Showing 790 items matching "manufacturing history"

-

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionClothing - Top Hat, n.d

Black top hat. High crowned, narrow brim with slightly rolled sides, edged with grosgrain ribbon, brushed surface. Leather headband, hat lined with cream silk. Small air hole in top of crown.Front: On headband inside hat ' 'English Manufacture' stamped in leather. Maker's stamp inside crown 'Extra Quality London' and Latin inscription Name tag 'ENT HENRY' -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionMachine - Sieve Vibrator, n.d

Port of Portland CollectionVibrator for grading samples of sand. 2 Horse Power electric motor, switch, power cord and plug assembly in green steel frame, container and sieve missing.Front: MANUFACTURED BY A.C. CHEERS, COBURG VICTORIAport of portland -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionBooklet - Brochure, Excelsior Catalogue of Type Faces for use in the Manufacture of Rubber Stamps, n.d

Portland Town CouncilWhite paper booklet with three staples at top. -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionAccessory - Badge - Back to Portland, November 14th to 21st, 1929, 1929

Displayed at History House.Metal round badge with faded image of a lifeboat under an open-sided cover shed. Colours: Blue, orange and green. Paper image under hard plastic surface. Metal back and pin.Front: Back to Portland/Nov. 14th to 21st 1929 (green print, around edge) Back: Side: Windsor MFG CB., 6 Albert St., Windsor (white print)back to portland, memorabilia, 1929 -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionAudio - Edison Sterling Record, Thomas A. Edison (TM), The Pullman Porters on Parade, 1913

Blue Amberol Records was the trademark name for cylinder records manufactured by Thomas A. Edison, Inc. in the US from 1912 to 1929. They replaced the 4-minute black wax Amberol cylinders introduced in 1908, which had replaced the 2-minute wax cylinders that had been the standard format since the late 1880s.[citation needed] Blue Amberols can play for as long as 4 minutes and 45 seconds[citation needed] and have a surface layer of the "indestructible" plastic celluloid, which Edison tinted a trademark blue color. Edison brand phonographs designed to play Amberol cylinders were named Amberolas. Displayed at History HouseEdison Sterling Record. Blue Amberol cylinder record.Front: Thomas A Edison PAT'D. 6. 2043. The Pullman Porters on Parade. Meeker (engraved, edge)music, amberol, blue amberol, thomas a edison, edward meeker -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionDecorative object - Commemorative Place - Naming of Portland Bay, n.d

Commemorative plate, manufactured by Adams. 'Lieutenant Grant - discovery and naming of Portland Bay, Dec 5 1800portland bay, 1800s, lieutenant grant, commemorative -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPamphlet - BROCHURE, Portland Aluminium Smelter, n.d

... . Contains history, economic importance, and manufacturing.... Contains history, economic importance, and manufacturing ...Two tri-fold brochures produced by Portland Aluminium. Contains history, economic importance, and manufacturing information. Black and white. Blue 'PORTLAND ALUMINIUM SMELTER' on front, above aerial photo of smelter. Back has diagram of smelter, area marked with blue numbers to match legend.portland aluminium smelter -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Typewriter, STOTT & HOARE PTY LTD, n.d

Manufactured by Stott and Hoare Pty Ltd, 91 William St Melbourne. Displayed in Portland Historical Society Museum, in History HouseCast iron frame with small carriage, patented dates on reverse. Painted black with decorative blue and gold stripesFront: No. 5 UNDERWOOD STANDARD TYPEWRITER (front)typewriter, office equipment -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionCard - Card - Air Rifle target Card, n.d

Cardboard Daisy air rifle target card. Beige cardboard, black print and target -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPostcard - Postcard - advertising John De Lacy's business Portland, c. 1909

Postcard, black and white, advertising John De Lacy's business, which included upholstery manufacture and import of carriage materials, and his stand at the Royal Agricultural Show between August 31 and September 4 1909. Photo of stall, description of business either side of photo.Back: 'Mr. Vivian Saddler, Glenthompson' - handwritten in black ink. Postmarked Melbourne Aug. 24 09. Also rifle club scores in pencil -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

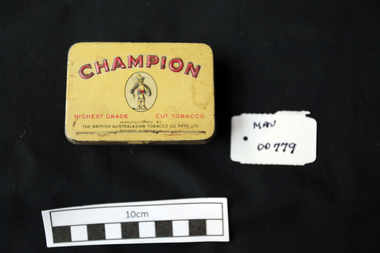

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Containers, tin, Tobacco ‘Champion’, c1940

W.D & H.O.Wills (Australia) Ltd began manufacturing tobacco products in 1913 at its Raleigh Park factory in Kensington, Sydney. In 1945 an estate of 16 acres was purchased at East Bentleigh, Melbourne, with a further 22 acres purchased later and the Virginia Park manufacturing branch was established. The 1950s were to be one of the most successful decades in the company’s history and it enjoyed a peak of 83 per cent market share in 1954. But this was also a period of increased competition as Phillip Morris and Rothmans entered the Australian tobacco market. By 1972, increased competition meant that the company’s market share had slipped to 39%. By the time tobacco advertising was banned on Australian radio and television in 1976, Wills' market share had fallen a further 6%. In 1985 Wills combined the separate factory operations in Sydney and in Melbourne into one site at Pagewood, Sydney which took on the name Virginia Park. In 1989 W.D & H.O.Wills (Australia) became a subsidiary of the British American Tobacco Industries group of companies. 1999 British American Tobacco merged with global competitor Rothmans International. Rothmans in Australia and Wills merged to form the wholly-owned subsidiary British American Tobacco Australia. The merger left British American Tobacco Australia, Phillip Morris and Imperial Tobacco Australia A tin with a hinged lid for 'Champion' Tobacco flakesCHAMPION / HIGHEST GRADE / CUT TOBACCO / MANUFACTURED BY / THE BRITISH AUSTRALIAN TOBACCO CO.PTY.LTDtobacco, cigarettes, brittish australian tobacco co. pty. ltd., moorabbin, bentleigh, cheltenham, early settlers, , wd &h.o.wills pty. ltd., east bentleigh, kensington , virginia park east bentleigh, champion flake tobacco -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

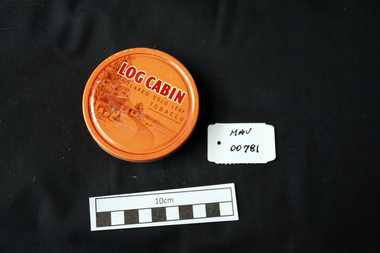

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Containers, tin, tobacco 'Log Cabin', 20thC

W.D & H.O.Wills (Australia) Ltd began manufacturing tobacco products in 1913 at its Raleigh Park factory in Kensington, Sydney. In 1945 an estate of 16 acres was purchased at East Bentleigh, Melbourne, with a further 22 acres purchased later and the Virginia Park manufacturing branch was established. The 1950s were to be one of the most successful decades in the company’s history and it enjoyed a peak of 83 per cent market share in 1954. But this was also a period of increased competition as Phillip Morris and Rothmans entered the Australian tobacco market. By 1972, increased competition meant that the company’s market share had slipped to 39%. By the time tobacco advertising was banned on Australian radio and television in 1976, Wills' market share had fallen a further 6%. In 1985 Wills combined the separate factory operations in Sydney and in Melbourne into one site at Pagewood, Sydney which took on the name Virginia Park. In 1989 W.D & H.O.Wills (Australia) became a subsidiary of the British American Tobacco Industries group of companies. 1999 British American Tobacco merged with global competitor Rothmans International. Rothmans in Australia and Wills merged to form the wholly-owned subsidiary British American Tobacco Australia. The merger left British American Tobacco Australia, Phillip Morris and Imperial Tobacco Australia Virginia Tobacco, or Flue-cured tobacco, is named after the US state where it was first cultivated. It is also called ‘bright tobacco’ because of the yellow to orange colour it achieves during curing. It grows particularly well in subtropical regions with light rainfall, such as Georgia, Florida and the Carolinas in the USA, Southern Brazil and Zimbabwe. In Australia, blends are predominantly Virginia, for example, Dunhill and Winfield. Virginia blends contain only flue-cured Virginia tobacco W.D & H.O. Wills Pty Ltd - In 1945 an estate of 16 acres was purchased at East Boundary Road, East Bentleigh, Melbourne, with a further 22 acres purchased later and the Virginia Park manufacturing branch was established. The plant was closed 1985 when the firm moved to Pagewood, Sydney New South WalesA circular tin with a lid that is opened by twisting a coin in the rim and closed by screwing the lid down. Instructions written on base of tin. Contained ‘Log Cabin’ tobacco.lid :LOG CABIN / FLAKED GOLD LEAF / TOBACCO / base ; LOG CABIN / SKRU SEAL / To open twist coin / to reseal screw lid / TOBACCOtobacco, cigarettes, smoking pipes, cigarette papers, moorabbin, cheltenham, bentleigh, log cabin tobacco, w d & h o wills pty ltd , british american tobacco ltd, rothmans international ltd, east bentleigh -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured objects, Cigarette papers ‘Zig Zag' x 2, 20thC

Rolling papers are small sheets, rolls, or leaves of paper which are sold for rolling cigarettes either by hand or with a rolling machine. When rolling a cigarette, one fills the rolling paper with tobacco. Rolling papers are most commonly made with wood pulp, hemp, flax, or rice straw as a base material. Zig-Zag papers, made in France, were the first interleaved brand (hence the name). Gold medal at 1900 Universal Exposition in Paris. 1860 Samuel Ramsden, a Yorkshire man, founded first paper mill in Victoria on the banks of the Yarra River, Fairfield, Melbourne. This was the Australian Paper and Pulp Company which for most of its history was called The Australian Paper Manufacturers Ltd. until it changed its name in 1986 to Amcor. In 1919 the company opened its mill on the corner of Upper Heidelberg Road and The Chandler Highway in Fairfield and remains there today. 2 packets of precut cigarette papers 'Zig Zag ' Paper Aust. Pty. Ltd. 60 leavesZIG ZAG PAPER AUST. PTY LTD 60 LEAVESciggarettes, cigarette papers, tobacco, moorabbin, cheltenham, early settlers, australian paper manufacturers, fairfield melbourne, zig zag cigarette papers ltd. amcor ltd, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

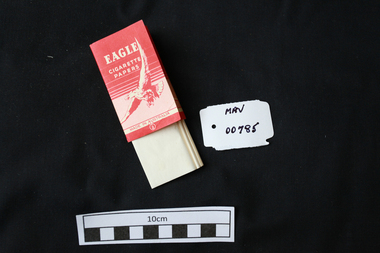

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured objects, Cigarette paper, ‘Eagle’, mid 20thC

Rolling papers are small sheets, rolls, or leaves of paper which are sold for rolling cigarettes either by hand or with a rolling machine. When rolling a cigarette, one fills the rolling paper with tobacco. Rolling papers are most commonly made with wood pulp, hemp, flax, or rice straw as a base material. 1860 Samuel Ramsden, a Yorkshire man, founded first paper mill in Victoria on the banks of the Yarra River, Fairfield, Melbourne. This was the Australian Paper and Pulp Company which for most of its history was called The Australian Paper Manufacturers Ltd. until it changed its name in 1986 to Amcor. In 1919 the company opened its mill on the corner of Upper Heidelberg Road and The Chandler Highway in Fairfield and remains there today. A packet of pre-cut cigarette papers 'Eagle ' brandEAGLE / CIGARETTE / PAPERS / MADE IN AUSTRALIA back 60 PAPERSciagarette papers, cigarettes, tobacco, melbourne, moorabin, paper mills, eagle cigarette papers ltd, australian paper manufacturers ltd, fairfield victoria, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Containers, tin, Tobacco 'Capstan' ‘Navy Cut’, c1940

W.D & H.O.Wills (Australia) Ltd began manufacturing tobacco products in 1913 at its Raleigh Park factory in Kensington, Sydney. In 1945 an estate of 16 acres was purchased at East Bentleigh, Melbourne, with a further 22 acres purchased later and the Virginia Park manufacturing branch was established. The 1950s were to be one of the most successful decades in the company’s history and it enjoyed a peak of 83 per cent market share in 1954. But this was also a period of increased competition as Phillip Morris and Rothmans entered the Australian tobacco market. By 1972, increased competition meant that the company’s market share had slipped to 39%. By the time tobacco advertising was banned on Australian radio and television in 1976, Wills' market share had fallen a further 6%. In 1985 Wills combined the separate factory operations in Sydney and in Melbourne into one site at Pagewood, Sydney which took on the name Virginia Park. In 1989 W.D & H.O.Wills (Australia) became a subsidiary of the British American Tobacco Industries group of companies. 1999 British American Tobacco merged with global competitor Rothmans International. Rothmans in Australia and Wills merged to form the wholly-owned subsidiary British American Tobacco Australia. The merger left British American Tobacco Australia, Phillip Morris and Imperial Tobacco Australia. Virginia Tobacco, or Flue-cured tobacco, is named after the US state where it was first cultivated. It is also called ‘bright tobacco’ because of the yellow to orange colour it achieves during curing. It grows particularly well in subtropical regions with light rainfall, such as Georgia, Florida and the Carolinas in the USA, Southern Brazil and Zimbabwe. In Australia, blends are predominantly Virginia, for example, Dunhill and Winfield. Virginia blends contain only flue-cured Virginia tobacco The W.D.&H.O.Wills Ltd manufacturing plant was situated in Boundary Road East Bentleigh 1945 – 85. Virginia Park is still a Commercial Business Area A tin with a hinged lid for 'Capstan' "Navy Cut tobacco Lid: CAPSTAN / NAVY CUT / W.D. & H.O. WILLS LTD inside lid - This tin of which only a / limited number will be / issued will be found convenient / for smokers as a vest / pocket container and can / easily be refilled with the / contents of the ordinary 1oz / packets of 'Capstan Tobacco'tobacco, cigarettes, cheltenham, moorabbin, early settlers, smoking pipes, cigarette papers, bentleigh, navy cut tobacco, w d & h o wills pty ltd , british american tobacco ltd, rothmans international ltd, east bentleigh, capstan tobacco -

Geelong RSL Sub Branch

Geelong RSL Sub BranchHistory - VX5104 L/Col Victor J Schofield MBE, early 20 Century

... . Timber materials used in the manufacture of both items. History ...These are original items of VX5104 L/Col VJ Schofield MBE who served with 23rd Battalion (The City of Geelong Regiment). In 1929 this Battalion was amalgamated with the 21st Battalion to become 23rd/21st Battalion and adopted the territorial designation of 'The City of Geelong Regiment/The Victorian Rangers'. The Battalion went to the Northern Territory during WW2 before being disbanded, however VX5104 VJ Schofield became redeployed and served in New Guinea during WW2. He was awarded an MBE for his service. (Reference The Argus (Melbourne, Vic.) Friday 20 July 1945. (Awards for Service in Papua-New Guinea). The original plaques were located at the Geelong Returned Soldiers, Sailors and Airman Woollen Mill (commonly referred to as the RS&S Mill). Schofields Father was responsible for the raising of the Mill, with Federal Funding, he was the CEO. It is not known if Victor John Schofield worked at this Mill but the plaques were found there and donated to the Geelong RSL Sub Branch by Roger Burt CEO of Godfrey Hirst Group during the Hirst takerover of the RS&S Mill.Two Plaques - one the Rising Sun, one the Maxwell Family Crest which is related to L/Col Schofield MBE. Timber materials used in the manufacture of both items.None on the Rising Sun. One The Maxwell Family Crest 'Rebiresco' Maxwell.ww2, vx5104 jc schofield mbe, papua-new guinea, city of geelong regiment, 23rd/21st battalion -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionClothing - Straw Boater Hat, Special Manufacture London & Melbourne Regd. No. 3124, n.d

Straw boater, natural colour, wide black grosgrain ribbon around crown of hat. Cord round crown attached to two metal clips on edge of brim. Leather headband with 'Self Conforming regd design No. 632799', in gold. Inside crown lined with cotton mesh and silk. Maker's mark on silk. Sticker with '7' attached to leather headband. -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionDecorative object - Plate, Glenelg Manufacturing Company, n.d

Rectangular brass plate. Front black with brass lettering. Small hole in each corner. 'MANUFACTURED BY Glenelg Manufacturing Co CASTERTON, VIC' -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionEquipment - Tennis Racquet, Manufactured for Melbourne Sports Depot Made in England, n.d

Wooden tennis racquet, gut strings, leather strip around end of handle. 'LONDON' stamped on side of handle. 'PH. 14 oz stamped on other sideFront: 'STRATE' gold lettering Back: 'Manufactured for MELBURNE SPORTS DEPOT MADE IN ENGLAND' - gold lettering -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionSouvenir - Tankard, c. 1984

White porcelain tankard. Gold rim top and bottom. Depiction of Henty landing at Portland, printed engraving inbrown, 19th November 1834.Back: Base: Victoria's 150 logo and details of manufacture.souvenir of portland, tankard, henty -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionDomestic object - Bottle (30 fl oz) - Jefferys Cordial Factory Casterton, n.d

Jeffreys Bros. 30 fl. oz. Clear glass bottle. Pyro label. Measurements 28.5cm x Top 2.5 x Bottom 27.5Front: 'JEFFREYS BROS' above BIG J logo, 30 Fl oz - beneath. Back: 'Contents manufactured by JEFFREYS BROS, 36 McPHERSON ST, CASTERTON VIC. PRESERVATIVE ADDED' Base: '1121, 5 SYMBOL, M' - impressed PRESERVATIVE ADDED -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomBooklet, G S Training Publications, AFV Identification Handbook, 1967

A soft covered loose leaf lace bound booklet showing photographs, silhouettes, recognition features, specifications and country of manufacture of principal AFV's of the major powers. With amendments Nos 1 & 2.Army Code No 70020afv recognition -

Eltham District Historical Society Inc

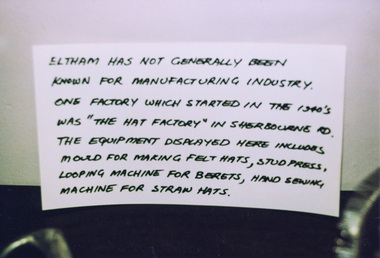

Eltham District Historical Society IncPhotograph, Hat making equipment, Heritage Week at 728 Main Road, Eltham, 1990, 1990

Two Colour photographs of hat making equipment,for Heritage Week display at the Local History Centre (former Courthouse), 728 Main Rod Eltham. (Home of Eltham District Historical Society) The equipment was used at the Hat Factory in Eltham which started in the 1940s. The equipment shown includes a mould for making felt hats, stud press, looping machine for berets and hand sewing machine for straw hats. Sign accompanying the display is hand written and reads: "Eltham has not generally been known for manufacturing industry. One factory which started in the 1940s was "the hat factory" in Sherbourne Rd. The equipment displayed here includes moulds for making felt hats, stud press, looping machines for berets, hand sewing machine for straw hats."heritage week, eltham, courthouse, hat factory, hat mould, activities -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, early 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them.Around the bottom side of the bottle and blown into the glass "ONE PINT" and on the opposite side "MILK". Below these markings is "This BOTTLE BELONGS TO MILK BOTTLES RECOVERY LTD" below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION. On the base of the bottle is molded a big "M". An identification mark of "90" over "9" is beneath the "M". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles, milk, dairy, farms, kiewa valley -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid 1800's (1834 Victorian dairy industry was founded) to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the large volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36"This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against sunlight penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it 6/33 and next to this "ONE PINT" and under this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, circa mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head was manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle which contained milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "3"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/36" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "15" glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded), until the time that cheaper containers were invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle, to contain milk, required its thickness because of the extensive handling (man and machine) before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle is a circle within it "6/35" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "20"milk, dairy, glass bottle -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a half pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them and this tint was to protect the contents from sun damage. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the top half of this bottle is "MILK" and opposite "HALF PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base is "2 M" underneath this "8/11" and underneath is "ISM -169"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles