Showing 630 items matching "tin container"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Jug, Late 19th or early 20th Century

... -Village Tin plating Food containers None. Rusty tin jug with small ...The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin.The use of tin to protect and store food and other items, revolutionised the world.Rusty tin jug with small pouring lip and handle. Very plain and possibly made from a jam tin and handle soldered on side.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Storage Tin, Late 19th or early 20th Century

... Container metal cylindrical plain tin with separate lid...-Village Tin plating Food containers None. Container metal ...The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin.The use of tin to protect and store food and other items, revolutionised the world.Container metal cylindrical plain tin with separate lid. Join line on side of cylinder. Very rusty.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Saucepan

It is no secret that copper is currently experiencing a huge upsurge in popularity. This is mainly thanks to its beautiful colour featuring heavily in the ranges of countless homeware retailers. There is, however, far more to this lustrous metal than just its appearance. For example, it has a greater level of thermal conductivity than any other metal (except silver); roughly 60% higher than aluminium and 3000% higher than stainless steel. This means copper is capable of heating up very quickly when compared to other metals. Perhaps a less commonly known property of copper is it being inherently antimicrobial. A wide range of harmful microbes are unable to survive for more than a couple of hours when in contact with a surface made of copper or one of its alloys (brass and bronze). This has led to it often being used for frequently touched surfaces such as door knobs, push plates and taps. A seemingly perfect material for cooking, it is therefore no surprise that it has been used in kitchens for millennia. But exactly when did we learn to utilise copper and its valuable assets? Origins It is hard to pin down an exact date when copper cookware was first introduced. Pieces discovered in regions of the middle east were dated as far back as 9000BC, suggesting cooking with copper began during the Neolithic period (≈10000-2000BC). As civilisations became increasingly capable in metallurgical techniques, metals such as copper became more widely used. It would have been around this time that copper replaced stone as the material used for making tools and cooking vessels. The use of copper is also well documented in Ancient Egypt. Not only was it used to produce water and oil containers, but it was also used to in medical practices. The antimicrobial nature of copper was exploited long before the concept of microorganisms was fully understood. The Smith Papyrus, a medical text written between 2600 and 2200BC records the use of copper in sterilising wounds and drinking water. Tin Lining Although copper is essential to many processes within the human body, it can become toxic if consumed in excess. It was this knowledge that gave rise to lining cookware with tin, a technique used for hundreds of years to prevent copper leaching in to food. These tin linings would eventually wear out and during the 18th and 19th century, it was common for people to send pans away to be re-tinned. This practice is becoming increasingly rare, as are the craftsmen who perform it. Despite this, there are still manufactures producing tin-lined copper cookware who also offer a re-lining service. Perhaps the best known of these is Mauviel, a French manufacturer who have been making this type of cookware since 1830. Tin has now largely been replaced by stainless steel as an interior cooking surface. Not only is it more cost effective, but the high grade of stainless steel used in premium cookware (typically 18/10) is highly resistant to corrosion and more durable than tin.Copper saucepans are still used in many kitchens.Small copper saucepan with long handle and three ridges around the circumference. Extensive corrosion.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, copper, saucepans, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDecorative object - Container, 1910 to 1945

... Vase Decorative Object Tin Vase Container of pressed metal ...A mass produced utilitarian item made for domestic decorative use. No history or manufacturing provenance currently available.The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown. The item is assessed as a collection asset as it is believed to have been produced after 1910 and before 1950.Container of pressed metal. The container has a broad, thin lip, and its round body flares outwards towards base, then tapers inwards to a short heel. A loop holding a metal ring is attached to the side, near the top. A decorative geometrical transfer pattern in blue and cream covers the body and inside of the lip. In the centre of one side is a round frame with the portrait of an Egyptian woman within.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, flower vase, decorative object, tin vase -

Flagstaff Hill Maritime Museum and Village

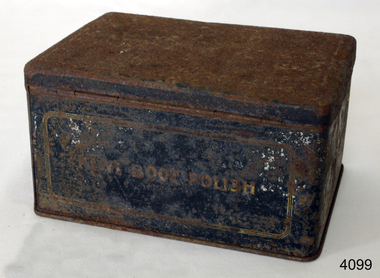

Flagstaff Hill Maritime Museum and VillageContainer - Tin, Kiwi Shoe Polish Manufacture, 1940s

... brush, scraper, & polish missing Container Tin Kiwi Shoe Polish ...The polish was developed in Australia by William Ramsay who named it Kiwi after the flightless bird endemic to New Zealand, the home country of his wife, Annie Elizabeth Meek Ramsay. Its success in Australia expanded overseas when it was adopted by both the British and American armies in World War I. In the UK, Kiwi was for many years manufactured at its British headquarters in Ealing (Brumwell Road, London W5 1DT). From here the factory manufactured for the UK market and exported the Kiwi brand too much of Europe and the Middle East. In the mid-1970s, as part of a major streamlining, the UK factory was closed with production switched to France. The UK operation moved to Surrey at Yately becoming, effectively, a sales and marketing office, with distribution contracted to a third party. In 1980, production for the UK market moved back to the UK and was housed in a factory near Huddersfield. The UK head office was relocated to Maidstone, Kent, where Kiwi had other product interests. Following the global merger with Nicholas Laboratories, the UK head office was again relocated to Slough at the Nicholas building on Bath Road.A significant product as Kiwi is an Australian brand name of shoe polish, first launched and sold in Australia in 1906 and as of 2005 sold in almost 180 countries. Previously owned by the Sara Lee Corporation since 1984, it was sold in 2011 to S. C. Johnson. It is the dominant shoe polish in some countries, including the United Kingdom and the United States, where it has about two thirds of the market. In Malaysia and Singapore, Kiwi has become such a household brand for a shoe polish that the word "kiwi" has been genericized into a verb in the Malay language, meaning "to polish one's shoes".Metal cleaning outfit of Kiwi boot polish brush, scraper, & polish missingKiwi Boot Polish to front of containerflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

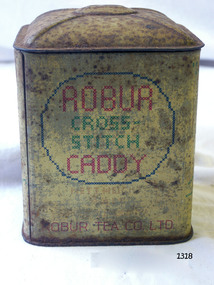

Flagstaff Hill Maritime Museum and VillageContainer

... pure tea act. Tin has sago inside. Container ...Container metal with lid labelled "Robur Cross Stitch Caddy" from the Robur Tea Co Ltd, printed in crosses and circles, painted yellow. Lid corroded and "R" imprinted in centre. Cross-stich scene of shepard and sheep. On bottom of tin embossed regarding the 1908 pure tea act. Tin has sago inside.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer

Container for jewellery, glass cylindrical and metal tin framework, hinged lid with clip with three ornate leaf legs (one broken). Faded aqua coloured cloth inside. Object in three fragments 1) upper section, lid and broken glass 2) broken glass section (semi-circle) 3) standflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, container, jewellery, jewellery box -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCoffee Tin

Container cylindrical for coffee. Made of coloured printed tin Bushels Pure Coffee. Mainly blue and orange in colour. Lid separates from the main body.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, container, bushels pure coffee, coffee container -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Containers, tin 'John Bull' Tyre Repair, mid 20thC

... for 'John Bull' Tyre repair outfit Containers, tin 'John Bull' Tyre ...John Cecil Burton and his brother Cecil Hubert formed The Leicester Rubber Company in 1906, to sell imported cycle tyres. The Company's patriotic 'John Bull' trade mark came into force a few years later in 1908. In 1915 the Rubber Company started to manufacture its own bicycle and pram tyres at its Evington Valley Road site in Leicester, and in 1928 they started to mass produce car and motorcycle tyres at the site. The name was changed to the John Bull Rubber Company in 1934, and in 1937 an associated company was formed to manufacture rubber to metal components - Metalastic. In 1955 the John Bull group companies merged, and in 1958 the company became part of the Dunlop Rubber Company.An empty blue tin with a hinged lid for 'John Bull' Tyre repair outfitLid top ; JOHN BULL Reg. T / REPAIR OUTFIT/John Bull Rubber Co. Ltd. Evington, Valley Mills, Leicester Trade Mark ;Central Photo of 'John Bull' encased in a circle around is written ' Made for the Man who will have the Best' / TRADE / MARK Lid Inside ; INSTRUCTIONS FOR REPAIRING PUNCTURES/ ................ Base ; RIDE / JOHN BULL TYRES / and you will have practically no use for this OUTFIT* tyres, rubber, bicycles, cars, prams, leicester, england, john bull rubber company, burton john c , hubert cecil, leicester rubber company, dunlop rubber pty ltd, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Containers, metal 'INGRAM' tooth powder, c1950

Ingram Tooth powder was popular with settlers who bought land and houses in the post World War 2 estates in the City of Moorabbin c1950 Ingrams Tooth Powder was used throughout Australia and was popular with the families settling in the post World War 11 Estates in the City of Moorabbin c1950A green and white tin that contained 'INGRAM' tooth cleaning powder. lid is missingFront ; INGRAM (T) / ammonium ion / TOOTH / POWDER ............./BRISTOL- MYERS PTY LTD SYDNEY Back ; Instructions for cleaning teeth -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Sewing equipment, sewing container, threads, needles, 20th C

This type of sewing equipment was widely used in many homes, in an era when hand-made clothes were the “norm.”, and clothes and hosiery were mended, darned or ‘re-made’ into another garment.. These cotton and silk threads are examples of those used for dressmaking, crochet and needlework by the women of the early settler families who made, mended or darned the clothes and hosiery in Moorabbin Shire c1900A tin with lid, containing various packets of sewing threads and needlesPackets ; CLARKE’S Fine Filosheen Grist / 20 yards 3076 Squirrel / No 40 : PRESTIGE ; NEWEY’S Spring ; PARAMOUNT Linen Finish THREAD ; Embassy rustless needles ; sewing, prestige cotton, needles, threads, moorabbin, bentleigh, ormond, craftwork, dressmaking, early settlers, market gardeners -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Container - Griffiths Tea Canister, 1900-1940

In 1873 James Griffiths migrated to Melbourne in order to start a tea Business. James lived in the Dandenongs at The Basin where he experimented with growing tea. Griffiths made tin canisters in the 2lbs size for their tea with common kitchen consumables listed on the front . The tins, when emptied, became useful kitchen canisters and helped promote the brand. Example of the names include Flour, Rice, Sugar, Sago, Candied Peel, Tapioca, Spices, Starch, Biscuits, Currants, Barley, String and of course Tea .Food storage rectangular tin, with a hinged lid. The outside is printed in cream and red with the name 'Griffith's Teas' and the word 'SAGO'. The text is set against a cream panel which is bordered with a decorative border of Australian native flora. The whole is set against a dark green background.On each other side of the tin is a different native Australian flower. The lid is impressed with a flannel flower.Printed on the front 'SAGO', also printed on the front and repeated on the top 'USE / GRIFFITHS' Teas / SYDNEY / MELBOURNE. ADELAIDE. BRISBANE'. On the front is the image of a train signal with the words 'SIGNAL / TRADE MARK'tea, james griffiths, canisters, city of moorabbin, cheltenham, melbourne, moorabbin, grocery stores, kitchen equipment -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Equipment - BRASSO, Reckitt and Colman Ltd, Metal Polish, 20thC

Reckitt & Sons' opened a branch in Sydney in1886. Brasso was developed by Reckitt & Sons in 1905. In 1938 Reckitt and Sons merged with J. and J. Colman to become Reckitt and Colman Ltd.Brasso was used by most Housewives for cleaning and polishing Kitchen Equipment in the City of Moorabbin during 20thC Metal container with blue sun burst effect, with a red circle with 'BRASSO' printed, in white and blue, inside. The instructions are printed on the back. FRONT: 'BRASSO' Back: Picture of the Royal Coat of Arms - By appointment to Her Majesty Queen ElizabethII. Suppliers of Metal Polish Reckitt & Colman Ltd. BRASSO Metal Polish for polishing Brass, Copper, Zinc, Steel, Pewter etc. SHAKE WELL Apply with a soft cloth. Polish off with a dry, soft cloth preferably before the polish has completely dried. DO NOT PLACE THIS TIN CLOSE TO THE FIRE Made in Australia by Reckitt & Colman (Australia) Ltd. No. 6 - Contents 6½ Fl oz when packed. brasso, metal polish -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - TOBACCO TIN: VIRGINIA BIRD'S EYE

... in the background. Label is discoloured. No lid. Container TOBACCO TIN ...Tobacco tin 8.5 H x 8.3 dia, no lid. With a yellow label and red printing. Virginia Bird's Eye manufactured by Thomas Bear & Sons Ltd. London. Label has an elephant standing beside some palm trees with hills in the background. Label is discoloured. No lid.personal effects, smoking accessories, toabcco tin, tobacco tin - virginia bird's eye, thomas bear & sons ltd -

Bendigo Historical Society Inc.

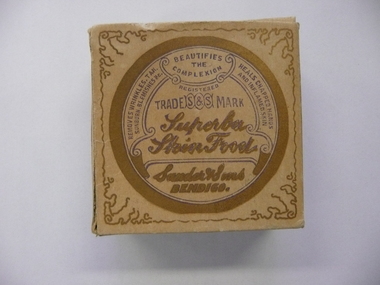

Bendigo Historical Society Inc.Container - SUPERBA SKIN FOOD

Small round tin in original box, containing Superb Skin Food, sole manufacturers Sander & Sons Bendigo, Vic, Australia. With directions sheet.Sander & Sons Bendigopersonal effects, cosmetics, cream -

Bendigo Historical Society Inc.

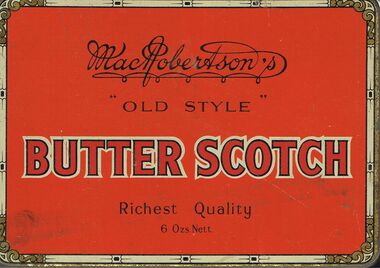

Bendigo Historical Society Inc.Container - LYDIA CHANCELLOR COLLECTION: MACROBERTSON'S OLD STYLE BUTTER SCOTCH 6 OZS NETT TIN BOX, 19/11/1942

MacRobertson's Old Style Butter Scotch 6 ozs Nett tin box / containing 2 x envelopes addressed to Mrs L. Chancellor , A.C.F. Branch , Taraxville , Golden Square , postmarked 19.11.1942. , 2 1/2 penny red Australia stamp, WW2 Penny - a Plane Certificates showing promotion to various ranks - in the Penny - a Plane Campaign - 16 x certificates - Flying officer / 5 x certificates Flight Lieutenant - signed A.R. Cutler V.C. / 4 x certificates - Squadron Leader / 27 x Seargean Pilot - some bearing the name of LYDIA CHANCELLOR. / Piece of paper 'Francis Greenway - his Life & times '/ Newspaper clipping from the Argus Newspaper 17.10. 1942. ' Penny -a Plane Fund Grows, describes campaign which is related to the amount of 'Jap' planes shot down - e.g. 'No 1 cards which contain 100 stamps - one for every Jap plane shot down - have been completed'ephemera, mementoes, lydia chancellor collection, collection, macrobertson's old style butter scotch tin 6 ozs nett / mrs l. chancellor 2 1/2 penny red australia stamp /penny - a plane certificates /campaign / a.r. cutler v.c. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - SWALLOW & ARIEL BISCUIT TIN, 1902

... DOMESTIC EQUIPMENT Containers tin Swallow & Ariel Ltd Biscuit ...Small rectangular biscuit tin commemorating Coronation of HM King Edward VII with portraits of him & HM Queen Alexandra plus scenes of coronation.Swallow & Ariel Ltd Biscuit Manufacturers Port Melbournedomestic equipment, containers, tin -

Bendigo Historical Society Inc.

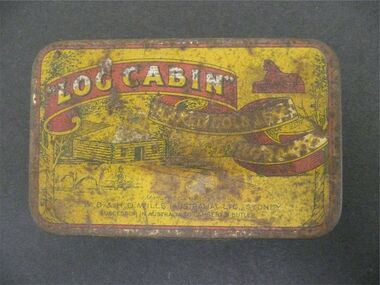

Bendigo Historical Society Inc.Container - TOBACCO TINS

... PERSONAL EFFECTS Smoking accessories toabcco tins (3) 3 tobacco ...3 tobacco tins, hinged lids. A. Yellow tin, 'Log Cabin' on front, yellow print on red scroll, K55 written in white on back ; b. Red tin ' Town Talk' written in white K 52 on back, ; white tin, 'Golden Pride' printed in gold on aqua scroll, K 56 on back, valued at $650 by Alexanders ( Alexanders, Melbourne: Golden Pride Tobacco Tin 2oz. PRINTS. Prints. Photo Gifts … Image 13 of 15. Back to Site. $650 Aug 2010 sourced 16/2/2016)personal effects, smoking accessories, toabcco tins (3) -

Bendigo Historical Society Inc.

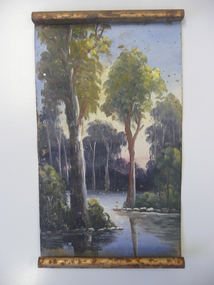

Bendigo Historical Society Inc.Container - OIL PAINTING ON TIN

... a river scene with Eucalyptus trees. Container OIL PAINTING ON TIN ...Oil painting on tin scroll showing a river scene with Eucalyptus trees.artwork, oil painting, on tin -

Bendigo Historical Society Inc.

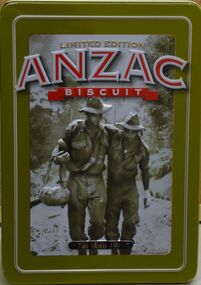

Bendigo Historical Society Inc.Container - ANZAC COLLECTION: BISCUIT TIN

... on back. Container ANZAC COLLECTION: BISCUIT TIN ...Anzac biscuit tin: on front ' limited edition Anzac biscuit' on bottom below image ' 'Tarakan 1945' Tin has khaki base colour, image is black and white, red and white text on tin. RSL story and Anzac biscuit story printed on back.military, world war 2, biscuit tin -

Bendigo Historical Society Inc.

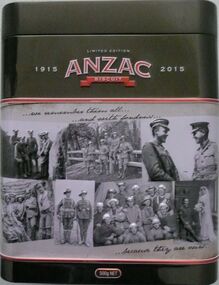

Bendigo Historical Society Inc.Container - ANZAC COLLECTION: BISCUIT TIN

... MILITARY World war 1 biscuit tin Modern Baking Pty Ltd, 140 ...Limited edition Anzac Biscuit in 1915 - 2015. Tin, with images of World War 1 personnel imprinted on side. The Anzac biscuit story is told on the back of the tin, and the source of the images shown on the front described - Australian War Memorial colleciton. Short story about RSL also given. Tin is black with sepia trim, red and white writing, all images in black and white.Modern Baking Pty Ltd, 140 Northcorp Boulevard, Broadmeadows, Vic.military, world war 1, biscuit tin -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - BUSH COLLECTION: EUMENTHOL JUJUBES TIN

Eumenthol Jujubes Tin Front has is gold- coloured with a blue label -Eumenthol Jujubes for the throat and lungs -medicated pastille-originated by G Inglis Hudson - Hudsons Eumenthol Chemical Co Pty ltd Sydney Australia . Inside the tin is a label -Hudsons Eumenthol Jujubes.person, individual, bush collection - personal -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - GRAHAM HOOKEY COLLECTION: BRASS 'COMFORTS' TIN

Brass gift box, presented to serving military personnel in World War 1. Attributed as being the brainchild of Princess Mary, daughter of King George V and Queen Mary. On top of tin the head of the Princess is surrounded by a laurel wreath. Embossed on top 'Imperium Britannicum', on bottom 'Christmas 1914' This tin was found in a secretaire given to Graham Hookey, inside the tin is gold woven epaulette, nibs for a dip pen and a small lock 'Miller' embossed on front. Also enclosed are two medals - one metal 'volunteered for active service' printed around outside of medal, other two appear to be off a uniform, another 'corps of engineers' gold badge. Rising sun medal with 'Australian Commonwealth Military Force' embossed.australia, military, brass comfort tin -

Bendigo Historical Society Inc.

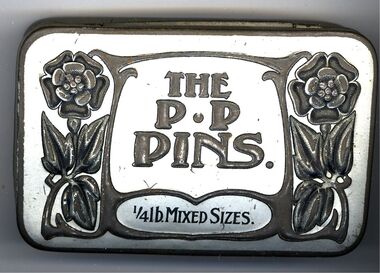

Bendigo Historical Society Inc.Domestic Object - MACKAY COLLECTION: PIN TIN

Mackay collection - Silver and grey Pin tin embossed with floral design and marked P.P.Pins 1/4lb mixed sizes.handcrafts, needlework containers, pins -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - 3 ELY BROS TINS

... . Container 3 ELY BROS TINS ...3 small round tins marked Eley Bros London percussion caps 100 caps No12 manufacturers of sporting ammunition.arms, materiel, gunpowder -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - GUNPOWDER TIN

... London & Glasgow. Container GUNPOWDER TIN ...Yellow tin with cap and partial paper label both sides reading Genuine Smokeless Amberlite Sporting Gunpowder can be loaded as black gunpowder No2 made only by Curtiss & Harvey Sandbank London & Glasgow.Curtiss & Harvey, Sandbank London & Glasgowarms, materiel, gunpowder -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - GUNPOWDER TIN

... for shotgun cartridges. Container GUNPOWDER TIN ...Black tin with cap with partial label in diamond shape on both sides reading Curtis and Harvey No2 The Diamond Grain Gunpowder sole agents for Victoria. Contains shot for shotgun cartridges.arms, materiel, gunpowder -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - TIN BOX

... PERSONAL EFFECTS Containers tin Tin decorated with transfer prints ...Tin decorated with transfer prints of kittens on 4 sides and lid, originally donated by Cr.R.Cooper whose Grandmother used the tin to store buttons, hinged lid with paper inside showing details of provenance.personal effects, containers, tin