Showing 668 items

matching nail

-

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps Museumknife, 1940's

Found buried at Camp 13, MurchisonCurned tipped knife blade with wire twisted around handle end, parts of original wood handle & 2 x nails.arms, edged, weapons -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumSandals - female, 1940's

Used by internees at Camp 3. Known as "Klip Klop" sandals, worn to lavatory and shower blocks early morningsPair of carved wooden platform heel sandals. Synthetic covering on heel and sole. Leather strap nailed in position to cover toessandals, wood, bissinger g, wied k and n, camp 3, tatura, ww2, costume, female, foorwear, handcrafts, woodwork -

Light Horse & Field Artillery Museum

Light Horse & Field Artillery MuseumMules hoof, World War One

Souvenired from Gallipoli.This item’s history is linked to the Gallipoli campaign and is deemed rare due to the uniqueness of the item and lack other comparitive examples.Mules hoof with hand made shoe and nails souvenired from Gallipoli. Item could be from either Turkish or British forces.Stamps at centre front near coronet band.dardanelles, hoof, horse shoe, gallipoli, great war, mule, pack transport, the great war, world war 1, world war one, ww1, wwi -

Parks Victoria - Maldon State Battery

Parks Victoria - Maldon State BatteryBoard, tools

Used to hang, organise and store tools associated with the operation of the battery or the assay.Large white painted, rectangular board made of 5 slats, with rusty nails in board and black painted tool mark silhouettes. -

Benalla Migrant Camp Inc.

Benalla Migrant Camp Inc.Functional object - Wooden Sea Chest, Zarins Sea Chest, 1940-50s

Sea chests held all the worldy belongings of migrant families, when they migrated by ship. Families were eligible for up to two chests depending on the size of the family. From the markings, it appears that there was a second chest, but this is the only chest from this family in our collection. This chest would have been purchased or built by the Zarins family and loaded at the harbour from which the migrant ship left - in this instance that location is unknown. A basic online search reveals that Villach-Austria refers to the DP camp (displaced persons' camp) that the Zarins family originated from. Maybe the chest had been picked up from there, or there were a group of camp residents coming to Australia, we can only guess why this is written on the chest at all. Heavy wooden chest with metal handles on both sides and lid is missing. Metal bands with nails fixed to front and back and sides.Villach-Austria, N-196, 2 piece, AUGUSTS ZARINS, Australia (painted on side of chest in white paint, by hand)wood, wooden, chest, sea chest, zarins -

Beechworth RSL Sub-Branch

Beechworth RSL Sub-BranchLegging

This legging is part of a pair of leggings which presumably would have been worn by a cavalry soldier in the Royal Australian Army to protect the lower legs when riding in armed conflict. This item most likely dates to the World War One era.As an article of WWI protective clothing for use in armed conflict by a cavalry soldier, this item is of historic value. Brown leather cylindrical shaped legging with two leather straps for fastening. One strap is attached to the lower edge of the interior. This crosses over the lower exterior and passes through a leather loop at the front, which is attached by four metallic nails. The strap then wraps around the gaiter and passes through a second leather loop at the front, which is also attached by four corroded metallic nails. This strap (along with a shorter strap that is sewn and nailed into the top of the legging) pass through two buckles at the top. Both buckles are made of brass. The straps then tuck under four final leather loops, two of which are bolted to the legging with three corroded nails. Top of legging also carries a small brass hook.legging, gaiter, first world war, world war one, world war 1, wwi, ww1, war, army, uniform, royal australian army, the great war -

Mont De Lancey

Mont De LanceyPeg Tool

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Peg Tool for shoe-making. Metal tool with leather handle, pointed one end and round disc on other end.bootmaking tools -

Mont De Lancey

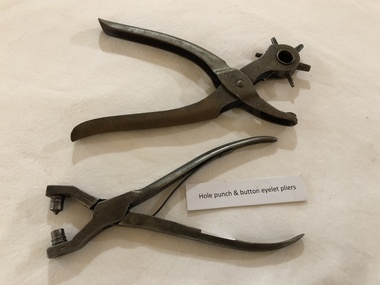

Mont De LanceyHole Punch and Button Eyelet Pliers

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.A metal hole punch, and metal button eyelet pliers, both used for shoe-making.AMG Darholeybootmaking tools -

Mont De Lancey

Mont De LanceyLegging

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade leather legging with 4 metal clips.boot covers, leggings -

Mont De Lancey

Mont De LanceyLasts

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.2 x wooden Lasts (Adult size) with metal screws. 1 x cast iron Last (Child size) with holes in base and a removable elevated top.Wooden: Size 6 (80) Cast Iron: Size 9 Dbootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Last on a four-footed base/stand. Last is removable from stand, and can be moved into different positions on top of the stand.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron double-ended Lap Last.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyBootmaker's Repair Stand

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden bookmaker's repair stand, opens slightly at one end. Two pieces of wood connected by two screws.bootmaking tools -

Mont De Lancey

Mont De LanceyHeel and Sole Cutters, Mobbs & Lewis

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron pieces - 1 Heel cutter and 1 Sole cutter.bootmaking tools -

Mont De Lancey

Mont De LanceyCircular Welt Cutter, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Welt Cutter with a wooden handle. -

Mont De Lancey

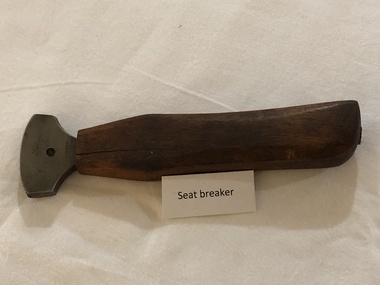

Mont De LanceySeat Breaker

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Seat Breaker with a wooden handle. -

Mont De Lancey

Mont De LanceyFudge Wheel

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Fudge Wheel with a wooden handle. -

Mont De Lancey

Mont De LanceyFoot Measure/Ruler

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden, folding, foot measure/ruler with brass clasps.bootmaking tools, measures, rulers -

Mont De Lancey

Mont De LanceyHammer and 2 Knives/Cutters

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron hammer with a wooden handle. Larger Cutter/knife, cast iron with a wooden handle. Smaller Cutter/knife, cast-iron with a wooden handleHammer: "London" Larger knife: "Pettys Sheffield".bootmaking tools, hammers, cutting tools -

Mont De Lancey

Mont De LanceyBootmaking Equipment

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Heel plate. Miscellaneous Sole plates. Hobnails and a tin of wooden sprigs.bootmaking tools, nails -

Mont De Lancey

Mont De LanceyHeel Shave and 2 Heels

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Heel Shave. 1 larger Leather heel piece. 1 smaller Leather heel piece.bootmaking tools, shaves -

Mont De Lancey

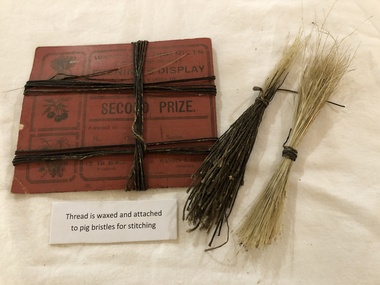

Mont De LanceyBootmaking Equipment, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade Waxed Thread attached to pig bristles, for boot stitching .bootmaking tools, thread waxers, threads -

Mont De Lancey

Mont De LanceyAwls and Awl Tips

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.5 x Cast iron Awls, all with wooden handles. 1 x container of spare Awl metal tips.bootmaking tools, awls, piercing tools -

Coal Creek Community Park & Museum

Coal Creek Community Park & Museum4 large nails

unknown4 nails, 2 of which are similar to one another. the shortest has a roughly cubic base beneath the head and a screw-through the other end. the longest does not have a flared-out head, but along with this two matching nails (which do have flared heads) has a pointed tip with a square cross-section. -

Whitehorse Historical Society Inc.

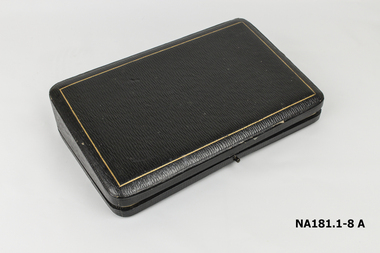

Whitehorse Historical Society Inc.Accessory - Manicure Set

Manicure set: Two jars with lids and a bow pattern.One nail buffer with matching pattern. Small brush with matching pattern - all above are silver. Nail file, eyebrow tweezers, cuticle press have scroll pattern. All these items have silver handle. The seven items are enclosed in a velvet lined leather case.personal effects-toilet requisites, manicure -

Friends of Westgarthtown

Friends of WestgarthtownSewing machine, Wertheim, Frankfurt

Hand sewing machine on stand with storage compartments. Ironwork frame, very decorative casting. Large wheel on right as part of sewing machine. Two wooden boxes on each side, with brass pull rings. Wooden box also for covering sewing machine. Decorative border around sewing mechanism. Frame is on wheels.Wertheim' cast in iron in centre of frame, and on both sides. 'Wertheim Francfort' on brass plaque nailed onto sewing machine, along with Wertheim symbol of man with pick.domestic items, sewing, machine, wertheim, francfort, domestic -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySki Boots - Cross Country

Cross country boots are no longer attached to the ski by three holes hooked onto 3 'nails'. Very dark brown solid leather boots with 3 steel loops each side on the lower and 2 steel hooks on the upper section of the opening. The tongue is high and padded. The laces are thick and yellow. The sole is a thick rubber with 3 toe holes (to attach to skis) at the front end.Outer side: embossed 'V'. Inside tongue: 'Vasque / Boots'. Bottom of sole: 'Vibram / 'Made in Italy'cross country boots, skiing boots, falls creek, snow, cross country skiing -

Orbost & District Historical Society

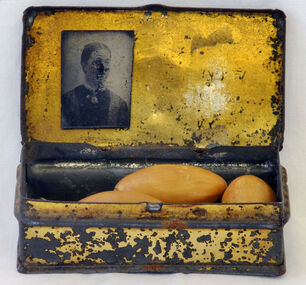

Orbost & District Historical Societytin

Probably used by soldier to hold mementos from home. Photo probably mother.Vesta tin containing 3 acorns, a black shoe button, a small cork, two small nails and a photo of a woman on a glass slide.container vestas mementos smoking -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - Trade Item - Nails x 2

These bolts have no known history but may have been used for attachment to railway sleepers or parts of a ship or used in roofing.These bolts are of interest only as antiquarian objects showing the types of nails or bolts used in a previous time. They may be useful for display.These are two large nails or bolts made of iron with a square knob on the top. There is some oxidisation and both bolts are slightly bent out of shape.bolts, nails -

Shepparton RSL Sub Branch

Shepparton RSL Sub BranchGerman WW1 Boot Heel Protector, Circa WW1

Used to make audible click when salutingBoot OrotectorsHorse shoe shaped heel proyector. Nail holes X 5. Mild steel. Angle iron protection also to outside of heelprotectors