Showing 754 items matching "metal work"

-

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Textile - Work Apron, 1883-1899

The personal 'carry-all', a cloth apron like article was utilised by Thomas Hamilton Osborne in his work with the Warrnambool Steamship Navigation Company. He was Company manager in 1883 until its dissolution in 1899. Osborne wrote many articles on early Warrnambool, particularly maritime material under the name of " Sliding Gunter". When he died he was buried at sea off the breakwater.His sister Mrs Annabella Kell is thought to have made this article.This is a significant item as T.H.Osborne was a key figure in 19th Century Warrnambool history, particularly in maritime affairs. Six sided, scalloped edges, four pockets, two metal hooks, purple woven fabric with yellow and gold embroidery, lifebuoy outline with W.S.N.Co and THO initials embroidered and two flags. Machine sewing of pockets and tab to base apron.W.S.N.Co THO initials on top of each other Two metal hookswork apron, warrnambool steamship navigation company, wsnc, thomas hamilton tracey osborne, annabella kell, sliding gunter -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Uniform - RAAF Jacket and trousers, 1940s

This RAAF uniform is believed to have belonged to Flying Officer Russell Miller, the son of William and Muriel Miller of Warrnambool. Russell Miller attended Warrnambool High School and worked for the Warrnambool City Council before enlisting in World War 11. He was killed in flying operations over Germany in 1944. Died 28 Sept 1944. Remembered at Rheinburg War Cemetery, Nordrhein-Westfalen, Germany. More info @ https://cwgc.org/find/find-war-dead This uniform is a poignant memento of one Warrnambool's brave heroes of World War 11.1 The jacket is made of navy blue wool with a rever collar, four front pockets, eight buttons with air force insignia and navy cloth lining. The two sleeves have metal insignia and black and cream braiding. Above the front left pocket is a stitched blue and white applique. The jacket has a cloth belt with a rusted metal buckle. .2 The trousers are made of navy blue wool with two pockets, a buttoned fly and there are six buttons evenly stitched around the waist band. There is also a metal clasp on the waist band. RAAFraaf, flying officer russell miller, raaf uniform 1940's -

Warrnambool and District Historical Society Inc.

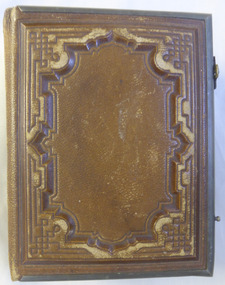

Warrnambool and District Historical Society Inc.Album - Portrait photos Frisch, Circa 1888

A collection of photographs depicting numerous people. Some have been taken by studios such as Lovewell & Co, Hider, Jordan and Daniel Clarke of Warrnambool. Most of the photos are unnamed but of those that are there is a Thom Wickham, E. M. Fleming, Henry and Stanly Frisch. There are also a number of photographs depicting land clearing and wood cutting also a couple of cards, one happy New year and Glaedelig Jul( Danish Merry Christmas)An album typical of the era with local family connections as well as work by local photographersBrown leather cover with gold figure work over embossing on the front with possibly the letter,”C”. The back cover is entirely embossed. Edges of metal clasp are on front and back cover but clasp part is missing. Gold edges to pages, which are all heavy card. Front inside page has pink briar roses with “Album” on card inserted through it.Jan 17th 1888. To Morris from H Bambrick?warrnambool, warrnambool photographers, lovewell & co, jordan photographers, daniel clarke, thom wickham, e m fleming, henry frisch, stanley frisch -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Album - Book, Mid 19th Century

This collection of photographs contains a number done by local photographers including Thomas Johnson, James Harvey, Daniel Clarke, J Hider and P Dawson of Hamilton( and also Warrnambool). Some photos are dated 1873 and 1867 and names include C C Hunt July 17/66. This album contains a number of photographs by some of Warrnambool’s earliest photographers and while the subjects are unknown, the still add to the body of work by these artists which have survived to this day. As visual recorders of people they have left a valuable resource in their work through the depiction of some of our earliest people but also a useful record of fashion and styles of the mid to late 20th century Brown leather cover with green metal edge and hinged locks (one Missing). Sepia photographs enclosed in cream card.On a hand written note inserted in the front, “ There are copies from paintings representing a young boy going to tea and returning as midshipman in a first class carriage, we think ***warrnambool, warrnambool photograph album, daniel clarke, p dawson, j hider, james harvey -

Ringwood and District Historical Society

Ringwood and District Historical SocietyDisplay case and 4 books, Lillian Horner memorial Prize presented to Miss J.D.Paddock in 1956 for distinguished work as an infant teacher in Ringwood, 1956

The Lillian Horner Memorial Prize was awarded to Miss Daisy Paddock for distinguished work as an infant teacher. Lillian Horner was a pioneer in infant teaching. She was born in May 1873 and died in February 1938. She encouraged mothers to interest themselves directly in the work of her infant grades so laid the foundations for the first Mother's Club. An annual prize of books was given to the infant teacher adjudged most worthy in a school under the Education Department, Victoria. to perpetuate her memory. In 1956 Daisy Paddock from Ringwood S.S.2997 won the prize. The books were The First Year in School by E.R. Boyce, The Merry-go-round by James Jeeves, One Little Boy by Julian Press, The Fairy Green by Rose Fyleman and Lavenders Blue,A Book of Nursery Rhymes by Kathleen Lines. The presentation case was made by former pupils who were then attending Ringwood Technical College.Wooden display case with metal plaque. Box with glass and wooden lid fastened by a brass clasp fixed by 4 wooden struts to a wooden tray base enclosing 5 books +Additional Keywords: Paddock, J.D. / Lillian Hornerpresented to Miss J.D. Paddock ,the Lillian Horner Memorial Prize 1956 -

Orbost & District Historical Society

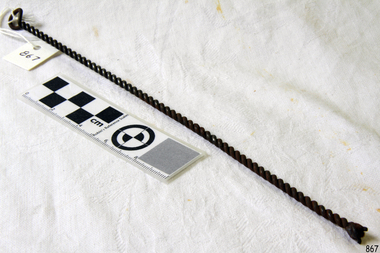

Orbost & District Historical Societywhips

This riding crop is a short type of whip without a lash, used in horse riding, It would have been used by a rural family in early Orbost.Horses played a vital role in the agricultural history of Orbost. This item is connected to that role.Two whips. .1 is a small leather riding whip with metal casings and small metal horse head at one end. This is a lady's riding crop. .2 is a very long buggy whip with metal casings. Both are hand-made.equestrian whip leather-work -

Orbost & District Historical Society

Orbost & District Historical Societyadvertisement, before 1933

John Tomlinson was the eldest son of Arthur James and Jessie Tomlinson who selected land at Tabbara in 1887. He worked in Temple's , the Herbert's store and for the Butter Factory until beginning his own business in 1906. He remained in business until 1933.A round metal tray with decorated edge. It is an engraved advertisement for J.S. Tomlinson.advertisement tomlinson commerce-orbost -

Australian Commando Association - Victoria

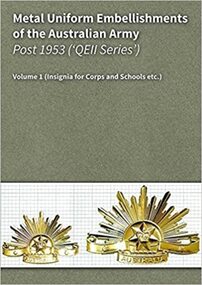

Australian Commando Association - VictoriaMetal Uniform Embellishments of the Australian Army Post 1953 Volume 1 - Insignia for Corps and Schools, 2017

... This 236 page, full-colour hard copy reference work.... melbourne This 236 page, full-colour hard copy reference work ...This 236 page, full-colour hard copy reference work, catalogues the metal insignia embellishments used by all Corps and Schools of the Australian Army (including philanthropic organisations), from 1953 through to the present. The book provides images of the front and the back of a given (metal) insignia set for each Corps etc. Each image set depicts the relevant hat badge, collar badges and epaulette title and/or cloth shoulder title applicable. The book's images record three distinctly different 'generations' of insignia manufacturing methods/types, including the: gilt brass and white metal items used in the 1953 to 1964 period; and anodised aluminium 'StayBright' insignia introduced as from 1964[ and 'BriteShine' insignia introduced with effect from 1997 (running through to the present). The full colour photographic images in the book are complimented by written descriptions which cite each item's distinguishing characteristics... including measures of: typical weight, height, width and thickness (at a given point). A discussion of copies and faked items is also provided, including microscope resolution images of 'tell tale' signs to look for. The entries in the book are organised alphabetically and match those used in the Authors' 614 page eBook version of this work (the eBook is a separate edition which provides scalable images of all relevant insignia and many manufacturing variants).The hard copy and electronic editions of this work are able to be used either separately or concurrently, as and when users require. Regards Mark Corcoran & Arthur Butler The Authors charlibravobooks.com Re: Copyright As the original authors we hold the sole copyright authority to sell this work. This item does not infringe on any copyright, trademark and/or intellectual property rights and we hold specific written publication approval from the Australian Defence Force. Soft cover, spiral bound 235 pagesaustralian army, post ww2 insignia -

Australian Commando Association - Victoria

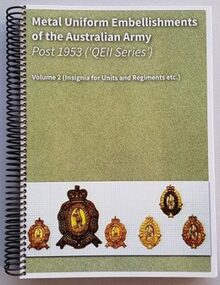

Australian Commando Association - VictoriaMetal Uniform Embellishments of the Australian Army Post 1953 Volume 2 - Insignia for Units and Regiments

This 305 page, full colour hard copy reference work, catalogues the series of metal uniform embellishments used by Units and Regiments of the Australian Army, from 1953 through to the date of publication. The book provides images of the front and the back of a given (metal) insignia set for each Unit or Regiment operating within the Australian Army since 1953 (including abolished formations). Each image set, depicts the relevant hat badge, collar badges and epaulette title and/or cloth shoulder title applicable. The book’s images document at least three distinctly different ‘generations’ of insignia manufacturing methods/types, including the: gilt brass and white metal items used in the 1953 to 1964 period; and anodised aluminium ‘StayBright’ insignia introduced as from 1964 and ‘BriteShine’ insignia introduced with effect from 1997 (running through to today). The full colour photographic images in the book are complimented by written descriptions which cite each item’s distinguishing characteristics… including measures of: typical weight, height, width and thickness (at a given point). A discussion of copies and faked items is also provided, including microscope resolution images of ‘tell tale’ signs to look for. The entries in this book are organised alphabetically and are consistent with those used in the Authors’ earlier publications (ie. the 614 page eBook version of Volume 1, as well as with the 236 page ‘Concise’ hard copy Editions of Volume 1). australian army insignia, post ww2 insignia and badges -

Orbost & District Historical Society

Orbost & District Historical Societymedications, 1940s - second half 20th century

These items were used or were available for sale by chemists in Orbost. Chemists who worked in Orbost included Henry Cottman; James Alfred Dubois Williams; Harry Arthur Murray; Miss P.E .Mason (Phyllis Estelle?); Miss Sybil Monica Buzza; Thomas James Frayer; Australia Shaw; James David Torley; John William Zimmer; Dalkeith William Steele; William Thomas Hollingsworth; E.E. Cohen; R.S. Anderson; Frances John Perry Faith Everard Pardew and Charles Anthony Wurf. The practices of early pharmacists are revealed through these glass bottles. The items have a clear association with Orbost. Seven containers. Six are cylindrical and one rectangular. 3217.1 and 3217.2 are pale green cylindrical 50 g containers with metal lids labelled "GRANTS ASTHMA POWDER" in red and white print. 3217.3 is a white glass jar with a green metal lid and a paper triangular label with white and navy print label, " REXONA OINTMENT".3217.4 is a small white cylindrical container with a red label with white print on green, "GREEN LABEL PILLS". 3217.5 is a white cylindrical plastic container with blue print, "JANOS JUNIPER CELERY MINERAL SPRINGS SALTS". 3217.6 is an empty narrow cylindrical blue and white container labelled, "DEWITTS PILLS". 3217.7 is a rectangular cardboard box, mottled brown with a white label and gown print,"6 X 2ml AMPOULES ANAEHAEMIN".medications-orbost-pharmacies containers-medications chemist pharmaceuticals -

Orbost & District Historical Society

Orbost & District Historical Societyhair accessories, mid 20th century

A bobby pin (also known as a kirby grip or hair grip in the United Kingdom) is a type of hairpin, usually of metal or plastic, used in coiffure to hold hair in place. It is a small double-pronged hair pin or clip that slides into hair with the prongs open and then the flexible prongs close over the hair to hold it in place. They are typically plain and unobtrusively colored, but some are elaborately decorated or jeweled. Bobby pins became popular in the 1920s to hold the new bobbed hairstyles. (ref. Wikipedia). These items were owned by Marjorie Burton. Marjorie Burton ( nee Whiteman), born 12 June, in Birmingham, England came to Orbost in 1995. In England she did office work – typing, shorthand and secretarial work - in accountants’ offices and also trained as a comptometrist with Burroughs in London. She came from a middle-class, working, church-going family. Her mother was a milliner who mademost of Marjorie’s clothes, hats and outfits. Marjorie married in 1938 to a salesman who later became a mechanic in the R.A.F. during WW11 These items are examples of women's hair accessories commonly used in the mid 20th century.Two packets of hair clips and one unused packet of henna shampoo. 2483.51 is a a set of 17 bobby pins on paper. On the back of the card are directions for a Steiner hair style. 2483.52 is a pack of 3 Dinkie silver metal clips for hair styling on a card. 2483.53 is an unopened sachet of powdered Henna shampoo. It is white with black text and green pictures.2483.51 - Kirbigrip 6d made in England Kirby Beard & Co 2483.52 - Made in England 2483.53 - Societe Francaise de Henne, Paris "Perfect -a -wave"hair-accessories bobby-pins shampoo kirbigrips burton-marjorie -

Orbost & District Historical Society

Orbost & District Historical Societybicycle pump, 1920's - 1940's

This hand pump would have been used on a tubed tyre. Hand pumps similar to this one were in use in the late 19th century through to the latter half of 20th century.During the 1930s and immediate post-World War II period few people owned cars as they were too expensive. To get to work most people either walked, relied on public transport, rode a bicycle or, if they could afford one, a motorcycle. A cylindrical silver metal bicycle tyre hand pump. It has a valve connection which is cloth covered and fits inside for storage. It can be fitted to a bracket on the bike frame.bicycle transport hand-pump -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Torch, 1935-1960

Diver's Submarine Electric Torches were first developed to give illumination for close examination work. They have to be self-contained, the older ones are powered by an accumulator type battery which could be recharged. Some models were fitted with a switch to turn the light off saving on the battery power. The lens is of a convex type and magnifies the light. Sometimes there was a protective grill across the glass or prongs to protect the glass from an impact. When fully charged the battery would last about seven hours. Torches are made from non-ferrous metal so as not to corrode in their watery environment. Siebe Gorman & Co Ltd has been producing hand-held, battery-powered, submarine electric torches for divers and the Ministry of Defence (MOD) since the 1920s. In 1961, the famous diving manufacturer C.E. Heinke merged with Siebe Gorman, and for a short while, torches were made with the combined 'Siebe Heinke' inscription. However, this linked inscription was later dropped, with a return to the Siebe Gorman name tag. Date of manufacture for these torches can be determined by their Admiralty Pattern (AP) number that was used to identify a particular item and were for naval stores use. Before NATO stock coding became more widely used, earlier MOD torches often have a simple four-digit group of AP numbers such as AP4456 or AP4458. In 1975 Siebe Gorman moved from their Neptune Works at Chessington in Surrey to a new location at Cwmbran in Wales and by this time their manufacture of diving equipment had declined. (For additional historic company information on Siebe & Gorman see notes section this document.)The item is significant as it gives us a snapshot into marine history and the development of diving equipment generally, especially that used for salvage operations before and during WW2. The company that made the torch Siebe Gorman was a leading inventor, developer and innovator of marine equipment with its early developments in helmets, compressors and other diving equipment. Items that are today eagerly sought after for maritime collections around the world. The items that have been donated to the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job.Diver's Torch brass with heavy glass screw on piece with four lugs attached contact spring inside. Leather hand strap missing."Siebe Gorman and Co Ltd, Makers, London." Has "A.P.4458" inscribed on front above glassflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, siebe, gorman, diver's torch, torch, diver, diving accessories -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bullet Mould, From 1600s to early 19th century

Musket balls are the ammunition used in muskets the weapons used during the English and American Civil Wars. The balls could be made from any metal alloy, but many were made from lead. Lead can be melted at reasonably low temperatures and so lead musket balls could be made over a camp fire. Lead could be readily sourced from such places like church roofs or even coffins, and recast from old musket balls, so it was an easy material to work with while preparing for battle. The soldier would carry a crucible in which to melt the lead, he would put the material into it and place it over the fire until it had formed into a liquid. Musket ball moulds like the subject item, had a small hole above one of the domes where the liquid could be poured into once the two domes were closed together. The soldier would wait until it cooled then opened the mould to reveal a solid lead ball inside. Because these were cast in halves even though pressed together, there would always be a small amount of liquid lead leakage which would form a thin crust around the ball. These needed to be filed off before being used inside a musket, so some soldiers would pop a few in their mouths and roll them around, chewing off the excess until the ball was smooth. The obvious downside to this method is that lead is poisonous. A tool used to make ammunition for black powder firearms either muskets or pistols from the early part of the 18th to mid 19th century. After this time enclosed brass cartridges that held the propellent powder and bullet were starting to come into wide spread use, negating the need for a firearm to first have black powder placed in a barrel then the ball rammed on top and finally the firearm primed with powder or a percussion cap.Musket rifle/ pistol bullet mold. Makes .50 -caliber- round balls with a sprew cutter to cut off excess lead.Marked 50flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shot pliers, lead shot, shot, armoury, firearms, bullet, cast bullet, lead ball, lead shot, scissor mould -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Joiner or Jack Plane, Late 19th to first quarter of the 20th century

A jack plane (or fore plane) is a general-purpose woodworking bench plane, used for dressing timber down to the correct size in preparation for truing and/or edge jointing. It is usually the first plane used on rough stock, but in exceptional cases can be preceded by the scrub plane. Jack planes are 300–460 mm long and 64–76 mm wide, with wooden-stocked planes sometimes being slightly wider. The blade is 44–57 mm wide that is often slightly convex (or ground with rounded corners) to prevent digging in to or marking the work. The cut is generally set deeper than on most other planes as the plane's purpose is to remove stock rather than to gain a good finish (smoothing planes are used for that). In preparing stock, the jack plane is used after the scrub plane and before the jointer plane and smoothing plane. The carpenters' name for the plane is related to the saying "jack of all trades" as jack planes can be made to perform some of the work of both smoothing and jointer planes, especially on smaller pieces of work. Its other name of the fore plane is more generally used by joiners and may come from the fact that it "is used before you come to work either with the Smooth Plane or with the Jointer". Early planes were all wood, except for the cutter, or combined a wood base with a metal blade holder and adjustment system on top. Although there were earlier all-metal planes, Leonard Bailey patented many all-metal planes and improvements in the late 19th century. A jack plane came to be referred to as a "No. 5" plane or a "Bailey pattern No. 5" at the end of the 19th century. A vintage tool made by an unknown company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could remove large amounts of timber. These jack or dressing planes came in various shapes and sizes to achieve a flat and even finish to timber surfaces before the use of smoothing planes and came in many sizes. A significant tool from the mid to late 19th century that is still in use today with early models sought after by collectors. It gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting edged hand tools. Tools that were themselves handmade shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items. Jack or Fore plane with blade and wedge. Marked "D Morris" (owner)flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, plane, fore plane, d morris, jack plane, wood working tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Chain Drill Attachment, Millers Falls Co, 1900-1931

An auxiliary tool for use with a breast drill or bit brace, when extra power is needed, or where pressure cannot be easily applied. The drill is automatically fed into the work by an adjustable friction feed which is automatically regulated by the resistance the drill encounters. These were made to fit on breast drills, and used for drilling metal, particularly round sections like a pipe. The chain is run around the object being drilled and gradually tightens as the hole is drilled, maintaining pressure while being a bit easier on the operator. Millers Falls Co. is a tool manufacturing company originally based in Millers Falls, Massachusetts, USA. It was established in Greenfield, Massachusetts in 1868 as Gunn & Amidon by Levi J. Gunn and Charles H. Amidon. Gunn and Amidon, along with a third partner, Henry L. Pratt built a factory in the north of Greenfield. After the Greenfield factory burned down, the company was reorganized as the Millers Falls Manufacturing Co. It merged with Backus Vise Co. in 1872 to form Millers Falls Co. In 1931 Millers Falls tools purchased the majority of the shares of Goodell-Pratt tools and merged with that manufacturer in 1932. In 1962 the company was acquired by Ingersoll Rand. In 1982, Ingersoll Rand sold the Millers Falls business to the newly created Millers Falls Tool Co. The company was head quartered in Alpha, New Jersey. Since 2002 the company trademark has belonged to Hangzhou Great Star Industrial, of Hangzhou, China. The item is associated with a tool manufacturing company established in the mid-19th century that pioneered the development of many types of tools used in many differing trades. The company grew to become a major supplier of tools around the world and today its tools that were produced during the mid-19th and early 20th centuries are now collectable items. Drill attachment with chain No 717 from 1925 catalogue 1/2 socket hole Millers Falls, Massachusettsflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, chain drill, mast drill, millers falls, drilling attachment, drilling tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePouch

Gunpowder Pouch, leather decorative with metal, spring operated release mechanism for releasing a measured amount of powder. Leather has finely worked landscape with 2 birds set in circular display on both sides of pouch. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, gun powder, musket, gunpowder -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Plant Stand, Late 19th Century (1898)

During the years 1869-1935 there were well over 250 registered bamboo furniture producers in Britain. The earliest recorded firm was Hubert Bill of 14 Little Camden St, London N.W., who claimed to have been established in (1869) while Daniel Jacobs & Sons of Hackney Road, London, were still in business in 1915, after 45 years of production. Design, quality, price and methods of construction were fairly consistent throughout the whole period, but it was the imaginative and often eccentric choice of subject matter that marked differentiation between the various firms. While most produced standard tables, stands and fire-screens, the more adventurous offered for sale items such as corner shelve units, charcoal barbecue grills and musical tea tables. Shelves were often covered with embossed leather paper designs, at first imported from Japan and then later produced in England. Some firms incorporated the knobbly roots of the bamboo stems into their designs, generally to form feet. Occasionally handles to drawers and cupboards were made with these roots although they were more commonly carved as imitations. Handles were mostly of cheap metal or brass. The ends of the bamboo canes were capped with stamped metal or turned bone, ivory or wooden discs. Methods of construction fell into three categories. First and most common is that of pegging. Bamboo stems being hollow, thick dowels can easily be glued into the joints. Some firms farmed out this work of `plugging' the ends of the canes to part-time workers at home. The second method, that of pinning, was far less satisfactory as bamboo tends to split lengthwise and therefore the jointed pieces eventually disintegrated. The most efficient method was that patented in 1888 (patent No 2383) by the firm of W. F. Needham in Birmingham. It consisted of metal shoes and covers for all joints which were made by wrapping a metal strip around the stems and soldering the overlapping ends. Some joints were further strengthened by a small pin or screw. Needham was by far the largest and most successful manufacturer and their individual and superior method of construction undoubtedly gained them their reputation. A. Englander & Searle of 34 Gt Eastern St and 31 Mare St, Hackney, London, were a firm particularly concerned with methods of construction. Although they seem to have entered the bamboo furniture market at a comparatively late date, about 1898, they produced inexpensive' bamboo, aimed particularly at the export trade. Stating in their catalogue that bamboo furniture “can be exported in one piece or it can be exported in pieces and put together again. The fixing up is much facilitated by a system of marking and numbering. Further, no glue is required for putting together as the screw system only is applied”. This method of construction best fits the Etagere and this item in the flagstaff collection and it is believed to have been made by A Englander & Searle, exported in a knock down form to Australia, purchased in kit form from a dealer here and put together by the purchaser. The bamboo plant stand is a significant item as it highlight furniture fashion of the late Victorian era. This item was highly sort after in its time and although mass produced, not many examples remain because the item is so fragile so this example is a valuable addition to the Flagstaff collection. It is believed,the construction method used is by a notable and respected maker in England of bamboo furniture that was aimed specifically at the export market and probably came to Australia in kit form to be assembled by the purchaser.Bamboo plant stand with octagonal top edged with tortoise shell bamboo the top is of wood and supported by four tortoise shell bamboo legs joined at the base by a square cane covered shelf. The tortoise shell appearance is brown lacquer. Item is part of the Giles Collection. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, furniture, plant stand, bamboo furniture, etagere, victorian furniture, simulated bamboo, tortise shell, a englander & searle, domestic furniture, giles collection, henry giles, cooramook, mailor’s flat, wangoom, 19th century household goods -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Barrel, 19th century

This small barrel looks well used. Unfortunately, the inscription on the barrel is indecipherable so its story is a mystery. However, the bungholes on the side are a clue that it was once used for storing liquid, likely to have been liquor. Barrels have been used over many centuries for transporting and storing a wide range of dry and liquid goods. They are made by tradesmen called coopers, who use heat and steam to bend and shape the wood to suit the work in hand. They add metal reinforcing, handles, spouts and suchlike, to complete they process. Their produce also includes buckets, casks and tubs. Ships transported bulk liquor in their cargo, stored in wooden barrels. The barrels' round shape allowed them to be easily moved by rolling them into place. The body's shape gave the barrels added strength and the iron bands helped the wooden sheaves stay in place. The tops and bottoms allowed for easy grip. The bungholes gave access to government representatives, who would sample the contents, measure the alcohol percentage, and charge the appropriate duty or tax; the process was called Ullaging and the instrument they used was a Hydrometer. Hundreds of barrels of cement were imported into Warrnambool in the late 19th century for the construction of the Warrnambool Breakwater. Barrel-shaped concrete blocks are still visible at shipwreck sites such as on the LOCH ARD wreck, which carried cement among its cargo.This small barrel is representative of 19th century containers used for transportation and storage of liquid such as liquor. It is a historic shape that is still used in modern times.Barrel; wooden barrel, cylindrical shape with metal bands or ribs for reinforcement. The side has two bungholes; one has a bung or stopper. Inscription on top (indecipherable). (indecipherable)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, barrel, cask, small barrel, trade, coopering, cooper, casket, transport, storage, bunghole -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fid, Late 19th to early 20th century

A Fid is a conical tapered wooden tool used for separating the strands of rope for splicing. They were a tool traditionally made of wood or bone used to work with rope and canvas in marlinespike seamanship. A Fid differs from a marlinspike in material and purposes. A marlinspike is used in working with wire rope, natural and synthetic lines also may be used to open shackles, and is made of metal. A Fid is used to hold open knots and holes in the canvas, and to separate the "lays" (or strands) of synthetic or natural rope for splicing. A variation of the Fid, the gripfid, is used for ply-split braiding. The gripfid has a jamming cleat to pull a cord back through the cord split by the fid's point. Modern Fids are typically made of aluminium, steel, or plastic. In addition to holding rope open to assist the creation of a rope splice, modern push fid's have markings for precise measurements in a variety of sizes of rope. The length of these fid’s is typically 21 or 22 times the diameter of rope to be spliced. Fids have been used since sailing vessels were first used to travel the worlds seas the tool was invented to be used to splice rope and with working with canvas sails. A Fid is a sailors tool that has maintained its general design for hundreds of years and gives a snapshot into what the working life was like for sailors on board sailing ships for hundreds of years. The tool in its original design is still in regular use today by recreational sailors all over the world to splice and join lengths of rope.Fid with Horn body and wood top.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fid, Mid 20th Century

A Fid is a conical tapered wooden tool used for separating the strands of rope for splicing. They were a tool traditionally made of wood or bone used to work with rope and canvas in marlinespike seamanship. A Fid differs from a marlinspike in material and purposes. A marlinspike is used in working with wire rope, natural and synthetic lines also may be used to open shackles, and is made of metal. A Fid is used to hold open knots and holes in the canvas, and to separate the "lays" (or strands) of synthetic or natural rope for splicing. A variation of the Fid, the gripfid, is used for ply-split braiding. The gripfid has a jamming cleat to pull a cord back through the cord split by the fid's point. Modern Fids are typically made of aluminium, steel, or plastic. In addition to holding rope open to assist the creation of a rope splice, modern push fid's have markings for precise measurements in a variety of sizes of rope. The length of these fid’s is typically 21 or 22 times the diameter of rope to be spliced. Fids have been used since sailing vessels were first used to travel the worlds seas the tool was invented to be used to splice rope and with working with canvas sails. A Fid is a sailors tool that has maintained its general design for hundreds of years and gives a snapshot into what the working life was like for sailors on board sailing ships for hundreds of years. The tool in its original design is still in regular use today by recreational sailors all over the world to splice and join lengths of rope.Metal Fid with a wooden bulb on top metal body tapering to a point. Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fid, Early 20th century

A Fid is a conical tapered wooden tool used for separating the strands of rope for splicing. They were a tool traditionally made of wood or bone used to work with rope and canvas in marlinespike seamanship. A Fid differs from a marlinspike in material and purposes. A marlinspike is used in working with wire rope, natural and synthetic lines also may be used to open shackles, and is made of metal. A Fid is used to hold open knots and holes in the canvas, and to separate the "lays" (or strands) of synthetic or natural rope for splicing. A variation of the Fid, the gripfid, is used for ply-split braiding. The gripfid has a jamming cleat to pull a cord back through the cord split by the fid's point. Modern Fids are typically made of aluminium, steel, or plastic. In addition to holding rope open to assist the creation of a rope splice, modern push fid's have markings for precise measurements in a variety of sizes of rope. The length of these fid's is typically 21 or 22 times the diameter of rope to be spliced. Fids have been used since sailing vessels were first used to travel the worlds seas the tool was invented to be used to splice rope and with working with canvas sails. A Fid is a sailors tool that has maintained its general design for hundreds of years and gives a snapshot into what the working life was like for sailors on board sailing ships for hundreds of years. The tool in its original design is still in regular use today by recreational sailors all over the world to splice and join lengths of rope.Fid, Metal and Wood top with brass ferrule between the two.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fid, Late 19th- early 20th Century

A Fid is a conical tapered wooden tool used for separating the strands of rope for splicing. They were a tool traditionally made of wood or bone used to work with rope and canvas in marlinespike seamanship. A Fid differs from a marlinspike in material and purposes. A marlinspike is used in working with wire rope, natural and synthetic lines also may be used to open shackles, and is made of metal. A Fid is used to hold open knots and holes in the canvas, and to separate the "lays" (or strands) of synthetic or natural rope for splicing. A variation of the Fid, the gripfid, is used for ply-split braiding. The gripfid has a jamming cleat to pull a cord back through the cord split by the fid's point. Modern fid's are typically made of aluminium, steel, or plastic. In addition to holding rope open to assist the creation of a rope splice, modern push fid's have markings for precise measurements in a variety of sizes of rope. The length of these fid's is typically 21 or 22 times the diameter of rope to be spliced. Fids have been used since sailing vessels were first used to travel the worlds seas the tool was invented to be used to splice rope and with working with canvas sails. A Fid is a sailors tool that has maintained its general design for hundreds of years and gives a snapshot into what the working life was like for sailors on board sailing ships for hundreds of years. The tool in its original design is still in regular use today by recreational sailors all over the world to splice and join lengths of rope.Wooden Fid with 3 rings around base of knob at the top of fid. Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Marlin Spike, Unknown possibly washed up from a wreck late 19th century

A marlinspike is a tool used in marine rope work it is shaped in the form of a polished metal cone tapered to a rounded or flattened point, it is used in such tasks as unlaying rope for splicing or untying knots. For drawing a marline tight and using a marlinspike hitch as well as for joining toggle ropes under tension in a belaying pin splice. Most marlin spikes are 15–30 cm long, but may reach 61 cm and more for working heavy cables and ropes. They are usually made from iron or steel, whereas fids, similar in shape and function, are formed from wood or bone. The marlinspike may be a separate tool or as an item on a pocket knife. Sailors who become proficient at knot tying, splicing, and sewing using the marlinspike are said to have mastered marlinespike seamanship, earning them the right to be known as marlin spikes or marlinspike seamen.A tool still very much in use today wherever a rope or cable requires joining, splicing etc the marlin spike tool design has not changed since first invented centuries ago as a sailors tool to splice and make repairs to ropes and cables on board a ship. This item gives a snapshot into the life sailors have on board sailing vessels past and present. Marlin Spike made of solid steel. Handle is bulbous and spike end is rounded.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, marlin spike -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Stretching Hook

Hand forged metal tool, possibly a sailmaker's hook with the hook broken. It may be a fire iron. The twisted metal is a skill learned by a blacksmith.The item is a handmade tool, an example of the work of a blacksmith. Smiths were sought after in colonial Australia. Their trade allowed them to custom make work for the different industries necessary for survival in a new land.Sailmaker's stretching tool; long thin metal rod bent in half, with centre forming a handle or loop, and long ends twisted together to form a stem. The loose ends are formed together but appear broken.warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, tool, sailmaker's tool, fire iron, blacksmith, twisted rod, twisted wire, sailmaker's hook -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Guillotine, c. 1880's

This guillotine is a hand operated machine specifically designed to cut through multiple sheets of paper or card. It has a very heavy and sharp single blade knife mounted between vertical guides or runners. The main users of a machine like this is in by the printing and publication binding industry. Book binding companies use a guillotine to evenly trim the pages of a book after it has been bound. The way the guillotine is used is - paper or card is stacked squarely on the flat table and pushed firmly against the back guide - the handle below the table at the front of the machine is wound around, which brings the back guide forward, pushing the paper stack forward and positioning the centre of the stack below the vertical frame - the upper wheel is wound around, which brings the clamp and firmly in position on top of the paper, to hold it very firmly - the large wheel on the side of the machine is turned around to lower the long sharp blade down onto the pages and cut them through. The sharp edge of the blade is protected somewhat from becoming blunt; a block of wood sits in the table under the stack of paper An early model of a guillotine was patented in 1837 by Thirault, who built a model with a fixed blade. Guillotines similar in principal to this one were patented by Guillaume Massiquot in 1844 and 1852. Over the years many improvements have been made and operation has moved from man power to electricity. Oscar Friedheim Ltd. was the importer and wholesaler of a large range of machinery and equipment for the printing and bookbinding industry. He sold most of his equipment under his own name. On this guillotine or paper cutter he refers to the origin of the guillotine’s manufacture only as “German Manufacrure”. A reference book “Commercial Bookbinding: a description of the processes and the various machines used" by Geo. Stephen, 1910, recommends Oscar Friedheim, amongst others, for the supply of “reliable cutting machines for hand or power”. It also recommends Oscar Friedheim’s for a wide range of other printing machinery and processes. OSCAR FRIEDHEIM LIMITED, LONDON Oscar Friedheim Ltd. was established in 1884 and operated from Ludgate in London. The company was an importer and wholesale supplier in the 1880’s, offering machinery and equipment for the printing and packaging industry for the UK and Ireland. The company became incorporated in 1913. An advertisement of 1913 includes a telegraphic code plus two telephone numbers for Oscar Friedheim Ltd and invites readers to call at the Ludgate, London, showrooms to see the machines working. The company later became Friedheim International Ltd. The book titled “Friedheim, A Century of Service 1884-1984 by Roy Brewer, celebrates Oscar Friedheim’s achievements. Friedheim International currently operates from Hemel Hempstead, on the northern outskirts of London UK. It promotes itself as “… the leading supplier of finishing, converting and packaging machinery to the printing, graphic arts, and highly varied packaging industries in the UK and Ireland. The company’s policy is simple – “employ the best people, work with the best equipment manufacturers in the world, and treat our customers as partners!” The company still sells guillotines. The guillotine is significant for its ability to represent aspects of the printing trade in Warrnambool and in a typical port town circa 1850 to 1910. It represents communication methods and processes used in the time before electrically powered equipment became common in industry.Guillotine (or paper cutter), hand operated. Metal framework with vertical guides, stand and metal mechanical parts including wheels and gears. Table with back guide; handle below front of table winds to move the back guide. A wheel at top of machine winds to adjust pressure of the clamp on the work on the table below it. The cutting blade fits between vertical guides; a timber insert in the table below the blade helps minimise the loss of sharpness of the blade. A handle on the side of the machine turns a large spoked wheel, which rotates a large gear, causing the blade to move up and down. Makers details are on a small oval plaque with embossed maker’s details is screwed onto main body. Maker is O Friedheim, London, and the machine is of German manufacture, circa late 1880’s.Maker’s plaque inscribed "O. FRIEDHEIM / London / German Manufacture"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, printing machinery, printer’s guillotine, paper guillotine, paper cutter machine, oscar friedheim ltd london, friedheim international ltd, bookbinding industry, printing industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Printing Press, Harrild and Sons, 1866

This Albion printing press was manufactured by Harrild & Sons of London and exported in 1868 from London to the colonial Western Victoria town of Coleraine, population of 700 at that time. It was installed in the Colerain Albion printing office. It was used to print the first edition of the Coleraine Albion newspaper in 1868 and continued until publication ceased in 1974. The Albion Press is still being used today by a volunteer printer in the “Examiners Office” in the village at Flagstaff Hill. Amongst the items produced are printed paper bags for the Tea Rooms and posters for visitors. ALBION PRINTING PRESS The Albion press was invented and manufactured in London by Richard Whittaker Cope around 1820 and was still being produced in the 1930s. The Albion was manufactured under licence by several companies from the 1850s onwards, one of which was Harrild & Sons of Fleet Works, London. Harrild & Sons describes its business as “printing materials manufacturer”. The business was established in 1807 by Robert Harrild and named R. Harrild & Co. In 1813 he showed that rollers could be used to ink a printing plate instead of inking balls, the method in use at the time. He then established a company to make the rollers. Eventually his company would make other printing materials and equipment. Robert’s sons joined him in the 1830s, when the company was renamed Harrild & Sons, and they continued to run the company after his death in 1853 and up until the mid-1900s. COLERAINE ALBION PRINTING OFFICE The Coleraine Albion Printing Office was established by W.L. Ambler. The first issue of the Coleraine Albion was dated 4th January 1868. Arrangements had been made to receive news from Melbourne, nearby provinces, other colonies and England. The second issue on 18 January 1868 printed articles from many agencies, including the Melbourne Age and the Warrnambool Examiner. The Albion office was sold to William Hatherleigh, formerly of Portland, in October 1868. Thereafter the Albion office had many owners. The last was L. A. & E. Oliver, who took over in January 1972 and was the last to be stated as printers and publishers of the Coleraine Albion. The office was wound up in 1974. The Albion Press and other equipment was distributed to Star printing in Terang. Star Printing donated the Albion press to Flagstaff Hill Maritime Village around 1980 and Stan Philp, owner of Philprint in Warrnambool, transported it to Warrnambool, brought it up to good working order and organised the supply of appropriate printer’s type. The Albion hand operated printing press is significant for producing the first newspaper in Coleraine, Western Victoria and continuing production for over 100 years. The Albion is technologically significant as a working example of a hand operated printer from the mid-19th century. The use of the printer is demonstrated by volunteers at Flagstaff Hill, printing items such as lolly and treat bays for use in the Village. The Albion is socially significant for its role in the isolated provincial colony, providing communication with the outside world, both in Australia and overseas. Newspaper printers were often amongst the first businesses of a small town. Printing press; hand operated Albion Press, Patent 2105. The machine has an upright iron frame at the back that supports the upper press that has a wooden handled metal bar is attached. The frame and legs support a thick metal flatbed. A metal leg supports the front of the press bed. The iron work is painted black with gold highlights. The decorative legs are finished with the golden feet of an animal. The frame above the metal bed includes a crown shaped finial symbol above the maker’s emblem. The maker’s details and the name of the printer are embossed on the upright frame. A plaque with the patent number is below a Lion and Unicorn emblem.Embossed maker’s emblem [A red cross - above a double ring – square inside ring – three banners below ring]. - Inside the double rings “PRINTING MATERIALS MANUFACTURE” - Inside the square, intertwined text “H & S” [representing Harrild & Sons] - Inside the three banners ““FLEET” “WORKS.” “LONDON.E.C.” Embossed across the shoulders “ALBION PRESS / HARRILD & SONS, / MAKERS LONDON.” Emblem above plaque [Lion and Unicorn] Embossed on the plaque “PATENT / 2105” Stamped into upright machine part above the printing bed “2105 / 1866” flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, albion press, printing press, 1866 printing press, printing equipment, communications, coleraine albion printing office, coleraine newspaper, albion newspaper, south west victoria newspapers, harrild and sons london, richard whittaker cope, star printing terang, philprint, coleraine albion, hand operated press -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Shelves, A. Englander & Searle, Late 19th Century (1898)

This music stand set of shelves is one of many 19th century items of furniture, linen and crockery donated to Flagstaff Hill Maritime Village by, Vera and Aurelin Giles. The items are associated with the Giles Family and are known as the “Giles Collection”. Many of the items of furniture, linen and crockery in the Lighthouse Keeper’s Cottage were donated by Vera and Aurelin Giles and mostly came from the simple home of Vera’s parents-in-law, Henry Giles and his wife Mary Jane (nee Freckleton) whose photos are in the parlour. They married in 1880. Henry, born at Tower Hill in 1858, was a labourer on the construction of the Breakwater before leaving in 1895 to build bridges in N.S.W. for about seven years. Mary Jane was born in 1860 at Cooramook. She attended Mailor’s Flat State School where she was also a student teacher before, as family legend has it, she became a governess at “Injemiara” where her grandfather, Francis Freckleton, once owned land. Henry and Mary’s family of six, some of whom were born at Mailor’s Flat and later children at Wangoom, lived with their parents at Wangoom and Purnim west, where Henry died in 1933 and Mary Jane in 1940. THE SHELVES During the years 1869-1935 there were well over 250 registered bamboo furniture producers in Britain. The earliest recorded firm was Hubert Bill of 14 Little Camden St, London N.W., who claimed to have been established in (1869 the first bamboo furniture maker), while Daniel Jacobs & Sons of Hackney Road, London, were still in business in 1915, after 45 years of production. Design, quality, price and methods of construction were fairly consistent throughout the whole period, but it was the imaginative and often eccentric choice of subject matter that marked the differentiation between the various firms. While most produced standard tables, stands and fire-screens, the more adventurous offered for sale items such as Corner shelve units, charcoal barbecue grills and musical tea tables. Shelves were often covered with embossed leather paper designs, at first imported from Japan and then later produced in England. Some firms incorporated the knobbly roots of the bamboo stems into their designs, generally to form feet. Occasionally handles to drawers and cupboards were made with these roots although they were more commonly carved as imitations. Handles were mostly of cheap metal or brass. The ends of the bamboo canes were capped with stamped metal or turned bone, ivory or wooden discs. Methods of construction fell into three categories. First and most common is that of pegging. Bamboo stems being hollow, thick dowels can easily be glued into the joints. Some firms farmed out this work of `plugging' the ends of the canes to part-time workers at home. The second method, that of pinning, was far less satisfactory as bamboo tends to split lengthwise and therefore the jointed pieces eventually disintegrated. The most efficient method was that patented in 1888 (patent No 2383) by the firm of W. F. Needham in Birmingham. It consisted of metal shoes and covers for all joints which were made by wrapping a metal strip around the stems and soldering the overlapping ends. Some joints were further strengthened by a small pin or screw. Needham was by far the largest and most successful manufacturer and their individual and superior method of construction undoubtedly gained them their reputation. A. Englander & Searle of 34 Gt Eastern St and 31 Mare St, Hackney, London, were a firm particularly concerned with methods of construction. Although they seem to have entered the bamboo furniture market at a comparatively late date, about 1898, they produced inexpensive bamboo, aimed particularly at the export trade. The company stated in their catalogue that bamboo furniture “can be exported in one piece or it can be exported in pieces and put together again. The fixing up is much facilitated by a system of marking and numbering. Further, no glue is required for putting together as the screw system only is applied”. This method of construction best fits the Etagere in the Flagstaff collection and it is believed to have been made by A Englander & Searle, exported in a knock down form to Australia, purchased in kit form from a dealer hear and put together by the owner. The Etagere is a significant item as it highlight furniture fashion of the late Victorian era. This item was highly sort after in its time and although mass produced, not many examples remain, so this example is a valuable addition to the Flagstaff collection. It is believed that the construction method used is by a notable and respected maker of bamboo furniture and that its production was aimed at the export market and probably came to Australia in kit form.Bamboo shelves: decorative free standing Etagere comprising three large shelves and one small shelf. Shelves are made of wood used to store either orange or bacon boxes (as there are no knots in the wood, imported from South America and cheap to recycle). Shelves are covered with embossed leather paper. Frame is made from tortoise shell bamboo (brown lacquer applied to simulate tortoise shell appearance). Ends of bamboo canes are covered with metal shoes and fixed with a pin. Other bamboo joints are fixed with round head steel screws. This item is part of the Giles Collection.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bamboo shelves, bamboo etagere, victorian furniture, furniture, bamboo furniture, embossed leather paper, simulated bamboo, tortise shell, a englander & searle, giles collection, henry giles, tower hill, cooramook, warrnambool breakwater, mailor’s flat, wangoom, 19th century furniture -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

... with both hands! Before your work can be bisque fired it should... to finish the work completely – use a metal kidney to polish ...The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Fork

... decorative work in the metal near the bone handle.... and there is more decorative work in the metal near the bone handle ...A toasting fork is a three pronged fork designed to be used to toast things over an open fireplace. Classically, a toasting fork could be stuck into a piece of bread and used to hold the bread in the fire, with a periodic rotation for even browning. For advanced players, it's possible to use a toasting fork to make toasted cheese sandwiches and other hot sandwiches. A typical toasting fork is made of wire, and many modern ones are telescopic, allowing people to fold the fork up or slide the handle in when not in use. This makes toasting forks easier to store and transport, while allowing people to keep their hands well clear of the fire when the fork is in use. The three slender prongs can be of varying length, depending on the design; prongs which are too long will mangle the bread, while short prongs will allow the bread to slide off, so most designers try to strike a happy medium. Before the arrival of gas and electric cook stoves, households relied on heavy duty wood and coal fired cookers, or simply open fireplaces. Such stoves required a great deal of energy and maintenance to run, so when someone wanted a quick snack, toasting something over an open fire could be much more appealing than wrestling with the cooker. Some people also undoubtedly found the experience of toasting something over an open fire to be enjoyable. https://www.delightedcooking.com/what-is-a-toasting-fork.htmIn the old days, there were no electric toasters, so the toasting fork used near an open flame proved extremely effective.Fork with three prongs with hook design on the two outside prongs. Neck features decorative twisted design and there is more decorative work in the metal near the bone handle.None. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village