Cassette, side 1 - Legacy Week by Legatee Grat Grattan, 1, Rainbow, Tape a Letter. 10 minutes per side. side 2 - as above.legatee, grat grattan, dureau house -

Parks Victoria - Gabo Island Lightstation

Parks Victoria - Gabo Island LightstationTables

Commonwealth government issue. This nest of tables are currently in use by the lighthouse staff.The set of three tables of descending size are designed in the same distinctive style as the bookcases and share the same wood type and finish (GILS 0012.2). Information on the underside of the tables indicates they were purchased by the Commonwealth through the Department of Transport for the CLS. The design bears the stylistic marks of the easily recognisable furnishings produced by the Kalmar firm, Sydney. Steven Kalmar (1909-1989), who migrated to Australia in 1939 and opened his own interiors business in 1949, played a significant role in popularising modernist design concepts in Australia drawing his ideas from Scandinavian and American trends. Born in Hungary, he trained as an architect and his contemporary affordable furnishings were especially suitable for the open-plan houses built in Australia’s new post-war suburbs. He closed the retail side of this in 1957 and concentrated on commissions, some for large-scale orders. One of these bulk orders came from the Commonwealth Government sometime between 1957 and the early 1970s, with several examples of light, compact and functional domestic furnishings supplied to lightstations in Victoria. Because the order was placed by the CLS, it is possible that Kalmar furnishings were also provided to lightstations in other states. Additional examples at Gabo Island include three bedside tables (GILS 0042.2 & 0076.10), chest of drawers (GILS 0077) and two bookcases (GILS 0012.2), with the backs of at least two of the furnishings bearing the Kalmar label. Kalmar furnishings in the other Victorian lightstations investigated by this study include bookcases at Cape Otway, Cape Nelson (3 examples) and Point Hicks (2 examples); two bedside tables at Cape Otway, and a long coffee table at Wilsons Promontory. The set of tables has first level contributory significance for their clear provenance, completeness and association with Steven Kalmar whose functional designs introduced modern, low cost furnishings to a number of Australia’s lightstations.Nest of three Scandinavian style tables, solid wood. Curved U shaped legs, one bar at base of table.Underside of GILS007.3:"C of A / D.O.T 1444248" (Commonwealth of Australia, Department of Transport.) •All tables have "16" on underside. -

Parks Victoria - Gabo Island Lightstation

Parks Victoria - Gabo Island LightstationNails

The five types of nails include a stamped steel nail made for wooden flooring; four copper nails used for boat building found at various locations on the island; two steel nails removed from the lantern room door during restoration in 2002 which possibly came with the Chance Bros. lantern room kit delivered in 1862; three galvanised steel nails used to pin the railway track to sleepers and decking on the jetty (the rail track carried a small trolley for unloading stores from supply ships); and a square copper nail found on the rocky shore on Tullaberga Island close to the location of the Monumental City wreck of 1853. The huge American steamer, Monumental City, was wrecked on 15 May 1853. Built in 1850, the ship was the first screw-propulsion steamer to cross the Pacific and was heading back to Sydney after dropping off Californians heading for the Victorian goldfields. Thirty-seven lives were lost, including the owner of the ship, Peter Strobel. A medal was awarded by Sydney residents to Charles Plummer who swam ashore with a line from the wreck. The tragedy renewed the urgency for a lighthouse on Gabo Island, and in 1862 when this was achieved an obelisk was erected as a memorial to those who perished. That year, Victorian PWD architect and designer of the lightstation buildings, Charles Maplestone, gave the following instructions: ‘You may remove the remains of the poor unfortunate shipwrecked of the Monumental City to the site on Gabo you propose but take scrupulous care to collect all the remains and inter them decently under the monument. Pray save any relics’.246 Heritage Victoria has 39 artefacts listed under the Historic Shipwrecks Act (S473) with a clear provenance to the Monumental City. While the copper nail has no documented provenance, it still has contributory significance as part of a diverse assemblage of relics that help to interpret the history of the Gabo Island Lightstation and the numerous shipwrecks that have occurred in its vicinity since the mid nineteenth century..1 Steel nail - flat. Stamped. This type of nail was used for secret nailing of flooring. Source of this nail is unknown. .2 Copper nails. This type of nail was used for boat building. Found at various locations around island. .3 Steel nails. Extracted from lantern room door during restoration 2002. .4 Galvanised steel nails. Used to pin railway track to timber sleepers and decking on jetty. Rail track carried a small trolley used during the unloading of stores from supply ships. .5. Copper nail square. This nail was found on the rocky shore line on Tullaberga Island close to the location of the wreck of the "Monumental City" wrecked May 1853. Nail found in June 2000. -

Flagstaff Hill Maritime Museum and Village

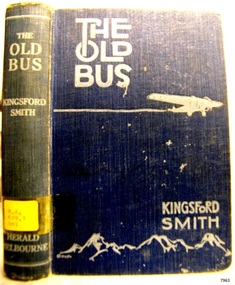

Flagstaff Hill Maritime Museum and VillageBook, The Old Bus